Impact of Thermal Treatment and Accelerated Aging on the Chemical Composition, Morphology, and Properties of Spruce Wood

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

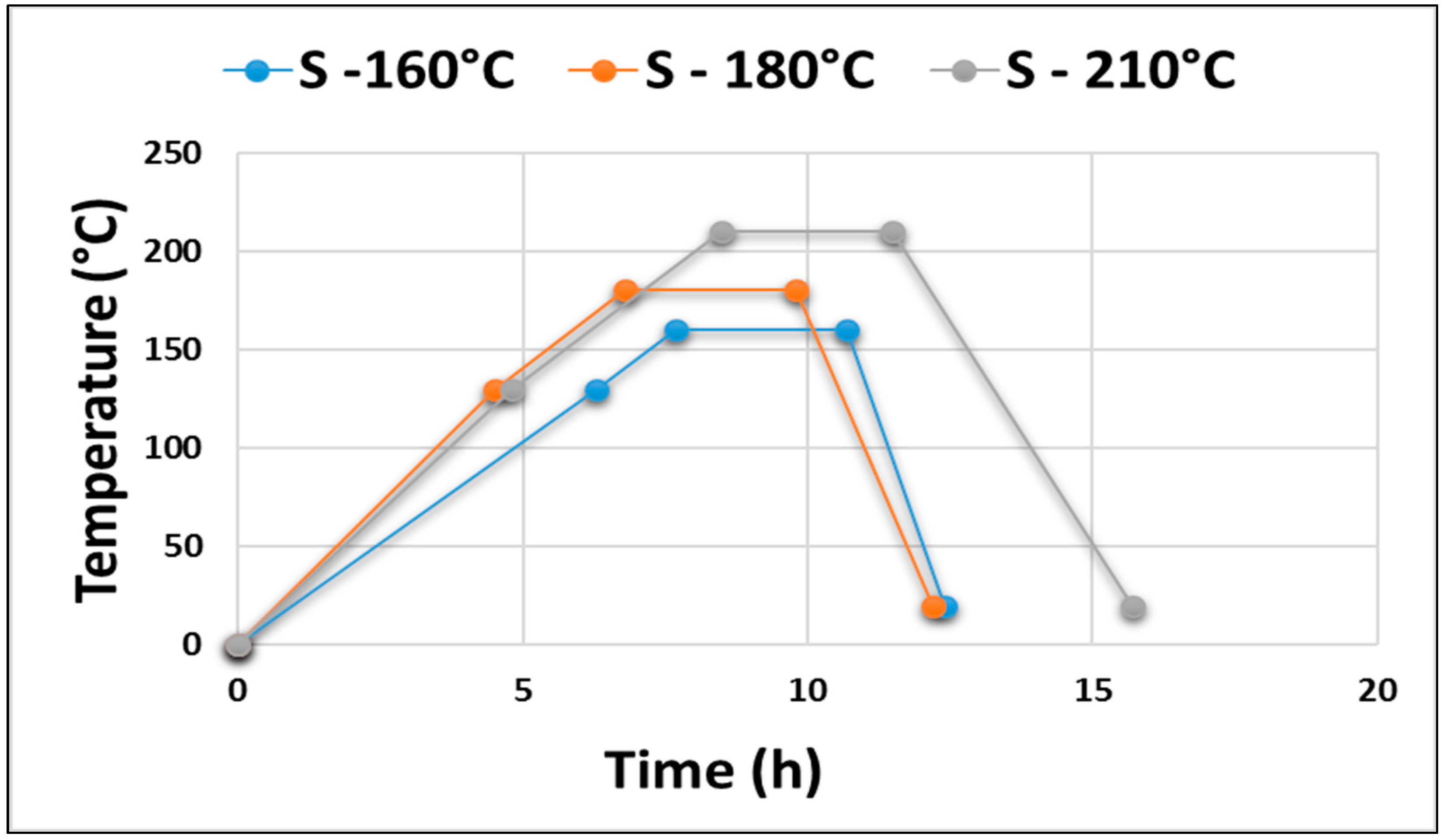

2.2. Thermal Modification

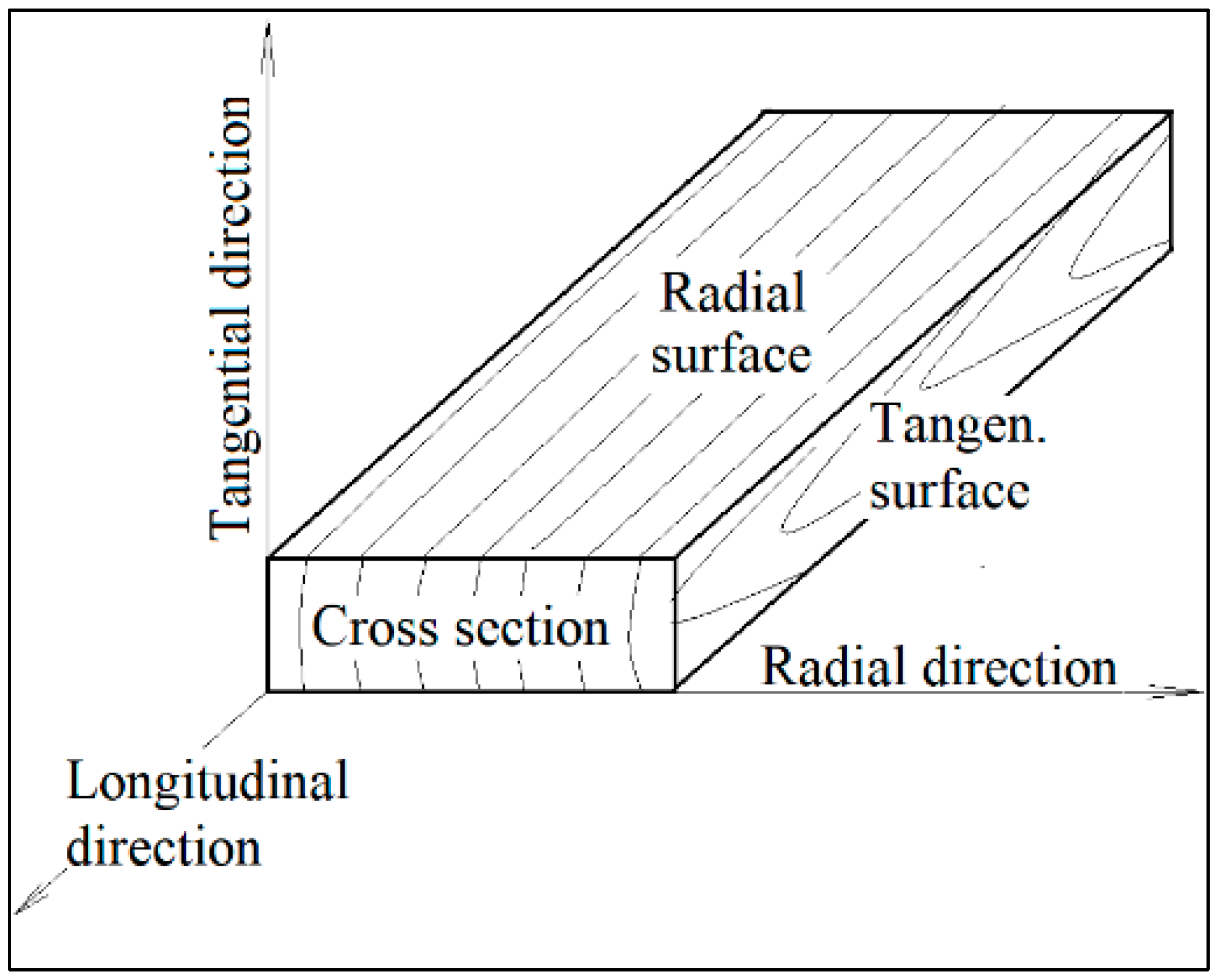

2.3. Accelerated Aging

2.4. Chemical Analyses

2.5. Color Measurement

2.6. Evaluation of Wood Surface Morphology

2.7. Wood Surface Wetting with Water

2.8. FTIR Spectroscopy

2.9. Fiber Tester Analysis

2.10. Evaluation of the Results

3. Results and Discussion

3.1. Chemical Analyses

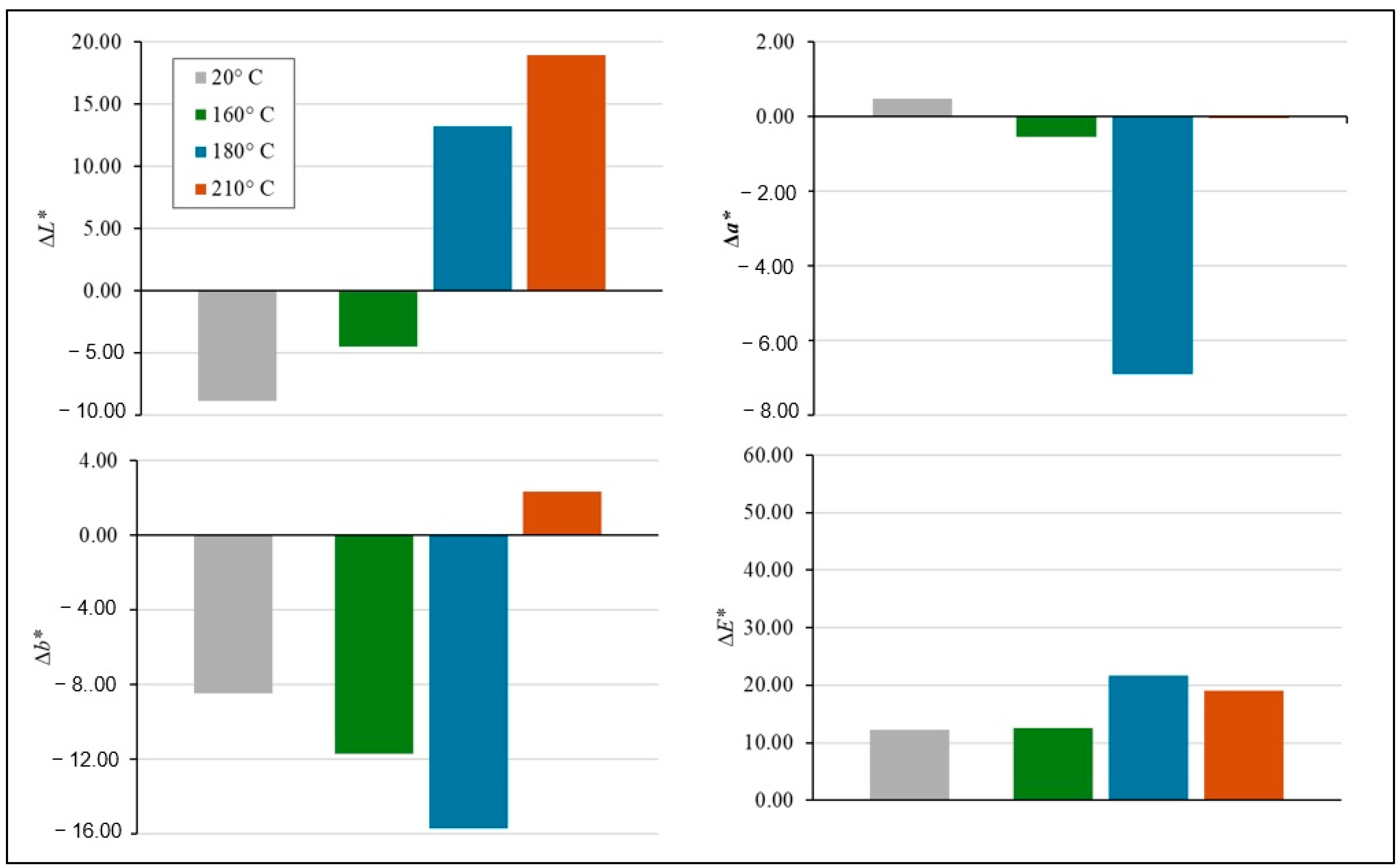

3.2. Color Changes

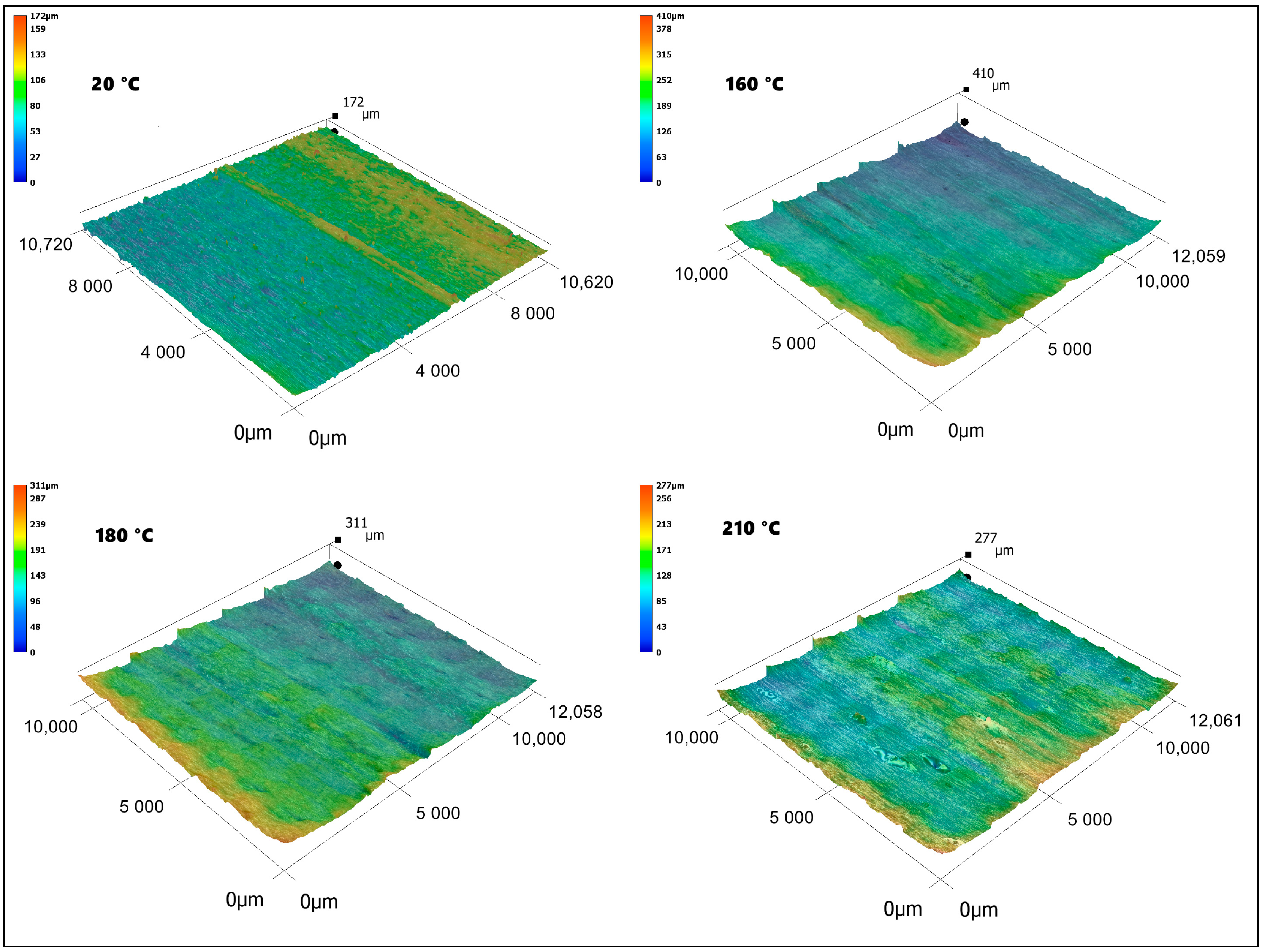

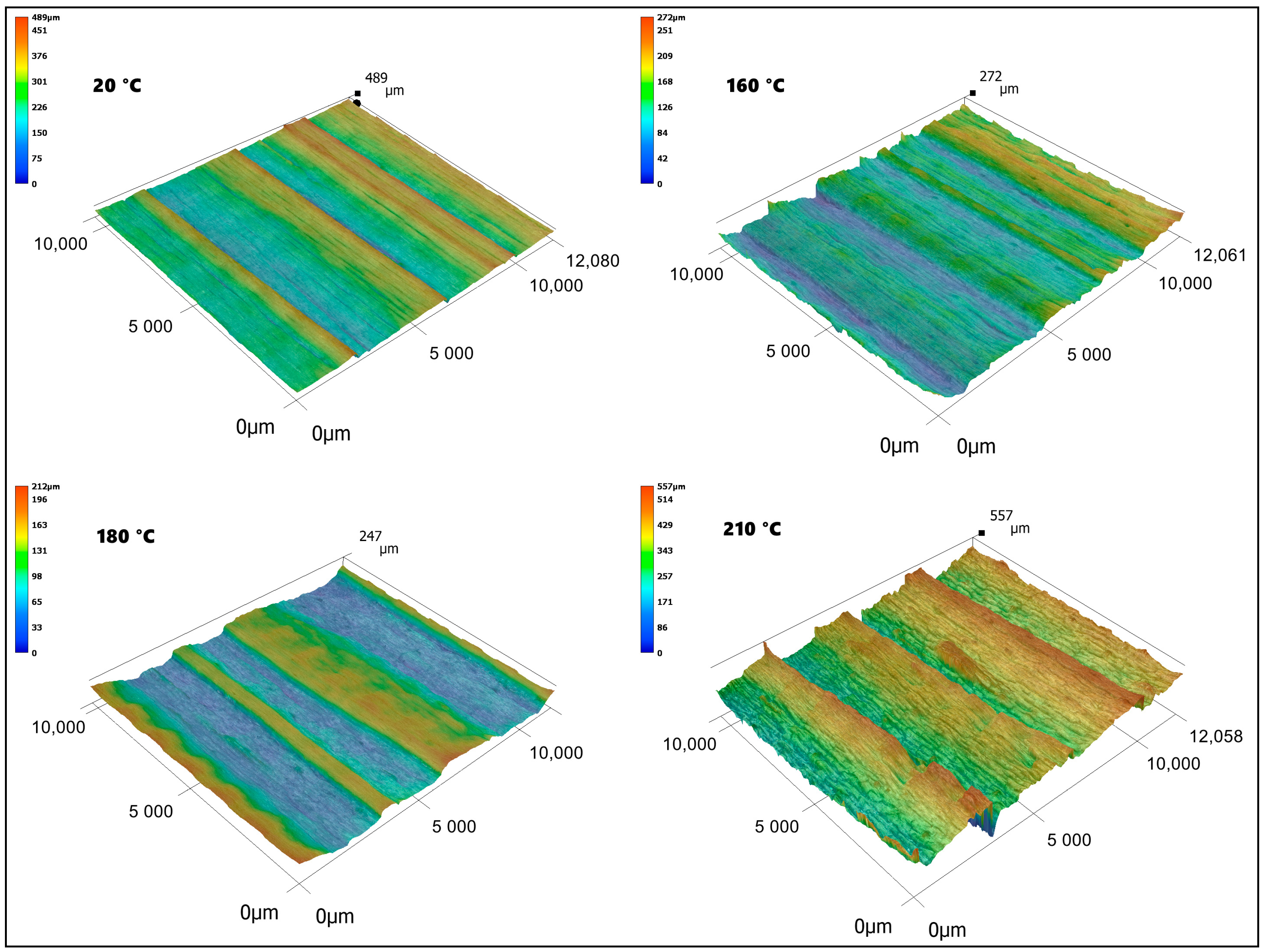

3.3. Morphology of Surfaces

3.4. Wetting of Spruce Wood with Water

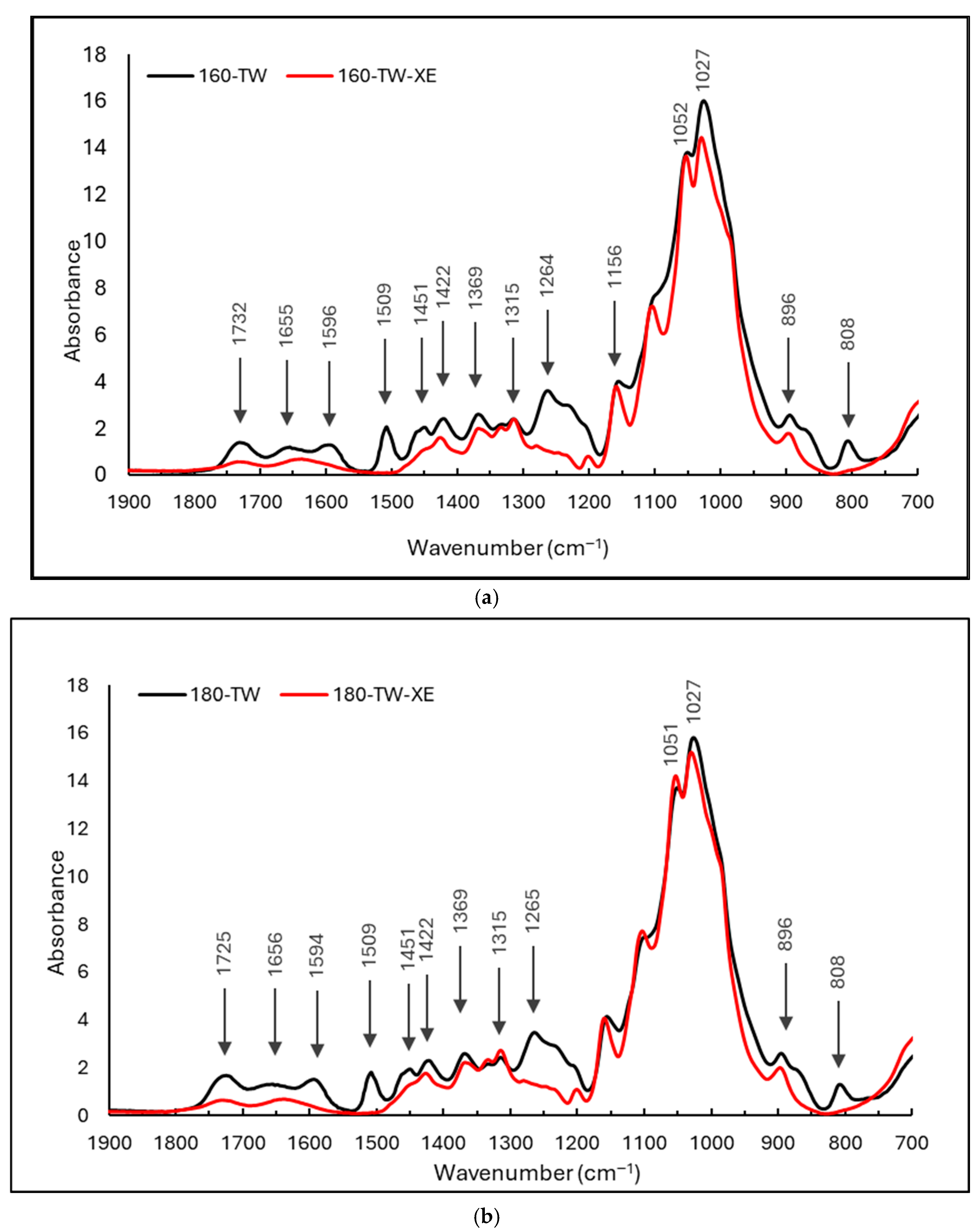

3.5. FTIR Spectroscopy

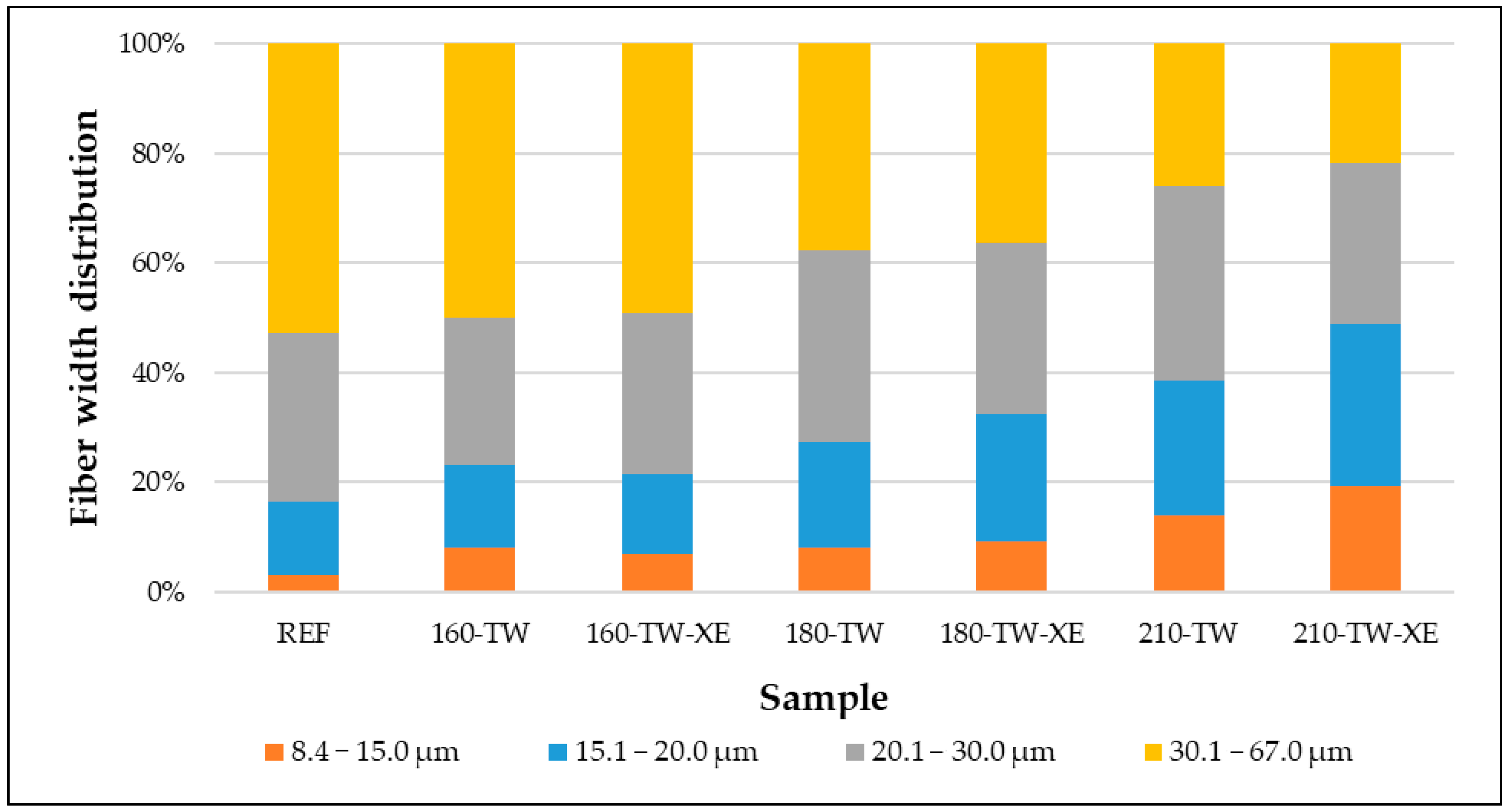

3.6. Fiber Tester Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Chichester, UK, 2006; ISBN 978-0-470-02172-9. [Google Scholar]

- Esteves, B.M.; Pereira, H.M. Wood Modification by Heat Treatment: A Review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of Thermal Modification on Color and Chemical Changes of Spruce and Oak Wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Acosta, R.; Arango, J.A.M.; Silva, E.J.D. Technologies Applied to Wood Heat Treatments, a Review: Tecnologías Aplicadas a Los Tratamientos Térmicos En Madera, Una Revisión. Sci. Technol. 2021, 26, 129–136. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Van Acker, J.; Tjeerdsma, B.F.; Kegel, E.V. Strength Properties of Thermally Modified Softwoods and Its Relation to Polymeric Structural Wood Constituents. Ann. For. Sci. 2007, 64, 679–690. [Google Scholar] [CrossRef]

- Militz, H. Heat Treatment Technologies in Europe: Scientific Background and Technological State-of-Art. In Proceedings of the Conference Enhancing the Durability of Lumber and Engineered Wood Products, Kissimmee, FL, USA, 11–13 February 2002; pp. 239–249. [Google Scholar]

- Baysal, E.; Kart, S.; Toker, H.; Degirmentepe, S. Some Physical Characteristics of Thermally Modified Oriental-Beech Wood. Maderas Cienc. Tecnol. 2014, 16, 291–298. [Google Scholar] [CrossRef]

- Gérardin, P. New Alternatives for Wood Preservation Based on Thermal and Chemical Modification of Wood—A Review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Jämsä, S.; Ahola, P.; Viitaniemi, P. Long-Term Natural Weathering of Coated ThermoWood. Pigment Resin. Technol. 2000, 29, 68–74. [Google Scholar] [CrossRef]

- Spear, M.J.; Dimitriou, A.; Marriott, R. Chemical Composition of Larch Oleoresin before and during Thermal Modification. Forests 2024, 15, 904. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Boonstra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of Thermally Modified Wood: Molecular Reasons for Wood Performance Improvement. Holz Roh Werkst. 1998, 56, 149–153. [Google Scholar] [CrossRef]

- Čekovská, H.; Gaff, M.; Osvald, A.; Kačík, F.; Kubš, J.; Kaplan, L. Fire Resistance of Thermally Modified Spruce Wood. BioResources 2017, 12, 947–959. [Google Scholar] [CrossRef]

- Svoboda, T.; Ruman, D.; Gaff, M.; Gašparík, M.; Miftieva, E.; Dundek, Ľ. Bending Characteristics of Multilayered Soft and Hardwood Materials. BioResources 2015, 10, 8461–8473. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of Wood Thermal Treatment and Its Effects on Decay Resistance: A Review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Kačíková, D.; Kubovský, I.; Ulbriková, N.; Kačík, F. The Impact of Thermal Treatment on Structural Changes of Teak and Iroko Wood Lignins. Appl. Sci. 2020, 10, 5021. [Google Scholar] [CrossRef]

- Cirule, D.; Sansonetti, E.; Andersone, I.; Kuka, E.; Andersons, B. Enhancing Thermally Modified Wood Stability against Discoloration. Coatings 2021, 11, 81. [Google Scholar] [CrossRef]

- Krauss, A.; Piernik, M.; Pinkowski, G. Cutting Power during Milling of Thermally Modified Pine Wood. Drv. Ind. 2016, 67, 215–222. [Google Scholar] [CrossRef]

- Todaro, L.; Liuzzi, S.; Pantaleo, A.M.; Lo Giudice, V.; Moretti, N.; Stefanizzi, P. Thermo-Modified Native Black Poplar (Populus nigra L.) Wood as an Insulation Material. iForest 2021, 14, 268–273. [Google Scholar] [CrossRef]

- Perdoch, W.; Benc, M.; Mazela, B. Wood from Field Tests as a Model for Assessing the Suitability of Post-Consumer Wood. Forests 2023, 15, 80. [Google Scholar] [CrossRef]

- González-Peña, M.M.; Curling, S.F.; Hale, M.D.C. On the Effect of Heat on the Chemical Composition and Dimensions of Thermally-Modified Wood. Polym. Degrad. Stab. 2009, 94, 2184–2193. [Google Scholar] [CrossRef]

- Majka, J.; Roszyk, E. Swelling Restraint of Thermally Modified Ash Wood Perpendicular to the Grain. Eur. J. Wood Prod. 2018, 76, 1129–1136. [Google Scholar] [CrossRef]

- Calonego, F.; Severo, E.; Sansígolo, C.; de Brito, A. Physical and Chemical Changes in Juvenile and Mature Wood of Shizolobium Parahyba Caused by Thermal Modification. J. Trop. For. Sci. 2020, 32, 333–340. [Google Scholar] [CrossRef]

- de Andrade Barbosa, J.; da Silva, B.M.; Ranzini, M.; Longui, E.L.; de Lima, I.L. Effect of thermal modification on wood properties of 38-year-old Cariniana legalis cultivated at different spacing. Sci. Electron. Arch. 2021, 14, 26–31. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Drożdżek, M.; Laskowska, A.; Grześkiewicz, M.; Bytner, O.; Radomski, A.; Mróz, A.; Betlej, I.; Zawadzki, J. Chemical Composition as a Factor Affecting the Mechanical Properties of Thermally Modified Black Poplar (Populus nigra L.). BioResources 2020, 15, 3915–3929. [Google Scholar] [CrossRef]

- Park, Y.; Han, Y.; Choi, Y.-S.; Lee, H.-M.; Yoon, S.-M.; Yeo, H.; Eom, C.-D. Correlation Analysis between Mass Loss of Wood Due to Thermal Modification and Equilibrium Moisture Content of Thermally Modified Wood. BioResources 2024, 19, 1283–1294. [Google Scholar] [CrossRef]

- Calonego, F.W.; Severo, E.T.D.; Furtado, E.L. Decay Resistance of Thermally-Modified Eucalyptus grandis Wood at 140 °C, 160 °C, 180 °C, 200 °C and 220 °C. Biores. Technol. 2010, 101, 9391–9394. [Google Scholar] [CrossRef] [PubMed]

- Niemz, P.; Hofmann, T.; Rétfalvi, T. Investigation of Chemical Changes in the Structure of Thermally Modified Wood. Maderas Cienc. Tecnol. 2010, 12, 69–78. [Google Scholar] [CrossRef]

- Salman, S.; Thévenon, M.F.; Pétrissans, A.; Dumarçay, S.; Candelier, K.; Gérardin, P. Improvement of the Durability of Heat-Treated Wood against Termites. Maderas Cienc. Tecnol. 2017, 19, 317–328. [Google Scholar] [CrossRef]

- Minkah, M.; Afrifah, K.; Batista, D.; Militz, H. Chemical and Mechanical Characterization of Thermally Modified Gmelina arborea Wood. Les/Wood 2021, 70, 31–44. [Google Scholar] [CrossRef]

- Bytner, O.; Drożdżek, M.; Laskowska, A.; Zawadzki, J. Influence of Thermal Modification in Nitrogen Atmosphere on the Selected Mechanical Properties of Black Poplar Wood (Populus nigra L.). Materials 2022, 15, 7949. [Google Scholar] [CrossRef] [PubMed]

- Antons, A.; Cīrule, D.; Andersone, I.; Verovkins, A.; Kuka, E. Influence of Different Modifications on Bending Strength of Wood. Key Eng. Mater. 2019, 800, 240–245. [Google Scholar] [CrossRef]

- Javed, M.A.; Kekkonen, P.M.; Ahola, S.; Telkki, V.-V. Magnetic Resonance Imaging Study of Water Absorption in Thermally Modified Pine Wood. Holzforschung 2014, 69, 899–907. [Google Scholar] [CrossRef]

- Alén, R.; Kotilainen, R.; Zaman, A. Thermochemical Behavior of Norway Spruce (Picea abies) at 180–225 °C. Wood Sci. Technol. 2002, 36, 163–171. [Google Scholar] [CrossRef]

- Gosselink, R.J.A.; Krosse, A.M.A.; van der Putten, J.C.; van der Kolk, J.C.; de Klerk-Engels, B.; van Dam, J.E.G. Wood Preservation by Low-Temperature Carbonisation. Ind. Crops Prod. 2004, 19, 3–12. [Google Scholar] [CrossRef]

- Yildiz, S.; Gezer, E.D.; Yildiz, U.C. Mechanical and Chemical Behavior of Spruce Wood Modified by Heat. Build. Environ. 2006, 41, 1762–1766. [Google Scholar] [CrossRef]

- Moliński, W.; Roszyk, E.; Jabloński, A.; Puszyński, J.; Cegiela, J. Mechanical Parameters of Thermally Modified Ash Wood Determined by Compression in Radial Direction. Maderas Cienc. Tecnol. 2016, 18, 577–586. [Google Scholar] [CrossRef]

- Korkut, S.; Aytin, A. Evaluation of Physical and Mechanical Properties of Wild Cherry Wood Heat-Treated Using the Thermowood Process. Maderas Cienc. Tecnol. 2015, 17, 171–178. [Google Scholar] [CrossRef]

- Gennari, E.; Picchio, R.; Lo Monaco, A. Industrial Heat Treatment of Wood: Study of Induced Effects on Ayous Wood (Triplochiton scleroxylon K. schum). Forests 2021, 12, 730. [Google Scholar] [CrossRef]

- Winandy, J.; Lebow, P. Modeling Strength Loss in Wood by Chemical Composition. Part I. An Individual Component Model for Southern Pine. Wood Fiber Sci. 2001, 33, 239–254. [Google Scholar]

- Esteves, B.M.; Domingos, I.J.; Pereira, H.M. Pine Wood Modification by Heat Treatment in Air. BioResources 2008, 3, 142–154. [Google Scholar] [CrossRef]

- Roszyk, E.; Stachowska, E.; Majka, J.; Mania, P.; Broda, M. Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus Excelsior Wood in Compression. Materials 2020, 13, 1647. [Google Scholar] [CrossRef]

- Demircioğlu, T.K.; Balıkoğlu, F.; İnal, O.; Arslan, N.; Ay, İ.; Ataş, A. Experimental Investigation on Low-Velocity Impact Response of Wood Skinned Sandwich Composites with Different Core Configurations. Mater. Today Commun. 2018, 17, 31–39. [Google Scholar] [CrossRef]

- ASTM-G155-05; Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM D1107-21; Standard Test Method for Ethanol-Toluene Solubility of Wood. ASTM International: West Conshohocken, PA, USA, 2021.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. In Laboratory Analytical Procedure (LAP); National Renewable Energy Laboratory: Denver, CO, USA, 2012. [Google Scholar]

- Seifert, V. Über ein neues Verfahren zur Schnellbestimmung der Rein-Cellulose. (About a New Method for Rapid Determination of Pure Cellulose). Papier 1956, 13, 301–306. [Google Scholar]

- Wise, L.E.; Murphy, M.; d’Addieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap. Trade J. 1946, 122, 35–43. [Google Scholar]

- Nuopponen, M.; Vuorinen, T.; Jämsä, S.; Viitaniemi, P. The Effects of a Heat Treatment on the Behaviour of Extractives in Softwood Studied by FTIR Spectroscopic Methods. Wood Sci. Technol. 2003, 37, 109–115. [Google Scholar] [CrossRef]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and Ecotoxicity of Heat-Treated Pine Wood Extractives. Wood Sci. Technol. 2011, 45, 661–676. [Google Scholar] [CrossRef]

- Kúdela, J.; Ihracký, P.; Kačík, F. Discoloration and Surface Changes in Spruce Wood after Accelerated Aging. Polymers 2024, 16, 1191. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Gao, J.; Chen, Y. Colour Responses of Black Locust (Robinia pseudoacacia L.) to Solvent Extraction and Heat Treatment. Wood Sci. Technol. 2010, 44, 667–678. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Fan, Y.; Tshabalala, M.A.; Stark, N.M. Heat-Induces Chemical and Color Changes of Extractive-Free Black Locust (Robinia pseudoacacia) Wood. BioResources 2012, 7, 2236–2248. [Google Scholar] [CrossRef]

- Pandey, K.K.; Vuorinen, T. Comparative Study of Photodegradation of Wood by a UV Laser and a Xenon Light Source. Polym. Degrad. Stab. 2008, 93, 2138–2146. [Google Scholar] [CrossRef]

- Allegretti, O.; Travan, L.; Cividini, R. Drying Techniques to Obtain White Beech. In Proceedings of the EDG Conference, Bled, Slovenia, 14–17 June 2009; pp. 7–13. [Google Scholar]

- Mokrzycki, W.; Tatol, M. Color Difference Delta E—A Survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Sandak, A.; Gordobil, O.; Poohphajai, F.; Herrera Diaz, R. Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation. Forests 2024, 15, 1097. [Google Scholar] [CrossRef]

- Gurau, L. Quantitative Evaluation of the Sanding Quality in Furniture Manufacturing; Transilvania University: Brașov, Romania, 2007; ISBN 978-973-598-126-6. [Google Scholar]

- Csanady, E.; Magoss, E.; Tolvaj, L. Quality of Machined Wood Surfaces; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-319-22418-3. [Google Scholar]

- Monaco, A.L.; Pelosi, C.; Agresti, G.; Picchio, R.; Rubino, G. Influence Fo Thermal Treatment on Selected Properties of Chestnut Wood and Full Range of Its Vidual Features. Drewno 2020, 63, 5–24. [Google Scholar] [CrossRef]

- Hamada, J.; Pétrissans, A.; Mothe, F.; Ruelle, J.; Pétrissans, M.; Gérardin, P. Variations in the Natural Density of European Oak Wood Affect Thermal Degradation during Thermal Modification. Ann. For. Sci. 2016, 73, 277–286. [Google Scholar] [CrossRef]

- Hamada, J.; Pétrissans, A.; Mothe, F.; Ruelle, J.; Pétrissans, M.; Gérardin, P. Intraspecific Variation of European Oak Wood Thermal Stability According to Radial Position. Wood Sci. Technol. 2017, 51, 785–794. [Google Scholar] [CrossRef]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Pichette, A. A Spectrocolorimetric and Chemical Study on Color Modification of Heat-Treated Wood during Artificial Weathering. Appl. Surf. Sci. 2012, 258, 5360–5369. [Google Scholar] [CrossRef]

- Marino, S.; Gaff, M.; Sethy, A.K.; Kamboj, G.; Rezaei, F.; Kačík, F.; Hosseini, S.B.; Li, H.; Hui, D. Enhancing the Fire Resistance Properties of Thermally Modified Robinia pseudoacacia Wood with Natural and Synthetic Flame Retardants: Chemical Characterisation and Fire Behaviour. Eur. J. Wood Prod. 2024, 82, 1145–1157. [Google Scholar] [CrossRef]

- Korkut, S.; Kocaefe, D. Effect of Heat Treatment on Wood Properties. Duzce Univ. J. For. 2009, 5, 11–34. [Google Scholar]

- Moliński, W.; Cunderlik, I.; Krauss, A.; Fabisiak, E.; Jurek, P. Gradient of Density and Tensile Strength along the Grains of Spruce Wood (Picea abies) within Individual Annual Rings. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. SGGW For. Wood Technol. 2009, 69, 87–92. [Google Scholar]

- Hazneza, S.; Evans, P.D. End-Grain Erosion of Douglas Fir Wood during Natural Weathering. Int. Wood Prod. J. 2016, 7, 3–11. [Google Scholar] [CrossRef]

- Preklet, E.; Tolvaj, L.; Tsuchikawa, S.; Varga, D. Photodegradation Properties of Earlywood and Latewood Spruce Timber Surfaces. Acta Silv. Lignaria Hung. 2021, 17, 9–20. [Google Scholar] [CrossRef]

- Andersone, I.; Andersons, B.; Avramidis, G.; Barbu, M.; Bergland, L.; Clemons, C.; Dietenberger, M.; Evans, P.; Frihart, C.; Ibach, R.; et al. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 978-0-429-10909-6. [Google Scholar]

- Williams, R.S.; Feist, W.C. Water Repellents and Water-Repellent Preservatives for Wood; FPL-GTR-109; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Chu, D.; Mu, J.; Avramidis, S.; Rahimi, S.; Liu, S.; Lai, Z. Functionalized Surface Layer on Poplar Wood Fabricated by Fire Retardant and Thermal Densification. Part 1: Compression Recovery and Flammability. Forests 2019, 10, 955. [Google Scholar] [CrossRef]

- Todaro, L.; Rita, A.; Moretti, N.; Cuccui, I.; Pellerano, A. Assessment of Thermo-Treated Bonded Wood Performance: Comparisons among Norway Spruce, Common Ash, and Turkey Oak. BioResources 2015, 10, 772–781. [Google Scholar] [CrossRef]

- Miklečić, J.; Jirouš-Rajković, V. Influence of Thermal Modification on Surface Properties and Chemical Composition of Beech Wood (Fagus sylvatica L.). Drv. Ind. 2016, 67, 65–71. [Google Scholar] [CrossRef]

- Bekhta, P.; Krystofiak, T.; Proszyk, S.; Lis, B. Evaluation of Dynamic Contact Angle of Loose and Tight Sides of Thermally Compressed Birch Veneer. Drv. Ind. 2018, 69, 387–394. [Google Scholar] [CrossRef]

- Zou, W.; Wang, Z.; Sun, Z.; Jiang, X.; Yu, M.; Song, L.; Sun, D. A thermochromic wood that can change colour at 24–40 °C and collect heat for heating flooring. Ind. Crops Prod. 2022, 186, 115293. [Google Scholar] [CrossRef]

- Zou, W.; Deng, J.; Wang, Z.; Sun, D.; Zou, N. Encapsulation of thermochromic tetradecyl myristate/methyl red compo-site via full poplar-based cellulose/lignin/SiO2 framework for preparation of thermochromic wood with thermal response and storage. Int. J. Biol. Macromol. 2024, 276, 133881. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, T.; Tolvaj, L.; Visi-Rajczi, E.; Varga, D. Chemical Changes of Steamed Timber during Short-Term Photodegradation Monitored by FTIR Spectroscopy. Eur. J. Wood Prod. 2022, 80, 841–849. [Google Scholar] [CrossRef]

- Godinho, D.; Ferreira, C.; Lourenço, A.; de Oliviera Araújo, S.; Quilhó, T.; Diamantino, T.C.; Gominho, J. The Behavior of Thermally Modified Wood after Exposure in Maritime/Industrial and Urban Environments. Heliyon 2024, 10, e25020. [Google Scholar] [CrossRef] [PubMed]

- Horikawa, Y.; Hirano, S.; Mihashi, A.; Kobayashi, Y.; Zhai, S.; Sugiyama, J. Prediction of Lignin Contents from Infrared Spectroscopy: Chemical Digestion and Lignin/Biomass Ratios of Cryptomeria japonica. Appl. Biochem. Biotechnol. 2019, 188, 1066–1076. [Google Scholar] [CrossRef]

- Torniainen, P.; Popescu, C.-M.; Jones, D.; Scharf, A.; Sandberg, D. Correlation of Studies between Colour, Structure and Mechanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine. Forests 2021, 12, 1165. [Google Scholar] [CrossRef]

- Geffert, A.; Geffertová, J.; Výbohová, E. Surface Changes of Beech and Pine Wood under the Influence of UV Radiation. Acta Fac. Xylologiae Zvolen 2020, 62, 5–18. [Google Scholar] [CrossRef]

- Temiz, A.; Terziev, N.; Jacobsen, B.; Eikenes, M. Weathering, Water Absorption, and Durability of Silicon, Acetylated, and Heat-Treated Wood. J. Appl. Polym. Sci. 2006, 102, 4506–4513. [Google Scholar] [CrossRef]

- Lionetto, F.; Del Sole, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring Wood Degradation during Weathering by Cellulose Crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Čabalová, I.; Zachar, M.; Kačík, F.; Tribulová, T. Impact of Thermal Loading on Selected Chemical and Morphological Properties of Spruce ThermoWood. BioResources 2019, 14, 387–400. [Google Scholar] [CrossRef]

- Sawoszczuk, T.; Wandelt, P.; Barański, A.; Łagan, J.M.; Łojewski, T.; Perlińska-Sipa, K. Degradation of Paper as Studied by Fiber Length Measurements After Hydrodynamical Treatment. In Proceedings of the International Conference Durability of Paper and Writing, Ljubljana, Slovenia, 16–22 November 2004; pp. 78–80. [Google Scholar]

- Tyrväinen, J. Wood and Fiber Properties of Norway Spruce and Its Suitability for Thermomechanical Pulping. Acta For. Fenn. 1995, 249, 7511. [Google Scholar] [CrossRef]

- He, L.; Zhang, T.; Zhao, Y.; Gao, J.; Zhang, Y.; Yang, Y.; He, Z.; Yi, S. Effect of Natural Tung Oil on Wood Shrinkage during the Thermal Modification Process. J. Clean. Prod. 2022, 379, 134450. [Google Scholar] [CrossRef]

| Step | Mode | Radiation Intensity (W·m−2) | Black Panel Temperature (°C) | Air Temperature (°C) | Relative Air Humidity (%) | Time (min) |

|---|---|---|---|---|---|---|

| 1 | Radiation | 0.35 | 63 | 48 | 30 | 102 |

| 2 | Radiation + water spraying | 0.35 | 63 | 48 | 90 | 18 |

| Sample | Extractives | Lignin | Cellulose | Holocellulose | Hemicelluloses |

|---|---|---|---|---|---|

| REF | 0.98 (0.05) | 26.24 (0.04) | 45.35 (0.26) | 73.43 (0.61) | 28.07 (0.68) |

| 160-TW | 2.11 (0.07) | 26.45 (0.07) | 45.48 (0.14) | 71.54 (0.31) | 26.06 (0.38) |

| 180-TW | 2.71 (0.26) | 28.65 (0.09) | 46.33 (0.21) | 66.93 (0.61) | 20.59 (0.81) |

| 210-TW | 3.49 (0.25) | 33.08 (0.05) | 50.64 (0.17) | 58.39 (0.12) | 7.75 (0.26) |

| 160-TW-XE | 1.63 (0.10) | 27.68 (0.40) | 45.38 (0.12) | 71.38 (0.36) | 26.00 (0.40) |

| 180-TW-XE | 2.25 (0.14) | 32.14 (0.18) | 46.23 (0.37) | 64.47 (0.27) | 18.24 (0.33) |

| 210-TW-XE | 3.07 (0.23) | 35.26 (0.43) | 52.56 (0.11) | 58.82 (0.22) | 6.26 (0.12) |

| Conditions | Color Coordinates | Basic Statistical Characteristics | Temperature (°C) | |||

|---|---|---|---|---|---|---|

| REF | 160 | 180 | 210 | |||

| Before Aging (TW) | L* | 85.07 | 75.99 | 58.46 | 32.09 | |

| s | 0.74 | 2.52 | 2.14 | 2.03 | ||

| a* | 3.44 | 7.05 | 12.67 | 7.02 | ||

| s | 0.37 | 0.57 | 0.65 | 1.25 | ||

| b* | 19.06 | 26.86 | 29.79 | 10.59 | ||

| s | 0.65 | 1.14 | 1.02 | 2.54 | ||

| After Aging (TW-XE) | L* | 76.27 | 71.51 | 71.71 | 51.00 | |

| s | 1.76 | 2.89 | 2.35 | 10.63 | ||

| a* | 3.91 | 6.50 | 5.77 | 6.97 | ||

| s | 0.64 | 0.86 | 0.80 | 1.82 | ||

| b* | 10.60 | 15.16 | 14.07 | 12.93 | ||

| s | 0.93 | 2.09 | 2.00 | 1.90 | ||

| Temperature (°C) | Statistical Characteristics | Roughness Parameters—Parallel to Fibers (μm) | |||||

|---|---|---|---|---|---|---|---|

| Before Aging (TW) | After Aging (TW-XE) | ||||||

| Ra | Rz | RSm | Ra | Rz | RSm | ||

| 20 (REF) | 3.16 | 25.47 | 487.62 | 11.57 | 86.78 | 1314.90 | |

| s | 0.78 | 6.53 | 116.91 | 2.75 | 15.09 | 685.25 | |

| 160 | 4.07 | 29.26 | 696.13 | 7.68 | 49.36 | 2037.03 | |

| s | 2.93 | 15.82 | 303.12 | 3.13 | 20.26 | 1049.18 | |

| 180 | 4.08 | 26.09 | 563.62 | 6.16 | 41.33 | 1350.95 | |

| s | 1.84 | 11.29 | 252.33 | 2.09 | 14.06 | 755.55 | |

| 210 | 4.34 | 27.65 | 582.96 | 11.01 | 75.96 | 1527.38 | |

| s | 1.49 | 8.62 | 329.68 | 5.21 | 37.32 | 864.09 | |

| Roughness parameters—perpendicular to fibers (μm) | |||||||

| Ra | Rz | RSm | Ra | Rz | RSm | ||

| 20 (REF) | 6.09 | 48.29 | 251.08 | 35.20 | 292.27 | 1180.421 | |

| s | 0.65 | 5.59 | 22.20 | 5.71 | 47.00 | 987.25 | |

| 160 | 7.99 | 54.54 | 522.26 | 23.46 | 151.31 | 1854.32 | |

| s | 2.35 | 16.37 | 398.98 | 5.38 | 32.22 | 1042.30 | |

| 180 | 5.15 | 43.71 | 227.50 | 33.45 | 149.60 | 2938.51 | |

| s | 1.41 | 11.49 | 208.09 | 7.03 | 20.70 | 1339.36 | |

| 210 | 5.86 | 46.76 | 242.61 | 48.19 | 213.55 | 1180.78 | |

| s | 2.10 | 14.29 | 235.75 | 12.85 | 93.12 | 1371.42 | |

| Temperature (°C) | Statistical Characteristics | Wetting Before Aging (TW) | Wetting After Aging (TW-XE) | ||

|---|---|---|---|---|---|

| Contact Angle θ (°) | Time of Wetting t (s) | Contact Angle θ (°) | Time of Wetting t (s) | ||

| 20 (REF) | s | 32 | 26 | 9 | 1.2 |

| 7 | 19 | 4 | 0.4 | ||

| 160 | s | 104 | 625 | 72 | 13.8 |

| 5 | 127 | 21 | 9.2 | ||

| 180 | s | 107 | 984 | 32 | 2.5 |

| 8 | 242 | 22 | 1.8 | ||

| 210 | s | 104 | 876 | 2 | 0.3 |

| 7 | 237 | 3 | 0.4 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kačík, F.; Kúdela, J.; Výbohová, E.; Jurczyková, T.; Čabalová, I.; Adamčík, L.; Kmeťová, E.; Kačíková, D. Impact of Thermal Treatment and Accelerated Aging on the Chemical Composition, Morphology, and Properties of Spruce Wood. Forests 2025, 16, 180. https://doi.org/10.3390/f16010180

Kačík F, Kúdela J, Výbohová E, Jurczyková T, Čabalová I, Adamčík L, Kmeťová E, Kačíková D. Impact of Thermal Treatment and Accelerated Aging on the Chemical Composition, Morphology, and Properties of Spruce Wood. Forests. 2025; 16(1):180. https://doi.org/10.3390/f16010180

Chicago/Turabian StyleKačík, František, Jozef Kúdela, Eva Výbohová, Tereza Jurczyková, Iveta Čabalová, Lukáš Adamčík, Elena Kmeťová, and Danica Kačíková. 2025. "Impact of Thermal Treatment and Accelerated Aging on the Chemical Composition, Morphology, and Properties of Spruce Wood" Forests 16, no. 1: 180. https://doi.org/10.3390/f16010180

APA StyleKačík, F., Kúdela, J., Výbohová, E., Jurczyková, T., Čabalová, I., Adamčík, L., Kmeťová, E., & Kačíková, D. (2025). Impact of Thermal Treatment and Accelerated Aging on the Chemical Composition, Morphology, and Properties of Spruce Wood. Forests, 16(1), 180. https://doi.org/10.3390/f16010180