Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies

Abstract

1. Introduction

2. The Next Generation EV Propulsion Systems

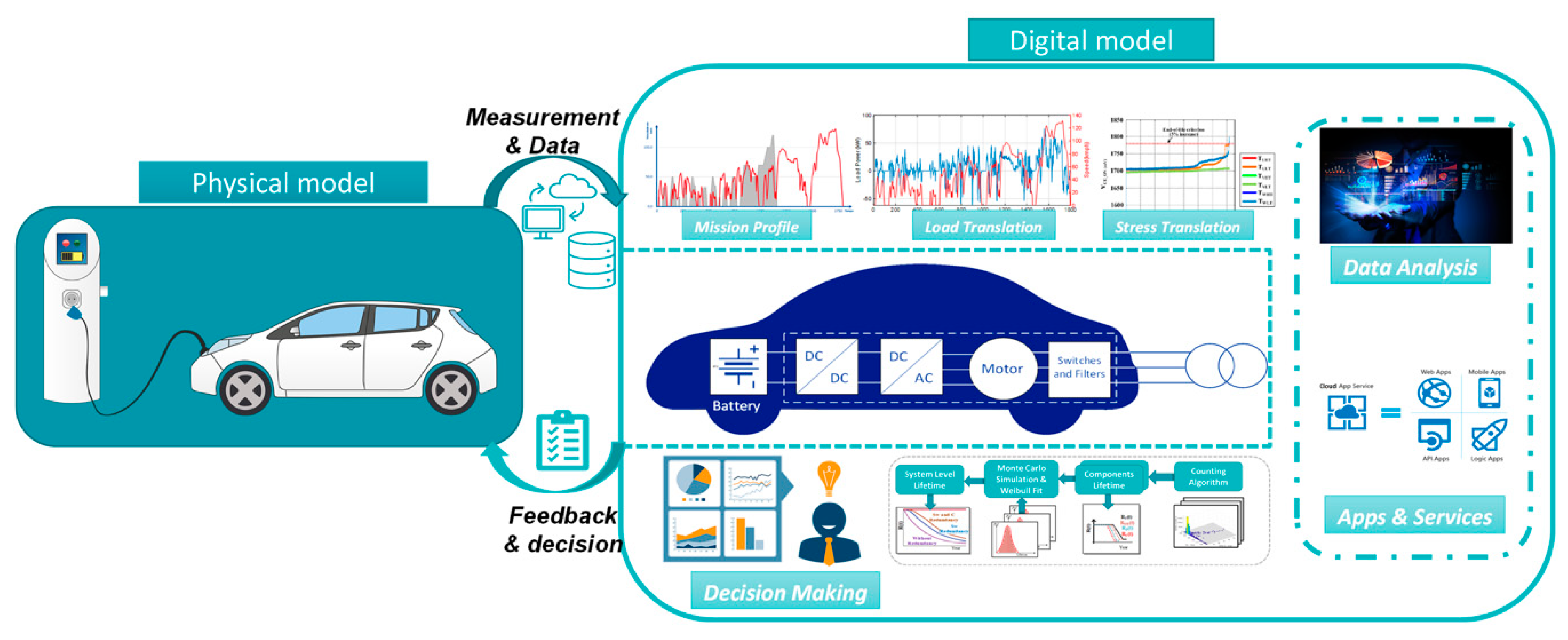

2.1. Digital Twin Development for EVs and Its Associated Benefits

- Ensuring a leap forward in user’s confidence, functionalities and energy efficiency of future EVs: These characteristics can estimate vehicle characteristics and usability. For example, affordability, driving range, range prediction, overall trip time and especially suitability of a long-range trip and comfort under all ambient conditions and traffic situations.

- Multi-Physics Modelling for stress analysis: This analysis can prevent failures by predicting them in advance, which, in turn, will help to reduce the downtime.

- Mission-profile-based reliability analysis for predictive maintenance: From the mission-profile-oriented accelerated lifetime testing, the degradation of the battery electric vehicle (BEV) drivetrain can be identified of the components critical to system reliability. Therefore, product developers will have more knowledge to be innovative in a fast and reliable way, testing many numbers and combinations of different variants of drivetrain components and experimenting with unorthodox approaches. Furthermore, using the data gathered from the vehicles’ digital twin can develop maintenance protocols/schedules to ensure that the components are available prior to their estimated failure in the EV and minimise inventory stockpiles.

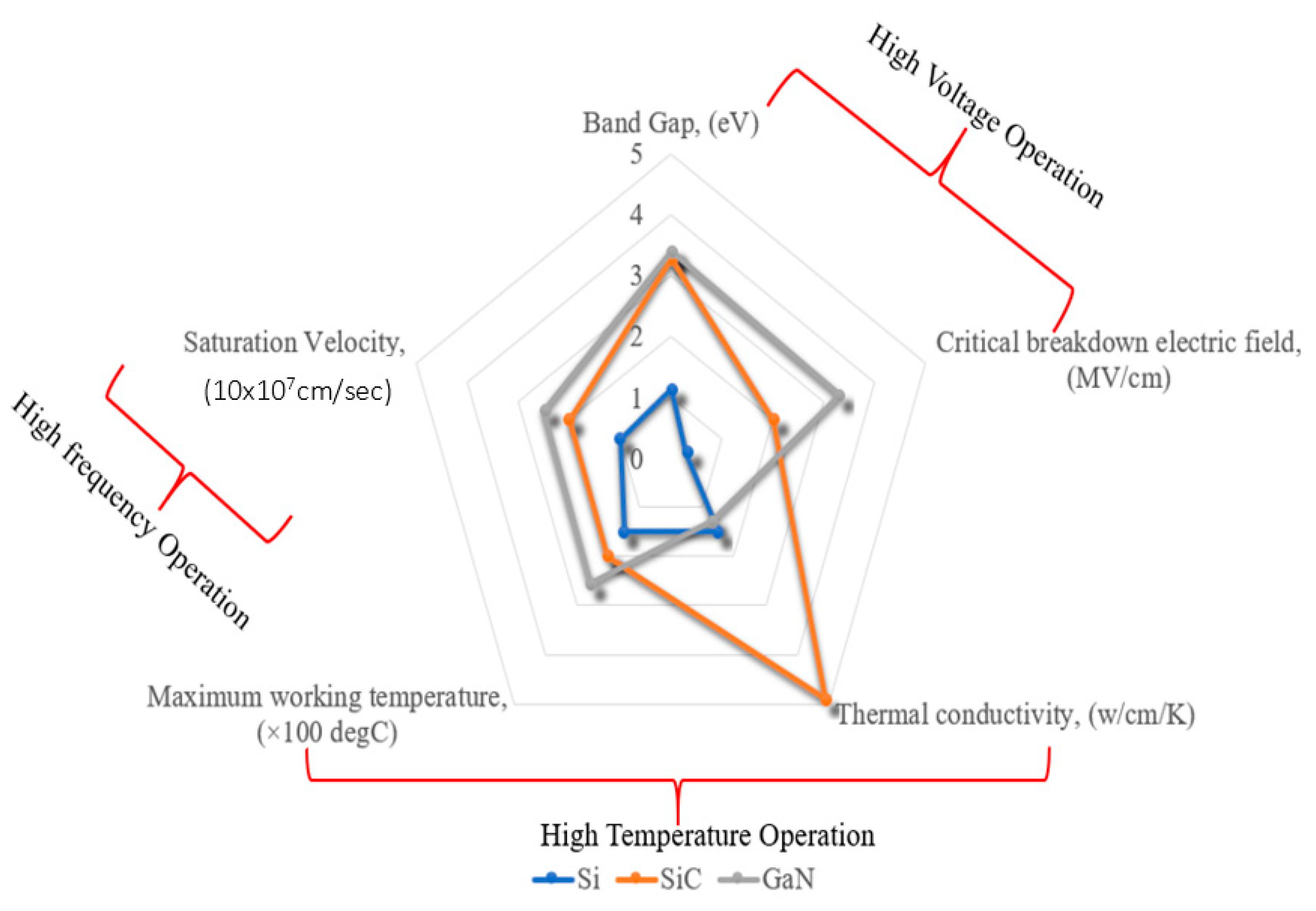

2.2. Power Electronics Interfaces Based on WBG Technologies

3. The Next Generation Solid-State Battery

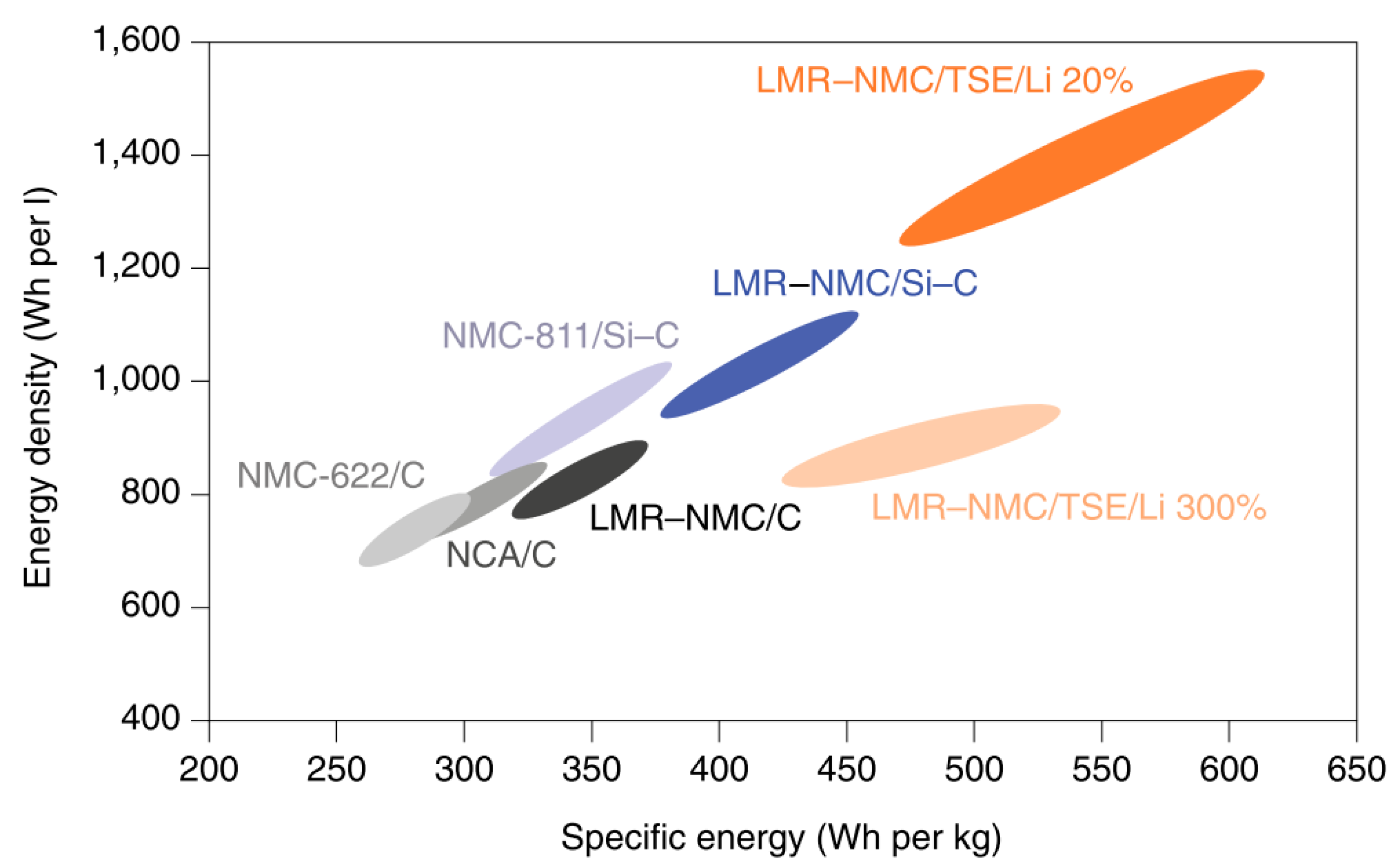

3.1. Recent Lithium Battery Technology Developments

3.2. Towards Solid-State Batteries

3.3. Challenges and Potential Solutions for the Solid-State Battery

- Poor wetting between Li and solid electrolyte: The poor wetting between lithium and solid electrolyte results in an interfacial resistance. Solid electrolytes, especially ceramic-based solid electrolytes, have relatively high interfacial resistance caused by poor wetting of Li. This inhibits the utilisation of Li in solid-state batteries. It was found out that polymer-based solid electrolytes, despite their lower ionic conductivity when compared to ceramic counterparts, shows enhanced Li wetting. Accordingly, Li wetting problem can be solved by using polymer/ceramic composites as electrolytes [43].

- Dendrite propagation and growth: When using Li metal, dendrite formation and propagation become serious problems in high power applications. Critical current density values for solid-state batteries are quite far away from the target value of 5 mA/cm2 [44,45]. Besides, there is a difference between plating (charging) and stripping (discharging), and the critical current density needs to be eliminated. The mechanism and possible solutions for that are still unclear, but special attention has been paid on producing the electrolytes as dense as possible, since the dendrite propagation is drastically inhibited in dense microstructures [43].

- Solid electrolyte synthesis: Solid electrolytes having high ionic conductivity is hard for synthesising, storing and handling. They require sophisticated methods, oxygen-free environments that make their use not cost-efficient. In this regard, there’s an ongoing desire to reduce the production cost and ease the handleability of the solid electrolytes.

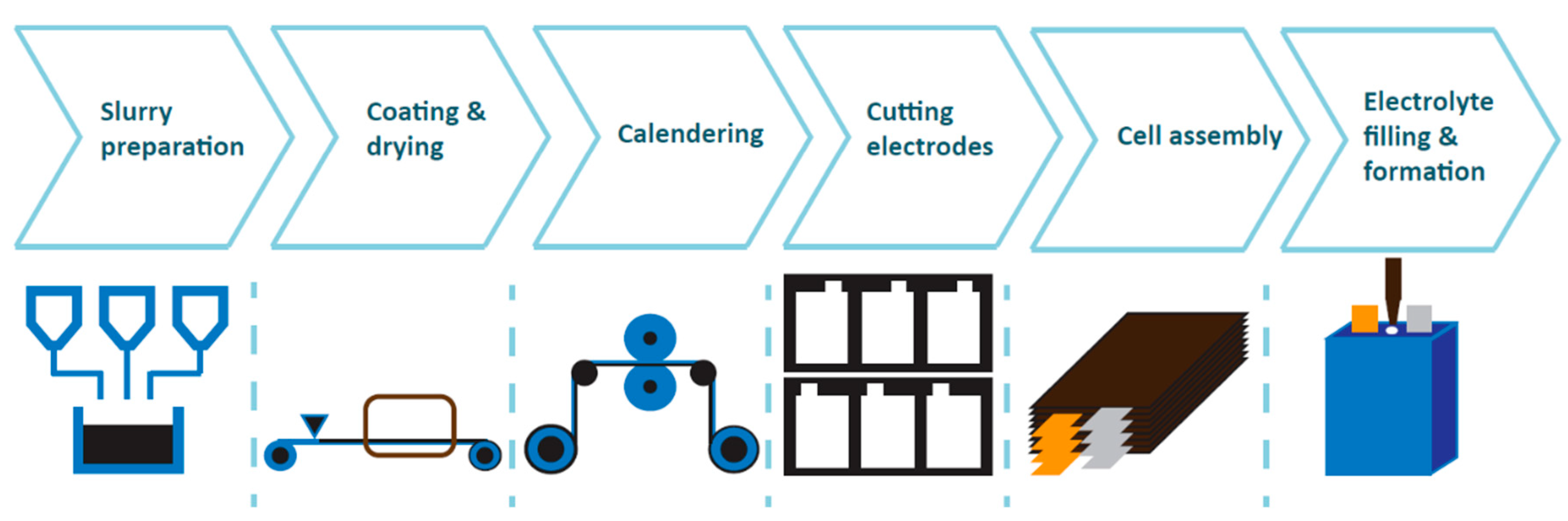

- Cell fabrication: Cell fabrication by using a ceramic type of electrolytes require hot pressing techniques that apply high pressure and temperature at the same time to ensure the smooth contact between electrolyte and electrodes (Figure 4). However, that problem can be solved by design engineering. Bulk type solid-state batteries can be assembled, and satisfying capacity retention could be gathered from these batteries [50]. On the other hand, scalability is the most important challenge for bulk-type battery designs. Polymers and polymer/ceramic composites are considered as a potential solution for large scale manufacturing of solid-state batteries because of their industrial-scale ease of production.

3.4. Self-Healing Batteries with Embedded Sensors

- Auto-repair of damaged electrodes to restore their conductivity.

- Regulation of ion transport within the cell.

- Minimising the effect of parasitic side reactions.

3.5. Second-Life: Challenges and Opportunities

4. Intelligent Bidirectional V2G and/or Ultra-High-Power Charging Systems

4.1. Introduction to Unidirectional and Bidirectional Charging Systems

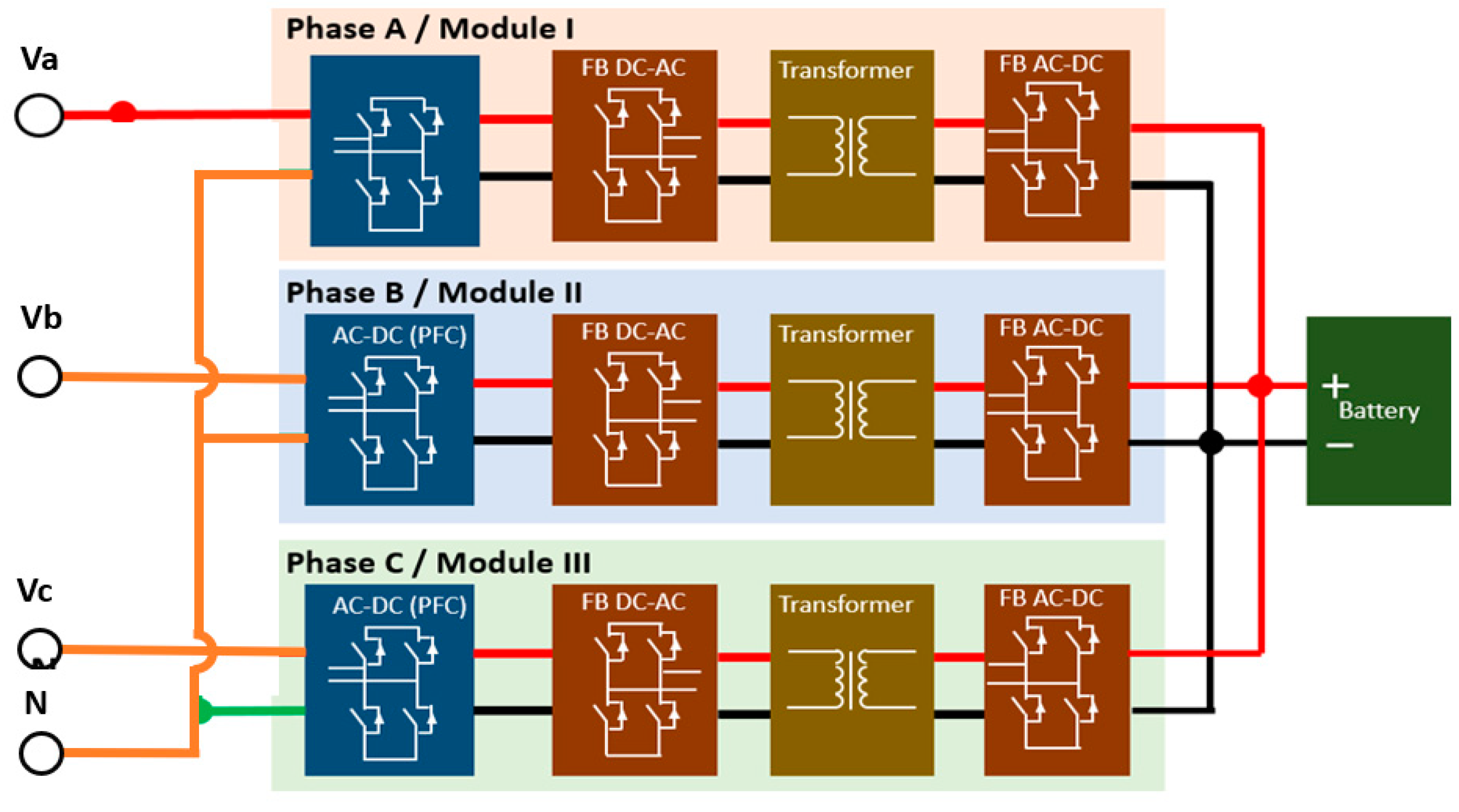

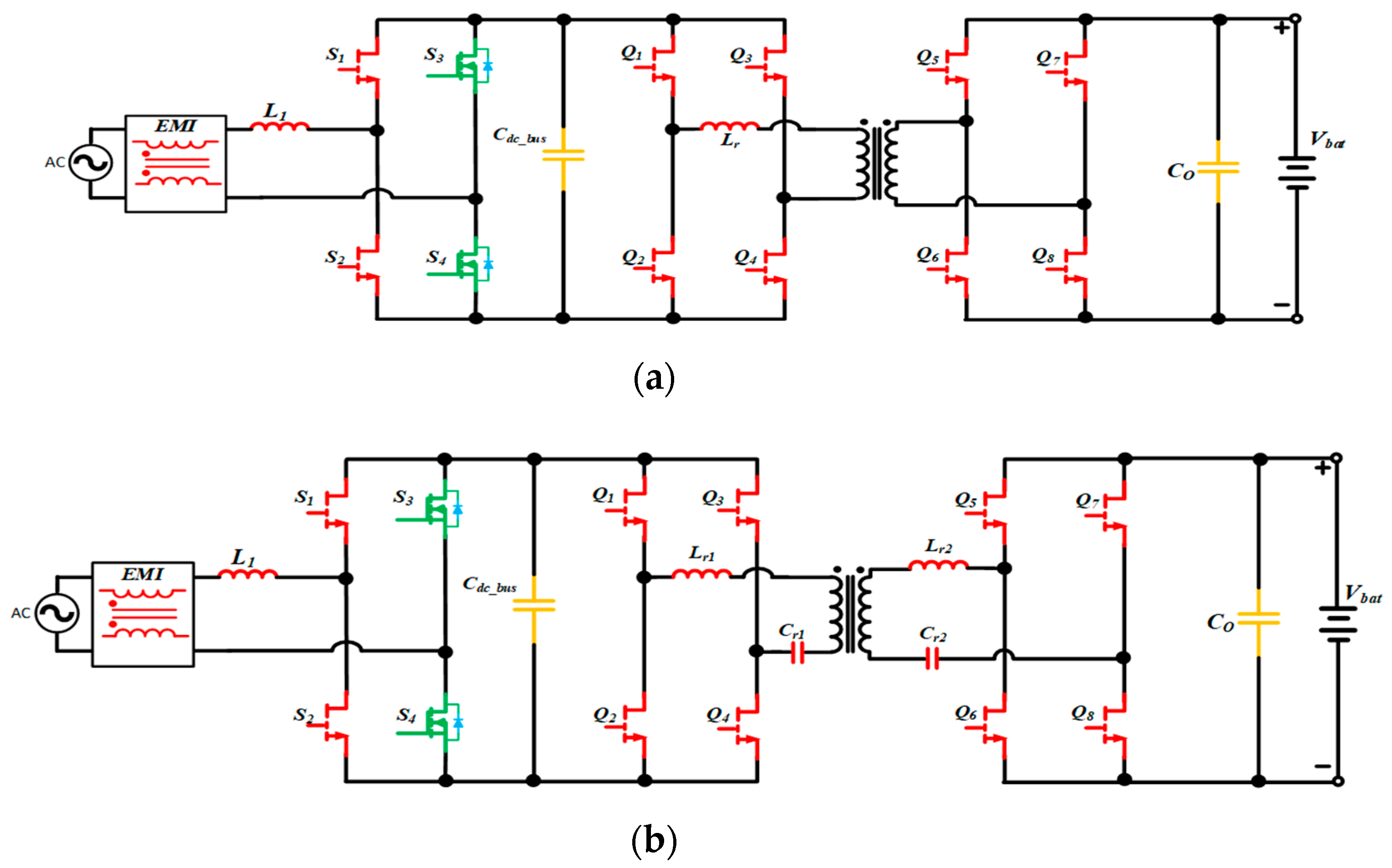

4.2. Wide Bandgap Devices for Bidirectional (V2G/G2V) On-Board Charging Systems

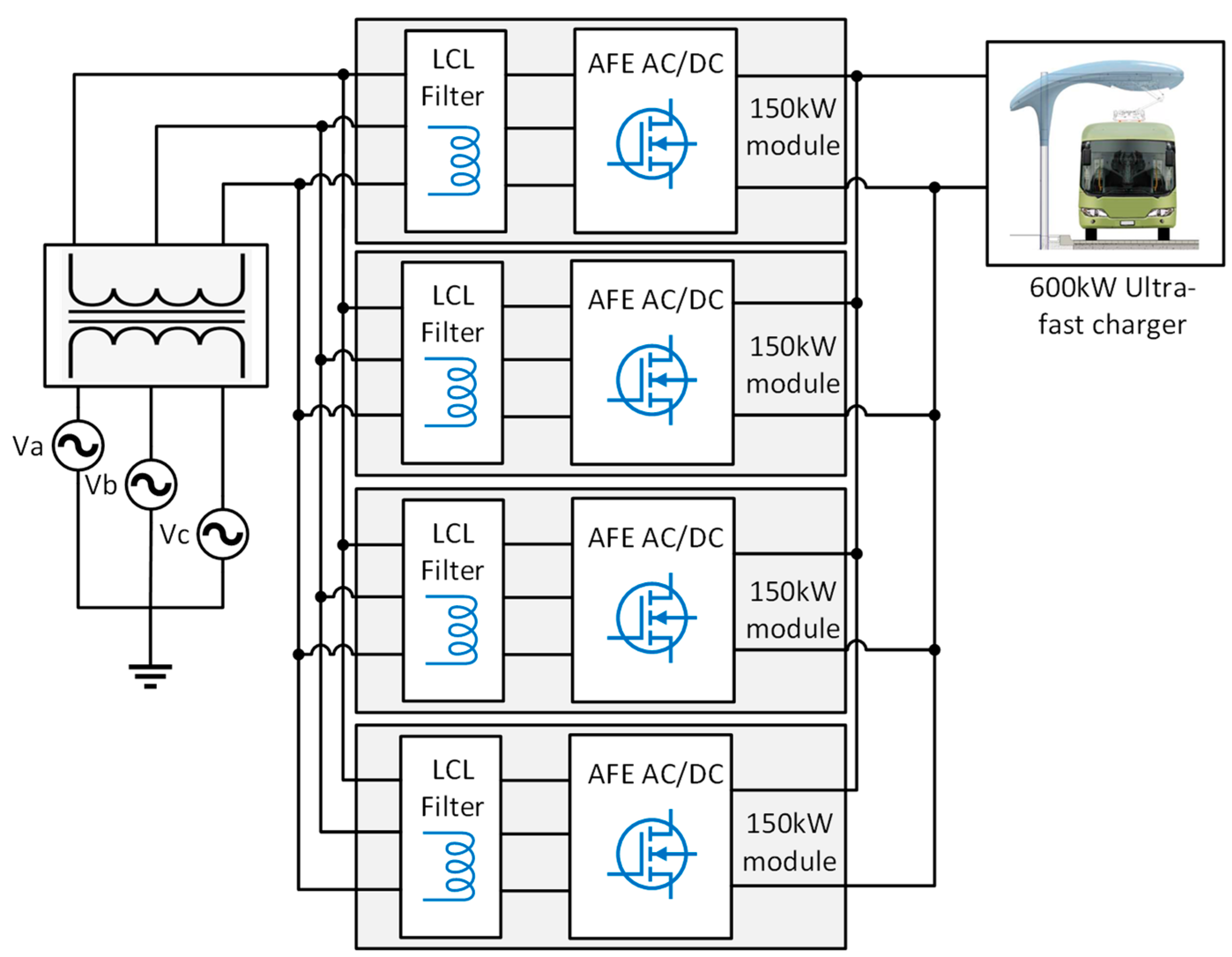

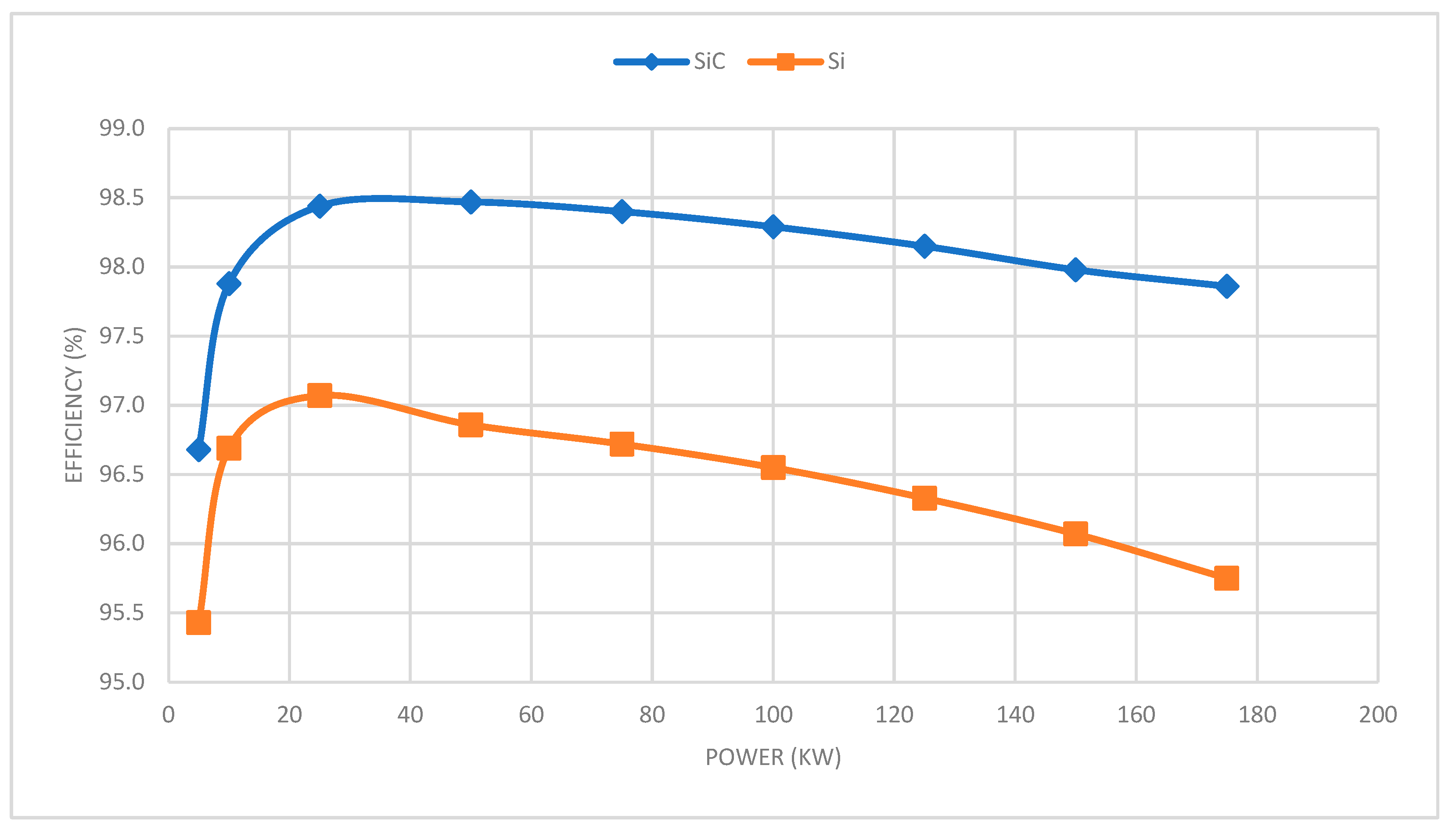

4.3. Ultra-High Power Off-Board Charging System

4.4. Intelligent Bidirectional Control Systems

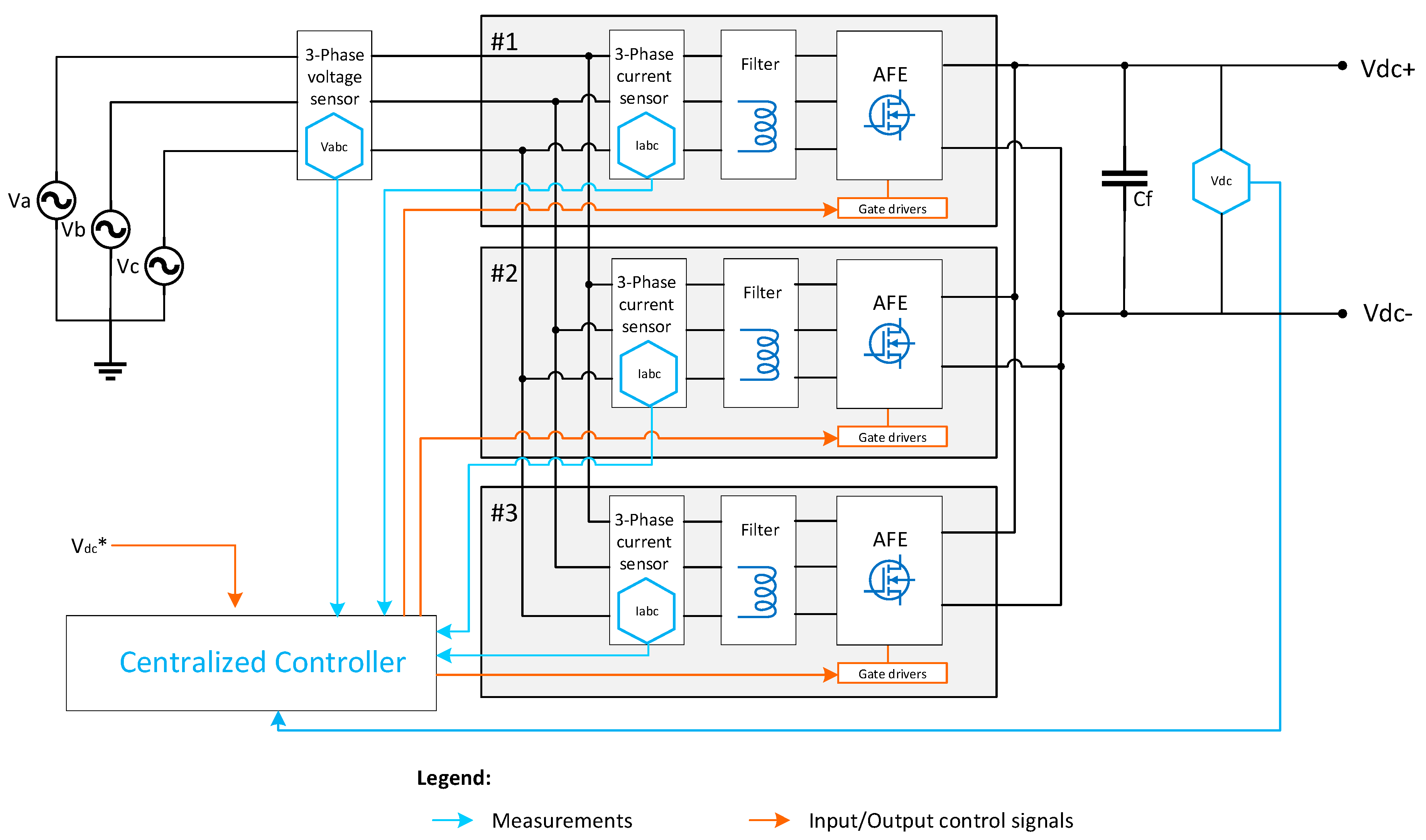

4.4.1. Centralised Control Systems for Modular PEC

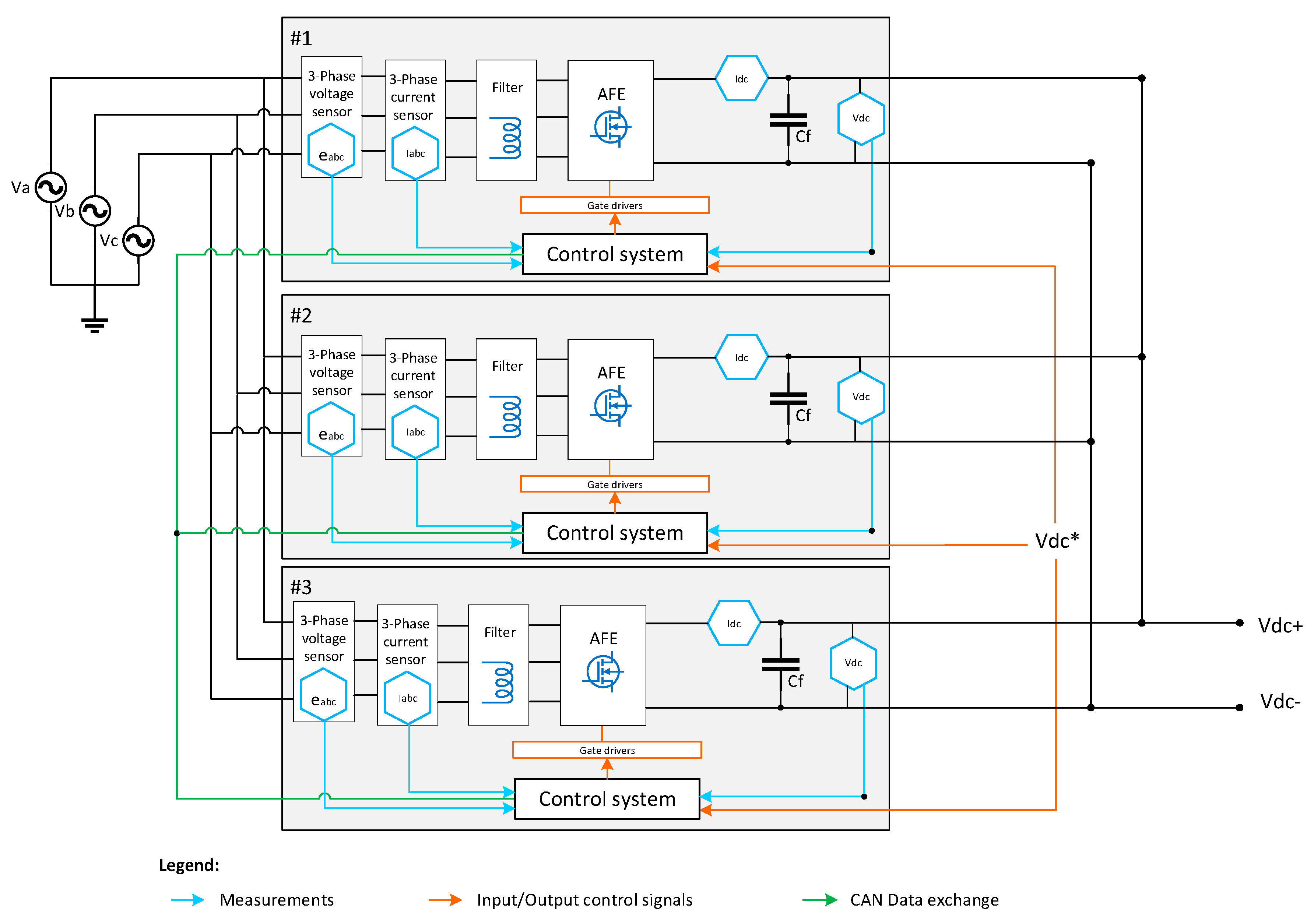

4.4.2. Distributed Control Systems for Modular PEC

5. The road to Climate Neutral Transport and Energy Sector

5.1. Sustainable Energy Communities

- Batteries can be used for energy arbitrage: for economic benefits, energy is stored when cheap in the wholesale market, and released when more expensive.

- Batteries can help in delaying or reducing investment needs in production, transmission or distribution infrastructure, this service is called capacity credit. This can be done by load levelling or peak shaving for instance.

- The fast response of batteries is necessary to provide high performance ancillary services such as voltage and frequency regulation.

- Behind the meter, batteries can help in reducing electricity bill, increasing of PV self-consumption in microgrids and backup power.

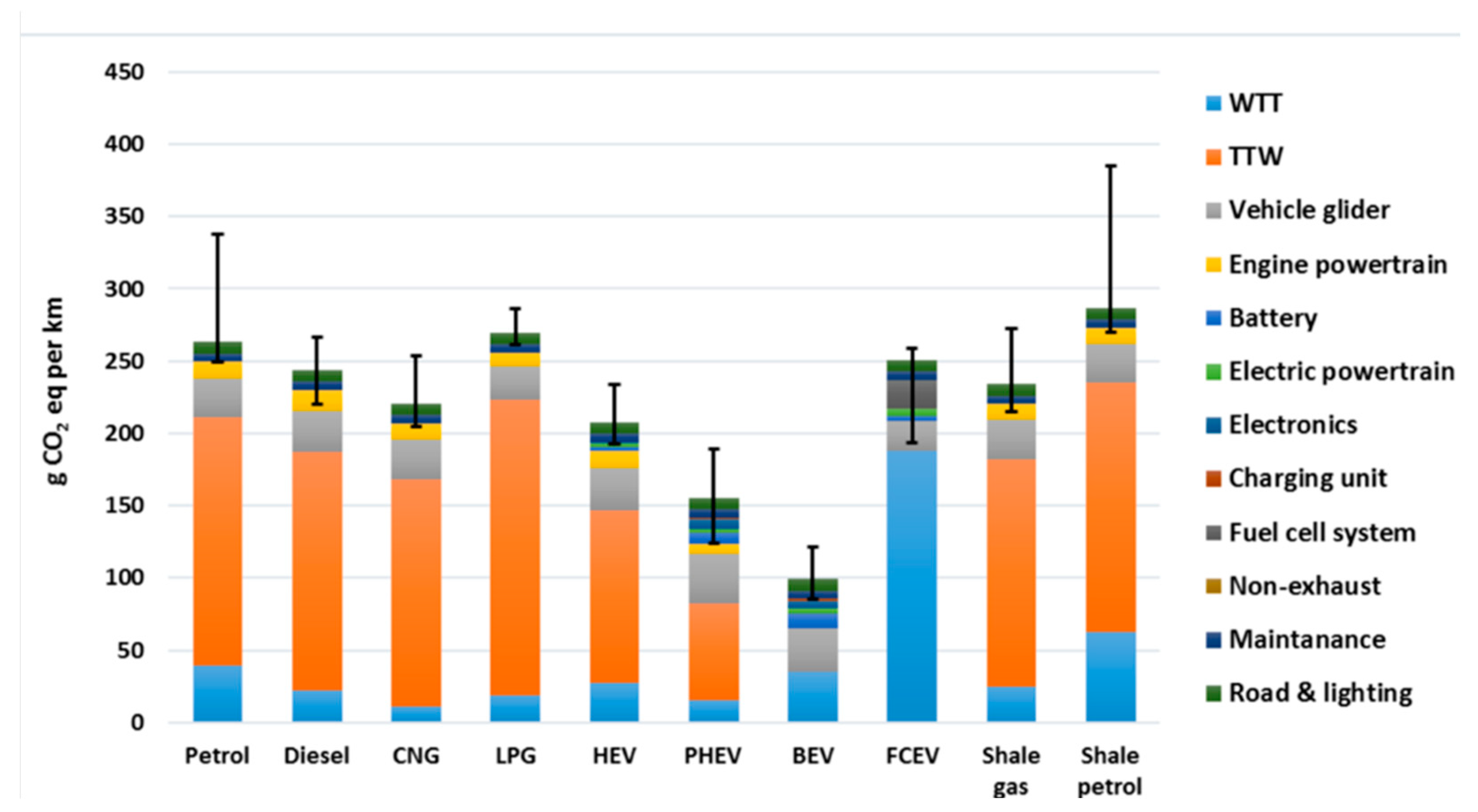

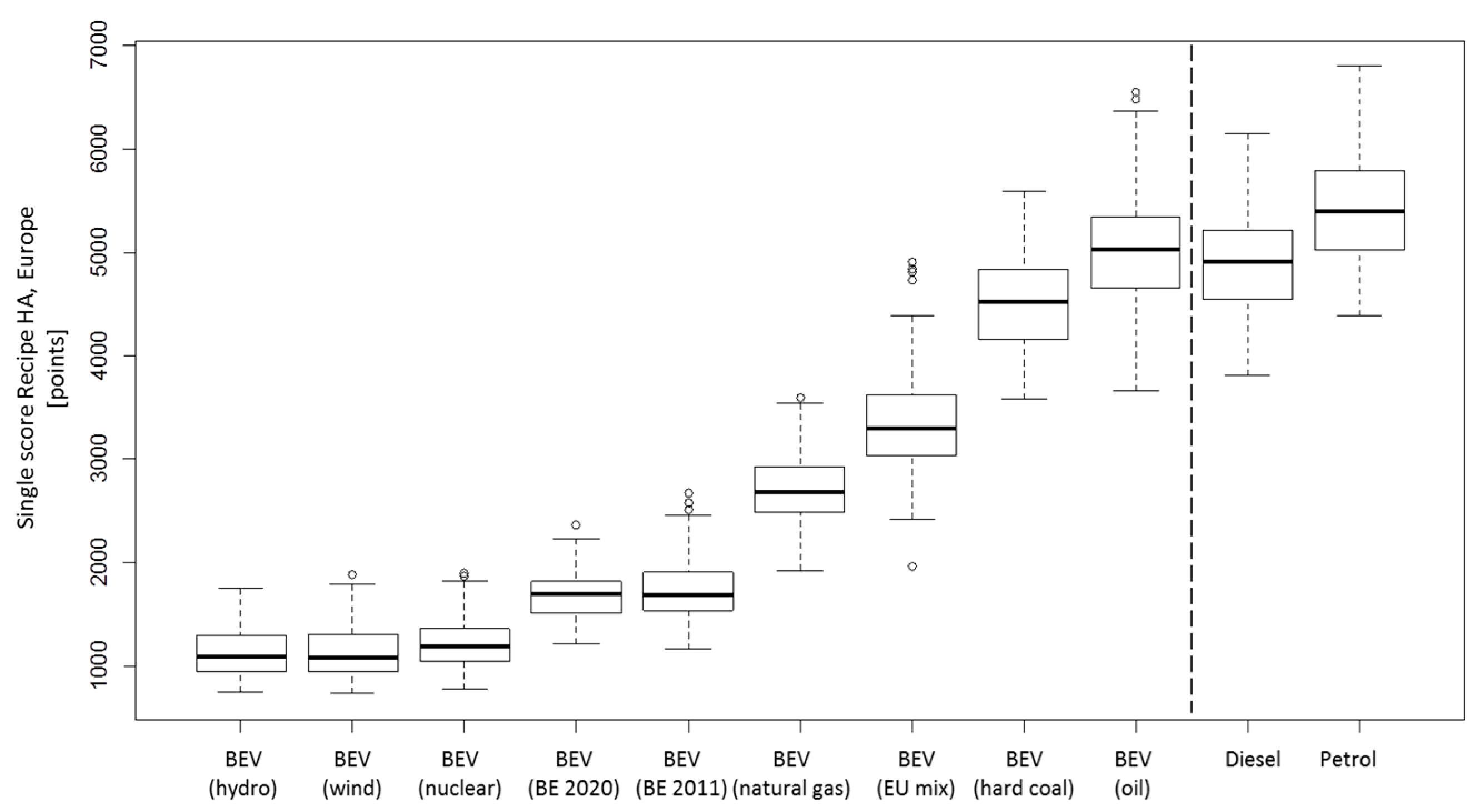

5.2. Current Impact on Climate Change

6. Autonomous Electric Vehicles (AEV)

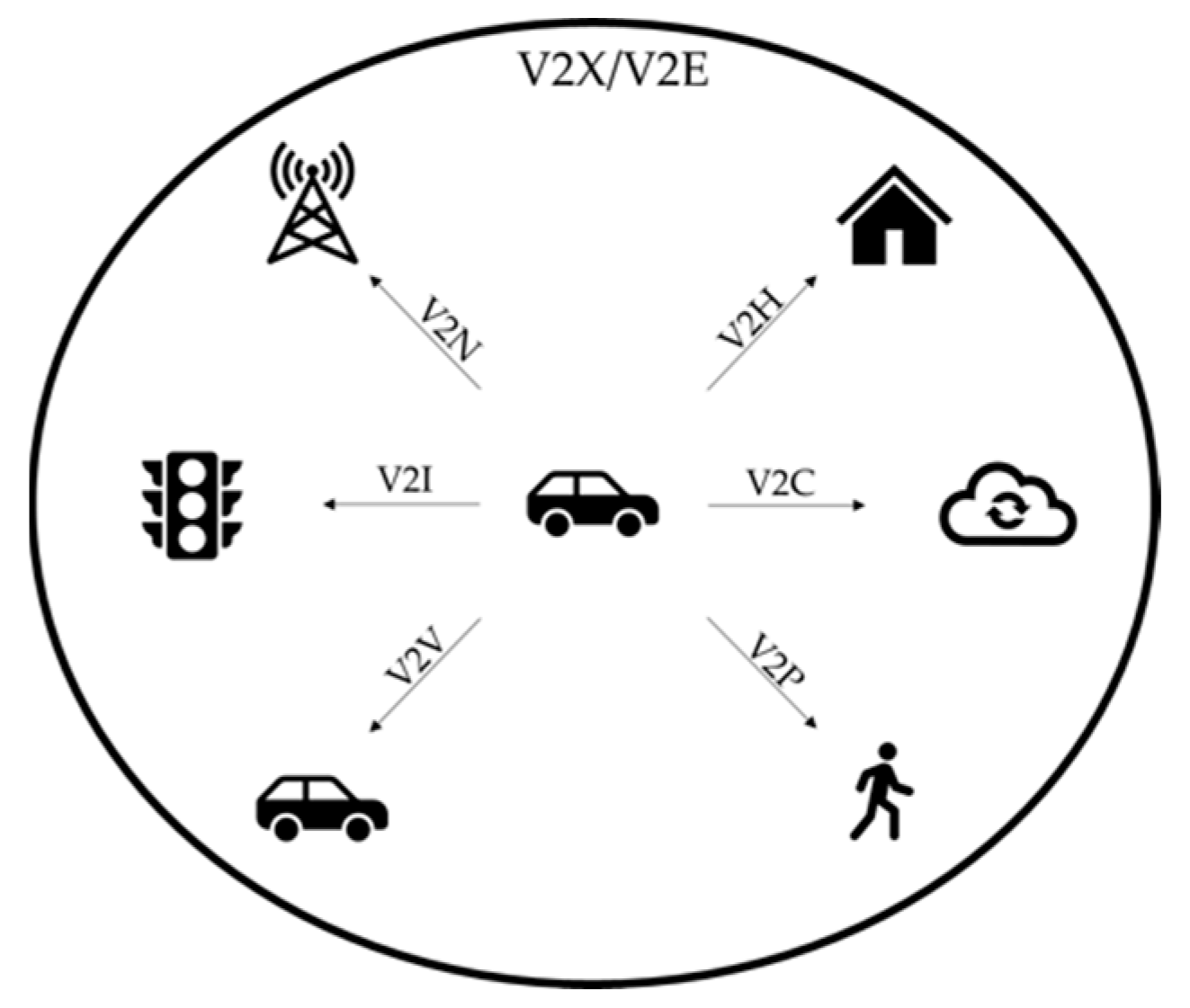

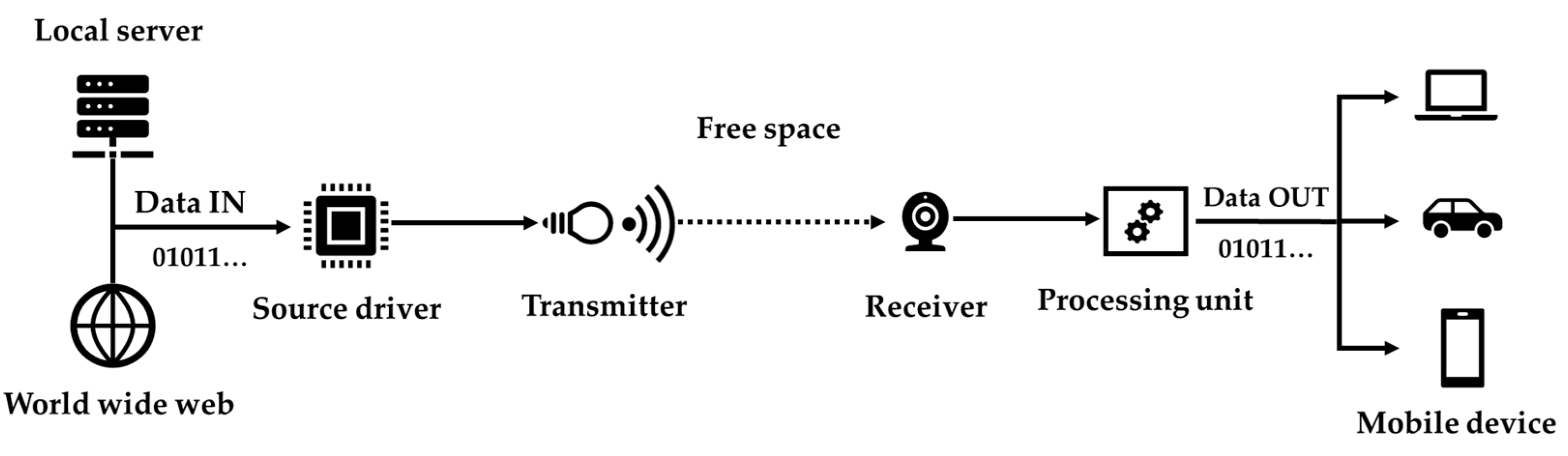

6.1. Wireless Communication as a Key Enabling Technology

6.2. Shared Autonomous Electric Vehicles (SAEV)

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chan, C.C.; Wong, Y.S.; Bouscayrol, A.; Chen, K. Powering Sustainable Mobility: Roadmaps of Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2009, 97, 603–607. [Google Scholar] [CrossRef]

- Lebeau, K.; van Mierlo, J.; Lebeau, P.; Mairesse, O.; Macharis, C. Consumer attitudes towards battery electric vehicles: A large-scale survey. Int. J. Electr. Hybrid Veh. 2013, 5, 28–41. [Google Scholar] [CrossRef]

- BloombergNEF. BloombergNEF’s 2019 Battery Price Survey BNEF. Available online: https://about.bnef.com/blog/battery-pack-prices-fall-as-market-ramps-up-with-market-average-at-156-kwh-in-2019/ (accessed on 3 February 2021).

- Berckmans, G.; Messagie, M.; Smekens, J.; Omar, N.; Vanhaverbeke, L.; van Mierlo, J. Cost projection of state of the art lithium-ion batteries for electric vehicles up to 2030. Energies 2017, 10, 1314. [Google Scholar] [CrossRef]

- Vijayagopal, R.; Rousseau, A. Benefits of electrified powertrains in medium-and heavy-duty vehicles. World Electr. Veh. J. 2020, 11, 12. [Google Scholar] [CrossRef]

- Simeu, S.K.; Brokate, J.; Stephens, T.; Rousseau, A. Factors influencing energy consumption and cost-competiveness of plug-in electric vehicles. World Electr. Veh. J. 2018, 9, 23. [Google Scholar] [CrossRef]

- Islam, E.S.; Moawad, A.; Kim, N.; Rousseau, A. Vehicle electrification impacts on energy consumption for different connected-autonomous vehicle scenario runs. World Electr. Veh. J. 2020, 11, 9. [Google Scholar] [CrossRef]

- Messagie, M.; Boureima, F.S.; Coosemans, T.; Macharis, C.; van Mierlo, J. A range-based vehicle life cycle assessment incorporating variability in the environmental assessment of different vehicle technologies and fuels. Energies 2014, 7, 1467–1482. [Google Scholar] [CrossRef]

- Marmiroli, B.; Messagie, M.; Dotelli, G.; van Mierlo, J. Electricity Generation in LCA of Electric Vehicles: A Review. Appl. Sci. 2018, 8, 1384. [Google Scholar] [CrossRef]

- Rangaraju, S. Impacts of electricity mix, charging profile, and driving behavior on the emissions performance of battery electric vehicles. A Belgian case study. Appl. Energy 2015, 148, 496–505. [Google Scholar] [CrossRef]

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- Yong, J.Y.; Ramachandaramurthy, V.K.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Shariff, S.M.; Iqbal, D.; Alam, M.S.; Ahmad, F. A State of the Art Review of Electric Vehicle to Grid (V2G) technology. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 561. [Google Scholar]

- Tran, D.D.; Vafaeipour, M.; el Baghdadi, M.; Barrero, R.; van Mierlo, J.; Hegazy, O. Thorough state-of-the-art analysis of electric and hybrid vehicle powertrains: Topologies and integrated energy management strategies. Renew. Sustain. Energy Rev. 2020, 119, 109596. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Foley, A.M.; Winning, I.J.; Gallachóir, B.P. State-of-the-art in electric vehicle charging infrastructure. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Ehsani, M.; Gao, Y.; Emadi, A. Electric Propulsion Systems. In Modern Electric, Hybrid Electric, and Fuel Cell Vehicles; CRC Press; Taylor & Francis Group: Oxford, UK, 2017. [Google Scholar]

- Chen, K.; Bouscayrol, A.; Lhomme, W. Energetic Macroscopic Representation and Inversion-based Control: Application to an Electric Vehicle with an Electrical Differential. J. Asian Electr. Veh. 2008, 6, 1097–1102. [Google Scholar] [CrossRef]

- Chan, C.C.; Bouscayrol, A.; Chen, K. Electric, hybrid, and fuel-cell vehicles: Architectures and modeling. IEEE Trans. Veh. Technol. 2010, 59, 589–598. [Google Scholar] [CrossRef]

- Koot, M.; Kessels, J.T.B.A.; de Jager, B.; Heemels, W.P.M.H.; van den Bosch, P.P.J.; Steinbuch, M. Energy management strategies for vehicular electric power systems. IEEE Trans. Veh. Technol. 2005, 54, 771–782. [Google Scholar] [CrossRef]

- Hofman, T.; Steinbuch, M.; van Druten, R.; Serrarens, A. Rule-based energy management strategies for hybrid vehicles. Int. J. Electr. Hybrid Veh. 2007, 1, 71–94. [Google Scholar] [CrossRef]

- Madni, A.; Madni, C.; Lucero, S. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Microsemi, P.P.G. Gallium Nitride (GaN) versus Silicon Carbide (SiC) in the High Frequency (RF) and Power Switching Applications. Available online: https://www.richardsonrfpd.com/docs/rfpd/Microsemi-A-Comparison-of-Gallium-Nitride-Versus-Silicon-Carbide.pdf (accessed on 3 February 2021).

- Rasool, H.; el Baghdadi, M.; Rauf, A.M.; Zhaksylyk, A.; Hegazy, O. A rapid non-linear computation model of power loss and electro thermal behaviour of three-phase inverters in EV drivetrains. In Proceedings of the 2020 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 24–26 June 2020. [Google Scholar]

- Keshmiri, N.; Wang, D.; Agrawal, B.; Hou, R.; Emadi, A. Current Status and Future Trends of GaN HEMTs in Electrified Transportation. IEEE Access 2020, 8, 70553–70571. [Google Scholar] [CrossRef]

- Sewergin, A.; Wienhausen, A.H.; Oberdieck, K.; de Doncker, R.W. Modular bidirectional full-SiC DC-DC converter for automotive applications. In Proceedings of the 2017 IEEE 12th International Conference on Power Electronics and Drive Systems (PEDS), Honolulu, HI, USA, 12–15 December 2017. [Google Scholar]

- Rui, R. Power Stage of 48V BSG Inverter. Infineon Appl. Note. Available online: https://www.infineon.com/dgdl/Infineon-20180802_AN-Power_stage_of_48V_BSG_inverter_V2.2-AN-v01_00-EN.pdf?fileId=5546d46265487f7b0165a3863b8e5bcf (accessed on 3 February 2021).

- Liu, Z.; Li, B.; Lee, F.C.; Li, Q. High-Efficiency High-Density Critical Mode Rectifier/Inverter for WBG-Device-Based On-Board Charger. IEEE Trans. Ind. Electron. 2017, 64, 9114–9123. [Google Scholar] [CrossRef]

- Rasool, H.; Zhaksylyk, A.; Chakraborty, S.; el Baghdadi, M.; Hegazy, O. Optimal Design Strategy and Electro-Thermal Modelling of a High-Power Off-Board Charger for Electric Vehicle Applications. In Proceedings of the 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 September 2020; pp. 1–8. [Google Scholar]

- Chakraborty, S.; Vu, H.; Hasan, M.M.; Tran, D.; el Baghdadi, M.; Hegazy, O. DC-DC Converter Topologies for Electric Vehicles, Plug-in Hybrid Electric Vehicles and Fast Charging Stations: State of the Art and Future Trends. Energies 2019, 12, 1569. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Fuchs, G.; Lunz, B.; Leuthold, M.; Sauer, D.U. Technology Overview on Electricity Storage. Inst. Power Electron. Electr. Drives 2012. [Google Scholar] [CrossRef]

- Li, M.; Lu, J.; Chen, Z.; Amine, K. 30 Years of Lithium-Ion Batteries. Adv. Mater. 2018, 30, 1800561. [Google Scholar] [CrossRef]

- Sun, Y.K.; Myung, S.T.; Park, B.C.; Prakash, J.; Belharouak, I.; Amine, K. High-energy cathode material for long-life and safe lithium batteries. Nat. Mater. 2009, 8, 320–324. [Google Scholar] [CrossRef]

- Philippot, M.; Alvarez, G.; Ayerbe, E.; van Mierlo, J.; Messagie, M. Eco-efficiency of a lithium-ion battery for electric vehicles: Influence of manufacturing country and commodity prices on ghg emissions and costs. Batteries 2019, 5, 23. [Google Scholar] [CrossRef]

- Schmuch, R.; Wagner, R.; Hörpel, G.; Placke, T.; Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 2018, 3, 267–278. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Y.C. A retrospective on lithium-ion batteries. Nat. Commun. 2020, 11, 1–4. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Goutam, S.; Miguel Oliveira, L.; Timmermans, J.M.; Omar, N.; Messagie, M.; Van den Bossche, P.; Van Mierlo, J. A comprehensive study on rechargeable energy storage technologies. J. Electrochem. Energy Convers. Storage 2016. [Google Scholar] [CrossRef]

- Berckmans, G.; De Sutter, L.; Marinaro, M.; Smekens, J.; Jaguemont, J.; Wohlfahrt-Mehrens, M.; van Mierlo, J.; Omar, N. Analysis of the effect of applying external mechanical pressure on next generation silicon alloy lithium-ion cells. Electrochim. Acta 2019, 306, 387–395. [Google Scholar] [CrossRef]

- Edström, K. BATTERY 2030+. Inventing the Sustainable Batteries of the Future. Research Needs and Future Actions. Available online: https://battery2030.eu/digitalAssets/860/c_860904-l_1-k_roadmap-27-march.pdf (accessed on 3 February 2021).

- Till, B. Global EV Outlook 2019 to Electric Mobility; IEA: London, UK, 2019. [Google Scholar]

- Pasta, M.; Armstrong, D.; Brown, Z.L.; Bu, J.; Castell, M.R.; Chen, P.; Cocks, A.; Corr, S.A.; Cussen, E.J.; Darnbrough, E. 2020 roadmap on solid-state batteries. J. Phys. Energy 2020, 2, 032008. [Google Scholar] [CrossRef]

- Randau, S.; Weber, D.A.; Kötz, O.; Koerver, R.; Braun, P.; Weber, A.; Ivers-Tiffée, E.; Adermann, T.; Kulisch, J.; Zeier, W.G.; et al. Benchmarking the performance of all-solid-state lithium batteries. Nat. Energy 2020, 5, 259–270. [Google Scholar] [CrossRef]

- Albertus, P.; Babinec, S.; Litzelman, S.; Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 2018, 3, 16–21. [Google Scholar] [CrossRef]

- Peled, E.; Menkin, S. Review—SEI: Past, Present and Future. J. Electrochem. Soc. 2017, 164, A1703. [Google Scholar] [CrossRef]

- Forsyth, M.; Porcarelli, L.; Wang, X.; Goujon, N.; Mecerreyes, D. Innovative Electrolytes Based on Ionic Liquids and Polymers for Next-Generation Solid-State Batteries. Acc. Chem. Res. 2019, 52, 686–694. [Google Scholar] [CrossRef] [PubMed]

- Jeong, K.; Park, S.; Lee, S.Y. Revisiting polymeric single lithium-ion conductors as an organic route for all-solid-state lithium ion and metal batteries. J. Mater. Chem. A 2019, 7, 1917–1935. [Google Scholar] [CrossRef]

- Kerman, K.; Luntz, A.; Viswanathan, V.; Chiang, Y.-M.; Chen, Z. Review—Practical Challenges Hindering the Development of Solid State Li Ion Batteries. J. Electrochem. Soc. 2017, 164, A1731. [Google Scholar] [CrossRef]

- Garbayo, I.; Struzik, M.; Bowman, W.J.; Pfenninger, R.; Stilp, E.; Rupp, J.L.M. Glass-Type Polyamorphism in Li-Garnet Thin Film Solid State Battery Conductors. Adv. Energy Mater. 2018, 8, 1702265. [Google Scholar] [CrossRef]

- Smekens, J.; Gopalakrishnan, R.; Steen, N.V.; Omar, N.; Hegazy, O.; Hubin, A.; Van Mierlo, J. Influence of electrode density on the performance of Li-ion batteries: Experimental and simulation results. Energies 2016, 9, 104. [Google Scholar] [CrossRef]

- Krauskopf, T.; Mogwitz, B.; Rosenbach, C.; Zeier, W.G.; Janek, J. Diffusion Limitation of Lithium Metal and Li–Mg Alloy Anodes on LLZO Type Solid Electrolytes as a Function of Temperature and Pressure. Adv. Energy Mater. 2019, 9, 1902568. [Google Scholar] [CrossRef]

- Truchot, C.; Dubarry, M.; Liaw, B.Y. State-of-charge estimation and uncertainty for lithium-ion battery strings. Appl. Energy 2014, 119, 218–227. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- de Sutter, L.; Berckmans, G.; Marinaro, M.; Wohlfahrt-Mehrens, M.; Berecibar, M.; van Mierlo, J. Mechanical behavior of Silicon-Graphite pouch cells under external compressive load: Implications and opportunities for battery pack design. J. Power Sources 2020, 451, 227774. [Google Scholar] [CrossRef]

- Campanella, A.; Döhler, D.; Binder, W.H. Self-Healing in Supramolecular Polymers. Macromol. Rapid Commun. 2018, 39, 1700739. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wu, H.; Chen, Z.; Mcdowell, M.T.; Cui, Y.; Bao, Z. Self-healing chemistry enables the stable operation of silicon microparticle anodes for high-energy lithium-ion batteries. Nat. Chem. 2013, 5, 1042. [Google Scholar] [CrossRef] [PubMed]

- Bobba, S.; Mathieux, F.; Blengini, G.A. How will second-use of batteries affect stocks and flows in the EU? A model for traction Li-ion batteries. Resour. Conserv. Recycl. 2019, 145, 279–291. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; van Mierlo, J.; van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Berecibar, M. Machine-learning techniques used to accurately predict battery life. Nature 2019, 568, 325–326. [Google Scholar] [CrossRef]

- Langer, E. Liquid Cooling in Electric Vehicles—What to Know to Keep EVs on the Go By; CPC: Preston, UK, 2019. [Google Scholar]

- SHabib; Khan, M.M.; Abbas, F.; Tang, H. Assessment of electric vehicles concerning impacts, charging infrastructure with unidirectional and bidirectional chargers, and power flow comparisons. Int. J. Energy Res. 2018, 42, 3416–3441. [Google Scholar]

- Chatterjee, P.; Hermwille, M. Tackling the Challenges of Electric Vehicle Fast Charging. ATZelectron. Worldw. 2020, 15, 18–22. [Google Scholar] [CrossRef]

- Dusmez, S.; Cook, A.; Khaligh, A. Comprehensive analysis of high quality power converters for level 3 off-board chargers. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Salgado-Herrera, N.M.; Anaya-Lara, O.; Campos-Gaona, D.; Medina-Rios, A.; Tapia-Sanchez, R.; Rodriguez-Rodriguez, J.R. Active Front-End converter applied for the THD reduction in power systems. In Proceedings of the 2018 IEEE Power & Energy Society General Meeting (PESGM), Portland, OR, USA, 5–10 August 2018. [Google Scholar]

- Kesler, M.; Kisacikoglu, M.C.; Tolbert, L.M. Vehicle-to-grid reactive power operation using plug-in electric vehicle bidirectional offboard charger. IEEE Trans. Ind. Electron. 2014, 61, 6778–6784. [Google Scholar] [CrossRef]

- Vu, H.N.; Abdel-Monem, M.; el Baghdadi, M.; van Mierlo, J.; Hegazy, O. Multi-objective optimization of on-board chargers based on state-of-the-art 650V GaN power transistors for the application of electric vehicles. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019. [Google Scholar]

- Yilmaz, M.; Krein, P.T. Review of Battery Charger Topologies, Charging Power Levels, and Infrastructure for Plug-In Electric and Hybrid Vehicles. IEEE Trans. Power Electron. 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Xue, L.; Shen, Z.; Boroyevich, D.; Mattavelli, P.; Diaz, D. Dual Active Bridge-Based Battery Charger for Plug-in Hybrid Electric Vehicle With Charging Current Containing Low Frequency Ripple. IEEE Trans. Power Electron. 2015, 30, 7299–7307. [Google Scholar] [CrossRef]

- Li, B.; Lee, F.C.; Li, Q.; Liu, Z. Bi-directional on-board charger architecture and control for achieving ultra-high efficiency with wide battery voltage range. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 3688–3694. [Google Scholar]

- Zhaksylyk, A.; Rasool, H.; Geury, T.; el Baghdadi, M.; Hegazy, O. Masterless Control of Parallel Modular Active front-end (AFE) Systems for Vehicles and Stationary Applications. In Proceedings of the 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 September 2020; pp. 1–6. [Google Scholar]

- Rachid, A.; El Fadil, H.; Koundi, M.; El Idrissi, Z.; Tahri, A.; Giri, F.; Guerrero, J.M. PQ Theory-Based Control of Single-Stage V2G Three-Phase BEV Charger for High-Voltage Battery. IFAC-PapersOnLine 2019, 52, 73–78. [Google Scholar] [CrossRef]

- Salgado-Herrera, N.M.; Campos-Gaona, D.; Anaya-Lara, O.; Medina-Rios, A.; Tapia-Sánchez, R.; Rodríguez-Rodríguez, J.R. THD reduction in wind energy system using type-4 Wind Turbine/PMSG applying the active front-end converter parallel operation. Energies 2018, 11, 2458. [Google Scholar] [CrossRef]

- Xing, K.; Lee, F.C.; Borojevic, D.; Ye, Z.; Mazumder, S. Interleaved PWM with discontinuous space-vector modulation. IEEE Trans. Power Electron. 1999, 14, 906–917. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Xie, S.; Yang, C. A control strategy for paralleled bi-directional DC-DC converters used in energy storage systems. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016. [Google Scholar]

- Pei, Y.; Jiang, G.; Yang, X.; Wang, Z. Auto-Master-Slave control technique of parallel inverters in distributed AC power systems and UPS. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No.04CH37551), Aachen, Germany, 20–25 June 2004; Volume 3. [Google Scholar]

- Meng, P.; Jian, Z.; Li, W.; Wang, Y. The study and application of CAN communication of rectifier parallel operation control system. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016. [Google Scholar]

- Zhang, H.; Shi, Y.; Wang, J.; Chen, H. A New Delay-Compensation Scheme for Networked Control Systems in Controller Area Networks. IEEE Trans. Ind. Electron. 2018, 65, 7239–7247. [Google Scholar] [CrossRef]

- Gray, M.S.; Gao, Z.; Button, R.M. Distributed, master-less control of modular DC-DC converters. In Proceedings of the 2nd International Energy Conversion Engineering Conference, Providence, RI, USA, 16–19 August 2004; Volume 3. [Google Scholar]

- Blaabjerg, F.; Teodorescu, R.; Liserre, M.; Timbus, A.V. Overview of control and grid synchronization for distributed power generation systems. IEEE Trans. Ind. Electron. 2006, 53, 1398–1409. [Google Scholar] [CrossRef]

- Messagie, M.; Mertens, J.; Oliveira, L.; Rangaraju, S.; Sanfelix, J.; Coosemans, T.; Van Mierlo, J.; Macharis, C. The hourly life cycle carbon footprint of electricity generation in Belgium, bringing a temporal resolution in life cycle assessment. Appl. Energy 2014, 134, 469–476. [Google Scholar] [CrossRef]

- Van Mierlo, J. The World Electric Vehicle Journal, The Open Access Journal for the e-Mobility Scene. World Electr. Veh. J. 2018, 9, 1. [Google Scholar] [CrossRef]

- i, Y.; Messagie, M.; Berecibar, M.; Hegazy, O.; Omar, N.; Van Mierlo, J. The impact of the vehicle-to-grid strategy on lithium-ion battery ageing process. In Proceedings of the 31st International Electric Vehicle Symposium and Exhibition (EVS 2018), Kobe, Japan, 30 September–3 October 2018. [Google Scholar]

- van Kriekinge, G.; de Cauwer, C.; van Mierlo, J.; Coosemans, T. Techno-Economical Assessment of Vehicle-to-Grid in a Microgrid: Case Study. In Proceedings of the 33th International Electric Vehicle Symposium and Exhibition (EVS 2020), Portland, OR, USA, 14–17 June 2020. [Google Scholar]

- Syed, A.; Crispeels, T.; Jahir Roncancio Marin, J.; Cardellini, G.; De Cauwer, C.; Coosemans, T.; van Mierlo, J.; Messagie, M. A Novel Method to Value the EV-Fleet’s Grid Balancing Capacity. In Proceedings of the 33th International Electric Vehicle Symposium and Exhibition (EVS 2020), Portland, OR, USA, 14–17 June 2020. [Google Scholar]

- De Cauwer, C.; van Kriekinge, G.; van Mierlo, J.; Coosemans, T.; Messagie, M. Integration of Vehicle-to-Grid in Local Energy Systems: Concepts and Specific Requirements. In Proceedings of the 33th International Electric Vehicle Symposium and Exhibition (EVS 2020), Portland, OR, USA, 14–17 June 2020. [Google Scholar]

- Arrinda, M.; Berecibar, M.; Oyarbide, M.; Macicior, H.; Muxika, E.; Messagie, M. Levelized cost of electricity calculation of the energy generation plant of a CO2 neutral micro-grid. Energy 2020, 208, 118383. [Google Scholar] [CrossRef]

- Hooftman, N.; Messagie, M.; van Mierlo, J.; Coosemans, T. The Paris Agreement and Zero-Emission Vehicles in Europe: Scenarios for the Road Towards a Decarbonised Passenger Car Fleet. In Towards User-Centric Transport in Europe 2; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Messagie, M.; Coosemans, T.; van Mierlo, J. The need for uncertainty propagation in life cycle assessment of vehicle technologies. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019. [Google Scholar]

- Narayanan, S.; Chaniotakis, E.; Antoniou, C. Shared autonomous vehicle services: A comprehensive review. Transp. Res. Part C Emerg. Technol. 2020, 111, 255–293. [Google Scholar] [CrossRef]

- Loeb, B.; Kockelman, K.M. Fleet performance and cost evaluation of a shared autonomous electric vehicle (SAEV) fleet: A case study for Austin, Texas. Transp. Res. Part A Policy Pract. 2019, 121, 374–385. [Google Scholar] [CrossRef]

- Golbabaei, F.; Yigitcanlar, T.; Bunker, J. The role of shared autonomous vehicle systems in delivering smart urban mobility: A systematic review of the literature. Int. J. Sustain. Transp. 2020, 1–18. [Google Scholar] [CrossRef]

- Haas, H. Wireless Data from Every Light Bulb. Available online: https://www.ted.com/talks/harald_haas_wireless_data_from_every_light_bulb/transcript (accessed on 3 February 2021).

- Maurer, M.; Christian Gerdes, J.; Lenz, B.; Winner, H. Autonomous Driving. Technical, Legal and Social Aspects; Springer: Berlin, Germany, 2016. [Google Scholar]

- Fagnant, D.J.; Kockelman, K. Preparing a nation for autonomous vehicles: Opportunities, barriers and policy recommendations. Transp. Res. Part A 2015, 77, 167–181. [Google Scholar] [CrossRef]

- Cohen, T.; Cavoli, C. Automated vehicles: Exploring possible consequences of government (non)intervention for congestion and accessibility. Transp. Rev. 2019, 39, 129–151. [Google Scholar] [CrossRef]

- Chen, T.D.; Kockelman, K.M.; Hanna, J.P. Operations of a shared, autonomous, electric vehicle fleet: Implications of vehicle & charging infrastructure decisions. Transp. Res. Part A Policy Pract. 2016, 94, 243–254. [Google Scholar]

- Iacobucci, R.; Mclellan, B.; Tezuka, T. Modeling shared autonomous electric vehicles: Potential for transport and power grid integration. Energy 2018, 158, 148–163. [Google Scholar] [CrossRef]

- Miao, K.; Ramachandaramurthy, V.K.; Yong, J.Y. Integration of electric vehicles in smart grid: A review on vehicle to grid technologies and optimization techniques. Renew. Sustain. Energy Rev. 2016, 53, 720–732. [Google Scholar]

- Rangaraju, S. Environmental Performance of Battery Electric Vehicles—Implications for Future Integrated Electricity and Transport System. Ph.D. Thesis, Vrije Univeristiet Brussel, Brussels, Belgium, 2018. [Google Scholar]

- Jones, E.C.; Leibowicz, B.D. Contributions of shared autonomous vehicles to climate change mitigation. Transp. Res. Part D Transp. Environ. 2019, 72, 279–298. [Google Scholar] [CrossRef]

| Type of Chargers | Location of Charger | Power Supply/Output | Typical Charging Time |

|---|---|---|---|

| Level 1 | Single phase On-board | Vac: 230 (EU) Vac: 120 (US) Output: 12–16 A; ~1.44 kW to ~1.92 kW | 8–10 h depending on model, used for home charging 3–8 km of range per hour of charging |

| Level 2 | Single/three phase On-board | Vac: 400 (EU) Vac: 240 (US) Output: 15–80 A; ~3.1 kW to ~19.2 kW | 4–8 h, available at home and publicly 16–32 km of range per hour of charging |

| Level 3 DC Fast Chargers (DCFC) | Three-phase Off-board | Uses a three-phase Vac: 208–600 AC circuit converted to direct current (DC) to the vehicle. Output: Up to 500 A; 50 kW up to 350 kW | 30–60 min 100–130 km of range per hour of charging |

| Next Generation: Ultra-Fast Charging System (UFCS) | Three-phase Off-board | Uses a three-phase Vac: 208–600 AC circuit converted to direct current (DC) to the vehicle. Output: 800 V, 400 kW or more | Time to charge to a 320 km range: approximately 7.5 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Mierlo, J.; Berecibar, M.; El Baghdadi, M.; De Cauwer, C.; Messagie, M.; Coosemans, T.; Jacobs, V.A.; Hegazy, O. Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electr. Veh. J. 2021, 12, 20. https://doi.org/10.3390/wevj12010020

Van Mierlo J, Berecibar M, El Baghdadi M, De Cauwer C, Messagie M, Coosemans T, Jacobs VA, Hegazy O. Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electric Vehicle Journal. 2021; 12(1):20. https://doi.org/10.3390/wevj12010020

Chicago/Turabian StyleVan Mierlo, Joeri, Maitane Berecibar, Mohamed El Baghdadi, Cedric De Cauwer, Maarten Messagie, Thierry Coosemans, Valéry Ann Jacobs, and Omar Hegazy. 2021. "Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies" World Electric Vehicle Journal 12, no. 1: 20. https://doi.org/10.3390/wevj12010020

APA StyleVan Mierlo, J., Berecibar, M., El Baghdadi, M., De Cauwer, C., Messagie, M., Coosemans, T., Jacobs, V. A., & Hegazy, O. (2021). Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electric Vehicle Journal, 12(1), 20. https://doi.org/10.3390/wevj12010020