Abstract

This study aimed to evaluate the adhesion behavior of wood from an E. urophylla × E. grandis clone using the application of melamine–urea–formaldehyde (MUF), resorcinol–formaldehyde (RF), and polyurethane (PUR) adhesives in test samples obtained from 12 glulam beams. Adhesives were characterized by their pH, viscosity, density, and solid content. The wood–adhesive interface was assessed through the shear strength, percentage of wood failure, delamination, and photomicrograph analysis. A microdensitometer with X-rays and a resistograph were used to determine the material density and drilling resistance of the elements. Adhesive pH values ranged from 6.35 to 9.05. MUF exhibited the highest viscosity (1169 cP), while the adhesive density varied between 1.29 and 1.67 g cm−3. No statistically significant difference in results was obtained for the shear strength in dry conditions. The MUF adhesive showed a lower percentage of wood failure compared to PUR and RF. In the delamination test, the wood beams glued with RF yielded the best results. Photomicrographs revealed the adhesive’s penetration into the wood’s anatomical structure. Densitometry and resistograph profiles accurately represented the beam balancing configuration. The adhesives PUR, RF, and MUF demonstrated suitability for producing glulam beams with the Eucalyptus clone wood evaluated in this study.

1. Introduction

The development of engineered lumber products using hardwoods has been gaining interest in the global market [1,2,3,4]. Among these, some species of the Eucalyptus genus are viable alternatives due to their characteristics, such as high productivity and a shortened growth cycle [5,6,7]. Although Eucalyptus is widely used as sawn timber and a raw material for pulp and paper, the interest in its use for developing higher value-added construction products, such as glued laminated timber (glulam), has been under evaluation [8,9,10]. Understanding the behavior of glued structural elements requires the investigation of the gluing process, with the adhesive performance observed by studying the glue line. Its integrity is an essential factor in ensuring product strength [11]. Physical and chemical conditions of surfaces during adhesion are important for achieving a high-performance bond [12].

The wood of the hybrid E. urophylla × E. grandis has physical and mechanical characteristics suitable for the production of glulam [13]. However, there are some difficulties related to gluing in high-density woods, which can be observed within the Eucalyptus genus, such as low wettability, high extractive contents, and low porosity and permeability [14]. The wood permeability directly affects the success of the adhesive application, as it can be influenced by the chemical, physical, and anatomical characteristics of the wood [15]. In the wood region, in the longitudinal direction of the fibers, the sapwood of E. grandis has greater permeability compared to the heartwood, whose vessels were obstructed by tyloses. When compared to other species, such as E. citriodora, E. grandis has a lower number of vessels per cm2; however, it exhibits greater permeability due to the larger diameter of its vessels [16,17].

An analysis of an adhesive bond should be conducted considering the adhesive/substrate system behavior. The adhesive penetration and distribution are influenced by inherent characteristics of the wood anatomy, referring to differences in elements’ dimensions and their size, arrangement, and cell cavity frequency [18,19]. In this context, the analysis of an adhesive’s interaction with wood should involve studying microscopic-scale images of the glue line to verify penetration into the cellular elements [20].

In addition to determining the wood species for use in glued piece production, the adhesive choice involves sustainable and economic considerations. The adhesive plays a crucial role in the strength of structural members, transferring stress from one component to another [21,22]. During the bonding process, the glue line strength should be greater than that of the wood, which occurs when the adhesive penetrates the wood’s cell cavities and diffuses into the cell walls, becoming rigid after curing [2,23], even at ambient temperatures [24]. In general, adhesives should have properties compatible with environmental conditions to which the structural elements will be exposed during their service life. This ensures the long-term performance and durability of the bonded components [5].

Among synthetic adhesives, the formaldehyde-based ones are prominent, including urea, melamine, phenol, resorcinol, and isocyanate [25,26,27]. Environmental concerns have led to the consideration of toxic volatile organic compound (VOC) adhesives [28]. Adhesives derived from castor oil and silicates are alternatives to address this issue [29,30], with satisfactory results in structural elements [24,31,32]. From this perspective, environmentally friendly adhesives are sustainable alternatives that aim to reduce environmental impacts without compromising their use in structural applications or as coatings [31].

Therefore, this study aimed to evaluate the adhesion behavior of wood from an E. urophylla × E. grandis clone using the application of melamine–urea–formaldehyde (MUF), resorcinol–formaldehyde (RF), and polyurethane (PUR) adhesives in test samples obtained from 12 glulam beams.

2. Materials and Methods

2.1. Materials

The wood used in this study was obtained from the hybrid clone E. urophylla × E. grandis, harvested from 11-year-old trees with a diameter of approximately 15 to 20 cm, planted in the southeastern region of Brazil, in the northern part of Espírito Santo State [33]. Sawn pieces (kiln-dried) had no preservative treatment and had mean nominal dimensions of 2.9 × 9.3 × 310.7 cm3 (thickness × width × length).

Adhesives commonly applied in the production of glued laminated wood beams were used, including resorcinol–formaldehyde (RF) (Casco®, Hexion, Columbus, OH, USA), two-component polyurethane based on castor oil (PUR) (Imperveg® AGT 1315) [13,33], and melamine–urea–formaldehyde (MUF) (Cascophen®) [34,35].

2.2. Adhesives Characterization

This procedure takes places before glulam beam manufacturing. The following parameters were studied: pH, viscosity, density, and solids content. Determination of pH was conducted using a digital pH meter (Alfakit®, AT355, Florianópolis, Brazil), at a 25 °C, by electrode immersion into a beaker containing 50 g of adhesive.

Adhesive viscosity was determined according to ASTM D-1084 [36], using a digital viscometer (Marte®, MVD-8, Santa Rita do Sapucaí, Brazil). The force needed to rotate a submerged disk at a constant speed measures adhesive viscosity. To determine adhesive solids content, a procedure was adapted from ASTM D1582-98 [37]. A sample of 10.0 g of adhesive was weighed on a precision balance (P1). Subsequently, the material was placed in an oven at 103 ± 2 °C until completely dry. After removing it, the material was weighed again (P2). Solid content was calculated as the P2 to P1 ratio, expressed in percentage.

2.3. Lamella Preparation and Assembly of Glulam Beams

As established by the Brazilian Association of Technical Standards, under NBR 7190-2 [38], the boards were identified, weighed, measured, and visually classified. Out of a total of 79 pieces assessed visually, 72 were deemed suitable for further processing into glulam. For each beam, six lamellas were defined, distributed according to their modulus of elasticity (MOE) obtained through static bending tests performed in a mechanical testing machine, in accordance with ABNT NBR 7190-6 [39]. The procedure adopted is called balancing and follows the recommendation that lamellas with higher MOE should be placed in the more stressed regions of the beam (upper and lower region), while lamellas with lower MOE should be allocated to the less stressed regions (central region) [40]. The region with the lowest MOE is also known as the “neutral axis”, which is characterized by lower normal stresses and higher shear stresses. This balancing allows for greater structural efficiency and optimized material utilization.

Adhesives were applied to lamellae surfaces using a spatula, and their uniformity was visually inspected. A grammage of 300 g/m2 with a double line of adhesive was used, and its application was controlled by weighing. Bonding process was performed at a pressure intensity of 1.0 MPa for a duration of 48 h at room temperature, using hydraulic presses arranged in series (Figure 1).

Figure 1.

Glulam beams in presses arranged in series.

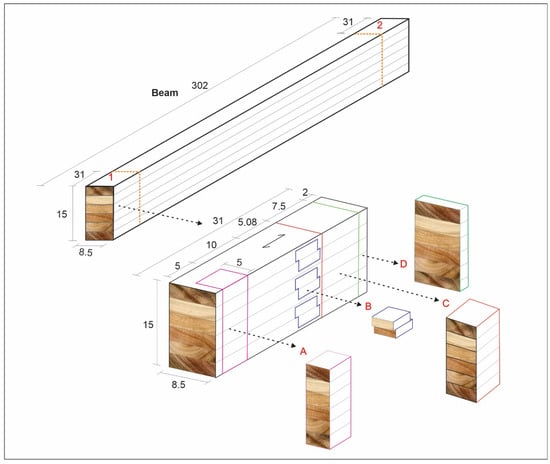

In total, 12 glulam beams were produced, divided into three treatments (PUR, RF, and MUF), with four repetitions each, based on the adhesive applied in the bonding process. To perform destructive tests, it was necessary to obtain test specimens from the glulam beams. The extracting test specimens are presented below (Figure 2).

Figure 2.

Scheme for extracting test specimens from glulam beams: (A) densitometry and resistograph, (B) shear strength at the glue line, (C) delamination, and (D) measurement of glue line thickness. Numbers 1 and 2 = ends of the glulam. Measured in centimeters.

2.4. The Shear at the Glue Line and Wood Failure

A shear bond test was performed, evaluating the bond quality of experimental samples obtained from glulam beams, following ASTM D905-08 [41], under dry and saturated conditions.

The percentage of wood failure was determined using a reticulated grid (10 rows × 10 columns) printed on a cellulose acetate sheet, overlaid on the sheared area, as recommended in D5266-13 [42].

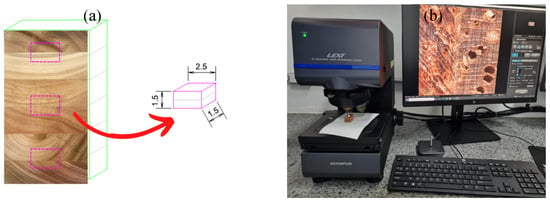

2.5. Measurement of Glue Line Thickness Through Photomicrography

To assess adhesive performance, it is essential to evaluate the glue line images and measure the thickness, which provides insights into the extent of the adhesive penetration into wood as well as the glue line physical condition. This study was conducted using the laser scanning image acquisition technique with a confocal microscope (Olympus Lext®, 3D Measuring Laser OLS5100, Tokyo, Japan). Data acquisition and measurement of the main and extended glue line thicknesses were performed using the Analysis Application Lext software ver. 3.1.1.

For each treatment, three experimental samples were extracted, located on neutral lines, from upper and lower lamellae. The samples presented nominal dimensions 2.5 × 1.5 × 1.5 cm3 (Figure 3a). The samples were heated in distilled water, and one of their sides to be analyzed under microscope was cut with a micrometer (Leica®, SM2000R, Bannockburn, IL, USA) to clean the surface and improve visibility in the equipment (Figure 3b).

Figure 3.

Position for obtaining test specimen (a) for measuring glue line using a confocal microscope (b).

2.6. Delamination

Glue line delamination was assessed according to procedures outlined in method B, EN 391 Code [43]. Removing test samples from glulam beams is illustrated in Figure 2. Before initiating the test, the total lengths of all glue lines on the front and back surfaces of the 24 test specimens were measured. Test specimens were placed in an autoclave, exposing surfaces to be analyzed to 77.5 ± 10 kPa vacuum pressure, for 30 min. The test was carried out at room temperature, taking into account the external environment during the experiment.

After vacuum release, water was applied under 550 ± 10 kPa pressure, for 2 h. After a single cycle, test samples were removed from the autoclave and subjected to a drying period of 15 h in an oven, at a temperature of 70 °C. After the test, the glue line openings were measured again, excluding delamination from the sides of the test samples. According to EN 391, lateral delamination does not represent adhesion performance and may suffer from edge effects, so using the central regions of the glue lines is recommended.

The delamination percentage is determined by the length of each glue line in which delamination occurred, divided by the glue line’s total length. According to the method adopted, the maximum allowable delamination is 4%.

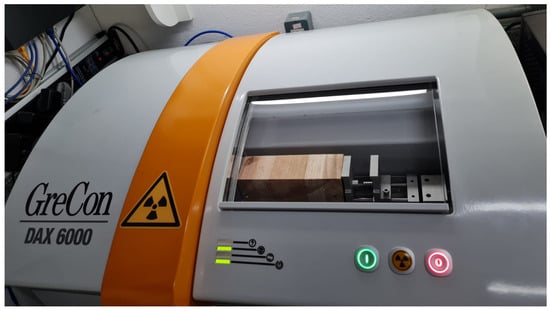

2.7. X-Ray Densitometry

The apparent density (g cm−3) analysis of the glued laminated timber beams for each treatment was performed using an X-ray densitometer (Grecon®, DAX-6000, Hanover, Germany). Samples were placed in the shielded internal compartment of the X-ray microdensitometer, and density readings were taken every 20 μm (Figure 4).

Figure 4.

X-ray microdensitometer by Grecon®, model DAX 6000, with a test sample inside.

The measurements were performed using an optimized measuring transducer, consisting of a combination of X-rays, with speeds ranging from 0.1 to 1 mm.s−1. The equipment has a data acquisition system that generates density profiles automatically.

2.8. Perforation Resistance

Specimens for drilling resistance tests were obtained with nominal dimensions of 15 × 8.5 × 5 cm3. They were placed in the R650-SC resistograph (Rinntech®, R650-SC, Heidelberg, Germany) (Figure 5). For micro-perforations, steel rods with a 1.5 mm diameter and a 3 mm cutting edge at their tip were used in the R650-SC resistograph.

Figure 5.

Drilling resistance test using the R650-SC resistograph.

When perforation begins, the steel rod is inserted into the specimen at a constant feed rate. As it passes through the sample, the rod encounters varying levels of resistance to perforation, which are influenced by the wood’s anatomical characteristics and/or adhesive in the glue line. The measurement recorded by the equipment is referred to as amplitude and is expressed as a percentage. These values are stored as data points in the device’s internal memory and are associated with the electronic energy consumption of the rotary motor in overcoming the resistance to drilling in the wood, relative to a reference value of the device [44].

Resistograph is based on the principle that drilling resistance is directly related to the density of the material being tested [45,46,47]. However, this method has limitations in assessing wood density, as it is necessary to consider the friction effect during perforation. Studies indicate that as the needle bit cuts through the wood, its chips can accumulate within the cutting channel, causing friction on the needle shaft and leading to an increase in drilling resistance [48,49].

To mitigate this effect, two opposite drilling directions were performed in resistograph to analyze lamellae resistance in the profiles, reducing reading errors and considering the specific drilling region. For the creation of drilling resistance profiles, mean values obtained in both directions were adopted.

Data from resistograph memory were exported and converted into files with extensions compatible with Excel software. For analysis, data were standardized, simplified, and represented as percentages [49,50].

2.9. Statistical Analysis

Statistical analyses were conducted using a completely randomized design (CRD), considering three treatments based on adhesive application for glulam bonding (PUR, RF, and MUF). The Henze–Zirkler test was used to check the multivariate normality of the data. Multivariate analysis of variance (MANOVA) was chosen because it provides a single analysis for all variables. The following assumptions for the application of multivariate analysis of variance were tested: absence of multivariate outliers, homogeneity of covariance and variance matrices, and absence of multicollinearity (R < 0.90).

The absence of outliers was checked through the calculation of Mahalanobis distance (p < 0.01). Box’s test was employed to examine the homogeneity of covariance and variance matrices. To verify the absence of multicollinearity, the Pearson correlation was used, in which the correlation between variables should be less than 0.90.

Analysis of variance was used to assess the effect of adhesive types employed on shear strength at glue line and wood failure, with the application of Wilks’ Lambda test (p < 0.05). Post hoc pairwise mean comparisons were performed using the Tukey test (p < 0.05). Data processing and analysis were conducted using R software ver. 4.3.1.

3. Results and Discussion

3.1. Adhesive Caracterization

For glulam beams, both the initial strength of the bonded joints and their stability throughout the product’s lifespan are essential for the proper functioning of bonded elements. Among the parameters assessed to check the piece bonding, one considers the rheological properties of the adhesives used [51]. Characteristics for PUR, REF, and MUF adhesives are listed in Table 1.

Table 1.

Properties of the studied adhesives.

The pH of the adhesive should be close to that of the wood to ensure a better quality of bond lines. Adhesives with a very low pH can cause foaming in the mix and impair bonding [52]. In addition, pH values should be within the 2.5 to 11.00 range, to prevent the adhesive-induced degradation of wood fibers [53]. Adhesives’ pH remained within the suggested range and yielded results like the literature [29,30,54].

The PUR adhesive exhibited a lower viscosity compared to RF and MUF adhesives. This favors the spreadability as well as the penetration and absorption of the adhesive into the wood [30]. However, excessively low viscosity values may lead to reduced shear strength [19]. Therefore, intermediate viscosity values can guarantee good gluing performance.

Results obtained for the adhesive density ranged from 1.29 to 1.67 g cm−3, consistent with values found in the literature [54,55]. The solids content is the fraction of the adhesive that polymerizes after wood pressing [56]. This property varied considerably between PUR and other adhesives. A high solids content contributes to the bond line’s quality, enhancing the adhesion of wood/adhesive [57].

3.2. Shear Strength in Bond Lines and Wood Failure

Results obtained for the shear strength in bond lines and the wood failure for adhesives used in this study are presented in Table 2, both for dry and saturated conditions. The data normality was checked using the Henze–Zirkler test (p < 0.05). Given that all assumptions were met, a multivariate analysis of variance was applied.

Table 2.

Shear strength in bond lines and wood failure under dry and saturated conditions.

There was no statistical difference in results obtained for the shear strength in the bond line under dry conditions. However, results for wood failure in this situation showed statistical differences. For the MUF adhesive, there was a lower percentage of wood failure compared to PUR and RF. Under saturated conditions, no statistical difference was found in the wood failure based on the adhesive.

It is worth noting that for both dry and saturated conditions, mean percentages for wood failure were higher than the minimum value (60%) recommended by ASTM D-5751 [58]. In addition, PUR under dry conditions and RF under both dry and saturated conditions exhibited results exceeding 75%, as recommended by ASTM D-2559 [59].

For this reason, results obtained for wood failure indicate a good adhesive quality, demonstrating that wood–adhesive interface strengths are higher than the wood strength. On the other hand, premature wood failures occur due to a lack of optimization between the adhesive and wood, since the failure occurs at lower stress levels compared to the wood’s resistance, damaging its structural potential [60,61].

In a study evaluating the shear strength in the bond line of Eucalyptus sp. joints bonded with different room-temperature curing adhesives (RF, sodium silicate, PVA—polyvinyl acetate, and PUR), the results showed no significant difference between the adhesives studied, except for the sodium silicate-based adhesive, which exhibited the lowest strength values [61].

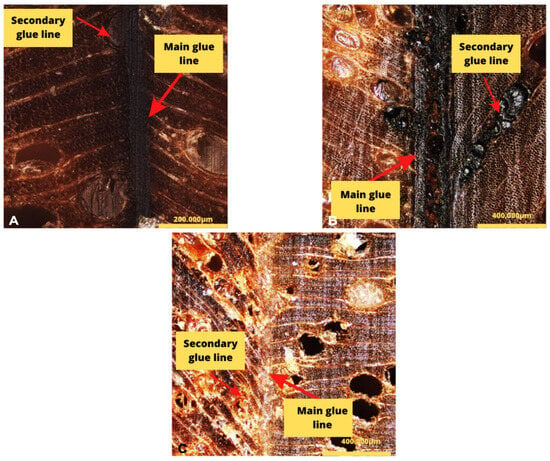

3.3. Measurement of Adhesive Bond Line Thickness

Figure 6 illustrates the wood–adhesive interface in the longitudinal plane of the bonded wood joints, a clonal hybrid of E. urophylla × E. grandis, for PUR, RF, and MUF adhesives.

Figure 6.

Photomicrographs of the wood–adhesive interface in the longitudinal plane of bonded wood joints, E. urophylla × E. grandis clone, for (A) polyurethane (PUR), (B) resorcinol–formaldehyde (RF), and (C) melamine–urea–formaldehyde (MUF).

The adhesive’s penetration into the wood’s anatomical structure was observed, especially in vessel elements and rays. This condition ensures a greater strength at the wood–adhesive interface. In photomicrographs, bond lines extended further for specimens with RF. Results obtained for the shear strength in bond lines for RF were higher than for PUR and MUF, for both moisture conditions.

There was a significant difference (F < 0.05) in the mean bond line thickness for the different adhesives. The highest mean bond line thickness (129.5 μm) was obtained with RF. The mean bond line thicknesses for PUR and MUF were 66.9 and 49.8 μm, respectively. This behavior can be explained by adhesives with different viscosities. Higher adhesive viscosities increase the spreading difficulty due to reduced fluidity, leading to less adhesive penetration into the wood’s capillary structure [30,62,63]. Additionally, efficient adhesive penetration into wood is associated with the adhesive wetting conditions, in addition to the adherent surface [64,65].

3.4. Delamination

The effectiveness of adhesives, when subjected to variations in moisture, pressure, and temperature, must be tested to ensure the structural functionality of the glulam element throughout its service life [66]. Results obtained from delamination tests are presented in Table 3.

Table 3.

Mean values found for wood delamination tests related to treatments with polyurethane (PUR), resorcinol–formaldehyde (RF), and melamine–urea–formaldehyde (MUF) adhesives.

The delamination test conducted demonstrated that the specimens bonded with RF exhibited the best delamination results along the glue line, meeting the requirements established by the EN 391 [43], for Method B, which specifies a maximum delamination of 4% after a single cycle. The favorable results obtained for the adhesive may be attributed to its greater penetration into the wood and its good resistance to moisture [9].

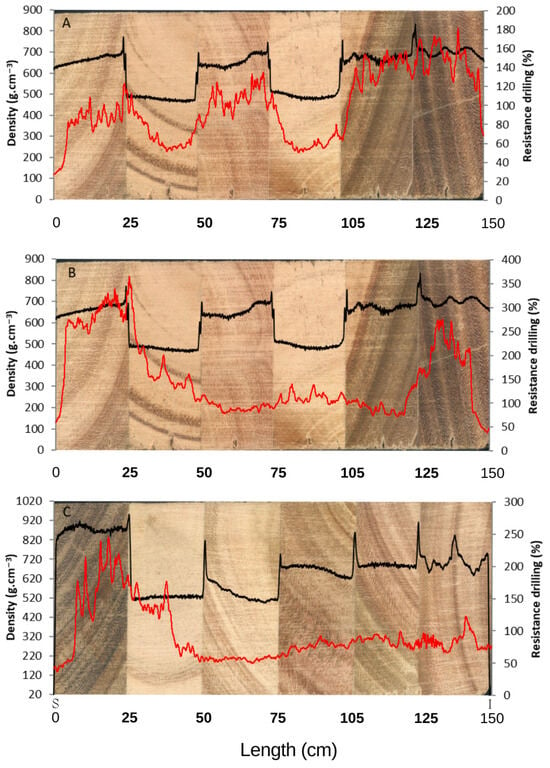

3.5. X-Ray Microdensitometry and Drilling Resistance

Mean values of the glulam beam’s apparent density obtained by the X-ray microdensitometry method and the drilling resistance measured by resistographs for each treatment (MUF, PUR, and RF) are presented in Table 4.

Table 4.

Mean values of apparent density using the X-ray technique and drilling resistance of glulam beams with polyurethane (PUR), resorcinol–formaldehyde (RF), and melamine–urea–formaldehyde (MUF) adhesives.

No significant difference was observed between RF and MUF treatments in the analysis of the apparent density and drilling resistance. Although the wood used in glulam beam manufacturing comes from the same batch, variations in their anatomical characteristics may exist [67], which could explain significant differences among the results of the PUR and the other adhesives.

X-ray microdensitometry allowed for the analysis of wood density profiles, with density peaks at points where the adhesive is present, itself presenting higher density than the wood.

Density and drilling resistance profiles for the adhesives are presented in Figure 7. In density profiles, the density peaks of the bond lines are observed. However, they do not offer the drilling resistance. As for the lamellae, it can be observed that density and drilling resistance profiles follow similar patterns. This behavior can be seen in regions with the highest density peaks (excluding bond lines).

Figure 7.

Apparent density profiles obtained by X-ray microdensitometry (in black) and resistance drilling (in red) of the glulam elements for adhesives: (A) polyurethane (PUR), (B) resorcinol–formaldehyde (RF), and (C) melamine–urea–formaldehyde (MUF). On the horizontal axis of the graph, the upper lamella is represented by the letter “S” and the lower lamella by the letter “I”.

These profiles represent the configuration used for glulam beam balancing, in which the lamellae with a higher modulus of elasticity are placed on the outer upper and lower regions, where the beams experience greater stress. Therefore, density and drilling resistance profiles allow for a reliable analysis of the structure of glulam elements and can be used as evaluation methods for quality control in this type of structure.

4. Conclusions

The mean percentages for wood failure were higher than the recommended minimum values for both dry and saturated conditions. Specifically, PUR under dry conditions and RF under both dry and saturated conditions showed results indicating their suitability for use in structural components.

Photomicrographs revealed that there was adhesive penetration into the wood’s anatomical structure of the E. urophylla × E. grandis clone, although it was incipient. The RF adhesive exhibited a thicker bond line, and images clearly showed adhesive penetration through extended bond lines.

RF showed superior characteristics in bonding when analyzing the shear strength, wood failure, and delamination. This adhesive is recommended for structural use in humid environments. However, PUR presents itself as an efficient and environmentally friendly option.

X-ray microdensitometry and drilling resistance tools can be employed as evaluation methods for the quality control of glulam structures.

All tested adhesives (PUR, RF, and MUF) in the E. urophylla × E. grandis wood demonstrated potential for glulam production. However, in high-humidity environments, the RF adhesive exhibited a superior performance. PUR showed a satisfactory performance and stands out as an efficient and environmentally friendly alternative. The MUF adhesive presented limitations related to wood failure, especially under dry conditions, indicating a lower performance compared to the other adhesives.

Author Contributions

Conceptualization, L.d.C.M. and P.G.d.A.S.; Data curation, L.d.C.M.; Formal analysis, L.d.C.M. and P.G.d.A.S.; Investigation, L.d.C.M. and C.G.F.d.S.; Methodology, L.d.C.M., C.G.F.d.S., D.M. and M.A.R.B.; Project administration, P.G.d.A.S.; Supervision, P.G.d.A.S., F.G.G., F.A.R.L. and M.P.O.; Validation, P.G.d.A.S.; Visualization, P.G.d.A.S.; Writing—original draft, L.d.C.M., C.G.F.d.S., D.M., M.P.O., M.A.R.B. and C.P.d.A.; Writing—review and editing, P.G.d.A.S., F.G.G., F.A.R.L. and C.P.d.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the “Fundação de Amparo à Pesquisa e Inovação do Estado do Espírito Santo” (FAPES/SEAG notice No 06/2015—PPE AGROPECUÁRIA), grant number (T.O. No 720/2016), and by the “Conselho Nacional de Desenvolvimento Cientifico e Tecnológico (CNPq)”, process number 409045/2016-0, with Professor Dr. Pedro Gutemberg de Alcântara Segundinho as the applicant, Call: Universal 2016, referring to the project “Avaliação numérica e experimental de vigas madeira laminada colada (MLC) produzidas de Eucalipto”.

Data Availability Statement

Data is contained within the article.

Acknowledgments

Authors express their gratitude to the Federal University of Espírito Santo, “Fundação de Amparo à Pesquisa e Inovação do Espírito Santo (FAPES)”, and the “Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq)”.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| Glulam | Glued laminated timber |

| MUF | Melamine–urea–formaldehyde |

| RF | Resorcinol–formaldehyde |

| PUR | Polyurethane |

| MOE | Modulus of elasticity |

| Fv0 | Shear strength in the bond line |

| PVA | Polyvinyl acetate |

| S | Upper lamella |

| I | Lower lamella |

References

- Glavinic, I.U.; Boko, I.; Toric, N.; Vrankovic, J.L. Application of Hardwood for Glued Laminated Timber in Europe. J. Croat. Assoc. Civ. Enginners 2020, 72, 607–616. [Google Scholar] [CrossRef]

- Morin-Bernard, A.; Blanchet, P.; Dagenais, C.; Achim, A. Use of Northern Hardwoods in Glued-Laminated Timber: A Study of Bondline Shear Strength and Resistance to Moisture. Eur. J. Wood Wood Prod. 2020, 78, 891–903. [Google Scholar] [CrossRef]

- Adhikari, S.; Quesada, H.; Bond, B.; Hammett, T. Potential of Hardwood Lumber in Cross Laminated Timber in North America: A CLT Manufacturer’s Perspective. Mass Timber Constr. J. 2020, 3, 1–9. [Google Scholar]

- Espinoza, O.; Buehlmann, U. Cross-Laminated Timber in the USA: Opportunity for Hardwoods? Curr. For. Rep. 2018, 4, 1–12. [Google Scholar] [CrossRef]

- Hänsel, A.; Sandak, J.; Sandak, A.; Mai, J.; Niemz, P. Selected Previous Findings on the Factors Influencing the Gluing Quality of Solid Wood Products in Timber Construction and Possible Developments: A Review. Wood Mater. Sci. Eng. 2022, 17, 230–241. [Google Scholar] [CrossRef]

- Balboni, B.M.; Wessels, C.B.; Ribeiro, M.L.; Garcia, J.N. Investigating the Use of Bow for Prestressing Lamellas of Glulam Beams Made with Young Eucalyptus grandis Timber. Constr. Build. Mater. 2023, 362, 129725. [Google Scholar] [CrossRef]

- Seng Hua, L.; Wei Chen, L.; Antov, P.; Kristak, L.; Md Tahir, P. Engineering Wood Products from Eucalyptus spp. Adv. Mater. Sci. Eng. 2022, 2022, 8000780. [Google Scholar] [CrossRef]

- Lara-Bocanegra, A.J.; Majano-Majano, A.; Arriaga, F.; Guaita, M. Eucalyptus globulus Finger Jointed Solid Timber and Glued Laminated Timber with Superior Mechanical Properties: Characterisation and Application in Strained Gridshells. Constr. Build. Mater. 2020, 265, 120355. [Google Scholar] [CrossRef]

- Oliveira, R.G.E.; Gonçalves, F.G.; Segundinho, P.G.A.; Oliveira, J.T.S.; Paes, J.B.; Chaves, I.L.S.; Brito, A.S. Analysis of Glue Line and Correlations between Density and Anatomical Characteristics of Eucalyptus grandis × Eucalyptus urophylla Glulam. Maderas. Cienc. Tecnol. 2020, 22, 495–504. [Google Scholar] [CrossRef]

- Moya, L.; Pérez Gomar, C.; Vega, A.; Sánchez, A.; Torino, I.; Baño, V. Relación Entre Parámetros de Producción y Propiedades Estructurales de Madera Laminada Encolada de Eucalyptus grandis. Maderas. Cienc. Tecnol. 2019, 21, 327–340. [Google Scholar] [CrossRef]

- Dietsch, P.; Tannert, T. Assessing the Integrity of Glued-Laminated Timber Elements. Constr. Build. Mater. 2015, 101, 1259–1270. [Google Scholar] [CrossRef]

- Bukhari, M.D.; Gohar, G.A.; Akhtar, A.; Ullah, S.; Akram, M.; Abid, J.; Raza, H. Adhesion Theories and Effect of Surface Roughness on Energy Estimation and Wettability of Polymeric Composites Bonded Joints: A-Review. VW Appl. Sci. 2019, 2, 74–86. [Google Scholar] [CrossRef]

- Segundinho, P.G.d.A.; Lopes, N.F.; Gonçalves, F.G.; Oliveira, R.F.; Oliveira, R.G.E.; Silva Oliveira, J.T.; da Mastela, L.C.; Belumat, M.A.R.; Paes, J.B. Analysis of Physical and Mechanical Properties of Glued Laminated Timber Elements Produced from Eucalyptus Residues. J. Indian Acad. Wood Sci. 2024, 21, 371–378. [Google Scholar] [CrossRef]

- Leggate, W.; McGavin, R.L.; Outhwaite, A.; Gilbert, B.P.; Gunalan, S. Barriers to the Effective Adhesion of High-Density Hardwood Timbers for Glue-Laminated Beams in Australia. Forests 2022, 13, 1038. [Google Scholar] [CrossRef]

- Acosta, A.P.; de Avila Delucis, R.; Santos, O.L.; Amico, S.C. A Review on Wood Permeability: Influential Factors and Measurement Technologies. J. Indian Acad. Wood Sci. 2024, 21, 175–191. [Google Scholar] [CrossRef]

- Quintilhan, M.T.; Oliveira, W.C.; Oliveira, A.C.; Luísa, B.; Pereira, C.; Môra, R. Physical properties and preservative treatment of Eucalyptus and Corymbia wood. Floresta 2021, 51, 410–418. [Google Scholar] [CrossRef]

- Moreira, G.G.; Hakamada, R.; Silva, R.M.L.d.; de Lemos, C.C.Z.; Florentino, A.L.; Gonçalves, J.L.d.M. Seedling Morphological Characteristics on Survival, Uniformity, and Growth during a Full Short Rotation in Eucalyptus grandis × E. urophylla Plantation. Forests 2023, 14, 1756. [Google Scholar] [CrossRef]

- Rindler, A.; Hansmann, C.; Konnerth, J. The Effect of Moisture on the Mechanical Response of Wood, Adhesive and Their Interphase by Means of Nanoindentation. Wood Sci. Technol. 2019, 53, 729–746. [Google Scholar] [CrossRef]

- Setter, C.; Zidanes, U.L.; Miranda, E.H.N.; Brito, F.M.S.; Mendes, L.M.; Junior, J.B.G. Influence of Wood Species and Adhesive Type on the Performance of Multilaminated Plywood. Environ. Sci. Pollut. Res. 2021, 28, 50835–50846. [Google Scholar] [CrossRef]

- Toumpanaki, E.; Shah, D.U.; Eichhorn, S.J. Beyond What Meets the Eye: Imaging and Imagining Wood Mechanical–Structural Properties. Adv. Mater. 2021, 33, 2001613. [Google Scholar] [CrossRef]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-Based Composites: A Review on Fundamentals and Processes of Bamboo Bonding. Compos. Part B Eng. 2022, 235, 109776. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding Melt Pool Characteristics in Laser Powder Bed Fusion: An Overview of Single- and Multi-Track Melt Pools for Process Optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Raydan, N.D.V.; Leroyer, L.; Charrier, B.; Robles, E. Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review. Molecules 2021, 26, 7617. [Google Scholar] [CrossRef] [PubMed]

- Shirmohammadli, Y.; Pizzi, A.; Raftery, G.M.; Hashemi, A. One-Component Polyurethane Adhesives in Timber Engineering Applications: A Review. Int. J. Adhes. Adhes. 2023, 123, 103358. [Google Scholar] [CrossRef]

- Tai, N.L.; Ghasemlou, M.; Adhikari, R.; Adhikari, B. Starch-Based Isocyanate- and Non-Isocyanate Polyurethane Hybrids: A Review on Synthesis, Performance and Biodegradation. Carbohydr. Polym. 2021, 265, 118029. [Google Scholar] [CrossRef]

- Okada, T.; Kobori, H.; Kojima, Y.; Suzuki, S.; Nishikido, K.; Hirose, A.; Takahashi, K. Evaluating the Durability of Structural Glulam Bonded with Aqueous Polymer-Isocyanate Adhesive by Two Kinds of Accelerated Aging Treatments. Eur. J. Wood Wood Prod. 2020, 78, 113–122. [Google Scholar] [CrossRef]

- Liu, J.; Yue, K.; Xu, L.; Wu, J.; Chen, Z.; Wang, L.; Liu, W.; Lu, W. Bonding Performance of Melamine-Urea–Formaldehyde and Phenol-Resorcinol–Formaldehyde Adhesive Glulams at Elevated Temperatures. Int. J. Adhes. Adhes. 2020, 98, 102500. [Google Scholar] [CrossRef]

- Juhaida, M.F.; Paridah, M.T.; Hilmi, M.M.; Sarani, Z.; Jalaluddin, H.; Mohamad Zaki, A.R. Liquefaction of Kenaf (Hibiscus cannabinus L.) Core for Wood Laminating Adhesive. Bioresour. Technol. 2010, 101, 1355–1360. [Google Scholar] [CrossRef]

- Faria, D.L.; Scatolino, M.V.; Lopes, T.A.; Mesquita Júnior, L.; Mota, G.d.S.; Guimarães Júnior, J.B.; Mendes, L.M.; Soriano, J. Performance of Glulam Beams Produced with Free-Formaldehyde Adhesive and Underexploited Rubber Wood Treated with Preservatives Solutions of Chromated Copper Borate and Pyrethroids. J. Adhes. Sci. Technol. 2020, 34, 1145–1162. [Google Scholar] [CrossRef]

- Bianche, J.J.; Carneiro, A.C.O.; Vital, B.R.; Andrade, B.G.; Gomes, R.M.; Araújo, S.d.O.; Souza, E.C. Improving the Understanding of Wood Bonding: Behavior of Different Adhesives on the Surface of Eucalyptus and Pine Wood. Int. J. Adhes. Adhes. 2022, 112, 102987. [Google Scholar] [CrossRef]

- Paraskar, P.M.; Prabhudesai, M.S.; Hatkar, V.M.; Kulkarni, R.D. Vegetable Oil Based Polyurethane Coatings—A Sustainable Approach: A Review. Prog. Org. Coat. 2021, 156, 156. [Google Scholar] [CrossRef]

- Brunetti, M.; Christovasilis, I.P.; Micheloni, M.; Nocetti, M.; Pizzo, B. Production Feasibility and Performance of Carbon Fibre Reinforced Glulam Beams Manufactured with Polyurethane Adhesive. Compos. B Eng. 2019, 156, 106267. [Google Scholar] [CrossRef]

- Oliveira, R.F.; Segundinho, P.G.d.A.; Silva, J.G.M.; Gonçalves, F.G.; Lopes, D.J.V.; Silva, J.P.M.; Lopes, N.F.; Mastela, L.d.C.; Paes, J.B.; de Souza, C.G.F.; et al. Eucalyptus-Based Glued Laminated Timber: Evaluation and Prediction of Its Properties by Non-Destructive Techniques. Forests 2024, 15, 1658. [Google Scholar] [CrossRef]

- Jeong, B.; Park, B.D.; Causin, V. Influence of Synthesis Method and Melamine Content of Urea-Melamine-Formaldehyde Resins to Their Features in Cohesion, Interphase, and Adhesion Performance. J. Ind. Eng. Chem. 2019, 79, 87–96. [Google Scholar] [CrossRef]

- Park, S.; Jeong, B.; Park, B.D. A Comparison of Adhesion Behavior of Urea-Formaldehyde Resins with Melamine-Urea-Formaldehyde Resins in Bonding Wood. Forests 2021, 12, 1037. [Google Scholar] [CrossRef]

- ASTM D-1084; Standard Test Methods for Viscosity of Adhesives. Annual Book of ASTM Standards. ASTM, American Society of Testing and Materials: West Conshohocken, PA, USA, 2021; pp. 1–16.

- ASTM D1582; Standard Test Method for Nonvolatile Content of Liquid Phenol, Resorcinol, and Melamine Adhesives. Annual Book of ASTM Standards. ASTM, American Society of Testing and Materials: West Conshohocken, PA, USA, 2017.

- ABNT NBR 7190-2:2022; Parte 2: Métodos de Ensaio Para Classificação Visual e Mecânica de Peças Estruturais de Madeira. ABNT, Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2022.

- ABNT NBR 7190-6:2022; Projeto de Estruturas de Madeira—Parte 6: Métodos de Ensaio para Caracterização de Madeira Lamelada Colada Estrutural. ABNT, Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2022.

- Zangiacomo, A.; Balanco, G.; Christoforo, A.; Lahr, F. Glued Laminated Timber Produced with Tropical Brazilian Wood Species. Curr. J. Appl. Sci. Technol. 2017, 23, 1–12. [Google Scholar] [CrossRef]

- ASTM D905-08; Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading. Annual Book of ASTM Standards. ASTM, American Society for Testing and Materials: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM D5266-13; Standard Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints. Annual Book of ASTM Standards. ASTM, American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- EN 391; Glued Laminated Timber: Delamination Test of Glue Lines. EN, European Committee for Standardization: Brussels, Belgium, 2001.

- Kloppenburg, A.M. Density Determination of Tropical Hardwoods with the Resistograph. Master’s Thesis, Materials Science and Engineering, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Papandrea, S.F.; Cataldo, M.F.; Zimbalatti, G.; Proto, A.R. Comparative Evaluation of Inspection Techniques for Decay Detection in Urban Trees. Sens. Actuators A Phys. 2022, 340, 113544. [Google Scholar] [CrossRef]

- Wu, X.; Li, G.; Jiao, Z.; Wang, X. Reliability of Acoustic Tomography and Ground-Penetrating Radar for Tree Decay Detection. Appl. Plant Sci. 2018, 6, e01187. [Google Scholar] [CrossRef]

- Nowak, T.P.; Jasieńko, J.; Hamrol-Bielecka, K. In Situ Assessment of Structural Timber Using the Resistance Drilling Method—Evaluation of Usefulness. Constr. Build. Mater. 2016, 102, 403–415. [Google Scholar] [CrossRef]

- Nutto, L.; Biechele, T. Drilling Resistance Measurement and the Effect of Shaft Friction—Using Feed Force Information for Improving Decay Identification on Hard Tropical Wood. In Proceedings of the 19th International Nondestructive Testing and Evaluation of Wood Symposium, Rio de Janeiro, Brazil, 22–25 September 2015. [Google Scholar]

- Sharapov, E.; Brischke, C.; Militz, H.; Smirnova, E. Prediction of Modulus of Elasticity in Static Bending and Density of Wood at Different Moisture Contents and Feed Rates by Drilling Resistance Measurements. Eur. J. Wood Wood Prod. 2019, 77, 833–842. [Google Scholar] [CrossRef]

- Oliveira, J.T.d.S.; Wang, X.; Vidaurre, G.B. Assessing Specific Gravity of Young Eucalyptus Plantation Trees Using a Resistance Drilling Technique. Holzforschung 2017, 71, 137–145. [Google Scholar] [CrossRef]

- Iždinský, J.; Reinprecht, L.; Sedliačik, J.; Kúdela, J.; Kučerová, V. Bonding of Selected Hardwoods with Pvac Adhesive. Appl. Sci. 2021, 11, 67. [Google Scholar] [CrossRef]

- Yusoh, A.S.; Md Tahir, P.; Anwar Uyup, M.K.; Lee, S.H.; Husain, H.; Khaidzir, M.O. Effect of Wood Species, Clamping Pressure and Glue Spread Rate on the Bonding Properties of Cross-Laminated Timber (CLT) Manufactured from Tropical Hardwoods. Constr. Build. Mater. 2021, 273, 121721. [Google Scholar] [CrossRef]

- Waheed, A.; Kazi, I.W.; Manzar, M.S.; Ahmad, T.; Mansha, M.; Ullah, N.; Ahmed Blaisi, N.I. Ultrahigh and Efficient Removal of Methyl Orange, Eriochrom Black T and Acid Blue 92 by Triazine Based Cross-Linked Polyamine Resin: Synthesis, Isotherm and Kinetic Studies. Colloids Surf. A Physicochem. Eng. Asp. 2020, 607, 125472. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Siuda, J.; Mirski, R.; Dziurka, D. Hemp Flour as a Formaldehyde Scavenger for Melamine-Urea-Formaldehyde Adhesive in Plywood Production. Bioresources 2020, 15, 4052–4064. [Google Scholar] [CrossRef]

- Donadon, B.F.; Mascia, N.T.; Vilela, R.; Trautwein, L.M. Experimental Investigation of Glued-Laminated Timber Beams with Vectran-FRP Reinforcement. Eng. Struct. 2020, 202, 109818. [Google Scholar] [CrossRef]

- Danielli, D.; Pires, M.R.; Araujo, E.S.; Lorenço, M.S.; Mori, F.A. Application of Myrcia Splendens Tannins in the Composition of Urea-Formaldehyde Adhesive for Sustainable Wood Bonding. Res. Soc. Dev. 2021, 10, e370101220543. [Google Scholar] [CrossRef]

- Amin, Y.; Adji, R.P.; Lubis, M.A.R.; Nugroho, N.; Bahtiar, E.T.; Dwianto, W.; Karlinasari, L. Effect of Glue Spread on Bonding Strength, Delamination, and Wood Failure of Jabon Wood-Based Cross-Laminated Timber Using Cold-Setting Melamine-Based Adhesive. Polymers 2023, 15, 2349. [Google Scholar] [CrossRef]

- ASTM D5751-99; Standard Specification for Adhesives Used for Laminate Joints in Nonstructural Lumber Products. Annual Book of ASTM Standards. ASTM, American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM D2559; Standard Specification for Structural Laminated Wood Products for Use under Exterior (Wet Use) Exposure Conditions. Annual Book of ASTM Standards. ASTM, American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Aicher, S.; Ahmad, Z.; Hirsch, M. Bondline Shear Strength and Wood Failure of European and Tropical Hardwood Glulams. Eur. J. Wood Wood Prod. 2018, 76, 1205–1222. [Google Scholar] [CrossRef]

- Bianche, J.J.; Teixeira, A.P.M.; Ladeira, J.P.S.; de Cássia Oliveira Carneiro, A.; Castro, R.V.O.; Lucia, R.M. Della. Shear in the Glue Line of Eucalyptus sp. Bonded with Different Adhesives and Weights. Floresta Ambiente 2017, 24, e00077114. [Google Scholar] [CrossRef]

- Gavrilovic-Grmusa, I.; Dunky, M.; Miljkovic, J.; Djiporovic-Momcilovic, M. Influence of the Viscosity of UF Resins on the Radial and Tangential Penetration into Poplar Wood and on the Shear Strength of Adhesive Joints. Holzforschung 2012, 66, 849–856. [Google Scholar] [CrossRef]

- Li, Z.; Chu, S.; Zhang, Y.; Lin, L.; Liu, X. Transforming Interface Properties of Wood Laminate Composites Functionalized by Adhesive Penetration. Compos. B Eng. 2023, 263, 110859. [Google Scholar] [CrossRef]

- Chandler, J.G.; Brandon, R.L.; Frihart, C.R. Examination of Adhesive Penetration in Modified Wood Using Fluorescence Microscopy. In Proceedings of the ASC Spring 2005 Convention and Exposition, Columbus, OH, USA, 17–20 April 2005. [Google Scholar]

- Shi, S.Q.; Gardner, D.J. Dynamic Adhesive Wettability of Wood. Wood Fiber Sci. 2001, 33, 58–68. [Google Scholar]

- Bazli, M.; Heitzmann, M.; Villacorta Hernandez, B. Durability of Fibre-Reinforced Polymer-Wood Composite Members: An Overview. Compos. Struct. 2022, 295, 115827. [Google Scholar] [CrossRef]

- Carrillo, I.; Vidal, C.; Elissetche, J.P.; Mendonça, R.T. Wood Anatomical and Chemical Properties Related to the Pulpability of Eucalyptus globulus: A Review. South. For. 2018, 80, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).