Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Samples

2.2. Weathering Tests

2.3. Characterisation Methods

2.3.1. Digitalisation

2.3.2. Colour Measurement

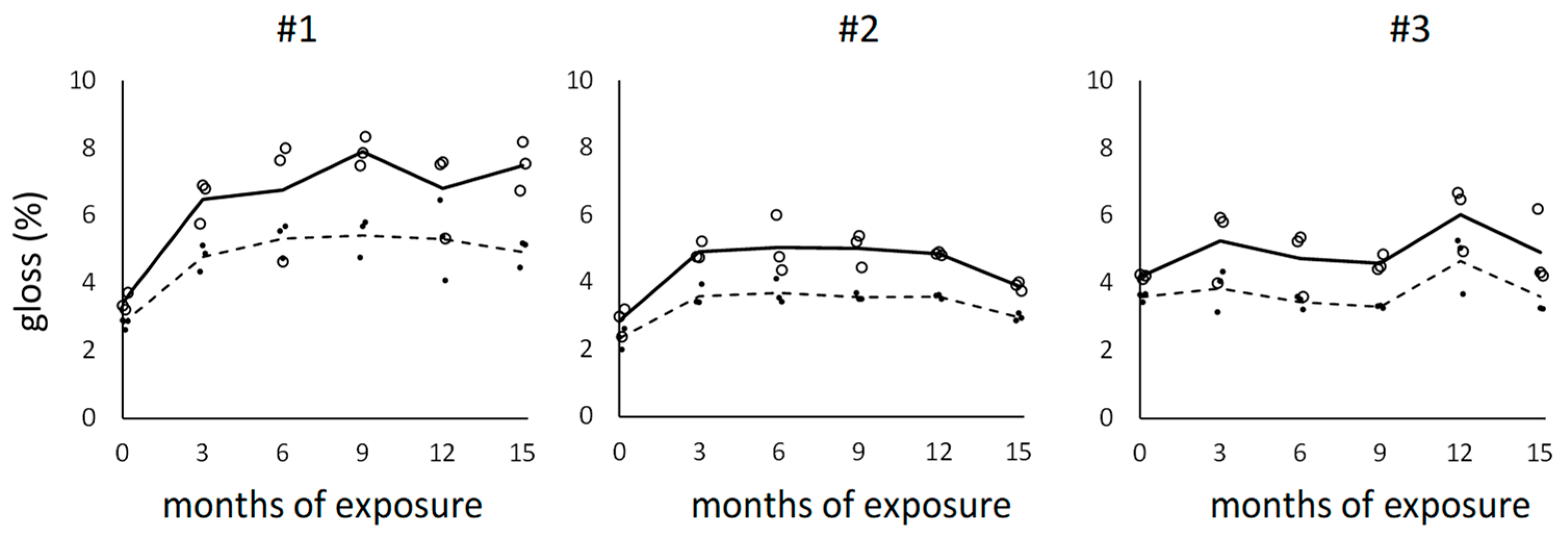

2.3.3. Gloss

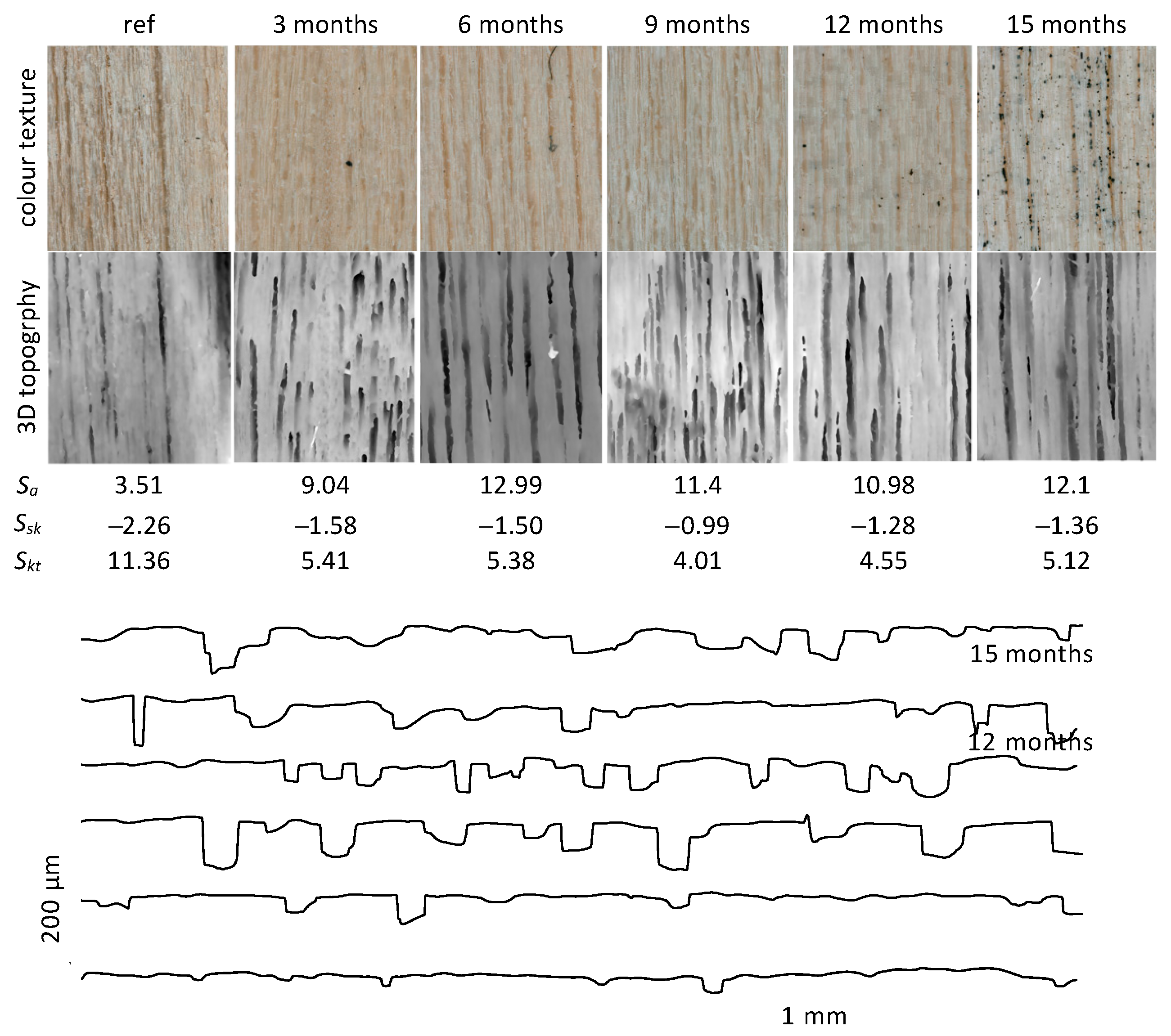

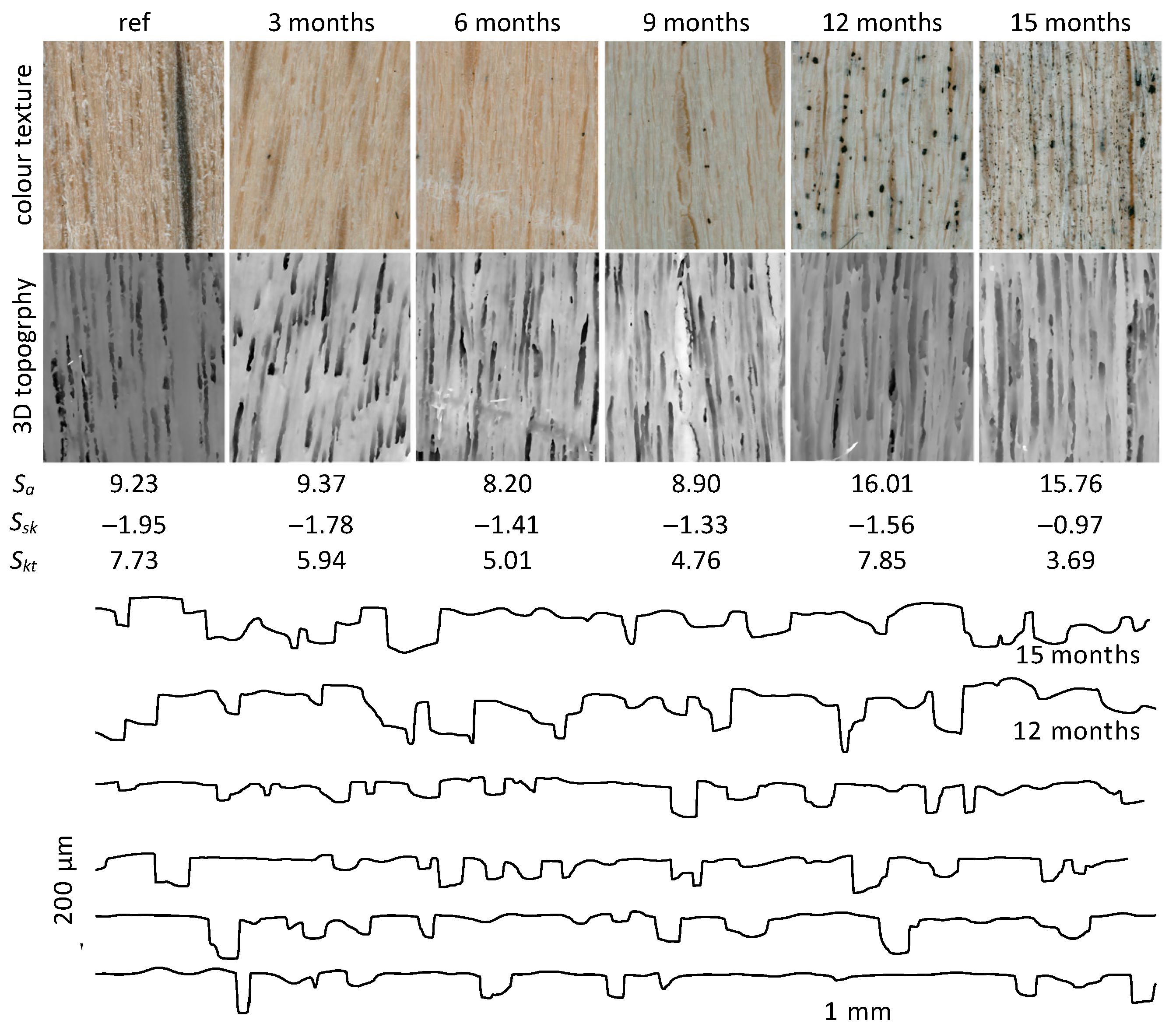

2.3.4. Microscopic Observation and 3D Roughness Measurement

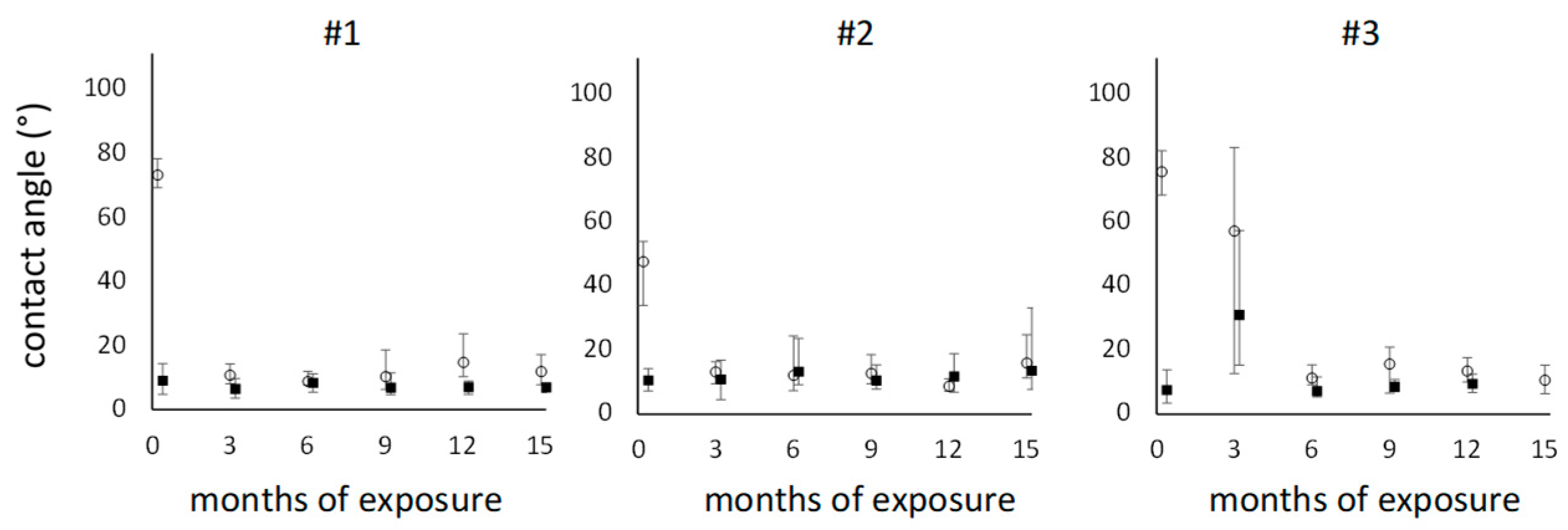

2.3.5. Contact Angle and Surface Free Energy

2.3.6. Infrared Measurement

2.3.7. Thermogravimetric Analysis

3. Results and Discussion

3.1. Appearance Changes

3.2. Surface Topography

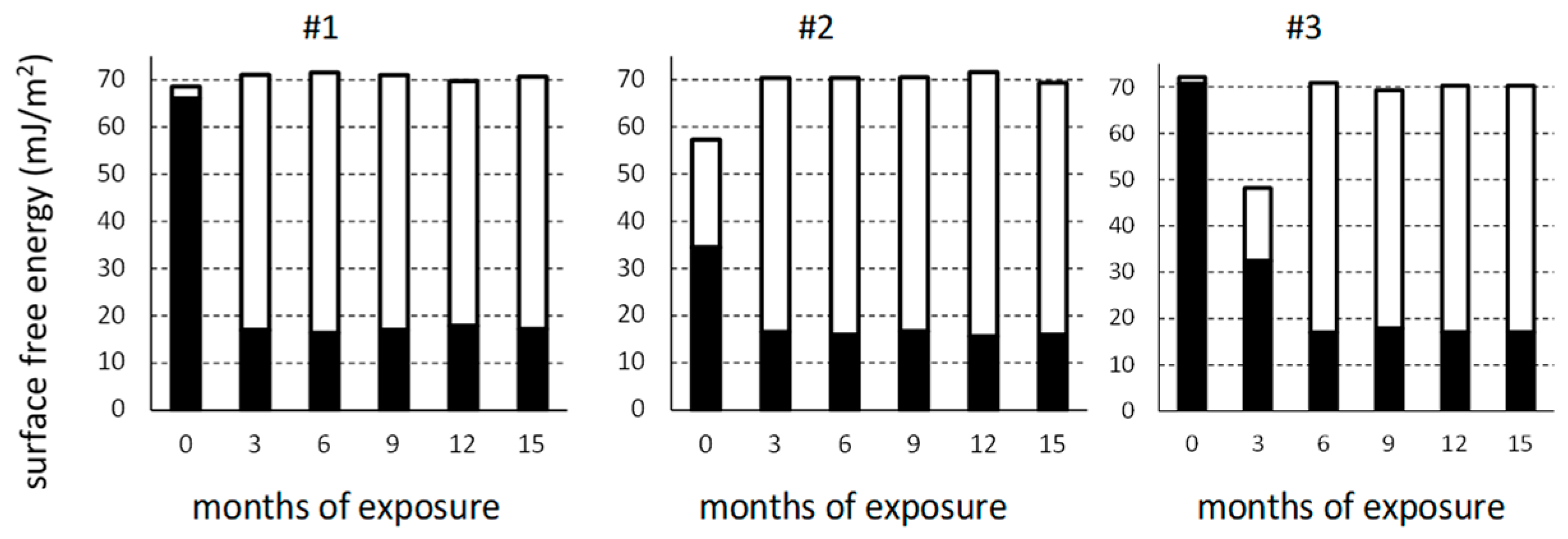

3.3. Wettability of Wood Surface

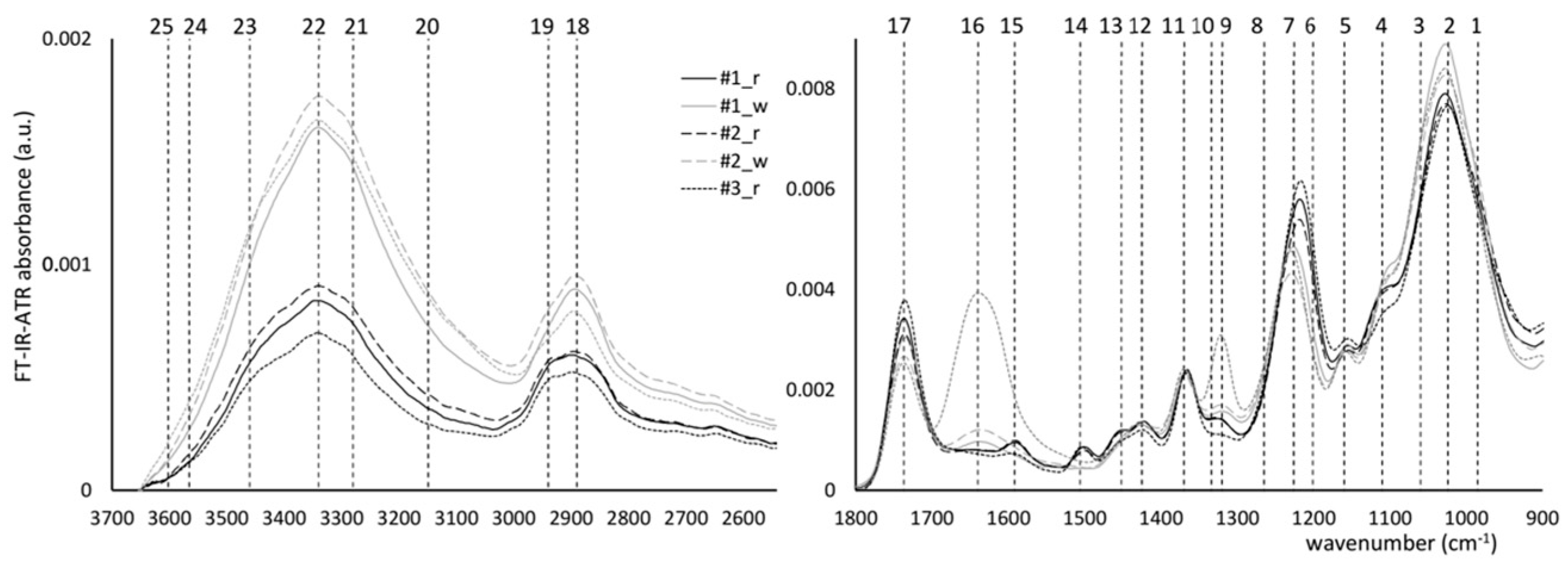

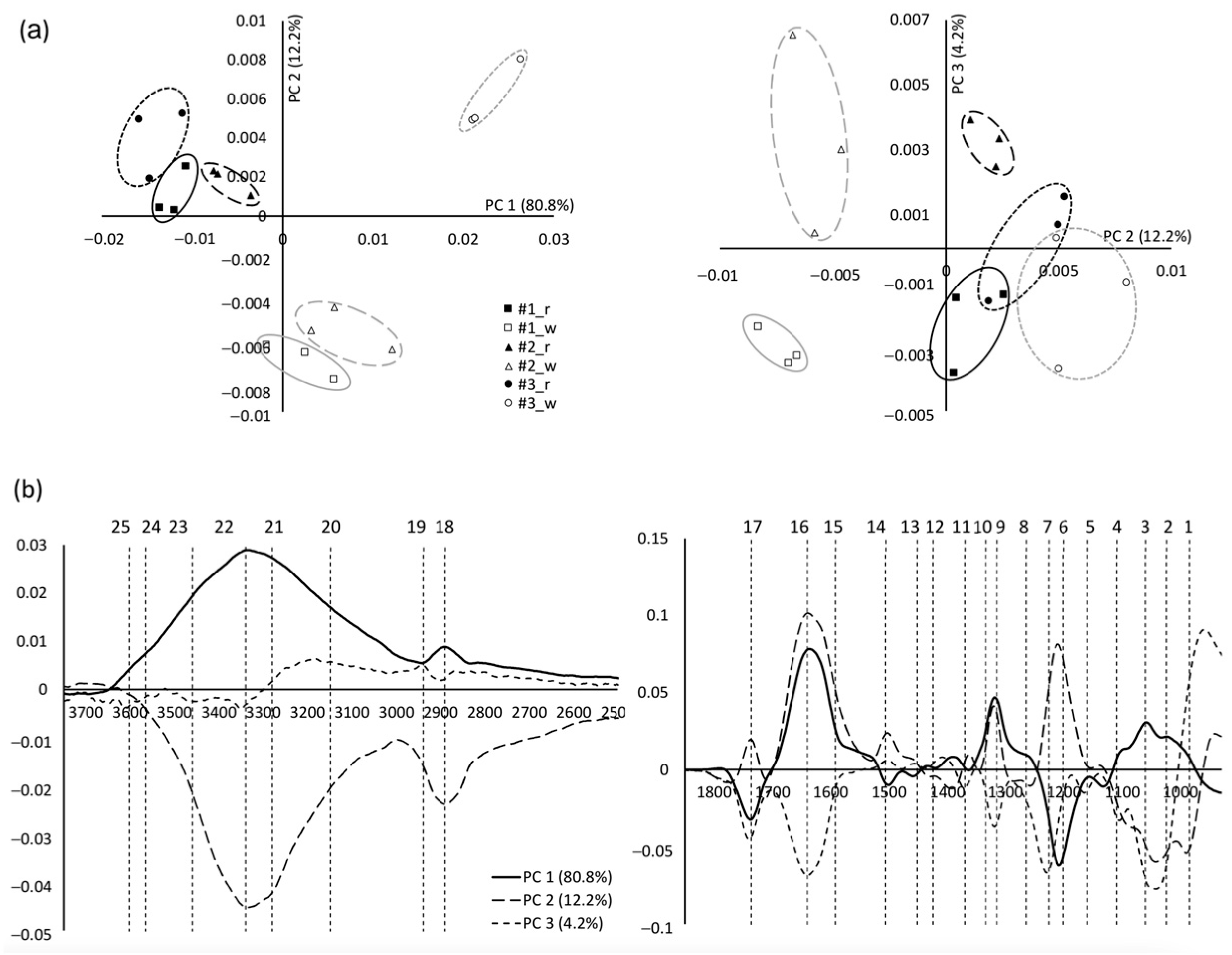

3.4. Chemical Changes in Wood Surface

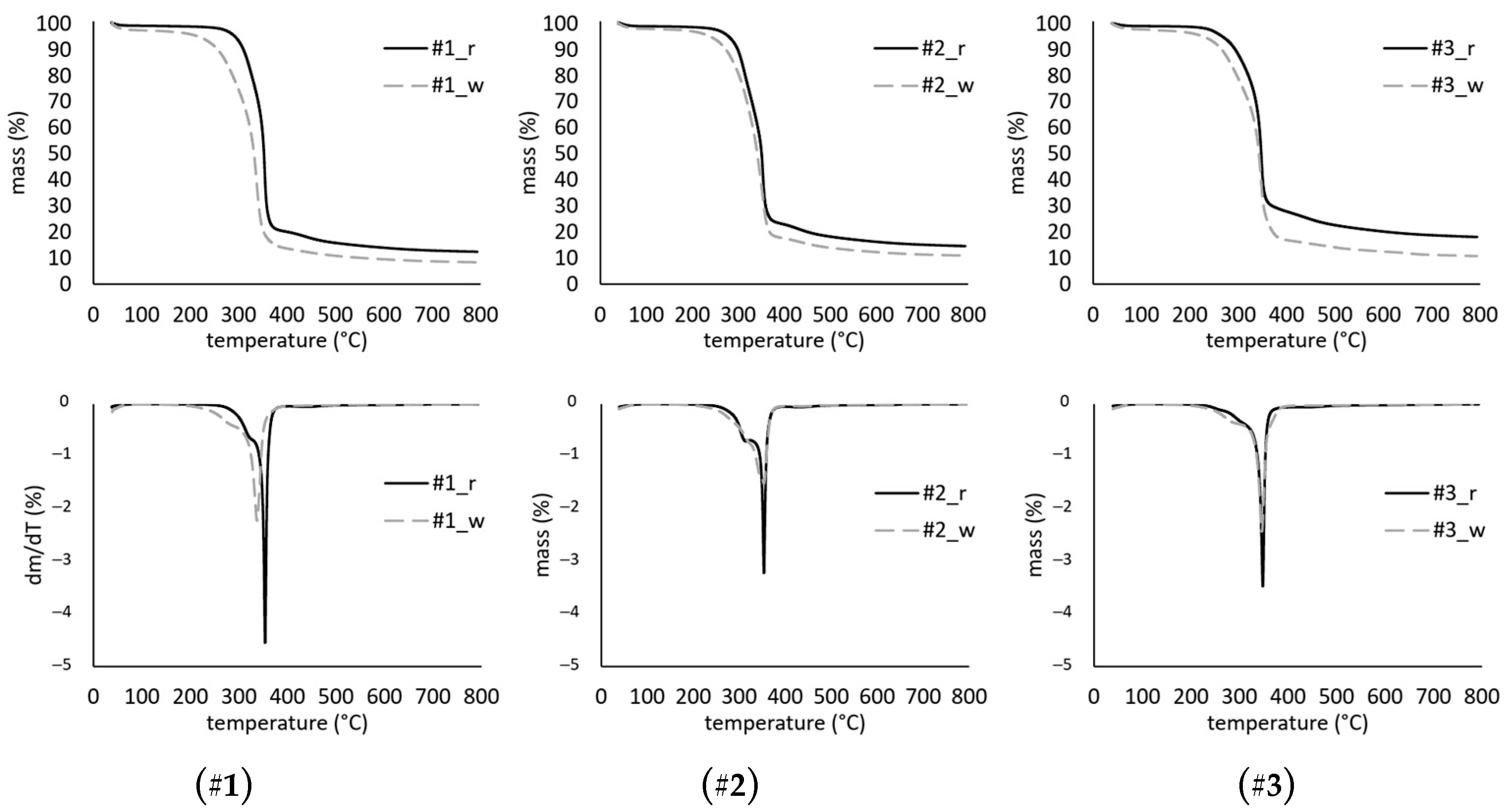

3.5. Thermal Properties of Weathered Wood

3.6. Practical Application of Conducted Research

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Williams, R.R. Weathering of wood. In Handbook of Wood Chemistry and Wood Composites, 1st ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 139–185. [Google Scholar]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Bio-Based Building Skin; Springer: Singapore, 2019. [Google Scholar]

- Rüther, P.; Time, B. External wood claddings—Performance criteria, driving rain and large-scale water penetration methods. Wood Mater. Sci. Eng. 2016, 10, 287–299. [Google Scholar] [CrossRef]

- Hill, C. An Introduction to Sustainable Resource Use; Taylor and Francis: London, UK, 2011. [Google Scholar]

- Hill, C. Wood Modification Chemical, Thermal and Other Processes; John Willey & Sons Ltd.: Chichester, UK, 2006. [Google Scholar]

- Hill, C.A.S.; Cetin, N.S.; Ozmen, Z. Potential catalysts for the acetylation of wood. Holzforschung 2000, 54, 269–272. [Google Scholar] [CrossRef]

- Ponnuchamy, V.; Sandak, A.; Sandak, J. Multiscale modelling investigation of wood modification with acetic anhydride. Phys. Chem. Chem. Phys. 2020, 22, 28448–28458. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Tanasă, F. Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions. Coatings 2020, 10, 629. [Google Scholar] [CrossRef]

- Rowell, R.M. Acetylation of wood: A journey from analytical technique to commercial reality. For. Prod. J. 2006, 56, 4–12. [Google Scholar]

- Jones, D.; Sandberg, D.A. Review of Wood Modification Globally—Updated Findings from COST FP1407. Interdiscip. Perspect. Built Environ. 2020, 1, 1–33. [Google Scholar] [CrossRef]

- Rowell, R.M. (Ed.) Chemical modification of wood. In Handbook of Wood Chemistry and Wood Composite; Taylor and Francis: Florida, FL, USA; CRC Press: Florida, FL, USA, 2005; pp. 381–420. [Google Scholar]

- Evans, P.D. Review of the weathering and photostability of modified wood. Wood Mater. Sci. Eng. 2009, 4, 2–13. [Google Scholar] [CrossRef]

- Usmanov, K.U. Degradation and stabilisation of cellulose acetates and some polymers based on vinyl fluoride. Polym. Sci. A 1978, 20, 1683–1690. [Google Scholar]

- Guo, J.; Wang, C.; Li, C.; Liu, Y. Effect of Acetylation on the Physical and Mechanical Performances of Mechanical Densified Spruce Wood. Forests 2022, 13, 1620. [Google Scholar] [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of Functional Treatments for Modified Wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Lykidis, C.; Papadopoulos, A.N. Durability of Accoya Wood in Ground Stake Testing after 10 Years of Exposure in Greece. Polymers 2020, 12, 1638. [Google Scholar] [CrossRef]

- Jirouš-Rajković, V.; Miklečić, J. Weathering resistance of modified wood—A review. In Proceedings of the Jubilee Annual 2017–2018 of the Croatian Academy of Engineering, Zagreb, Croatia, 4 June 2018; pp. 223–246. [Google Scholar]

- Rowell, R.; Bongers, F. Coating Acetylated Wood. Coatings 2015, 5, 792–801. [Google Scholar] [CrossRef]

- Bongers, F.; Creemers, J.; Kattenbroek, B.; Homan, W. Performance of coatings on acetylated Scots pine after more than nine years outdoor exposure. In Proceedings of the Second European Conference on Wood Modification, Göttingen, Germany, 6–7 October 2005; pp. 125–129. [Google Scholar]

- Sandak, A.; Földvári-Nagy, E.; Poohphajai, F.; Diaz, R.H.; Gordobil, O.; Sajinčič, N.; Ponnuchamy, V.; Sandak, J. Hybrid Approach for Wood Modification: Characterization and Evaluation of Weathering Resistance of Coatings on Acetylated Wood. Coatings 2021, 11, 658. [Google Scholar] [CrossRef]

- Evans, P.D.; Wallis, A.F.A.; Owen, N.L. Weathering of chemically modified wood surfaces—Natural weathering of Scots pine acetylated to different weight gains. Wood Sci. Technol. 2000, 34, 151–165. [Google Scholar] [CrossRef]

- Mantanis, G.I. Chemical modification of wood by acetylation or furfurylation—A review of the present scaled-up technologies. BioResources 2017, 12, 4478–4489. [Google Scholar] [CrossRef]

- Hukka, A.; Viitanen, H. A mathematical model of mould growth on wooden material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Noël, M.; Dimitriou, A. A Method for Accelerated Natural Weathering of Wood Subsurface and Its Multilevel Characterization. Coatings 2021, 11, 126. [Google Scholar] [CrossRef]

- Gaitán-Alvarez, J.; Berrocal, A.; Mantanis, G.I.; Moya, R.; Araya, F. Acetylation of tropical hardwood species from forest plantations in Costa Rica: An FTIR spectroscopic analysis. J. Wood Sci. 2020, 66, 49. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. IR Study on Cellulose with the Varied Moisture Contents: Insight into the Supramolecular Structure. Materials 2020, 13, 4573. [Google Scholar] [CrossRef]

- Gonultas, O.; Candan, Z. Chemical characterization and FTIR spectroscopy of thermally compressed eucalyptus wood panels. Maderas. Cienc. Y Tecnol. 2018, 20, 431–442. [Google Scholar] [CrossRef]

- Mitsui, K. Photo-bleaching of acetylated wood. In Proceedings of the Fifth European Conference on Wood Modification, Riga, Latvia, 20–21 September 2010; pp. 65–72. [Google Scholar]

- Chao, Y.-Y.; Hung, K.-C.; Xu, J.-W.; Wu, T.-L.; Wu, J.-H. Effects of Acetylated Veneer on the Natural Weathering Properties of Adhesive-Free Veneer Overlaid Wood–Plastic Composites. Polymers 2020, 12, 513. [Google Scholar] [CrossRef] [PubMed]

- Gobakken, L.R.; Høibø, O.A.; Solheim, H. Factors influencing surface mould growth on wooden claddings exposed outdoors Wood Mater. Sci. Eng. 2010, 5, 1–12. [Google Scholar]

- Gobakken, L.R.; Høibø, O.A.; Solheim, H. Mould growth on paints with different surface structures when applied on wooden claddings exposed outdoors. Int. Biodeterior. Biodegrad. 2010, 64, 339–345. [Google Scholar] [CrossRef]

- Gobakken, L.R.; Vestøl, G.I. Surface mould and blue stain fungi on coated Norway spruce cladding. Int. Biodeterior. Biodegrad. 2012, 75, 181–186. [Google Scholar] [CrossRef]

- Kotradyová, V.; Teischinger, A. Exploring the Contact Comfort within Complex Well-Being in Microenvironment. Adv. Mat. Res. 2014, 899, 356–362. [Google Scholar] [CrossRef]

- Sandak, A.; Brzezicki, M.; Sandak, J. Trends and perspectives in the use of timber and derived products in building façades. In New Materials in Civil Engineering; Samui, P., Kim, D., Iyer, N.R., Chaudhary, S., Eds.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 333–374. [Google Scholar]

- Wood, K.A.; Cypcar, C.; Hedhli, L. Predicting the exterior durability of new fluoropolymer coatings. J. Fluor. Chem. 2000, 104, 63–71. [Google Scholar] [CrossRef]

- Bobadilha, G.D.S.; Stokes, C.E.; Ohno, K.M.; Kirker, G.; Lopes, D.J.V.; Nejad, M. Physical, Optical, and Visual Performance of Coated Cross-Laminated Timber during Natural and Artificial Weathering. Coatings 2021, 11, 252. [Google Scholar] [CrossRef]

- Fojutowski, A.; Koziróg, A.; Kropacz, A.; Noskowiak, A. The susceptibility of some acetylated hardwood species to mould fungi attack—An attempt to objectify the assessment. Int. Biodeter. Biodegr. 2014, 86, 60–65. [Google Scholar] [CrossRef]

- Lie, S.K.; Vestøl, G.I.; Høibø, O.; Gobakken, L.R. Visual appearance of unpainted wood: Mould coverage, lightness and uniformity. Int. Wood Prod. J. 2019, 10, 9–15. [Google Scholar] [CrossRef]

- Žlahtič, M.; Humar, M. Influence of artificial and natural weathering on the hydrophobicity and surface properties of wood. BioResources 2016, 11, 4964–4989. [Google Scholar] [CrossRef]

- Qin, Z.; Gao, Q.; Zhang, S.; Li, J. Surface free energy and dynamic wettability of differently machined poplar woods. BioResources 2014, 9, 3088–3103. [Google Scholar] [CrossRef]

- Jankowska, A.; Rybak, K.; Nowacka, M.; Boruszewski, P. Insight of Weathering Processes Based on Monitoring Surface Characteristic of Tropical Wood Species. Coatings 2020, 10, 877. [Google Scholar] [CrossRef]

- Herrera Díaz, R.; Gordobil, O.; de Hoyos-Martinez, P.L.; Sandak, A.; Labidi, J. Hydrophobization and Photo-Stabilization of Radiata Pinewood: The Effect of the Esterification on Thermal and Mechanical Properties. Forests 2020, 11, 1243. [Google Scholar] [CrossRef]

- Schwanninger, M.; Stefke, B.; Hinterstoisser, B. Qualitative Assessment of Acetylated Wood with Infrared Spectroscopic Methods. J. Near Infrared Spectrosc. 2011, 19, 349–357. [Google Scholar] [CrossRef]

- Reinprecht, L.; Mamonová, M.; Pánek, M.; Kacík, F. The impact of natural and artificial weathering on the visual, colour and structural changes of seven tropical woods. Eur. J. Wood Wood Prod. 2018, 76, 175–190. [Google Scholar] [CrossRef]

- Pandey, K.K. A note on the influence of extractives on the photodiscoloration and photo-degradation of wood. Polym. Degrad. Stab. 2005, 87, 375–379. [Google Scholar] [CrossRef]

- Arpaci, S.S.; Tomak, E.D.; Ermeydan, M.; Yıldırım, I. Natural weathering of sixteen wood species: Changes on surface properties. Polym. Degrad. Stab. 2020, 183, 109415. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. Wood degradation under UV irradiation: A lignin characterization. J. Photoch. Photobio. B 2016, 158, 184–191. [Google Scholar] [CrossRef]

- Beall, F.C.; Eickner, H.W. Thermal Degradation of wood Components: A Review of the Literature; U.S. Forest Products Laboratory: Madison, WI, USA, 1970; pp. 1–26.

- Jeske, H.; Schirp, A.; Cornelius, F. Development of a thermogravimetric analysis (TGA) method for quantitative analysis of wood flour and polypropylene in wood plastic composites (WPC). Thermochimica. Acta 2012, 543, 165–171. [Google Scholar] [CrossRef]

- Slopiecka, K.; Bartocci, P.; Fantozzi, F. Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. In Proceedings of the Third International Conference on Applied Energy, Perugia, Italy, 16–18 May 2011. [Google Scholar]

- Feist, W.C.; Hon, D.S. Chemistry of weathering and protection. Adv. Chem. Ser. 1984, 207, 401–451. [Google Scholar] [CrossRef]

- Kotradyová, V.; Sandak, A.; Sandak, J.; Alfredsen, G. Multi-criteria decision support tool for selection of biobased façade materials. In Proceedings of the 5th International Conference Forum Wood Building Baltic, Tallinn, Estonia, 26–28 February 2024; pp. 180–181. [Google Scholar]

- Hill, C.; Hughes, M.; Gudsell, D. Environmental Impact of Wood Modification. Coatings 2021, 11, 366. [Google Scholar] [CrossRef]

- Niklewski, J.; Sandak, J.; van Niekerk, P.B.; Brischke, C.; Acquah, R.; Sandak, A. Simplified environmental analysis of the long-term performance of wood cladding and decking. In Proceedings of the Wood Conference on Timber Engineering (WCTE), Oslo, Norway, 19–22 June 2023; pp. 549–557. [Google Scholar]

- Sandak, A.; Gordobil, O.; Poohphajai, F.; Herrera Diaz, R.; Sandak, J. Raw Data for Publication: Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation. Forests 2024, 15, 1097. [Google Scholar] [CrossRef]

| Exposure Month | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean temp (°C) | 12 | 14 | 19 | 24 | 25 | 25 | 17 | 14 | 7 | 1 | 4 | 4 | 17 | 19 | 24 |

| Total rain (mm) | 32 | 108 | 50 | 36 | 27 | 17 | 6 | 1 | 28 | 3 | 1 | 7 | 4 | 15 | 5 |

| Days of rain | 8 | 11 | 15 | 10 | 10 | 14 | 3 | 6 | 4 | 4 | 3 | 11 | 11 | 21 | 12 |

| RH (%) | 49 | 45 | 51 | 51 | 50 | 52 | 68 | 62 | 69 | 74 | 82 | 55 | 55 | 67 | 49 |

| Mean wind (km/h) | 7 | 9 | 7 | 9 | 8 | 6 | 5 | 5 | 4 | 3 | 3 | 5 | 6 | 6 | 8 |

| Band Number | Peak Position (cm−1) | IR Band Assignment |

|---|---|---|

| 1 | 985 | CO valence vibrations |

| 2 | 1024 | CO stretching in cellulose and non-cellulose polysaccharides |

| 3 | 1060 | C–O + C–C stretch of cellulose |

| 4 | 1110 | Aromatic skeletal; C–C stretch |

| 5 | 1160 | CO stretching in ester groups in lignin |

| 6 | 1201 | untreated cellulose (ρ OH; δ CH) |

| 7 | 1240 | antisymmetric C–O stretching vibration |

| 8 | 1265 | guaiacyl ring vibrations and CO stretching lignin, C–C and C–O stretching |

| 9 | 1320 | C–H vibration in cellulose; C–O in syringil and condensed guaiacyl units |

| 10 | 1334 | vibration in CH and stretching in CO related to syringil ring |

| 11 | 1370 | C–H deformation vibrations of the CH3 group |

| 12 | 1425 | vibration of aromatic structures in lignin |

| 13 | 1452 | aromatic skeletal vibrations of lignin and CH2 vibration in cellulose |

| 14 | 1508 | aromatic skeletal vibrations of lignin and C=O stretching |

| 15 | 1592 | conjugated carbonyl C=O stretching |

| 16 | 1650 | absorbed water (hydrogen-bonded), conjugated carbonyls –C=C–C=O |

| 17 | 1740 | non-conjugated carbonyl C=O stretching, molecular vibrations of acetyl C=O groups |

| 18 | 2890 | C-H stretching in methyl and methylene groups |

| 19 | 2940 | asymmetric stretching vibrations of CH related to methyl and methylene in lignin, cellulose and hemicellulose |

| 20 | 3149 | -OH stretching in cellulose |

| 21 | 3280 | C-H stretching in methyl and methylene groups |

| 22 | 3340 | -O(3)H O(5) intramolecular hydrogen bonds in cellulose |

| 23 | 3460 | moderately H-bonded water |

| 24 | 3565 | valence vibration of H bonded OH groups |

| 25 | 3602 | weakly H-bonded water |

| Parameters | #1r | #1w | #2r | #2w | #3r | #3w |

|---|---|---|---|---|---|---|

| T5% | 292.4 | 219.1 | 278.8 | 241.9 | 276.4 | 230.5 |

| T50% | 352.4 | 331.9 | 350.6 | 341.2 | 347.4 | 342.7 |

| Tmax | 353.9 | 337.2 | 353.6 | 353.3 | 347.9 | 345.8 |

| Residue | 12.1 | 8.4 | 12.2 | 11.8 | 17.9 | 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandak, A.; Gordobil, O.; Poohphajai, F.; Herrera Diaz, R. Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation. Forests 2024, 15, 1097. https://doi.org/10.3390/f15071097

Sandak A, Gordobil O, Poohphajai F, Herrera Diaz R. Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation. Forests. 2024; 15(7):1097. https://doi.org/10.3390/f15071097

Chicago/Turabian StyleSandak, Anna, Oihana Gordobil, Faksawat Poohphajai, and Rene Herrera Diaz. 2024. "Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation" Forests 15, no. 7: 1097. https://doi.org/10.3390/f15071097

APA StyleSandak, A., Gordobil, O., Poohphajai, F., & Herrera Diaz, R. (2024). Weathering of Wood Modified with Acetic Anhydride—Physical, Chemical, and Aesthetical Evaluation. Forests, 15(7), 1097. https://doi.org/10.3390/f15071097