Abstract

Despite many outdoors applications, the number of works aimed to determine the effect of changing conditions on the properties of glulam beams, in particular those produced in non-standard arrangements, is few. Therefore, the aim of this study was to assess changes in flexural strength properties (MOE, MOR) of the beams stored for 30 months in varying conditions. Analyzed variants of pine GLT beams included five-meter-long structural elements reinforced with oak timber, high-quality pine timber and steel rods stored both in the roofed shed outdoors and inside the climatic chamber. Moisture content of the beam varied significantly depending on the placement of the sensors (on the surface or inside the beam). The average modulus of elasticity after 30 months of storage decreased by approx. 7% compared to initial values. The results varied depending on both the assumed beam arrangement and the applied conditions.

1. Introduction

Growing attention is being focused on the development of sustainable structural materials [1]. Consequently, as a result of modern industrialization, more and more studies are being conducted each year on engineered wood products (EWP). These are composite materials manufactured from hardwoods or softwoods comprising a wide range of wood-based products such as for example particleboard, laminated veneer lumber (LVL), cross laminated timber (CLT), oriented strand boards (OSB) and glued laminated timber (GLT) also known as glulam [2,3]. GLT is mainly used in the forms of load-bearing beams, columns or roof framing in residential and public constructions. Due to the laminating process these materials are considered to be stronger than solid wood as a result of the lack of anatomical defects, great strength to weight ratio, availability in various dimensions, good strength characteristics and higher moisture resistance [4]. However, increasing performance demands and decreasing availability of high-quality timber resulted in the fact that research in this area is still progressing and concerns, e.g., reinforcement with steel rods [5,6,7], implementation of timber with lower strength classes [8,9,10], different species [11,12,13] and the effects of deteriorating factors [14,15,16].

According to Ansell [17], at the beginning wood-based composites were predominantly used for indoor applications; however, nowadays they are frequently seen in outdoor applications exposed to changing weather conditions as well [18]. In addition to changing ambient humidity, GLT stored outdoors is also susceptible to weathering process and degradation by fungi, which can significantly affect the mechanical characteristics of structural beams [19,20,21]. It is especially important since maintaining a proper level of strength throughout the whole service life of the glulam beams is crucial for the safety of people [22,23]. It is well known that the mechanical properties of wood are closely dependent on its moisture content and temperature [24]. Moreover, in case of wood-based GLT with layered structure an uneven swelling and shrinkage between the adjacent layers can occur, especially in the conditions of cyclic climate changes. Consequently, it can lead to negative effects such as deformation or distortion of the lamellas appearing as warps, cracks and delamination which strongly affect the mechanical characteristics of the final product [25]. That is why so much attention of scientists and industry representatives is focused on the development of wood modification methods causing its hydrophobization. In order to do that, many new both chemical and physical strategies are being discovered and tested each year [26].

Kržišnik et al. [18] investigated changes in mechanical properties of three-layer glulam beams (83 × 68 × 1100 mm) made of Norway spruce. Studies have shown that after two years of outdoor exposure some slight signs of fungal decay were observed in case of untreated samples. Moreover, the overall performance of glulam was affected by a deterioration in shear strength and increased delamination of polyurethane bond lines. Furthermore, Niklewski et al. [27] investigated the effect of various connection details and structural protection of Norway spruce glulam during one year of rain-exposed experiment. It was found that wood moisture content ranged from 15% to 27% for most of the time. Studies have also shown that protection of beams by cladding their sides or covering their upper surface allowed to keep wood moisture content below the critical point where the process of biodegradation by wood-decaying fungi begins. Moreover, as observed by Pousette and Sandberg [28], fluctuating humidity during a five-year experiment can also result in the formation of cracks which can have a crucial influence on wood mechanical strength [29]. Kánnár et al. [30] analyzed changes in the mechanical properties of spruce glulam-based structure during 5 years of outdoor exposure under the load. Based on the outcomes, it was found that shear strength and bending strength of beams were significantly lowered. The authors stated that few cracking lines and no signs of biological degradation were observed. Moreover, it was concluded that more studies are needed to fully understand the behavior of glulam stored outdoors.

Despite a significant influence of storage conditions on the mechanical performance of glulam beams, a majority of available studies still concern only standard beam layouts or small lab-scale samples. Therefore, the aim of this study was to assess changes in flexural strength characteristics of five-meter-long pine glulam beams containing lamellas varying in modulus of elasticity and those reinforced with steel rods or hardwood timber, during 30 months of storage in a different conditions.

2. Materials and Methods

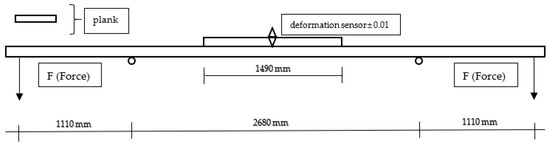

The research material was mainly pine (Pinus sylvestris L.) and oak (Quercus robur L.) timber purchased from sawmill Witkowscy (Wieluń, Poland). Regardless of the species, each piece of timber then used as a lamella for GLT was characterized by the following dimensions: 120 × 25 × 5000 mm (width × thickness × length). In order to arrange the assumed sets of lamellas based on their strength, purchased timber was tested for modulus of elasticity (MOE). It was determined by measuring the deflection for applied load according to Figure 1.

Figure 1.

Experimental setup used for determinations of MOE.

Implemented method for MOE determination was developed and tested during previous studies [31]. Preliminary load was 30.4 N and at that value the deformation sensor was set at zero before increasing the load to 61.8 N. Each piece of timber was deflected 8 times; however, the values of deflection were recorded only for the final five repetitions. MOE was calculated according to Equation (1).

where: F means the force (N); a means the distance from the force to the support (mm); l is the length of the deflection measuring section (mm); f is the level of deformation (mm); and J means the moment of inertia (mm4).

The research assumptions included the production of four variants of eight-layer structural beams. Variant labeled as KN (Figure 2a) consisted of eight pine timber pieces characterized by low modulus of elasticity. Contrary to KN beams, variant labeled as KW (Figure 2b) consisted of pine timber of high MOE values in the external layers. Variant KD (Figure 2c) consisted of two external layers of oak timber and six layers of pine timber inside. Variant KS (Figure 2d) was asymmetrically reinforced with two ribbed steel rods in a tensile zone which were characterized by following properties declared by the producer (Konsorcjum Stali, Poznań, Poland): nominal diameter of 14 mm, rod diameter of 13 mm, tensile strength at yield point of 355 MPa, tensile strength of 420 MPa, longitudinal elasticity modulus of 210 GPa and density of 8.85 g/cm3. In each of the boards between which rods were placed two grooves (ø7 mm) were milled at a distance of approx. 48 mm from the axis of timber.

Figure 2.

Variants of manufactured beams labeled as: (a) KN; (b) KW; (c) KD; (d) KS.

The distribution of the average modulus of elasticity values in individual layers of beams is presented in Table 1.

Table 1.

Values of MOE for individual lamellas.

Boards were glued with a formulation consisting of melamine–urea–formaldehyde (MUF1247) adhesive and dedicated hardener with trade name 2526 introduced in the amount of 20% of resin mass as recommended by the producer AkzoNobel (Amsterdam, Netherlands). Adhesive was applied by the roller in the amount of approx. 220 g/m2. Beams were cold-pressed under a pressure of 0.48 MPa for 20 h using industrial press system equipped with hydraulic cylinders, commonly used for glued structural elements production (FOST, Czersk, Poland). Pressing process was conducted in a laboratory room with controlled ambient conditions: relative humidity of 65 ± 5% and temperature of 21 ± 2%. Twelve beams with the dimensions of 120 × 200 × 5000 mm (width × thickness × length) were manufactured for each variant.

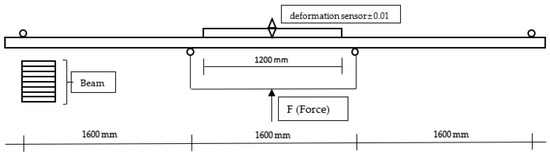

Produced beams were conditioned in laboratory room for 7 days (RH of 65 ± 5%, temperature of 21 ± 2%). After that, initial moisture content and modulus of elasticity of the beams were determined. MC was determined with HIT-3 hammer moisture meter (TANEL, Gliwice, Poland). Mechanical properties of produced GLT were evaluated according to EN 408 [32]. MOE of the beams was investigated using the experimental setup presented in Figure 3.

Figure 3.

Setup for beams MOE determinations.

Maximum force of testing machine was 500 kN and the loading speed was 0.20–0.25 mm/s. MOE was determined by loading the beam eight times with the force of 25 kN; however, the value of strain was recorded only for the last five repetitions. Parameters such as force corresponding to deflection (ΔF) and deflection (Δs) were determined based on the course of characteristic curve (f(F) = s). Final value of MOE was calculated according to the Equation (2).

where: ∆F means force corresponding to deflection (N), l means length of the deflection measuring section (mm), a means distance from the applied force to the support (mm), b means width of beam (mm), h means height of beam (mm) and ∆s means deflection (mm).

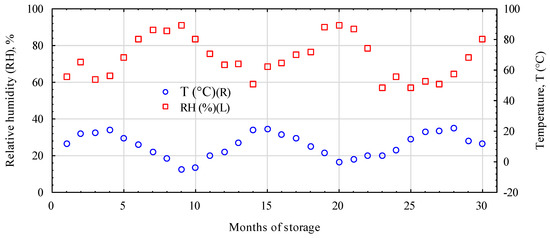

After determining the initial parameters, the beams were stored in two ways for 30 months from May 2020 to October 2022. Half of the beams from each variant were stored in climatic chamber (5.5 m × 2 m × 2 m) at constant temperature of 24 ± 2 °C and two assumed relative humidity levels of 35 ± 5% and 85 ± 5%, changing every 3 months. These parameters were provided by a humidifier (PPH Eltom, Warsaw, Poland) and air conditioner (Mitsubishi Electric, Warsaw, Poland), both controlled by automatic control system (APAR Control, Raszyn, Poland). The other half of the beams were stored in a roofed shed (6 m × 3 m × 3.3 m) with three sides covered which allowed free flow of air from the outside while protecting the beams against precipitations. Monthly parameters of outdoor conditions for considered storage period, recorded by the meteorological station located in Poznań, Poland belonging to Polish Institute of Meteorology and Water Management are shown in Figure 4.

Figure 4.

Outdoor conditions during the storage period.

To perform the tests, beams from the shed were extracted after 10, 20 and 30 months of storage, while the beams from the chamber only after 20 and 30 months. Each beam was evaluated in terms of its moisture content and MOE. Moisture content was measured in two ways: surface MC by HIT-3 hammer moisture meter (TANEL, Gliwice, Poland) and internal MC of the beam by the sensors placed in the middle of the beam’s height, driven through wood to a depth reaching the axis of the beam, connected to WRD-100 moisture meter (TANEL, Gliwice, Poland). Three measuring points in each beam were used to carry the investigations of moisture content. MOE was determined using the setup presented in Figure 3, according to previously described method. After that they were placed back into storage. In addition, after the storage process lasting 30 months was completed, modulus of rupture (MOR) of the beams was also investigated by exerting the force until the beam breaks. The values of MOR were calculated according to Equation (3). Final values of both MOE and MOR are expressed as the average of 12 repetitions for each variant (within each variant, 6 beams were tested after storage in the shed and 6 after storage in the chamber).

where: Fmax means force at which the beam failed (N), and kh means coefficient related to the height of the beam.

The collected results were analyzed with the use of Statistica 13.0 package (StatSoft Inc., Tulsa, OK, USA). Evaluation was performed using analysis of variance (ANOVA) at the significance level of α = 0.05. Whiskers shown in the figures represent 0.95 confidence intervals.

3. Results and Discussion

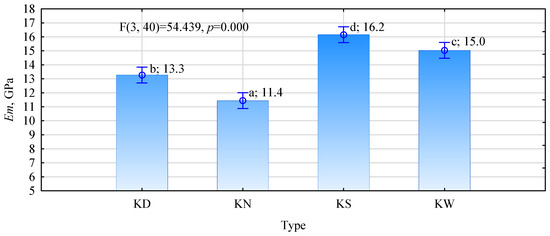

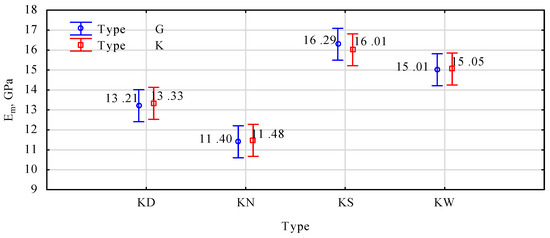

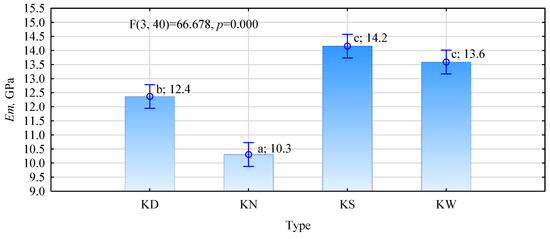

The produced beams were tested for the modulus of elasticity in the four-point bending system and after that, they were divided into two groups, i.e., intended for storage in climatic chamber (labeled as K) and for storage in roofed shed (labeled as G). Produced types of beams, according to the assumptions, differed significantly in the average MOE values (Figure 5). The analysis of homogeneous groups performed with HSD Tukey test showed that the observed tendencies are consistent with a data presented in Table 1. The positive influence of steel rods is clearly visible, because without them the stiffness of KS beams should be slightly higher than observed for KN type beams.

Figure 5.

Initial modulus of elasticity determined for analyzed types of beams (letters a, b, c, d mark homogeneous groups).

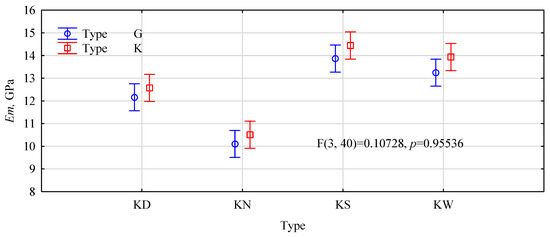

As can be seen from the data presented in Figure 6, the prepared groups of beams showed very similar average values of MOE, which should allow for easier analysis of the influence of storage conditions. However, the observed MOE of wooden beams was significantly affected by their moisture content (MC) at the time of measurement. The influence of MC on the flexural strength of wood-based materials is rather complicated. It is linear only in the certain area, and in that case, it is suggested to convert the obtained MOE values into the same value of MC. However, taking into account that the average MC of individual beams differed only by about 1.5%, the conventional conversion was abandoned. In general, the observations showed that both in the case of beams with similar MC, and MC ranging from 8% to 14%, the variability of MOE results was more affected by the assumed structure of the beams than their MC. Although the data presented in Figure 7 indicate that there were some differences between the MC of individual groups; however, it was not confirmed by any of the implemented tests: HSD Tukey test, Scheffé test and Bonferroni test. Therefore, it should be assumed that the groups of beams analyzed at this stage of the research were characterized by similar MC.

Figure 6.

Graphical interpretation of the interaction (G means stored in the shed, K means stored in climatic chamber).

Figure 7.

Moisture content of depending on the structure and storage method.

The moisture content of the beams before storage was determined only for outer layers with a hammer moisture meter. It was assumed that in this case MC measured this way was representative for the entire cross-section, as the sawn timber and the beams themselves have been in the same conditions for a very long time.

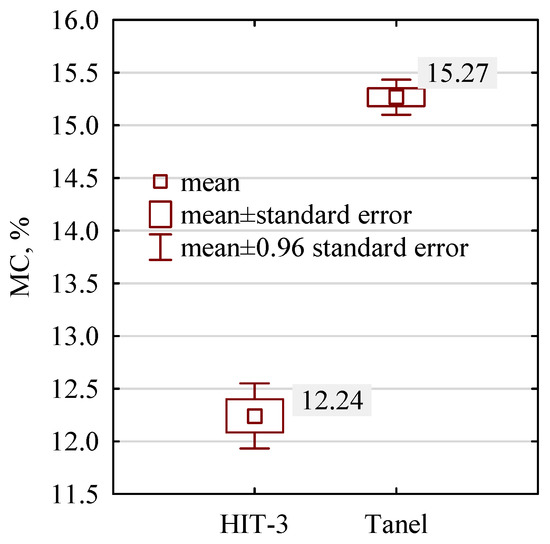

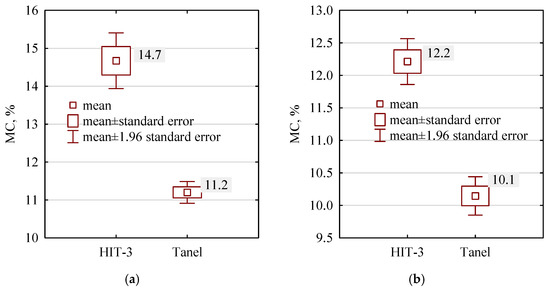

After the first storage period, the flexural modulus of the beams was assessed only for variants stored outside in the shed. Before measuring the MOE, the MC was measured both superficially and internally. As can be seen from the data in Figure 8, the MC inside the beam was much higher than the MC of the near-surface layers. The observed relationship is consistent with changes in relative humidity recorded during this period. The difference was over 3%, so the superficial measurement did not reflect the actual condition of the analyzed beams.

Figure 8.

Moisture content of the beams depending on the measurement method.

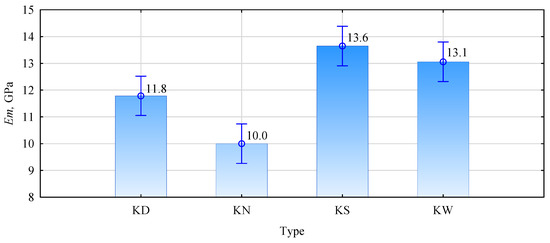

Perhaps not only the increase in humidity but also other factors could affect the observed decrease in MOE as well (Figure 6 and Figure 9). For KN and KD types a decrease was approx. 1.45 GPa, for KW type it was 1.94 GPa and for KS type it was nearly 2.60 GPa. What is quite interesting is that the decrease in steel rods-reinforced beams (KS) was the most noticeable when compared to other types of manufactured structural elements. Perhaps the stresses which occurred earlier in the KS beams during the seasoning period had the influence in this case. However, implementing the conversion of MOE to include the changes in MC showed that changes, or more precisely, a decrease in MOE was 3% for every 1% of changing MC. It is a value similar to frequently observed data presented in charts or tables concerning formulas for converting mechanical parameters of wood (e.g., Bauschinger formula).

Figure 9.

Modulus of elasticity of the beams after first storage period.

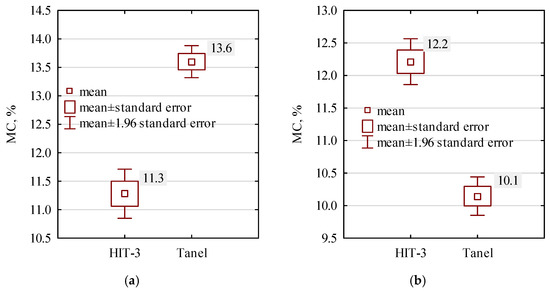

After the second storage period (20 months), the tendencies in the case of beams stored in climatic chamber and outdoors were different. In the first case, the beams were subjected to the assessment of MOE after storing in the conditions of low RH. For this reason, the MC of deeper layers was higher than in the case of external layers and the difference was 2.3%. The beams stored outside, under the roof, on the other hand, were characterized by the MC of 12.2% in the superficial layers and approx. 10% when measured internally. Moreover, beams stored in climatic chamber had about 1% higher MC; however, the observed difference between the superficial and internal measurements was similar (2.1%) (Figure 10).

Figure 10.

Moisture content of beams stored for 20 months: (a) in climatic chamber; (b) outdoors.

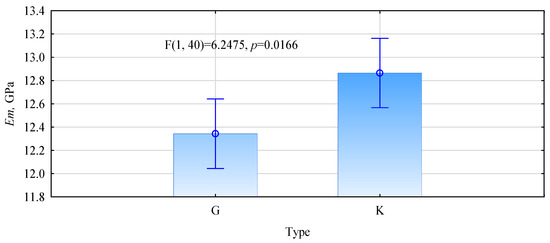

The two-factor analysis showed that MOE of analyzed beams was significantly different depending on the type of the beam (Figure 11). Moreover, it was found that the MOE of KS type beams was no longer significantly higher than the MOE of KW type beams. The analysis of the effect of storage method showed that the beams stored in climatic chamber were characterized by higher MOE values than the beams stored outdoors under the roof, despite their higher MC. The most noticeable decrease in MOE was observed in the case of KS beams, and the change was much greater than observed for other variants. Moreover, no interaction between the type of the beam and the storage method was observed (Figure 12). It means that changes in the MOE of the beam were related to where they were stored, not the way they were arranged and reinforced (Figure 13).

Figure 11.

Modulus of elasticity of the beams after second storage period (letters a, b, c mark homogeneous groups).

Figure 12.

Graphical interpretation of the interaction after 20 months of storage (G means stored in the shed, K means stored in climatic chamber).

Figure 13.

The effect of storage method on modulus of elasticity of the beams.

The beams after the last storage period (30 months) were evaluated after being exposed to rising relative humidity again. Therefore, in both cases, regardless of the storage method, much higher MC was noted for superficial measurement than in the case of MC measured internally (Figure 14). Furthermore, beams stored in the climatic chamber showed almost 2% higher MC values than beams stored outside.

Figure 14.

Moisture content of beams stored for 30 months: (a) in climatic chamber; (b) outdoors.

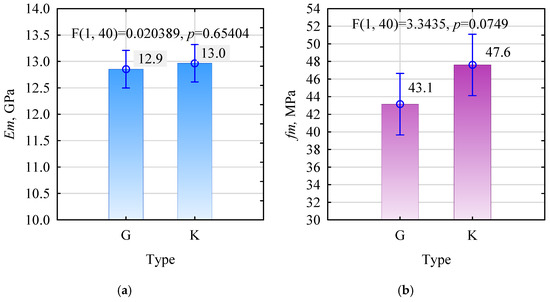

Despite almost 2% higher MC, the beams stored in the chamber achieved the same level of MOE as the beams stored outside (Figure 15). Before the experiment started, as mentioned before, the beams were selected in such way that they were characterized by an almost the same modulus of elasticity. Despite the increase in the MC of the beams by about 2%, the decrease in their flexural modulus was decreased only by 6.5%. There is also no reason to reject the null hypothesis that a decrease in MOR was not affected by the storage conditions. Slightly higher values were obtained for beams stored in climatic chamber but observed differences turned out to not be statistically significant. Perhaps if the MC, which is less favorable for the beams stored in climatic chamber, would be taken into consideration, the observed changes could be major enough to be statistically significant.

Figure 15.

The results of: (a) MOE of the beams; (b) MOR of the beams depending on storage method.

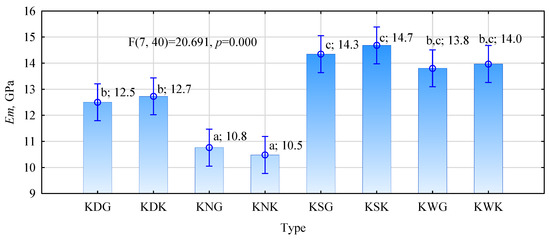

More detailed analysis showed that regardless of the changes in MC, the beams characterized by large differences in the MOE between the outer and inner lamellas (KS and KW) were the most susceptible to deterioration. Furthermore, as can be seen from data summarized in Figure 16, the KW type beams showed similar results as KD type beams. Moreover, the difference between the flexural modulus of KS and KW type beams has also decreased. It turned out that KD type beams performed favorably in these tests and no adverse signs of cracking or delamination resulting from the differences in the characteristics of softwood and hardwood were observed in their case.

Figure 16.

The results of modulus of elasticity depending on the beam type and storage method (letters a, b, c mark homogeneous groups).

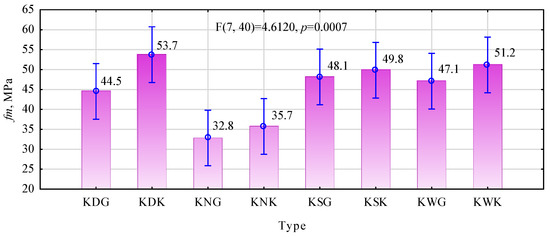

The observed changes in MOE under the influence of storage conditions of KS type beams may also translate into their static bending strength being lower than expected (Figure 17). Nevertheless, this type of beams showed the smallest differences in bending strength between the beams stored in chamber and outside. The biggest differences, however, can be observed for the beams containing oak timber in the external layers. In this case, the difference was over 9 MPa, which is nearly 20%. In general, the beams stored outside under the roof were characterized by a much lower strength. The relatively small number of repetitions, however, does not allow for a very detailed analysis and deep interpretation. It should also be taken into account that during the assumed research period, the beams stored outside under the roof were exposed to small monthly fluctuations in relative humidity and much greater changes in temperature, including drops below zero degrees Celsius, which probably changed in a much more noticeable way on a daily basis than those recorded in the monthly cycles.

Figure 17.

The results of bending strength depending on the beam type and storage method.

4. Conclusions

Analysis of flexural strength of the beams during storage for 30 months allowed to draw the following conclusions. The analysis showed that the conditions during storage (climatic chamber or outdoors under the roof) have a significant effect on the modulus of elasticity of all analyzed variants of structural beams. As expected for material made of wood, changes in temperature and relative humidity of the air have a negative effect on the properties of material. Changes in modulus of elasticity are the most visible in the case of beams reinforced with steel rods in a tensile zone probably due to the occurrence of initial stresses. In addition, variants of beams in which the outer lamellas differing significantly in modulus of elasticity from the middle layer are also more susceptible to stresses resulting from changing conditions. Modulus of rupture showed similar tendency as modulus of elasticity. The method of moisture content measurement (superficial or internal) has a significant effect on the final moisture content of the beam. It can be concluded that it is best to consider measurements both values in the experiments to obtain the actual condition of the beam. In general, during 30 months of storage, the modulus of elasticity of the beams decreased by about 7% compared to the initial value. Further studies are planned to investigate in more detail the process of deterioration of the beam properties under varying outdoor conditions.

Author Contributions

Conceptualization, R.M. and M.K.; methodology, R.M.; software, R.C. and J.W.; validation, J.K., J.W. and M.K.; formal analysis, R.M. and R.C.; investigation, M.K., J.W. and R.C.; resources, R.M.; data curation, R.M. and J.K.; writing—original draft preparation, R.M., J.K. and M.K.; writing—review and editing, R.M. and J.K.; visualization, R.M.; supervision, R.M.; project administration, R.M.; funding acquisition, R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Centre for Research and Development (grant number BIOSTRATEG3/344303/14/NCBR/2018).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Raftery, G.M.; Whelan, C. Low-Grade Glued Laminated Timber Beams Reinforced Using Improved Arrangements of Bonded-in GFRP Rods. Constr. Build. Mater. 2014, 52, 209–220. [Google Scholar] [CrossRef]

- Seng Hua, L.; Wei Chen, L.; Antov, P.; Kristak, L.; Md Tahir, P. Engineering Wood Products from Eucalyptus spp. Adv. Mater. Sci. Eng. 2022, 2022, 8000780. [Google Scholar] [CrossRef]

- Kowaluk, G.; Nicewicz, D. Engineered Wood Products. Biul. Inf. Ośrodka Badaw.-Rozw. Przemysłu Płyt Drew. W Czarnej Wodzie 2020, 1–2, 71–77. [Google Scholar]

- Mirski, R.; Dziurka, D.; Chuda-Kowalska, M.; Kawalerczyk, J.; Kuliński, M.; Łabęda, K. The Usefulness of Pine Timber (Pinus sylvestris L.) for the Production of Structural Elements. Part II: Strength Properties of Glued Laminated Timber. Materials 2020, 13, 4029. [Google Scholar] [CrossRef]

- Mirski, R.; Kuliński, M.; Dziurka, D.; Thomas, M.; Antonowicz, R. Strength Properties of Structural Glulam Elements from Pine (Pinus sylvestris L.) Timber Reinforced in the Tensile Zone with Steel and Basalt Rods. Materials 2021, 14, 2574. [Google Scholar] [CrossRef]

- Navaratnam, S.; Thamboo, J.; Ponnampalam, T.; Venkatesan, S.; Chong, K.B. Mechanical Performance of Glued-in Rod Glulam Beam to Column Moment Connection: An Experimental Study. J. Build. Eng. 2022, 50, 104131. [Google Scholar] [CrossRef]

- Hubbard, C.; Salem, O. Fire Resistance of a Fully Concealed, Moment-Resisting New Timber Connection Utilizing Mechanically-Fastened Steel Rods. Fire Saf. J. 2022, 129, 103546. [Google Scholar] [CrossRef]

- Wdowiak-Postulak, A. Basalt Fibre Reinforcement of Bent Heterogeneous Glued Laminated Beams. Materials 2020, 14, 51. [Google Scholar] [CrossRef]

- Balmori, J.-A.; Basterra, L.-A.; Acuña, L. Internal GFRP Reinforcement of Low-Grade Maritime Pine Duo Timber Beams. Materials 2020, 13, 571. [Google Scholar] [CrossRef]

- Dziurka, D.; Kawalerczyk, J.; Walkiewicz, J.; Derkowski, A.; Mirski, R. The Possibility to Use Pine Timber Pieces with Small Size in the Production of Glulam Beams. Materials 2022, 15, 3154. [Google Scholar] [CrossRef] [PubMed]

- Derkowski, A.; Kuliński, M.; Trociński, A.; Kawalerczyk, J.; Mirski, R. Mechanical Characterization of Glued Laminated Beams Containing Selected Wood Species in the Tension Zone. Materials 2022, 15, 6380. [Google Scholar] [CrossRef]

- Morin-Bernard, A.; Blanchet, P.; Dagenais, C.; Achim, A. Glued-Laminated Timber from Northern Hardwoods: Effect of Finger-Joint Profile on Lamellae Tensile Strength. Constr. Build. Mater. 2021, 271, 121591. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Timbolmas, C.; Bravo, R.; Valverde-Palacios, I.; Gallego, A. Improving Ductility and Bending Features of Poplar Glued Laminated Beams by Means of Embedded Carbon Material. Constr. Build. Mater. 2021, 304, 124469. [Google Scholar] [CrossRef]

- Heräjärvi, H.; Möttönen, V.; Reinikkala, M.; Stöd, R. Absorption–Desorption Behaviour and Dimensional Stability of Untreated, CC Impregnated and Pine Oil Treated Glulam Made of Scots Pine and Norway Spruce. Int. Biodeterior. Biodegrad. 2014, 86, 66–70. [Google Scholar] [CrossRef]

- Fortino, S.; Hradil, P.; Metelli, G. Moisture-Induced Stresses in Large Glulam Beams. Case Study: Vihantasalmi Bridge. Wood Mater. Sci. Eng. 2019, 14, 366–380. [Google Scholar] [CrossRef]

- Schmidt, E.; Riggio, M. Monitoring Moisture Performance of Cross-Laminated Timber Building Elements during Construction. Buildings 2019, 9, 144. [Google Scholar] [CrossRef]

- Ansell, M. Wood Composites; Woodhead Publishing: Sawston, UK, 2015; ISBN 1-78242-477-6. [Google Scholar]

- Kržišnik, D.; Grbec, S.; Lesar, B.; Plavčak, D.; Šega, B.; Šernek, M.; Straže, A.; Humar, M. Durability and Mechanical Performance of Differently Treated Glulam Beams during Two Years of Outdoor Exposure. Drv. Ind. 2020, 71, 243–252. [Google Scholar] [CrossRef]

- Meierhofer, U.A. Behavior of Glulam Timber Treated with Water-Borne or Organic Preservatives after Five Years of Weathering. Holz Als Roh-Und Werkst. 1988, 46, 53–58. [Google Scholar] [CrossRef]

- Ohmura, W.; Yamamoto, K.; Ido, H.; Nagao, H.; Kato, H.; Momohara, I.; Matsunaga, H.; Miyatake, A.; Kodate, Y. Change in Durability of Glued Laminated Timber under Accelerated Decay Conditions and Compression Strength Perpendicular to the Grain after Decay. Wood Ind. 2006, 61, 446–451. [Google Scholar]

- Stirling, R.; Knudson, R.M.; Feng, M.W.; Morris, P.I. Field Performance of Glued Laminated Timber (Glulam) Manufactured from Thin Treated Lamina. For. Prod. J. 2022, 72, 29–36. [Google Scholar] [CrossRef]

- Toratti, T.; Schnabl, S.; Turk, G. Reliability Analysis of a Glulam Beam. Struct. Saf. 2007, 29, 279–293. [Google Scholar] [CrossRef]

- AmaniDashlejeh, A.; Loss, C. Reliability-Based Design Optimization of Strengthened and Reinforced Glulam Beams in Bending. Wood Mater. Sci. Eng. 2022, 1–19. [Google Scholar] [CrossRef]

- Gerhards, C.C. Effect of Moisture Content and Temperature on the Mechanical Properties of Wood: An Analysis of Immediate Effects. Wood Fiber Sci. 1982, 14, 4–36. [Google Scholar]

- Nakajima, S.; Sakabe, Y.; Kimoto, S.; Ohashi, Y. Deterioration of Clt under Humid and Dry Cyclic Climate. In Proceedings of the XV International Conference on Durability of Building Materials and Components, Barcelona, Spain, 30 June–3 July 2020; pp. 2–3. [Google Scholar]

- Jiang, J.; Du, J.; Li, H.; Mei, C.; Gong, X. Hydrophobicity Improvement on Wood for a Better Application of This Bio-Based Material. Coatings 2022, 12, 1465. [Google Scholar] [CrossRef]

- Niklewski, J.; Isaksson, T.; Frühwald Hansson, E.; Thelandersson, S. Moisture Conditions of Rain-Exposed Glue-Laminated Timber Members: The Effect of Different Detailing. Wood Mater. Sci. Eng. 2018, 13, 129–140. [Google Scholar] [CrossRef]

- Pousette, A.; Sandberg, K. Glulam Beams and Columns after 5 Years Exposure to Outdoor Climate. In Proceedings of the 2nd International Conference of Timber Bridges, WoodWorks Las Vegas, NV, USA, 30 September–3 October 2013. [Google Scholar]

- Oltean, L.; Teischinger, A.; Hansmann, C. Influence of Temperature on Cracking and Mechanical Properties of Wood during Wood Drying–A Review. BioResources 2007, 2, 789–811. [Google Scholar]

- Kánnár, A.; Karácsonyi, Z.; Andor, K.; Csóka, L. Analysis of Glued-Laminated Timber Structure during Five Years of Outdoor Operation. Constr. Build. Mater. 2019, 205, 31–38. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Chuda-Kowalska, M.; Wieruszewski, M.; Kawalerczyk, J.; Trociński, A. The Usefulness of Pine Timber (Pinus sylvestris L.) for the Production of Structural Elements. Part I: Evaluation of the Quality of the Pine Timber in the Bending Test. Materials 2020, 13, 3957. [Google Scholar] [CrossRef]

- EN 408; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. European Committee for Standardization: Brussels, Belgium, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).