Modelling Wood Product Service Lives and Residence Times for Biogenic Carbon in Harvested Wood Products: A Review of Half-Lives, Averages and Population Distributions

Abstract

1. Introduction

2. The Origins of Biogenic Carbon Analysis for Harvested Wood Products

2.1. Some Text on History

| Category | IPCC 2003 [39] Appendix Only | IPCC 2006 [43] Tier 2 | IPCC 2014 [5], Tier 2 and IPCC 2019 [6], Tier 1 | |||

|---|---|---|---|---|---|---|

| Sawnwood | Saw wood | 35 | Solid wood products | 30 | Sawnwood | 35 |

| Wood-based panels | Veneer, plywood and structural panels | 30 | Wood-based panels | 25 | ||

| Non-structural panels | 20 | |||||

| Pulp and paper | Paper | 2 | Paper products | 2 | Paper and paperboard | 2 |

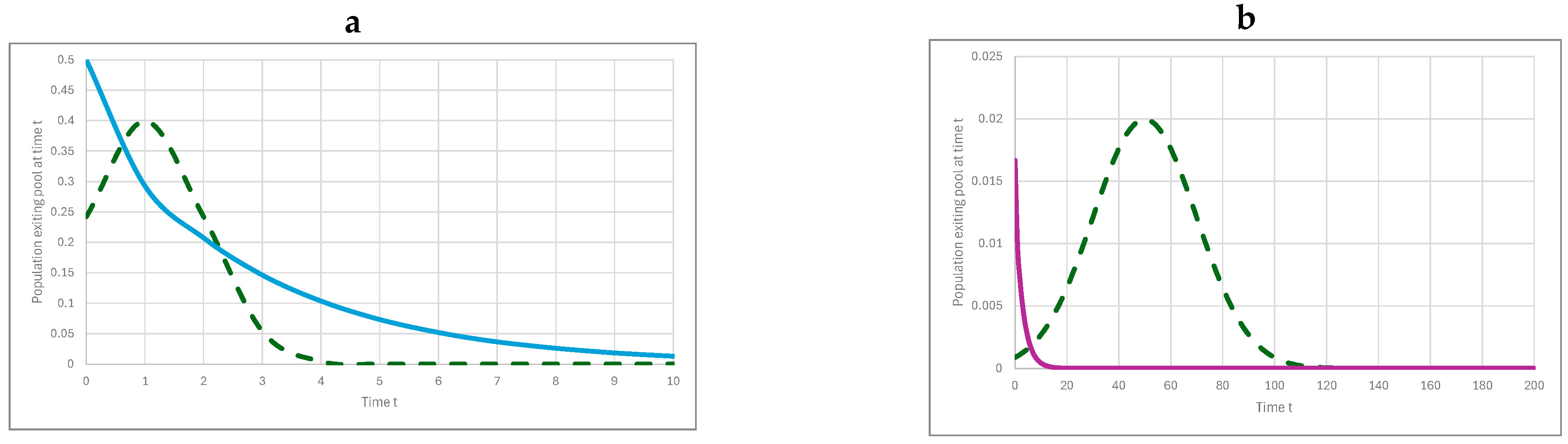

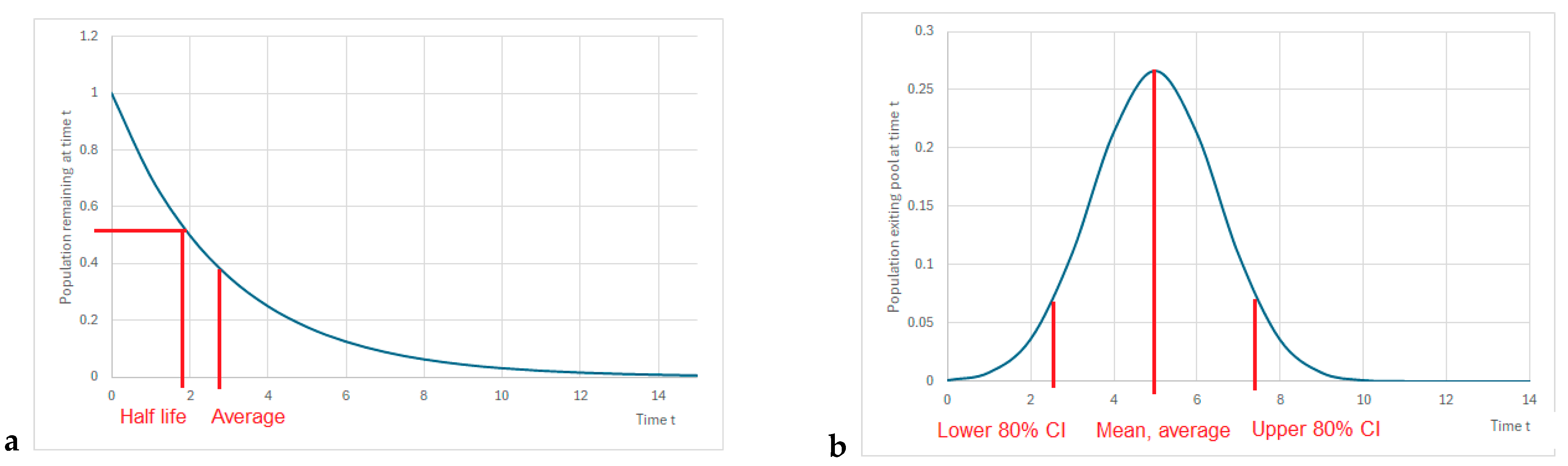

2.2. History of the Maths—First Order Decay

2.3. Benefits of Using First Order Decay

2.4. Beyond the IPCC

3. History of Other Mathematical Approaches

4. Estimating Product Lifespan

4.1. Service Life Values from ISO 15686-1 and Survey Data

4.2. Half-Life Estimates from Other Sources

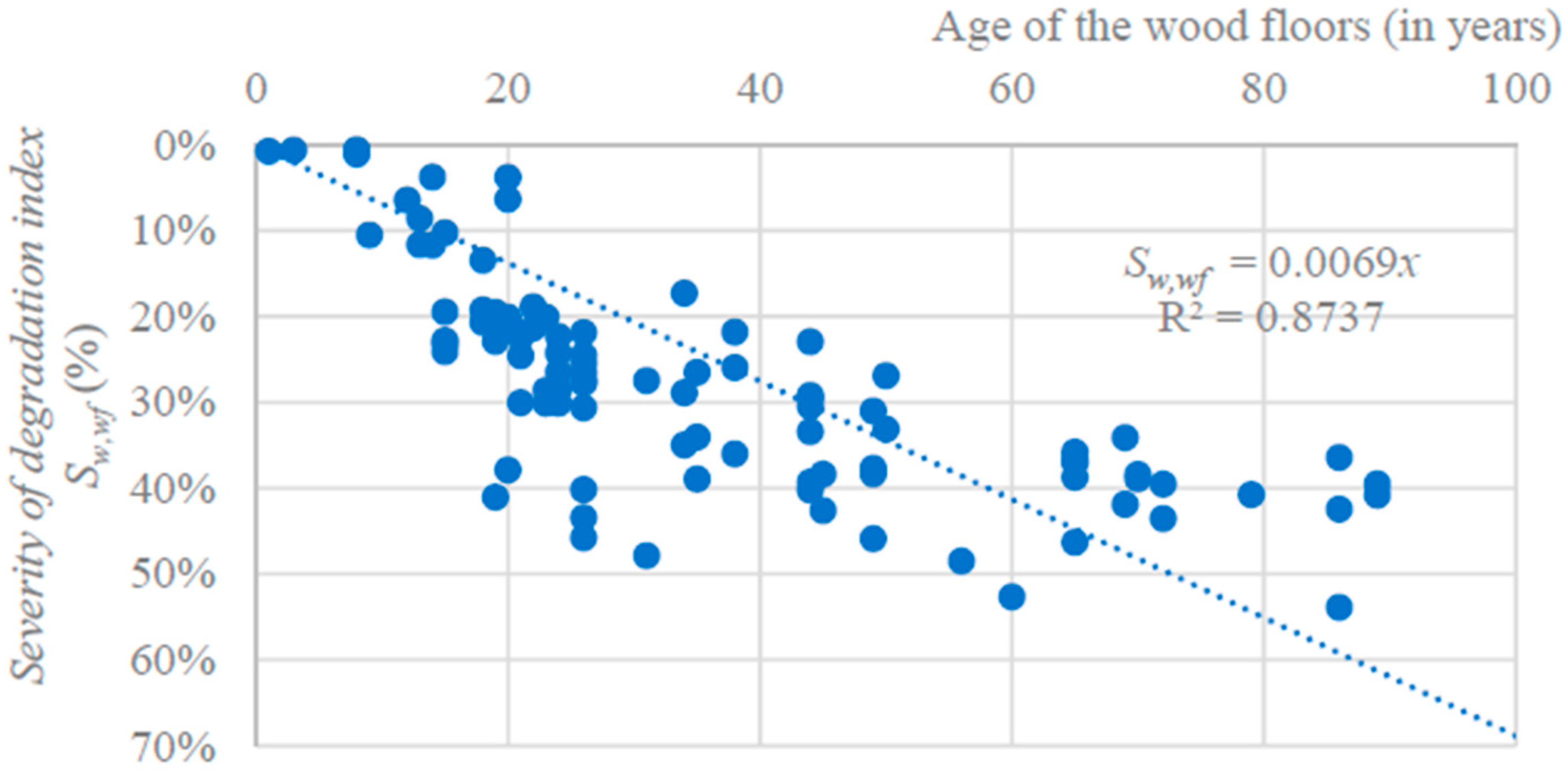

4.3. A Service Life Population Examples—Flooring Products

4.4. Using Service Life Data and ISO 15686

5. Using Other Methods

5.1. Tier 2 and Tier 3 Methods

5.2. Comparing Half-Lives and Other Functions

5.3. Some Notes on the Gamma Distribution

5.4. Chi-Squared Distribution

5.5. Continuing to Use Half-Life Data

5.6. Considerations for Future Work

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| bioPE | Biobased polyethylene |

| bioPET | Biobased polyester terephthalate |

| CHP | Combined heat and power |

| CRCF | Carbon removals and carbon farming |

| EPD | Environmental product declaration |

| ESL | Estimated service life |

| FAOSTAT | Food and Agriculture Organization of the United Nations database on food and agriculture data (https://www.fao.org/faostat/en/#home, accessed on 10 May 2025) |

| FOD | First order decay |

| GHG | Greenhouse gas |

| GGR | Greenhouse gas removal |

| HWP | Harvested wood products |

| IPCC | Intergovernmental Panel on Climate Change |

| ISO | International Standards Organization |

| LCA | Lifecycle assessment |

| LULUCF | Land use, land use change and forestry |

| NIR | National inventory report |

| OSB | Oriented strand board |

| PB | Particleboard |

| RSL | Reference service life |

| RSS | Residual sum of squares |

| SWDS | Solid waste disposal site |

| UNFCCC | United Nations Framework Convention on Climate Change |

| USDA | United States Department of Agriculture |

| WPC | Wood plastic composite |

References

- Iordan, C.-M.; Hu, X.; Arvesen, A.; Kauppi, P.; Cherubini, F. Contribution of forest wood products to negative emissions: Historical comparative analysis from 1960 to 2015 in Norway, Sweden and Finland. Carbon Balance Manag. 2018, 13, 12. [Google Scholar] [CrossRef] [PubMed]

- Nasiri, B.; Piccardo, C.; Hughes, M. Estimating the material stock in wooden residential houses in Finland. Waste Manag. 2021, 135, 318–326. [Google Scholar] [CrossRef] [PubMed]

- Kallio, A.M.I.; Houtmeyers, S.; Aza, A. On carbon substitution and storage factors for harvested wood products in the context of climate change mitigation in the Norwegian forest sector. Environ. Clim. Technol. 2023, 27, 254–270. [Google Scholar] [CrossRef]

- UNFCCC. Kyoto Protocol Reference Manual: On Accounting of Emissions and Assigned Amount. 2008. Available online: https://unfccc.int/resource/docs/publications/08_unfccc_kp_ref_manual.pdf (accessed on 10 May 2025).

- IPCC. 2013 Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Hiraishi, T., Krug, T., Tanabe, K., Srivastava, N., Baasansuren, J., Fukuda, M., Troxler, T.G., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- IPCC. Chapter 12: Harvest Wood Products. In Intergovernmental Panel on Climate Change (IPCC). Volume 4 Agriculture, Forestry, and Other Land Use; 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2019. Available online: www.ipcc-nggip.iges.or.jp/public/2019rf/index.html (accessed on 7 May 2025).

- Hashimoto, S. Different accounting approaches to harvested wood products in national greenhouse gas inventories: Their incentives to achievement of major policy goals. Environ. Sci. Policy 2008, 11, 756–771. [Google Scholar] [CrossRef]

- Forster, E.J.; Healey, J.R.; Newman, G.; Styles, D. Circular wood use can accelerate global decarbonisation but requires cross-sectoral coordination. Nat. Commun. 2023, 14, 6766. [Google Scholar] [CrossRef]

- Council of the EU. Council Greenlights EU Certification Framework for Permanent Carbon Removals, Carbon Farming and Carbon Storage in Products. 2024. Available online: https://www.consilium.europa.eu/en/press/press-releases/2024/11/19/council-greenlights-eu-certification-framework-for-permanent-carbon-removals-carbon-farming-and-carbon-storage-in-products/ (accessed on 7 May 2025).

- Hammar, T.; Hansson, P.-A.; Seleborg, M.; Stendahl, J.; Jonsson, R. Climate Effects of a Forestry Company—Including Biogenic Carbon Fluxes and Substitution Effects (2021 Update). 2022. Available online: https://pub.epsilon.slu.se/26913/1/hammar_t_et_al_220204.pdf (accessed on 7 May 2025).

- Stora Enso. Annual Report 2024. Available online: https://www.storaenso.com/-/media/documents/download-center/documents/annual-reports/2024/storaenso_annual_report_2024.pdf (accessed on 7 May 2025).

- ISO (2025) ISO 13391:2025; Wood and Wood-Based Products—Greenhouse Gas Dynamics. International Organization for Standardization: Geneva, Switzerland, 2025.

- Marland, E.S.; Stellar, K.; Marland, G.H. A distributed approach to accounting for carbon in wood products. Mitig. Adapt. Strateg. Glob. Change 2010, 15, 71–91. [Google Scholar] [CrossRef]

- Spear, M.; Hill, C.; Norton, A.; Price, C. Wood in Construction in the UK: An Analysis of Carbon Abatement Potential. Available online: https://www.theccc.org.uk/wp-content/uploads/2019/07/Wood-in-Construction-in-the-UK-An-Analysis-of-Carbon-Abatement-Potential-BioComposites-Centre.pdf (accessed on 25 April 2025).

- Spear, M.J.; Hill, C.A.S.; Price, C. A conceptual methodology for estimating stored sequestered carbon in the built environment. In Smart Innovation, Systems and Technologies, Vol 23, Sustainability and Energy in Buildings 2020; Littlewood, J., Howlett, R.J., Jain, L.C., Eds.; Springer: Singapore, 2021; Chapter 32; pp. 381–393. [Google Scholar] [CrossRef]

- Hill, C.A.S. The environmental consequences concerning the use of timber in the built environment. Front. Built Environ. 2019, 5, 129. [Google Scholar] [CrossRef]

- Kalcher, J.; Praxmarer, G.; Teischinger, A. Quantification of future availabilities of recovered wood from Austrian residential buildings. Resour. Conserv. Recycl. 2017, 123, 143–152. [Google Scholar] [CrossRef]

- Arehart, J.H.; Hart, J.; Pomponi, F.; D’Amico, B. Carbon sequestration and storage in the built environment. Sustain. Consum. Prod. 2021, 27, 1047–1063. [Google Scholar] [CrossRef]

- Matsumoto, R.; Kayo, C.; Kita, S.; Nakamura, K.; Lauk, C.; Funada, R. Estimation of carbon stocks in wood products for private building companies. Sci. Rep. 2022, 12, 18112. [Google Scholar] [CrossRef]

- Robson, D.; Sadler, P.; Newman, G. Carbon sequestered in UK forest products and wood based panels in construction: Helping to meet UK’s greenhouse gas emission reduction targets. Int. Wood Prod. J. 2014, 5, 139–145. [Google Scholar] [CrossRef]

- Irle, M.; Velez, G.; Belloncle, C.; Bonnin, E.; Lahaye, M. Recycling waste fibreboard. In Proceedings of the International Panel Products Symposium 2019, Llandudno, Wales, UK, 8–9 October 2019; Spear, M., Ed.; pp. 163–170. [Google Scholar]

- Spear, M.J.; Norton, A.; Hill, C.A.S.; Price, C.; Ormondroyd, G.A. Wood based panels in modern methods of construction for housing: Greenhouse gas abatement analysis. In Proceedings of the International Panel Products Symposium 2019, Llandudno, Wales, UK, 8–9 October 2019; Spear, M.J., Ed.; pp. 95–108. [Google Scholar]

- Muller, B.D.; Bader, H.-P.; Baccini, P. Long term coordination of timber production and consumption using a dynamic material and energy flow analysis. J. Ind. Ecol. 2004, 8, 65–87. [Google Scholar] [CrossRef]

- Ingeson A Carbon storage potential of harvested wood: Summary and policy implications. Mitig Adapt. Strat. Glob Change 2011, 16, 307–323. [CrossRef]

- ISO (2025) ISO 13391-1:2025; Wood and Wood-Based Products—Greenhouse Gas Dynamics—Part 1: Framework for Value Chain Calculations. International Organization for Standardization: Geneva, Switzerland, 2025.

- Hurmekoski, E.; Myllyviita, T.; Seppälä, J.; Heinonen, T.; Kilpeläinen, A.; Pukkala, T.; Mattila, T.; Hetemäki, L.; Asikainen, A.; Peltola, H. Impact of structural changes in wood-using industries on net carbon emissions in Finland. J. Ind. Ecol. 2020, 24, 899–912. [Google Scholar] [CrossRef]

- Forster, E.; Styles, D.; Healey, J.R. Temperate forests can deliver future wood demand and climate-change mitigation dependent on afforestation and circularity. Nat. Commun. 2025, 16, 3872. [Google Scholar] [CrossRef]

- Irle, M.; Privat, F.; Couret, L.; Belloncle, C.; Deroubaix, G.; Bonnin, E.; Cathala, B. Advanced recycling of post-consumer solid wood and MDF. Wood Mater. Sci. Eng. 2019, 14, 19–23. [Google Scholar] [CrossRef]

- Sikkema, R.; Junginger, M.; McFarlane, P.; Faaij, A. The GHG contribution of the cascaded use of harvested wood products in comparison with the use of wood for energy—A case study on available forest resource in Canada. Environ. Sci. Policy 2013, 31, 96–108. [Google Scholar] [CrossRef]

- Budzinski, M.; Bezama, A.; Thrän, D. Estimating the potentials for reducing the impacts on climate change by increasing the cascade use and extending the lifetime of wood products in Germany. Resour. Conserv. Recycl. 2020, X6, 100034. [Google Scholar] [CrossRef]

- Spear, M.J.; Dimitriou, A.; Curling, S.F.; Ormondroyd, G.A. Developments in the recycling of wood and wood fibre in the UK: A review. Fibers 2025, 13, 23. [Google Scholar] [CrossRef]

- Sikkema, R.; Dallemand, J.F.; Matos, C.; van der Velde, M.; San-Miguel-Ayanz, J. How can the ambitious goals for the EU’s future bioeconomy be supported by sustainable and efficient wood sourcing practices? Scand. J. For. Res. 2017, 32, 551–558. [Google Scholar] [CrossRef]

- Navare, K.; Arts, W.; Faraca, G.; Van den Bosche, G.; Sels, B.; Van Acker, K. Environmental impact assessment of cascading use of wood in bio-fuels and bio-chemicals. Resour. Conserv. Recycl. 2022, 186, 106588. [Google Scholar] [CrossRef]

- Spear, M.J. The benefits of circular economy approaches in the wood panels industry on the magnitude of harvested wood product carbon storage. In Proceedings of the International Panel Products Symposium 2023, Llandudno, Wales, UK, 3–4 October 2023; pp. 23–40. [Google Scholar]

- Wei, X.; Zhao, J.; Hayes, D.J.; Daigneault, A.; Zhu, H. A life cycle and product type based estimator for quantifying the carbon stored in wood products. Carbon Balance Manag. 2023, 18, 1. [Google Scholar] [CrossRef] [PubMed]

- Karjalainen, T.; Kellomaki, S.; Pussinen, A. Role of Wood-based Products in Absorbing Atmospheric Carbon. Silva Fenn. 1994, 28, 67–80. [Google Scholar] [CrossRef]

- Pingoud, K.; Perala, A.-L.; Soimakallio, S.; Pussinen, A. Greenhouse Gas Impacts of Harvested Wood Products: Evaluation and Development of Methods. VTT Research Notes 2189. 2003. Available online: https://publications.vtt.fi/pdf/tiedotteet/2003/T2189.pdf (accessed on 11 July 2025).

- Brunet-Navarro, P.; Jochheim, H.; Muys, B. The effect of increasing lifespan and recycling rate on carbon storage in wood products from theoretical model to application for the European wood sector. Mitig Adapt Strat. Clim. Change 2017, 22, 1193–1205. [Google Scholar] [CrossRef]

- IPCC. Good Practice Guidance for Land Use, Land-Use Change and Forestry. Appendix 3a.1 Harvested Wood Products: Basis for Future Methodological Development. Intergovernmental Panel on Climate Change (IPCC) National Inventories Programme Technical Support Unit, Institute for Global Environmental Strategies. Hayama, Japan. 2003. Available online: https://www.ipcc-nggip.iges.or.jp/public/gpglulucf/gpglulucf_files/Chp3/App_3a1_HWP.pdf (accessed on 7 May 2025).

- Sathre, R.; Gustavsson, L. Energy and carbon balances of wood cascade chains. Resour. Conserv. Recycl. 2006, 47, 332–355. [Google Scholar] [CrossRef]

- Lim, B.; Brown, S.; Schlamadinger, B. Carbon accounting for forest harvesting and wood products: Review and evaluation of the different approaches. Environ. Sci. Policy 1999, 2, 207–216. [Google Scholar] [CrossRef]

- Johnson, C.M.T.; Radeloff, V.C. Global mitigation potential of carbon stored in harvested wood products. Proc. Natl. Acad. Sci. USA 2019, 116, 14526–14531. [Google Scholar] [CrossRef]

- IPCC. Chapter 12: Harvest Wood Products. In 2006 Intergovernmental Panel on Climate Change (IPCC) Guidelines for National Greenhouse Gas Inventories, Volume 4, Agriculture, Forestry, and Other Land Use; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Row, C.; Phelps, R.B. Wood carbon flows and storage after timber harvest. In Forests and Global Change, Vol. 2: Forest Management Opportunities for Mitigating Carbon Emissions; Sampson, R.N., Hair, D., Eds.; American Forests: Washington, DC, USA, 1996; pp. 27–58. [Google Scholar]

- Skog, K.E.; Nicholson, G.A. Carbon cycling through wood products: The role of wood and paper products in carbon sequestration. For. Prod. J. 1998, 48, 75–83. [Google Scholar]

- Eggers, T. The impacts of manufacturing and utilisation of wood products on the European carbon budget. EFI Intern. Rep. 2002, 9, 90. [Google Scholar]

- Pingoud, K.; Perälä, A.L.; Pussinen, A. Carbon dynamics in wood products. Mitig. Adapt. Strateg. Glob. Change 2001, 6, 91–111. [Google Scholar] [CrossRef]

- Pingoud, K.; Savolainen, I.; Seppälä, H. Greenhouse impact of Finnish forest sector including forest products and waste management. Ambio 1996, 25, 318–326. [Google Scholar]

- Nabuurs, G. Significance of wood products in forest sector carbon balances. In Forest Ecosystems, Forest Management and the Global Carbon Cycle; NATO ASI series; Springer: Berlin/Heidelberg, Germany, 1996; Chapter 20; Volume 40, pp. 245–256. [Google Scholar]

- Skog, K.; Nicholson, G. Carbon sequestration in wood and paper products. In The Impact of Climate Change on America’s Forests: A Technical Document Supporting the 2000 USDA Forest Service RPA Assessment; Joyce, L.A., Birdsey, R., Eds.; Gen. Tech. Rep. RMRS-GTR-59; U.S. Department of Agriculture, Forest Service, Rocky Mountain Research Station: Fort Collins, CO, USA, 2000; pp. 79–88. [Google Scholar]

- Nabuurs, G.J.; Sikkema, R. The Role of Harvested Wood Products in National Carbon Balances: An Evaluation of Alternatives for IPCC Guidelines; IDN Research Report 98/3; IDN-DLO: Wageningen, The Netherlands, 1998. [Google Scholar]

- Gjesdal, S.F.T.; Flugsrud, K.; Mykkelbost, T.C.; Rypdal, K. A Balance of Use of Wood Products in Norway; Report 96:04; Norwegian Pollution Control Authority SFT: Oslo, Norway, 1996; 54p. [Google Scholar]

- Hashimoto, S.; Nose, M.; Obara, T.; Moriguchi, Y. Wood products: Potential carbon sequestration and impact on net carbon emissions of industrialized countries. Environ. Sci. Policy 2002, 5, 183–193. [Google Scholar] [CrossRef]

- Marland, E.; Marland, G. The treatment of long-lived, carbon containing products in inventories of carbon dioxide emissions to the atmosphere. Environ. Sci. Policy 2003, 6, 139–152. [Google Scholar] [CrossRef]

- Newman, G.; Spear, M.; Corbey, S. Using Wood in Construction as a Significant Greenhouse Gas Removal Mechanism. Woodknowledge Wales. 2025. Available online: https://woodknowledge.wales/using-wood-in-construction-as-a-significant-greenhous-gas-removal-mechanism/ (accessed on 30 May 2025).

- Spear, M. How long is ‘long enough’? Carbon storage and wood products. In Proceedings of the 20th Annual Meeting of the Northern European Network for Wood Science and Engineering, Edinburgh, UK, 23–24 October 2024. [Google Scholar]

- Kayo, C.; Tsunetsugu, Y.; Noda, H.; Tonosaki, M. Carbon balance assessments of harvested wood products in Japan taking account of inter-regional flows. Environ. Sci. Policy 2014, 37, 215–226. [Google Scholar] [CrossRef]

- Smith, J.E.; Heath, L.S.; Shog, K.E.; Birdsey, R.A. Methods for Calculating Forest Ecosystem and Harvested Carbon with Standard Estimates for Forest Types of the United States; GTR-NE-343; U.S. Department of Agriculture, Forest Service, Northeastern Research Station: Newton Square, PA, USA, 2006; 222p. [Google Scholar]

- Murray, L.T.; Woodall, C.; Lister, A.; Farley, C.; Andersen, H.-E.; Heath, L.; Atkins, J.; Domke, G.; Oishi, C.; Stockmann, K.; et al. Chapter 5: Quantifying greenhouse gas sources and sinks in managed forest systems. In Quantifying Greenhouse Gas Fluxes in Agriculture and Forestry: Methods for Entity-Scale Inventory, 2nd ed.; Hanson, W.L., Itle, C., Edquist, K., Eds.; Technical Bulletin Number 1939; U.S. Department of Agriculture, Office of the Chief Economist: Washington, DC, USA, 2024. [Google Scholar]

- Skog, K.E. Sequestration of carbon in harvested wood products for the United States. For. Prod. J. 2008, 58, 56–72. [Google Scholar]

- Poudel, B.C.; Sathre, R.; Bergh, J.; Gustavsson, L.; Londström, A.; Hyvönen, R. Potential effects of intensive forestry on biomass production and total carbon balance in north-central Sweden. Environ. Sci. Policy 2012, 15, 106–124. [Google Scholar] [CrossRef]

- Höglmeier, K.; Steubing, B.; Weber-Blaschke, G.; Richter, K. LCA-based optimization of wood utilization under special consideration of a cascading use of wood. J. Environ. Manag. 2015, 152, 158–170. [Google Scholar] [CrossRef]

- Thomsen, A.; van der Flier, K. Understanding obsolescence: A conceptual model for buildings. Build. Res. Inf. 2011, 39, 352–362. [Google Scholar] [CrossRef]

- Zhou, W.; O’Neill, E.; Moncaster, A.; Reiner, D.M.; Guthrie, P. Forecasting urban residential stock turnover dynamics using system dynamics and Bayesian model averaging. Appl. Energy 2020, 275, 115388. [Google Scholar] [CrossRef]

- Bohne, R.A.; Bergsdal, H.; Brattebo, H.; Hovde, P.J. Estimation of the service life of buildings and building components. In Proceedings of the Towards the City Surface of Tomorrow, Conference Proceedings, Vienna, Austria, 8–9 June 2006; Brunner, P.H., Jakl, T., Ober, E., Eds.; pp. 29–33. [Google Scholar]

- Penaloza, D.; Erlandsson, M.; Berlin, J.; Walinder, M.; Falk, A. Future scenarios for climate mitigation of new construction in Sweden: Effects of different technological pathways. J. Clean. Prod. 2018, 187, 1025–1035. [Google Scholar] [CrossRef]

- Kayo, C.; Tonosaki, M. Lifetimes of buildings in Japan. Resour. Conserv. Recycl. 2022, 185, 106504. [Google Scholar] [CrossRef]

- Thompson, D.A.; Matthews, R.W. The Storage of Carbon in Trees and Timber. Forestry Commission Research Information Note 160. 1989; 6p. Available online: https://cdn.forestresearch.gov.uk/2023/06/RIN160.pdf (accessed on 5 May 2025).

- Miatto, A.; Schandl, H.; Tanikawa, H. How important are realistic building lifespan assumptions for material stock and demolition waste accounts? Resour. Conserv. Recycl. 2017, 122, 143–154. [Google Scholar] [CrossRef]

- Mason Earles, J.; Yah, S.; Skog, K.E. Timing of carbon emissions from global forest clearance. Nat. Clim. Change Lett. 2012, 2, 682–685. [Google Scholar] [CrossRef]

- Oguchi, M.; Murakami, S.; Tasaki, T.; Daigo, I.; Hashimoto, S. Lifespan of commodities. Part II. Methodologies for Estimating Lifespan Distribution of Commodities. J. Ind. Ecol. 2010, 14, 613–626. [Google Scholar] [CrossRef]

- Zhou, W.; Moncaster, A.; Reiner, D.M.; Guthrie, P. Estimating Lifetimes and Stock Turnover Dynamics of Urban Residential Buildings in China. Sustainability 2019, 11, 3720. [Google Scholar] [CrossRef]

- Brunet-Navarro, P.; Jochheim, H.; Muys, B. Modelling carbon stocks and fluxes in the wood product sector: A comparative review. Glob. Change Biol. 2016, 22, 2555–2569. [Google Scholar] [CrossRef]

- Hart, J.; Pomponi, F. More timber in construction: Unanswered questions and future challenges. Sustainability 2020, 12, 3473. [Google Scholar] [CrossRef]

- Heath, L.S.; Birdsey, R.A.; Row, C.; Plantinga, A.J. Carbon pools and flux in U.S. forest products. In Forest Ecosystems, Forest Management, and the Global Carbon Cycle; Apps, M.J., Proce, D.T., Eds.; NATO ASI series I: Global Environmental Changes; Springer: Berlin/Heidelberg, Germany, 1996; Volume 40, pp. 271–278. [Google Scholar]

- Rüter, S. Der Beitrag der Stofflichen Nutzung von Holz zum Klimaschautz—Das Modell WoodCarbonMonitor. PhD Thesis, Technische Universitat Munchen, Munich, Germany, 2016. [Google Scholar]

- Zhang, X.; Chen, J.; Dias, A.C.; Yang, H. Improving carbon stock estimates for in-use harvested wood products by linking production and consumption—A global case study. Environ. Sci. Technol. 2020, 54, 2565–2574. [Google Scholar] [CrossRef]

- Cherubini, F.; Guest, G.; Strømman, A.H. Application of probability distributions to the modelling of biogenic CO2 fluxes in life cycle assessment. GCB Bioenergy 2012, 4, 784–798. [Google Scholar] [CrossRef]

- Dias, A.C.; Louro, M.; Arroja, L.; Capela, I. The contribution of wood products to carbon sequestration in Portugal. Ann. For. Sci. 2005, 62, 903–909. [Google Scholar] [CrossRef]

- Burschel, P.; Kürsten, E.; Larson, B.C.; Weber, M. Present role of German forests and forestry in the national carbon budget and options to its increase. Water Air Soil Pollut. 1993, 70, 325–340. [Google Scholar] [CrossRef]

- Poker, J.; Dieter, M.; Thoroe, C. Integration of Harvested Wood Products into Accounting Approaches of the Carbon Dioxide Cycle in the Forestry Sector; Working Paper 2002/03; Institute for Economics, Federal Research Centre for Forestry and Forest Products: Hamburg, Germany, 2002. [Google Scholar]

- Sikkema, R.; Schelhaas, M.J.; Nabuurs, G.J. International Carbon Accounting of Harvested Wood Products: Evaluation of Two Models for the Quantification of Wood Product Related Emissions and Removals, Contribution of The Netherlands to the International Collaborative Study; Report No. 410200111; National Institute of Public Health and the Environment: Bilthoven, The Netherlands, 2002. [Google Scholar]

- Jaakko Pöyry Consulting. Usage and Life Cycle of Wood Products; NCAS Technical Report No. 8; Australian Greenhouse Office: Canberra, Australia, 1999. [Google Scholar]

- ISO (2011) ISO 15686-1:2011; Buildings and Constructed Assets—Service Life Planning Part 1: General Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2011.

- Aktas, C.B.; Bilec, M.M. Service life prediction of residential interior finishes for life cycle assessment. Int. J. Life Cycle Assess. 2012, 17, 362–371. [Google Scholar] [CrossRef]

- Coelho, P.; Silva, A.; de Brito, J. How long can a wooden flooring system last? Buildings 2021, 11, 23. [Google Scholar] [CrossRef]

- Braun, M.; Winner, G.; Schwarzbauer, P.; Stern, T. Apparent Half-life dynamics of Harvested Wood Products (HWPs) in Austria: Development and analysis of weighted time-series for 2002 to 2011. For. Policy Econ. 2016, 63, 28–34. [Google Scholar] [CrossRef]

- Menzies, G.F. Whole Life Analysis of Timber, Modified Timber and Aluminium-Clad Timber Windows: Service Life Planning (SLP), Whole Life Costing (WLC) and Life Cycle Assessment (LCA); Heriot-Watt University: Edinburgh, UK, 2013. [Google Scholar]

- Asif, M.; Muneer, T.; Kubie, J. Sustainability analysis of window frames. Build. Serv. Eng. Res. Technol. 2005, 26, 71–87. [Google Scholar] [CrossRef]

- Vandenbroucke, M. Rapport-Technische Levensduur van Gebouwcomponenten (Technical Lifetime of Components in Construction); OVAM: Mechelen, Belgium, 2018. (In Dutch) [Google Scholar] [CrossRef]

- Guest, G.; Strømman, A.H. Climate change impacts due to biogenic carbon. Addressing the issue of attribution using two metrics with very different outcomes. J. Sustain. For. 2014, 33, 298–326. [Google Scholar] [CrossRef]

- Fossdal, S. Energi og Miljøregnskap for Bygg (Energy and Environmental Accounting for Construction); NBI: Oslo, Norway, 1995. (In Norwegian) [Google Scholar]

- Nyrud, A.Q.; Hundhausen, U.; Heinemann, U.; Alfredsen, G.; Gobakken, L.R.; Vestol, G.I. Innovative Byggematerialer av tre—Klimaendring og Forbbedret Levetid. Treteknisk rapport 87, (In Norwegian: Innovative Wood Building Materials—Climate Change and Improved Life). 2015. Available online: https://www.treteknisk.no/publikasjoner/rapport/87-innovative-byggematerialer-av-tre--klimaendring-og-forbedret-levetid (accessed on 7 May 2025).

- Cheng, Y.S.; Han, Y.; Park, J.-H.; Son, W.-L.; Park, J.-S.; Park, M.-J.; Yeo, H. Study on methods for determining half-life of domestic wooden panel among Harvested Wood Products. J. Korean Wood Sci Technol. 2014, 42, 309–317. [Google Scholar] [CrossRef]

- Kers, J.; Alao, P.F.; Kattamanchi, T. Methodics for Defining the Half-Lives of Harvested Wood Products as Country Specific Ones for Estonia. TalTech Report, 2022; 38p. Available online: https://kliimaministeerium.ee/media/9541/download (accessed on 7 May 2025).

- Brunet-Navaro, P.; Jochheim, H.; Kroiher, F.; Muys, B. Effect of cascade use on the carbon balance of the German and European wood sectors. J. Clean. Prod. 2018, 170, 137–146. [Google Scholar] [CrossRef]

- Scharai-Rad, M.; Welling, J. Environmental and Energy Balances of Wood Products and Substitutes; Food and Agriculture Organization of the United Nations: Rome, Italy, 2002. [Google Scholar]

- Peterson, A.K.; Solberg, B. Greenhouse gas emissions, life cycle inventory and cost-efficiency of using laminated wood instead of steel construction. Case: Beams at Gardermoen Airport. Environ. Sci. Policy 2002, 5, 169–182. [Google Scholar] [CrossRef]

- Eaton, R.A.; Hale, M.D.C. Wood: Decay, Pests and Protection; Chapman and Hall Ltd.: London, UK, 1993. [Google Scholar]

- Brischke, C.; Meyer-Veltrup, L.; Bornemann, T. Moisture performance and durability of wooden facades and decking during six years of outdoor exposure. J. Build. Eng. 2017, 13, 207–215. [Google Scholar] [CrossRef]

- Morris, P.I.; Wang, J. Scheffer index as preferred method to define decay risk zones for above ground wood in building codes. Int. Wood Prod. J. 2011, 2, 67–70. [Google Scholar] [CrossRef]

- Brischke, C.; Selter, V. Mapping the decay hazard in wooden structures in topographically divergent regions. Forests 2020, 11, 510. [Google Scholar] [CrossRef]

- Dias, A.C.; Louro, M.; Arroja, L.; Capela, I. Comparison of methods for estimating carbon in harvested wood products. Biomass Bioenergy 2009, 33, 213–222. [Google Scholar] [CrossRef]

- ProMietrecht. Tabelle Wirtschaftliche Lebensdauer—Schadenersatz bei Neu fur Alt. 2019. Available online: https://www.promietrecht.de/Schaden/Abwehr-von-Forderungen/Tabellewirtschaftliche-Lebensdauer-Schadenersatz-bei-Neu-fuer-Alt-E2569.htm (accessed on 7 May 2025).

- Goulouti, K.; Favre, D.; Giorgi, M.; Padey, P.; Galimshina, A.; Habert, G.; Lasvaux, S. Dataset of service life data for 100 building elements and technical systems, including their descriptive statistics and fitting to lognormal distribution. Data Brief 2020, 36, 107062. [Google Scholar] [CrossRef] [PubMed]

- Kayo, C.; Sanjo, K.; Sato, I.; Liu, M.; Prasetyadi, G.V.; Hirahara, S. Carbon stocks of particleboard and fiberboard in Japan. Sci. Rep. 2023, 13, 9846. [Google Scholar] [CrossRef]

- Guest, G.; Cherubini, F.; Strømman, A.H. Global warming potential of carbon dioxide emissions from biomass stored in the Anthroposphere and used for bioenergy at end of life. J. Ind. Ecol. 2012, 17, 20–30. [Google Scholar] [CrossRef]

- Bates, L.; Jones, B.; Marland, E.; Marland, G.; Ruseva, T.; Kowalczyk, T.; Hoyle, J. Accounting for harvested wood products in a forest offset program: Lessons from California. J. For. Econ. 2017, 27, 50–59. [Google Scholar] [CrossRef]

- Li, L.; Wei, X.; Zhao, J.; Hayes, D.; Daigneualt, A.; Weiskittel, A.; Kizha, A.R.; O’Neill, S.R. Technological advancement expands the carbon storage in harvested wood products in Maine, USA. Biomass Bioenergy 2022, 161, 457. [Google Scholar] [CrossRef]

- Dymond, C.C. Forest carbon in North America: Annual storage and emissions from British Columbia’s harvest, 1965–2065. Carbon Balance Manag. 2012, 7, 8. [Google Scholar] [CrossRef]

- Athena Sustainable Materials Institute. Minnesota Demolition Survey: Phase Two Report, Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2004.

- Winistorfer P, Chen Z, Lippke B, Stevens N: Energy consumption and greenhouse gas emissions related to the use, maintenance and disposal of a residential structure. Wood Fiber Sci. 2005, 37, 128–139.

- Haapio, A.; Viitaniemi, P. Environmental effect of structural solutions and building materials to a building. Environ. Impact Assess Rev. 2008, 28, 587–600. [Google Scholar] [CrossRef]

- Wiseman, A. Durability Guidelines for Building Wall Envelopes; Public Works & Government Services Canada: Ottawa, ON, Canada, 1997. [Google Scholar]

- Werner, F.; Richter, K. Wooden building products in comparative LCA: A literature review. Int. J. Life Cycle Assess 2007, 12, 470–479. [Google Scholar] [CrossRef]

- Australian Building Codes Board. Durability in Buildings; Australian Building Codes Board: Canberra, Australia, 2006. [Google Scholar]

- Lstiburek, J. Increasing the durability of building constructions. Build Sci. Digest 2006, 144, 1–24. [Google Scholar]

- Forster, E.J.; Healey, J.R.; Dymond, C.; Styles, D. Commercial afforestation can deliver effective climate change mitigation under multiple decarbonization pathways. Nat. Commun. 2021, 12, 3831. [Google Scholar] [CrossRef] [PubMed]

| Country/ Region | Reference | HWP Category | Half-Life in Use (Years) | Fraction Loss Each Year (ln(2)/Half-Life) |

|---|---|---|---|---|

| Defaults | IPCC 2003 [39] | Saw wood | 35 | 0.0198 |

| Veneer, plywood, structural panels | 30 | 0.0231 | ||

| Non-structural panels | 20 | 0.0347 | ||

| Paper | 2 | 0.3466 | ||

| Finland | Pingoud et al., 2001 [47] | Saw wood and plywood (based on change in inventory of products) | 30 | 0.0231 |

| Finland | Karjalainen et al., 1994 [36] | Saw wood and plywood average | 50 | 0.0139 |

| Paper from mechanical pulp, average | 7 | 0.0990 | ||

| Paper from chemical pulp, average | 5.3 | 0.1308 | ||

| Finland | Pingoud et al., 1996 [48] | Average for paper | 1.8 | 0.3851 |

| Newsprint, household, sanitary paper | 0.5 | 1.3863 | ||

| Linerboard, fluting and folding boxboard | 1 | 0.6931 | ||

| 80% of printing and writing paper | 1 | 0.6931 | ||

| 20% of printing and writing paper | 10 | 0.0693 | ||

| Netherlands | Nabuurs 1996 [49] | Paper | 2 | 0.3466 |

| Packing wood | 3 | 0.2310 | ||

| Particleboard | 20 | 0.0347 | ||

| Saw wood average | 35 | 0.0198 | ||

| Saw wood spruce and poplar | 18 | 0.0385 | ||

| Saw wood oak and beech | 45 | 0.0154 | ||

| United States | Skog and Nicholson 2000 [50] | Saw wood | 40 | 0.0173 |

| Structural panels | 45 | 0.0154 | ||

| Non structural panels | 23 | 0.0301 | ||

| Paper (free sheet) | 6 | 0.1155 | ||

| Other paper | 1 | 0.6931 |

| End Use or Product | Half-Life (Years) | |

|---|---|---|

| Smith et al. (2006) [58] | Murray et al. (2024) [59] | |

| New residential construction | ||

| Single family | 100 | 87.8 |

| Multi-family | 70 | 53.7 |

| Mobile homes | 12 | 12 |

| Residential upkeep and improvement | 30 | 30 |

| New non-residential construction | ||

| All except railroads | 67 | 67 |

| Railroad ties | 12 | 12 |

| Railcar repair | 12 | 12 |

| Manufacturing | ||

| Household furniture | 30 | 30 |

| Commercial furniture | 30 | 30 |

| Other products | 12 | 12 |

| Shipping (wooden containers, pallets, dunnage) | 6 | 6 |

| Other uses for lumber and products | 12 | 12 |

| Solid wood exports | 12 | 12 |

| Paper | 2.6 | 2.6 |

| Wood Product | Calculated From | Year at Which 50% of Stock Remains (Half-Life) |

|---|---|---|

| Softwood lumber | Many categories of wood with % in use and specific half-lives | 35 |

| Hardwood lumber | Several categories of wood with % in use and half-lives | 13 |

| Softwood plywood | Typical applications | 38 |

| OSB | Typical applications | 60 |

| Non-structural panels | Typical applications | 26 |

| Miscellaneous products | As per [58], Table 3 | 12 |

| Paper | With assumed HL of 2.6 but 48% recovery for recycling and 70% fibre retention during recycling | 4 |

| Oak Product | Year of Maximum Decay | 95% Decay Period | Gamma Parameters | |

|---|---|---|---|---|

| k | θ | |||

| Waste, bark, fuel | 2 | 18 | 1.305 | 4.918 |

| Pulpwood | 1 | 5 | 1.418 | 1.196 |

| Particleboard | 15 | 40 | 3.676 | 5.419 |

| Pallet, packaging | 2 | 5 | 3.196 | 0.683 |

| Fencing | 40 | 80 | 6.662 | 6.976 |

| Construction | 150 | 300 | 6.740 | 26.045 |

| Mining | 40 | 1000 | 1.128 | 308.594 |

| HWP Type | Half-Life Range (Years) | Half-Life (Individual Values from Each Source) | Average (Individual Values if Used) | Sources |

|---|---|---|---|---|

| Sawnwood and plywood | 27.7 to 52 | 35 [6] | [6] | |

| 36, 48.8 ([87] ~ from SI) | [87] | |||

| Mean 31.4 [87] | ||||

| 30 [36] ~ | [36] | |||

| 48.6 [47] * | 31, 39, 53.8 [47] | [47] | ||

| 30 [50] ~ | [50] | |||

| 27.7, 34.7, 41.6, 42.3, 43.7, 49.2, 52 [90] * | 40, 50, 60, 61, 63, 71, 75 [90] | [90] | ||

| Panels and boards | 0.7 to 45 | 25 [6] | [6] | |

| [50] ** | [50] | |||

| 20 [51] | [51] | |||

| 9.7 [21] * | 14 [21] | [21] | ||

| 0.7, 3.5, 7, 17.3, 20.8 [21] * | 1, 5, 10, 25, 30 [21] | |||

| Paper | 0.5 to 10 | 2 [6] | [6] | |

| 4 [36] | [36] | |||

| [47] ** | [47] | |||

| 1, 6 [50] | [50] | |||

| 2 [51] | [51] | |||

| Some specific HWPs | ||||

| Packaging and pallets | 0.06 to 6.2 | 1.0, 1.6 [87] | [87] | |

| Mean 1.5 [87] | ||||

| 6 [50] | [50] | |||

| 3 [51] | [51] | |||

| 6 [91] ** | [91] | |||

| Furniture | 8.7 to 30 | 3.5, 6.9, 17 [87] | [87] | |

| Mean 8.8 [87] | ||||

| 30 [50] | [50] | |||

| 35 [91] ** | [91] | |||

| Doors and window frames | 6.9 to 45.1 | [90] ** | [90] | |

| 20, 35, 40 [92] | [92] | |||

| 38.8 to 45.1 [88] * | 56 to 65; | |||

| [88] ~ | 68 to 80; | |||

| 71 to 83 [88] | [88] | |||

| 27.4, 32.4 [89] * | 39.6, 46.7 [89] | [89] | ||

| Flooring | 20.8 to 34.7 | 20.8 [87] | [87] | |

| 44 [86] | [86] | |||

| Exterior cladding and terrace | 6.9 to 15.9 | 6.9 and 15.9 [93] * | 10 and 23 decking [93] | [93] |

| [93] ~ | 50 to 60 years cladding [93] | |||

| Insulation | 27.7 to 42 | 20.8 [90] ~ | 30 [90] ~ | [90] |

| 27.7, 31.2, 34.7 [90] * | 40, 45, 50 [90] | |||

| HWP Type | First Order Decay | ||

|---|---|---|---|

| Decay Rate Tier 2 | Decay Rate Tier 3 | Half-Life | |

| Solidwood | 0.0231 | 30 | |

| Wood packaging | 0.5 | 1.386 | |

| Wood construction | 0.033 | 21 | |

| Wood furniture | 0.05 | 13.86 | |

| Wood other uses | 0.04 | 17.33 | |

| Paper and paperboard | 0.3466 | 2 | |

| Paper printing and writing | 0.1 | 6.93 | |

| Other paper and paperboard | 1.0 | 0.693 | |

| Exponential | Logistic | Normal | Log-Normal | Weibull | |

|---|---|---|---|---|---|

| Half-life (years) | 459 | 66 | 72 | 101 | 79 |

| Parameter a | - | 0.09555 | 22.60593 | 0.66116 | 3.14451 |

| Parameter b | - | - | - | - | 88.35761 |

| RSS | 0.02091 | 0.00644 | 0.00565 | 0.00449 | 0.00498 |

| Other | Paper | Fiberboard | Sawnwood | Plywood/Veneer Panels | |

|---|---|---|---|---|---|

| Year of max decay | 20 | 2 | 20 | 35 | 30 |

| 95% decay period | 50 | 5 | 40 | 150 | 75 |

| Shape | 4.124 | 3.196 | 6.557 | 2.151 | 4.161 |

| Scale | 6.242 | 0.683 | 3.509 | 29.982 | 9.334 |

| Source | [37] | [43] | [37] | [37] | [37] |

| HWP Type | Half-Life | References |

|---|---|---|

| Single family homes | 90 | [60,111,112] |

| Multifamily homes | 75 | [60,111,113,114] |

| Commercial buildings | 75 | [60,111,113,114] |

| Residential upkeep and moveable homes | 30 | [60,115,116,117] |

| Furniture and other manufacturing | 38 | [60,115,116,117] |

| Shipping | 2 | personal communication |

| Other | 38 | [60] |

| Paper | 2.5 | [60] |

| Category | Subcategory | Sub-Subcategory | Market Share (%) | Half-Life (Years) |

|---|---|---|---|---|

| Construction | Formwork | 7.27 | 0.75 | |

| Railroad ties | 0.19 | 20.8 | ||

| Fences | 1.50 | 16.0 | ||

| Poles and posts | 1.24 | 20.8 | ||

| Windows | 2.02 | 20.8 | ||

| Doors | 3.81 | 19.1 | ||

| Floors | 4.38 | 20.8 | ||

| Carpenter work | Glue laminated/cross laminated timber | 25.1 | 48.8 | |

| Wall elements | 1.93 | 48.8 | ||

| Stairs | 0.33 | 20.8 | ||

| Sauna cabinets | 0.06 | 16.0 | ||

| Floors | 1.84 | 20.8 | ||

| Wood-glass-constructions | 0.11 | 16.0 | ||

| Other wooden goods for construction | 5.38 | 36.0 | ||

| Other carpenter work | 1.99 | 36.0 | ||

| Barracks | 2.31 | 24.3 | ||

| Houses | 9.75 | 71.0 | ||

| Category half-life 31.4 years | ||||

| Furniture | Outdoor | 0.92 | 3.5 | |

| Office | 4.86 | 6.9 | ||

| Private | 3.61 | 17.0 | ||

| Category half-life 8.8 years | ||||

| Packaging | Boxes/other packaging | 3.67 | 1.0 | |

| Pallets | 17.68 | 1.6 | ||

| Category half-life 1.5 years | ||||

| Total | Total half-life 14.6 years | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spear, M.J.; Hart, J. Modelling Wood Product Service Lives and Residence Times for Biogenic Carbon in Harvested Wood Products: A Review of Half-Lives, Averages and Population Distributions. Forests 2025, 16, 1162. https://doi.org/10.3390/f16071162

Spear MJ, Hart J. Modelling Wood Product Service Lives and Residence Times for Biogenic Carbon in Harvested Wood Products: A Review of Half-Lives, Averages and Population Distributions. Forests. 2025; 16(7):1162. https://doi.org/10.3390/f16071162

Chicago/Turabian StyleSpear, Morwenna J., and Jim Hart. 2025. "Modelling Wood Product Service Lives and Residence Times for Biogenic Carbon in Harvested Wood Products: A Review of Half-Lives, Averages and Population Distributions" Forests 16, no. 7: 1162. https://doi.org/10.3390/f16071162

APA StyleSpear, M. J., & Hart, J. (2025). Modelling Wood Product Service Lives and Residence Times for Biogenic Carbon in Harvested Wood Products: A Review of Half-Lives, Averages and Population Distributions. Forests, 16(7), 1162. https://doi.org/10.3390/f16071162