Case Study of Holistic Energy Management Using Genetic Algorithms in a Sliding Window Approach

Abstract

1. Introduction

- Comparison of real-world drives and driving cycles in regard to the EMS

- Application of a GA to an automotive EMS

- Analysis of the optimization results

- Critical assessment of the use of a GA for an EMS

2. Related Work

- Thermal management system: This includes systems that only consider the powertrain and those that combine powertrain and heating, ventilation, and air conditioning (HVAC). The variables are typically the energy that is used for thermal management and the internal states of the system.

- Hybrid energy-storage system: The considered literature deals with an EMS for storage comprising a lithium-ion battery and super-capacitors. All of these strategies aim to optimize the power split between the two sources.

- Variable gear ratio: Here, the focus lies on a gear-shifting schedule in order to minimize energy consumption.

- Multiple electric machines: The literature cited on this row describes EMS for the use of multiple electric machines. All sources focus on optimizing the power split between the machines.

- Variable voltage: Here, the EMS for the variable intermediate circuit voltage is considered. Only one source is found that focuses on the EMS and not on the overall system. The reason for this is that the optimal voltage for the machine can be computed analytically. Therefore, the focus is on the modeling of the machine.

- HVAC: HVAC constitutes the second largest energy consumer. Therefore, it provides leverage for the EMS. The variable that is adapted is the power consumed by the HVAC. In addition to the energy consumption, the thermal comfort of the passengers is taken into account.

- Driving strategies: Here, the literature on the development of driving strategies aiming to minimize energy consumption is cited. This is achieved by adapting the velocity profile.

3. Basics of Multi-Objective Optimization

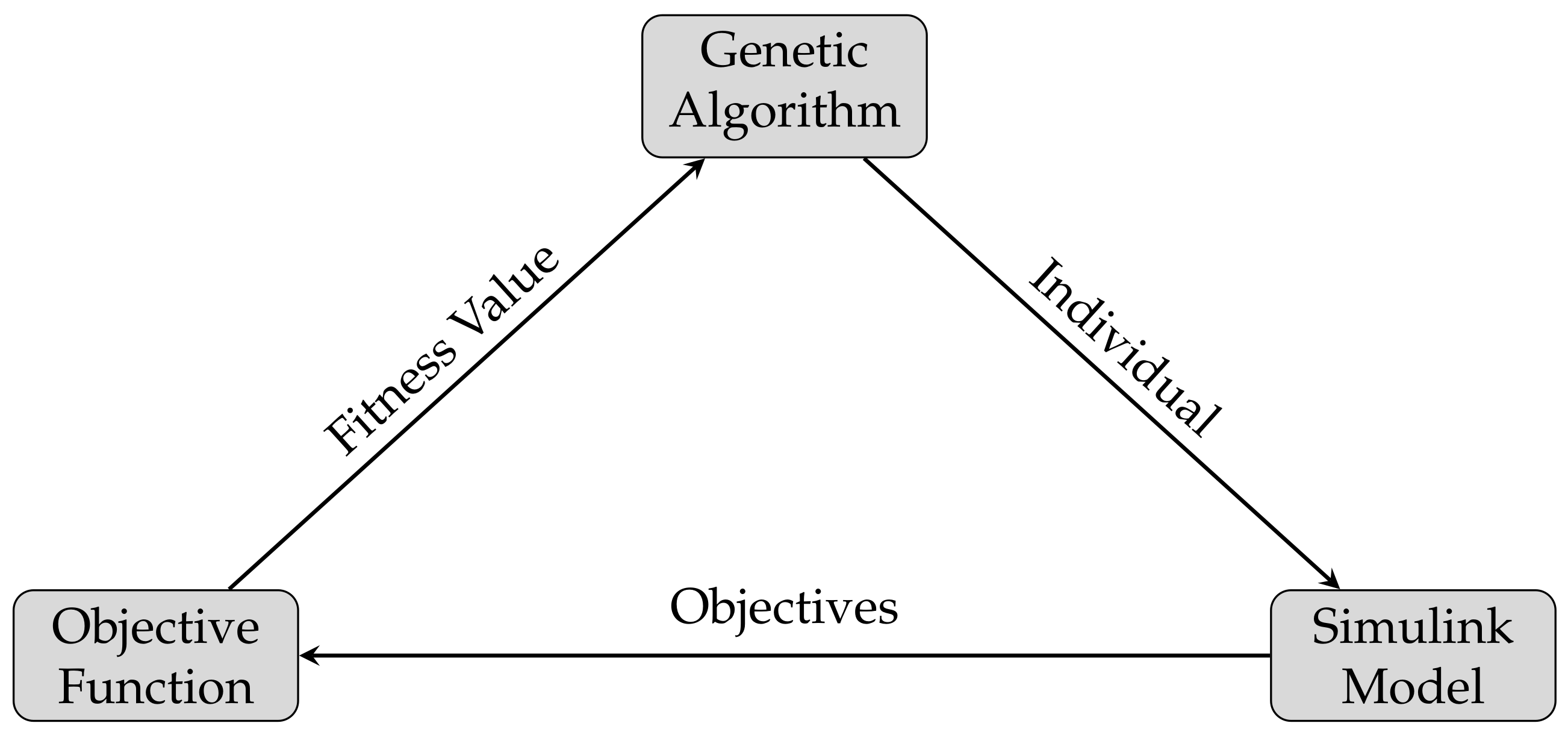

4. Approach

5. Results

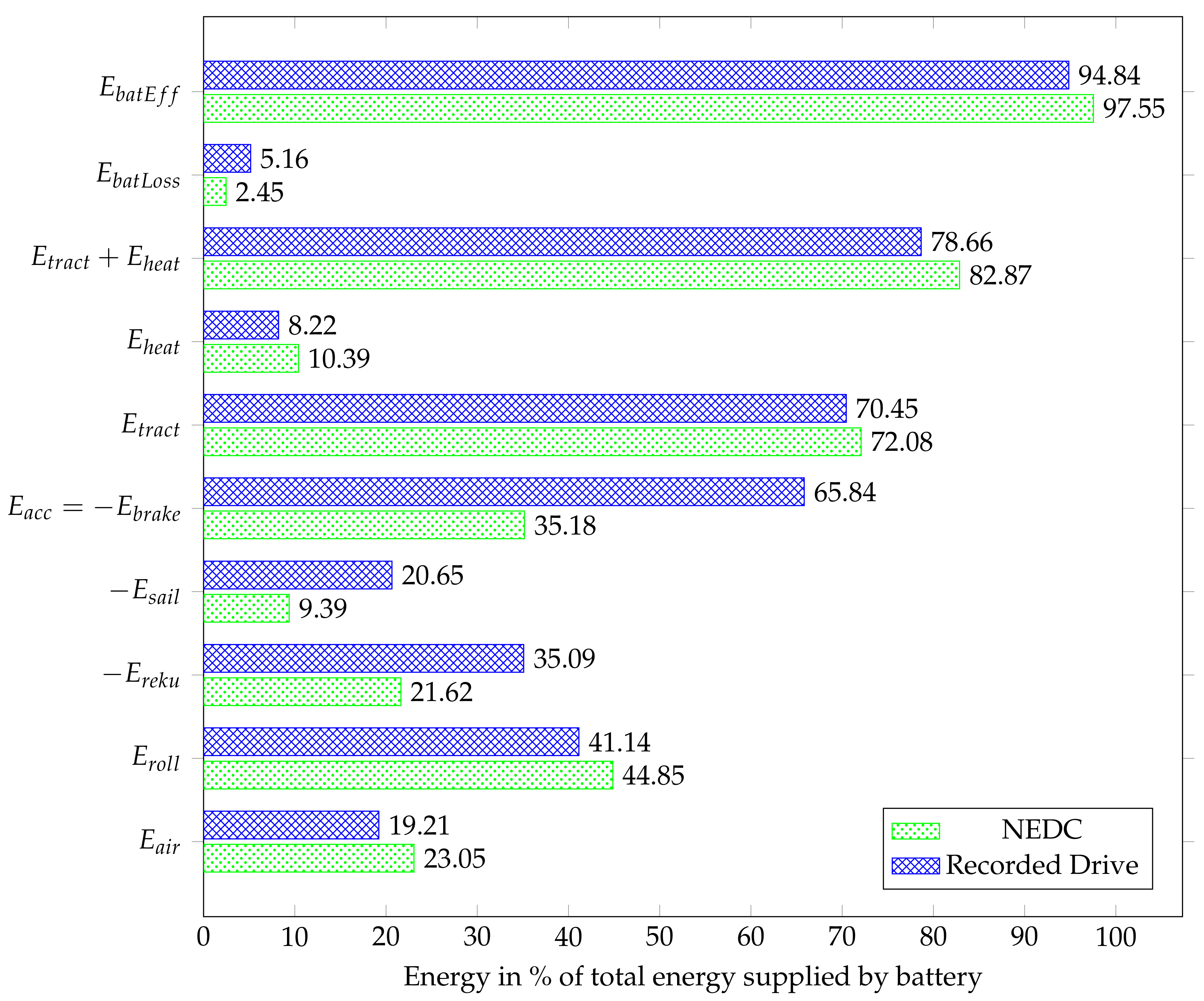

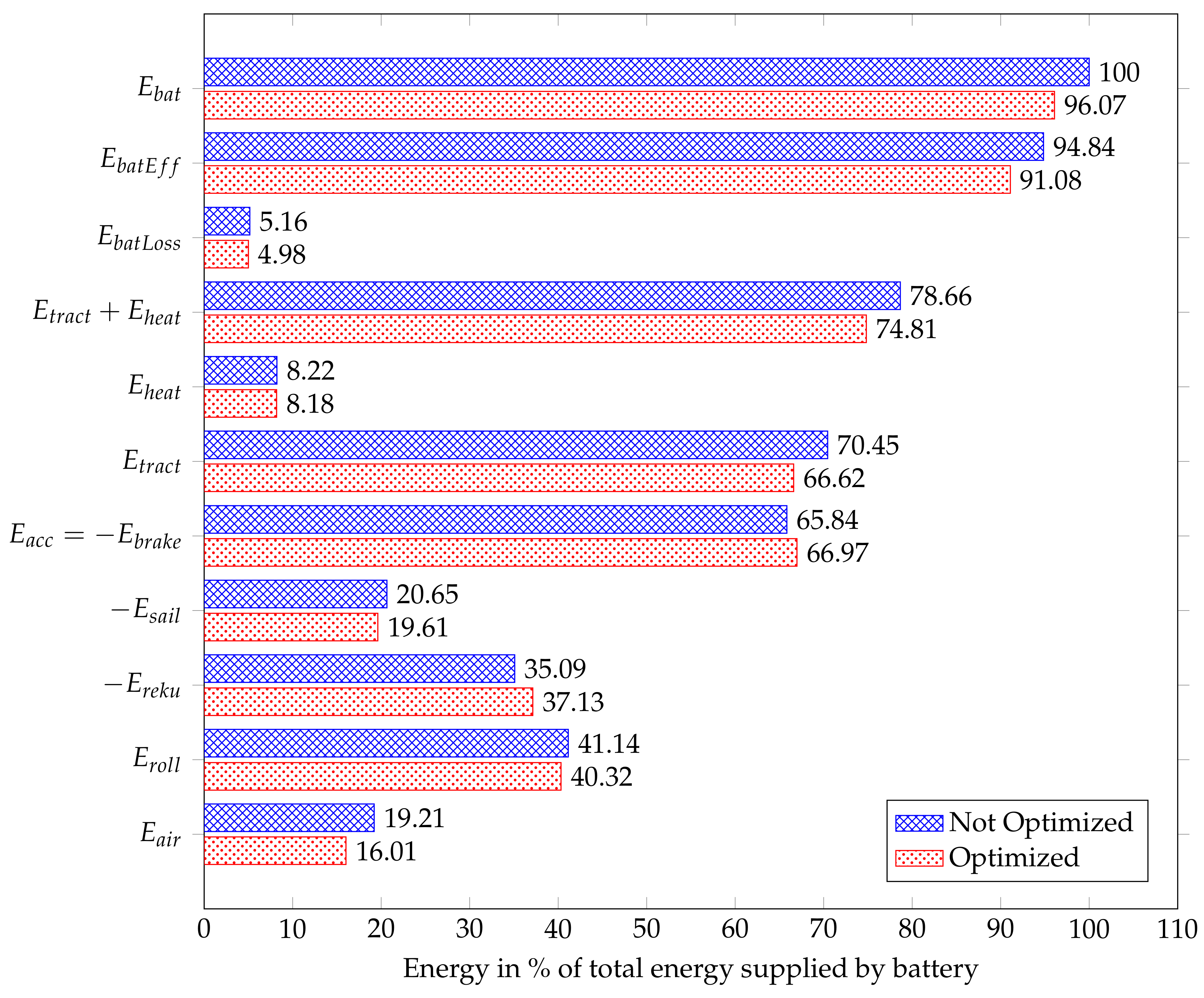

- is the total electric energy provided by the battery. .

- is the electrical energy taken from the battery that can be used by the auxiliary consumers and the drivetrain.

- is the electrical energy that is lost in the battery. It is computed as: with being the internal resistance of the battery dependent on current, temperature, and state-of-charge.

- is the electrical energy used to heat the cabin. Because it can be computed as , it is directly influenced by the optimization algorithm.

- is the total mechanical energy needed for driving. It can be computed as .

- is the mechanical energy that is used for accelerating the vehicle. Only the positive acceleration is considered in this value. .

- is the mechanical energy needed to decelerate the vehicle. Because , it follows that .

- is the mechanical energy that is used during the deceleration of the vehicle to overcome the roll and the air resistance. Like , is negative.

- is the electrical energy that can be recuperated into the battery. Like , is negative.

- is the mechanical energy needed to overcome the rolling resistance. .

- is the mechanical energy needed to overcome the air resistance. .

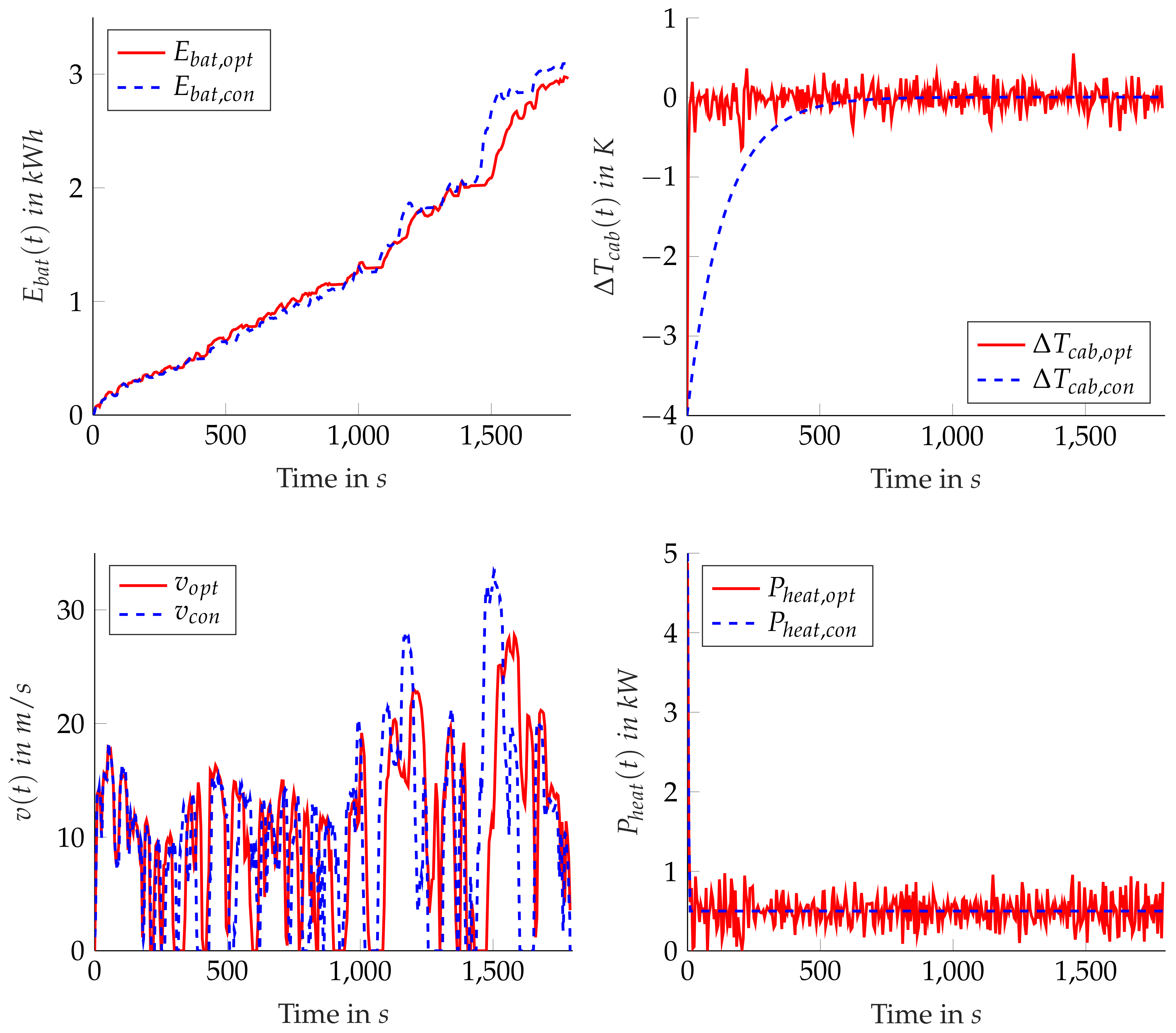

- The proposed approach led to a significant reduction in the total consumed energy, while keeping the driving time nearly constant and the cabin temperature within acceptable limits.

- The holistic approach considering and at the same time had an impact on the battery losses, by avoiding to store the energy in the battery, using it directly for heating instead.

- The execution of the model took about 95% of the total optimization time. This made the GA very dependent on the run time of the simulation model.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BEV | Battery electric vehicle |

| EMS | Energy management system |

| GA | Genetic algorithm |

| HEV | Hybrid electric vehicle |

| HVAC | Heating, ventilation and air conditioning |

| NEDC | New European Driving Cycle |

References

- Nikowitz, M. Advanced Hybrid and Electric Vehicles: System Optimization and Vehicle Integration; Lecture Notes in Mobility; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Salmasi, F.R. Control Strategies for Hybrid Electric Vehicles: Evolution, Classification, Comparison, and Future Trends. IEEE Trans. Veh. Technol. 2007, 56, 2393–2404. [Google Scholar] [CrossRef]

- Basler, A. Eine Modulare Funktionsarchitektur zur Umsetzung einer Gesamtheitlichen Betriebsstrategie für Elektrofahrzeuge: Dissertation; KIT Scientific Publishing: Karlsruhe, Germany: 2015; Volume 42. [Google Scholar]

- Auer, M.; Wiedemann, J.; Widdecke, N.; Kuthada, T. Increase of Range of Battery Electric Vehicles through Thermal Management. ATZ Worldw. 2015, 117, 64–71. [Google Scholar] [CrossRef]

- Leighton, D. Combined Fluid Loop Thermal Management for Electric Drive Vehicle Range Improvement. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8. [Google Scholar] [CrossRef]

- Enthaler, A.; Weustenfeld, T.; Gauterin, F.; Koehler, J. Thermal management consumption and its effect on remaining range estimation of electric vehicles. In Proceedings of the 2014 International Conference on Connected Vehicles and Expo (ICCVE), Vienna, Austria, 3–7 November 2014; pp. 170–177. [Google Scholar] [CrossRef]

- Styler, A.; Podnar, G.; Dille, P.; Duescher, M.; Bartley, C.; Nourbakhsh, I. Active Management of a Heterogeneous Energy Store for Electric Vehicles. In Proceedings of the 2011 IEEE Forum on Integrated and Sustainable Transportation Systems, Vienna, Austria, 29 June–1 July 2011. [Google Scholar]

- Zheng, C.; Li, W.; Liang, Q. An Energy Management Strategy of Hybrid Energy Storage Systems for Electric Vehicle Applications. IEEE Trans. Sustain. Energy 2018, 9, 1880–1888. [Google Scholar] [CrossRef]

- Demircalı, A.; Sergeant, P.; Koroglu, S.; Kesler, S.; Öztürk, E.; Tumbek, M. Influence of the temperature on energy management in battery-ultracapacitor electric vehicles. J. Clean. Prod. 2018, 176, 716–725. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, X.; Jia, M.; Zheng, Y. Energy Management Strategy for the Hybrid Energy Storage System of Pure Electric Vehicle Considering Traffic Information. Appl. Sci. 2018, 8, 1266. [Google Scholar] [CrossRef]

- Song, Z.; Li, J.; Hou, J.; Hofmann, H.; Ouyang, M.; Du, J. The battery-supercapacitor hybrid energy storage system in electric vehicle applications: A case study. Energy 2018, 154, 433–441. [Google Scholar] [CrossRef]

- Azizi, I.; Radjeai, H. A new strategy for battery and supercapacitor energy management for an urban electric vehicle. Electr. Eng. 2018, 100, 667–676. [Google Scholar] [CrossRef]

- Armenta, J.; Núñez, C.; Visairo, N.; Lázaro, I. An advanced energy management system for controlling the ultracapacitor discharge and improving the electric vehicle range. J. Power Sources 2015, 284, 452–458. [Google Scholar] [CrossRef]

- Trovão, J.P.; Silva, M.A.; Dubois, M.R. Coupled energy management algorithm for MESS in urban EV. IET Electr. Syst. Transp. 2017, 7, 125–134. [Google Scholar] [CrossRef]

- Rizoug, N.; Mesbahi, T.; Sadoun, R.; Bartholomeüs, P.; Le Moigne, P. Development of new improved energy management strategies for electric vehicle battery/supercapacitor hybrid energy storage system. Energy Effic. 2018, 11, 823–843. [Google Scholar] [CrossRef]

- Guo, L.; Gao, B.; Chen, H. Online Shift Schedule Optimization of 2-Speed Electric Vehicle Using Moving Horizon Strategy. IEEE/ASME Trans. Mechatron. 2016, 21, 2858–2869. [Google Scholar] [CrossRef]

- Shanding, Y.; Qiang, S.; Habibi, S. Dynamic optimization method for speed ratio of electric vehicle with two-speed transmission system. In Proceedings of the 2016 IEEE International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 21–23 October 2016; pp. 530–536. [Google Scholar] [CrossRef]

- Gunji, D.; Fujimoto, H. Efficiency analysis of powertrain with toroidal continuously variable transmission for Electric Vehicles. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 6614–6619. [Google Scholar] [CrossRef]

- Gao, B.; Xiang, Y.; Chen, H.; Liang, Q.; Guo, L. Optimal Trajectory Planning of Motor Torque and Clutch Slip Speed for Gear Shift of a Two-Speed Electric Vehicle. J. Dyn. Syst. Meas. Control 2015, 137, 061016. [Google Scholar] [CrossRef]

- Zhu, B.; Zhang, N.; Walker, P.; Zhou, X.; Zhan, W.; Wei, Y.; Ke, N. Gear shift schedule design for multi-speed pure electric vehicles. Proc. Inst. Mech. Eng. Part D J. Autom. Eng. 2015, 229, 70–82. [Google Scholar] [CrossRef]

- An, J.; Binder, A. Operation Strategy with Thermal Management of E-Machines in Pure Electric Driving Mode for Twin-Drive-Transmission (DE-REX). In Proceedings of the 2017 IEEE Vehicle Power and Propulsion Conference (VPPC), Belfort, France, 11–14 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. Design and Experimental Evaluations on Energy Efficient Control Allocation Methods for Overactuated Electric Vehicles: Longitudinal Motion Case. IEEE/ASME Trans. Mechatron. 2014, 19, 538–548. [Google Scholar] [CrossRef]

- Hu, M.; Zeng, J.; Xu, S.; Fu, C.; Qin, D. Efficiency Study of a Dual-Motor Coupling EV Powertrain. IEEE Trans. Veh. Technol. 2015, 64, 2252–2260. [Google Scholar] [CrossRef]

- Liang, J.; Yang, H.; Wu, J.; Zhang, N.; Walker, P.D. Shifting and power sharing control of a novel dual input clutchless transmission for electric vehicles. Mech. Syst. Signal Process. 2018, 104, 725–743. [Google Scholar] [CrossRef]

- Hung, Y.H.; Wu, C.H. A combined optimal sizing and energy management approach for hybrid in-wheel motors of EVs. Appl. Energy 2015, 139, 260–271. [Google Scholar] [CrossRef]

- Wacker, P.; Wheldon, L.; Sperlich, M.; Adermann, J.; Lienkamp, M. Influence of active battery switching on the drivetrain efficiency of electric vehicles. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; pp. 33–38. [Google Scholar] [CrossRef]

- Sakhdari, B.; Azad, N. An Optimal Energy Management System for Battery Electric Vehicles. IFAC-PapersOnLine 2015, 48, 86–92. [Google Scholar] [CrossRef]

- Roscher, M.A.; Leidholdt, W.; Trepte, J. High efficiency energy management in BEV applications. Int. J. Electr. Power Energy Syst. 2012, 37, 126–130. [Google Scholar] [CrossRef]

- Becker, G. Ein Fahrerassistenzsystem zur Vergrößerung der Reichweite von Elektrofahrzeugen; Springer Vieweg: Wiesbaden, Germany, 2016. [Google Scholar]

- Madhusudhanan, A.K. A method to improve an electric vehicle’s range: Efficient Cruise Control. Eur. J. Control 2018. [Google Scholar] [CrossRef]

- Wu, X.; He, X.; Yu, G.; Harmandayan, A.; Wang, Y. Energy-Optimal Speed Control for Electric Vehicles on Signalized Arterials. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2786–2796. [Google Scholar] [CrossRef]

- Fritsch, M.; Scherler, S.; Xiaobo, L.H. Eine Intelligente Fahrerassistenzfunktion zum Energieoptimalen Fahrbetrieb für Elektrofahrzeuge. In ASIM/GI STS/GMMS Workshop 2016; ARGESIM Verlag: Lippstadt, Germany, 2016. [Google Scholar]

- Vaz, W.S.; Nandi, A.K.; Koylu, U.O. A Multiobjective Approach to Find Optimal Electric-Vehicle Acceleration: Simultaneous Minimization of Acceleration Duration and Energy Consumption. IEEE Trans. Veh. Technol. 2016, 65, 4633–4644. [Google Scholar] [CrossRef]

- Dib, W.; Chasse, A.; Moulin, P.; Sciarretta, A.; Corde, G. Optimal energy management for an electric vehicle in eco-driving applications. Control Eng. Pract. 2014, 29, 299–307. [Google Scholar] [CrossRef]

- Flehmig, F.; Kästner, F.; Knödler, K.; Knoop, M. Eco-ACC für Elektro- und Hybridfahrzeuge. ATZ Automobiltech. Z. 2014, 116, 22–27. [Google Scholar] [CrossRef]

- Suchaneck, A. Energiemanagement-Strategien für Batterieelektrische Fahrzeuge; Forschungsberichte aus der Industriellen Informationstechnik; KIT Scientific Publishing: Karlsruhe, Germany, 2018; Volume 17. [Google Scholar]

- Branke, J.; Deb, K.; Miettinen, K.; Slowinski, R. (Eds.) Multiobjective Optimization: Interactive and Evolutionary Approaches; Lecture Notes in Computer Science; Springer: Berlin, Germany, 2008; Volume 5252. [Google Scholar]

- Vanderplaats, G.N. Numerical Optimization Techniques for Engineering Design: With Applications, 3rd ed.; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill: New York, MY, USA, 2001. [Google Scholar]

- Deb, K. An efficient constraint handling method for genetic algorithms. Comput. Methods Appl. Mech. Eng. 2000, 186, 311–338. [Google Scholar] [CrossRef]

- Du, K.L.; Swamy, M.N.S. Search and Optimization by Metaheuristics; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Adermann, J.; Kreibich, J.; Lienkamp, M. Experimental Study of Energy Consumption Variation in Recurring Driving Trips. J. Electr. Eng. 2017, 5, 253–261. [Google Scholar] [CrossRef][Green Version]

- Danquah, B.; Alexander Koch, A.; Weiß, T.; Lienkamp, M.; Pinnel, A. Modular, Open Source Simulation Approach: Application to Design and Analyze Electric Vehicles. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monaco, Monaco, 8–10 May 2019. [Google Scholar]

- Romaus, C.; Gathmann, K.; Bocker, J. Optimal energy management for a hybrid energy storage system for electric vehicles based on Stochastic Dynamic Programming. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar]

- Minnerup, K.; Herrmann, T.; Steinstraeter, M.; Lienkamp, M. Concept for a Holistic Energy Management System for Battery Electric Vehicles Using Hybrid Genetic Algorithms. In Proceedings of the 2018 IEEE 88th Vehicular Technology Conference (VTC-Fall), Chicago, IL, USA, 27–30 August 2018; pp. 1–6. [Google Scholar] [CrossRef]

| Component | Optimization-Based | Heuristic | ||

|---|---|---|---|---|

| Online | Offline | Derived from Optimization | Not Derived from Optimization | |

| Thermal management system | [4] | - | - | [5,6] |

| Hybrid energy storage | [7] | [8] | [9,10,11] | [12,13,14,15] |

| Variable gear ratio | - | [16,17] | [18,19] | [20] |

| Multiple electric machines | - | [21] | [22,23,24] | [25] |

| Variable voltage | - | - | - | [26] |

| HVAC | [27] | - | - | [28] |

| Driving strategies | [29,30,31] | [32,33,34] | [35] | - |

| Holistic EMS | [36] | - | [3] | - |

| Parameter | Value |

|---|---|

| Population size | (number of parameters per section l) |

| Number of max. generations | 50 |

| Crossover-fraction | |

| Mutation rate | feasible adaption |

| Elitism | population size |

| Selection | rank-based |

| Discretization step of time-dependent optimization parameters | 5 s [43] |

| Discretization step of space-dependent optimization parameters | 400 m |

| Configuration | Reduction of Energy Consumption | Time Relative to Original Traveling Time |

|---|---|---|

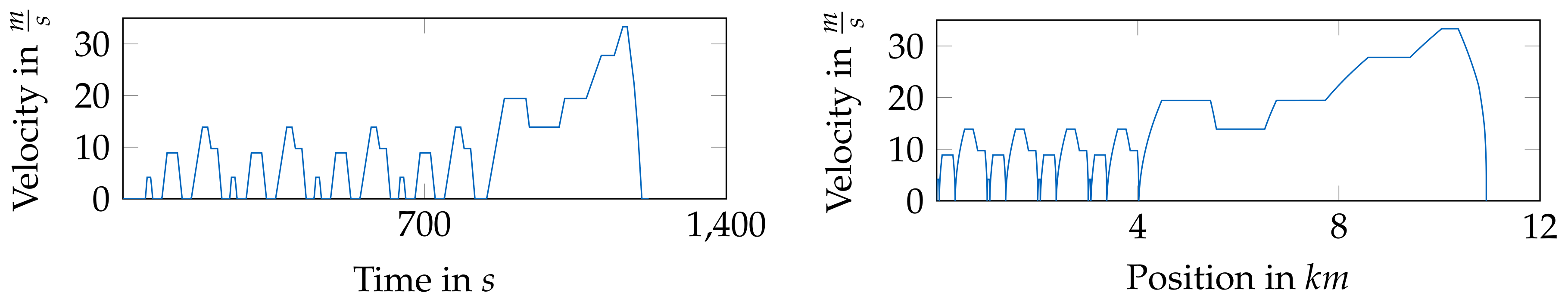

| Recorded Drive | ||

| NEDC | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minnerup, K.; Herrmann, T.; Steinstraeter, M.; Lienkamp, M. Case Study of Holistic Energy Management Using Genetic Algorithms in a Sliding Window Approach. World Electr. Veh. J. 2019, 10, 46. https://doi.org/10.3390/wevj10020046

Minnerup K, Herrmann T, Steinstraeter M, Lienkamp M. Case Study of Holistic Energy Management Using Genetic Algorithms in a Sliding Window Approach. World Electric Vehicle Journal. 2019; 10(2):46. https://doi.org/10.3390/wevj10020046

Chicago/Turabian StyleMinnerup, Katharina, Thomas Herrmann, Matthias Steinstraeter, and Markus Lienkamp. 2019. "Case Study of Holistic Energy Management Using Genetic Algorithms in a Sliding Window Approach" World Electric Vehicle Journal 10, no. 2: 46. https://doi.org/10.3390/wevj10020046

APA StyleMinnerup, K., Herrmann, T., Steinstraeter, M., & Lienkamp, M. (2019). Case Study of Holistic Energy Management Using Genetic Algorithms in a Sliding Window Approach. World Electric Vehicle Journal, 10(2), 46. https://doi.org/10.3390/wevj10020046