Machine Learning in Reverse Logistics: A Systematic Literature Review

Abstract

1. Introduction

- RQ1: Which machine learning techniques are most frequently applied in reverse logistics processes?

- RQ2: What are the main objectives for using ML in reverse logistics?

- RQ3: What performance and validation metrics are reported in studies on ML applied to reverse logistics?

- RQ4: What are the main challenges and limitations encountered in applying ML to reverse logistics?

- RQ5: What methodological and technological gaps emerge from the literature, indicating opportunities for future research?

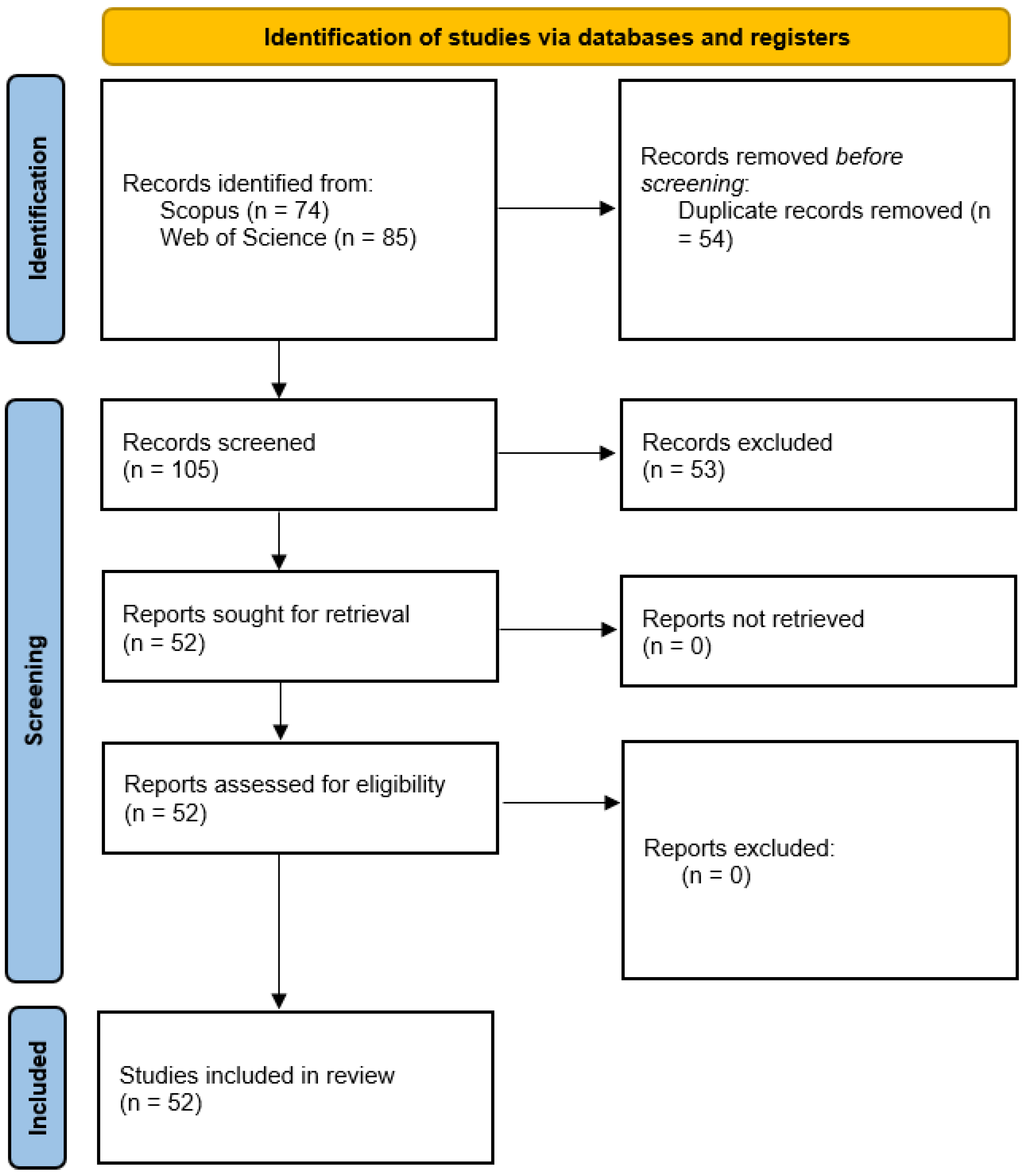

2. Materials and Methods

2.1. General Methodology

- Machine learning *: It refers to “machine learning” in general, including all variations and derivations of the term;

- Deep learning: It covers deep learning techniques, an important subfield within ML;

- Neural network *: It includes both artificial and deep neural networks, which are known for their ability to model complex relationships in data;

- Supervised learning: It refers to supervised learning, where models are trained with labeled data;

- Unsupervised learning: It refers to unsupervised learning, which is used to identify patterns without explicit labels in the data;

- Reinforcement learning: It covers reinforcement learning techniques, which are relevant for optimization and decision-making in dynamic environments;

- Decision tree *: It includes decision trees and their variants, which are common and interpretable ML methods;

- Random forest *: It covers random forests, which are ensemble techniques based on multiple decision trees.

- Closed-loop supply chain and closed-loop supply chain: They are variations referring to “closed-loop supply chains,” a concept associated with reverse logistics and the circular economy;

- Reverse logistics and reverse supply chain: They cover “reverse logistics” and variations, with or without hyphens.

2.2. Quality Assessment

3. Results and Discussion

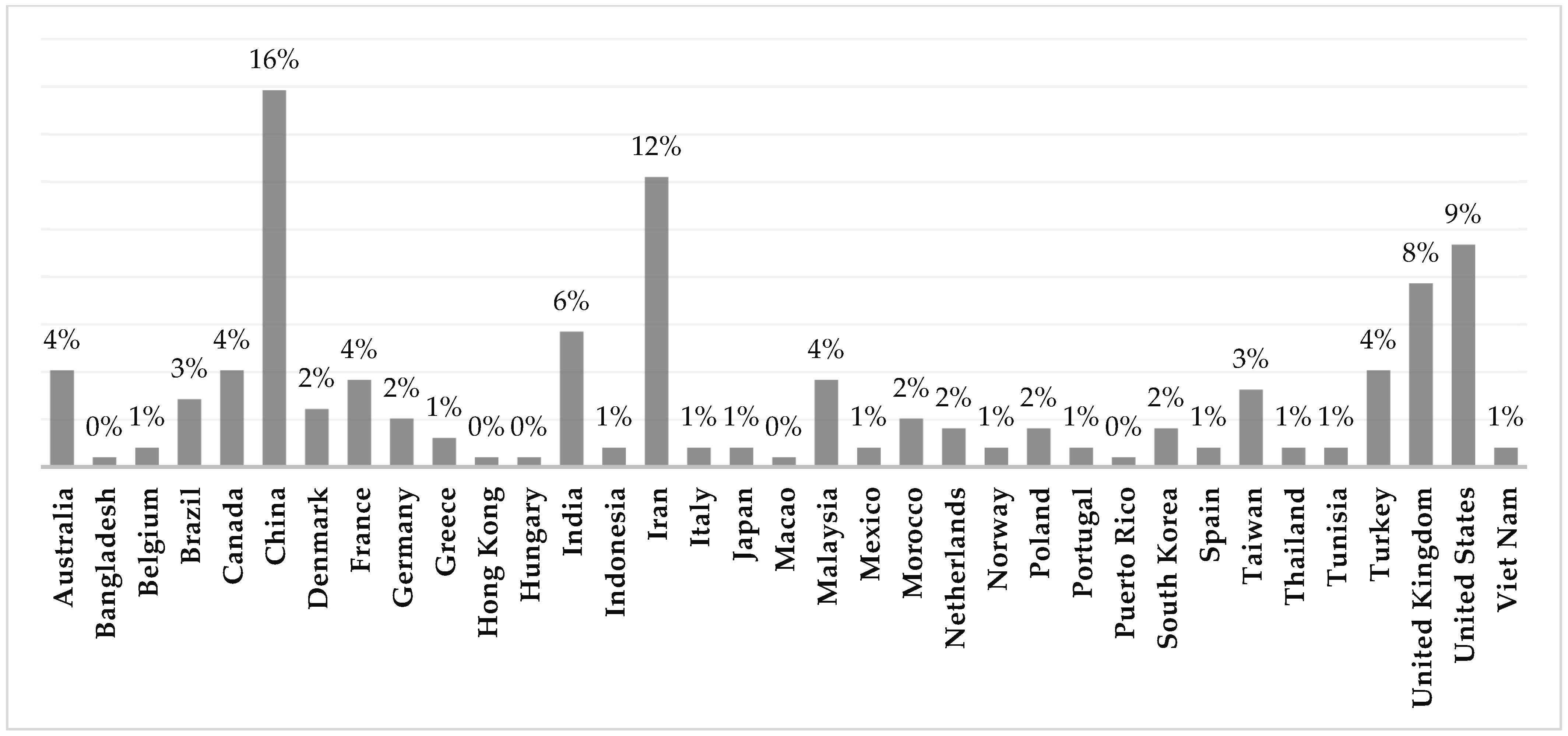

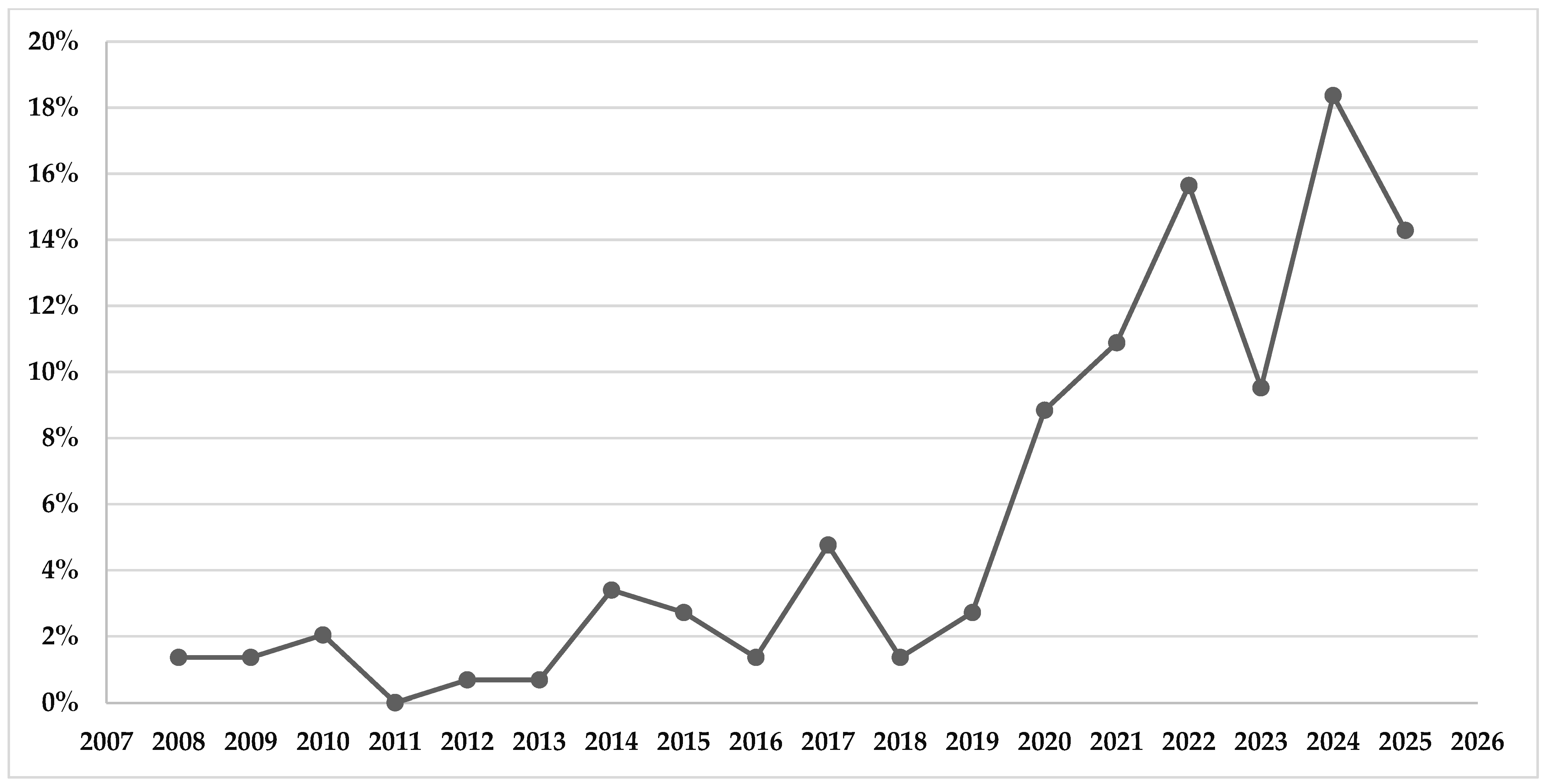

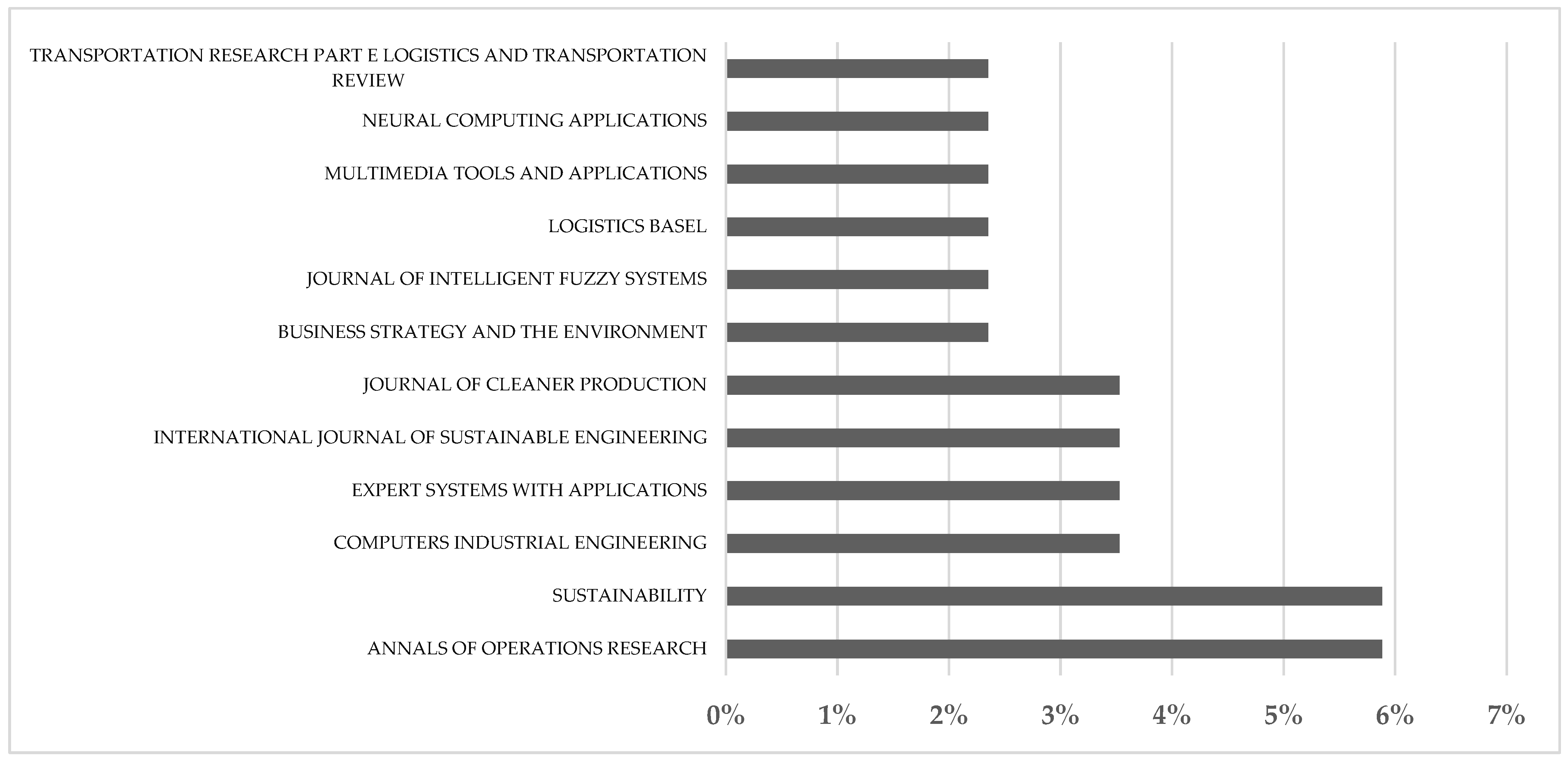

3.1. Bibliometric Analysis

3.2. Content Analysis

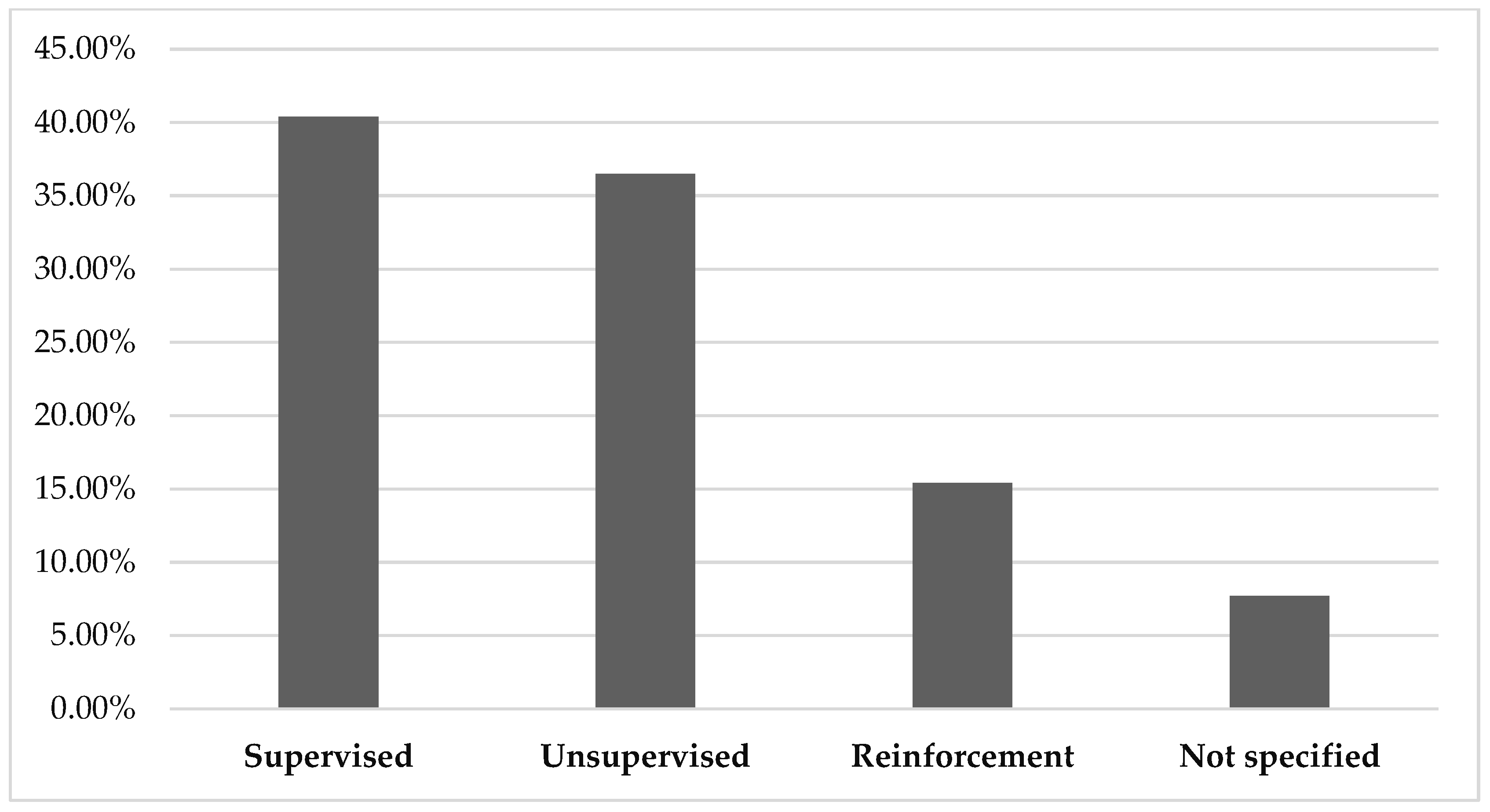

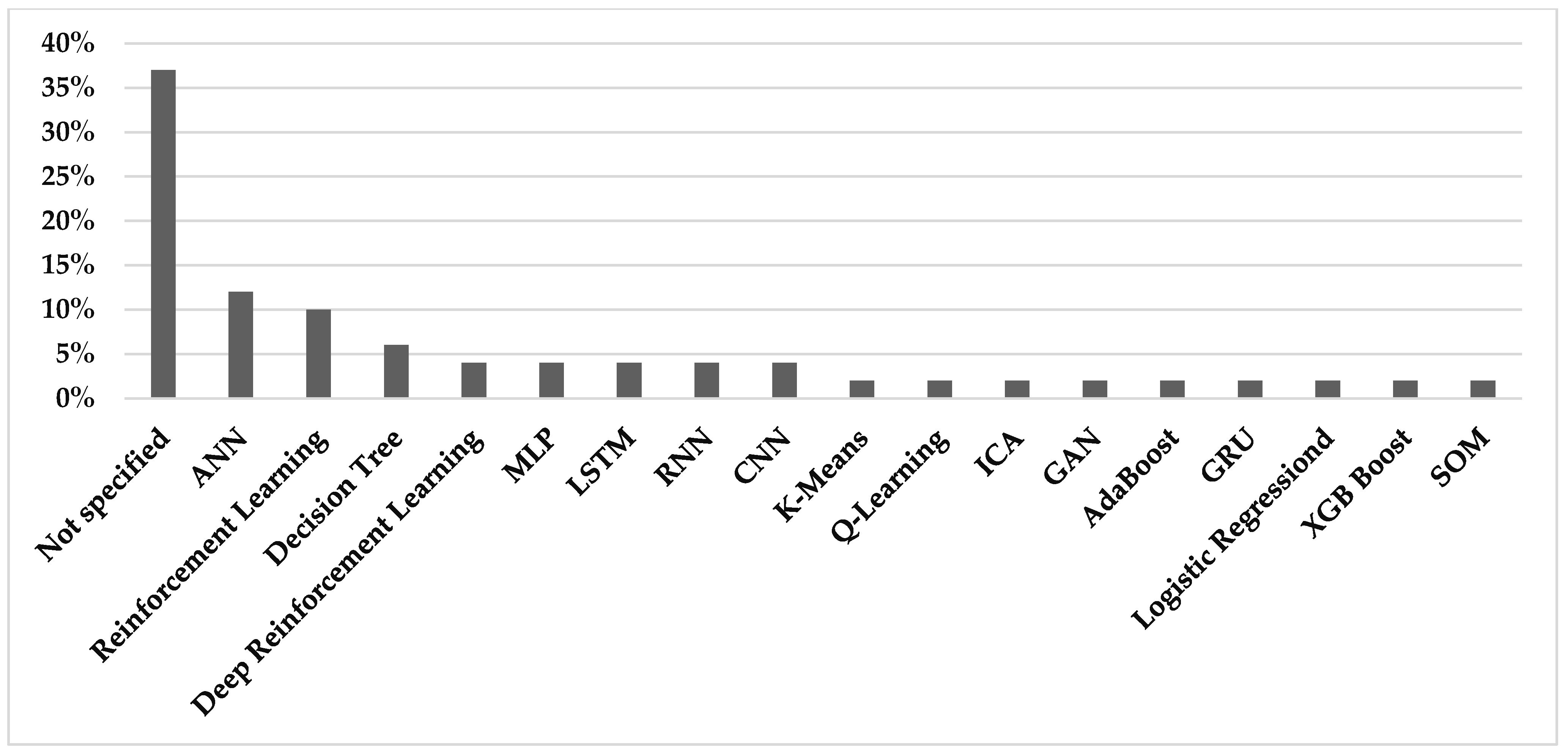

3.2.1. RQ1: Which ML Techniques Are Most Frequently Applied in RL Processes?

3.2.2. RQ2: What Are the Main Objectives for Using ML in Reverse Logistics?

3.2.3. RQ3: What Performance and Validation Metrics Are Reported in Studies on ML Applied to RL?

3.2.4. RQ4: What Are the Main Challenges and Limitations Encountered in Applying ML to RL?

3.2.5. RQ5: What Methodological and Technological Gaps Emerge from Literature, Indicating Opportunities for Future Research?

4. Conclusions

- (i)

- Validation of hybrid ML–RL pipelines under uncertain and dynamic conditions;

- (ii)

- Development of FAIR-compliant and open-access RL datasets with standardized metadata;

- (iii)

- Integration of explainable AI methods to enhance interpretability and managerial trust;

- (iv)

- Implementation of co-simulation frameworks combining ML, simulations, and digital twins to enable real-time decision-making.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. UNEP. Beyond an Age of Waste: Turning Rubbish into a Resource: Global Waste Management Outlook; UNEP: Nairobi, Kenya, 2024; ISBN 978-92-807-4129-2. [Google Scholar]

- Baldé, C.P.; Kuehr, R.; Yamamoto, T.; McDonald, R.; Althaf, S.; Bel, G.; Deubzer, O.; Fernandez-Cubillo, E.; Forti, V.; Gray, V.; et al. Global E-waste Monitor 2024; International Telecommunication Union (ITU) e United Nations Institute for Training and Research (UNITAR): Genebra, Switzerland; Bonn, Germany, 2024; pp. 1–150. [Google Scholar]

- Rogers, D.; Tibben-Lembke, R. Going Backwards: Reverse Logistics Trends and Practices; Reverse Logistics Executive Council: Reno, NV, USA; University of Nevada: Reno, NV, USA, 1998. [Google Scholar]

- Sonar, H.; Dey Sarkar, B.; Joshi, P.; Ghag, N.; Choubey, V.; Jagtap, S. Navigating Barriers to Reverse Logistics Adoption in Circular Economy: An Integrated Approach for Sustainable Development. Clean. Logist. Supply Chain 2024, 12, 100165. [Google Scholar] [CrossRef]

- Bhowmik, O.; Chowdhury, S.; Ashik, J.H.; Mahmud, G.I.; Khan, M.M.; Hossain, N.U.I. Application of Artificial Intelligence in Reverse Logistics: A Bibliometric and Network Analysis. Supply Chain Anal. 2024, 7, 100076. [Google Scholar] [CrossRef]

- Sahu, S.K.; Mokhade, A.; Bokde, N.D. An Overview of Machine Learning, Deep Learning, and Reinforcement Learning-Based Techniques in Quantitative Finance: Recent Progress and Challenges. Appl. Sci. 2023, 13, 1956. [Google Scholar] [CrossRef]

- Vidyasagar, M. A Tutorial Introduction to Reinforcement Learning. SICE J. Control Meas. Syst. Integr. 2023, 16, 172–191. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P. Adopting Artificial Intelligence for Enhancing the Implementation of Systemic Circularity in the Construction Industry: A Critical Review. Sustain. Prod. Consum. 2023, 35, 509–524. [Google Scholar] [CrossRef]

- Raut, S.; Hossain, N.U.I.; Kouhizadeh, M.; Fazio, S.A. Application of Artificial Intelligence in Circular Economy: A Critical Analysis of the Current Research. Sustain. Futur. 2025, 9, 100784. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Govindan, K.; Ghosh Dastidar, S.; Sharma, P. Applications of Artificial Intelligence in Closed-Loop Supply Chains: Systematic Literature Review and Future Research Agenda. Transp. Res. Part E Logist. Transp. Rev. 2024, 184, 103455. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Gil, A.C. Como Elaborar Projetos de Pesquisa, 6th ed.; Atlas: São Paulo, Brazil, 2008. [Google Scholar]

- De Medeiros Filho, A.R.; Russo, S.L. Trademarks as an Indicator: Systematic Review and Bibliometric Analysis of Literature. Biblios 2018, 71, 50–67. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Ouzzani, M.; Hammady, H.; Fedorowicz, Z.; Elmagarmid, A. Rayyan-a Web and Mobile App for Systematic Reviews. Syst. Rev. 2016, 5, 210. [Google Scholar] [CrossRef] [PubMed]

- Bardin, L. Análise de Conteúdo; Edições 70: São Paulo, Brazil, 2011. [Google Scholar]

- Ashtab, S.; Tosarkani, B.M. Scenario-Based Multi-Objective Optimisation Model Based on Supervised Machine Learning to Configure a Plastic Closed-Loop Supply Chain Network. Int. J. Bus. Perform. Supply Chain Model. 2023, 14, 106. [Google Scholar] [CrossRef]

- Bittencourt, E.S.; Fontes, C.H.D.O.; Moya Rodriguez, J.L.; Filho, S.Á.; Ferreira, A.M.S. Forecasting of the Unknown End-of-Life Tire Flow for Control and Decision Making in Urban Solid Waste Management: A Case Study. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 38, 193–201. [Google Scholar] [CrossRef] [PubMed]

- Dabo, A.-A.A.; Hosseinian-Far, A. An Integrated Methodology for Enhancing Reverse Logistics Flows and Networks in Industry 5.0. Logistics 2023, 7, 97. [Google Scholar] [CrossRef]

- Fernandes De Souza, J.A.; Silva, M.M.; Rodrigues, S.G.; Machado Santos, S. A Forecasting Model Based on ARIMA and Artificial Neural Networks for End–of–Life Vehicles. J. Environ. Manag. 2022, 318, 115616. [Google Scholar] [CrossRef]

- Ghosh, A.; Pathak, D.; Bhola, P.; Bhattacharjee, D.; Sivarajah, U. Analysing Product Attributes of Refurbished Laptops Based on Customer Reviews and Ratings: Machine Learning Approach to Circular Consumption. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- González Rodríguez, G.; Gonzalez-Cava, J.M.; Méndez Pérez, J.A. An Intelligent Decision Support System for Production Planning Based on Machine Learning. J. Intell. Manuf. 2020, 31, 1257–1273. [Google Scholar] [CrossRef]

- Monteiro, E.S.; Da Rosa Righi, R.; Barbosa, J.L.V.; Alberti, A.M. APTM: A Model for Pervasive Traceability of Agrochemicals. Appl. Sci. 2021, 11, 8149. [Google Scholar] [CrossRef]

- Najmi, A.; Kanapathy, K.; Aziz, A.A. A Pathway to Involve Consumers for Exchanging Electronic Waste: A Deep Learning Integration of Structural Equation Modelling and Artificial Neural Network. J. Mater. Cycles Waste Manag. 2022, 24, 410–424. [Google Scholar] [CrossRef]

- Pan, W.; Miao, L. Dynamics and Risk Assessment of a Remanufacturing Closed-Loop Supply Chain System Using the Internet of Things and Neural Network Approach. J. Supercomput. 2023, 79, 3878–3901. [Google Scholar] [CrossRef]

- Rezaei, O.; Sahraeian, R.; Hosseini, S.M.H. A Multi-Objective Optimization Framework to Design the Closed-Loop Supply Chain Network Using Machine Learning for Demand Prediction. Process Integr. Optim. Sustain. 2025, 9, 1521–1542. [Google Scholar] [CrossRef]

- Temur, G.T.; Bolat, B. Evaluating Efforts to Build Sustainable WEEE Reverse Logistics Network Design: Comparison of Regulatory and Non-Regulatory Approaches. Int. J. Sustain. Eng. 2017, 10, 358–383. [Google Scholar] [CrossRef]

- Achamrah, F.E.; Riane, F.; Sahin, E.; Limbourg, S. An Artificial-Immune-System-Based Algorithm Enhanced with Deep Reinforcement Learning for Solving Returnable Transport Item Problems. Sustainability 2022, 14, 5805. [Google Scholar] [CrossRef]

- Du, W.; Zhou, X.; Wang, C.; Rong, D. Research on Ecological Logistics Evaluation Model Based on BCPSGA-BP Neural Network. Multimed. Tools Appl. 2019, 78, 30271–30295. [Google Scholar] [CrossRef]

- Guo, J.; Chen, L.; Wang, Z. Optimization of a Closed-Loop Supply Chain System Considering Government Incentives Mechanism under Deep Learning Algorithms. Comput. Ind. Eng. 2025, 205, 111146. [Google Scholar] [CrossRef]

- Gutierrez-Franco, E.; Mejia-Argueta, C.; Rabelo, L. Data-Driven Methodology to Support Long-Lasting Logistics and Decision Making for Urban Last-Mile Operations. Sustainability 2021, 13, 6230. [Google Scholar] [CrossRef]

- Kumar Jauhar, S.; Singh, A.; Kamble, S.; Tiwari, S.; Belhadi, A. Reverse Logistics for Electric Vehicles under Uncertainty: An Intelligent Emergency Management Approach. Transp. Res. Part E Logist. Transp. Rev. 2024, 192, 103806. [Google Scholar] [CrossRef]

- Li, M.-Y.; Shih, F.-Y. Solving the Green Reverse Logistics Problem in E-Commerce Using a Reinforcement Learning Based Genetic Algorithm. Electron. Commer. Res. Appl. 2024, 68, 101455. [Google Scholar] [CrossRef]

- Pooya, A.; Mansoori, A.; Eshaghnezhad, M.; Ebrahimpour, S.M. Neural Network for a Novel Disturbance Optimal Control Model for Inventory and Production Planning in a Four-Echelon Supply Chain with Reverse Logistic. Neural Process. Lett. 2021, 53, 4549–4570. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, S.; Li, M.; Ren, G.; Ren, X.; Xiong, X.; Zhang, Y. Multi-Echelon Inventory Optimization of Waste Electrical and Electronic Equipment Closed-Loop Supply Chain Based on Reinforcement Learning under Carbon Tax Policy. Eng. Appl. Artif. Intell. 2025, 154, 110987. [Google Scholar] [CrossRef]

- Zhang, H.; Li, N.; Lin, J. Modeling the Decision and Coordination Mechanism of Power Battery Closed-Loop Supply Chain Using Markov Decision Processes. Sustainability 2024, 16, 4329. [Google Scholar] [CrossRef]

- Boujarif, A.; Coit, D.W.; Jouini, O.; Zeng, Z.; Heidsieck, R. A Deep-Learning-Based Framework to Predict the Reliability of Multicomponent Repairable Systems in a Closed-Loop Supply Chain. IEEE Trans. Reliab. 2025, 74, 3809–3823. [Google Scholar] [CrossRef]

- Gayialis, S.P.; Kechagias, E.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A. A Predictive Maintenance System for Reverse Supply Chain Operations. Logistics 2022, 6, 4. [Google Scholar] [CrossRef]

- Mazhar, M.I.; Kara, S.; Kaebernick, H. Remaining Life Estimation of Used Components in Consumer Products: Life Cycle Data Analysis by Weibull and Artificial Neural Networks. J. Oper. Manag. 2007, 25, 1184–1193. [Google Scholar] [CrossRef]

- Zacharaki, A.; Vafeiadis, T.; Kolokas, N.; Vaxevani, A.; Xu, Y.; Peschl, M.; Ioannidis, D.; Tzovaras, D. RECLAIM: Toward a New Era of Refurbishment and Remanufacturing of Industrial Equipment. Front. Artif. Intell. 2021, 3, 570562. [Google Scholar] [CrossRef]

- Boresta, M.; Pinto, D.M.; Stecca, G. Bridging Operations Research and Machine Learning for Service Cost Prediction in Logistics and Service Industries. Ann. Oper. Res. 2024, 342, 113–139. [Google Scholar] [CrossRef]

- Molnár, A.; János, V.; Csiszárik-Kocsir, Á. Deriving the Classical and New-Keynesian Phillips Curves Using Machine Learning Simulations. Decis. Mak. Appl. Manag. Eng. 2024, 7, 546–567. [Google Scholar] [CrossRef]

- Eruguz, A.S.; Karabağ, O.; Tetteroo, E.; Van Heijst, C.; Van Den Heuvel, W.; Dekker, R. Customer-to-Customer Returns Logistics: Can It Mitigate the Negative Impact of Online Returns? Omega 2024, 128, 103127. [Google Scholar] [CrossRef]

- Seidi, M.; Kimiagari, A.M. A hybrid Genetic Algorithm-Neural Network Approach for Pricing Cores and Remanufactured Cores. S. Afr. J. Ind. Eng. 2012, 21, 131–148. [Google Scholar] [CrossRef]

- Efendigil, T.; Önüt, S.; Kongar, E. A Holistic Approach for Selecting a Third-Party Reverse Logistics Provider in the Presence of Vagueness. Comput. Ind. Eng. 2008, 54, 269–287. [Google Scholar] [CrossRef]

- Olivares-Vera, D.A.; Ovalle-Magallanes, E.; Hernández-Vázquez, J.I.; Hernández-Vázquez, J.O.; Gutierrez-Hernandez, D.A.; Olivares-Vera, A.D.P. Performance Evaluation of YOLO Models for Damage Identification in Tertiary Packaging. Signal Image Video Process. 2025, 19, 498. [Google Scholar] [CrossRef]

- Panjehfouladgaran, H.; Lim, S.F.W.T. Reverse Logistics Risk Management: Identification, Clustering and Risk Mitigation Strategies. Manag. Decis. 2020, 58, 1449–1474. [Google Scholar] [CrossRef]

- Rakhshan, K.; Daneshkhah, A.; Morel, J.-C. Stakeholders’ Impact on the Reuse Potential of Structural Elements at the End-of-Life of a Building: A Machine Learning Approach. J. Build. Eng. 2023, 70, 106351. [Google Scholar] [CrossRef]

- Rezaei Zeynali, F.; Parvin, M.; ForouzeshNejad, A.A.; Jeyzanibrahimzade, E.; Ghanavati-Nejad, M.; Tajally, A. A Heuristic-Based Multi-Stage Machine Learning-Based Model to Design a Sustainable, Resilient, and Agile Reverse Corn Supply Chain by Considering Third-Party Recycling. Appl. Soft Comput. 2025, 174, 113042. [Google Scholar] [CrossRef]

- Shahidzadeh, M.H.; Shokouhyar, S.; Javadi, F.; Shokoohyar, S. Unscramble Social Media Power for Waste Management: A Multilayer Deep Learning Approach. J. Clean. Prod. 2022, 377, 134350. [Google Scholar] [CrossRef]

- Shahidzadeh, M.H.; Shokouhyar, S. Shedding Light on the Reverse Logistics’ Decision-Making: A Social-Media Analytics Study of the Electronics Industry in Developing vs Developed Countries. Int. J. Sustain. Eng. 2022, 15, 161–176. [Google Scholar] [CrossRef]

- Shahidzadeh, M.H.; Shokouhyar, S. Revolutionizing Reverse Supply Chain Decision-Making: Deep Social Media Analysis in Qualitative Comparative Analysis. Comput. Ind. Eng. 2025, 206, 111241. [Google Scholar] [CrossRef]

- Shokouhyar, S.; Shahidzadeh, M.H. Mastering Supply Chain’s Decision-Making Establishing SDG’s Goal: A Social Media Analytics Study of the Electronic Devices in Developing and Developed Countries. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Tietz Cazeri, G.; Sigahi, T.F.A.C.; Rampasso, I.S.; Moraes, G.H.S.M.; Zanon, L.G.; Gavira, M.O.; Eustachio, J.H.P.P.; Leal Filho, W.; Anholon, R. A multicriteria approach for assessing the maturity of supply chains regarding the implementation of circular economy practices in Brazil. Int. J. Sustain. Dev. World Ecol. 2024, 31, 611–625. [Google Scholar] [CrossRef]

| Scopus | Web of Science |

|---|---|

| TITLE-ABS-KEY (“machine learning *” OR “deep learning” OR “neural network *” OR “supervised learning” OR “unsupervised learning” OR “reinforcement learning” OR “Decision tree *” OR “random forest *”) AND TITLE-ABS-KEY(“closed loop supply chain” OR “closed-loop supply chain” OR “reverse logistics” OR “reverse supply-chain”) | TS = (“machine learning *” OR “deep learning” OR “neural network *” OR “supervised learning” OR “unsupervised learning” OR “reinforcement learning” OR “Decision tree *” OR “random forest *”) AND TS = (“closed loop supply chain” OR “closed-loop supply chain” OR “reverse logistics” OR “reverse supply-chain”) |

| Category | Articles |

|---|---|

| Forecasting | [19,20,21,22,23,24,25,26,27,28,29] |

| Optimization | [30,31,32,33,34,35,36,37,38] |

| Reliability | [39,40,41,42] |

| Pricing | [43,44,45,46] |

| Classification | [47,48,49,50,51] |

| Consumers | [26,52,53,54,55] |

| Challenge | Description | Consequences | Articles |

|---|---|---|---|

| Data scarcity/quality | Return flows are irregular, heterogeneous, and often untracked; historical data are distributed across ERP systems, carriers, sorting centers, and 3PL providers, resulting in gaps and disparate formats. | Models learn low-reliability patterns; intensive data cleaning required. | [19,27] |

| Uncertainties | Abrupt changes in operational reality can alter the behavior of certain variables. | Predictive models become obsolete → forecast errors above 50%; optimized routing based on “outdated” demand increases empty mileage. | [22] |

| Computational cost in hybrid models | Robust models can be highly demanding in computational terms. | Execution time can increase from minutes to hours/days → impractical for daily decision-making; energy and cloud consumption raise operational costs. | [51] |

| Research Gap | Current Shortcoming | Inspiration/Promising Research Directions |

|---|---|---|

| Explicit uncertainty modeling | In some cases, uncertainties are modeled, but more in-depth discussion on this aspect is lacking. | Use and comparison of models considering uncertainties, including fuzzy, grey systems, and others. |

| Real-time pipelines (streaming) | Most prototypes run on historical data instead of real-time data collection. | Digital twin implementation. |

| Hybrid ML | Few studies combine more than one type of ML. | Use of supervised and unsupervised learning models together. |

| Metadata standards & FAIR data | Lack of formal descriptions: data origin, processing, licenses. | Implementation of standardized metadata (e.g., schema.org, JSON-LD) and creation of dataset cards specifically for reverse logistics, facilitating transparency and data reuse. |

| Public, multi-scale benchmarks | Data repository models are not standardized, and there is a lack of public databases. | Government repositories (e.g., E-waste Monitor). |

| Explainable AI (XAI) applied to RL | Integrating XAI to accelerate interpretation of results is promising. | Application of SHAP to MILP for post-model analysis; visual analytics in reverse transport dashboards. |

| Deep ML + simulation integration | Connections remain “external”: simulation generates data, ML predicts, and then optimization decides (serial pipelines). | Advanced integration: co-simulation DES–ReL, Sim2Real ReL (training in ABS and applying in operation), and federated digital twin frameworks with embedded ML, overcoming serial pipelines. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, A.F.S.d.; Moris, V.A.d.S.; Silva, J.E.A.R.d.; Voltarelli, M.A.; Sigahi, T.F.A.C. Machine Learning in Reverse Logistics: A Systematic Literature Review. Algorithms 2025, 18, 650. https://doi.org/10.3390/a18100650

Silva AFSd, Moris VAdS, Silva JEARd, Voltarelli MA, Sigahi TFAC. Machine Learning in Reverse Logistics: A Systematic Literature Review. Algorithms. 2025; 18(10):650. https://doi.org/10.3390/a18100650

Chicago/Turabian StyleSilva, Abner Fernandes Souza da, Virginia Aparecida da Silva Moris, João Eduardo Azevedo Ramos da Silva, Murilo Aparecido Voltarelli, and Tiago F. A. C. Sigahi. 2025. "Machine Learning in Reverse Logistics: A Systematic Literature Review" Algorithms 18, no. 10: 650. https://doi.org/10.3390/a18100650

APA StyleSilva, A. F. S. d., Moris, V. A. d. S., Silva, J. E. A. R. d., Voltarelli, M. A., & Sigahi, T. F. A. C. (2025). Machine Learning in Reverse Logistics: A Systematic Literature Review. Algorithms, 18(10), 650. https://doi.org/10.3390/a18100650