Abstract

Three-dimensional printing technologies are transforming various sectors with promising technological abilities and economic outcomes. For instance, 3D-printed concrete (3DPC) is revolutionizing the construction sector with a promise to cut projects’ costs and time. Therefore, 3DPC has been subjected to extensive research and development to optimize the mechanical and thermal performance of concrete walls produced by 3D printing. In this paper, we conduct a comparative investigation of the thermal performance of various infill structures of 3DPC walls. The targeted outcome is to produce an infill structure with optimized thermal performance to reduce building energy consumption without incurring additional material costs. Accordingly, a computational model is developed to simulate the thermal behavior of various infill structures that can be used for 3DPC walls. The concrete composition and the concrete-to-void fraction are maintained constant to focus on the impact of the infill structure (geometric variations). The thermal performance and energy-saving potential of the 3DPC walls are compared with conventional construction materials, including clay and concrete bricks. The results show that changing the infill structure of the 3DPC walls influences the walls’ thermal conductivity and, thereby, the building’s thermal performance. The thermal conductivity of the examined infill structures is found to vary between 0.122 to 0.17 W/m.K, while if these structures are successful in replacing conventional building materials, the minimum annual saving in energy cost will be about $1/m2. Therefore, selecting an infill structure can be essential for reducing building energy consumption.

1. Introduction

Three-dimensional (3D) printing technologies are transforming various sectors with vast technical and economic advantages. For instance, three-dimensional-printed concrete (3DPC) walls revolutionized the construction sector with promising potential to produce energy-efficient buildings at reduced cost and construction time. These gains are not limited to the building owners or end-users, but they positively impact the environment and the global community at large. The reduction of energy consumption in the residential sector will help reduce energy-related emissions, achieve the global objective of net-zero emissions by 2050, and limit climate change. The construction industry is responsible for about 38% of greenhouse gas emissions [1,2,3]. Therefore, reducing the construction time will directly reduce the emissions produced by the construction equipment and the labor cost; 3D printing has been demonstrated to save up to 60% of construction waste, 70% of production time, and 80% of labor expenses when compared to conventional concrete building methods [4]. However, 3DPC technologies are still in the early stages and undergoing extensive research and development to utilize their full potential and realize environmentally friendly materials that can make the future building more sustainable and environmentally benign [5].

The technology of 3D printing, scientifically named additive manufacturing technology, is defined based on ASTM (F2792-12a) as a process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies [6]. Along with the assistance of computer-aided designing (CAD) to generate the model, this process involves three primary steps: (1) the CAD design of the product, (2) slicing software to convert the CAD model into layers, and (3) the G-code describing the path for printing these layers. Thus, the 3D printing machine includes a computer or a processor responsible for executing the printing assignments in an optimized sequence. However, to achieve the optimum concrete printing results, the combination of the concrete mixture properties and the printing parameters must be simultaneously optimized. These cutting-edge machines can manufacture significantly more complicated structures with excellent precision when used in building rather than conventional formwork. In addition to printing concrete, this technique can also be used for printing polymers, metals, and ceramics for building [7]. Further details on the recent advances in 3DPC and concrete materials can be found elsewhere [8,9,10].

The contemporary built environment relies on concrete as an essential element for construction, which comprises the most significant share by volume due to its numerous favorable characteristics, including its strength, high durability and design flexibility, fire resistance, and availability at low cost [11]. Concrete is commonly prepared by mixing portions of cement, fine and coarse aggregates, mineral admixtures, and water. Conventional concrete casting methods utilize wooden or metal formwork to cast the concrete into the desired shape. One of the major drawbacks of traditional concrete casting is the need for wooden and metal formwork, which costs 50% of the overall concrete cost [12]. Moreover, when it comes to building complicated geometries, conventional construction techniques cannot do so without structural support and formwork [13], which limits the concrete structure design [9]. However, 3DPC technology has vast potential in multiple aspects, including enhancing material and design flexibility, reducing material and labor costs, and improving construction agility [9]. Furthermore, the 3DPC technique enables air cavities to be created in the wall while optimizing the structure for maximum mechanical and thermal performances [13]. For extrusion-based 3D printing innovations, contour crafting and solid printing have become the primary building method in the construction sector.

The numerous advantages of 3DPC has motivated many companies to invest in and capitalize on these technologies. Accordingly, the industrial sector has witnessed a successful demonstration with promising potential to be explored in the near future. For example, CyBe, Apis Cor, and Winsun are examples of many companies that develop and provide 3DPC solutions and are already in the construction market employing 3DPC in different construction projects around the world [14]. For instance, the WinSun firm used the contour crafting technique to build a five-story residence in China in 2015. The Acciona Company 3D printed a pedestrian bridge using D-shape technology in 2016. Another demonstration project is that constructed by Apis Cor, through 3D printing. It was marked as the largest 3D-printed building with a 640 m2 area and a height of 9.5 m. During this project, it was reported that the number of workers was reduced to only three while the 3D concrete printing machine executed most of the work [15]. Thus, the future of 3D printing in the building of homes, bridges, and skyscrapers seems more promising in light of the rising construction sector throughout the world.

The mechanical performance and sustainability of 3DPC are of great importance and relevance to the development of 3DPC technologies, which were the focus of numerous articles. For example, Han et al. [16] measured the axial loading on large-scale 3DPC walls. Their research outcomes will contribute to the development of the Code for Design of Concrete Structure. Additional studies considering mechanical and sustainability performance include [17,18,19]. The published literature shows systematic progress in investigating the mechanical performance of 3DPC to establish standardized codes and regulations for construction [20]. However, a limited number of studies have been dedicated to examining and standardizing the thermal performance of 3DPC. Thus, the optimization of the 3DPC wall infill structure for enhanced thermal performance is the scope of this study.

The thermal performance of the built environment is an essential parameter for improving the building’s energy efficiency. It was reported that the exterior walls are responsible for a substantial share of heat loss that can reach as much as 25% of the total thermal energy loss [13]. Al-Tamimi et al. [21] investigated the optimum geometry of holes within concrete bricks to reduce the thermal conductivity of walls and thereby reduce energy consumption in buildings for air conditioning in hot climate conditions such as in Saudi Arabia. They considered 23 different models and used FEM to evaluate heat transfer through these brick configurations and determine the impact on the building’s internal wall temperature. Interestingly, their results showed that the inner temperature could be reduced by as much as 7.18 °C when a 51% hallow ratio is utilized.

The thermal performance of conventional concrete has been widely studied and included in many building guidelines and standards to achieve desired human comfort and energy saving. However, 3DPC is still relatively new in the construction market, with novel design parameters that significantly influence the thermal behavior of these walls [22]. For example, the inclusion of air cavities or filling materials, the variation in thicknesses, and cross-sectional structures are some techniques proposed for controlling the thermal performance of 3DPC walls. In this regard, some researchers constructed a 3DPC wall for testing thermal performance and energy savings [23]. Yawen He et al. [24] studied the energy-saving potential of a large-scale 3DPC building with an integrated green wall system. They utilized 3D-printed multifunctional wall modular units to serve as building enclosures and supports for the green wall. The results, based on a prototype of this wall design developed in China, showed improved thermal comfort and energy-saving potential. Sun et al. [25] experimentally tested the thermal performance of a 3DPC wall. They reported high non-uniformity in temperature distribution, which was attributed to the variations in the printing path and the cross-section design. They highly recommend further studies of 3DPC walls to ensure that printed wall designs achieve the required thermal insulation.

A limited number of studies has evaluated the effect of the cavity configurations of 3DPC walls on the overall thermal performance of the wall. Alkhalidi and Hatuqay [26] investigated the energy performance of 3DPC walls with triangular cavities. They predicted the effect of wall thickness and the number of rows on the thermal performance of the printed wall. Marais et al. [27] conducted a similar study on 3DPC walls with rectangular cavities. The main drawback of both studies is that they limited the number of cavity shapes investigated. Suntharalingam et al. [13,28,29] have since overcome this drawback by creating FEMs of the printed wall with four different cavity shapes at different configurations, wall thicknesses, and number of rows. Unfortunately, the concrete volume fractions in their models were not the same. Thus, their assessment of the effect of the cavity shape is not accurate. The current study overcomes this point by constructing finite element models of the 3DPC wall with different infill shapes with equal volume fractions. Furthermore, it provides a comparative performance analysis between the examined shapes and the conventional building materials.

Therefore, the contribution of this study can be highlighted in the following outcomes, which have not been considered in previous research works:

- Several infill structures are modeled for optimizing their geometry based on printable shapes, while the void-to-concrete ratio of these structures is maintained constant.

- The thermal performance of each infill structure is evaluated after determining the effective thermal conductivity of that infill structure.

- The thermal performance of 3DPC walls based on the studied infill geometry is compared with conventional building materials, including concrete brick walls, red clay brick walls, and insulated red brick walls.

- The study also considered two cases in which steel wire joints are used in different arrangements to reinforce 3DPC walls, which have not been considered in the literature. Moreover, the impact of implementing these 3DPC walls in building on energy consumption is evaluated, and the potential economic advantage is estimated and discussed in comparison with conventional building materials.

2. Methodology and Analysis

In order to investigate the impact of the variation of the internal structure (infill structure) of 3DPC walls on the thermal performance of these walls, several 3D drawings of wall-sections were developed with various infill structures that should be 3D printable. These 3DPC wall-sections were selected based on the geometries commonly reported in the literature. For each type of infill section, a representative unit with fixed concrete to void fraction was selected, meshed, and introduced for heat transfer modeling. In the FEM, the model was solved subject to the boundary conditions, which will be explained in the following section. The results determine the effective thermal conductivity of each infill structure and to compare its thermal performance with other infill structures as well as conventional materials. Further details and description of the approach of this investigation are provided in the following sections.

2.1. Geometries of 3DPC Walls

One of the advantages of 3D concrete printing is the vast flexibility this technology offers for infill structure geometry. Therefore, infill geometry can be an additional factor that can be optimized for building energy efficiency. Thus, for example, the infill structure of the exterior walls—which is responsible for heat losses into or out of the building envelope—can be redesigned to minimize heat transfer for better building energy efficiency. This can be achieved by creating interior air cavities within the wall. However, these cavities must not compromise the walls’ strength and mechanical properties.

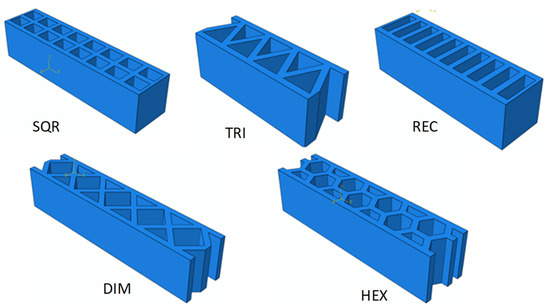

Furthermore, since 3D printing technology executes the printing project in a layer-by-layer approach, repeated unit design is preferred for the current study. Therefore, in this study, five different 3D-printed wall-sections were selected. These geometries were selected subject to one constraint: they all must have the exact void-to-concrete fraction (volume of concrete to volume of air per unit). Figure 1 presents the selected geometries that were considered.

Figure 1.

Isometric view of selected sections of 3DPC walls with different infill structures.

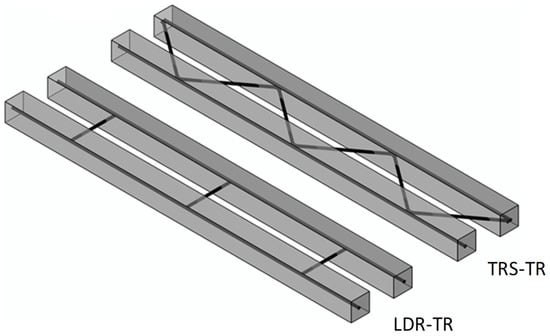

Figure 2 presents the case of 3DPC walls reinforced with steel wire joints in two arrangements, i.e., truss type (TRS-TR) and ladder type (LDR-TR). These steel joints are expected to enhance the strength of 3DPC walls, but they may also influence the thermal performance of these walls. Therefore, the thermal performance of these reinforced designs was examined and compared with that of the designs presented in Figure 1.

Figure 2.

Two types of reinforced 3DPC wall sections.

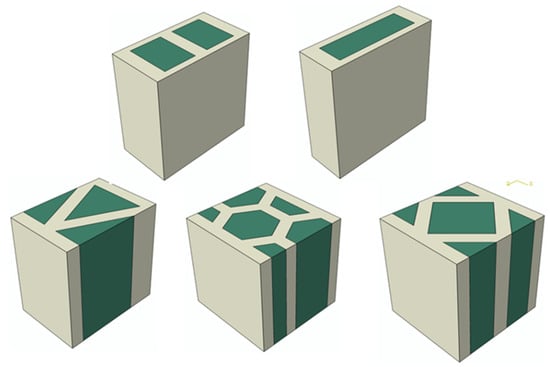

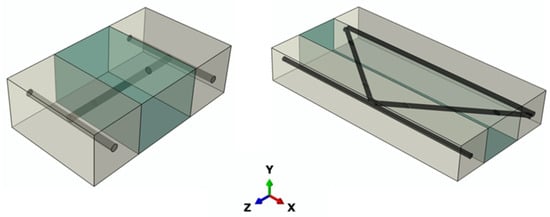

Hence, both infill groups have periodic structures, and it is sufficient to create a representative unit cell for each type. This unit cell creates the structure of the printed wall by repeating itself in the three orthogonal directions X, Y, and Z. Figure 3 shows the different unit cells for the different types of infill structures. Figure 4 shows the unit cells of the 3DPC wall, which are reinforced with joint reinforcement. To display the inner details, the concrete and void were given transparent colors. The width of the wall in both groups is 0.2 m.

Figure 3.

The unit cells of the 3DP concrete wall for the different shapes considered.

Figure 4.

Isometric view of two unit cells for reinforced 3DPC wall.

2.2. Heat Transfer Analysis

In the heat transfer process between the two sides of the 3DPC walls, the three processes of conduction, convection, and radiation are involved; however, conduction dominates the heat transfer, considering the stagnant air within the infill and the relatively low temperatures of the surfaces. The heat transfer by convection and radiation dominates between the ambient air and the outer and inner wall surfaces. Accordingly, the temperature distribution within the 3DPC wall for steady state, three-dimensional heat conduction in a homogenous medium with constant thermal conductivity considering no heat source is governed by the following partial differential equation [21].

where the heat flux along x direction is in (W/m2),

and the thermal conductivity k is in (W/m.K) and are given as

2.3. Finite Element Modeling

The finite element models of the different types of 3D-printed concrete walls were divided into two groups depending on the reinforcement strategy. The first group was entirely made from printed concrete and reinforced with internal infill with different cavity shapes. These cavity shapes were triangular (TRI), square (SQR), hexagonal (HEX), rectangular (REC), and diamond (DIM). These models were designed carefully to have an equal void fraction, which was 0.48. Figure 1 shows the different types of investigated infills. The second group was reinforced with steel wire joint reinforcements, which are used extensively to reinforce traditional brick walls. In 3D-printed walls, joint reinforcements were placed manually between layers during the printing process. The most common types of steel wire joint reinforcements are LDR-TR and TRS-TR. Figure 2 illustrates a printed layer reinforced with joint reinforcements. The void and steel fractions were 0.397 and 0.014, respectively, and the steel wire diameter was 8 mm. Table 1 lists the input thermal conductivities of all materials used in this study.

Table 1.

Thermal conductivities of the materials considered in this study.

2.4. Boundary Conditions

The thermal conductivity of construction materials was measured by using the guarded hot-plate (GHP) technique, which works on the principle proposed in the early 1900s by Dickinson and Van Dusen [33]. In this technique, a temperature gradient is applied on two opposing faces of the test sample, while the remaining faces are insulated. These conditions generate a constant heat flux going towards the front with low temperature. By measuring the total heat flux (), the thermal conductivity of the sample can be calculated as follows:

where and are the thermal conductivity and the thickness of the sample in the same direction as the temperature gradient is applied, respectively. is the temperature, whereas the subscript hot and cold represent the hot and cold faces of the sample, respectively.

The thermal conductivity of any material can be predicted numerically by applying the same boundary conditions as the hot guarded-plate method, where hot and cold temperatures are applied across two opposite faces of a finite element model.

These hot and cold temperatures generate heat flux flowing towards the cold surface. The total heat flux is calculated at the cold surface by the simulation FEM software package ABAQUS [34]. Finally, by knowing the dimensions of the FEM of the material, the thermal conductivity is calculated by using Equation (2). The ABAQUS software is part of the multiphysics modeling and simulation package, one of the widely used commercial software for solving various engineering problems, including dynamic, material behavior, and optimization problems. The software can generate the mesh, discretize the solution model, and solve the model based on user-defined conditions [34].

2.5. Energy Savings and Economic Outcomes

Furthermore, the economic performance of the 3DPC wall was compared with conventional brick walls considering the city of Makkah, in Saudi Arabia, as it was reported to have the highest cooling degree-days (CDDs) value in Saudi Arabia [35]. It must be emphasized that the CDD varies from one location to another according to the climate zone, and a larger CDD number indicates more cooling hours required to maintain the building interior within human comfort. The current economic analysis considered a location where the building cooling load dominates, but this analysis is still valid for locations where the heating load dominates. In such a case, heating degree-days (HDDs) accounts for the number of hours when heating is required.

This implies that using the proposed 3DPC walls, characterized by low thermal conductivity, would have a high economic advantage in territories with climate types such as Desert, Oceanic, and Humid Continental. It would also have a moderate economic advantage in territories with Equatorial, Mediterranean, and Humid Subtropical climate zones. This is due to the annual variations in the temperature difference, or the CDDs, as will be shown by the following equation.

The amount of heat transferred through the wall can be calculated as follows:

where is the thermal transmittance of the wall, is the wall’s surface area, and and are the indoor and outdoor temperatures set as 21 °C and 30 °C, respectively. The outdoor temperature is the daily mean outdoor temperature of Makkah, Saudi Arabia. Wall conductance is the reciprocal of the total thermal resistance of the wall R and can be determined based on the following relations:

where K is the overall thermal conductivity of the wall, Δx is the thickness of the wall, and A is the surface area, which is assumed to be one square meter. The calculations for the 3DPC wall reinforced with LDR-TR and TRS-TR steel wire joint were examined at 12 cm vertical spacing between joint reinforcement.

In order to calculate the energy saved for each case, the heat transferred through the conventional wall, , was incorporated into the following equation:

Here, is the energy saved, is the heat transferred through the 3DPC wall, COP is the coefficient of performance of the cooling system (assuming that the air conditioner is positioned in a window), and Δt is the annual equivalent of full-load cooling operation hours, which can be calculated by using the following equation:

where is the design temperature of the outdoor air, which is 37 °C, and is the annual operation hours of the air conditioner, which is assumed to be 8760 h/y (i.e., 24 h per day).

Finally, the annual saved energy cost can be calculated as follows:

where is the electricity cost, which is 0.08 USD/kWh. The electricity prices for the residential sector in Saudi Arabia depend on the monthly consumption, which is 0.05 USD/kWh for consumption below 6000 kWh/month, and 0.08 USD/kWh for consumption above 6000 kWh/month.

3. Results and Discussion

3.1. Mesh Independence of Developed Model

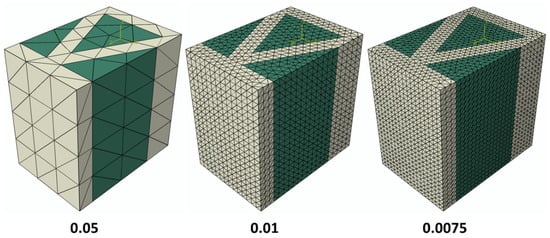

Mesh sensitivity analysis was carried out for one of the constructed models, i.e., TRI, to determine the optimal element size that gives accurate results with minimum computational time. Therefore, eight different mesh sizes were examined, varying from 75 mm to 2.5 mm. Figure 5 shows the TRI infill unit cell after applying the finite element model mesh at three different mesh sizes.

Figure 5.

Three different mesh sizes of the triangular infill unit cell.

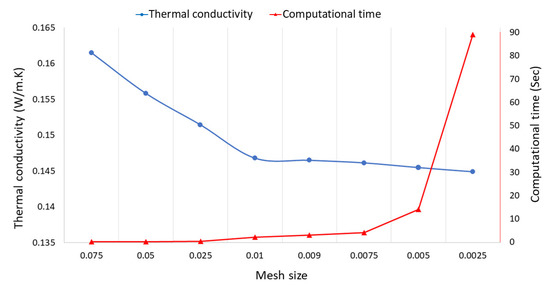

The results of the mesh sensitivity analysis are shown in Figure 6. The thermal conductivity decreased as the mesh sizes decreased. This decrease was significant when the mesh size was larger than 0.01 m and very minimal when the mesh size was smaller than 0.01 m. The computational time, on the other hand, increased with decreases in the mesh size. However, the computational time increase was insignificant when the mesh size was refined to 0.0075 m. At smaller mesh sizes, i.e., 0.005 and 0.0025 m, the increase in computational time was quite significant. Therefore, a mesh size of 0.0075 m was considered for this study.

Figure 6.

Mesh sensitivity analysis showing variation in the thermal conductivity and computational time versus mesh size.

3.2. Effect of Infill Shapes

Steady-state boundary conditions were applied to all the constructed models in the Z directions to predict the thermal conductivity of each 3DPC wall unit cell in the through-thickness direction. As evident from the results (Table 2), the infill shape influenced the through-thickness thermal conductivity of the 3DPC walls. The lowest thermal conductivity of 0.122 W/m.K was found in the 3DPC wall with the DIM shape infill. HEX and SQU infills came next, with almost equal thermal conductivity values of 0.130 and 0.131 W/m.K. The TRI infill shape had a higher thermal conductivity value of 0.146 W/m.K. The 3DPC model with the rectangular infill exhibited the highest thermal conductivity of 0.17 W/m.K.

Table 2.

Thermal conductivities of the 3DPC wall unit cell models with different infill shapes.

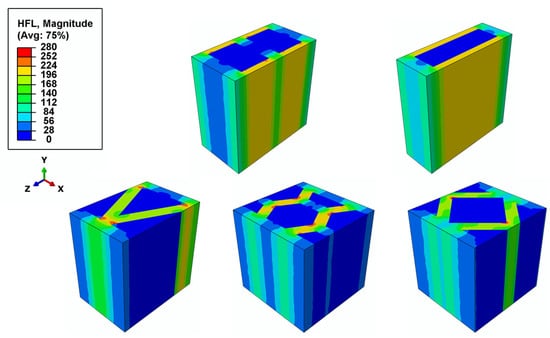

Figure 7 shows the heat flux within the unit cells of different infill structures of 3DPC walls. From Table 2 and Figure 7, it is clear that two main factors controlled the thermal conductivity of these models, firstly, the distance needed for the heat to transfer from the hot surface to the cold one. The 3DPC wall with DIM infill had the longest distance and the lowest thermal conductivity. In contrast, the 3DPC wall with a rectangular infill had the shortest distance and the highest thermal conductivity. The second factor was the existence of branches that reduced heat transfer to the other side. This could be seen by comparing the 3DPC wall with REC and SQR infills.

Figure 7.

Heat flux within the 3DPC walls for the various infill shapes.

3.3. Effect of Wire Joint Reinforcements

The through-thickness thermal conductivity of the 3DPC wall reinforced with LDR-TR and TRS-TR steel wire joints were examined at various vertical spacing values between joint reinforcements. As shown in Table 3, the 3DPC wall reinforced with a TRS-TR steel wire joint had lower thermal conductivity than that reinforced with an LDR-TR steel wire joint. The thermal conductivity of the 3DPC wall reinforced with the TRS-TR steel wire joint was almost half that of the 3DPC wall reinforced with the LDR-TR steel wire joint when the vertical spacing between the reinforcement was 6 cm. However, this difference in thermal conductivity decreased with the increase in the vertical spacing between the reinforcement.

Table 3.

Thermal conductivity of 3DPC wall reinforced with LDR-TR and TRS-TR steel wire joints at various vertical spacings between joint reinforcements.

3.4. Comparison with Conventional Brick

The through-thickness thermal conductivity of conventional brick walls constructed with different types of bricks was obtained experimentally by Ahmad and Al-Hadrami [36,37]. The thermal conductivity values of brick wall samples constructed from fired-red clay and concrete bricks were reported to be 0.495 and 0.976 W/m.K, respectively. The 3DPC wall exhibited much lower thermal conductivity than conventional brick walls.

Table 4 shows the values of wall conductance and heat transferred through the different types of conventional and 3DPC walls. The various infill structures used for 3DPC exhibited variation in their thermophysical properties include thermal conductivity, thickness, wall conductance, and the corresponding heat transfer rate through the wall. These variations are due to structure variation.

Table 4.

Thermal characteristics of conventional and 3DPC walls.

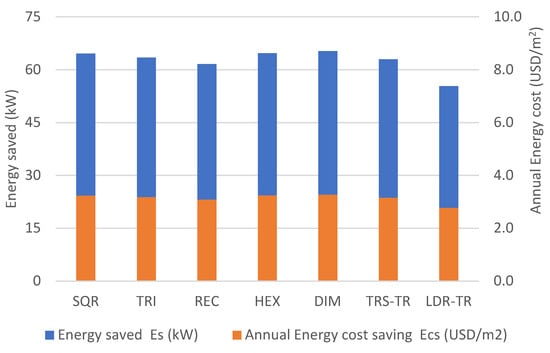

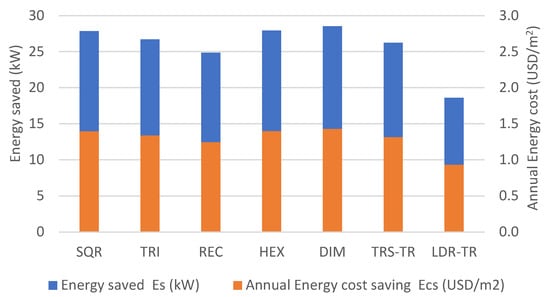

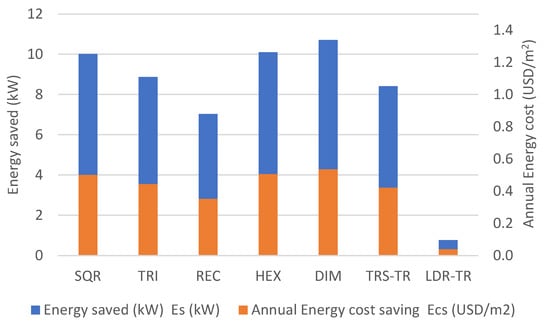

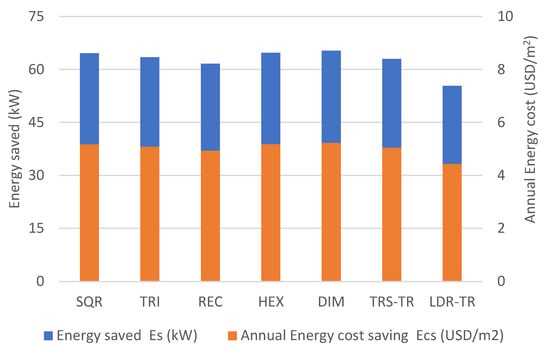

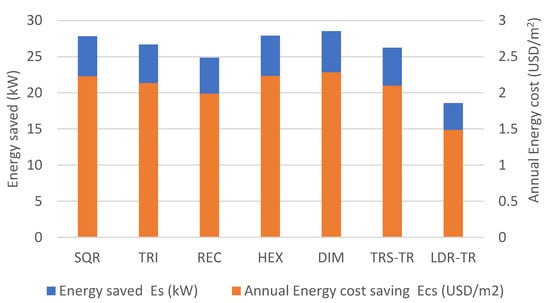

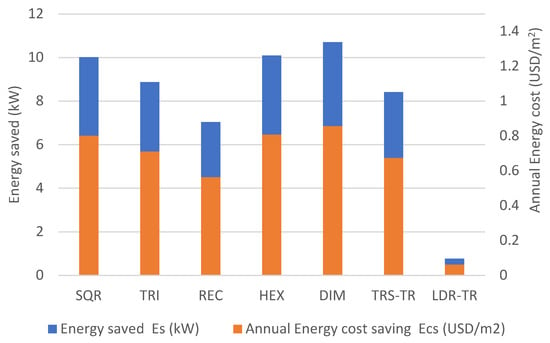

In Figure 8, Figure 9, Figure 10, Figure 11, Figure 12 and Figure 13, the energy and economic performance of the 3DPC infill structures are presented and compared with the conventional wall materials that are commonly used in contemporary buildings, such as concrete brick walls, red clay brick walls, and insulated red brick walls. The electricity rate for the residential sector in Saudi Arabia changes according to the monthly consumption category, whether it falls below or above 6000 kWh per month. Thus, the electricity rate is 0.05 USD/kWh for consumption below 6000 kWh and 0.08 USD/kWh for consumption above 6000 kWh.

Figure 8.

Energy saved and associated electricity cost ($0.05/kWh) using different 3DPC infill structures versus a concrete brick wall.

Figure 9.

Energy saved and associated electricity cost reduction ($0.05/kWh) using different 3DPC infill structures versus a red clay brick wall.

Figure 10.

Energy saved and associated electricity cost reduction ($0.05/kWh) using different 3DPC infill structures versus an insulated red brick wall.

Figure 11.

Energy saved and associated electricity cost ($0.08/kWh) using different 3DPC infill structures versus a concrete brick wall.

Figure 12.

Energy saved and associated electricity cost reduction ($0.08/kWh) using different 3DPC infill structures versus red clay brick wall.

Figure 13.

Energy saved and associated electricity cost reduction ($0.08/kWh) using different 3DPC infill structures versus an insulated red brick wall.

The potential energy savings and electricity bill reductions in the case of utilizing the various 3DPC infill structures compared with the concrete brick wall are presented in Figure 8 based on the electricity rate of 0.05 USD/kWh. The saved energy rates were over 60 kW, except for the case of LDR-TR, which fell just below 60 kW. At the same time, the potential annual energy cost reduction was around 3 USD/m2. It could be noticed that the size of the building and the type of the building in terms of energy consumption have a significant impact on the overall energy savings and potential electricity bill reduction.

In Figure 9, the energy and economic performance of these 3DPC infill structures are compared with another building material that is widely used, especially in exterior walls, i.e., the red clay brick wall, which is considered an excellent thermal insulator. Though red clay brick walls appeared to perform better than concrete brick walls, the 3DPC infill structures outperformed the red clay brick, as clearly shown in Figure 9. The various infill structures considered achieved an energy saving rate of about 25 kW except for the LDR-TR, which achieved over 15 kW. Nevertheless, a minimum annual energy cost reduction of about 1 USD/m2 was expected.

In Figure 10, the energy and economic performance of the 3DPC infill structures is compared against the case of insulated red brick. The figure shows relative variation in the performance of the various 3DPC infill structures. For example, the LDR-TR shows a minimum advantage with comparable thermal performance. However, the various other structures achieved an average of about 9 kW energy saving with an average cost reduction of less than 0.5 USD/m2.

Figure 11 shows an average annual energy cost reduction of over 4 USD/m2, which is achievable if 3DPC walls utilizing the proposed structures are used to replace the concrete brick walls. However, this figure decreases to about 2 USD/m2 for the case of red clay brick, as shown in Figure 12, while in Figure 13, these 3DPC infill structures present an average annual energy cost of about 0.08 USD/m2. In addition to the economic advantage, the presented potential energy saving will contribute significantly to reducing carbon emissions due to residential energy consumption and help mitigate the global challenge of climate change.

Table 5 summarizes the amount of energy saved and the annual energy cost savings for the different 3DPC infill structures compared with the three conventional walls, i.e., concrete brick walls, red clay brick walls, and insulated red clay brick walls. In this table, the electricity rating considered for electricity cost reduction is 0.08 USD/kWh. The table shows as high as 5 USD/m2 in annual electricity bill savings. However, further detailed studies are required to include the initial cost and provide clarification on overall building life cycle costing. Nevertheless, the current economic evaluation reveals that the future of 3DPC is promising to reduce building construction and energy consumption costs, as thoroughly discussed in the preceding sections.

Table 5.

Energy-saving for each 3DPC wall compared with three different types of conventional walls.

4. Conclusions

The thermal performance of various 3DPC wall infill structures was numerically modeled to investigate the optimization of the infill shape for maximum thermal performance with minimum variation in the added materials. The infill structure was found to influence the thermal conductivity of the examined 3DPC walls. For example, among the tested infill structure geometries, the DIM shape achieved the lowest thermal conductivity of 0.122 W/m.K, while the HEX, SQR, and TRI shapes achieved 0.130, 0.131, and 0.146 W/m.K, respectively. The highest thermal conductivity of 0.17 W/m.K was achieved by the REC infill shape. Buswell et al. [38] reported testing two 3DPC wall designs with structures comparable to that presented in Figure 1. The thermal conductivities of the tested structures ranged from 0.122 to 0.244 W/m.K. These values were produced based on a UKAS-accredited EN 12667 guarded hot plate apparatus [38]. The calculated thermal conductivities of the various infill designs considered in the current study are within this range, i.e., 0.122–0.170 W/m.K. This serves as an experimental validation of the current numerical work.

In addition, the study examined the impact of using TRS-TR and LDR-TR steel wire joints to reinforce the 3DPC walls on thermal performance. The results revealed that the thermal conductivity of the 3DPC wall with TRS-TR is almost half that of the LDR-TR. However, the conductivities were found to decrease with increased vertical spacing between the joint reinforcements. These results provide the construction designer with informative options to make the choice that serves the building’s needs. However, a few limitations should also be highlighted, including the interlayer variation in the 3DPC walls, which may result in variation in the thermal conductivity of the concrete structure. This point, in addition to the possibility of variation in the concrete compositions, should be further investigated in future studies.

Author Contributions

A.A.A. (Abdullah A. AlZahrani): Project administration, Funding acquisition, Investigation, Formal analysis, Writing—original draft. A.A.A. (Abdulrahman A. Alghamdi): Conceptualization, Methodology, Modeling, Validation, Formal analysis. A.A.B.: Modeling, Writing—review and editing, Resources. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the support provided by Umm Al-Qura University (UQU) and the Ministry of Education.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cao, X.; Dai, X.; Liu, J. Building Energy-Consumption Status Worldwide and the State-of-the-Art Technologies for Zero-Energy Buildings during the Past Decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Gengnagel, C.; Baverel, O.; Burry, J.; Ramsgaard Thomsen, M.; Weinzierl, S. Correction to: Impact: Design with All Senses. In Proceedings of the Design Modelling Symposium Berlin; Springer: Berlin/Heidelberg, Germany, 2019; p. C1. [Google Scholar]

- Divyah, N.; Prakash, R.; Srividhya, S.; Sivakumar, A. Parametric Study on Lightweight Concrete-Encased Short Columns under Axial Compression-Comparison of Design Codes. Struct. Eng. Mech. 2022, 83, 387–400. [Google Scholar] [CrossRef]

- El Sakka, F.; Hamzeh, F. 3D Concrete Printing in the Service of Lean Construction. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017. [Google Scholar]

- Barbosa, M.S.; dos Anjos, M.A.S.; Cabral, K.C.; Dias, L.S. Development of Composites for 3D Printing with Reduced Cement Consumption. Constr. Build. Mater. 2022, 341, 127775. [Google Scholar] [CrossRef]

- ASTM. International Standard Terminology for Additive Manufacturing Technologies. Available online: https://www.astm.org/f2792-12.html (accessed on 16 July 2022).

- Laubier, R.; Wunder, M.; Witthöft, S.; Rothballer, C. The Boston Consulting Group (BCG) Global. 23 January 2018. Available online: https://www.bcg.com/publications/2018/will-3d-printing-remodel-construction-industry (accessed on 5 August 2022).

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing: Technology, Applications, Markets, and Opportunities for the Built Environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Khan, S.A.; Koç, M.; Al-Ghamdi, S.G. Sustainability Assessment, Potentials and Challenges of 3D Printed Concrete Structures: A Systematic Review for Built Environmental Applications. J. Clean. Prod. 2021, 303, 127027. [Google Scholar] [CrossRef]

- Liu, J.; Setunge, S.; Tran, P. 3D Concrete Printing with Cement-Coated Recycled Crumb Rubber: Compressive and Microstructural Properties. Constr. Build. Mater. 2022, 347, 128507. [Google Scholar] [CrossRef]

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental Assessment of Green Concrete Containing Natural Zeolite on the Global Warming Index in Marine Environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Habert, G. Environmental Implications and Opportunities of Digital Fabrication. In Expanding Boundaries: Systems Thinking in the Built Environment; vdf Hochschulverlag AG an der ETH Zürich: Zürich, Switzerland, 2016; pp. 304–308. [Google Scholar]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental Assessment of Large-Scale 3D Printing in Construction: A Comparative Study between Cob and Concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- World’s Largest 3D Printed Building. Available online: https://www.apis-cor.com/dubai-project (accessed on 9 April 2022).

- Han, X.; Yan, J.; Liu, M.; Huo, L.; Li, J. Experimental Study on Large-Scale 3D Printed Concrete Walls under Axial Compression. Autom. Constr. 2022, 133, 103993. [Google Scholar] [CrossRef]

- Daungwilailuk, T.; Pheinsusom, P.; Pansuk, W. Uniaxial Load Testing of Large-Scale 3D-Printed Concrete Wall and Finite-Element Model Analysis. Constr. Build. Mater. 2021, 275, 122039. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. Mechanical Characterization of 3D Printable Concrete. Constr. Build. Mater. 2019, 227, 116710. [Google Scholar] [CrossRef]

- Mahadevan, M.; Francis, A.; Thomas, A. A Simulation-Based Investigation of Sustainability Aspects of 3D Printed Structures. J. Build. Eng. 2020, 32, 101735. [Google Scholar] [CrossRef]

- Aramburu, A.; Calderon-Uriszar-Aldaca, I.; Puente, I. 3D Printing Effect on the Compressive Strength of Concrete Structures. Constr. Build. Mater. 2022, 354, 129108. [Google Scholar] [CrossRef]

- Al-Tamimi, A.S.; Al-Osta, M.A.; Al-Amoudi, O.S.B.; Ben-Mansour, R. Effect of Geometry of Holes on Heat Transfer of Concrete Masonry Bricks Using Numerical Analysis. Arab. J. Sci. Eng. 2017, 42, 3733–3749. [Google Scholar] [CrossRef]

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D Printing in the Construction Industry—A Systematic Review of the Thermal Performance in Buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- Araújo, R.A.; Martinelli, A.E.; Cabral, K.C.; Dantas, A.F.; Silva, I.F.; Xavier, A.A.; Santos, A.L. Thermal Performance of Cement-Leca Composites for 3D Printing. Constr. Build. Mater. 2022, 349, 128771. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-Saving Potential of 3D Printed Concrete Building with Integrated Living Wall. Energy Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, J.; Li, Z.; Feng, X. Experimental Study on the Thermal Performance of a 3D Printed Concrete Prototype Building. Energy Build. 2021, 241, 110965. [Google Scholar] [CrossRef]

- Alkhalidi, A.; Hatuqay, D. Energy Efficient 3D Printed Buildings: Material and Techniques Selection Worldwide Study. J. Build. Eng. 2020, 30, 101286. [Google Scholar] [CrossRef]

- Marais, H.; Christen, H.; Cho, S.; De Villiers, W.; Van Zijl, G. Computational Assessment of Thermal Performance of 3D Printed Concrete Wall Structures with Cavities. J. Build. Eng. 2021, 41, 102431. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Numerical Study of Fire and Energy Performance of Innovative Light-Weight 3D Printed Concrete Wall Configurations in Modular Building System. Sustainability 2021, 13, 2314. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Corradi, M.; Nuwanthika, D. Fire Performance of Innovative 3D Printed Concrete Composite Wall Panels—A Numerical Study. Case Stud. Constr. Mater. 2021, 15, e00586. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Committee D16 on Thermal Insulation. Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ISO E. 6946: 2017; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2017.

- Lemmon, E.W.; Jacobsen, R.T. Viscosity and Thermal Conductivity Equations for Nitrogen, Oxygen, Argon, and Air. Int. J. Thermophys. 2004, 25, 21–69. [Google Scholar] [CrossRef]

- Zarr, R.R. A History of Testing Heat Insulators at the National Institute of Standards and Technology. Ashrae Trans. 2001, 107, 661. [Google Scholar]

- Abaqus Unified FEA—SIMULIATM by Dassault Systèmes®. Available online: https://www.3ds.com/products-services/simulia/products/abaqus/ (accessed on 28 February 2022).

- Al-Hadhrami, L.M. Comprehensive Review of Cooling and Heating Degree Days Characteristics over Kingdom of Saudi Arabia. Renew. Sustain. Energy Rev. 2013, 27, 305–314. [Google Scholar] [CrossRef]

- Al-Hadhrami, L.; Ahmad, A. Assessment of Thermal Performance of Different Types of Masonry Bricks Used in Saudi Arabia. Appl. Therm. Eng. 2009, 29, 1123–1130. [Google Scholar] [CrossRef]

- Ahmad, A.; Al-Hadhrami, L.M. Thermal Performance and Economic Assessment of Masonry Bricks. Therm. Sci. 2009, 13, 221–232. [Google Scholar] [CrossRef]

- Freeform Construction: Mega-Scale Rapid Manufacturing for Construction. Autom. Constr. 2007, 16, 224–231. [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).