1. Introduction

Electrification is nowadays one of the most widely spread strategies to reduce transport sector emissions [

1]. The automotive market is experiencing a remarkable development towards electrification, and for the passenger car segment, there is a wide offer of models with a full electric or a plug-in hybrid electric drivetrain, allowing for pure electric driving over most of the driven distances. However, electrifying heavy-duty vehicles such as long-haul trucks and coaches is significantly more challenging, since these types of vehicle require large and heavy batteries to reach a useful driving distance, thus reducing the payload and making the whole case less feasible from an economic perspective.

In order to reduce the size of the battery while keeping the usability of the vehicle unchanged, dynamic charging could be used. With dynamic charging, energy is transferred to the vehicle while in motion. This energy may be used not only to propel the vehicle but also to charge the battery so that it can be used at a later stage. Electric Road Systems (ERS) represent the physical implementation of different dynamic charging principles: inductive, in which the power is transferred via coupled magnetic field, capacitive, using coupled electric field, and conductive, in which there is a physical connection, and the electric current flows directly between the electric road and the vehicle.

Previous work on the cost of different ERS concluded that, on the basis of data from today’s existing pilot test sites, conductive ERS can be built at a significant lower cost than the competing alternatives [

2,

3]. Moreover, conductive ERS placed at ground level (either under the vehicle or on the side) can be used by both heavy and light vehicles, resulting in a much lower total system cost from a societal perspective. Up to four pilot test sites for different conductive ERS are currently operating in Sweden, and the Swedish government has recently signed agreements with Germany [

4] and France [

5] to collaborate on the development of ERS technology. Therefore, an assessment of the safety challenges associated with this technology is necessary.

This article analyses one of the main safety hazards with all the conductive ERS proposed so far: the absence of a reliable protective earth connection. Since the vehicle is supplied with electricity using some kind of sliding contacts (“pick-ups”) that move relative to the power supply lines allowing the vehicle to connect/disconnect at any time, none of the proposed solutions can guarantee that a solid protective earth connection exists at all times while the vehicle is connected to the power supply. This in turn implies that, unlike what happens in trams and railways, the body of the vehicle cannot be connected to earth at all times, so potentially dangerous situations in which an insulation fault results in an energized vehicle body cannot be avoided completely.

Compared to Battery Electric Vehicles (BEVs), the electric power system of a vehicle running on a conductive ERS may not be completely isolated from earth potential, and as shown in the next section, at least part of the electric system on-board could be energized with respect to earth. Therefore, understanding the evolution of the chassis’ and vehicle body’s electrical potential during both normal and fault situations becomes safety-critical.

2. Materials and Methods

In order to assess the safety conditions of an electric vehicle (EV) supplied by a conductive ERS, an electrical model of the whole system (vehicle and infrastructure) implemented in LTSpice is proposed in this article. The model was used to estimate the chassis potential and the touch current under different operation conditions. Since the model relies on a number of input parameters such as insulation and parasitic impedances, which in turn depend on the physical implementation of both the ERS infrastructure and the vehicle itself, experimental tests were conducted in order to validate the simulation results.

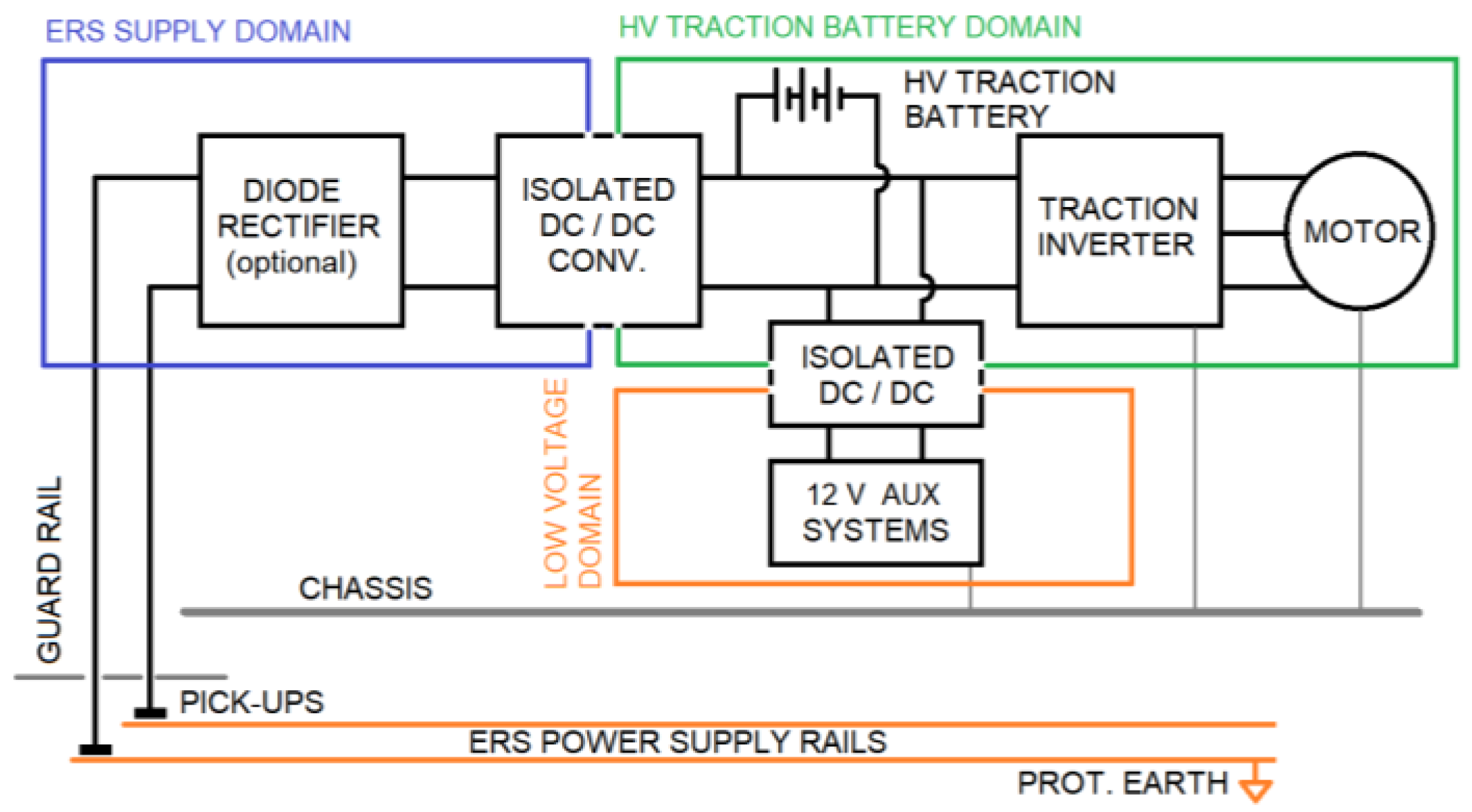

Three electrical domains exist in a vehicle suited for conductive ERS operation (see

Figure 1). In normal operation conditions, these domains are isolated from one another: I) one domain is coupled to the high-voltage (HV) traction battery (like in normal BEVs), with a high impedance (commonly referred to as “floating”) with respect to both the vehicle’s chassis and the ERS power supply; II) one domain is coupled to the low-voltage (usually 12 or 24 V) system; and III) one domain is coupled to the ERS power supply, thus with a low impedance to its ground/earth potential.

The high-voltage traction battery domain is essentially the same as for BEVs. The HV traction battery supplies the main power electronic converter and the traction motor, as well as any other auxiliary devices that there could be.

The low-voltage domain is created from the previous one through an isolated DC–DC converter in order to power instrumentation, computers, lights, infotainment, etc., usually at 12 V but, in many heavy vehicles, at 24 V. The chassis may be used as the negative pole and conductor for this domain.

Finally, the ERS power supply domain is the part of the electric system on-board that is added in order to use the conductive ERS. It consists of the contact devices (“pick-ups”) interfacing the ERS and collecting the current from the ERS power supply lines, a rectifier (if needed), which is usually single-quadrant, to rectify the currents from the ERS, and an isolated DC–DC converter to transfer the energy to the HV traction battery domain. In most solutions, the pick-ups are mounted in a metallic sub-frame that is also electrically floating with respect to everything else, acting as a guard-rail for electric safety purposes.

The ERS can supply the vehicle acting as either an unregulated DC voltage source or a variable/AC source. In the first case, no rectifier is needed, and the pick-ups can be directly connected to the isolated DC–DC converter, transferring the electric power to the HV traction battery domain. The solutions implemented by Siemens (eHighways) or Alstom (APS) are examples of ERS with a DC supply [

6,

7].

However, some of the proposed technical implementations of conductive ERS feature a power supply that is not purely DC. In the Elways solution, the reported power supply is a bipolar AC (two sinusoidal waves of the same amplitude and frequency, phase shifted 180 degrees) [

8,

9], while in the Elonroad solution, the vehicle is connected to short segments that, as the vehicle moves, are alternatively connected to an unregulated DC voltage level (typically 600 V) or earth, resulting in a square-wave voltage signal at the pick-ups. The pick-ups provide at least three contact points reaching three consecutive power segments of 1 m each, every second of which is always at a near-zero voltage, while the rest are commutated between +600 V and zero [

8,

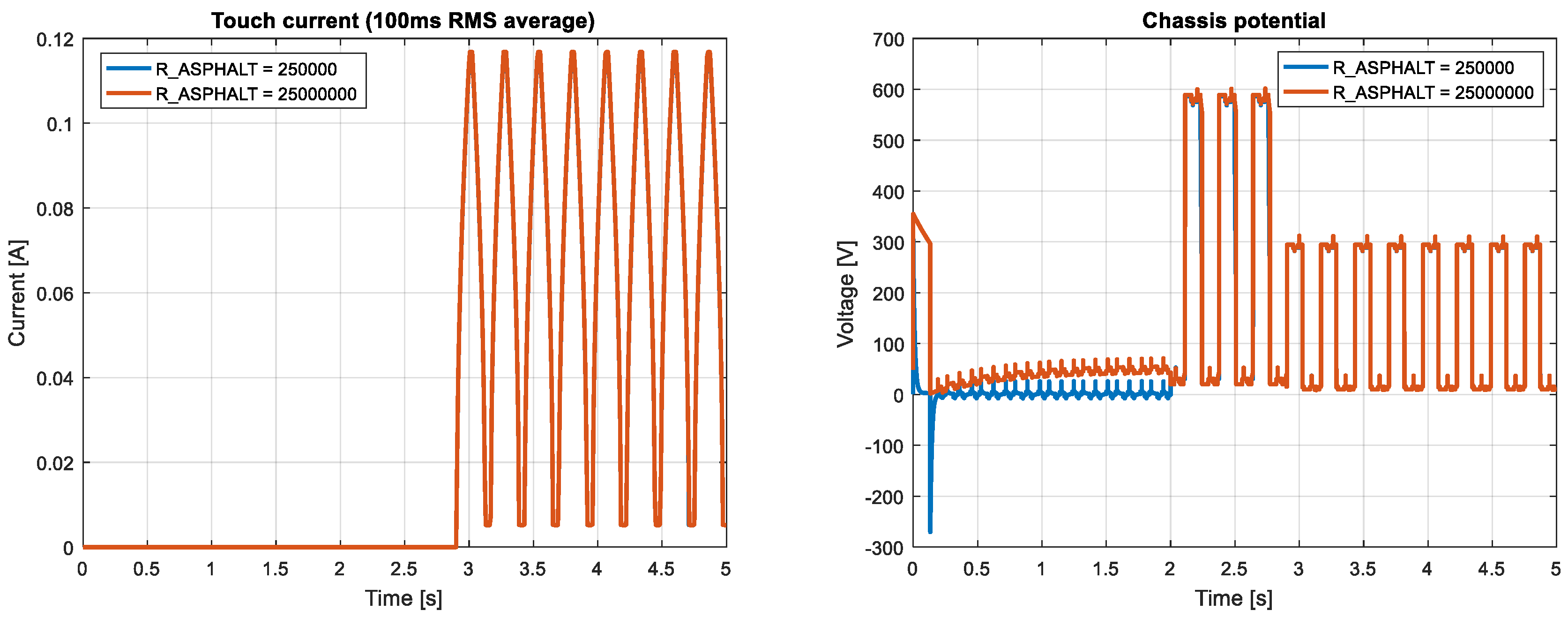

9]. Mostly because of the parasitic capacitances in the system, some of this square-wave voltage (at the input to the rectifier) is coupled to the vehicle chassis and body, which could potentially affect the performance of any chassis potential-monitoring device used. The chassis of the vehicle is, under normal conditions, also floating with respect to the external ERS power supply earth, only coupled through the parasitic resistance and capacitance of the tires and asphalt. However, since the ERS power supply is earthed, there is a risk that an insulation fault in this part of the electric system provides a low-impedance path to the vehicle chassis, creating a hazard for people outside the vehicle that could get in touch with the energized parts.

Figure 1 shows a general schematic of the electric system onboard, representing the main components.

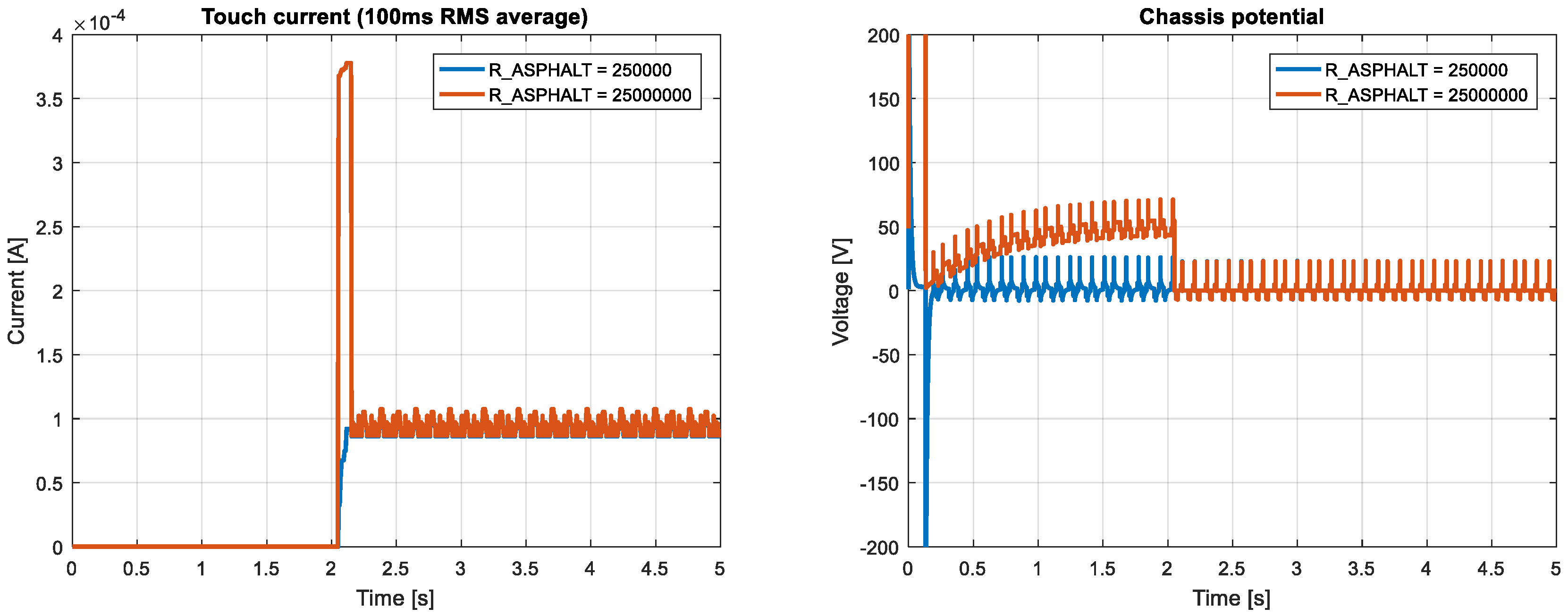

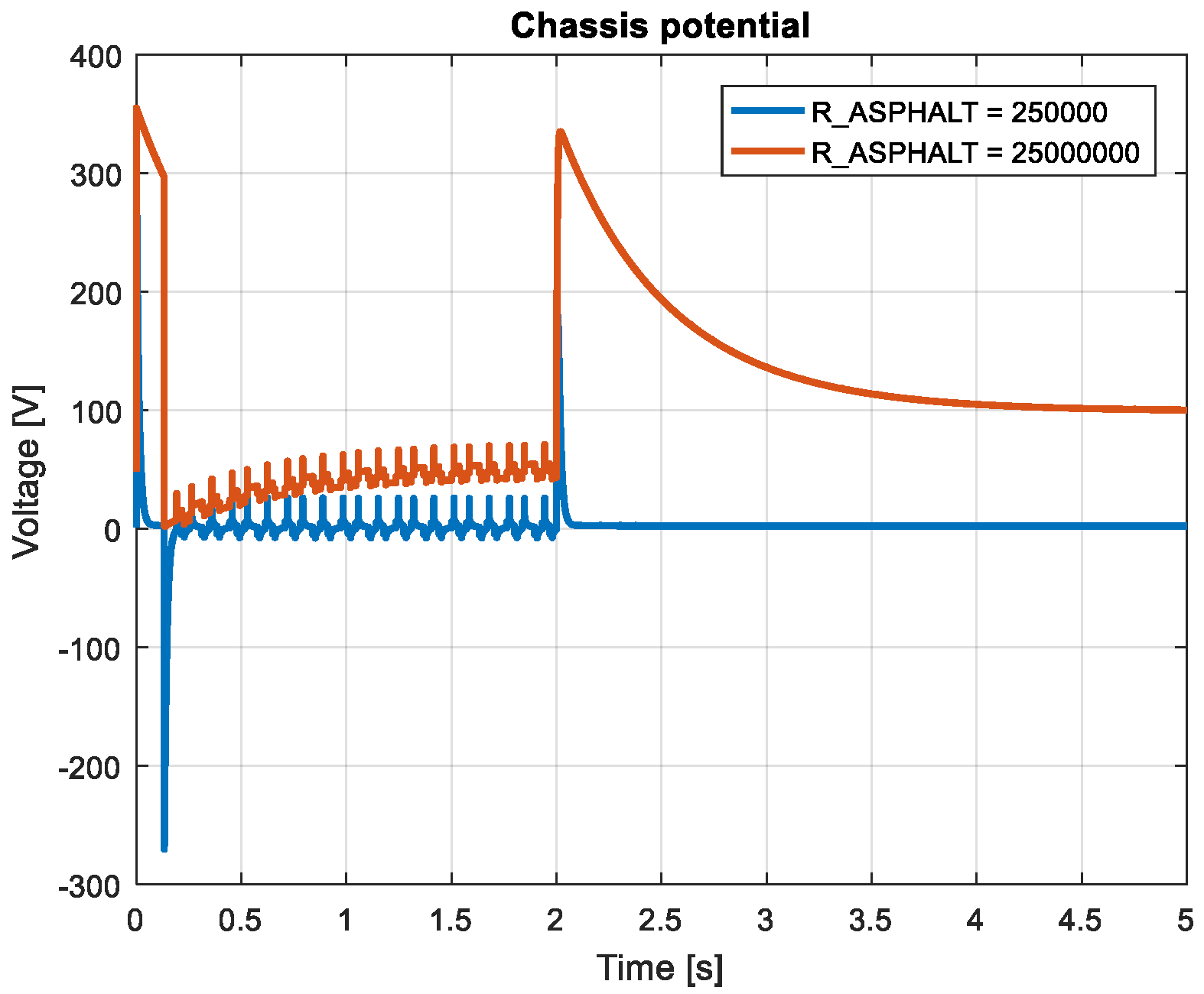

In order to simulate the effect of a human body in touch with the chassis of the vehicle, a resistor of 2.5 kΩ was placed between the vehicle chassis and the earth. The resistance value chosen was of course dependent on a number of factors: contact surface area, humidity conditions, type of shoes that the person is wearing (if any), etc. However, 2.5 kΩ seemed a reasonable value for this analysis, corresponding to very conservative assumptions from a safety point of view (e.g., a barefoot person standing on an earthed plate touching the vehicle with a whole hand). Since a relatively low value of resistance was assumed, the touch current was used to evaluate the potential hazard in different cases. On the basis of the charts published in [

10,

11] presenting different thresholds for perception, pain, and heart affection, the average root mean square (RMS) value of the touch current over 100 ms was used, and the safety limit was set to 5 mA.

All cases were simulated for an ERS supplying an AC square-wave voltage as in the Elonroad solution, since the authors had access to their pilot test-track to conduct experimental tests. In order to make the simulations as realistic as possible, some of the most critical parameters were measured directly in the test vehicle and trailer used at the Eloroad test site. The parameter values used for normal operation conditions are presented in

Table 1.

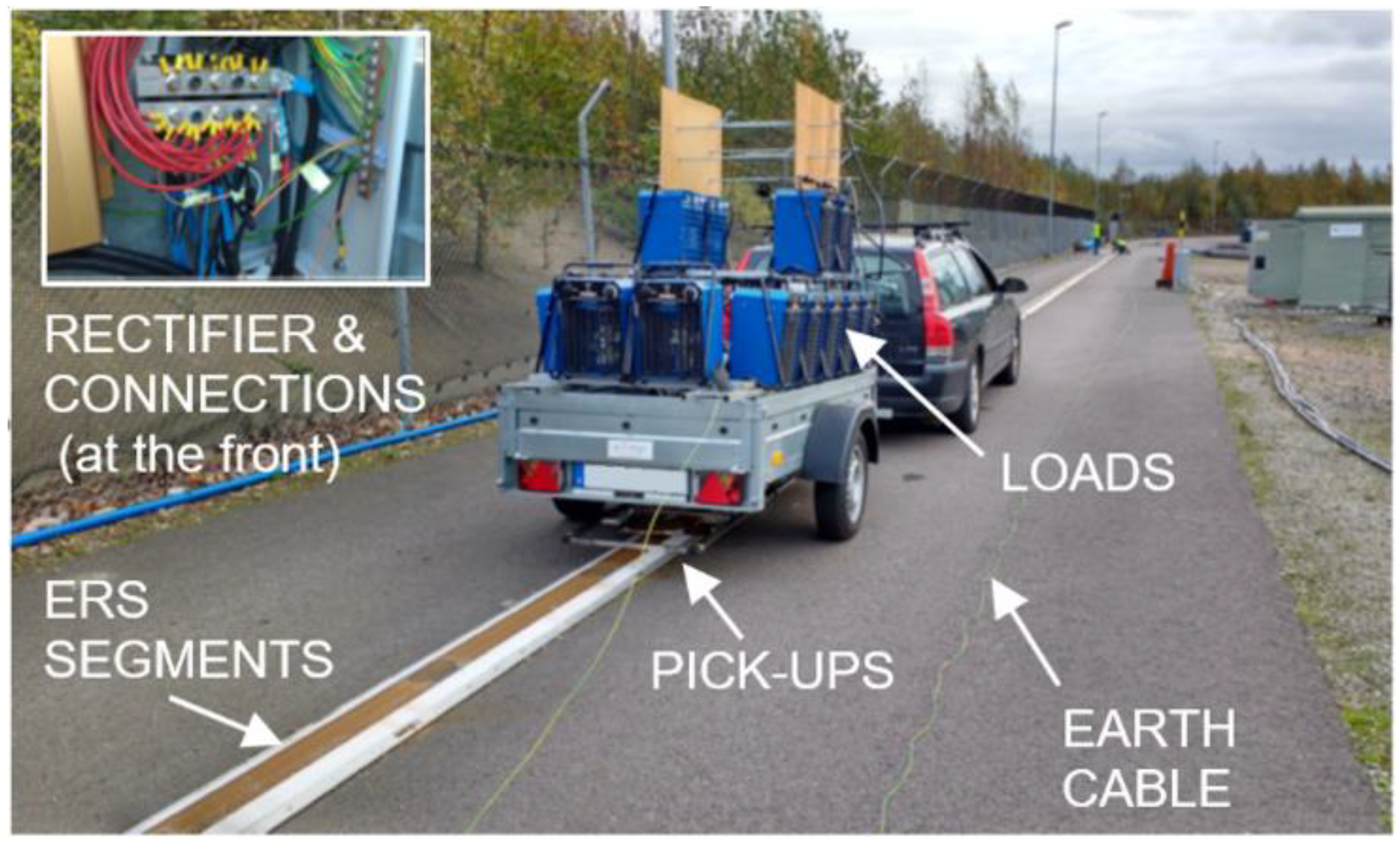

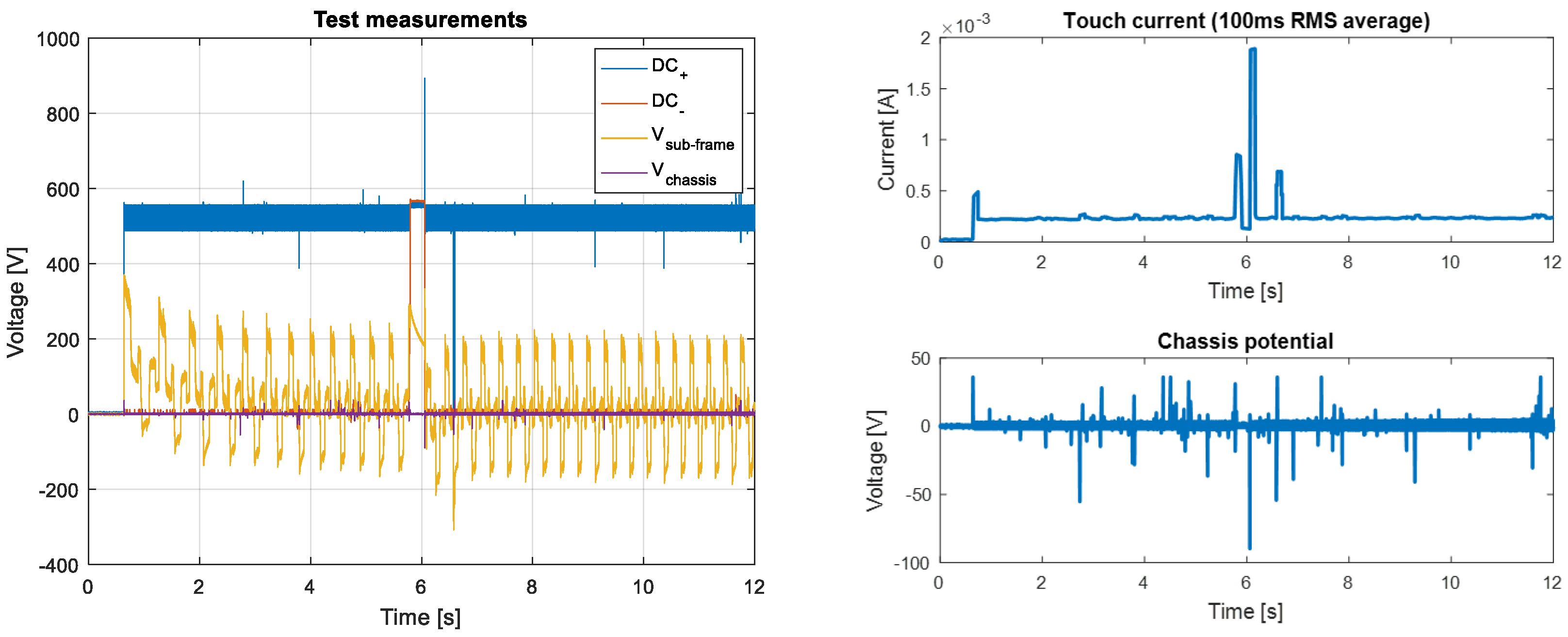

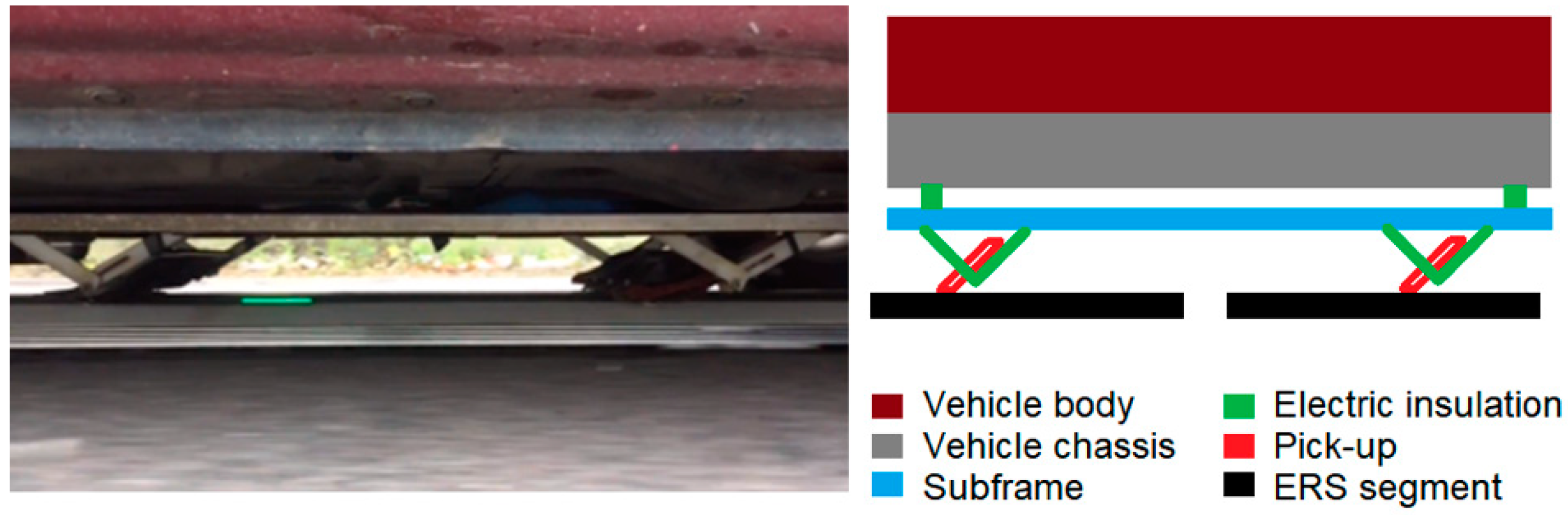

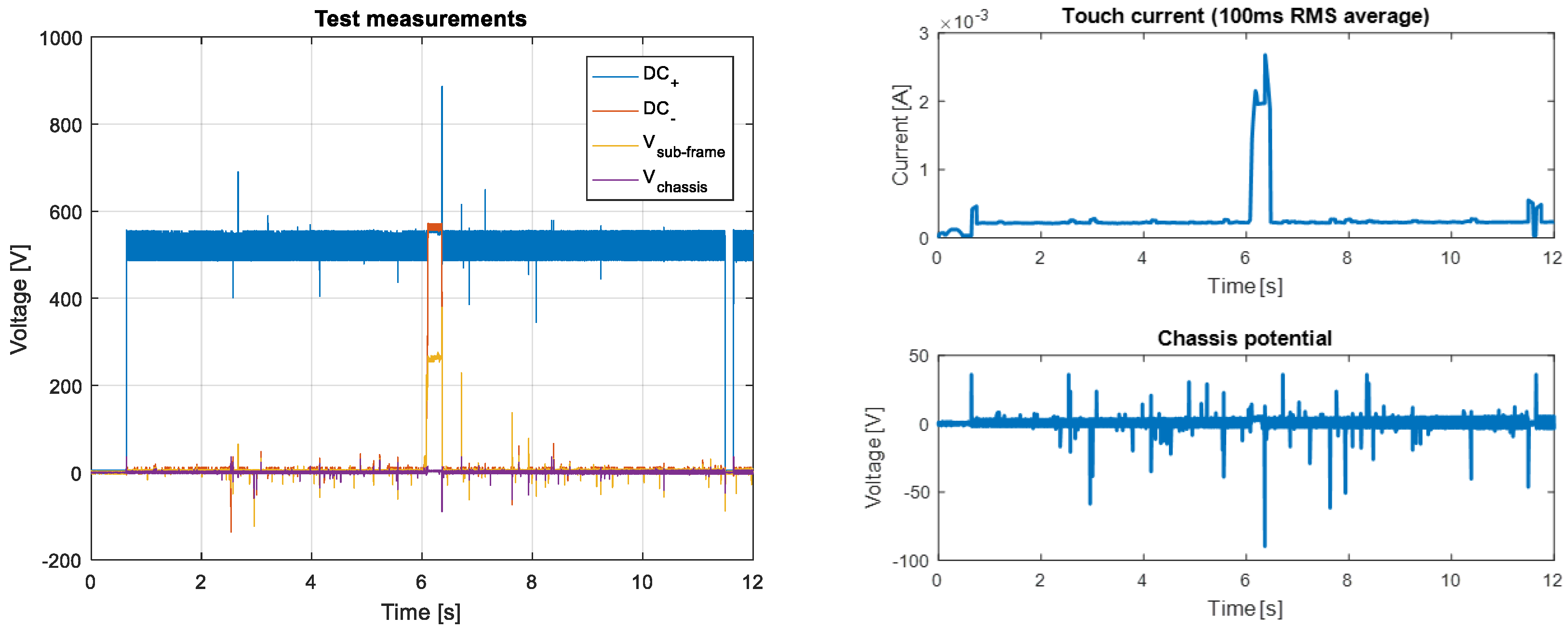

The experimental test setup consisted of a purposely built trailer equipped with three pick-ups installed on a sub-frame, as explained in the previous sections. The current from the pick-ups was rectified and consumed in a rack of industrial heaters mounted on the trailer, as seen in

Figure 2.

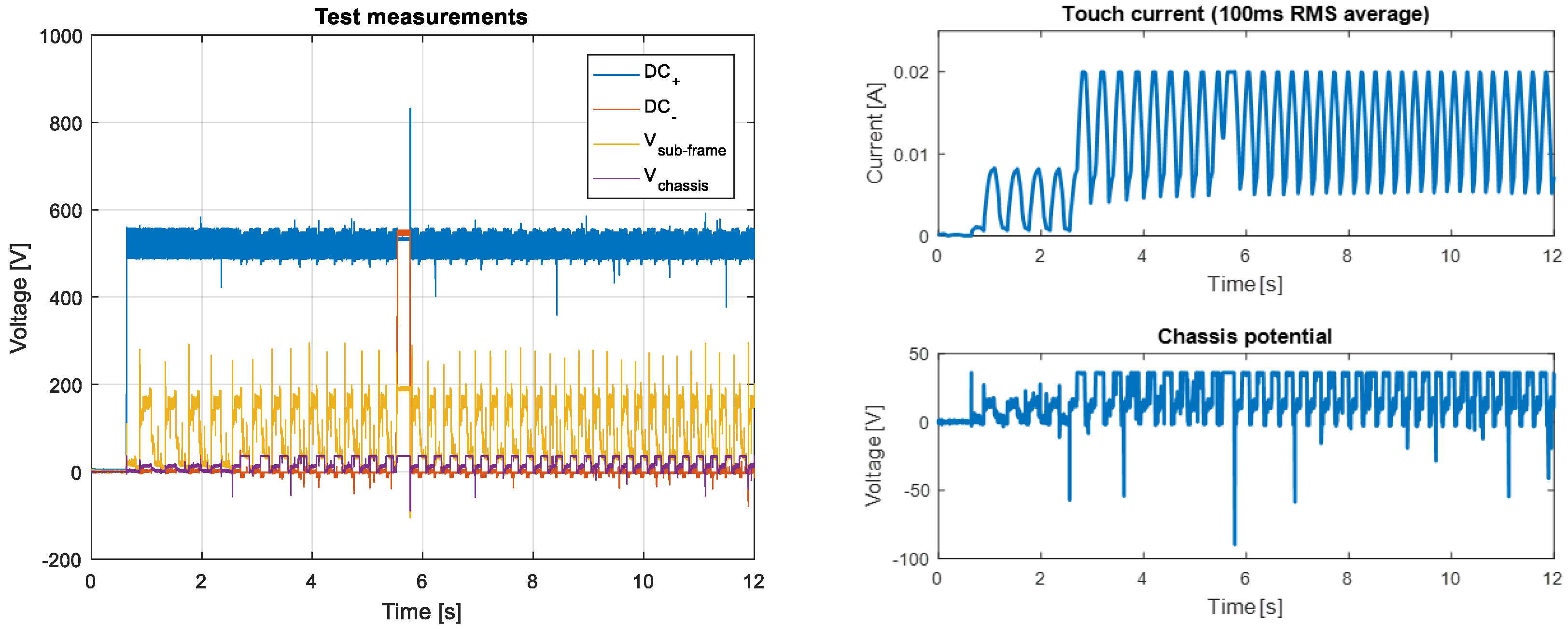

The voltages of the positive and negative terminal of the DC link at the rectifier output, together with the potential of the sub-frame (or guard-rail) and the earth potential (available through a long cable earthed at the rectifying station) were logged in every test, referred to the chassis potential. In addition, a 1.8 kΩ resistor was connected between the chassis of the vehicle and earth at all times, emulating a human body. This 1.8 kΩ resistor was readily available at the time of the experiments and therefore was chosen for the human body emulation despite being somewhat smaller than the one used in the simulations (2.5 kΩ) which, as stated before, already implied very conservative assumptions. The difference in human body resistance influenced the results to some extent; however, since there were uncertainties in several other parameters in the model (especially those due to parasitic effects), this difference was regarded as acceptable, and the experimental tests could be used to validate the model behaviour, at least qualitatively.

4. Conclusions and Future work

Conductive ERS technology appears as a promising solution for transport electrification. However, there are still a number of safety challenges that must be assessed. With the help of simulations and experimental measurements, this article analyses a number of potentially hazardous cases in which a too high chassis potential could result in dangerous touch current levels for people or animals around the vehicle.

Although both the models and the experimental measurements reflected the same trends and the obtained values were reasonably similar, further sensitivity analyses should be performed to evaluate the influence of the different model parameters in the final results.

Moreover, a new set of measurements is planned in order to complement the preliminary measurements presented in this article with additional fault cases and operating conditions.

Finally, an additional safety system must be developed and tested in the experimental setup, especially under the insulation fault cases.