Feasibility of Bonding High-Moisture-Content Wood Using Nothofagus chilean Species

Abstract

:1. Introduction

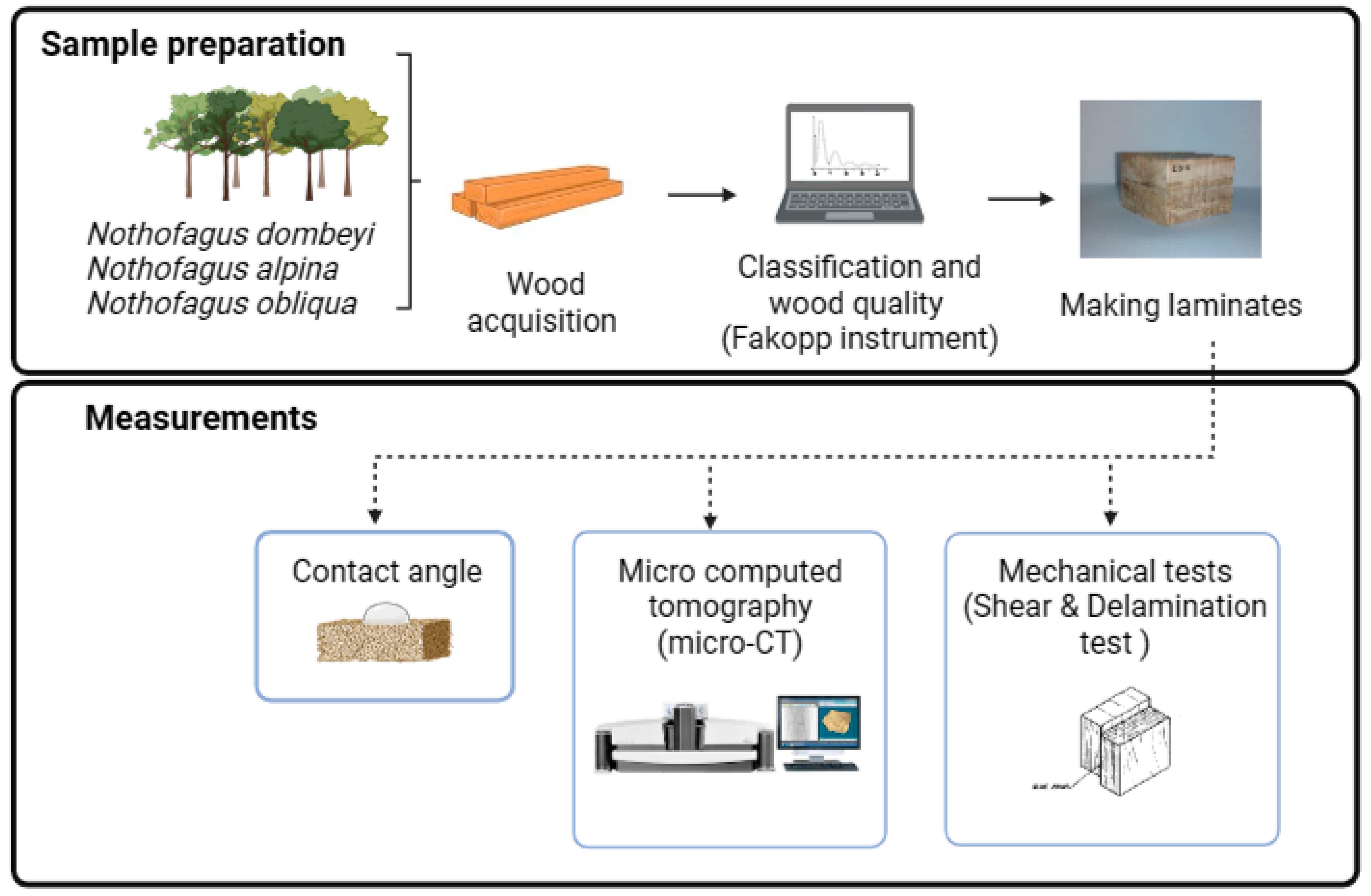

2. Materials and Methods

2.1. Origin of Raw Material

2.2. Characterization of Physical and Morphological Properties of Wood

2.2.1. Physical Parameters

2.2.2. Micro-Computed Tomography (Micro-CT)

2.2.3. Contact Angle Testing

2.3. Manufacture of Green Glued Laminate

2.4. Mechanical Tests

2.4.1. Shear Test

2.4.2. Delamination Test

2.5. Statistical Analysis

3. Results

3.1. Characterization of Physical Properties

3.2. Mechanical Tests

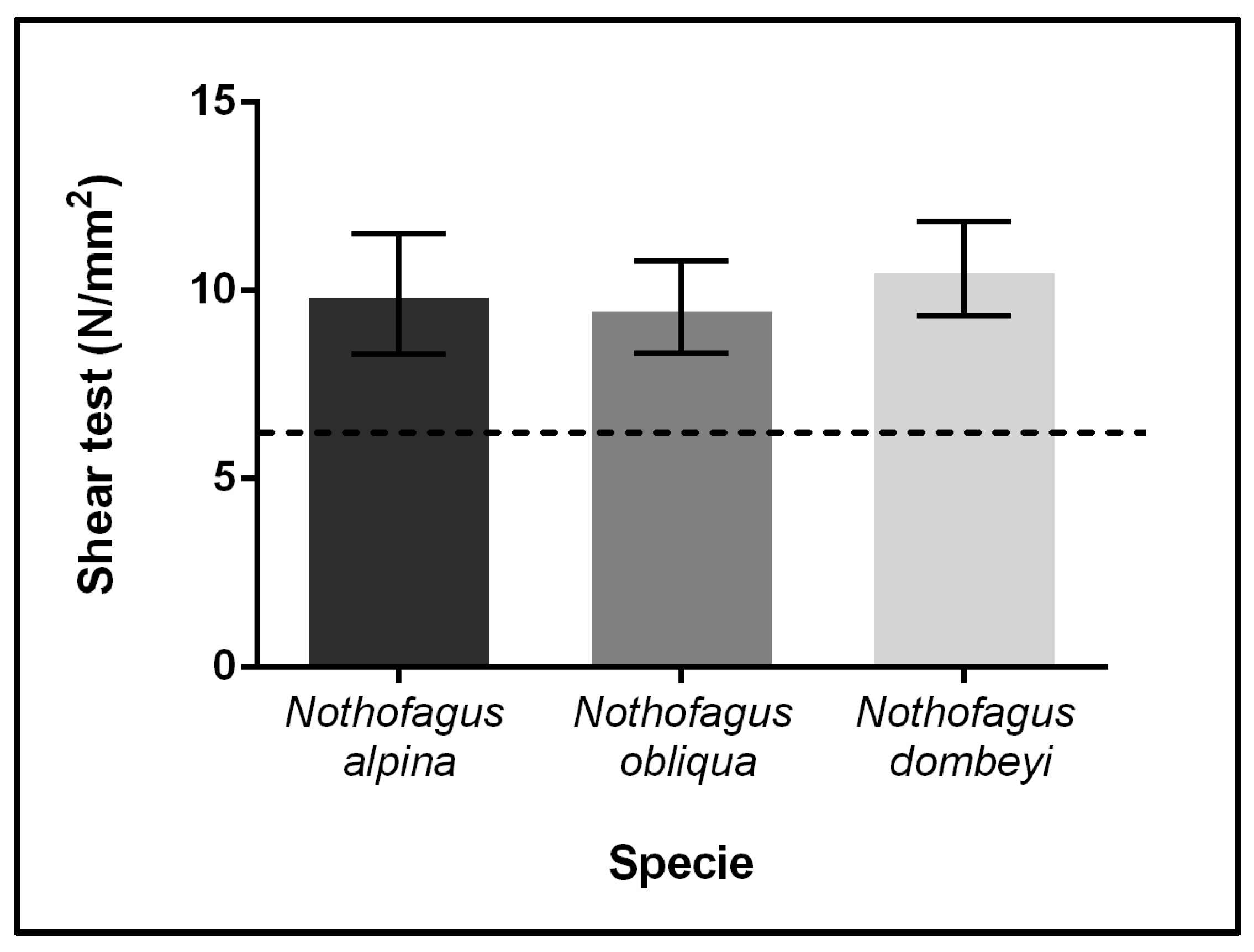

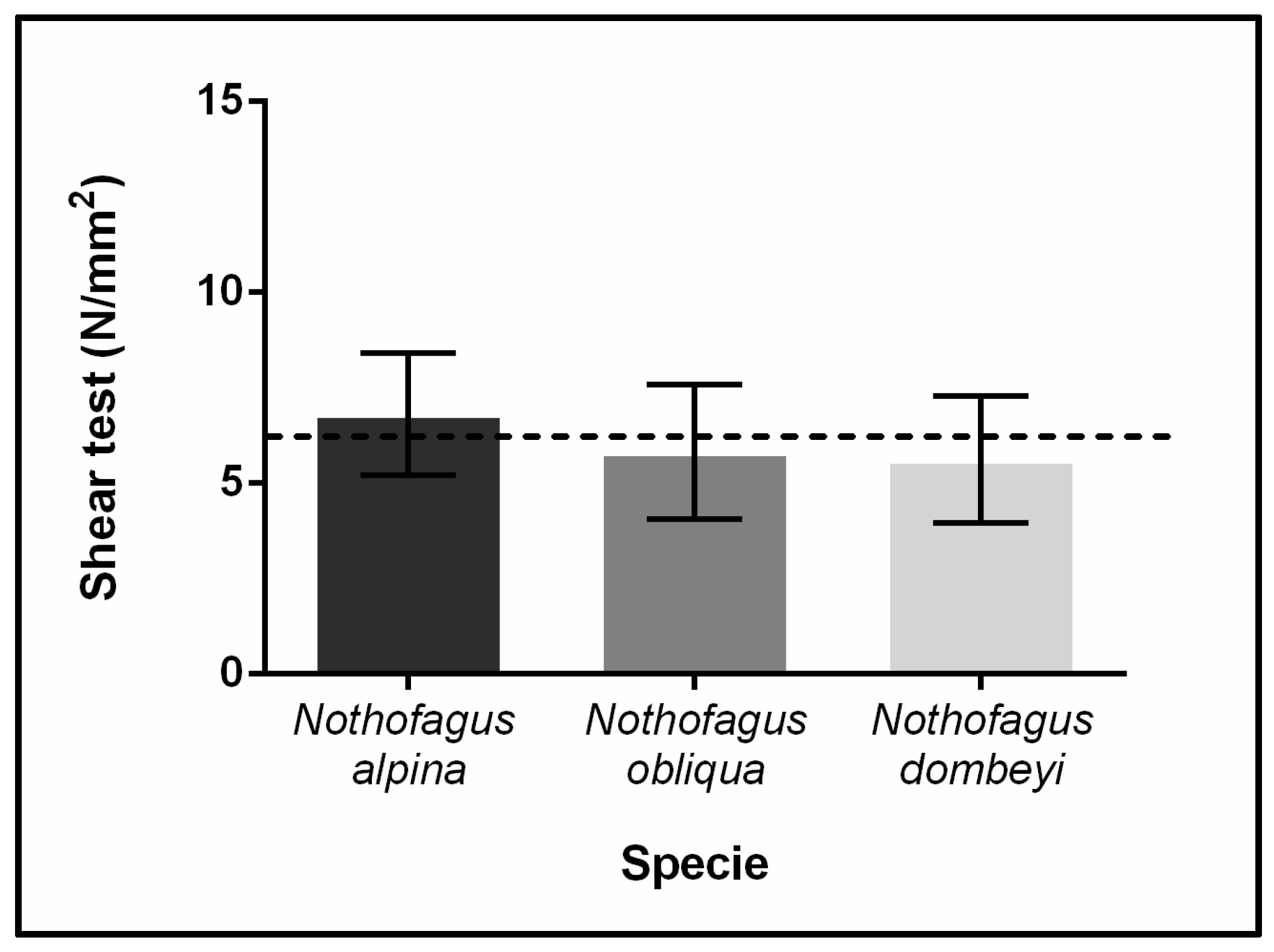

3.2.1. Shear Test

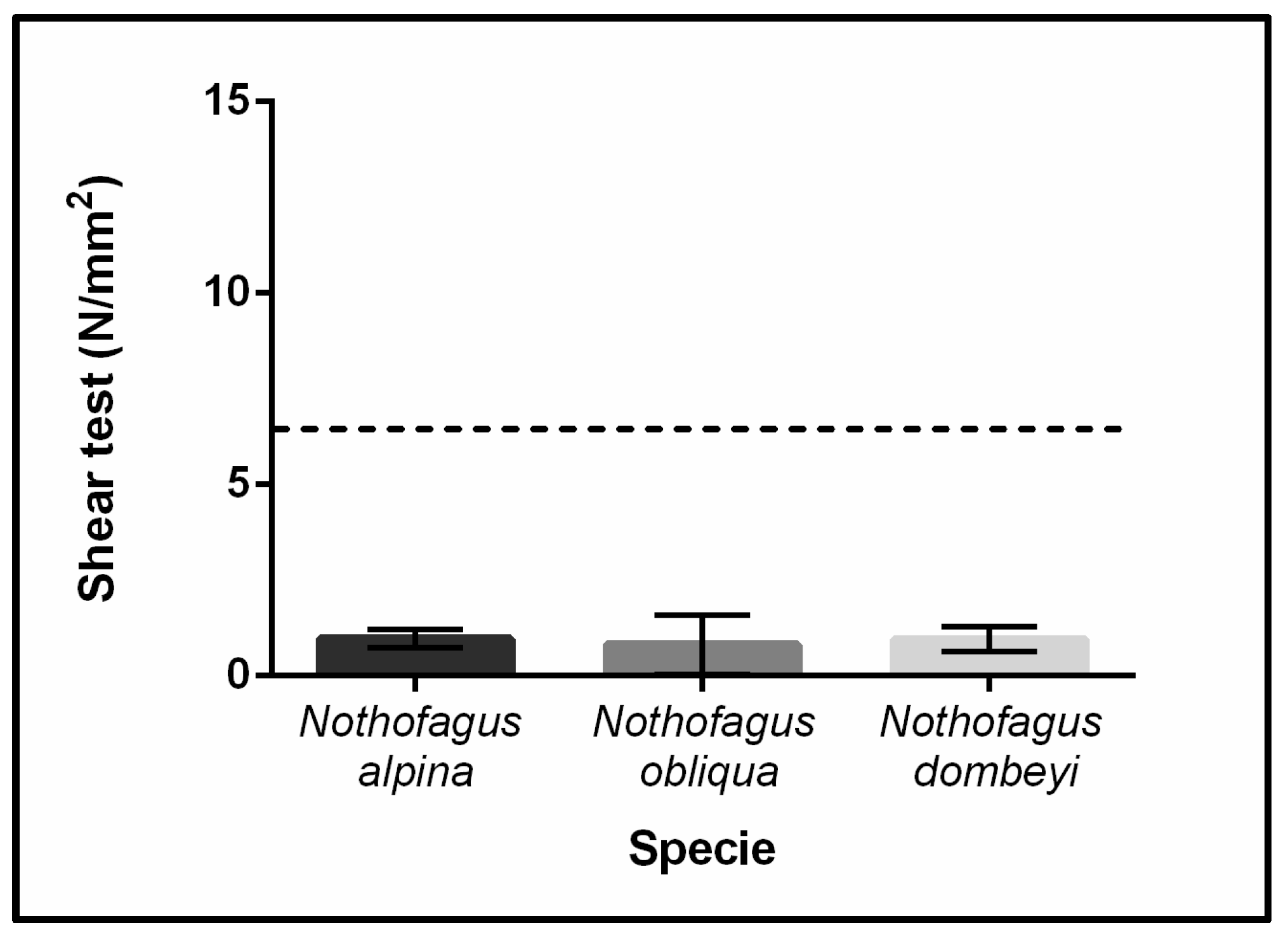

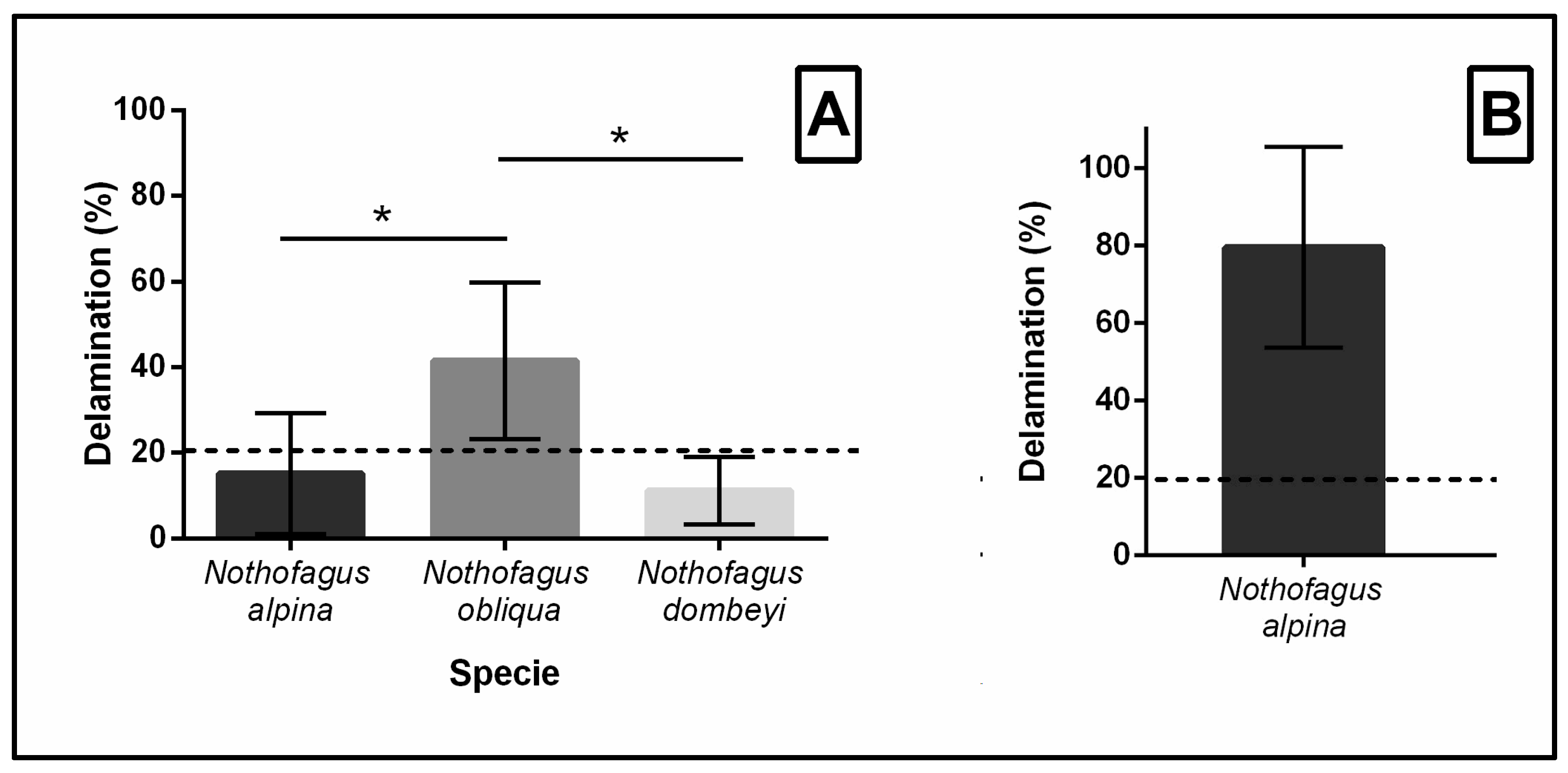

3.2.2. Delamination Test

3.3. Morphological Characterization

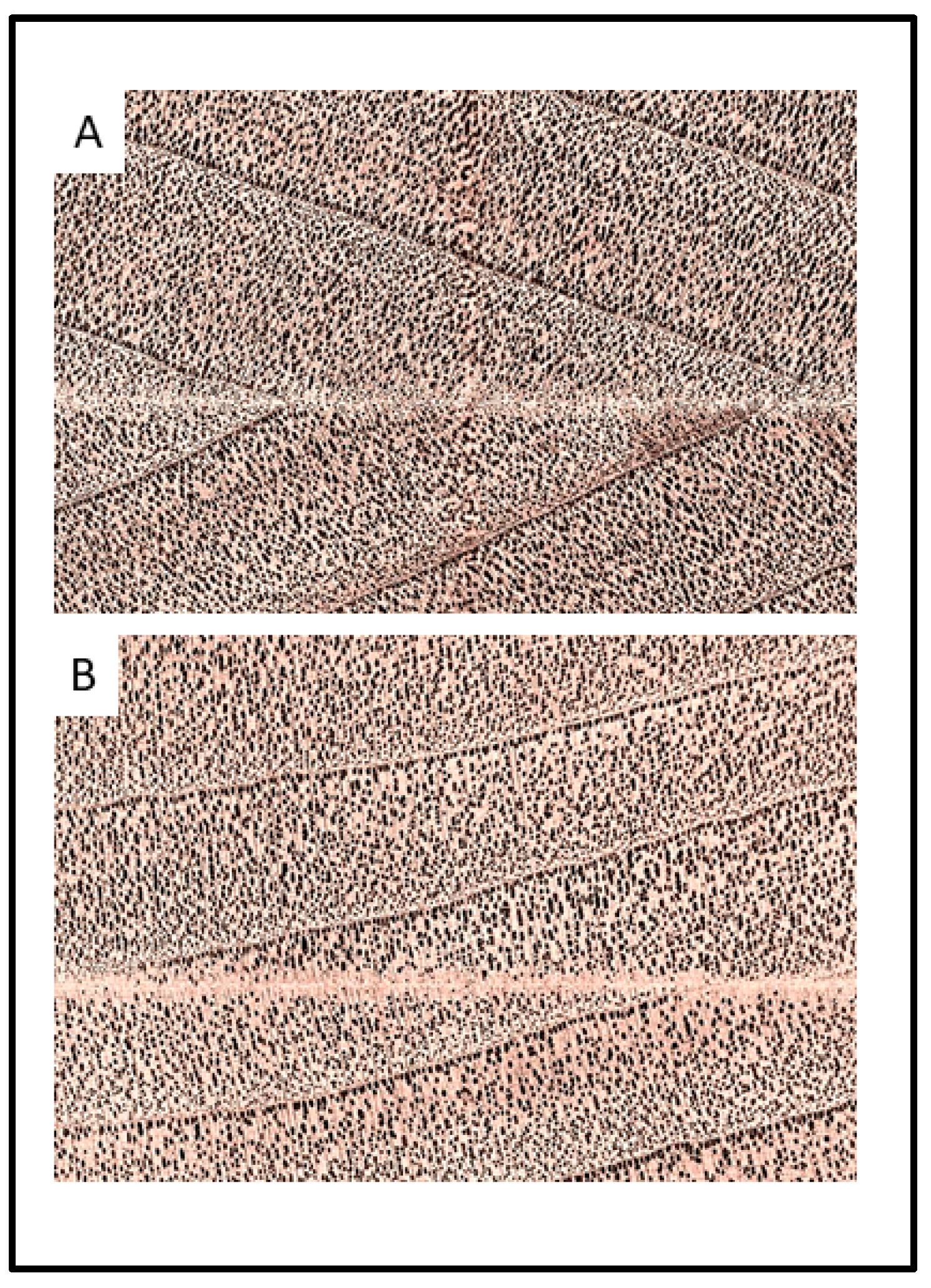

3.3.1. Characterization by Microcomputed Tomography (Micro-CT)

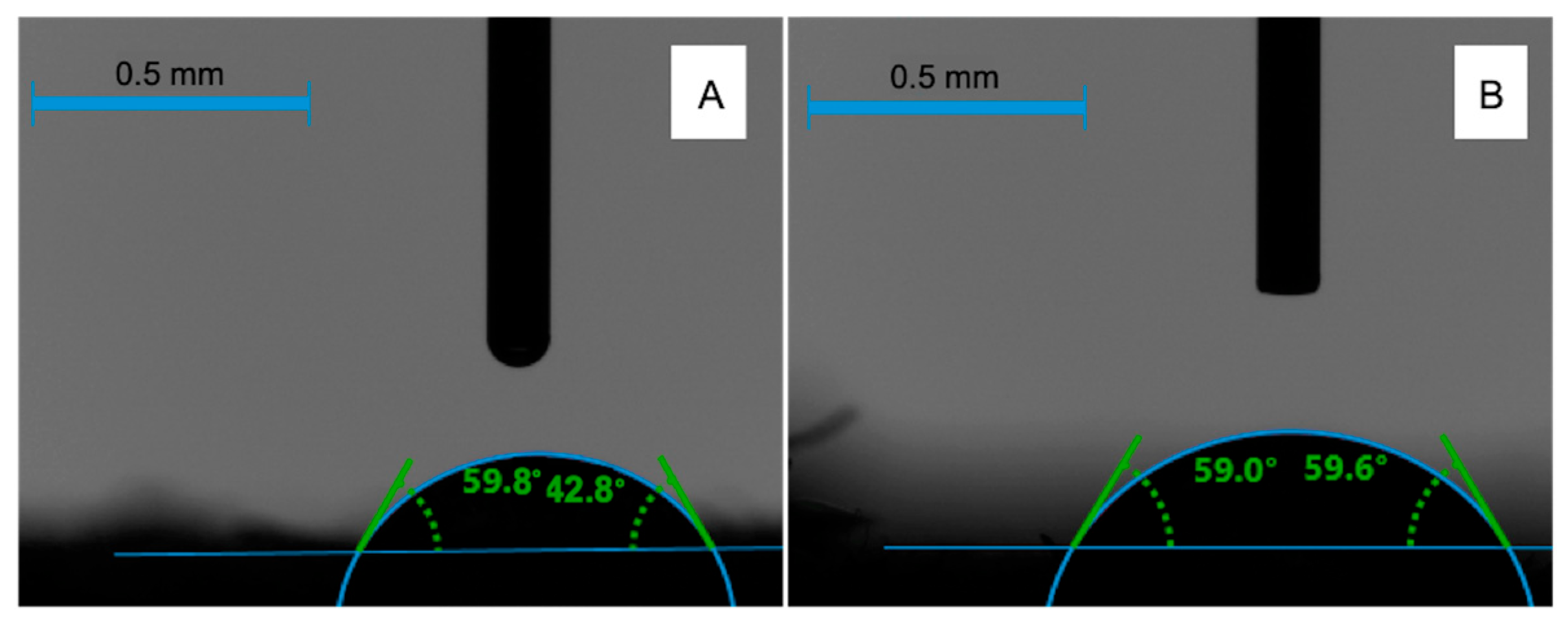

3.3.2. Measurement of the Surface Wettability of Wood by the Contact Angle Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brockerhoff, E.G.; Barbaro, L.; Castagneyrol, B.; Forrester, D.I.; Gardiner, B.; González-Olabarria, J.R.; Lyver, P.O.; Meurisse, N.; Oxbrough, A.; Taki, H.; et al. Forest Biodiversity, Ecosystem Functioning and the Provision of Ecosystem Services. Biodivers. Conserv. 2017, 26, 3005–3035. [Google Scholar] [CrossRef]

- Rodríguez-Grau, G.; Pinto-González, F.; Cortés-Rodríguez, P.; Marín-Uribe, C. Native Wood Revaluation through Green Gluing: A Systematic Review. In World Conference on Timber Engineering; WCTE: Chile, Santiago, 2021. [Google Scholar]

- Riquelme-Buitano, T.; González, P.F.O.; Donoso, P.J. Comparing Growth of Nothofagus Alpina and Nothofagus Obliqua in Pure and Mixed Plantations in the Intermediate Depression of the Los Ríos Region, Chile. Bosque 2023, 44, 263–272. [Google Scholar] [CrossRef]

- Instituto Forestal. Memoria INFOR 2019; INFOR: Sino Plaza, Hong Kong, 2020. [Google Scholar]

- Juacida, P.R.; Siebert, W.H.; Torres, U.M.; Edad, Y. Durabilidad Natural de Renovales de Nothofagus Obliqua. Bosque 2000, 21, 73–77. [Google Scholar] [CrossRef]

- Ugarte Hidalgo, M. Caracterizaciόn Del Crecimiento En Renovales de Roble (Nothofagus Obliqua (Mirb). Oerst) En La Comuna de Curacautín, Regiόn de La Araucanía; Universidad de Chile: Santiago, Chile, 2014. [Google Scholar]

- Sterley, M. Green Gluing of Wood; KTH-Royal Institute of Technology: Stockholm, Sweden, 2004. [Google Scholar]

- Rodríguez-Grau, G.; Marín-Uribe, C.; Cortés-Rodríguez, P.; Montero, C.; Rosales, V.; Galarce, C. Bibliometric Analysis of the Green Gluing Technique (2000–2020): Trends and Perspectives. Forests 2022, 13, 1714. [Google Scholar] [CrossRef]

- Sultana, R.; Rashedi, A.; Khanam, T.; Jeong, B.; Hosseinzadeh-Bandbafha, H.; Hussain, M. Life Cycle Environmental Sustainability and Energy Assessment of Timber Wall Construction: A Comprehensive Overview. Sustainability 2022, 14, 4161. [Google Scholar] [CrossRef]

- NCh176/1; Madera-Parte 1: Determinación Del Contenido de Humedad. Instituto Nacional de Normalización: Santiago, Chile, 2019.

- NCh176/2; Madera-Parte 2: Determinación de Densidad. Instituto Nacional de Normalización: Santiago, Chile, 1988.

- Balmori Roiz, J.A.; Acuña Rello, L.B.; Otero, L.A. Estudio de La Influencia de La Dirección de La Fibra En La Velocidad de Propagación de Ultrasonidos (FAKOPP) En Madera Estructural de “Pinus Sylvestris L. y “Pinus Radiata D. Don.”. In Proceedings of the 6th Rehabend Congress, Burgos, Spain, 24–27 May 2016. [Google Scholar]

- Grabianowski, M.; Manley, B.; Walker, J.C.F. Acoustic Measurements on Standing Trees, Logs and Green Lumber. Wood Sci. Technol. 2006, 40, 205–216. [Google Scholar] [CrossRef]

- Romano-Matos, V.; Tundidor-Camba, A.; Vera, S.; Videla, A.R. Improvement of Plasterboard Properties by the Control of Polymethylhydrosiloxane Dosage, Stirring Time, and Drying Temperature Applied to the Calcium Sulfate Hemihydrate and Water Mixture. Materials 2023, 16, 5084. [Google Scholar] [CrossRef]

- Kazup, Á.; Fegyverneki, G.; Gácsi, Z. Evaluation of the Applicability of Computer-Aided Porosity Testing Methods for Different Pore Structures. Metallogr. Microstruct. Anal. 2022, 11, 774–789. [Google Scholar] [CrossRef]

- Qin, Z.; Gao, Q.; Zhang, S.; Li, J. Surface Free Energy and Dynamic Wettability of Differently Machined Poplar Woods. Bioresources 2014, 9, 3088–3103. [Google Scholar] [CrossRef]

- Popper, R.; Niemz, P.; Eberle, G. ETH Library Influence of Extractives on Water Vapour Sorption by the Example of Wood Species from Chile Influence of Extractives on Water Vapour Sorption by the Example of Wood Species from Chile. Wood Res. 2006, 51, 95–96. [Google Scholar]

- ASTM (D905); Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading. ASTM International: West Conshohocken, PA, USA, 2021.

- NCh 2148; Madera Laminada Encolada Estructural—Requisitos, Métodos de Muestreo e Inspección. Instituto Nacional de Normalización: Santiago, Chile, 2013.

- ISO 12580:2007; Timber Structures—Glued Laminated Timber—Methods of Test for Glue-Line Delamination. ISO: Geneva, Switzerland, 2007.

- Yang, J.L.; Evans, R. Prediction of MOE of Eucalypt Wood from Microfibril Angle and Density. Holz als Roh—Und Werkst. 2003, 61, 449–452. [Google Scholar] [CrossRef]

- Kumar, C.; Psaltis, S.; Turner, I.; Brancheriau, L.; Hopewell, G.; Lee, D.; Bailleres, H. Predicting Performance of Sawn Boards by Using Transverse Cores of Standing Trees; University of Queensland: Brisbane, Australia, 2019. [Google Scholar]

- Cordeiro, L.A.; Miranda, B.D.; Carneiro, M.E.; Missio, A.L.; Klock, U.; Cademartori, P.H.G.D. The Effect of Sanding on the Wettability and Surface Quality of Imbuia, Red Oak and Pine Wood Veneers. Maderas. Cienc. y Tecnol. 2023, 25. [Google Scholar] [CrossRef]

- Hebbar, R.S.; Isloor, A.M.; Ismail, A.F. Contact Angle Measurements. In Membrane Characterization; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 219–255. ISBN 9780444637918. [Google Scholar]

- Jankowska, A.; Zbieć, M.; Kozakiewicz, P.; Koczan, G.; Oleńska, S.; Beer, P. The Wettability and Surface Free Energy of Sawn, Sliced and Sanded European Oak Wood. Cienc. y Tecnol. 2018, 20, 443–454. [Google Scholar] [CrossRef]

- Setter, C.; Lira Zidanes, U.; Hélio de Novais Miranda, E.; Maria Silva Brito, F.; Marin Mendes, L.; Benedito Guimarães Junior, J. Influence of Wood Species and Adhesive Type on the Performance of Multilaminated Plywood. Environ. Sci. Pollut. Res. 2021, 28, 50835–50846. [Google Scholar] [CrossRef]

- Alia-Syahirah, Y.; Paridah, M.T.; Hamdan, H.; Anwar, U.M.K.; Nordahlia, A.S.; Lee, S.H. Effects of Anatomical Characteristics and Wood Density on Surface Roughness and Their Relation to Surface Wettability of Hardwood. J. Trop. For. Sci. 2019, 31, 269–277. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and Pore Size Distribution of Different Wood Types as Determined by Mercury Intrusion Porosimetry. Eur. J. Wood Wood Prod. 2011, 69, 649–657. [Google Scholar] [CrossRef]

- Jang, E.-S.; Kang, C.-W. Changes in Gas Permeability and Pore Structure of Wood under Heat Treating Temperature Conditions. J. Wood Sci. 2019, 65, 37. [Google Scholar] [CrossRef]

- Salin, J.G. Drying of Liquid Water in Wood as Influenced by the Capillary Fiber Network. Dry. Technol. 2008, 26, 560–567. [Google Scholar] [CrossRef]

- Arai Mizutani, K.M.; Oshima, K.; Iida, I. Physical and Mechanical Properties of Wood after Moisture Conditioning. J. Wood Sci. 2001, 47, 185–191. [Google Scholar]

- Bockel, S.; Harling, S.; Konnerth, J.; Niemz, P.; Weiland, G.; Hogger, E.; Pichelin, F. Modifying Elastic Modulus of Two-Component Polyurethane Adhesive for Structural Hardwood Bonding. J. Wood Sci. 2020, 66, 69. [Google Scholar] [CrossRef]

- Li, X.; Ashraf, M.; Kafle, B.; Subhani, M. Effect of Fibre Orientation on the Bond Properties of Softwood and Hardwood Interfaces. Buildings 2023, 13, 1011. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The Strength and Stiffness of Oriented Wood and Cellulose-Fibre Materials: A Review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Lissouck, R.O.; Ngono Mvondo, R.R.; Ateba, F.R.; Pommier, R. Investigation of Green-Glued Laminated Timber from the Congo Basin: Durability, Mechanical Strength and Variability Trends of the Bondlines. South. For. 2022, 84, 225–241. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Y.; Cao, Y.; Li, G.; Liao, Y. Influence of Surface Roughness on Contact Angle Hysteresis and Spreading Work. Colloid. Polym. Sci. 2020, 298, 1107–1112. [Google Scholar] [CrossRef]

- Sinderski, L.G.Z. Contact Angle and Roughness of Wood, a Short Review. Ciência da Madeira 2020, 11, 1–11. [Google Scholar] [CrossRef]

- Benkreif, R.; Brahmia, F.Z.; Csiha, C. Influence of Moisture Content on the Contact Angle and Surface Tension Measured on Birch Wood Surfaces. Eur. J. Wood Wood Prod. 2021, 79, 907–913. [Google Scholar] [CrossRef]

- Milne, A.J.B.; Amirfazli, A. The Cassie Equation: How It Is Meant to Be Used. Adv. Colloid. Interface Sci. 2012, 170, 48–55. [Google Scholar] [CrossRef]

- Bobji, M.S.; Kumar, S.V.; Asthana, A.; Govardhan, R.N. Underwater Sustainability of the “Cassie” State of Wetting. Langmuir 2009, 25, 12120–12126. [Google Scholar] [CrossRef]

- Xiang, H.; Xia, H.; Chen, H.; Mi, H. Influence of Moisture-Curing Reaction on the Mechanical Properties of One-Component Polyurethane Mixtures. J. Mater. Sci. 2021, 56, 15069–15086. [Google Scholar] [CrossRef]

- Shirmohammadli, Y.; Pizzi, A.; Raftery, G.M.; Hashemi, A. One-Component Polyurethane Adhesives in Timber Engineering Applications: A Review. Int. J. Adhes. Adhes. 2023, 123, 103358. [Google Scholar] [CrossRef]

| Specie | Properties at 6% MC | Density (kg/m3) | MOE (GPa) |

|---|---|---|---|

| Nothofagus alpina | Mean | 571.2 | 8.80 |

| SD | 47.3 | 2.4 | |

| Cov (%) | 8.3 | 26.9 | |

| Nothofagus obliqua | Mean | 568.5 | 8.84 |

| SD | 34.7 | 3.4 | |

| Cov (%) | 6.1 | 39.02 | |

| Nothofagus dombeyi | Mean | 598 | 10.2 |

| SD | 48.2 | 1.5 | |

| Cov (%) | 8.1 | 14.4 |

| Specie | Average Porosity (%) | Average Porosity in Glue Line (%) |

|---|---|---|

| Nothofagus alpina | 59.1 | 38.6 |

| Nothofagus obliqua | 43.1 | 27.7 |

| Nothofagus dombeyi | 57.7 | 37.9 |

| Specie | θ (°) | γ (mN/m) | γdS (mN/m) | γPS(mN/m) |

|---|---|---|---|---|

| Nothofagus alpina | 54.00 | 50.29 ± 0.44 | 29.02 ± 0.23 | 21.27 ± 0.21 |

| Nothofagus obliqua | 40.55 | 57.97 ± 6.00 | 28.02 ± 0.77 | 29.96 ± 5.00 |

| Nothofagus dombeyi | 65.60 | 53.76 ± 14.00 | 40.87 ± 8.00 | 12.89 ± 6.00 |

| Specie | θ (°) | γ (mN/m) | γdS (mN/m) | γPS (mN/m) |

|---|---|---|---|---|

| Nothofagus alpina | 60.30 | 54.92 ± 2.20 | 41.085 ± 0.31 | 13.08 ± 1.89 |

| Nothofagus obliqua | 59.30 | 39.16 ± 4.07 | 30.15 ± 3.98 | 0.01 ± 0.09 |

| Nothofagus dombeyi | n.d. | n.d. | n.d. | n.d. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosales, V.; Rodríguez-Grau, G.; Galarce, C.; Montero, C.; Alvarado, C.; Muñoz, L.; Pommier, R. Feasibility of Bonding High-Moisture-Content Wood Using Nothofagus chilean Species. Forests 2023, 14, 2386. https://doi.org/10.3390/f14122386

Rosales V, Rodríguez-Grau G, Galarce C, Montero C, Alvarado C, Muñoz L, Pommier R. Feasibility of Bonding High-Moisture-Content Wood Using Nothofagus chilean Species. Forests. 2023; 14(12):2386. https://doi.org/10.3390/f14122386

Chicago/Turabian StyleRosales, Víctor, Gonzalo Rodríguez-Grau, Carlos Galarce, Claudio Montero, Claudia Alvarado, Lisa Muñoz, and Régis Pommier. 2023. "Feasibility of Bonding High-Moisture-Content Wood Using Nothofagus chilean Species" Forests 14, no. 12: 2386. https://doi.org/10.3390/f14122386

APA StyleRosales, V., Rodríguez-Grau, G., Galarce, C., Montero, C., Alvarado, C., Muñoz, L., & Pommier, R. (2023). Feasibility of Bonding High-Moisture-Content Wood Using Nothofagus chilean Species. Forests, 14(12), 2386. https://doi.org/10.3390/f14122386