Integrating Detailed Timber Assortments into Airborne Laser Scanning (ALS)-Based Assessments of Logging Recoveries

Abstract

:1. Introduction

2. Materials and Methods

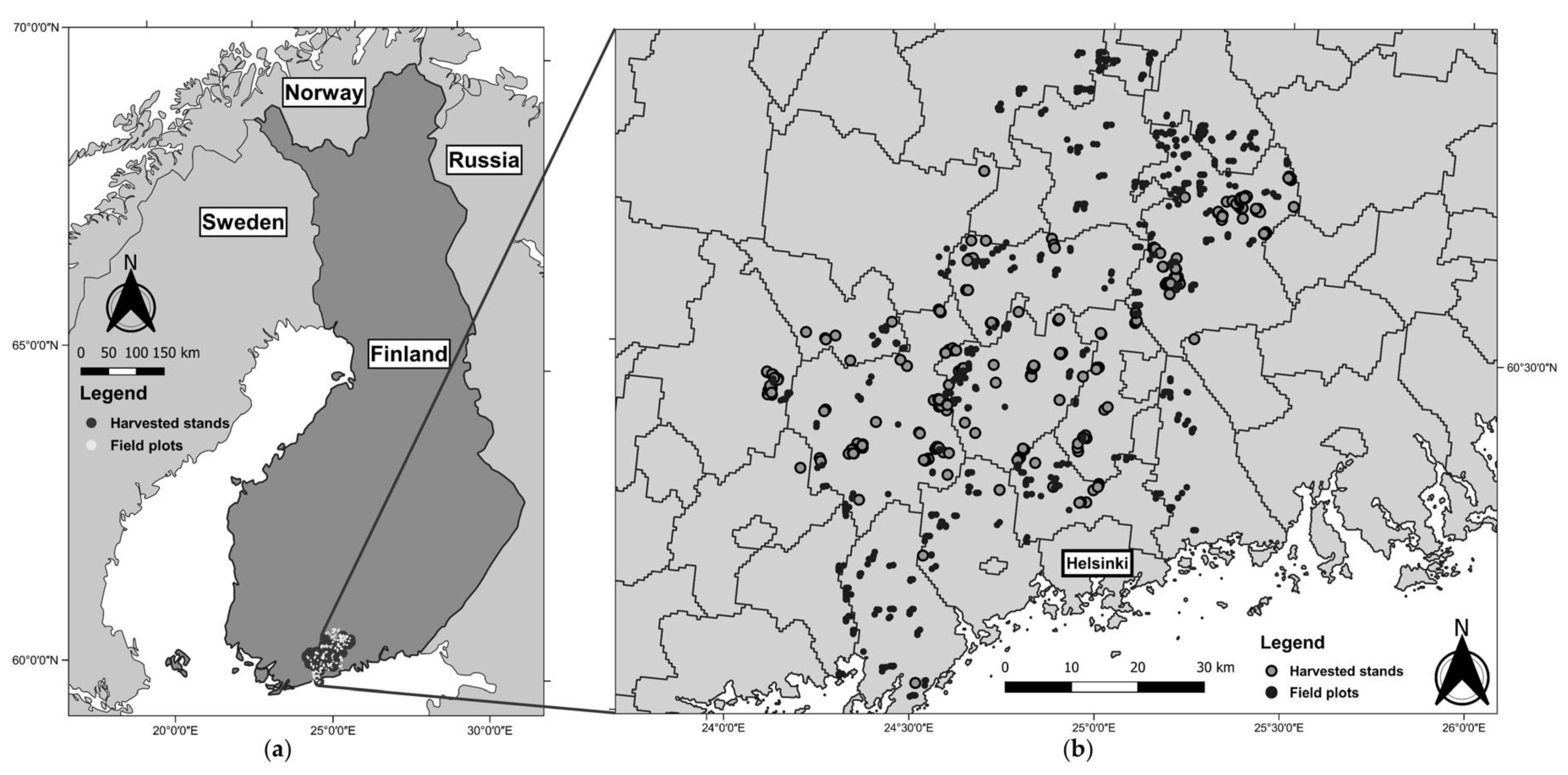

2.1. Materials

2.1.1. Field Data

2.1.2. Harvester Data

2.1.3. Field Plots

2.1.4. ALS Data and Aerial Images

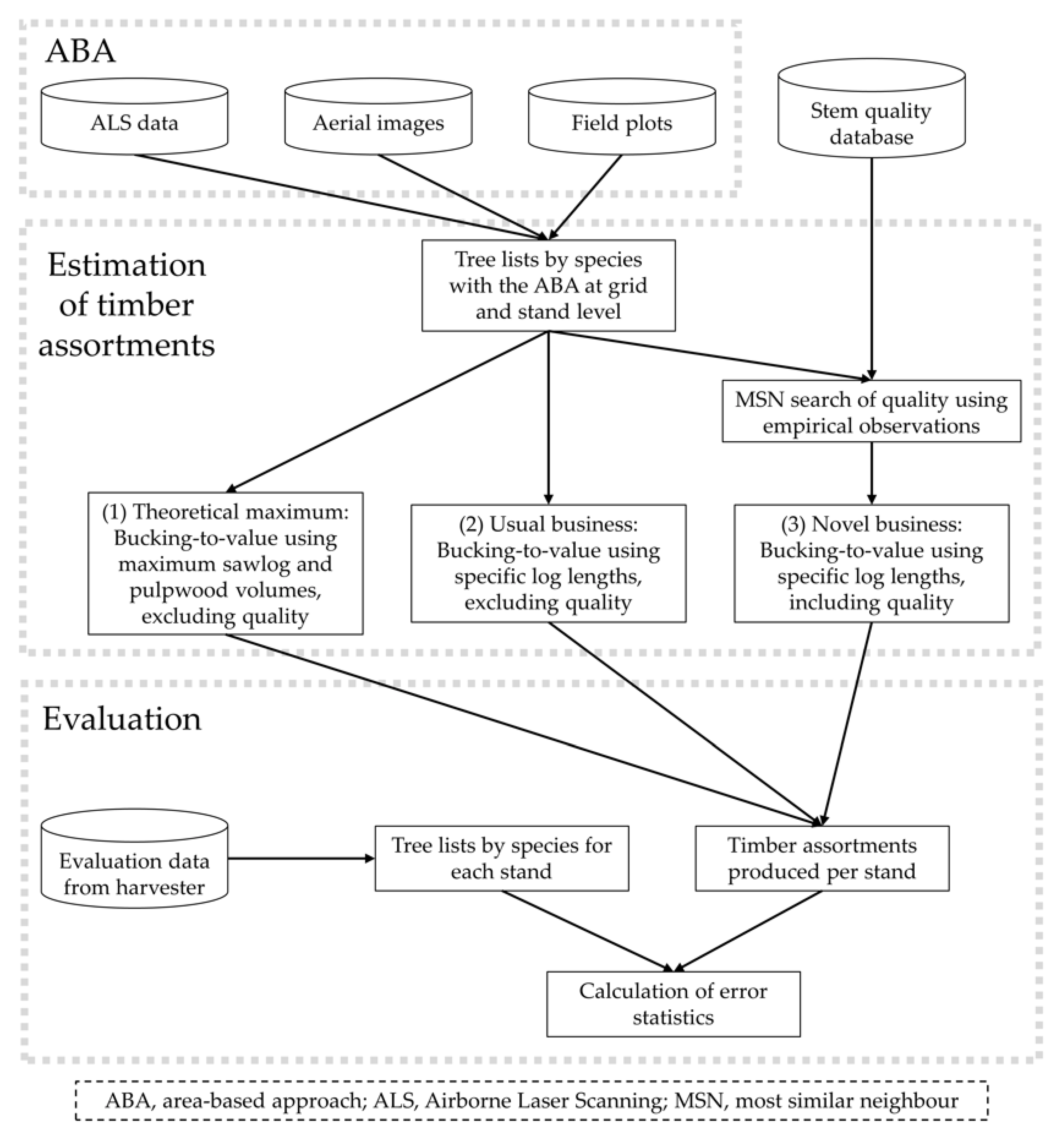

2.2. Methods

2.2.1. Prediction of Stand-Level Timber Assortments Using ALS Data and Aerial Images

- (1)

- An initial set of variables explaining species distribution, total volume, basal area and mean tree size was selected using correlations;

- (2)

- An exhaustive search was then carried out for the initial feature set by testing different feature combinations and minimizing the root mean square errors (RMSEs) of the species volumes, basal area and mean tree size. The number of most similar neighbours was set at six, which means that every grid cell was allotted to the six most similar field plots and their MSN weights. Tree lists (also known as lists of stems) were predicted for each grid cell and weighted by the average of the trees measured from the six most similar field plots;

- (3)

- The information from the predicted tree lists at the grid level was aggregated at the stand level.

2.2.2. Alternative Bucking Methods for Deriving Timber Assortments for each Stand

3. Results

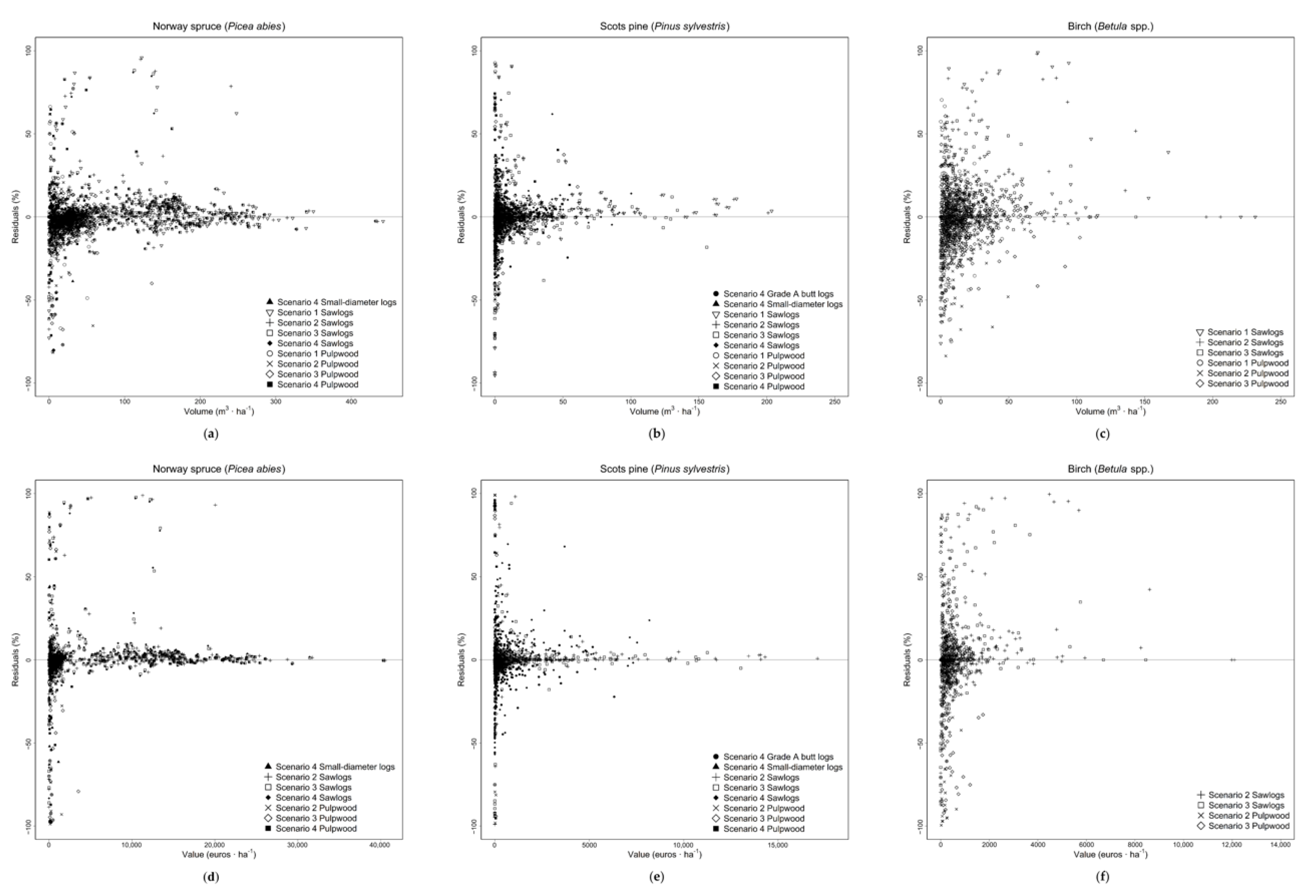

3.1. Differences in Timber Assortments due to Tree List Prediction and Simulated Bucking

3.2. Differences in Volume Estimates due to Tree List Prediction

3.3. Residual Errors

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holopainen, M.; Vastaranta, M.; Hyyppä, J. Outlook for the Next Generation’s Precision Forestry in Finland. Forests 2014, 5, 1682–1694. [Google Scholar] [CrossRef] [Green Version]

- Kankare, V.; Vauhkonen, J.; Tanhuanpää, T.; Holopainen, M.; Vastaranta, M.; Joensuu, M.; Krooks, A.; Hyyppä, J.; Hyyppä, H.; Alho, P.; et al. Accuracy in estimation of timber assortments and stem distribution—A comparison of airborne and terrestrial laser scanning techniques. ISPRS J. Photogramm. Remote Sens. 2014, 97, 89–97. [Google Scholar] [CrossRef]

- Siipilehto, J.; Lindeman, H.; Vastaranta, M.; Yu, X.; Uusitalo, J. Reliability of the predicted stand structure for clear-cut stands using optional methods: Airborne laser scanning-based methods, smartphone-based forest inventory application Trestima and pre-harvest measurement tool EMO. Silva Fenn. 2016, 50, 1568. [Google Scholar] [CrossRef] [Green Version]

- Sanz, B.; Malinen, J.; Leppänen, V.; Valbuena, R.; Kauranne, T.; Tokola, T. Valuation of growing stock using multisource GIS data, a stem quality database, and bucking simulation. Can. J. For. Res. 2018, 48, 888–897. [Google Scholar] [CrossRef]

- Malinen, J.; Kilpeläinen, H.; Piira, T.; Redsven, V.; Wall, T.; Nuutinen, T. Comparing model-based approaches with bucking simulation-based approach in the prediction of timber assortment recovery. Forestry 2007, 80, 309–321. [Google Scholar] [CrossRef] [Green Version]

- Hyvönen, P.; Lempinen, R.; Lappi, J.; Laitila, J.; Packalen, T. Joining up optimisation of wood supply chains with forest management: A case study of North Karelia in Finland. Forestry 2019, 93, 163–177. [Google Scholar] [CrossRef]

- White, J.C.; Wulder, M.A.; Varhola, A.; Vastaranta, M.; Coops, N.C.; Cook, B.D.; Pitt, D.; Woods, M. A best practices guide for generating forest inventory attributes from airborne laser scanning data using an area-based approach. For. Chron. 2013, 89, 722–723. [Google Scholar] [CrossRef] [Green Version]

- White, J.C.; Coops, N.C.; Wulder, M.A.; Vastaranta, M.; Hilker, T.; Tompalski, P. Remote Sensing Technologies for Enhancing Forest Inventories: A Review. Can. J. Remote Sens. 2016, 42, 619–641. [Google Scholar] [CrossRef] [Green Version]

- White, J.C.; Tompalski, P.; Vastaranta, M.; Wulder, M.A.; Saarinen, N.; Stepper, C.; Coops, N.C. A Model Development and Application Guide for Generating an Enhanced Forest Inventory Using Airborne Laser Scanning Data and an Area-Based Approach; Natural Resources Canada, Canadian Forest Service, Canadian Wood Fibre Centre: Victoria, BC, Canada, 2017; pp. 1–48. [Google Scholar] [CrossRef]

- Peuhkurinen, J.; Maltamo, M.; Malinen, J. Estimating Species-Specific Diameter Distributions and Saw Log Recoveries of Boreal Forests from Airborne Laser Scanning Data and Aerial Photographs: A Distribution-Based Approach. Silva Fenn. 2008, 42, 625–641. [Google Scholar] [CrossRef] [Green Version]

- Gobakken, T.; Næsset, E. Estimation of Diameter and Basal Area Distributions in Coniferous Forest by Means of Airborne Laser Scanner Data. Scand. J. For. Res. 2004, 19, 529–542. [Google Scholar] [CrossRef]

- Laasasenaho, J. Taper curve and volume functions for pine, spruce and birch. Commun. Inst. For. Fenn. 1982, 108, 1–74. [Google Scholar]

- Mehtätalo, L. Valtakunnalliset puukohtaiset tukkivähennysmallit männylle, kuuselle, koivuille ja haavalle [Nationwide species-specific sawlog reduction models for Scots pine, Norway spruce, birches and aspen]. Metsätieteen Aikakausk. 2002, 4, 575–591. [Google Scholar] [CrossRef] [Green Version]

- Kangas, A.; Maltamo, M. Anticipating the Variance of Predicted Stand Volume and Timber Assortments with Respect to Stand Characteristics and Field Measurements. Silva Fenn. 2002, 36, 799–811. [Google Scholar] [CrossRef] [Green Version]

- Maltamo, M.; Karjalainen, T.; Repola, J.; Vauhkonen, J. Incorporating tree-and stand-level information on crown base height into multivariate forest management inventories based on airborne laser scanning. Silva Fenn. 2018, 52, 10006. [Google Scholar] [CrossRef]

- Holopainen, M.; Vastaranta, M.; Rasinmäki, J.; Kalliovirta, J.; Mäkinen, A.; Haapanen, R.; Melkas, T.; Yu, X.; Hyyppä, J. Uncertainty in timber assortment estimates predicted from forest inventory data. Eur. J. For. Res. 2010, 129, 1131–1142. [Google Scholar] [CrossRef]

- Karjalainen, T. Predicting commercial tree quality by means of airborne laser scanning. Diss. For. 2020, 307, 1–60. [Google Scholar] [CrossRef]

- Malinen, J.; Maltamo, M.; Harstela, P. Application of Most Similar Neighbor Inference for Estimating Marked Stand Characteristics Using Harvester and Inventory Generated Stem Databases. Int. J. For. Eng. 2001, 12, 33–41. [Google Scholar] [CrossRef]

- Kivinen, V.-P.; Uusitalo, J.; Nummi, T. Comparison of four measures designed for assessing the fit between the demand and output distributions of logs. Can. J. For. Res. 2005, 35, 693–702. [Google Scholar] [CrossRef]

- Kivinen, V.-P. Design and testing of stand-specific bucking instructions for use on modern cut-to-length harvesters. Diss. For. 2007, 37, 1–65. [Google Scholar] [CrossRef] [Green Version]

- Bouvier, M.; Durrieu, S.; Fournier, R.A.; Renaud, J.P. Generalizing predictive models of forest inventory attributes using an area-based approach with airborne LiDAR data. Remote Sens. Environ. 2015, 156, 322–334. [Google Scholar] [CrossRef]

- Vastaranta, M.; Yrttimaa, T.; Saarinen, N.; Yu, X.; Karjalainen, M.; Nurminen, K.; Karila, K.; Kankare, V.; Luoma, V.; Pyörälä, J.; et al. Airborne Laser Scanning Outperforms the Alternative 3D Techniques in Capturing Variation in Tree Height and Forest Density in Southern Boreal Forests. Balt. For. 2018, 24, 268–277. [Google Scholar]

- Pyörälä, J.; Saarinen, N.; Kankare, V.; Coops, N.C.; Liang, X.; Wang, Y.; Holopainen, M.; Hyyppä, J.; Vastaranta, M. Variability of wood properties using airborne and terrestrial laser scanning. Remote Sens. Environ. 2019, 235, 111474. [Google Scholar] [CrossRef]

- Bollandsås, O.M.; Maltamo, M.; Gobakken, T.; Lien, V.; Næssset, E. Prediction of Timber Quality Parameters of Forest Stands by Means of Small Footprint Airborne Laser Scanner Data. Int. J. For. Eng. 2011, 22, 14–23. [Google Scholar] [CrossRef]

- Saukkola, A.; Melkas, T.; Riekki, K.; Sirparanta, S.; Peuhkurinen, J.; Holopainen, M.; Hyyppä, J.; Vastaranta, M. Predicting Forest Inventory Attributes Using Airborne Laser Scanning, Aerial Imagery, and Harvester Data. Remote Sens. 2019, 11, 797. [Google Scholar] [CrossRef] [Green Version]

- Skogforsk. StanForD/StanForD 2010-Standard for Forest Machine Data and Communication. 2018. Available online: http://www.skogforsk.se/english/projects/stanford/ (accessed on 29 June 2021).

- Suomen Metsäkeskus. Puustotulkintakoealojen Maastotyöohje. 2018. Available online: https://www.metsakeskus.fi/sites/default/files/document/koealojen-maastotyoohje.pdf (accessed on 29 June 2021).

- Axelsson, P. DEM generation from laser scanner data using adaptive TIN models. In Proceedings of the International Archives of Photogrammetry and Remote Sensing, Amsterdam, The Netherlands, 16–22 July 2000; pp. 110–117. [Google Scholar]

- Valbuena, R.; Mauro, F.; Arjonilla, F.J.; Manzanera, J.A. Comparing airborne laser scanning-imagery fusion methods based on geometric accuracy in forested areas. Remote Sens. Environ. 2011, 115, 1942–1954. [Google Scholar] [CrossRef]

- Malinen, J.; Kilpeläinen, H.; Verkasalo, E. Validating the predicted saw log and pulpwood proportions and gross value of Scots pine and Norway spruce harvest at stand level by Most Similar Neighbour analyses and a stem quality database. Silva Fenn. 2018, 52, 9972. [Google Scholar] [CrossRef]

- Malinen, J.; Kilpeläinen, H.; Ylisirniö, K. Description and evaluation of Prehas software for pre-harvest assessment of timber assortments. Int. J. For. Eng. 2014, 25, 66–74. [Google Scholar] [CrossRef]

- Metsäkustannus Oy. Roundwood Prices for Standing Sales. 2021. Available online: https://www.metsalehti.fi/puunhinta/puunhinta/ (accessed on 27 April 2021).

- Paavilainen, L. (Ed.) Finnish Forest Cluster Research Programme WOOD WISDOM (1998–2001); Tekes: Helsinki, Finland, 2002; pp. 1–441. [Google Scholar]

- Sanz, B.; Malinen, J.; Heiskanen, J.; Tokola, T. Need for Pre-Harvest Clearing of Understory Vegetation Determined by Airborne Laser Scanning. Forests 2020, 11, 294. [Google Scholar] [CrossRef] [Green Version]

- Vähä-Konka, V.; Maltamo, M.; Pukkala, T.; Kärhä, K. Evaluating the accuracy of ALS-based removal estimates against actual logging data. Ann. For. Sci. 2020, 77, 84. [Google Scholar] [CrossRef]

- Tokola, T.; Heikkilä, J. Improving Satellite Image Based Forest Inventory by Using A Priori Site Quality Information. Silva Fenn. 1997, 31, 67–78. [Google Scholar] [CrossRef] [Green Version]

| Field Plots | Harvested Stands | |||||||

|---|---|---|---|---|---|---|---|---|

| Variable | Minimum | Mean | Maximum | SD | Minimum | Mean | Maximum | SD |

| DBH (cm) | 5.0 | 19.8 | 47.3 | 8.7 | 7.4 | 22.4 | 41 | 3.9 |

| Height (m) | 4.7 | 16.8 | 32.7 | 5.9 | 7.5 | 19.3 | 25.1 | 2.3 |

| Density (stems·ha−1) | 60 | 1398 | 8205 | 1091 | 32.9 | 519.9 | 1093 | 217.7 |

| Volume (m3·ha−1) | 7.0 | 193.9 | 693.3 | 127.9 | 8.8 | 235 | 565.2 | 110.5 |

| Basal area (m2·ha−1) | 2.3 | 22.1 | 52.2 | 10.2 | 1.2 | 21.5 | 50.6 | 9 |

| Norway spruce basal area (m2·ha−1) | 0.0 | 9.9 | 52.2 | 11.9 | 0 | 14.8 | 38 | 8.6 |

| Scots pine basal area (m2·ha−1) | 0.0 | 7.4 | 40.9 | 9.7 | 0 | 2.4 | 20.4 | 3.8 |

| Birch basal area (m2·ha−1) | 0.0 | 4.7 | 38.2 | 6.2 | 0 | 3.5 | 28 | 3.7 |

| Bucking Method | Timber Assortments | Quality Included | |

|---|---|---|---|

| Scenario 1 | Maximum sawlog and pulpwood volumes | Sawlogs | No |

| Pulpwood | |||

| Scenario 2 | Scots pine and Norway spruce: sawlog lengths at 30 cm intervals Birch: veneer logs of lengths 4.7 m, 5.0 m, 6.0 m and 6.7 m | Sawlogs | No |

| Pulpwood | |||

| Scenario 3 | Scots pine and Norway spruce: sawlog lengths at 30 cm intervals Birch: veneer logs of lengths 4.7 m, 5.0 m, 6.0 m and 6.7 m | Sawlogs | Yes |

| Pulpwood | |||

| Scenario 4 | Sawlog lengths at 30 cm intervals | Grade A butt logs (only for Scots pine) | Yes |

| Sawlogs | |||

| Small-diameter logs | |||

| Pulpwood |

| Minimum Diameter (cm) | Minimum Length (m) | Maximum Length (m) | Minimum WPC (EUR/m3) | Maximum WPC (EUR/m3) | ||

|---|---|---|---|---|---|---|

| Scots pine | Grade A butt logs | 21.0 | 2.8 | 6.1 | 68 | 129 |

| Sawlogs | 15.0 | 3.7 | 5.8 | 57 | 98 | |

| Small-diameter logs | 12.0 | 3.1 | 4.0 | 28 | 65 | |

| Pulpwood | 7.0 | 2.8 | 5.2 | 17 | 17 | |

| Norway spruce | Sawlogs | 16.0 | 3.7 | 6.1 | 62 | 98 |

| Small-diameter logs | 12.0 | 2.8 | 4.9 | 31 | 65 | |

| Pulpwood | 7.0 | 2.8 | 5.2 | 26 | 26 | |

| Birch | Sawlogs | 18.0 | 4.7 | 6.7 | 55 | 65 |

| Pulpwood | 7.0 | 2.8 | 6.1 | 17 | 17 |

| Norway Spruce (Picea abies) | Scots Pine (Pinus sylvestris) | Birch (Betula spp.) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 1 | Scenario 2 | Scenario 3 | |

| Sawlogs | |||||||||||

| Average volume based on harvester data (m3·ha−1) | 126.8 | 121.6 | 116.1 | 115.4 | 21.3 | 21.1 | 16.4 | 10.9 | 24.0 | 18.5 | 10.6 |

| Average volume based on ABA data (m3·ha−1) | 114.9 | 109.1 | 105.0 | 104.3 | 26.3 | 26.0 | 20.8 | 12.6 | 18.7 | 13.7 | 7.5 |

| RMSE (m3·ha−1) | 53.4 | 51.9 | 49.3 | 49.1 | 32.3 | 31.9 | 24.6 | 16.5 | 30.2 | 26.7 | 16.6 |

| RMSE% | 42.1 | 42.7 | 42.5 | 42.5 | 151.3 | 151.1 | 150.4 | 152.1 | 126.0 | 144.2 | 157.1 |

| Bias (m3·ha−1) | 11.9 | 12.5 | 11.1 | 11.2 | −4.9 | −4.9 | −4.5 | −1.7 | 5.3 | 4.8 | 3.1 |

| Bias% | 9.4 | 10.3 | 9.6 | 9.7 | −23.2 | −23.0 | −27.3 | −16.1 | 22.0 | 26.1 | 28.8 |

| SD (m3·ha−1) | 52.1 | 50.4 | 48.1 | 47.9 | 31.9 | 31.6 | 24.3 | 16.5 | 29.8 | 26.3 | 16.4 |

| Pulpwood | |||||||||||

| Average volume based on harvester data (m3·ha−1) | 23.0 | 28.3 | 32.8 | 19.0 | 2.7 | 2.9 | 7.3 | 5.8 | 8.4 | 13.9 | 20.8 |

| Average volume based on ABA data (m3·ha−1) | 26.9 | 32.8 | 36.1 | 19.8 | 5.3 | 5.6 | 10.4 | 7.7 | 9.6 | 14.7 | 20.5 |

| RMSE (m3·ha−1) | 15.1 | 17.8 | 20.2 | 12.2 | 5.8 | 6.0 | 11.6 | 9.5 | 8.2 | 12.3 | 18.6 |

| RMSE% | 65.7 | 62.8 | 61.5 | 64.4 | 217.5 | 208.3 | 158.6 | 163.1 | 98.0 | 88.5 | 89.5 |

| Bias (m3·ha−1) | −4.0 | −4.5 | −3.3 | −0.8 | −2.6 | −2.7 | −3.1 | −1.9 | −1.3 | −0.8 | 0.3 |

| Bias% | −17.2 | −15.9 | −10.1 | −4.1 | −98.0 | −94.1 | −41.7 | −32.6 | −15.3 | −6.1 | 1.5 |

| SD (m3·ha−1) | 14.6 | 17.2 | 20.0 | 12.2 | 5.2 | 5.3 | 11.2 | 9.3 | 8.1 | 12.3 | 18.6 |

| Residual wood | |||||||||||

| Average volume based on harvester data (m3·ha−1) | 5.5 | 5.4 | 6.3 | 6.4 | 0.5 | 0.5 | 0.8 | 0.9 | 1.5 | 1.5 | 2.5 |

| Average volume based on ABA data (m3·ha−1) | 4.2 | 4.0 | 4.8 | 5.0 | 0.6 | 0.6 | 1.0 | 1.1 | 1.7 | 1.7 | 2.1 |

| RMSE (m3·ha−1) | 3.6 | 3.6 | 4.0 | 4.0 | 0.8 | 0.8 | 1.3 | 1.4 | 1.8 | 1.7 | 3.7 |

| RMSE% | 66.2 | 66.8 | 62.8 | 62.2 | 167.3 | 169.5 | 158.7 | 155.1 | 118.2 | 119.4 | 147.2 |

| Bias (m3·ha−1) | 1.3 | 1.3 | 1.5 | 1.5 | −0.1 | −0.1 | −0.2 | −0.2 | −0.2 | −0.2 | 0.4 |

| Bias% | 24.4 | 25.0 | 23.4 | 22.7 | −23.4 | −23.4 | −19.5 | −17.7 | −12.9 | −13.1 | 16.9 |

| SD (m3·ha−1) | 3.4 | 3.3 | 3.7 | 3.7 | 0.8 | 0.8 | 1.3 | 1.4 | 1.8 | 1.7 | 3.6 |

| Norway Spruce (Picea abies) | Scots Pine (Pinus sylvestris) | Birch (Betula spp.) | ||||||

|---|---|---|---|---|---|---|---|---|

| Scenario 2 | Scenario 3 | Scenario 4 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 2 | Scenario 3 | |

| Total | ||||||||

| Average WPC based on harvester data (EUR·m−3) | 68.0 | 65.5 | 66.6 | 52.1 | 42.8 | 48.5 | 32.8 | 24.8 |

| Average WPC based on ABA data (EUR·m−3) | 63.3 | 61.5 | 62.9 | 61.1 | 51.3 | 59.6 | 30.9 | 23.8 |

| RMSE (EUR·m−3) | 17.5 | 16.3 | 16.1 | 32.6 | 27.6 | 32.0 | 15.3 | 10.7 |

| RMSE% | 25.7 | 24.8 | 24.1 | 62.7 | 64.4 | 66.1 | 46.6 | 43.1 |

| Bias (EUR·m−3) | 4.6 | 4.0 | 3.7 | −9.0 | −8.5 | −11.1 | 1.8 | 1.0 |

| Bias% | 6.8 | 6.1 | 5.6 | −17.2 | −20.0 | −22.9 | 5.5 | 4.0 |

| SD (EUR·m−3) | 16.9 | 15.8 | 15.7 | 31.5 | 26.3 | 30.1 | 15.2 | 10.7 |

| Sawlogs | ||||||||

| Average WPC based on harvester data (EUR·m−3) | 82.9 | 82.5 | 82.7 | 58.8 | 57.1 | 55.2 | 49.0 | 47.5 |

| Average WPC based on ABA data (EUR·m−3) | 79.5 | 79.2 | 79.4 | 72.3 | 70.2 | 69.0 | 46.6 | 45.5 |

| RMSE (EUR·m−3) | 23.8 | 23.9 | 24.0 | 38.8 | 37.4 | 37.9 | 22.4 | 22.6 |

| RMSE% | 28.7 | 29.0 | 29.0 | 66.0 | 65.5 | 68.7 | 45.7 | 47.4 |

| Bias (EUR·m−3) | 3.4 | 3.3 | 3.3 | −13.5 | −13.1 | −13.8 | 2.4 | 2.1 |

| Bias% | 4.1 | 4.0 | 4.0 | −22.9 | −23.0 | −24.9 | 4.9 | 4.3 |

| SD (EUR·m−3) | 23.6 | 23.7 | 23.9 | 36.5 | 35.1 | 35.4 | 22.3 | 22.5 |

| Pulpwood | ||||||||

| Average WPC based on harvester data (EUR·m−3) | 25.7 | 25.7 | 25.7 | 12.8 | 12.8 | 12.8 | 15.9 | 15.9 |

| Average WPC based on ABA data (EUR·m−3) | 25.2 | 25.2 | 25.2 | 15.6 | 15.6 | 15.6 | 16.0 | 16.0 |

| RMSE (EUR·m−3) | 4.9 | 4.9 | 4.9 | 8.1 | 8.1 | 8.1 | 4.7 | 4.7 |

| RMSE% | 19.3 | 19.3 | 19.3 | 63.7 | 63.7 | 63.7 | 29.5 | 29.5 |

| Bias (EUR·m−3) | 0.5 | 0.5 | 0.5 | −2.8 | −2.8 | −2.8 | −0.1 | −0.1 |

| Bias% | 2.0 | 2.0 | 2.0 | −21.9 | −21.9 | −21.9 | −0.4 | −0.4 |

| SD (EUR·m−3) | 4.9 | 4.9 | 4.9 | 7.7 | 7.7 | 7.7 | 4.7 | 4.7 |

| Total Volume | Grade A Butt Logs (Scenario 4) | Small-Diameter Logs (Scenario 4) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Norway Spruce (Picea abies) | Scots Pine (Pinus sylvestris) | Birch (Betula spp.) | Norway Spruce (Picea abies) | Scots Pine (Pinus sylvestris) | Birch (Betula spp.) | Scots pine (Pinus sylvestris) | Norway Spruce (Picea abies) | Scots Pine (Pinus sylvestris) | Norway Spruce (Picea abies) | Scots Pine (Pinus sylvestris) | ||

| Volume before Bucking | Volume after Bucking | Volume | WPC | Volume | WPC | |||||||

| Average volume (m3·ha−1) or WPC (EUR·m−3) based on harvester data | 166.8 | 34.3 | 37.4 | 155.3 | 24.5 | 33.8 | 5.2 | 72.5 | 14.4 | 1.7 | 36.5 | 36.1 |

| Average volume (m3·ha−1) or WPC (EUR·m−3) based on ABA data | 154.8 | 36.5 | 32.4 | 145.9 | 32.2 | 30.1 | 7.4 | 93.6 | 17.0 | 3.3 | 35.9 | 46.9 |

| RMSE (m3·ha−1 or EUR·m−3) | 69.2 | 37.6 | 36.5 | 63.7 | 35.9 | 35.4 | 8.4 | 54.7 | 9.6 | 3.5 | 8.1 | 27.3 |

| RMSE% | 42.0 | 146.1 | 103.7 | 41.0 | 146.4 | 104.6 | 162.0 | 75.5 | 66.4 | 206.8 | 22.3 | 75.8 |

| Bias (m3·ha−1 or EUR·m−3) | 14.4 | −7.7 | 4.6 | 9.3 | −7.7 | 3.8 | −2.2 | −21.1 | −2.5 | −1.6 | 0.6 | −10.9 |

| Bias% | 8.7 | −29.9 | 13.0 | 6.0 | −31.3 | 11.2 | −43.0 | −29.1 | −17.5 | −95.9 | 1.7 | −30.2 |

| SD (m3·ha−1 or EUR·m−3) | 67.8 | 36.9 | 36.3 | 63.1 | 35.1 | 35.3 | 8.1 | 50.6 | 9.3 | 3.1 | 8.1 | 25.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanz, B.; Malinen, J.; Sirparanta, S.; Peuhkurinen, J.; Leppänen, V.; Melkas, T.; Riekki, K.; Kauranne, T.; Vastaranta, M.; Tokola, T. Integrating Detailed Timber Assortments into Airborne Laser Scanning (ALS)-Based Assessments of Logging Recoveries. Forests 2021, 12, 1221. https://doi.org/10.3390/f12091221

Sanz B, Malinen J, Sirparanta S, Peuhkurinen J, Leppänen V, Melkas T, Riekki K, Kauranne T, Vastaranta M, Tokola T. Integrating Detailed Timber Assortments into Airborne Laser Scanning (ALS)-Based Assessments of Logging Recoveries. Forests. 2021; 12(9):1221. https://doi.org/10.3390/f12091221

Chicago/Turabian StyleSanz, Blanca, Jukka Malinen, Sanna Sirparanta, Jussi Peuhkurinen, Vesa Leppänen, Timo Melkas, Kirsi Riekki, Tuomo Kauranne, Mikko Vastaranta, and Timo Tokola. 2021. "Integrating Detailed Timber Assortments into Airborne Laser Scanning (ALS)-Based Assessments of Logging Recoveries" Forests 12, no. 9: 1221. https://doi.org/10.3390/f12091221

APA StyleSanz, B., Malinen, J., Sirparanta, S., Peuhkurinen, J., Leppänen, V., Melkas, T., Riekki, K., Kauranne, T., Vastaranta, M., & Tokola, T. (2021). Integrating Detailed Timber Assortments into Airborne Laser Scanning (ALS)-Based Assessments of Logging Recoveries. Forests, 12(9), 1221. https://doi.org/10.3390/f12091221