Abstract

This study aims to evaluate the structural behaviour of dowel laminated timber (DLT) made of fast-growing pine and eucalyptus lamellae and different dowel diameters. Shear tests on dowelled connections and four-point bending tests on structural size panels were performed, and the slip modulus and bending properties, respectively, were obtained. The bending stiffness and strength of pine panels fastened with guatambú (5.05 and 20.05 kN/mm2) or eucalyptus dowels (5.29 and 17.13 kN/mm2), suggesting that dowel species had no influence on the panel’s bending properties. The analysis of the bending stiffness and strength of eucalyptus panels fastened with 18 mm (11.04 and 44.29 kN/mm2) or with 15 mm dowel diameter (11.06 and 51.50 kN/mm2) indicated that dowel diameter had no substantial influence on the bending properties. Furthermore, the stiffness values of the panels were similar to those of their constitutive individual lamellas, which, in turn, did not comply with the structural requirements of the Uruguayan Standard. Additional analytical results of the effective stiffness using the slip modulus were close to those found in the experimental bending tests. The results from this study are useful in understanding the mechanical behaviour of DLT panels and provide the basis for the improvement of Uruguayan mass timber products.

1. Introduction

In Uruguay, forest projections up to 2030 indicate the availability of a minimum of 3 million m3 year−1 of pine and 0.2 million m3 year−1 of eucalyptus for mechanical transformation [1]. This is the consequence of a national plan developed over the past three decades that promoted the plantation of fast-growing species for structural applications and pulp production. The country counts 1 million hectares, mostly of pine and eucalyptus, with 90% of the plantations sustainable managed, having forest FSC or PEFC certification [2]. With average growing rates of 19 to 24 m3 ha−1y−1, trees grow so fast in intensively managed plantations that they reach sawn timber commercial size in 25 years or fewer [3]. Part of this biomass is being harvested and used for lumber and engineered wood products (EWPs). Commonly, for structural products, the cutting cycles adopted by the Uruguayan forest companies are 25 and 18 years for pine and eucalyptus, respectively. Consequently, wood from these trees showed high percentages of juvenile wood with physical and mechanical properties inferior to those of mature wood.

Recently, the national government started to implement a national plan to promote the use of timber for structural applications using several initiatives [4]. One involves the use of mass timber products in mid- and high-rise residential buildings. The term mass timber refers to a family of EWPs of large section size developed to surpass the limitations imposed by small dimensions, dimension instability, and the variability of wood, offering the construction industry a viable alternative to steel and concrete [5,6].

The industrial, residential and transport sectors in Uruguay consume 89% of the produced energy [7]. Wood products from renewable forest resources require less energy in their production than traditional materials such as concrete and steel. However, the consumption of wood and EWPs in the Uruguayan construction sector is still marginal, and in 2019 represented 1.25% of the total of 16,000,000 m3 of wood extracted in that year [8]. A novel mass timber company recently opened in the country (Arboreal 2022) is expected to contribute to expanding timber construction and share the market of mid- and high-rise buildings with the traditional building sector.

Worldwide, the growing concern for the environment and the multiple benefits of using mass timber are leading to the positioning of structural timber as the best alternative to traditional building materials. Construction systems that massively use timber have been steadily increasing in the last decade due to governmental enforcement policies to comply with the Paris Agreement goals [9]. Forests sequestering atmospheric CO2 and wood products storing the carbon for a long period have the potential to contribute to the mitigation of greenhouse effects [10].

Super-tall buildings with mass timber as the main structural material are being developed in a “contest manner” [11]. Industrialisation, the velocity of construction, and improvement in building performance have also motivated engineers and architects to prescribe mass timber products in projects where the limits are more related to code construction rather than the technological possibilities of the material [12].

Dowel laminated timber (DLT) is a mass timber product exclusively made of timber with no adhesive. It is composed of a series of sawn timber boards (also called lamellas) placed on edge and parallel to each other, fastened together with wooden dowels. Lamellas, usually from coniferous species are 20 to 45 mm thick. Dowels, generally prepared from hardwoods with diameters between 12 and 24 mm and moisture contents (MC) inferior to those of the lamellas, are placed in pre-drilled holes at the mid-height of the lamellas and regularly spaced at 200–300 mm o.c. Typical MCs of 6%–8% for dowels and 12%–16% for lamellas are preferred in the manufacturing process [13]. Thus, dowels tend to equilibrate to the MC of the lamellas and expand, and in doing so, they ensure the joint work of all lamellas and generate a single element. The key is to replace adhesives and/or metal connections with wooden connectors having physical and mechanical properties that guarantee the correct performance of the wood dowel assembly.

Examples of DLT panels used as roofs, floors, and walls are present in several building projects worldwide, for example, E3 Flat in Germany, Thoma Head Office in Austria, and Smithers Airport in Canada (http://www.brettstapel.org, accessed on 9 September 2023, StructureCraft 2020).

At the industrial level, in Central Europe and North America, several companies are dedicated to DLT production. Most of them are small-sized industries located in Austria, Germany, Switzerland, the UK, and Canada. In general, technical information about DLT is provided by the manufacturers due to the limited or lack of standards. In Europe, for instance, the technical information is approved by the European Technical Assessment (ETA) on a case-by-case basis [14].

At the academic level, research on DLT products is under development. The literature covers horizontal panels [15,16], vertical panels [17], and beams [18,19,20]. Some studies include the fabrication process (i.e., including dowels), the evaluation of structural properties, and modelling [18,21]. In addition, an exhaustive review of the most recent advances in wooden connectors for multi-layered EWPs has been recently published [14]. It is worth noting that most works report on panels made of structural softwood lamellas and hardwood dowels. For example, Plowas et al. [22] investigated the mechanical performance of horizontal panels made of larch lamellas and beech dowels by conducting four-point bending tests and found mean values of DLT strength and stiffness similar to those of standard timber sections.

The structural behaviour of DLT relies within other parameters on the performance of the connections. Therefore, it is crucial to understand the interaction between the lamellas and the dowel. Furthermore, for modelling purposes, the mechanical jointed beams theory, also called the “gamma method”, is frequently used to model the structural behaviour of multi-layered panels. The method described in appendix B of EN 1995-1-1 [23] was employed to derive the bending stiffness of DLT panels made of larch timbers and beech dowels [15]. In this method, the stiffness of the connection between neighbouring lamellas is required and can be obtained via double-shear tests [24,25,26].

The use of low-grade Uruguayan timber and the replacement of adhesives and metal fasteners with wooden dowels as a means of joining constituent lamellae of laminated timber products deserve to be explored at the national level. This paper presents part of the results from a comprehensive study on DLT made of Uruguayan fast-growing species, focusing on the load-carrying capacity of the dowelled connections and the bending performance of structural size panels.

2. Materials and Methods

2.1. Materials

The lumber for this study came from two commercial plantations devoted to pine (Pinus elliotti) and eucalyptus (Eucalyptus grandis), respectively. Climate and soil conditions lead to fast growth rates, which, in turn, produce high percentage of juvenile wood. Both plantations have sawmills and are located in Rivera province (30°54′09″ S, 55°33′02″ W, and 30°56′13″ S, 55°33′35″ W) in the northeast of Uruguay. The pine and eucalyptus plantations comprised 27-year-old and 19-year-old trees, respectively. One hundred and forty 2-by-6 pine boards and one hundred 2-by-4 eucalyptus boards that have been previously kiln-dried at the mills, having none or negligible face knots near the neutral axis and/or with minimal deformations, were selected. The sawing pattern of the majority of boards was flatsawn. The width of the annual rings for pine ranged from 10 mm to 15 mm, while no distinct growth rings in eucalyptus were appreciated. All boards were covered with plastic film and transported to the LATU for further processing and evaluation. The boards were 4S-planned and cut to final lamellae dimensions of 138 × 50 × 2850 mm3 and 89 × 36 × 1900 mm3 for pine and eucalyptus, respectively. All lamellae were equilibrated to a target moisture content (MC) of 16%, typical for indoors in Uruguay. The MC of the lamellas was assessed using a resistance xilohigrometer (Lignomat) with a tolerance of (±1.5%). Three measurements per piece were taken, and the corresponding average was computed. The lamellas were divided into two groups per species to prepare connection specimens and DLT panels.

The dowels for the connections and the panels are sourced from different hardwoods and diverse diameters. Eucalyptus (Eucalyptus grandis) and guatambú (Balfourodendron riedelianum) dowels of 20 mm diameter, and red gum (Eucalyptus tereticornis) dowels of 18 and 15 mm diameters, were prepared and stored in a climate chamber until they reached 8% MC.

Prior to panel construction, all lamellae were non-destructively tested to evaluate the dynamic and static bending moduli of elasticity (Ed and Em). The Ed was determined via stress wave testing using a Fakopp Microsecond Timer (Ágfalva, Hungary). The Em was obtained via 4-point bending test carried out on a universal testing machine (Minebea 250 kN, Tokyo, Japan), with the specimens loaded up to 40% of the maximum load value, which has been previously estimated. Mean values of stiffness for pine lamellae with density of 399 kg/m3 were 6.27 kN/mm2 (COV = 21%) and 5.37 kN/mm2 (COV = 25%) for Ed and Em, respectively. Eucalyptus lamellae, with density of 475 kg/m3, show mean values of 11.86 kN/mm2 (COV = 10%) and 10.57 kN/mm2 (COV = 12%) for Ed and Em, respectively. For each species, the lamellae were sorted into four groups according to their modulus of elasticity, and they were used to manufacture the panels, assuring that each panel contained lamellas from each group.

Four different lamella–dowel combinations were considered in preparing timber-to-timber connections, i.e., (i) pine lamellae fastened with 20 mm guatambú dowels (PG20p), (ii) pine lamellae fastened with 20 mm eucalyptus dowels (PE20p), (iii) eucalyptus lamellae fastened with 18 mm red gum dowels (ET18p), (iv) eucalyptus lamellae fastened with 15 mm red gum dowels (ET15p).

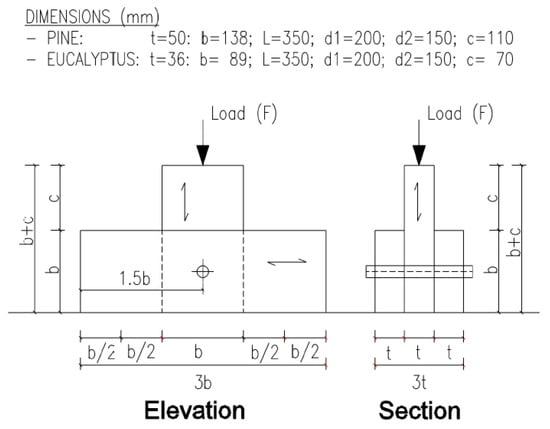

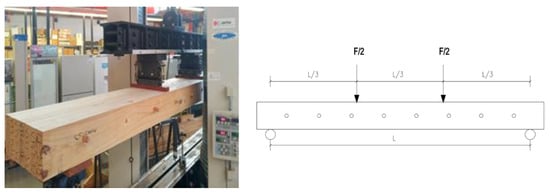

Test series for shear plane tests are summarised in Table 1. Specimens loaded perpendicular to the grain direction were prepared according to the geometric configuration established in EN 1380 [27], as shown in Figure 1.

Table 1.

Summary of the test specimens for the shear test.

Figure 1.

Configuration of shear test specimens with side members loaded perpendicular to grain.

Prior to shear tests, all specimens were conditioned in a controlled humidity chamber at (20 ± 2) °C and (65 ± 5)% relative humidity until they reached values close to 12% MC.

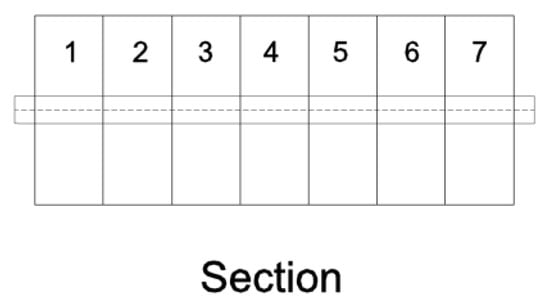

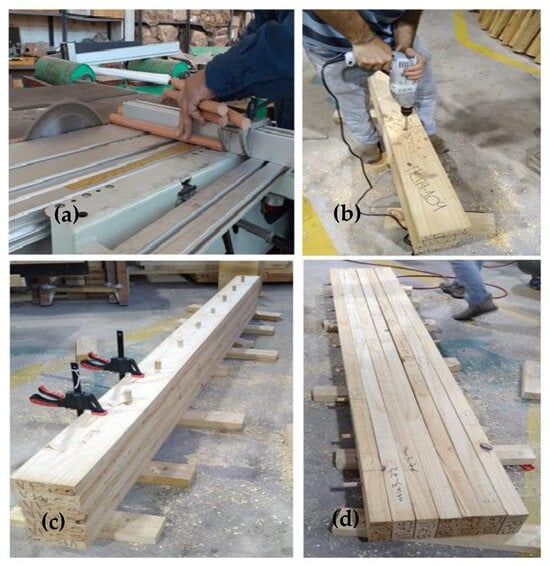

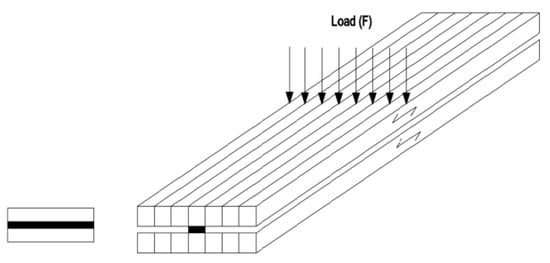

Four DLT series with identical lamella–dowel combinations as the connections were prepared to determine the bending properties of structural size panels. Each panel consisted of seven lamellas fastened, together with dowels separated @ 300 mm oc. and @ 200 mm oc., to pine and eucalyptus panels, respectively. A row of holes with 0.5 mm tolerance with respect to the dowel size was drilled at the mid-height of the panel (i.e., mid-height of face laminations and perpendicular to the loading direction), and dowels were inserted manually with a rubber hammer. Therefore, an efficient connection via the swelling of the dowel was expected. The final dimensions of DLT panels were 138 × 350 × 2850 mm3 and 89 × 252 × 1900 mm3 for pine (PPG20 and PPE20) and eucalyptus (PET18 and PET15), respectively. Test series for bending tests are summarised in Table 2. Panel configuration and manufacturing process are shown in Figure 2 and Figure 3, respectively.

Table 2.

Summary of the test specimens for the bending test, including dowel characteristics and lamella properties.

Figure 2.

Configuration of structural size DLT showing lamella position within the panel, according to their stiffness: low (1 and 7), medium (2 and 6), lowest (3 and 5), and highest (4).

Figure 3.

Fabrication of structural size DLT panels: (a) dowel preparation, (b) drilling, (c) pressing, (d) DLT panel.

After manufacturing, all panels were stored in a service class 1 environment for two weeks to allow time for moisture migration from the lamellas to the dowels, causing dowels to expand and lock into place.

2.2. Experimental Procedure

2.2.1. Determination of the Slip Modulus (Ks) of the Dowelled Connection

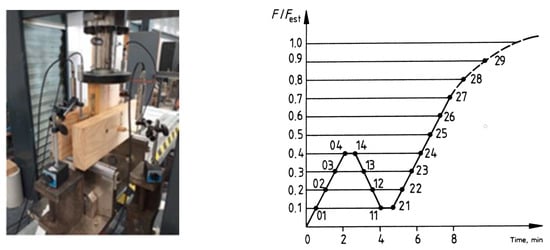

Double-shear connection tests were carried out on a universal testing machine (Controls) with a 50 kN load cell according to the loading procedure described in EN 26891 [28]. The experimental set-up for perpendicular to the grain tests is shown in Figure 4. Two transducers mounted on the two side lumber members were used to measure the relative displacement of the connection.

Figure 4.

Test setup for slip modulus determination perpendicular to the grain (left) and loading procedure established in EN 26891 (right).

The loading procedure was based on the estimated maximum load (Fmax,est) obtained from destructive tests conducted on three specimens per series. It comprised two cycles: a preload cycle until 40% of the Fmax,est was achieved, after which point the load was reduced to 10% of the Fmax,est, and a final loading cycle at a constant displacement rate of 0.05 mm/s. The slip modulus (Ks) was determined via Equation (1) established in EN 26891 [28], based on the gradient of the line that corresponds with the initial points of 10% Fmax,est and 40% Fmax,est on the load–deformation curve.

where v01 is the slip equivalent to load 0.1 Fmax,est; v04 is the slip equivalent to load 0.4 Fmax,est.

After testing, a full cross-section of the specimen (including the three pieces that comprised the connection) was cut close to the failure zone for MC and density determination in accordance with EN 13183-1 [29].

2.2.2. Bending Tests

Four-point bending tests on structural size DLT panels to obtain the bending strength (fm), local (Em,l), and global (Em,g) modulus of elasticity were conducted according to EN 408 [30]. The spans were 2485 mm and 1605 mm for pine and eucalyptus DLTs, respectively. The panels were flatwise oriented to represent a typical floor span and loaded using two equally separated line loads acting across the entire width of the specimen until failure. Tests were carried out using a universal testing machine with a 250 kN load cell. The load was applied at a constant rate of 0.4 mm/s. Deformations were recorded using extensometers located at the mid-span of the underside of the panel until the panel attained 40% of the estimated maximum load, ensuring that the load cycle and its corresponding deformation felt within the elastic range. At that point, extensometers were removed, and the load application continued until rupture. The ultimate load was recorded with the load head displacement. Test configuration is depicted in Figure 5. After bending tests, one sample per panel, each containing the seven lamellas, was cut close to the failure zone for MC and density determination.

Figure 5.

Test setup for bending properties determination.

2.2.3. Analytical Method

In order to gain a better understanding of the mechanical behaviour of the DLT panels under bending and to assess if the panel behaves as a fully composite plate or as a series of individual beams [15], the “gamma method” was employed. The effective bending stiffness ((EI)ef) defined in the Mechanical Jointed Beams Theory is given in Equation (2).

where Ei is the modulus of elasticity of the sawn timbers derived from the dynamic modulus of elasticity using Equations (3) and (4) for pine and eucalyptus, respectively, N/mm2.

where Edyn is the dynamic modulus of elasticity of the constituent boards of the experimental DLT panels computed from the experimental NDT reported in Section 2.1.

Ii is the second moment of area of the section being considered, mm4; ai is the distance from the centroid of the section being considered to the neutral axis of the entire section, mm; γi is the fastener efficient factor given via Equation (5).

where si is the regular spacing between wood connectors, mm; Ki is the slip modulus of the connector, N/mm; l is the span of the panel, mm.

The connection efficiency factor, γi, is dependent on the slip modulus of the connector and is always between zero, where no connection is present, and one, where fully rigid connection is attained. In this paper, an idealised cross-layered panel, as shown in Figure 6, was assumed.

Figure 6.

Idealised cross-layered DLT panel (adapted from Bell 2018 [15]).

The idealised panel was thought of as a three-layer arrangement with the core layer represented by the stiffness of the dowels included at regular distances and the top and bottom layers represented by the stiffness of the laminations.

In a DLT panel, the connector is located at the centroid of the section; thus, it will not contribute additional stiffness to the panel. However, when the DLT panel bends, the transverse cross-section does not bend to the assumed curvature, so there is an additional stiffness provided by the fastener. According to EN 26891 [28], 15 mm is the maximum deformation that the connection is allowed before the test is finished. Furthermore, BS 5268-2 (2002) [31] established a maximum of 14 mm for the deflection of a floor to maintain vibration serviceability. On this basis, Bell [15] compute the effective stiffness of the section considering 14 mm as the maximum distance that a fictional element is inserted into the effective section model away from the centroid of the section. In this present paper, the same approach was employed.

2.3. Statistical Analysis

Descriptive statistics, including tests of normality, with measurements of skewness and kurtosis, frequency histograms and normal probability graphs, were first used to analyse the data of the dowelled connections and the panels. Shapiro–Wilk test (n ˂ 50) to confirm the normality of data sets was secondly performed. Subsequently, Levene’s test to assess equality of variances (p-value > 0.05) was performed.

Student’s t-test for independent samples was then used to compare (p < 0.05) the mechanical properties and density of the dowelled connections within each lamella species group (i.e., pine or eucalyptus). For pine, the influence of the dowel species (i.e., eucalyptus or guatambu), and for eucalyptus, the influence of the dowel diameter (i.e., 18 mm or 15 mm) on the performance of the joint was analysed.

Similarly, Student’s t-test was used to compare (p < 0.05) the mechanical properties and density of the DLT panels within each lamella species group (i.e., pine or eucalyptus). For pine DLT, the influence of the dowel species (i.e., eucalyptus or guatambu), and for eucalyptus DLT, the influence of the dowel diameter (i.e., 18 mm or 15 mm) on the performance of the panel, were analysed. The statistical analyses were carried out using Microsoft Excel (2016) and InfoStat (2018) software.

3. Results and Discussion

3.1. Shear Tests

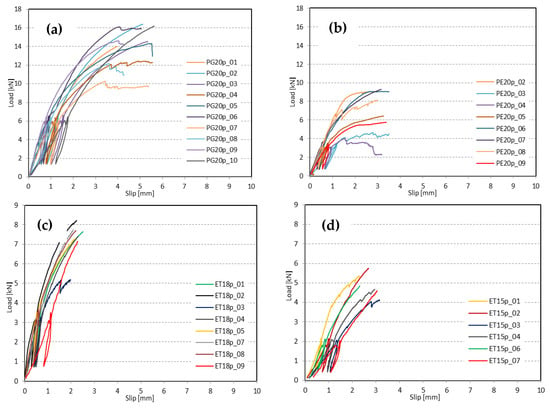

Mechanical properties and density of dowelled connections are given in Table 3 and presented graphically in Figure 7.

Table 3.

Results of shear tests. Mean values and SD.

Figure 7.

Load–slip curves of shear specimens: (a) pine joints assembled with guatambú or (b) eucalyptus and 20 mm dowels, and (c) eucalyptus joints assembled with 15 mm or (d) 18 mm red gum dowels.

The shear capacity (Fs) was defined as the maximum load detected during the tests. Student’s t-test indicated that pine joints assembled with guatambú dowels (PG20p) showed significantly higher (p < 0.05) load-carrying capacity and stiffness compared to those corresponding to pine lamellas and eucalyptus dowels (PE20p). The eucalyptus joints assembled with 18 mm diameter dowels (ET18p) showed significantly superior load-carrying capacity and stiffness (p < 0.05) compared to its counterpart jointed with 15 mm dowels (ET15p). A comparison of the density within each lamella species group (i.e., PG20p vs. PE20p and ET18p vs. ET15p) indicated no significant difference regardless of dowel species or dowel diameter.

Figure 7 depicts the load–slip curves of pine joints assembled with different dowel species (i.e., guatambú and eucalyptus) and eucalyptus joints fastened with different dowel diameters (i.e., 18 and 15 mm dowel diameters) in perpendicular to the grain shear tests.

For all specimens, the same failure pattern was observed. The load was transferred through the dowel to the neighbouring lamella via combined stress of bending and shear in the dowel itself and via embedment on the lamella. At the end of the test, the dowel through the outer lamellae remained horizontal after failure, corresponding to failure mode IV according to EN 1995-1-1 [23], in which two plastic hinges were formed. Typical failure of the side lamellas and the dowel is depicted in Figure 8. In most tests, failure occurred in the dowel and not in the wooden boards. This observation is consistent with the findings reported by Frontini et al. [26] for softwood dowelled connections.

Figure 8.

Connection failure of selected 20 mm diameter dowel in shear test.

3.2. Bending Tests

The experimental values of global and local modulus of elasticity in bending and density were adjusted to 12% MC. The experimental values of bending strength were adjusted to the 150 mm reference size by the kh factor per EN 384 [32]. Table 4 summarises the results obtained in bending tests of structural size DLT panels.

Table 4.

Results of bending tests. Mean values 1,2 and SD.

The variation of the stiffness within each series was quite small, either for pine (COV = 6%) or eucalyptus (COV = 5%) panels. Therefore, even though the number of replicates per series was limited, the observations below can be generalised. Regarding strength, the variability within the pine series (COV = 18% and 21% for PPG20 and PPE20, respectively), although somehow superior to that of the eucalyptus series (COV = 13% and 17% for PET15 and PET18, respectively) agreed with the range found in the literature [15,16,22]. In addition, the variability of lamella stiffness (Ed = 21% for pine and Ed=10% for eucalyptus) corresponded to low-grade timber, which will not be representative of commercial DLT production. Nevertheless, in general, the variability of lamella stiffness determined by E-grading could lead to differences compared to values of commercial DLT panels if, in the industry, lamella were sorted by visual grading. On the other hand, lumber stiffness within a visual grade has also a certain degree of variability due to its inherent naturally grown characteristics. The variation in MOE of glued laminated beams made of visually graded lumber was evaluated by Moody et al. [33]. They compared the experimental stiffness for laminating grades of lumber with industry values and found differences of 4%–16% for Douglas Fir/Larch and 2%–19% for Southern Pine, respectively.

Student´s t-test established that the bending properties of pine panels fastened with guatambú dowels had no significant difference (α = 0.05) from those of panels joined with eucalyptus dowels. This finding suggests that dowel species had no influence on the structural properties of DLT panels, which is consistent with previous works [13]. Furthermore, the bending strength and stiffness of PPG20 and PPE20 were similar to those of the individual lumbers that comprised the panels, which did not comply with the requirements for the structural grade of the Uruguayan standard UNIT 1261 [34]. This result implies that pine lumber for DLT production should be selected from structural grades.

For eucalyptus DLT, the Student’s t-test results indicated that panels fastened with 15 mm diameter dowels showed no significant differences (α = 0.05) compared to those fastened with 18 mm diameter dowels, indicating that dowel diameter did not affect the bending properties of the panels. This finding, which contradicts results from the shear tests, could be attributed to the more complex behaviour of the DLT panel under bending stresses where the loads are shared by multiple lamellas, in this study seven, and the fastener. Moreover, the bending strength of PET15 and PET18 were in the range of values that can be expected for the EF1 timber grade of the Uruguayan standard UNIT 1262 [35], while values of panel stiffness were lower compared to the respective expected EF1 grade.

The relationship between the elastic behaviour of the panel and the lamellas was evaluated by computing, for each panel, the stiffness ratio of the panel to their constitutive lamellas. A ratio greater than 1 indicates that DLT panels have superior stiffness with respect to the average of lamellas, denoting collaborative work between lamellas and dowels. In this study, most ratios were close or slightly superior to 1 (i.e., 1.05, 1.01, and 1 for PPE20, PET18, and PET15, respectively) except for PPG20 with a quotient of 0.95. This could be attributed to the high density and structural properties of guatambú dowels compared to the respective pine lamination properties. Further ongoing research on embedment tests supports this observation. In our study, the system factor (ksys) for mechanically jointed laminated plates suggested in the Eurocode 5 should be 1.

Generally, the literature on DLT mainly reports on panels made of softwood lamellas and hardwood dowels. The bending performance (MOE and MOR) of pine DLT panels were inferior to those reported in the literature (i.e., PPG20 and PPE20) for similar size and configuration (cross-section and length), yet failure type was similar [15,22].

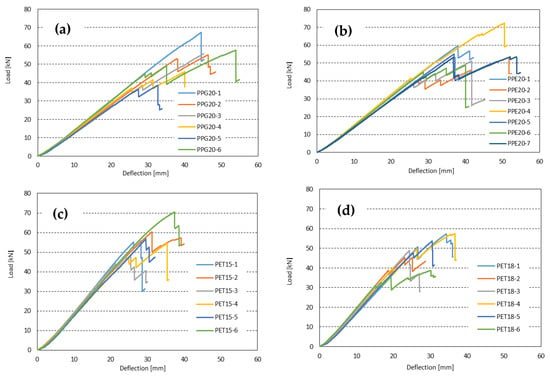

The load–deformation curves of DLT panels under bending are presented in Figure 9, and typical failures are shown in Figure 10.

Figure 9.

Load–deflection curves of DLT panels: pine lamellas assembled with 20 mm diameter dowels of (a) guatambú, and (b) eucalyptus, and eucalyptus lamellas assembled with red gum dowels of (c) 15 mm and (d) 18 mm diameter.

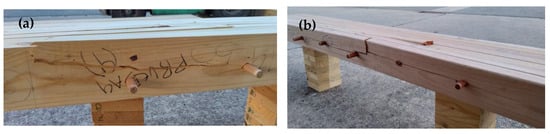

Figure 10.

Typical failure type in structural size DLT panels made of (a) pine and (b) eucalyptus.

No differences in failure modes between pine and eucalyptus DLT were observed. All DLT panels showed a linear load–deformation behaviour, regardless of the lamella–dowel combination. Very few panels behaved as a whole system and failed accordingly (e.g., PPG20-1). Instead, in most cases, the load–deformation curve was proportional until a sharp drop of strength occurred, shown by several phases in the load–deformation curve. In general, the phases observed in the curve reflected the amount of lamellas failing. This pattern suggests that some lamellas within the DLT panel have lower strength properties than others. As they fail (mainly due to tension in the bottom side of the panel), the stress is transferred through the dowels to the adjacent lamella, allowing the panel to still be capable of taking the load before complete failure occurs. This observation is consistent with our panel configuration, where lamellas of different properties were used. It is interesting to note that a similar failure pattern for nail laminated timber under bending was reported by Li et al. [36].

In general, crack propagation started close to knots or areas with pronounced slope of grain and transmitted along the grain. Brittle splitting failure perpendicular to the grain around the dowels was observed in a few panels, as shown in Figure 10. Bell [15] suggested that the insertion of dowels in the panel may weaken the timbers. Furthermore, no physical sign of dowel withdrawal in none of the panels was observed. However, during service life, changes in the RH of the environment would affect the dimension stability of the panel and its components, i.e., individual lamellas and dowels. In this study, where flatsawn boards were used, radial shrinkage/swelling across the width and tangential shrinkage/swelling across the depth of panels would occur over time. The dimensional instability could lead to separation between adjacent lamellas and loosened dowels. Previous studies [37] on the dimension stability of drilled holes on softwoods showed that swelling of the wood material reduced the hole diameter and shrinkage increased the diameter. For pine, 3.59% and 6.02% of radial and tangential shrinkage, respectively, can be expected. For eucalyptus, the respective percentages would be 4.54% and 8.80%. The mechanosorptive behaviour of DLT panels will be investigated in further works.

3.3. Analytical Results

Using the physical properties of the lamellas and the slip modulus of the connections obtained in the shear tests, the γ-method was applied, and the effective stiffness values of the DLT panels were obtained. Table 5 and Table 6 show the values of the parameters used in the gamma method and the effective bending stiffness, respectively.

Table 5.

Panel properties used in the mechanically jointed beam method.

Table 6.

Longitudinal stiffness of the DLT panels obtained via the mechanically jointed beam method and experimental bending tests.

The results shown in Table 6 revealed that the effective stiffness values computed using the γ-method were close to those obtained via the bending tests. The percentage difference between the empirical results and the analytically derived values was, in the four cases, less than 0.1%. The small difference between the effective stiffness and the empirical stiffness suggests that the γ-method is a suitable option for determining the stiffness of a DLT panel.

The effective stiffness acquired from the analytical model confirmed the experimental test findings. The stiffness of the dowel connections did not show a main impact on the overall performance of the panels, mostly due to the low stiffness of the formed connection and the location of the dowel at the centroid of the cross-section. Both analytical and experimental results suggested that the DLT panel behaved as a series of parallel beams, having all their grain direction parallel to the length rather than an orthotropic plate material.

4. Conclusions

This study aims to evaluate the structural behaviour of dowel laminated timber made of fast-growing pine and eucalyptus lamellae and different dowel species and diameters. The test specimens were constructed using low-grade timbers. Based on the results and observations, the following conclusions can be drawn:

- The mean modulus of elasticity and the bending strength of DLT panels were similar to those of the individual lumbers, suggesting no composite action was achieved. Dowel species and dowel diameter had no substantial influence on the bending properties of structural size panels yet showed an effect on the slip modulus and shear capacity of the dowelled connections.

- The most common failure mode under bending indicates that some lamellas within the DLT panel are weaker than others. As they fail by tension, the stress is transferred through the dowels to the adjacent lamellas until complete panel failure occurs. A good match between the analytical estimation and the experimental results of the bending stiffness of structural size panels was found.

- The structural performance of DLT could be improved with better timber quality. Increasing the depth of the boards or using different E-grade species for DLT production could be potential solutions to fulfil the structural requirements. Since the design of DLT panels is usually driven by serviceability limit states, the addition of multiple layers of plywood to the top side of the panel would increase the overall stiffness and probably reduce vibrations. Further research on sustainable materials as a replacement of concrete for a typical compression slab that complies with the requirements of the serviceability limit states of the EC-5 will be very valuable.

Ongoing research focusing on embedment strength and dimensional stability of dowels will address important issues previously mentioned and will contribute to a better understanding of the overall performance of DLT systems.

Author Contributions

Conceptualisation, D.G., S.B. and L.M., Methodology, G.B., D.G. and L.M.; Investigation, G.B., D.G., S.Q., S.A. and L.M.; writing—original draft preparation, G.B. and L.M.; writing—review and editing, L.M.; supervision, D.G. and L.M.; project administration, L.M.; funding acquisition, L.M., D.G., S.B. and S.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Agency of Research and Innovation (ANII), Grant # FMV 2019_1_156162.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge Cinthia Planchon and Ignacio Torino for their technical assistance and Carlos Mantero for providing part of the materials for dowel fabrication.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Uruguay XXI. Forestry Sector in Uruguay. Investment, Export and Country Brand Promotion Agency. 2022. Available online: https://www.uruguayxxi.gub.uy/uploads/informacion/2ec25967b8d7bfd72de685fbe8d201e06b5507bd.pdf (accessed on 10 July 2023).

- Martínez, G. Biological control of forest pests in Uruguay. In Forest Pest and Disease Management in Latin America: Modern Perspectives in Natural Forests and Exotic Plantations; Springer: Berlin/Heidelberg, Germany, 2020; pp. 7–30. [Google Scholar]

- Moya, L.; Lagurada Mallo, F.; Cagno, M.; Cardoso, A.; Gatto, F.; O’Neill, H. Physical and Mechanical Properties of Loblolly and Slash Pine Wood from Uruguayan Plantations. Forest Prod. J. 2013, 63, 128–137. [Google Scholar] [CrossRef]

- Hoja de Ruta para la Construcción de Vivienda Social en Madera en Uruguay. National Housing Department, Uruguay. 2022. Available online: https://www.gub.uy/ministerio-vivienda-ordenamiento-territorial/comunicacion/publicaciones/hoja-ruta-construccion-vivienda-social-madera-uruguay#dropdown (accessed on 10 July 2023).

- Harte, A.M. Mass timber—The Emergence of a Modern Construction Material. J. Struct. Integr. Maint. 2017, 2, 121–132. [Google Scholar] [CrossRef]

- Ayanleye, S.; Udele, K.; Nasir, V.; Zhang, X. Durability and Protection of Mass Timber Structures: A review. J. Build. Eng 2021, 46, 103731. [Google Scholar] [CrossRef]

- Ministerio de Industria, Energía y Minería. Balance Energético Nacional, BEN Uruguay 2022. Montevideo, Uruguay. 2023. Available online: https://ben.miem.gub.uy/balance.php (accessed on 9 August 2023).

- Soust-Verdaguer, B.; Moya, L.; Llatas, C. Evaluación de Impactos Ambientales de Viviendas en Madera: El caso de “La Casa Uruguaya”. Maderas-Cienc. Technol. 2022, 24, 1–12. [Google Scholar] [CrossRef]

- UNFCCC. The Paris Agreement. Paris Climate Change Conference, 21st Meeting, 20 December 2015. 2016. Available online: https://unfccc.int/documents/184656 (accessed on 10 July 2023).

- Zhao, J.; Wei, X.; Ling, L. The potential for storing carbon by harvested wood products. Front. For. Glob. Chang. 2022, 5, 1055410. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Moya, L. Comparative BIM-based Life Cycle Assessment of Uruguayan Timber and Concrete-Masonry Single-Family Houses in Design Stage. J. Clean. Prod. 2020, 277, 121958. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359.e13. [Google Scholar] [CrossRef]

- Sotayo, A.; Bradley, D.; Bather, M.; Sareh, P.; Oudjene, M.; El-Houjeyri, I.; Harte, A.M.; Mehra, S.; O’Ceallaigh, C.; Haller, P.; et al. Review of state of the art of dowel laminated timber members and densified wood materials as sustainable engineered wood products for construction and building applications. Dev. Built Environ. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Han, L.; Kutnar, A.; Sandak, J.; Sustersic, I.; Sandberg, D. Adhesive-and Metal-Free Assembly Techniques for Prefabricated Multi-Layered Wood Products: A Review on Wooden Connectors. Forests 2023, 14, 311. [Google Scholar] [CrossRef]

- Bell, T. A Detailed Investigation into the Engineering Properties and Challenges Affecting the Potential Introduction of a UK Grown Dowel-Laminated Timber Floor Panel into the Domestic Construction Market. Ph.D. Thesis, University of Strathclyde, Glasgow, UK, 2018. [Google Scholar]

- Ogunrinde, O. Evaluation of Bending Performance of Nail laminated and Dowel Laminated Timber. Master’s Thesis, University of New Brunswick, Fredericton, NB, Canada, 2019. [Google Scholar]

- Sandhaas, C.; Schädle, P.; Ceccotti, A. Innovative Timber Building Systems: Comparative Testing and Modelling of Earthquake Behaviour. Bull. Earthq. Eng. 2018, 16, 1961–1985. [Google Scholar] [CrossRef]

- Sotayo, A.; Bradley, D.F.; Bather, M.; Oudjene, M.; El-Houjeyri, I.; Guan, Z. Development and structural behaviour of adhesive free laminated timber beams and cross laminated panels. Constr. Build. Mater. 2020, 259, 119821. [Google Scholar]

- El-Houjeyri, I.; Thi, V.D.; Oudjene, M.; Khelifa, M.; Rogaume, Y.; Sotayo, A.; Guan, Z. Experimental Investigations on Adhesive Free Laminated Oak Timber Beams and Timber-to-Timber Joints Assembled Using Thermo-Mechanically Compressed Wood Dowels. Constr. Build. Mater. 2019, 222, 288–299. [Google Scholar] [CrossRef]

- Derikvand, M.; Hosseinzadeh, S.; Fink, G. Mechanical Properties of Dowel Laminated Timber Beams with Connectors made of Salvaged Wooden Materials. J. Arch. Eng. 2021, 27, 04021035. [Google Scholar] [CrossRef]

- Dourado, N.; Pereira, F.A.M.; Lousada, J.L.; de Moura, M.F.S.F. Experimental and numerical analysis of wood boards joining using wood-pin connectors. Constr. Build. Mater. 2019, 222, 556–565. [Google Scholar] [CrossRef]

- Plowas, W.; Bell, T.; Hairstans, R.; Williamson, J. Understanding the Compatibility of UK Resource for Dowel Laminated Timber Construction; The University of Edinburgh: Edinburgh, UK, 2015; pp. 1–12. [Google Scholar]

- EN 1995-1-1; Eurocode 5. Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings. CEN: Brussels, Belgium, 2016.

- Jung, K.; Kitamori, A.; Komatsu, K. Evaluation on structural performance of compressed wood as shear dowel. Holzforschung 2008, 62, 461–467. [Google Scholar] [CrossRef]

- Shanks, J.; Walker, P. Strength and stiffness of all-timber pegged connections. J. Mater. Civil Eng. 2009, 21, 10–18. [Google Scholar] [CrossRef]

- Frontini, F.; Siem, J. Load carrying capacity and stiffness of Softwood Wooden Dowel Connections. Int. J. Archit. Herit. 2018, 14, 376–397. [Google Scholar] [CrossRef]

- EN 1380; Timber Structures—Test Methods—Load Bearing Nails, Screws, Dowels and Bolts. CEN: Brussels, Belgium, 2009.

- EN 26891; Timber Structures—Joints Made with Mechanical Fasteners—General Principles for the Determination of Strength and Deformation Characteristics. CEN: Brussels, Belgium, 1991.

- EN 13183-1; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method. CEN: Brussels, Belgium, 2002.

- EN 408:2011+A1:2012; Timber Structures—Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties. CEN: Brussels, Belgium, 2019.

- BS 5268-2; Structural Use of Timber—Part 2: Code of Practice for Permissible Stress Design, Materials and Workmanship. British Standards Institution: London, UK, 2002.

- EN 384; Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density. CEN: Brussels, Belgium, 2016.

- Moody, R.C.; De Sousa, P.P.; Little, J.K. Variation in Stiffness of Horizontally Laminated Glulam Timber Beams. Forest Prod. J. 1988, 38, 39–45. [Google Scholar]

- UNIT 1261; Madera Aserrada de Uso Estructural. Clasificación Visual. Madera de Pino Taeda y Pino Ellioti. Instituto Uruguayo de Normas Técnicas: Montevideo, Uruguay, 2018.

- UNIT 1262; Madera Aserrada de Uso Estructural. Clasificación Visual. Madera de Eucalipto. Instituto Uruguayo de Normas Técnicas: Montevideo, Uruguay, 2018.

- Li, Z.; Feng, W.; He, M.; Chen, F.; Sun, X. Bending Performance of Nail Laminated Timber: Experimental, Analytical and Numerical Analyses. Constr. Build. Mat. 2023, 389, 131766. [Google Scholar] [CrossRef]

- Sydor, M.; Majka, J.; Lagová, N. Effective Diameters of Drilled Holes in Pinewood in Response to Changes in Relative Humidity. BioResources 2021, 16, 5407–5421. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).