Refining Carbon Balance Estimates of Harvested Wood Products: A Generalizable Tier-3 Production Approach for China

Abstract

1. Introduction

2. Materials and Methods

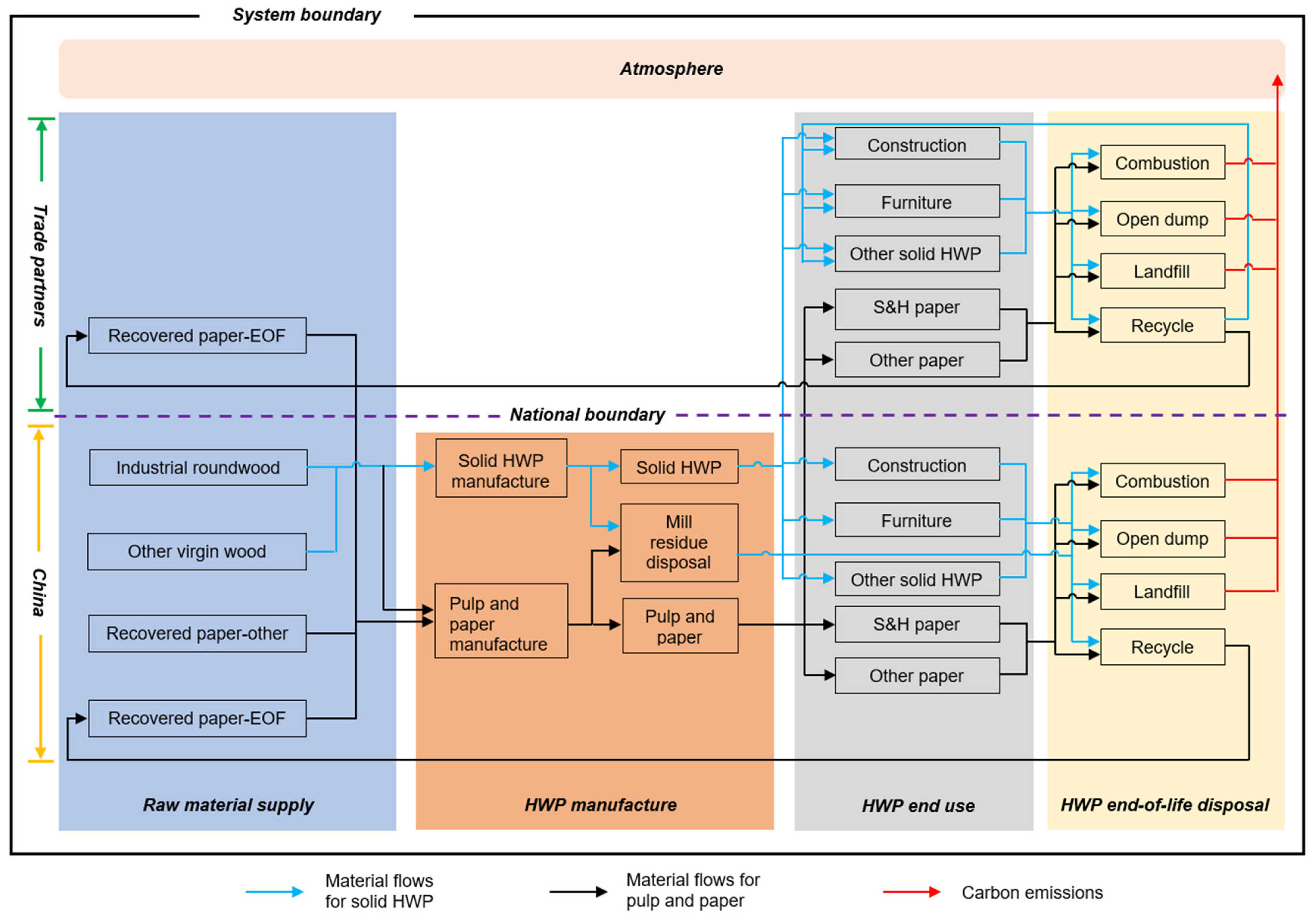

2.1. China-Specific Analytical Framework of Tier-3 Production Approach

2.1.1. Overall Analytical Framework

2.1.2. Raw Material Supply

2.1.3. Harvested Wood Product Manufacture

2.1.4. Harvested Wood Product End Use

2.1.5. Harvested Wood Product End-of-Life Disposal

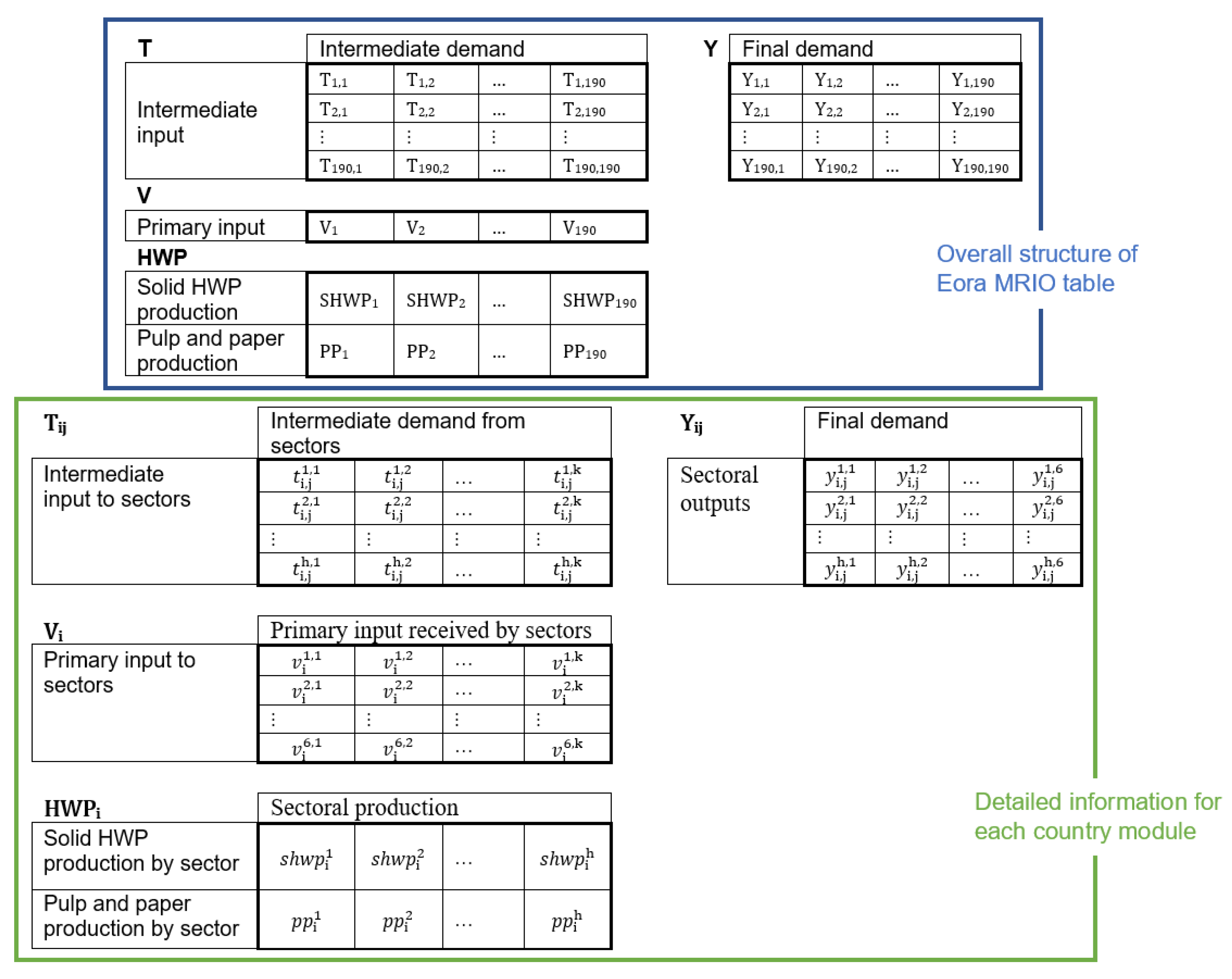

2.2. Using Eora Multi-Regional Input–Output Model to Allocate Harvested Wood Product End Uses

2.2.1. Linking Harvested Wood Product (HWP) Production and Consumption by an HWP-Extended Multi-Regional Input–Output Table

2.2.2. Modification of Eora Multi-Regional Input–Output Table to Exclude Virtual HWP Consumption

2.2.3. Estimating Harvested Wood Products Consumed by End Users

2.3. Estimating Biogenic Carbon Stocks and Emissions in the Life Cycle

2.3.1. Carbon Stocks of In-Use Harvested Wood Products

2.3.2. Carbon Stocks and Emissions of Landfills and Open Dumps (Or Stockpiles)

2.4. Sensitivity Analysis

2.5. Data Source

3. Results

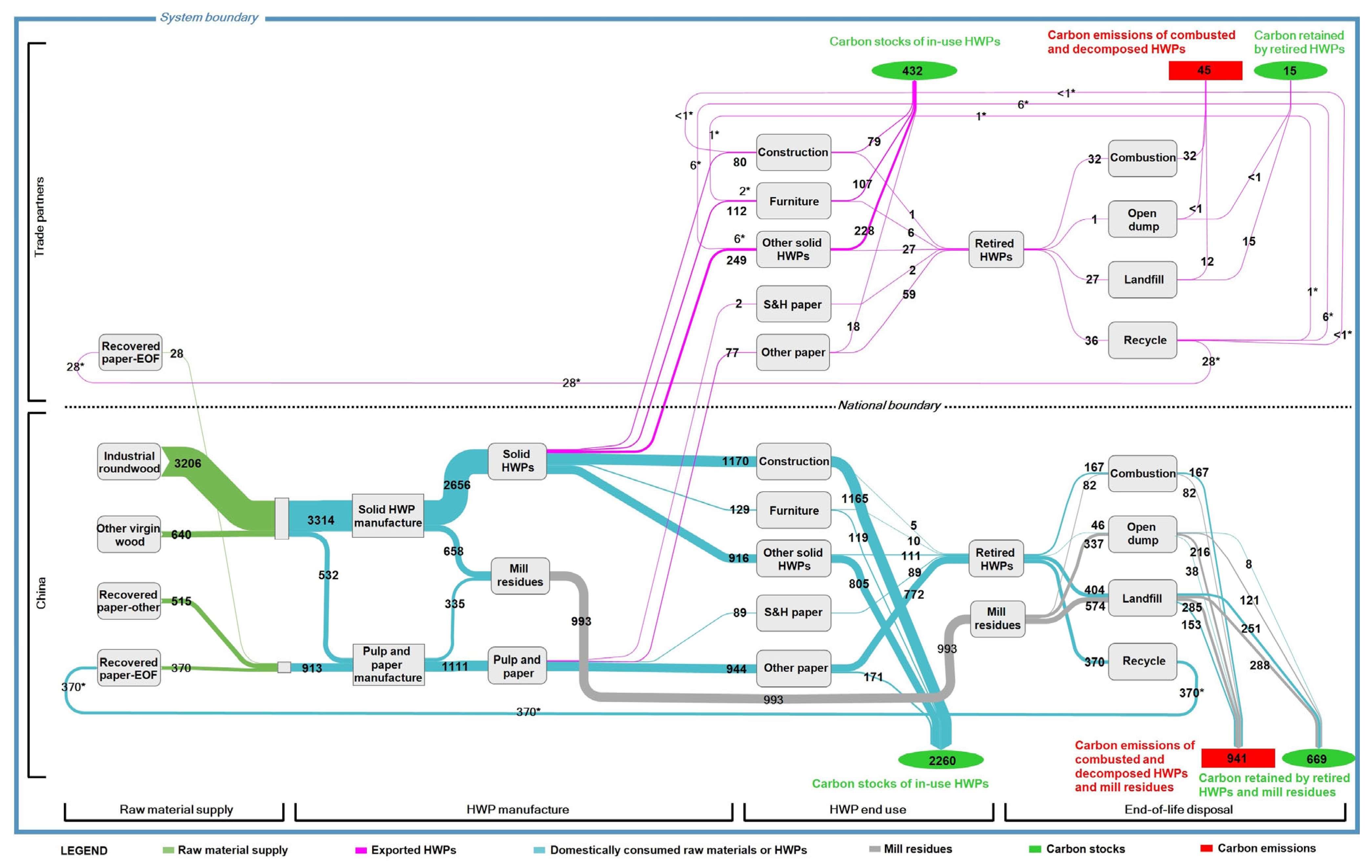

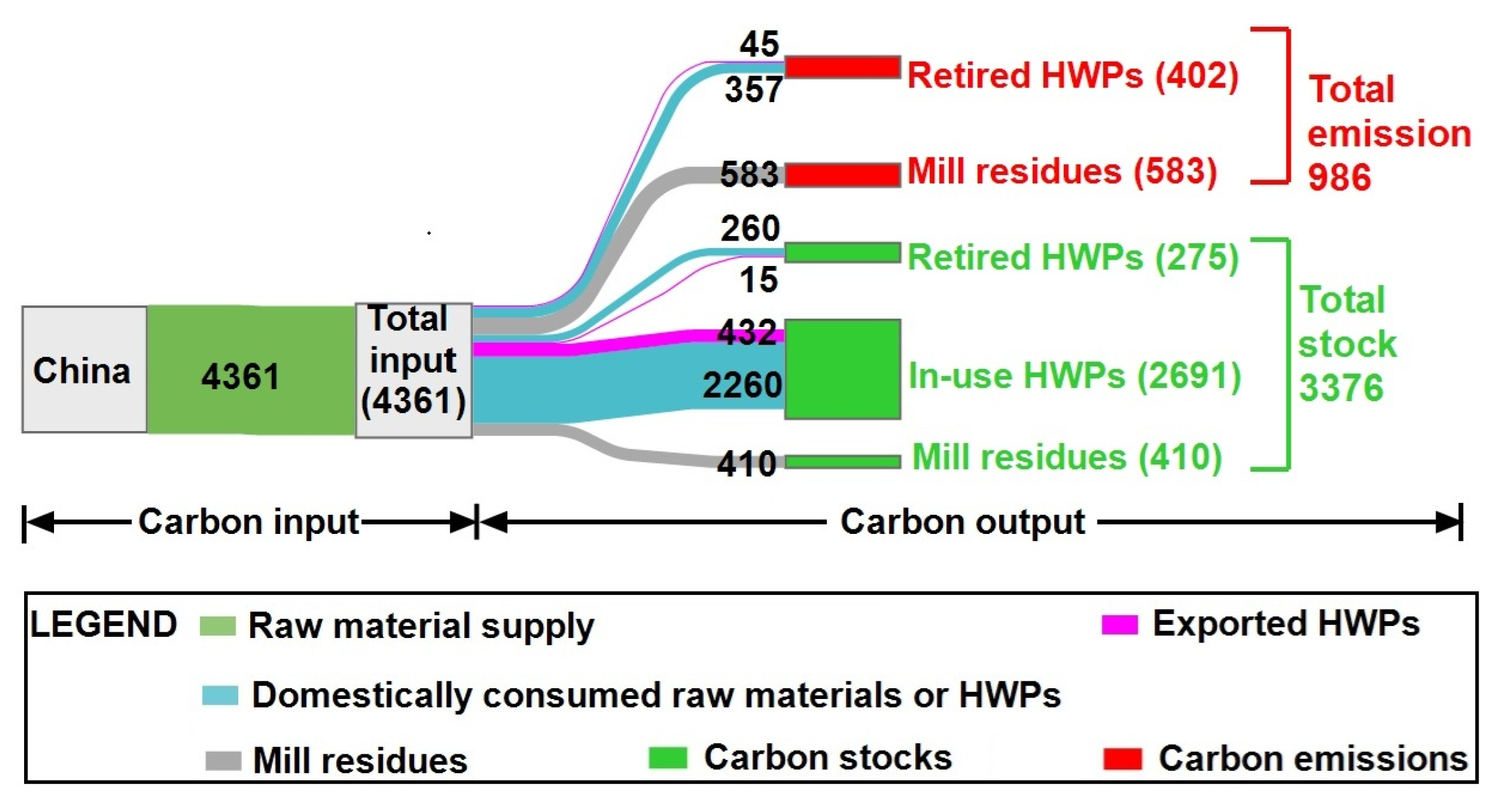

3.1. Overall Material Flows and Carbon Balance of China-Produced Harvested Wood Products

3.2. Carbon Stocks and Sinks Distributed in China and Major Trade Partners

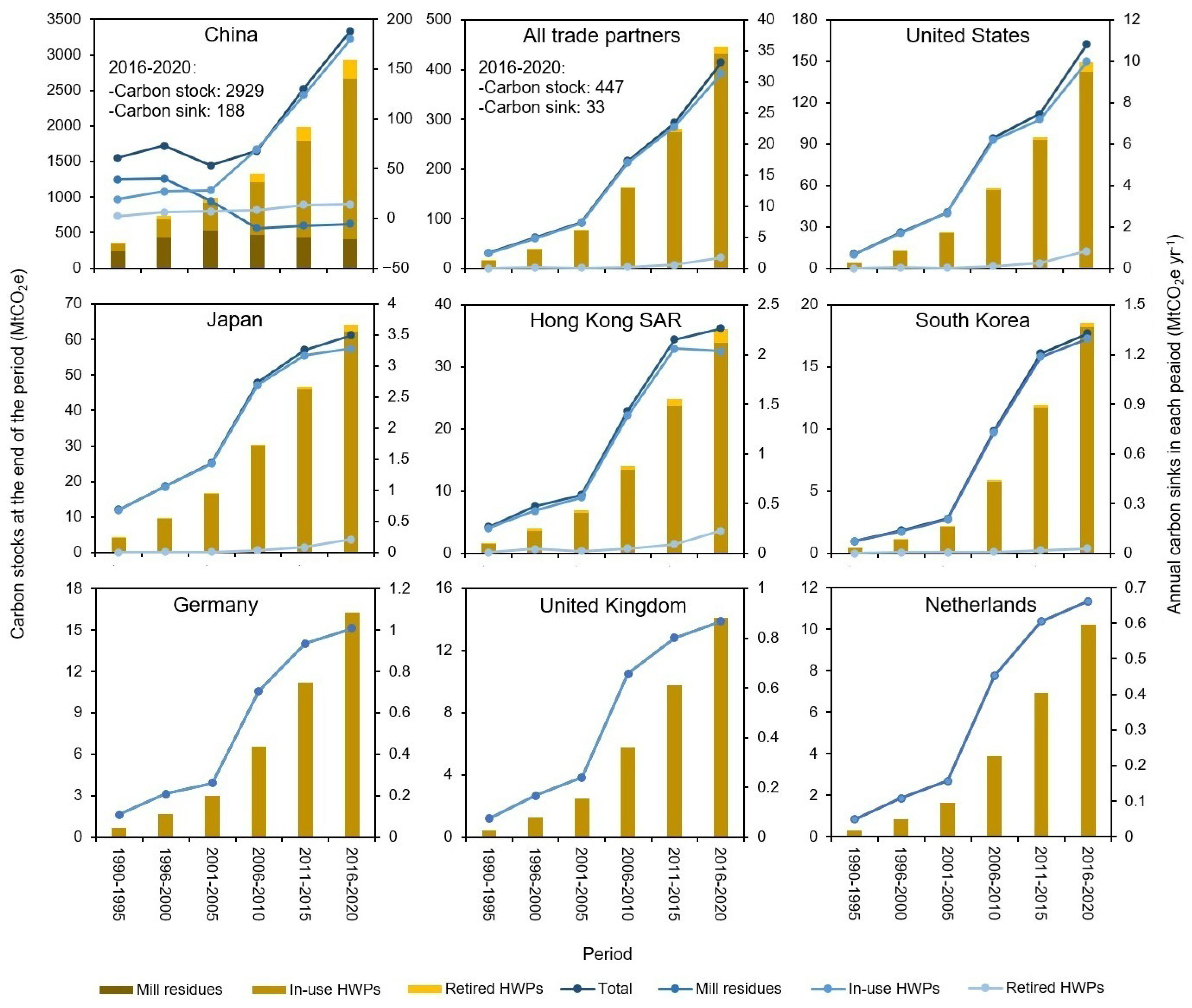

3.3. Potential Factors Influencing Carbon Stock Estimates

4. Discussion

4.1. Carbon Removal of China-Produced Harvested Wood Products for Climate Change Mitigation

4.2. Estimate Comparison and Implications for Improvement of Accounting Approaches

4.3. Methodological Contributions

4.4. Practical Contributions

4.5. Limitations of the Study

5. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HWPs | Harvested wood products |

| IPCC | Intergovernmental Panel on Climate Change |

| PA | Production Approach |

| PA-DC | Production Approach Domestic Consumption |

| SDA | Simple Decay Approach |

| SCA | Stock-Change Approach |

| AFA | Atmospheric Flow Approach |

| Recovered paper-EOF | The paper collected and recovered in the end-of-life disposal stage |

References

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. Forestry 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Johnston, C.M.T.; Radeloff, V.C. Global mitigation potential of carbon stored in harvested wood products. Proc. Natl. Acad. Sci. USA 2019, 116, 14526–14531. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Cabiyo, B.; Fried, J.S.; Collins, B.M.; Stewart, W.; Wong, J.; Sanchez, D.L. Innovative wood use can enable carbon-beneficial forest management in California. Proc. Natl. Acad. Sci. USA 2021, 118, e2019073118. [Google Scholar] [CrossRef]

- Dai, M.; Sun, M.; Chen, B.; Shi, L.; Jin, M.; Man, Y.; Liang, Z.; de Almeida, C.M.V.B.; Li, J.; Zhang, P.; et al. Country-specific net-zero strategies of the pulp and paper industry. Nature 2024, 626, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Curtis, P.G.; Slay, C.M.; Harris, N.L.; Tyukavina, A.; Hansen, M.C. Classifying drivers of global forest loss. Science 2018, 361, 1108–1111. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Searchinger, T.D.; Zionts, J.; Waite, R. The carbon costs of global wood harvests. Nature 2023, 620, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Report of the Conference of the Parties Serving as the Meeting of the Parties to the Kyoto Protocol on Its Seventh Session, Held in Durban from 28 November to 11 December 2011. Available online: http://unfccc.int/resource/docs/2011/cmp7/eng/10a01.pdf (accessed on 29 July 2025).

- Intergovernmental Panel on Climate Change. Chapter 12: Harvest Wood Products. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 4, Agriculture, Forestry, and Other Land Use; Institute for Global Environmental Strategies: Kanagawa, Japan, 2006; pp. 12.1–12.33. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4_Volume4/V4_12_Ch12_HWP.pdf (accessed on 29 July 2025).

- Intergovernmental Panel on Climate Change. 2013 Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2014; pp. 2.110–2.134. Available online: https://www.ipcc-nggip.iges.or.jp/public/kpsg/pdf/KP_Supplement_Entire_Report.pdf (accessed on 29 July 2025).

- Intergovernmental Panel on Climate Change. Chapter 12: Harvest Wood Products. In 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 4 Agriculture Forestry, and Other Land Use; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; pp. 12.1–12.49. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch12_HarvestedWoodProducts.pdf (accessed on 29 July 2025).

- Brunet-Navarro, P.; Jochheim, H.; Muys, B. Modelling carbon stocks and fluxes in the wood product sector: A comparative review. Glob. Chang. Biol. 2016, 22, 2555–2569. [Google Scholar] [CrossRef]

- Geng, A.; Yang, H.; Chen, J.; Hong, Y. Review of carbon storage function of harvested wood products and the potential of wood substitution in greenhouse gas mitigation. For. Policy Econ. 2017, 85, 192–200. [Google Scholar] [CrossRef]

- Buongiorno, J.; Johnston, C.; Zhu, S. An assessment of gains and losses from international trade in the forest sector. For. Policy Econ. 2017, 80, 209–217. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, J.; Lenzen, M.; Brunet-Navarro, P.; Dias, A.C.; Shao, S.; Liu, G.; Cao, Z.; Hu, W.; Lu, F.; et al. Carbon balance of China-made wood products assessed using a trade-linked approach. Environ. Sci. Technol. 2025, 59, 10227–10238. [Google Scholar] [CrossRef]

- Sanquetta, C.R.; Tomé, M.; Dias, A.C.; Maas, G.C.V.; Sanquetta, F.T.I. Carbon storage and CO2 dynamics from harvested wood products in Brazil during 1900–2016. Carbon Bal. Manag. 2019, 10, 417–429. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, H.; Tu, Q.; Yang, H. Methodological comparison of the production approach 2013 and 2019 for quantifying the carbon stock in harvested wood products in China. Front. Environ. Sci. 2022, 10, 758857. [Google Scholar] [CrossRef]

- Wei, X.; Zhao, J.; Hayes, D.J.; Daigneault, A.; Zhu, H. A life cycle and product type based estimator for quantifying the carbon stored in wood products. Carbon Bal. Manag. 2023, 18, 1. [Google Scholar] [CrossRef]

- Ménard, I.; Thiffault, E.; Magnan, M.; Kurz, W.A.; Hébert, F.; Boucher, J.-F. Improving carbon storage and greenhouse gas emissions avoidance through harvested wood products use. Trees Forest. People 2025, 19, 100757. [Google Scholar] [CrossRef]

- Gordeev, R.V.; Pyzhev, A.I. Evaluating carbon emissions and removals resulting from Russia’s trade in harvested wood products. For. Policy Econ. 2025, 172, 103444. [Google Scholar] [CrossRef]

- Sato, A.; Nojiri, Y. Assessing the contribution of harvested wood products under greenhouse gas estimation: Accounting under the Paris Agreement and the potential for double-counting among the choice of approaches. Carbon Bal. Manag. 2019, 14, 15. [Google Scholar] [CrossRef]

- Kayo, C.; Kalt, G.; Tsunetsugu, Y.; Tsunetsugu, Y.; Hashimoto, S.; Komata, H.; Noda, R.; Oka, H. The default methods in the 2019 Refinement drastically reduce estimates of global carbon sinks of harvested wood products. Carbon Bal. Manag. 2021, 16, 37. [Google Scholar] [CrossRef]

- Chen, J.; Colombo, S.J.; Ter-Mikaelian, M.; Heath, L.S. Carbon profile or the managed forests in Canada in the 20th century: Sink or source? Environ. Sci. Technol. 2014, 48, 9859–9866. [Google Scholar] [CrossRef]

- Kayo, C.; Tsunetsugu, Y.; Noda, H.; Tonosaki, M. Carbon balance assessments of harvested wood products in Japan taking account of inter-regional flows. Environ. Sci. Policy 2014, 37, 215–226. [Google Scholar] [CrossRef]

- Marland, E.; Marland, G.; Stockmann, K. The present net impact value for the atmospheric emission of forest carbon from harvested wood products. Environ. Model. Assess. 2025, 30, 253–264. [Google Scholar] [CrossRef]

- Horan, W.; Quilligan, M.; Bishop, G.; Styles, D. Improving biogenic carbon and land use accounting for construction wood. Resour. Conserv. Recy. 2025, 222, 108434. [Google Scholar] [CrossRef]

- Manley, B.; Evison, D. An estimate of carbon stocks for harvested wood products from logs exported from New Zealand to China. Biomass Bioenerg. 2018, 113, 55–64. [Google Scholar] [CrossRef]

- Kanemoto, K.; Lenzen, M.; Peters, G.P.; Moran, D.D.; Geschke, A. Frameworks for comparing emissions associated with production, consumption, and international trade. Environ. Sci. Technol. 2012, 46, 172–179. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Chen, J.; Dias, A.C.; Yang, H. Improving carbon stock estimates for in-use harvested wood products by linking production and consumption—A global case study. Environ. Sci. Technol. 2020, 54, 2565–2574. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, M.; Kanemoto, K.; Moran, D.; Geschke, A. Mapping the structure of the world economy. Environ. Sci. Technol. 2012, 46, 8374–8381. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, M.; Kanemoto, K.; Moran, D.; Geschke, A. Building Eora: A global multi-regional input-output database at high country and sector resolution. Econ. Syst. Res. 2013, 25, 20–49. [Google Scholar] [CrossRef]

- Moran, D.; Wood, R. Convergence between the Eora, WIOD, EXIOBASE, and open EU’s consumption-based carbon accounts. Econ. Syst. Res. 2014, 26, 245–261. [Google Scholar] [CrossRef]

- China Technical Association of the Paper Industry. Almanac of China Paper Industry 2021; China Light Industry Press: Beijing, China, 2021; pp. 1–150. (In Chinese) [Google Scholar]

- Zhang, X.; Yang, H.; Chen, J. Life-cycle carbon budget of China’s harvested wood products in 1900–2015. For. Policy Econ. 2018, 92, 181–192. [Google Scholar] [CrossRef]

- Brunet-Navarro, P.; Jochheim, H.; Franz, K.; Muys, B. Effect of cascade use on the carbon balance of the German and European wood sectors. J. Clean. Prod. 2018, 170, 137–146. [Google Scholar] [CrossRef]

- Bozzolan, N.; Grassi, G.; Mohren, F.; Nabuurs, G.J. Options to improve the carbon balance of the harvested wood products sector in four EU countries. GCB Bioenergy 2024, 16, e13104. [Google Scholar] [CrossRef]

- Joint Forest Sector Questionnaire Definitions. Available online: https://unece.org/sites/default/files/2025-04/DEF-EN-JQ-for-2024-data.pdf (accessed on 29 July 2025).

- Intergovernmental Panel on Climate Change. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: New York, NY, USA, 2014; p. 47. [Google Scholar]

- Steeck, J.; Wieland, H.; Pauliuk, S.; Wiedenhofer, D. A review of methods to trace material flows into final products in dynamic material flow analysis: Comparative application of six methods to the United States and EXIOBASE3 regions Part 2. J. Ind. Ecol. 2023, 27, 436–456. [Google Scholar] [CrossRef]

- Lenzen, M.; Geschke, A.; West, J.; Fry, J.; Malik, A.; Giljum, S.; i Canals, L.M.; Piñero, P.; Lutter, S.; Wiedmann, T.; et al. Implementing the material footprint to measure progress towards Sustainable Development Goals 8 and 12. Nat. Sustain. 2022, 5, 157–166. [Google Scholar] [CrossRef]

- Leontief, W. Environmental repercussions and the economic structure: An input-output approach. Rev. Econ. Stat. 1970, 52, 262–271. [Google Scholar] [CrossRef]

- Bates, L.; Jones, B.; Marland, E.; Marland, G.; Ruseva, T.; Kowalczyk, T.; Hoyle, J. Accounting for harvested wood products in a forest offset program: Lessons from California. J. For. Econ. 2017, 27, 50–59. [Google Scholar] [CrossRef]

- Cherubini, F.; Guest, G.; Strømman, A.H. Application of probability distributions to the modeling of biogenic CO2 fluxes in life cycle assessment. GCB Bioenergy 2012, 4, 784–798. [Google Scholar] [CrossRef]

- Marland, E.; Marland, G. The treatment of long-lived carbon-containing products in inventories of carbon dioxide emissions to the atmosphere. Environ. Sci. Policy 2003, 6, 139–152. [Google Scholar] [CrossRef]

- Marland, S.E.; Stellar, K.; Marland, G.H. A distributed approach to accounting for carbon in wood products. Mitig. Adapt. Strateg. Glob. Change 2010, 15, 71–91. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Chapter 3: Solid Waste Disposal. In 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 4 Agriculture Forestry, and Other Land Use; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; pp. 3.1–3.25. [Google Scholar]

- Cai, B.; Lou, Z.; Wang, J.; Sarkis, J.; Liu, J.; Gao, Q. CH4 mitigation potentials from China landfills and related environmental co-benefits. Sci. Adv. 2018, 4, eaar8400. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Zhao, X.; Bai, Y.; Wang, W.; Zhao, Y.; Wan, H.; Xie, Z.; Shi, X.; Wu, B.; Wang, G.; et al. Carbon pools in China’s terrestrial ecosystems: New estimates based on an intensive field survey. Proc. Natl. Acad. Sci. USA 2018, 115, 4021–4026. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; He, N.; Liu, M.; Xu, L.; Wang, L.; Zhu, J.; Zeng, N.; Yan, P.; Si, G.; Zhang, X.; et al. Carbon sequestration of Chinese forests from 2010 to 2060: Spatiotemporal dynamics and its regulatory strategies. Sci. Bull. 2022, 67, 836–843. [Google Scholar] [CrossRef] [PubMed]

- World Bank Group. The World Bank Data. Available online: https://data.worldbank.org/indicator (accessed on 29 April 2025).

- Wang, M.; Yue, C.; He, J.; Zhang, P.; Xu, M.; Li, Y.; Wang, J.; Wang, L.; Xu, C. Can wood harvest followed by forest regrowth enhance carbon sequestration of the forest sector in China? Global Planet. Change 2024, 243, 104626. [Google Scholar] [CrossRef]

- Myllyviita, T.; Soimakallio, S.; Judl, J.; Seppälä, J. Wood substitution potential in greenhouse gas emission reduction-review on current state and application of displacement factors. For. Ecosyst. 2021, 8, 42. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, C.; Chen, X.; Jia, L.; Guo, X.; Chen, R.; Zhang, M.; Chen, Z.; Wang, H. Carbon peak and carbon neutrality in China: Goals, implementation path and prospects. China Geol. 2021, 4, 720–746. [Google Scholar] [CrossRef]

- Dieter, M. Analysis of trade in illegally harvested timber: Accounting for trade via third party countries. For. Policy Econ. 2009, 11, 600–607. [Google Scholar] [CrossRef]

| Input Variables and Parameters of the Assessment Model | Percentage Changes in Carbon Stock Estimates | ||||

|---|---|---|---|---|---|

| Mill Residues | In-Use HWPs | Retired HWPs | Total | ||

| Wood material supply | Raw material supply | 10.0 | 10.0 | 10.0 | 10.0 |

| Domestic harvest fraction | 0.0 | 10.0 | 10.0 | 8.8 | |

| HWP manufacture | Solid HWP production efficiency | −5.0 | 1.3 | 2.5 | 0.7 |

| Virgin pulp production efficiency | −2.4 | 0.1 | 1.3 | −0.1 | |

| HWP end use | Intermediate demand of countries | - | 0.0 | −0.2 | 0.0 |

| Final demand of countries | - | 0.0 | 0.2 | 0.0 | |

| HWP half-life | - | 1.8 | −7.3 | 0.9 | |

| HWP end-of-life disposal | Fraction of retired HWPs and mill residues that were combusted | −1.7 | 0.0 | −4.2 | −0.6 |

| Fraction of retired HWPs and mill residues disposed of in open dumps (or stockpile) | 0.1 | 0.0 | 12.5 | 1.0 | |

| Fraction of retired HWPs and mill residues disposed of in landfills | 3.1 | 0.0 | 9.7 | 1.1 | |

| Fraction of retired HWPs that were recycled | - | 0.9 | −4.0 | 0.4 | |

| Half-life of HWP disposed of in open dumps and landfills | 7.7 | - | 4.3 | 1.3 | |

| Fraction of anaerobic condition of HWP in landfills | 0.0 | - | 1.0 | 0.1 | |

| Fraction of degradable component in anaerobic decomposition | −5.6 | - | −3.5 | −1.0 | |

| Methane collection fraction | 0.2 | - | 0.5 | 0.1 | |

| Methane oxidation fraction | 1.1 | - | 0.6 | 0.2 | |

| Effects of 1900–1989 HWP production | 58.0 | 3.4 | 80.0 | 16.2 | |

| Tier-3 PA | Tier-2 PA | Tier-2 SCA | TLA | |

|---|---|---|---|---|

| Data source | This study | This study | [34] | [15] |

| Carbon stocks by 2020/2015 | 3376/2268 * | 3418 | 4456 * | 4375 |

| Mill residues | 410/438 * | 410 | 513 * | 470 |

| In-use HWPs | 2691/1634 * | 2781 | 3284 * | 3455 |

| China | 2260/1359 * | - | - | 2905 |

| Trade partners | 432/275 * | - | - | 550 |

| Retired HWPs | 275/196 * | 227 | 659 * | 449 |

| China | 260/190 * | - | - | 429 |

| Trade partners | 15/6 * | - | - | 20 |

| Carbon sinks in 2016–2020/2011–2015 | 221/154 * | 225 | 272 * | 294 |

| Mill residues | −6/−7 * | −6 | −7 * | −4 |

| In-use HWPs | 211/147 * | 217 | 267 * | 274 |

| China | 180/124 * | - | - | 233 |

| Trade partners | 31/23 * | - | - | 41 |

| Retired HWPs | 16/14 * | 14 | 12 * | 24 |

| China | 14/14 * | - | - | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X. Refining Carbon Balance Estimates of Harvested Wood Products: A Generalizable Tier-3 Production Approach for China. Forests 2025, 16, 1603. https://doi.org/10.3390/f16101603

Zhang X. Refining Carbon Balance Estimates of Harvested Wood Products: A Generalizable Tier-3 Production Approach for China. Forests. 2025; 16(10):1603. https://doi.org/10.3390/f16101603

Chicago/Turabian StyleZhang, Xiaobiao. 2025. "Refining Carbon Balance Estimates of Harvested Wood Products: A Generalizable Tier-3 Production Approach for China" Forests 16, no. 10: 1603. https://doi.org/10.3390/f16101603

APA StyleZhang, X. (2025). Refining Carbon Balance Estimates of Harvested Wood Products: A Generalizable Tier-3 Production Approach for China. Forests, 16(10), 1603. https://doi.org/10.3390/f16101603