Adding Value to Wood-Based Products: A Systematic Literature Review on Drivers

Abstract

1. Introduction

1.1. Added Value: A Theoretical Overview

1.2. Adding Value to Wood-Based Products

1.3. Research Questions

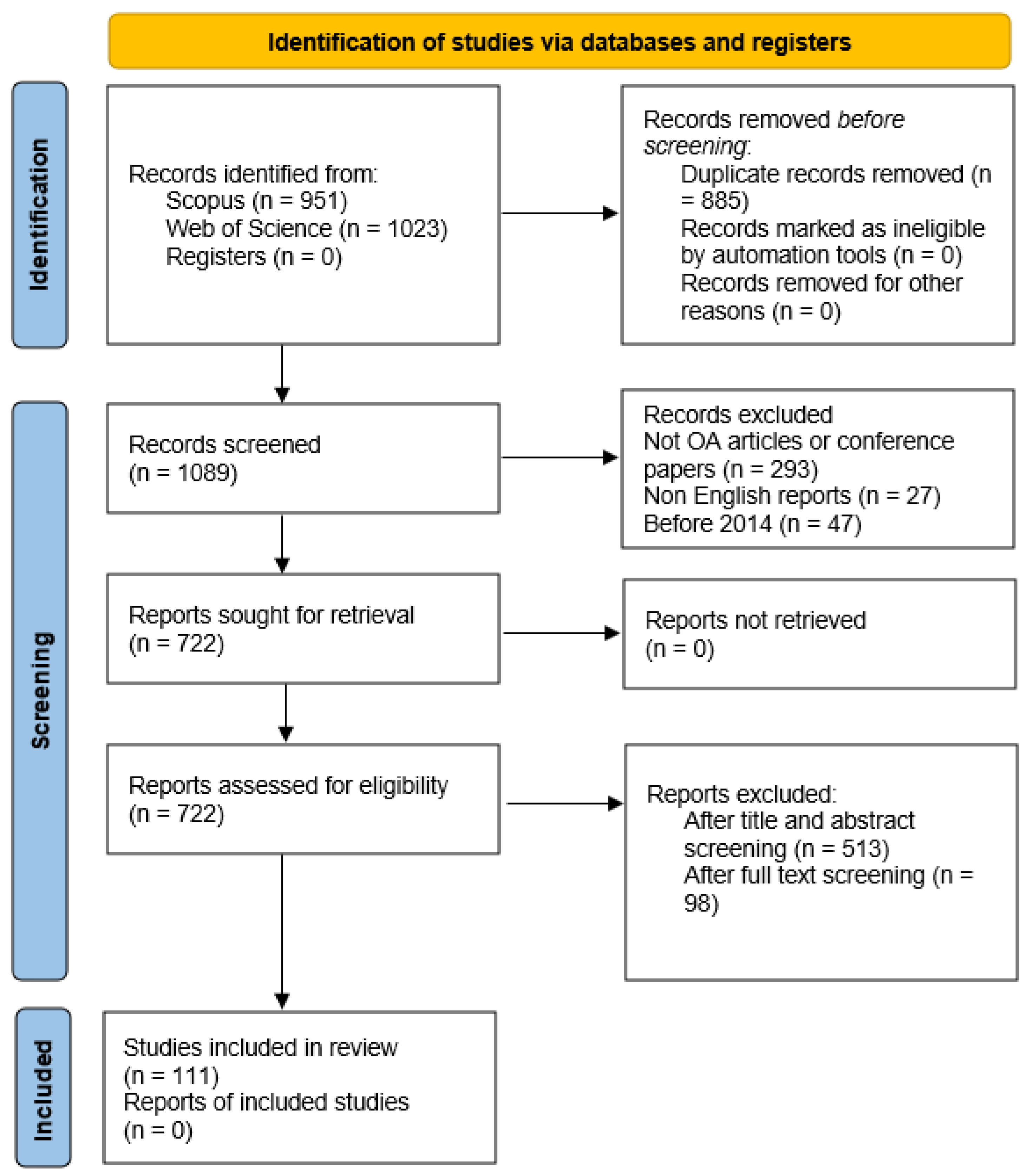

2. Materials and Methods

2.1. Search Strategy

2.2. Eligibility Criteria

2.3. Data Extraction

3. Results and Discussion

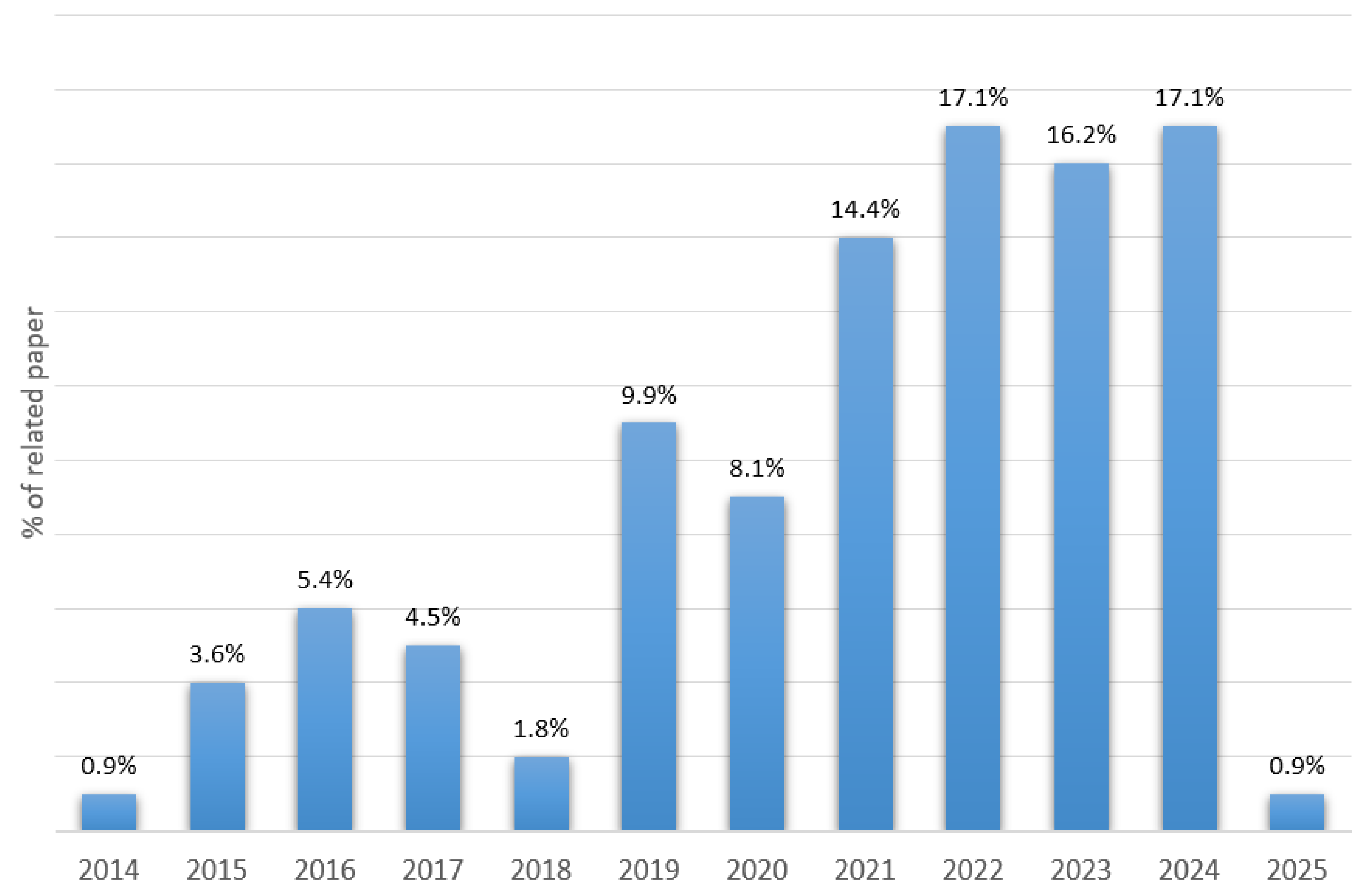

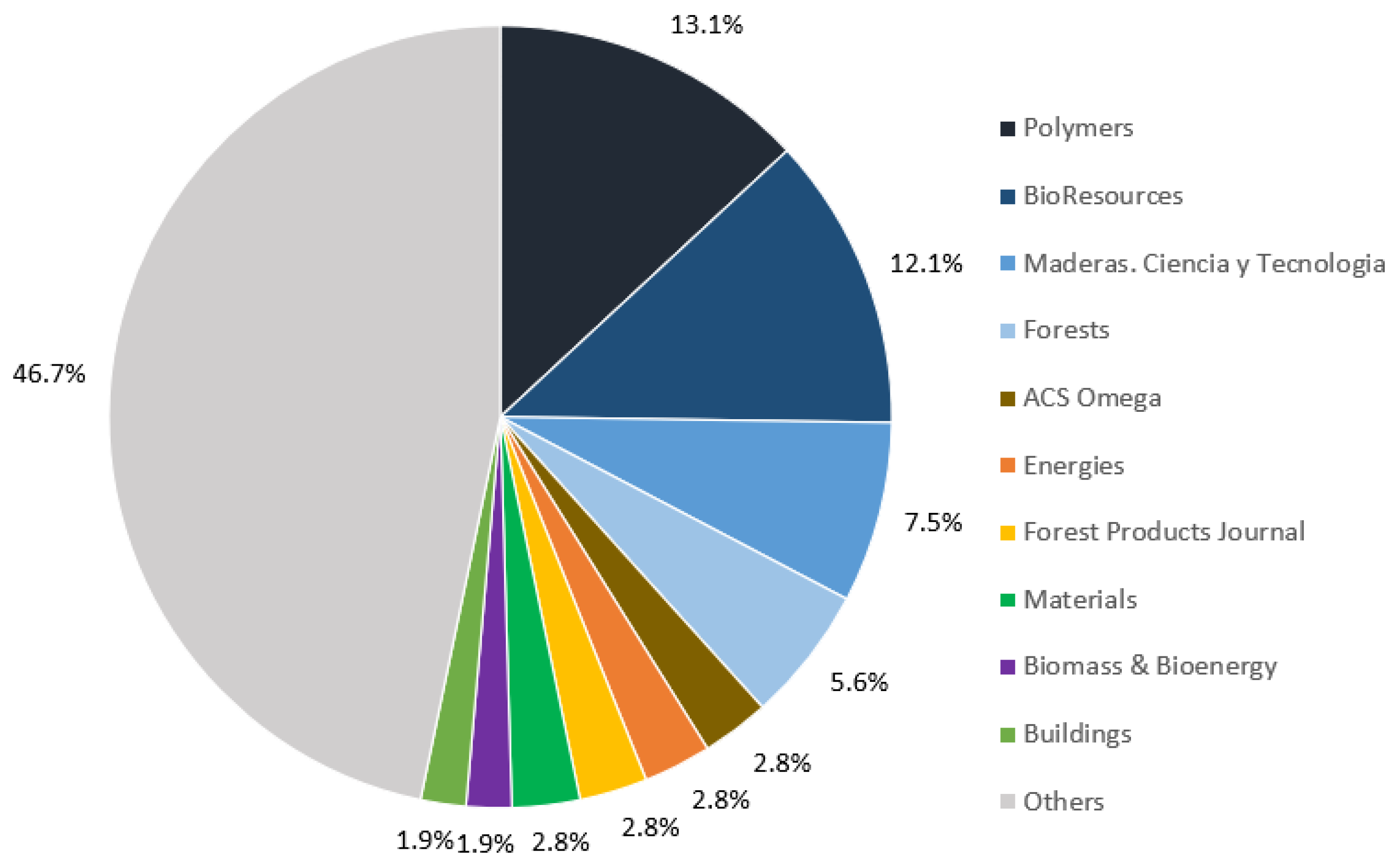

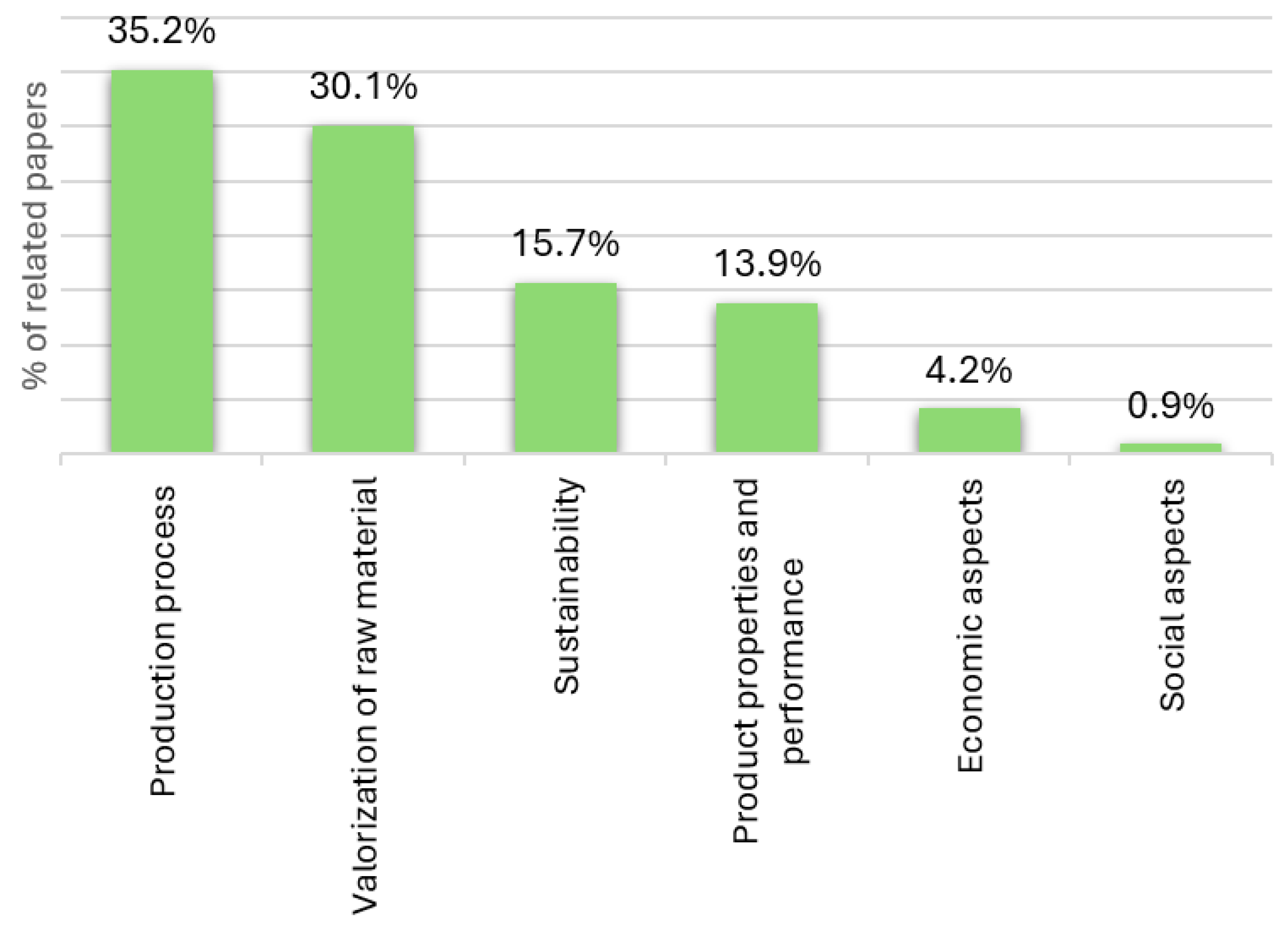

3.1. Descriptive Analysis of the Reviewed Studies

3.2. “Added Value” Only as a Label or a Defined Concept

3.3. Product Category and Methods of Adding Value

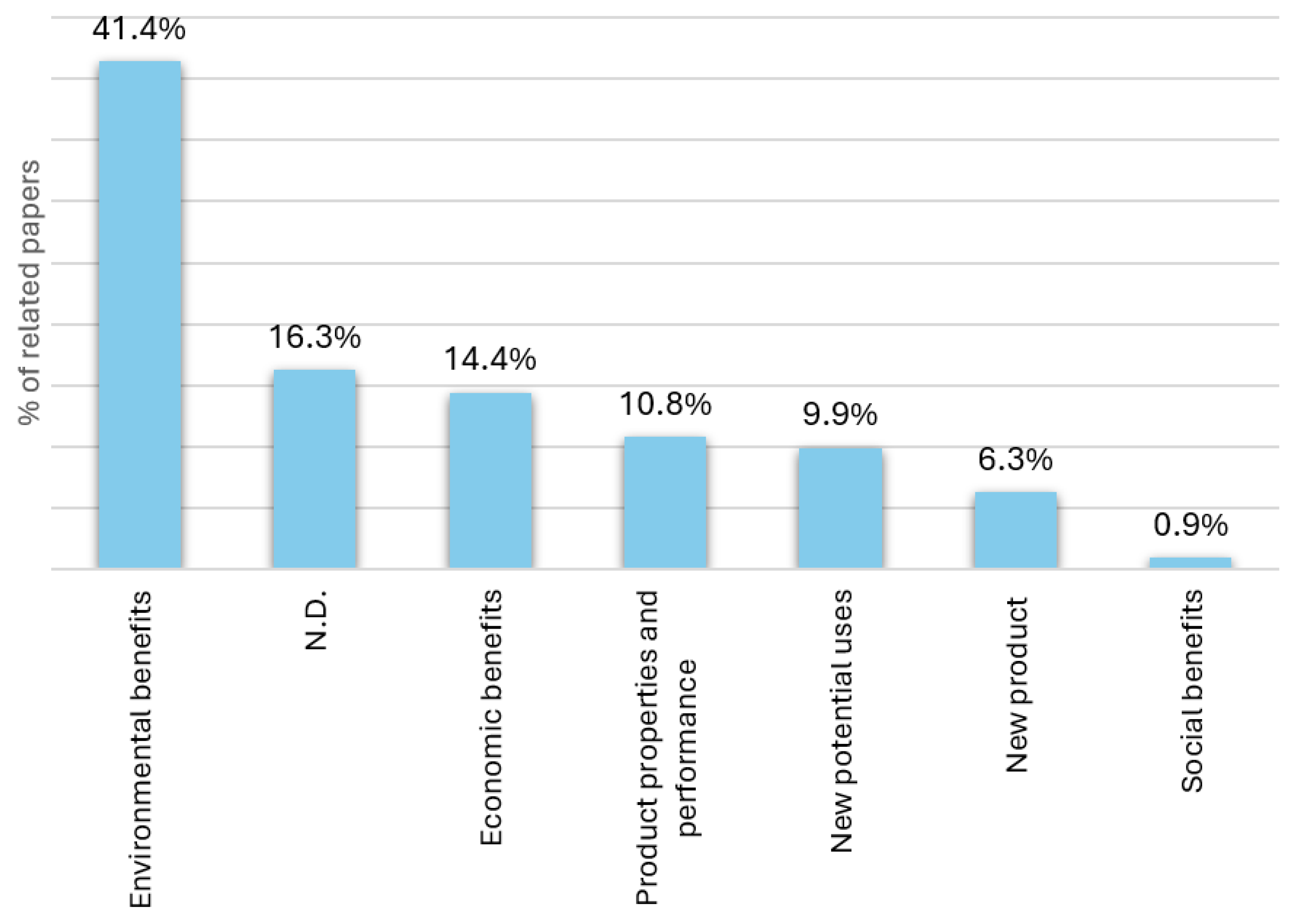

3.4. Outcomes of Adding Value

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| ID | Title | Type of Document | Country | Citation |

|---|---|---|---|---|

| 1 | Multi-Criteria Decision-Making Model for the Material Flow of Resonant Wood Production. | Scientific paper | Slovakia | [70] |

| 2 | Characterization of solid and vapor products from thermochemical conversion of municipal solid waste woody fractions. | Scientific paper | USA | [71] |

| 3 | Evaluation of OSB panels using residual wood with low contents of castor oil polyurethane resin. | Scientific paper | Brazil | [72] |

| 4 | Gluing characteristics of Papua New Guinea timber species for various non-structural applications. | Scientific paper | Australia | [73] |

| 5 | Bonding performance optimization of homogeneous and hybrid hardwood CLT using the Taguchi experimental design method. | Scientific paper | USA | [74] |

| 6 | Bonding quality of two lesser-used wood species Brachystegia spiciformis and Julbernardia globiflora from Mozambique. | Scientific paper | Brazil | [75] |

| 7 | Physicochemical characterization and thermal behavior of different wood species from the Amazon Biome. | Scientific paper | Brazil | [76] |

| 8 | Integrating offline object tracking, signal processing, and artificial intelligence to classify relevant events in sawmilling operations. | Scientific paper | Romania | [77] |

| 9 | Massaranduba sawdust: A potential source of charcoal and activated carbon. | Scientific paper | Brazil | [78] |

| 10 | Influence of coupling agent in compatibility of post-consumer HDPE in thermoplastic composites reinforced with eucalyptus fiber | Scientific paper | Brazil | [65] |

| 11 | Rendering wood veneers flexible and electrically conductive through delignification and electroless Ni plating. | Scientific paper | China | [79] |

| 12 | Visual detection application of lightweight convolution and deep residual networks in wood production. | Scientific paper | China | [80] |

| 13 | Study on the dyeing and fastness properties of ash veneer with acid dyes. | Scientific paper | South Korea | [81] |

| 14 | Some properties of wood plastic composites made from rubberwood, recycled plastic and silica. | Scientific paper | Thailand | [82] |

| 15 | assessment of the conversion of biomass and industrial waste products to activated carbon. | Scientific paper | USA | [83] |

| 16 | Anatomical characterization of black wattle wood for the pulp and paper production. | Scientific paper | Brazil | [84] |

| 17 | Acoustic and strength characterization of particleboard and micronized rubber powder composites. | Scientific paper | USA | [85] |

| 18 | Fabrication of PVA–Silica sol wood composites via delignification and freezing pretreatment. | Scientific paper | China | [86] |

| 19 | The influence of fly ash on the mechanical properties of water immersed all waste composites. | Scientific paper | Romania | [87] |

| 20 | Decision-making model for the specification of wood as an input for the production of wooden musical instruments. | Scientific paper | Slovakia | [88] |

| 21 | Analysis of wood products from an added value perspective: The Uruguayan forestry case. | Scientific paper | Uruguay | [51] |

| 22 | Some properties of linoleum and wood laminated flooring panels with magnesium substrate. | Scientific paper | Turkey | [89] |

| 23 | Strong and durable wood designed by cell wall bulking combined with cell lumen filling. | Scientific paper | China | [90] |

| 24 | Influence of age and trunk positions on physicomechanical properties of Anthocleista grandiflora Gilg wood. | Scientific paper | Ghana | [91] |

| 25 | Heat treatment of Tunisian soft wood species: Effect on the durability, chemical modifications and mechanical properties. | Scientific paper | Tunisia | [92] |

| 26 | Financial analysis of innovative wood products and carbon finance to support forest restoration in California. | Scientific paper | USA | [93] |

| 27 | Particleboards produced with different proportions of Hevea brasiliensis: Residual wood valorization in higher value added products. | Scientific paper | Brazil | [94] |

| 28 | Are relational capital and marketing important? The case of the wood sector of Galicia (Spain) and Portugal. | Scientific paper | Spain | [95] |

| 29 | Cross-laminated timber rocking walls with slip-friction connections. | Scientific paper | USA | [96] |

| 30 | Physical and mechanical properties of eco-friendly composites made from wood dust and recycled polystyrene. | Scientific paper | Greece | [97] |

| 31 | Can structural timber foster short procurement chains within Mediterranean forests? A research case in Sardinia. | Scientific paper | Italy | [98] |

| 32 | A study on properties of charcoal producing from alien tree species: Cinnamomum burmannii. | Scientific paper | Taiwan | [99] |

| 33 | Acrylic resin filling cell lumen enabled laminated poplar veneer lumber as structural building material. | Scientific paper | China | [100] |

| 34 | Board assignment heuristics for nail laminated out-of-grade timber. | Scientific paper | Australia | [101] |

| 35 | Structural properties of commercial australian plantation hardwood CLT. | Scientific paper | Australia | [102] |

| 36 | Characterization of the wood properties of Cedrelinga cateniformis as substitute for timbers used for window manufacturing and outdoor applications. | Scientific paper | Germany | [103] |

| 37 | Effect of microwave pretreatment on permeability and drying properties of wood. | Scientific paper | China | [104] |

| 38 | Ex-ante eco-efficiency assessment of dendromass production: conception and experiences of an innovation project. | Scientific paper | Austria | [105] |

| 39 | Effects of heat treatment on the color change and dimensional stability of Gmelina arborea and Melia azedarach woods. | Proceedings paper | Indonesia | [106] |

| 40 | Color change and consumer preferences towards color of heat-treated Korean white pine and royal paulownia woods. | Scientific paper | South Korea | [107] |

| 41 | Probing the effects of density on combustion performance of cement-bonded particleboard produced from wood processing residues. | Scientific paper | China | [108] |

| 42 | A new type of engineered wood product: Cross-laminated-thick veneers. | Scientific paper | China | [109] |

| 43 | Reducing waste to improve product quality in the wooden pallet production process by using lean six sigma approach in PT. | Proceedings paper | Indonesia | [110] |

| 44 | MOE distribution in visually graded Ponderosa Pine lumber harvested from restoration programs in Southern Oregon and Northern California. | Scientific paper | USA | [111] |

| 45 | Productivity and costs of forest cutting in a pine stand under two thinning methods. | Scientific paper | Brazil | [112] |

| 46 | The status, trend, and global position of China’s forestry industry: an anatomy based on the global value chain paradigm. | Scientific paper | China | [113] |

| 47 | Structural application of lightweight panels made of waste cardboard and beech veneer. | Scientific paper | Bulgaria | [114] |

| 48 | Changes of meranti, padauk, and merbau wood lignin during the ThermoWood Process. | Scientific paper | Slovakia | [115] |

| 49 | Preparation of water-based alkyl ketene dimer (AKD) nanoparticles and their use in superhydrophobic treatments of value-added teakwood products. | Scientific paper | Thailand | [116] |

| 50 | Some exploitation properties of wood plastic composites (WPC), based on high density polyethylene and timber industry waste. | Scientific paper | Latvia | [117] |

| 51 | Can small and medium-sized companies increase the value added from wood-based side streams?. | Scientific paper | Finland | [118] |

| 52 | Liquefaction behaviour of twelve tropical hardwood species in phenol. | Scientific paper | India | [119] |

| 53 | Value added and employment effects in Finland when wood fibre is substituted for plastic in food packaging-A case study. | Scientific paper | Finland | [120] |

| 54 | Strategic pathways for a bioeconomy with high value-added products: Lessons learnt from the Latvian forest sector. | Scientific paper | Latvia | [121] |

| 55 | Impact of thermal treatment on the properties of assacú (Hura crepitans L.) and murici (Byrsonima crispa A.Juss.) Amazon woods. | Scientific paper | Brazil | [59] |

| 56 | Properties and cost of natural rubber latex foam using biomass ash filler from agarwood pellets. | Scientific paper | Thailand | [122] |

| 57 | Effects of ultrasound pretreatment on microstructure and drying characteristics of Eucalyptus urophylla × E. grandis. | Scientific paper | China | [123] |

| 58 | Preparation and physicochemical properties of biochar from the pyrolysis of pruning waste of typical fruit tee in North China. | Scientific paper | China | [124] |

| 59 | Grading of recovered Norway spruce (Picea abies) timber for structural purposes. | Scientific paper | Spain | [125] |

| 60 | Sustainability impact assessment of forest bioenergy value chains in Quebec (Canada)-A ToSIA approach. | Scientific paper | Canada | [126] |

| 61 | Bending behaviour of cross-laminated timber stressed-skin panels manufactured with mountain pine (Pinus uncinata Ramond ex DC.). | Scientific paper | Spain | [127] |

| 62 | Increasing the calorific properties of sawdust waste from pellets by torrefaction. | Scientific paper | Romania | [128] |

| 63 | Effects and modeling of sawdust torrefaction for beech pellets. | Scientific paper | Romania | [129] |

| 64 | Effect of incorporation of lignin as bio-polyol on the performance of rigid lightweight wood–polyurethane composite foams. | Scientific paper | China | [130] |

| 65 | Turning trash to treasure: the influence of carbon waste source on the photothermal behaviour of plasmonic titanium carbide interfaces. | Scientific paper | Canada | [131] |

| 66 | Physico-mechanical properties of the wood of freijo, Cordia goeldiana (Boraginacea), produced in a multi-stratified agroforestry system in the southwestern Amazon. | Scientific paper | Brazil | [132] |

| 67 | Janka hardness evaluation of plantation-grown Eucalyptus nitens for engineered flooring applications. | Scientific paper | Australia | [133] |

| 68 | Evaluation of pressing time in the production of edge glued panel with adhesive polyurethane derived from castor oil. | Scientific paper | Brazil | [64] |

| 69 | Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: elaboration and performances evaluation. | Scientific paper | France | [134] |

| 70 | Properties of 3D-printed wood sawdust-reinforced PLA composites. | Scientific paper | Turkey | [135] |

| 71 | Using deciduous branch wood and conifer spindle wood to manufacture panels with transverse structure. | Scientific paper | Romania | [136] |

| 72 | Ecofriendly panels for building with eucalyptus sawdust and vegetal polyurethane resin: a mechanical evaluation. | Scientific paper | Brazil | [137] |

| 73 | Eucalyptus-based Glued Laminated Timber: evaluation and prediction of its properties by non-destructive techniques. | Scientific paper | Brazil | [138] |

| 74 | Characterisation of Rhizophora particleboard using bio-oil-based phenol formaldehyde (PF) resin. | Scientific paper | Malaysia | [56] |

| 75 | Impact of torrefaction process temperature on the energy content and chemical composition of stool tree (Alstonia congenisis Engl) woody biomass. | Scientific paper | Nigeria | [139] |

| 76 | Wood waste valorization: ethanol based organosolv as a promising recycling process. | Scientific paper | Italy | [57] |

| 77 | Strategy for the analysis of lignocellulosic biomass to select a viable transformation route in the Colombian context. | Scientific paper | Colombia | [140] |

| 78 | Characterization of birch wood residue after 2-furaldehyde obtaining, for further integration in biorefinery processing. | Scientific paper | Latvia | [141] |

| 79 | Residual birch wood lignocellulose after 2-furaldehyde production as a potential feedstock for obtaining fiber. | Scientific paper | Latvia | [142] |

| 80 | Quantitative analysis of feedstock structural properties can help to produce willow biochar with homogenous pore system. | Scientific paper | Finland | [143] |

| 81 | Success factors of wood veneer as an overlay material for panel-based furniture manufacturing in Malaysia. | Scientific paper | Malaysia | [144] |

| 82 | Valorization of hazardous organic solid wastes towards fuels and chemicals via fast (catalytic) pyrolysis. | Scientific paper | Greece | [145] |

| 83 | Valorization of heat-treated wood after service life through a cascading process for the production of lignocellulosic derivatives. | Scientific paper | Spain | [146] |

| 84 | Feasibility of bonding high-moisture-content wood using Nothofagus chilean species. | Scientific paper | Chile | [147] |

| 85 | Effect of heat treatment on colour changes of black alder and beech veneers. | Scientific paper | Romania | [148] |

| 86 | Glossiness evaluation of coated wood surfaces as function of varnish type and exposure to different conditions. | Scientific paper | Romania | [149] |

| 87 | Some coating properties of black alder wood as a function of varnish type and application method. | Scientific paper | Romania | [150] |

| 88 | Oak biomass in the form of wood, bark, brushwood, leaves and acorns in the production process of multifunctional biochar. | Scientific paper | Poland | [151] |

| 89 | Perceptions of producers of small wooden objects in Brazil’s central-west region about highlighted attributes of nine species from the Caatinga biome. | Scientific paper | Brazil | [53] |

| 90 | Characterization of pellets produced from extracted sawdust: effect of cooling conditions and binder addition on composition, mechanical and thermochemical properties. | Scientific paper | Finland | [152] |

| 91 | Mechanical property of 9 years old thinning of teak plantation in Thailand. | Proceedings paper | Greece | [153] |

| 92 | Novel biodegradable poly (lactic acid)/wood leachate composites: investigation of antibacterial, mechanical, morphological, and thermal properties. | Scientific paper | Iran | [154] |

| 93 | Effect of furfurylation on hierarchical porous structure of poplar wood. | Scientific paper | China | [155] |

| 94 | Evaluation of dimensional stability, surface roughness, colour, flexural properties and decay resistance of thermically modified Acacia auriculiformis. | Scientific paper | India | [156] |

| 95 | Structure-property relationships of hydrothermally treated western hemlock. | Scientific paper | USA | [58] |

| 96 | Developing and evaluating composites based on plantation eucalyptus rotary-cut veneer and high-density polyethylene film as novel building materials. | Scientific paper | China | [157] |

| 97 | Wood fibres as additives in mortars: A sustainable reinforcement. | Proceedings paper | Greece | [158] |

| 98 | Validation of sustainability benchmarking tool in the context of value-added wood products manufacturing activities. | Scientific paper | USA | [159] |

| 99 | The re-/up-cycling of wood waste in wood-polymer composites (WPCs) for common applications. | Scientific paper | Romania | [160] |

| 100 | Hygromorphic response dynamics of 3D-printed wood-PLA composite bilayer actuators. | Scientific paper | Slovenia | [66] |

| 101 | Collaboration and shared logic for creating value-added in three Finnish wooden multi-storey building projects. | Scientific paper | Finland | [161] |

| 102 | Supply network configuration archetypes for the circular exploitation of solid waste. | Scientific paper | Greece | [162] |

| 103 | Evaluation of some physico-mechanical properties and formaldehyde emission of ecological chipboards produced from annual residue plant stems. | Scientific paper | Turkey | [163] |

| 104 | Wood waste turned into value added products: Thermal plasticization by benzylation process. | Scientific paper | Turkey | [164] |

| 105 | Effect of hot-pressing temperature on the properties of eco-friendly fiberboard panels bonded with hydrolysis lignin and phenol–formaldehyde resin. | Scientific paper | Bulgaria | [165] |

| 106 | Characteristics of the waste wood biomass and its effect on the properties of wood sanding dust/recycled PP composite. | Scientific paper | Latvia | [166] |

| 107 | Regenerated waste tire powders as fillers for wood fiber composites. | Scientific paper | China | [167] |

| 108 | Construction of nanofibrillar networked wood aerogels derived from typical softwood and hardwood: a comparative study on the in situ formation mechanism of nanofibrillar networks. | Scientific paper | China | [168] |

| 109 | The characteristics of moisture and shrinkage of Eucalyptus urophylla × E. grandis wood during conventional drying. | Scientific paper | China | [169] |

| 110 | High-strength, thermally stable, and processable wood fiber/polyamide composites for engineering structural components. | Scientific paper | China | [170] |

| 111 | Technical and benefit evaluation of fruit-wood waste gasification heating coproduction of an activated carbon system. | Scientific paper | China | [52] |

References

- de Chernatony, L.; Harris, F.; Dall’Olmo Riley, F. Added Value: Its Nature, Roles and Sustainability. Eur. J. Mark. 2000, 34, 39–56. [Google Scholar] [CrossRef]

- Smith, A. An Inquiry into the Nature and Causes of the Wealth of Nations; Oxford University Press: Oxford, UK, 1776. [Google Scholar]

- Grönroos, C. On Value and Value Creation in Service: A Management Perspective. J. Creat. Value 2017, 3, 125–141. [Google Scholar] [CrossRef]

- Özdilek, Ü. Value Expectation, Expression and Estimation. J. Creat. Value 2016, 2, 245–256. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Oliver, R.L. Value as Excellence in the Consumption Experience. In Consumer Value; Holbrook, M., Ed.; Routledge: London, UK, 1999; p. 224. [Google Scholar]

- Ramsay, J. The Real Meaning of Value in Trading Relationships. Int. J. Oper. Prod. Manag. 2005, 25, 549–565. [Google Scholar] [CrossRef]

- Reina-Usuga, L.; Camino, F.; Gomez-Casero, G.; Jara Alba, C.A. Rural Tourism Initiatives and Their Relationship to Collaborative Governance and Perceived Value: A Review of Recent Research and Trends. J. Dest. Mark. Manag. 2024, 34, 100926. [Google Scholar] [CrossRef]

- Sheth, J.N.; Newman, B.I.; Gross, B.L. Why We Buy What We Buy: A Theory of Consumption Values. J. Bus. Res. 1991, 22, 159–170. [Google Scholar] [CrossRef]

- Sweeney, J.C.; Soutar, G.N. Consumer Perceived Value: The Development of a Multiple Item Scale. J. Retail. 2001, 77, 203–220. [Google Scholar] [CrossRef]

- Lind, P. Competitiveness through Increased Added Value: A Challenge for Developing Countries. J. Comp. Int. Manag. 2005, 8, 42–57. [Google Scholar]

- Forbes, N.; Wield, D. From Followers to Leaders: Managing Technology and Innovation in Newly Industrializing Countries; Routledge: London, UK; New York, NY, USA, 2002. [Google Scholar]

- Menger, C. Principles of Economics; Free Press: Glencoe, IL, USA, 1950. [Google Scholar]

- Levitt, T. Marketing Success Through Differentiation-of Anything; Harvard Business Review: Brighton, MI, USA, 1980. [Google Scholar]

- Zeithaml, V.A. Consumer Perceptions of Price, Quality, and Value: A Means-End Model and Synthesis of Evidence. J. Mark. 1988, 52, 2–22. [Google Scholar] [CrossRef]

- Naumann, E. Creating Customer Value: The Path to Sustainable Competitive Advantage; Thomson Executive Press: Cincinnati, OH, USA, 1995. [Google Scholar]

- Alhallaq, H.; Younas, M.; Kamal, S.; Champion, B. Exploring the Effects of Value Added Services on Perceived Value of Mobile Payment in the UK. In Proceedings of the Digital Transformation for a Sustainable Society in the 21st Century; Pappas, I.O., Mikalef, P., Dwivedi, Y.K., Jaccheri, L., Krogstie, J., Mäntymäki, M., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 25–36. [Google Scholar]

- Sweeney, J.C.; Soutar, G.N.; Johnson, L.W. The Role of Perceived Risk in the Quality-Value Relationship: A Study in a Retail Environment. J. Retail. 1999, 75, 77–105. [Google Scholar] [CrossRef]

- Bauer, R.A. Consumer Behavior as Risk Taking. In Marketing Classics: A Selection of Influential Articles; Enis, B.M., Cox, K.K., Eds.; Allyn&Bacon: Boston, MA, USA, 1969; pp. 119–127. [Google Scholar]

- Kähkönen, A.-K.; Lintukangas, K. Key Dimensions of Value Creation Ability of Supply Management. Int. J. Oper. Prod. Manag. 2018, 38, 979–996. [Google Scholar] [CrossRef]

- Brandenburger, A.M.; Stuart, H.W., Jr. Value-Based Business Strategy. J. Econ. Manag. Strategy 1996, 5, 5–24. [Google Scholar] [CrossRef]

- Stern, J.M.; Stewart III, G.B.; Chew Jr, D.H. Eva®: An Integrated Financial Management System. Eur. Financ. Manag. 1996, 2, 223–245. [Google Scholar] [CrossRef]

- Sirmon, D.G.; Hitt, M.A.; Ireland, R.D. Managing Firm Resources in Dynamic Environments to Create Value: Looking Inside the Black Box. Acad. Manage Rev. 2007, 32, 273–292. [Google Scholar] [CrossRef]

- De Martino, M. Value Creation for Sustainability in Port: Perspectives of Analysis and Future Research Directions. Sustainability 2021, 13, 12268. [Google Scholar] [CrossRef]

- Friedman, M. The Social Responsibility of Business Is to Increase Its Profits. In Corporate Ethics and Corporate Governance; Zimmerli, W.C., Holzinger, M., Richter, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 173–178. [Google Scholar]

- Friedman, M. A Friedman Doctrine—The Social Responsibility of Business Is to Increase Its Profits. The New York Times, 13 September 1970; 17. [Google Scholar]

- Freudenreich, B.; Lüdeke-Freund, F.; Schaltegger, S. A Stakeholder Theory Perspective on Business Models: Value Creation for Sustainability. J. Bus. Ethics 2020, 166, 3–18. [Google Scholar] [CrossRef]

- Freeman, R.E. Strategic Management: A Stakeholder Approach; Pitman: Boston, MA, USA, 1984. [Google Scholar]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Strategy: Techniques for Analyzing Industries and Competitors; Free Press: New York, NY, USA, 1980. [Google Scholar]

- Normann, R.; Ramírez, R. Designing Interactive Strategy: From Value Chain to Value Constellation, 1st ed.; Wiley: Chichester, UK, 1994. [Google Scholar]

- Porter, M.E.; Kramer, M.R. Creating Shared Value: How to Reinvent Capitalism—and Unleash a Wave of Innovation and Growth; Harvard Business Review: Brighton, MI, USA, 2011. [Google Scholar]

- Brewer, A.M. The Concept of Value: Symbolic Artefact or Useful Tool. In Handbook of Logistics and Supply Chain Management; Elsevier Ltd.: Amsterdam, The Netherlands, 2001; pp. 127–139. [Google Scholar]

- Goldaraz-Salamero, N.; Sierra-Perez, J.; Negro, F.; Zanuttini, R.; Blanc, S.; Brun, F. Integrated sustainability assessment of wood building products: The case of larch and chestnut cascading systems in Northern Italy. Sci. Total Environ. 2024, 951, 175601. [Google Scholar] [CrossRef]

- Macdonald, E.; Hubert, J. A review of the effects of silviculture on timber quality of Sitka spruce. Forestry 2002, 75, 107–138. [Google Scholar] [CrossRef]

- Zanuttini, R.; Bonzano, E.; Negro, F.; Oreglia, G.L.; Cremonini, C. Preliminary Assessment of Sweet Chestnut and Mixed Sweet Chestnut-Poplar OSB. Forests 2020, 11, 496. [Google Scholar] [CrossRef]

- Negro, F.; Espinoza, O.; Brunori, A.; Cremonini, C.; Zanuttini, R. Professionals’ Feedback on the PEFC Fair Supply Chain Project Activated in Italy after the “Vaia” Windstorm. Forests 2021, 12, 946. [Google Scholar] [CrossRef]

- Zubizarreta, M.; Arana-Landín, G.; Siguenza, W.; Cuadrado, J. Forest Certification and Its Impact on Business Management and Market Performance: The Key Role of Motivations. FPE 2024, 166, 103266. [Google Scholar] [CrossRef]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable Forest Operations (SFO): A New Paradigm in a Changing World and Climate. Sci. Total Environ. 2024, 634, 1385–1397. [Google Scholar] [CrossRef] [PubMed]

- Hartsch, F.; Dreger, F.A.; Englund, M.; Hoffart, E.; Rinkenauer, G.; Wagner, T.; Jaeger, D. Positive and Negative Work Practices of Forest Machine Operators: Interviews and Literature Analysis. Forests 2022, 13, 2153. [Google Scholar] [CrossRef]

- Landscheidt, S.; Kans, M. Evaluating factory of the future principles for the wood products industry: Three case studies. Procedia Manuf. 2019, 38, 1394–1401. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- EN ISO 9001; Quality Management Systems—Requirements. CEN: Brussels, Belgium, 2015.

- Shupe, T.F.; Vlosky, R.P. Why and How to Market Wood Products. LSUAgCenter. Available online: www.LSUAgCenter.com (accessed on 18 January 2025).

- Xiaoou, H.; Hansen, E. Marketing Organization and Implementation in Private U.S. Sawmilling Companies. BioBus 2017, 2, 1–13. [Google Scholar] [CrossRef]

- Calvano, S.; Negro, F.; Ruffinatto, F.; Zanuttini-Frank, D.; Zanuttini, R. Use and Sustainability of Wood in Acoustic Guitars: An Overview Based on the Global Market. Heliyon 2023, 9, e15218. [Google Scholar] [CrossRef]

- Mañes-Navarrete, D.; Redón-Santafé, M.; Paya-Zaforteza, I. Timber structures designed for disassembly: A cornerstone for sustainability in 21st century construction. J. Build. Eng. 2024, 96, 110619. [Google Scholar] [CrossRef]

- Bais-Moleman, A.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Nguyen, D.; Luedtke, J.; Nopens, M.; Krause, A. Production of wood-based panel from recycled wood resource: A literature review. Eur. J. Wood Wood Prod. 2023, 81, 557–570. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Br. Med. J. 2021, 372, 71. [Google Scholar] [CrossRef]

- Dieste, A.; Cabrera, M.N.; Clavijo, L.; Cassella, N. Analysis of wood products from an added value perspective: The Uruguayan forestry case. Maderas-Cienc. Tecnol. 2019, 21, 305–316. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, H.; Chen, D.; Zhou, J. Technical and benefit evaluation of fruit-wood waste gasification heating coproduction of an activated carbon system. ACS Omega 2021, 6, 633–641. [Google Scholar] [CrossRef]

- Seabra, C.C.; Angelo, H.; de Almeida, A.N.; Gonçalez, J.C.; de Paula, M.F.; da Silva Goulart, G.; Afonso, S.R.; de Souza, E.P.; Gontijo, A.B. Perceptions of producers of small wooden objects in Brazil’s central-west region about highlighted attributes of nine species from the Caatinga biome. For. Prod. J. 2022, 72, 74–84. [Google Scholar] [CrossRef]

- Kogabayev, T.; Maziliauskas, A. The definition and classification of innovation. Holistica 2017, 8, 59–72. [Google Scholar] [CrossRef]

- Kurzinski, S.; Crovella, P.; Kremer, P. Overview of Cross-Laminated Timber (CLT) and Timber Structure Standards Across the World. MTCJ 2022, 5, 1–13. [Google Scholar] [CrossRef]

- Omar, N.N.; Mustafa, I.S.; Abdullah, N.; Hashim, R. Characterisation of Rhizophora particleboard using bio-oil-based phenol formaldehyde (PF) resin. J. Oil Palm Res. 2017, 29, 66–73. [Google Scholar] [CrossRef]

- Pazzaglia, A.; Gelosia, M.; Giannoni, T.; Fabbrizi, G.; Nicolini, A.; Castellani, B. Wood waste valorization: Ethanol based organosolv as a promising recycling process. Waste Manag. 2023, 170, 75–81. [Google Scholar] [CrossRef]

- Song, K.; Ganguly, I.; Eastin, I.; Dou, C.; Bura, R.; Dichiara, A. Structure-property relationships of hydrothermally treated western hemlock. SN Appl. Sci. 2019, 1, 84. [Google Scholar] [CrossRef]

- Leite, A.; do Nascimento, C.; Cruz, I.; de Oliveira, M.; de Araújo, R.; do Nascimento, C.; Higuchi, N. Impact of thermal treatment on the properties of assacú (Hura crepitans L.) and murici (Byrsonima crispa A. Juss.) Amazon woods. N. Z. J. For. Sci. 2024, 54, 14. [Google Scholar] [CrossRef]

- Osabohien, R.; Jaffar, A.H.; Oluwayemisi, A.; Karakara, A.A. Global value chain participation, globalisation and sustainable development in ASEAN. Res. Glob. 2024, 9, 100253. [Google Scholar] [CrossRef]

- Janker, J.; Mann, S.; Rist, S. Social sustainability in agriculture—A system-based framework. J. Rural Stud. 2019, 65, 32–42. [Google Scholar] [CrossRef]

- Cui, L.; Yang, K.; Lei, Z.; Lim, M.K.; Hou, Y. Exploring stakeholder collaboration based on the sustainability factors affecting the sharing economy. Sustain. Prod. Consump. 2022, 30, 218–232. [Google Scholar] [CrossRef]

- Bruzzese, S.; Blanc, S.; Novelli, S.; Brun, F.A. Multicriteria Analysis to Support Natural Resource Governance: The Case of Chestnut Forests. Resources 2023, 12, 40. [Google Scholar] [CrossRef]

- Mölleken, R.E.; Trianoski, R.; Neto, S.C.; Pereira, C.R.; Iwakiri, S.; Azevedo, E.C. Evaluation of pressing time in the production of edge glued panel with adhesive polyurethane derived from castor oil. Appl. Adhes. Sci. 2016, 4, 9. [Google Scholar] [CrossRef][Green Version]

- Catto, A.L.; Stefani, B.V.; Ribeiro, V.F.; Santana, R.M.C. Influence of coupling agent in compatibility of post-consumer HDPE in thermoplastic composites reinforced with eucalyptus fiber. Mater. Res. 2014, 17, 203–209. [Google Scholar] [CrossRef]

- Tomec, D.; Straze, A.; Haider, A.; Kariz, M. Hygromorphic response dynamics of 3D-printed wood-PLA composite bilayer actuators. Polymers 2021, 13, 3209. [Google Scholar] [CrossRef]

- Negro, F.; Bergman, R. Carbon stored by furnishing wood-based products: An Italian case study. Maderas-Cienc. Tecnol. 2019, 21, 65–76. [Google Scholar] [CrossRef]

- Ranacher, L.; Wallin, I.; Valsta, L.; Kleinschmit, D. Social dimensions of a forest-based bioeconomy: A summary and synthesis. Ambio 2020, 49, 1851–1859. [Google Scholar] [CrossRef]

- Barata, J.; Kayser, I. Industry 5.0—Past, Present, and Near Future. Procedia Comput. Sci. 2023, 219, 778–788. [Google Scholar] [CrossRef]

- Alác, P.; Culík, M. Multi-Criteria Decision-Making Model for the Material Flow of Resonant Wood Production. Sustainability 2017, 9, 502. [Google Scholar] [CrossRef]

- Ayiania, M.; Terrell, E.; Dunsmoor, A.; Carbajal-Gamarra, F.M.; Garcia-Perez, M. Characterization of solid and vapor products from thermochemical conversion of municipal solid waste woody fractions. Waste Manag. 2019, 84, 277–285. [Google Scholar] [CrossRef]

- Barbirato, G.H.A.; Lopes, W.E.; Martins, R.H.B.; de Campos, C.I.; Fiorelli, J. Evaluation of OSB panels using residual wood with low contents of castor oil polyurethane resin. Maderas-Cienc. Tecnol. 2024, 26, 1–10. [Google Scholar] [CrossRef]

- Belleville, B.; Lancelot, K.; Galore, E.; Fehrmann, J.; Ozarska, B. Gluing characteristics of Papua New Guinea timber species for various non-structural applications. Maderas-Cienc. Tecnol. 2024, 26, 1–16. [Google Scholar] [CrossRef]

- Bencsik, B.; Denes, L.; Nkeuwa, W.N.; Hassler, C.C.; Norris, J.R.; McNeel, J.F. Bonding performance optimization of homogeneous and hybrid hardwood CLT using the Taguchi experimental design method. Constr. Build. Mater. 2024, 456, 139234. [Google Scholar] [CrossRef]

- Bila, N.F.; Trianoski, R.; Iwakiri, S.; Manhiça, A.A.; Rocha, M.P.D. Bonding quality of two lesser-used wood species Brachystegia spiciformis and Julbernardia globiflora from Mozambique. Maderas-Cienc. Tecnol. 2021, 23, 1–12. [Google Scholar] [CrossRef]

- Bimestre, T.A.; Silva, F.S.; Tuna, C.E.; dos Santos, J.C.; de Carvalho, J.A.; Canettieri, E.V. Physicochemical characterization and thermal behavior of different wood species from the Amazon Biome. Energies 2023, 16, 2257. [Google Scholar] [CrossRef]

- Borz, S.A.; Păun, M. Integrating offline object tracking, signal processing, and artificial intelligence to clas-sify relevant events in Sawmilling operations. Forests 2020, 11, 1333. [Google Scholar] [CrossRef]

- Castro, J.P.; Nobre, J.C.; Napoli, A.; Bianchi, M.L.; Moulin, J.C.; Chiou, B.S.; Williams, T.G.; Wood, D.F.; Avena-Bustillos, R.J.; Orts, W.J.; et al. Massaranduba sawdust: A potential source of charcoal and activated carbon. Polymers 2019, 11, 1276. [Google Scholar] [CrossRef]

- Chen, M.; Zhou, W.; Chen, J.; Xu, J. Rendering wood veneers flexible and electrically conductive through delignification and electroless Ni plating. Materials 2019, 12, 3198. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; He, Z.; Chao, B.; Guo, H. Visual detection application of lightweight convolution and deep residu-al networks in wood production. Wirel. Commun. Mob. Comput. 2022, 2022, 9465433. [Google Scholar] [CrossRef]

- Cho, H.; Lee, B.; Shim, E. Study on the dyeing and fastness properties of ash veneer with acid dyes. ACS Omega 2023, 8, 20561–20568. [Google Scholar] [CrossRef]

- Chotikhun, A.; Kittijaruwattana, J.; Arsyad, W.; Salca, E.; Hadi, Y.; Hiziroglu, S. Some properties of wood plastic composites made from rubberwood, recycled plastic and silica. Forests 2022, 13, 427. [Google Scholar] [CrossRef]

- Coker, E.; Lujan-Flores, X.; Donaldson, B.; Yilmaz, N.; Atmanli, A. An assessment of the conversion of bio-mass and industrial waste products to activated carbon. Energies 2023, 16, 1606. [Google Scholar] [CrossRef]

- Coldebella, R.; Giesbrecht, B.; Pedrazzi, C.; Machado, P.; Dalla Costa, H.; Vivian, M.; Denardi, L.; Gomes, C. Anatomical characterization of black wattle wood for the pulp and paper production. Cienc. Rural 2023, 53, e20210865. [Google Scholar] [CrossRef]

- Cole, J.; Street, J.; Blake, C. Acoustic and strength characterization of particleboard and micronized rubber powder composites. For. Prod. J. 2022, 72, 37–43. [Google Scholar] [CrossRef]

- Cong, R.; Cai, T.; Ge-Zhang, S.; Yang, H.; Zhang, C. Fabrication of PVA–Silica sol wood composites via del-ignification and freezing pretreatment. Polymers 2024, 16, 1949. [Google Scholar] [CrossRef]

- Cosnita, M.; Balas, M.; Cazan, C. The influence of fly ash on the mechanical properties of water immersed all waste composites. Polymers 2022, 14, 1957. [Google Scholar] [CrossRef]

- Culík, M.; Giertliová, B.; Aláč, P.; Hajdúchová, I. Decision-making model for the specification of wood as an input for the production of wooden musical instruments. Cent. Eur. For. J. 2023, 69, 69–76. [Google Scholar] [CrossRef]

- Dilik, T.; Hiziroglu, S. Some properties of linoleum and wood laminated flooring panels with magnesium substrate. BioResources 2015, 10, 1667–1674. [Google Scholar] [CrossRef][Green Version]

- Dong, Y.; Qi, Y.; Dong, X.; Li, Y. Strong and durable wood designed by cell wall bulking combined with cell lumen filling. Polymers 2024, 16, 93. [Google Scholar] [CrossRef] [PubMed]

- Dorwu, F.; Mensah, P.; Antwi, K.; de Melo, R.; Pimenta, A.; Paula, E.; Rusch, F. Influence of age and trunk positions on physicomechanical properties of Anthocleista grandiflora Gilg wood. Matéria Rio J. 2024, 29. [Google Scholar] [CrossRef]

- Elaieb, M.; Candelier, K.; Pétrissans, A.; Dumarçay, S.; Gérardin, P.; Pétrissans, M. Heat treatment of Tunisian soft wood species: Effect on the durability, chemical modifications and mechanical properties. Maderas-Cienc. Tecnol. 2016, 17, 699–710. [Google Scholar] [CrossRef]

- Elias, M.; Dees, J.; Cabiyo, B.; Saksa, P.; Sanchez, D. Financial analysis of innovative wood products and carbon finance to support forest restoration in California. For. Prod. J. 2023, 73, 31–42. [Google Scholar] [CrossRef]

- Faria, D.L.; Eugênio, T.M.C.; Lopes, D.E.; Protásio, T.P.; Mendes, L.M.; Junior, J.B.G. Particleboards pro-duced with different proportions of hevea brasiliensis: Residual wood valorization in higher value added products. Cienc. Agrotec. 2021, 45, e012420. [Google Scholar] [CrossRef]

- Fernandez Jardón, C.-M.; da Silva, A.F.C. Are relational capital and marketing important? The case of the wood sector of Galicia (Spain) and Portugal. Bus. Theory Pract. 2023, 24, 512–521. [Google Scholar] [CrossRef]

- Fitzgerald, D.; Miller, T.H.; Sinha, A.; Nairn, J.A. Cross-laminated timber rocking walls with slip-friction connections. Eng. Struct. 2020, 220, 110973. [Google Scholar] [CrossRef]

- Foti, D.; Voulgaridou, E.; Karastergiou, S.; Taghiyari, H.; Papadopoulos, A. Physical and mechanical proper-ties of eco-friendly composites made from wood dust and recycled polystyrene. J. Renew. Mater. 2022, 10, 75–88. [Google Scholar] [CrossRef]

- Fragiacomo, M.; Riu, R.; Scotti, R. Can structural timber foster short procurement chains within Mediterra-nean forests? A research case in Sardinia. SEEFOR-South-East Eur. For. 2015, 6, 107–117. [Google Scholar] [CrossRef]

- Fu, C.H.; Lin, J.C.; Liu, L.C.; Wang, S.H.; Lin, Y.J. A study on properties of charcoal producing from alien tree species: Cinnamomum burmannii. Forests 2022, 13, 1412. [Google Scholar] [CrossRef]

- Gao, X.; Liu, Y.; Qi, Y.; Gong, R.; Yao, F.; Luo, J.; Zhao, Y.; Dai, Y.; Wang, J.; Lian, C.; et al. Acrylic resin filling cell lumen enabled laminated poplar veneer lumber as structural building material. Polymers 2022, 14, 5277. [Google Scholar] [CrossRef] [PubMed]

- Gattas, J.; Reid, C.; Dakin, T.; Shanks, J.; McGavin, R. Board assignment heuristics for nail laminated out-of-grade timber. Aust. J. Civ. Eng. 2024, 1–14. [Google Scholar] [CrossRef]

- Gutierrez, M.; Ettelaei, A.; Kotlarewski, N.; Lee, M. Structural properties of commercial australian plantation hardwood CLT. Buildings 2023, 13, 208. [Google Scholar] [CrossRef]

- Haag, V.; Koch, G.; Melcher, E.; Welling, J. Characterization of the wood properties of Cedrelinga caten-iformis as substitute for timbers used for window manufacturing and outdoor applications. Maderas-Cienc. Tecnol. 2020, 22, 23–36. [Google Scholar] [CrossRef]

- He, X.; Xiong, X.; Xie, J.; Li, Y.; Wei, Y.; Quan, P.; Mou, Q.; Li, X. Effect of microwave pretreatment on perme-ability and drying properties of wood. BioResources 2017, 12, 3850–3863. [Google Scholar] [CrossRef]

- Hesser, F.; Groiss-Fürtner, D.; Woitsch, L.; Mair-Bauernfeind, C. Ex-ante eco-efficiency assessment of den-dromass production: Conception and experiences of an innovation project. Land 2023, 12, 839. [Google Scholar] [CrossRef]

- Hidayat, W.; Febrianto, F.; Purusatama, B.D.; Kim, N.H. Effects of heat treatment on the color change and dimensional stability of Gmelina arborea and Melia azedarach woods. E3S Web Conf. 2018, 68, 03010. [Google Scholar] [CrossRef]

- Hidayat, W.; Qi, Y.; Jang, J.H.; Park, B.H.; Banuwa, I.S.; Febrianto, F.; Kim, N.H. Color change and con-sumer preferences towards color of heat-treated Korean white pine and royal paulownia woods. J. Korean Wood Sci. Technol. 2017, 45, 213–222. [Google Scholar] [CrossRef]

- Hou, J.; Wang, S.; Jiang, Y.; Jin, Y.; Yu, Y. Probing the effects of density on combustion performance of ce-ment-bonded particleboard produced from wood processing residues. J. Adv. Concr. Technol. 2021, 19, 1016–1024. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, J.; Peng, H.; Chen, J.; Wang, Y.; Zhu, R.; Yu, W.; Zhang, Y. A new type of engineered wood product: Cross-laminated-thick veneers. Case Stud. Constr. Mater. 2024, 20, e02753. [Google Scholar] [CrossRef]

- Ishak, A.; Siregar, K.; Ginting, R.; Gustia, D. Reducing waste to improve product quality in the wooden pallet production process by using lean six sigma approach in PT. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1003, 012090. [Google Scholar] [CrossRef]

- Jahedi, S.; Muszynski, L.; Riggio, M.; Blengino, B.; Bhandari, S. MOE distribution in visually graded Pon-derosa Pine lumber harvested from restoration programs in Southern Oregon and Northern California. Wood Fiber Sci. 2022, 54, 90–98. [Google Scholar] [CrossRef]

- Jesús Vera Cabral, O.M.; da Silva Lopes, E.; Rodrigues, C.K.; Filho, A.F. Productivity and costs of forest cut-ting in a pine stand under two thinning methods. Floresta 2020, 50, 1883–1891. [Google Scholar] [CrossRef]

- Jiang, Y.; Su, H. The status, trend, and global position of China’s forestry industry: An anatomy based on the global value chain paradigm. Forests 2023, 14, 2040. [Google Scholar] [CrossRef]

- Jivkov, V.; Simeonova, R.; Antov, P.; Marinova, A.; Petrova, B.; Kristak, L. Structural application of light-weight panels made of waste cardboard and beech veneer. Materials 2021, 14, 5064. [Google Scholar] [CrossRef]

- Kacíková, D.; Kubovsky, I.; Gaff, M.; Kacík, F. Changes of meranti, padauk, and merbau wood lignin during the ThermoWood Process. Polymers 2021, 13, 993. [Google Scholar] [CrossRef] [PubMed]

- Kaewsaneha, C.; Roeurn, B.; Apiboon, C.; Opaprakasit, M.; Sreearunothai, P.; Opaprakasit, P. Preparation of water-based alkyl ketene dimer (AKD) nanoparticles and their use in superhydrophobic treatments of val-ue-added teakwood products. ACS Omega 2022, 7, 27400–27409. [Google Scholar] [CrossRef] [PubMed]

- Kajaks, J.; Zagorska, A.; Mežinskis, A. Some exploitation properties of wood plastic composites (WPC), based on high density polyethylene and timber industry waste. Mater. Sci. (Medžiagotyra) 2015, 21, 396–399. [Google Scholar] [CrossRef]

- Kuhmonen, I.; Näyhä, A.; Solaranta, M.; Keränen, J. Can small and medium-sized companies increase the value added from wood-based side streams? Silva. Fenn. 2024, 58, 23080. [Google Scholar] [CrossRef]

- Kumar, A.; Sethy, A.; Chauhan, S. Liquefaction behaviour of twelve tropical hardwood species in phenol. Maderas-Cienc. Tecnol. 2019, 20, 211–220. [Google Scholar] [CrossRef]

- Lahtinen, T.; Viitanen, J.; Mutanen, A.; Lintunen, J. Value added and employment effects in Finland when wood fibre is substituted for plastic in food packaging-A case study. Trees For. People 2025, 19, 100741. [Google Scholar] [CrossRef]

- Laktuka, K.; Kubule, A.; Vamza, I.; Rozakis, S.; Blumberga, D. Strategic pathways for a bioeconomy with high value-added products: Lessons learnt from the Latvian forest sector. Biomass Bioenerg. 2024, 190, 107400. [Google Scholar] [CrossRef]

- Limhengha, S.; Chueangchayaphan, N.; Karrila, S.; Madmaeroh, N.; Yangthong, H. Properties and cost of natural rubber latex foam using biomass ash filler from agarwood pellets. BioResources 2023, 18, 5585–5598. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Yang, L.; Wu, Z. Effects of ultrasound pretreatment on microstructure and drying char-acteristics of Eucalyptus urophylla × E. grandis. BioResources 2019, 13, 5953–5964. [Google Scholar] [CrossRef]

- Liu, X.; Ren, X.; Dong, J.; Wang, B.; Gao, J.; Wang, R.; Yao, J.; Cao, W. Preparation and physicochemical properties of biochar from the pyrolysis of pruning waste of typical fruit tee in North China. BioResources 2023, 18, 8536–8556. [Google Scholar] [CrossRef]

- Llana, D.; Iñiguez-González, G.; Plos, M.; Turk, G. Grading of recovered Norway spruce (Picea abies) timber for structural purposes. Constr. Build. Mater. 2023, 398, 132440. [Google Scholar] [CrossRef]

- Locoh, A.; Thiffault, É.; Barnabé, S. Sustainability impact assessment of forest bioenergy value chains in Quebec (Canada)-A ToSIA approach. Energies 2022, 15, 6676. [Google Scholar] [CrossRef]

- Luengo, E.; Gilabert-Sanz, S.; Oliver-Villanueva, J.V.; Osuna-Sequera, C.; Hermoso, E. Bending behaviour of cross-laminated timber stressed-skin panels manufactured with mountain pine (Pinus uncinata Ramond ex DC.). Wood Mater. Sci. Eng. 2024, 19, 906–917. [Google Scholar] [CrossRef]

- Lunguleasa, A.; Ayrilmis, N.; Spirchez, C.; Croitoru, C. Increasing the calorific properties of sawdust waste from pellets by torrefaction. BioResources 2019, 14, 7821–7839. [Google Scholar] [CrossRef]

- Lunguleasa, A.; Spirchez, C.; Griu, T. Effects and modeling of sawdust torrefaction for beech pellets. BioResources 2015, 10, 4726–4739. [Google Scholar] [CrossRef][Green Version]

- Luo, S.; Gao, L.; Guo, W. Effect of incorporation of lignin as bio-polyol on the performance of rigid light-weight wood–polyurethane composite foams. J. Wood Sci. 2020, 66, 23. [Google Scholar] [CrossRef]

- Margeson, M.J.; Atwood, M.; Dasog, M. Turning trash to treasure: The influence of carbon waste source on the photothermal behaviour of plasmonic titanium carbide interfaces. ChemPhysChem 2024, 26, e202400806. [Google Scholar] [CrossRef] [PubMed]

- Mascarenhas, A.; Sccoti, M.; de Melo, R.; Correa, F.; de Souza, E.; Pimenta, A. Physico-mechanical properties of the wood of freijo, Cordia goeldiana (Boraginacea), produced in a multi-stratified agroforestry system in the southwestern Amazon. Acta Amazon. 2021, 51, 171–180. [Google Scholar] [CrossRef]

- Millaniyage, K.; Kotlarewski, N.; Wallis, L.; Taoum, A.; Nolan, G. Janka hardness evaluation of plantation-grown Eucalyptus nitens for engineered flooring applications. Buildings 2022, 12, 1862. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crop. Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Narlioglu, N.; Salan, T.; Alma, M. Properties of 3D-printed wood sawdust-reinforced PLA composites. BioResources 2021, 16, 5467–5480. [Google Scholar] [CrossRef]

- Olarescu, A.M.; Lunguleasa, A.; Radulescu, L. Using deciduous branch wood and conifer spindle wood to manufacture panels with transverse structure. BioResources 2022, 17, 6445–6463. [Google Scholar] [CrossRef]

- Oliveira, J.J.; Simonassi, N.; Lopera, H.; Monteiro, S.; Vieira, C.; Lopes, F. Ecofriendly panels for building with eucalyptus sawdust and vegetal polyurethane resin: A mechanical evaluation. Case Stud. Constr. Mater. 2023, 18, e01839. [Google Scholar] [CrossRef]

- Oliveira, R.; Segundinho, P.; da Silva, J.; Gonçalves, F.; Lopes, D.; Silva, J.; Lopes, N.; Mastela, L.; Paes, J.; de Souza, C.; et al. Eucalyptus-based Glued Laminated Timber: Evaluation and prediction of its properties by non-destructive techniques. Forests 2024, 15, 1658. [Google Scholar] [CrossRef]

- Oyebode, W.A.; Ogunsuyi, H.O. Impact of torrefaction process temperature on the energy content and chemical composition of stool tree (Alstonia congenisis Engl) woody biomass. CRGSC 2021, 4, 100115. [Google Scholar] [CrossRef]

- Piedrahita-Rodríguez, S.; Alzate-Ramírez, A.F.; Baumberger, S.; Cézard, L.; Ortiz-Sánchez, M.; Escobar García, D.A.; Zetty Arenas, A.M.; Moustakas, K.; Cardona Alzate, C.A. Strategy for the analysis of lignocellulosic biomass to select a viable transformation route in the Colombian context. Enviro. Sci. Pollut. Res. 2024. [Google Scholar] [CrossRef] [PubMed]

- Puke, M.; Godina, D.; Kirpluks, M.; Brazdausks, P.; Rizikovs, J. Characterization of birch wood residue after 2-furaldehyde obtaining, for further integration in biorefinery processing. Polymers 2021, 13, 4366. [Google Scholar] [CrossRef] [PubMed]

- Puke, M.; Godina, D.; Kirpluks, M.; Rizikovs, J.; Brazdausks, P. Residual birch wood lignocellulose after 2-furaldehyde production as a potential feedstock for obtaining fiber. Polymers 2021, 13, 1816. [Google Scholar] [CrossRef]

- Rasa, K.; Viherä-Aarnio, A.; Rytkönen, P.; Hyväluoma, J.; Kaseva, J.; Suhonen, H.; Jyske, T. Quantitative analysis of feedstock structural properties can help to produce willow biochar with homogenous pore system. Ind. Crop. Prod. 2021, 166, 113475. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Ioras, F.; Ark, C.K.; Ab Latib, H. Success factors of wood veneer as an overlay material for panel-based furniture manufacturing in Malaysia. BioResources 2020, 15, 1311–1322. [Google Scholar] [CrossRef]

- Rekos, K.C.; Charisteidis, I.D.; Tzamos, E.; Palantzas, G.; Zouboulis, A.I.; Triantafyllidis, K.S. Valorization of hazardous organic solid wastes towards fuels and chemicals via fast (catalytic) pyrolysis. Sustain. Chem. 2022, 3, 91–111. [Google Scholar] [CrossRef]

- Robles, E.; Herrera, R.; De Hoyos Martínez, P.L.; Fernández Rodríguez, J.; Labidi, J. Valorization of heat-treated wood after service life through a cascading process for the production of lignocellulosic derivatives. Resour. Conserv. Recycl. 2021, 170, 105602. [Google Scholar] [CrossRef]

- Rosales, V.; Rodríguez-Grau, G.; Galarce, C.; Montero, C.; Alvarado, C.; Muñoz, L.; Pommier, R. Feasibility of bonding high-moisture-content wood using Nothofagus chilean species. Forests 2023, 14, 2386. [Google Scholar] [CrossRef]

- Salca, E.; Kobori, H.; Inagaki, T.; Kojima, Y.; Suzuki, S. Effect of heat treatment on colour changes of black alder and beech veneers. J. Wood Sci. 2016, 62, 297–304. [Google Scholar] [CrossRef]

- Salca, E.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness evaluation of coated wood surfaces as function of varnish type and exposure to different conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Salca, E.; Krystofiak, T.; Lis, B.; Mazela, B.; Proszyk, S. Some coating properties of black alder wood as a function of varnish type and application method. BioResources 2016, 11, 7580–7594. [Google Scholar] [CrossRef]

- Saletnik, B.; Saletnik, A.; Zagula, G.; Bajcar, M.; Puchalski, C. Oak biomass in the form of wood, bark, brushwood, leaves and acorns in the production process of multifunctional biochar. Molecules 2022, 27, 7191. [Google Scholar] [CrossRef]

- Sermyagina, E.; Martinez, C.; Lahti, J.; Nikku, M.; Mänttäri, M.; Kallioinen-Mänttäri, M.; Vakkilainen, E. Characterization of pellets produced from extracted sawdust: Effect of cooling conditions and binder addition on composition, mechanical and thermochemical properties. Biomass Bioenerg. 2022, 164, 106562. [Google Scholar] [CrossRef]

- Seviset, S.; Piromgran, T.; Saributr, U.; Porncharoen, R.; Raerai, K.; Charoensettasilp, S. Mechanical property of 9 years old thinning of teak plantation in Thailand. MATEC Web Conf. 2017, 95, 03004. [Google Scholar] [CrossRef]

- Shahavi, M.; Selakjani, P.; Abatari, M.; Antov, P.; Savov, V. Novel biodegradable poly (lactic acid)/wood leachate composites: Investigation of antibacterial, mechanical, morphological, and thermal properties. Polymers 2022, 14, 1227. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Jiang, P.; Guo, D.; Li, G.; Chu, F.; Yang, S. Effect of furfurylation on hierarchical porous structure of poplar wood. Polymers 2021, 13, 32. [Google Scholar] [CrossRef]

- Shukla, S. Evaluation of dimensional stability, surface roughness, colour, flexural properties and decay resistance of thermically modified Acacia auriculiformis. Maderas-Cienc. Tecnol. 2019, 21, 433–446. [Google Scholar] [CrossRef]

- Song, W.; Wei, W.; Ren, C.; Zhang, S. Developing and evaluating composites based on plantation eucalyptus rotary-cut veneer and high-density polyethylene film as novel building materials. BioResources 2016, 11, 3318–3331. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kampragkou, P.; Kamperidou, V. Wood fibres as additives in mortars: A sustainable reinforcement. IOP Conf. Ser. Earth Environ. Sci. 2023, 1196, 012067. [Google Scholar] [CrossRef]

- Tasdemir, C.; Gazo, R. Validation of sustainability benchmarking tool in the context of value-added wood products manufacturing activities. Sustainability 2019, 11, 2361. [Google Scholar] [CrossRef]

- Teaca, C.; Shahzad, A.; Duceac, I.; Tanasa, F. The re-/up-cycling of wood waste in wood-polymer composites (WPCs) for common applications. Polymers 2023, 15, 3467. [Google Scholar] [CrossRef]

- Toppinen, A.; Miilumki, N.; Vihemki, H.; Toivonen, R.; Lhtinen, K. Collaboration and shared logic for creating value-added in three Finnish wooden multi-storey building projects. Wood Mater. Sci. Eng. 2019, 14, 269–279. [Google Scholar] [CrossRef]

- Tsolakis, N.; Zissis, D.; Srai, J.S. Supply network configuration archetypes for the circular exploitation of solid waste. Int. J. Integr. Supply Manag. 2020, 13, 302–333. [Google Scholar] [CrossRef]

- Uğur, C.; Bektaş, I. Evaluation of some physico-mechanical properties and formaldehyde emission of ecological chipboards produced from annual residue plant stems. Drvna Industrija 2024, 75, 349–357. [Google Scholar] [CrossRef]

- Üner, B.; Köse, G.; Yürümez, Y.; Yalçın, Ö.Ü.; Akgül, M. Wood waste turned into value added products: Thermal plasticization by benzylation process. Drv. Ind. 2016, 67, 315–322. [Google Scholar] [CrossRef]

- Valchev, I.; Savov, V.; Yordanov, I.; Petrin, S.; Antov, P. Effect of hot-pressing temperature on the properties of eco-friendly fiberboard panels bonded with hydrolysis lignin and phenol–formaldehyde resin. Polymers 2024, 16, 1059. [Google Scholar] [CrossRef]

- Vitolina, S.; Shulga, G.; Neiberte, B.; Jaunslavietis, J.; Verovkins, A.; Betkers, T. Characteristics of the waste wood biomass and its effect on the properties of wood sanding dust/recycled PP composite. Polymers 2022, 14, 468. [Google Scholar] [CrossRef]

- Xu, X.; Tian, F.; Li, X. Regenerated waste tire powders as fillers for wood fiber composites. BioResources 2020, 15, 3029–3040. [Google Scholar] [CrossRef]

- Yan, W.; Qing, Y.; Li, Z.; Li, L.; Luo, S.; Wu, Y.; Chen, D.; Wu, Y.; Tian, C. Construction of nanofibrillar networked wood aerogels derived from typical softwood and hardwood: A comparative study on the in situ formation mechanism of nanofibrillar networks. Molecules 2024, 29, 938. [Google Scholar] [CrossRef]

- Yang, L.; Zheng, J.; Huang, N. The characteristics of moisture and shrinkage of Eucalyptus urophylla × E. grandis wood during conventional drying. Materials 2022, 15, 3386. [Google Scholar] [CrossRef] [PubMed]

- You, Z.; Wang, H.; Zhang, F.; Zhang, H.; Zou, C.; Zhou, Z.; Wang, Y.; Xiao, Z.; Liang, D.; Wang, Q.; et al. High-strength, thermally stable, and processable wood fiber/polyamide composites for engineering structural components. Adv. Sci. 2024, 12, 2408708. [Google Scholar] [CrossRef] [PubMed]

| Abbreviation | Terms |

|---|---|

| CLT | Cross-Laminated Timber |

| DfD | Designed for Disassembly |

| EVA | Economic Value Added |

| GLT | Glue-Laminated Timber |

| GVC | Global Value Chain |

| OSB | Oriented Strand Board |

| PICO | Population, Intervention, Comparison, and Outcome |

| PERVAL | Perceived value |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| SMEs | Small and medium-sized enterprises |

| RBV | Resource-based view |

| SFO | Sustainable Forest Operations |

| TCV | Theory of consumption values |

| WPC | Wood–plastic composites |

| W-PU | Wood–polyurethane |

| PICO Element | |

|---|---|

| Population (P) | Scientific papers on wood-based products |

| Intervention (I) | Elaboration of the concept of “added value”; innovative technologies or methods used to add value |

| Comparison (C) | “Added value” is mentioned but not elaborated |

| Outcome (O) | Definitions of the concept of “added value”; assessments of the different products studied and the approaches to adding value |

| Variables | Categories |

|---|---|

| ID, title, author(s), year of publication | N/A |

| Added value concept: label or elaborated | “Yes”, “No”, “Not explicitly” |

| Where value is added | “Wood-based product”, “Wood sector” |

| Wood-based products | “Biochar/Biomass”, “Packaging”, “Paper”, “Pellet”, “Solid wood”, “Wood extractives”, “GLT and CLT”, “Wood-based panel”, “Wood-based composite”, “Other products”, “N.D.—Not Determined” |

| Product category | “Structural”, “Not structural”, “Both”, “N.D.—Not Determined” |

| Methods used to add value | Production process: “Efficient silvicultural treatment”, “Alternative destination”, “Improving decision-making in production process” “Innovative production techniques”, “New product”, “Innovative pretreatment”, “Transformation of waste material” Valorisation of raw material: “Use of lesser-used woods”, “Use of local wood”, “Use of low quality wood”, “Use of secondary wood materials, “Use of waste material” Product technology: “Conferring new properties”, “Highlighting properties”, “Improvement of the properties” Sustainability: “Cascading use”, “LCA”, “Recycling”, “Substitution of over-exploited species”, “Use of alternative adhesives”, “Use of alternative varnishes”, “Use of local resources” Economic aspects: “Circular bioeconomy”, “Creation of short supply chains”, “Global value chain”, “Marketing and relational capital” Social aspects: “Collaboration and shared logic”, “Direct marketing and personal contact” |

| Aspects of added value | “Alternative destination”, “Conferring new properties”, “Economic benefits”, “Increased employment”, “New products”, “Quality/performance improvement”, “Sustainability” |

| Outcomes of adding value | “Economic benefits”, “Environmental benefits”, “New potential uses”, “New products”, “Product quality and performance”, “N.D.—Not Determined” |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calvano, S.; Negro, F.; Blanc, S.; Bruzzese, S.; Brun, F.; Zanuttini, R. Adding Value to Wood-Based Products: A Systematic Literature Review on Drivers. Forests 2025, 16, 590. https://doi.org/10.3390/f16040590

Calvano S, Negro F, Blanc S, Bruzzese S, Brun F, Zanuttini R. Adding Value to Wood-Based Products: A Systematic Literature Review on Drivers. Forests. 2025; 16(4):590. https://doi.org/10.3390/f16040590

Chicago/Turabian StyleCalvano, Silvana, Francesco Negro, Simone Blanc, Stefano Bruzzese, Filippo Brun, and Roberto Zanuttini. 2025. "Adding Value to Wood-Based Products: A Systematic Literature Review on Drivers" Forests 16, no. 4: 590. https://doi.org/10.3390/f16040590

APA StyleCalvano, S., Negro, F., Blanc, S., Bruzzese, S., Brun, F., & Zanuttini, R. (2025). Adding Value to Wood-Based Products: A Systematic Literature Review on Drivers. Forests, 16(4), 590. https://doi.org/10.3390/f16040590