Abstract

In traditional scheduling problems, job processing times are considered constant and known in advance. This assumption is, however, a simplification when it comes to hand-intensive real-life production contexts because workers usually induce variability in the job processing times due to several factors such as learning, monotony, fatigue, psychological factors, etc. These effects can decrease or increase the actual processing time when workers execute a job. The academic literature has reported several modeling and resolution approaches to deal with the phenomenon in a variety of configurations. However, there is no comprehensive review of these research outputs to the best of our knowledge. In this paper, we follow a systematic approach to review relevant contributions addressing the scheduling problem with learning and deterioration effects. Modeling approaches for learning and deterioration effects, objective functions, and solution methods employed in the literature are the main topics for the taxonomy proposed in this review. A total of 455 papers from 1999 to 2021 are included and analyzed. Different areas of interest are presented, and some opportunities for future research are identified.

1. Introduction

Scheduling is defined as the assignment of a set of jobs to a set of resources (machines, workers) over time in order to minimize one or more objective functions [1]. In classical scheduling problems, the job processing time is considered constant and known in advance, while in stochastic scheduling models, the processing time is modeled as a probability function also known in advance. However, these assumptions are a simplification of real contexts in which the inclusion of workers’ behavior impacts job processing times and system performance. Pinedo [1] acknowledged that human characteristics thus have an impact, particularly in cases where manual operations are involved. In manual operations, the time to complete tasks may increase when resources deteriorate due to fatigue or may decrease when resources improve workers’ productivity. Hence, in general terms, human characteristics can be grouped into two categories, depending on the effect on the execution of the job: learning or deterioration effects [2].

The scheduling problems with learning a deteriorating effect is part of the family of scheduling problems with time-changing effects. Since the 1990s, authors have expressed their interest in such problems where the job processing times are affected by their locations in the sequence. While it is true that the first idea that arises from learning processes relates to the tasks carried out only by humans, it is also relevant in mixed environments (interaction between machines and humans) because human expertise in activities such as maintenance and monitoring are determined in system performance. In the same way, machines and devices managed by artificial intelligence can take advantage of the learning process [2]. Similarly, when we talk about deterioration processes, we usually think of them as affecting mainly machines, but this can happen in the case of humans such as fatigue or aging. Consequently, it is relevant to take into account these adaptations to the traditional scheduling problem. Finally, they have come closer to real production systems.

In scheduling theory, the inclusion of human factors dates back to the work of Moray et al. [3], who presented one of the first contributions on this subject, adding behavior and workload when operators are confronted with multiple tasks. Dessouky et al. [4] subsequently concluded that some human characteristics and behaviors may affect human performance at work and thereby impact the job processing time. The phenomenon of learning effects in industrial environments had already been introduced by Wright [5], but Biskup [6] was the first author to introduce the learning effect in a single-machine scheduling problem, while Gupta and Gupta [7] were pioneers in the study of deterioration effects on a single machine scheduling problem.

In recent years, the number of publications addressing scheduling problems with learning or deterioration effects has increased. Some of the published literature reviews focus mainly on the learning effect. For instance, Biskup [8] reviewed the progress of the learning effect on scheduling problems and formally distinguished between position-based and time-based learning. Anzanello and Fogliatto [9] presented the state-of-the-art related to learning and forgetting curves, describing each model and showing their opportunities and limitations for applications in industrial settings. Lodree et al. [10] presented a framework for scheduling and the integration of human factors (physical and/or cognitive human characteristics and behaviors). While they emphasized the importance of interdisciplinary cooperation, Azzouz et al. [11] reviewed several learning models and proposed categories to classify the most common approaches. Recently, Xu and Hall [12] presented a review of fatigue forecasting and measurement methods, as well as the integration of fatigue forecasting into work–rest scheduling, shift scheduling and personnel scheduling.

The current paper builds upon those previous works by proposing a systematic approach instead of following a narrative structure. The aim is to review relevant works published between 1999 and 2021, and then from there to analyze the scope and contributions of short-listed studies and highlight opportunities for further research. The review protocol presented in this paper can be further replicated to update future research progress on this topic. The contribution of this review is therefore at least twofold. First, with the arrival of the fourth industrial revolution (Industry 4.0), human work continues to be essential, especially in performing highly complex jobs. Therefore, understanding how the behavior of human beings can be modeled contributes to improving decision-making in labor-intensive manufacturing systems, especially where labor is costly [13]. Second, reviewed models can help to incorporate changes in working conditions due to the COVID-19 pandemic, which has produced new challenges and needs for industrial systems, mainly when they require human workers.

This paper is organized as follows. Section 2 presents the research methodology. Section 3 describes the results. This includes bibliometric analysis, categorization and analysis associated with the problem characteristics. In addition, different approaches to modeling learning and deteriorating effects are introduced. Finally, this section deals with the classification of the solution methods found in the literature. Section 4 discusses the main findings of this review and highlights opportunities for future research. Conclusions are drawn in Section 5.

2. Materials and Methods

This paper follows the principles of systematic literature reviews [14,15] to build upon published works on the analysis of the current state of knowledge. In contrast to narrative reviews, a systematic approach allows the application of a well-defined, unbiased, and reproducible protocol for the identification and analysis of documents. The literature review presented here was carried out according to the protocol presented by Badger et al., (2000): (i) identification of the research question; (ii) collection and selection of articles; and (iii) analysis of short-listed articles and presentation of results. This protocol is documented below.

2.1. Research Questions

With the objective of identifying approaches related to scheduling problems with learning and deteriorating effects, a general research question was defined as follows: To what extent have scheduling problems been modeled and solved to deal with learning and deteriorating effects in job processing times?

To properly address the above question, five specific research questions are formulated as follows:

RQ1: What are the directions toward which researchers are focusing scheduling problems with learning and deterioration effects?

RQ2: What are the system configurations studied in the literature?

RQ3: Which have been the most common objective functions considered?

RQ4: What approximations have been used in the scientific literature to model both learning and deterioration effects?

RQ5: What solution methods have been used to solve the problems?

2.2. Collection and Selection of Articles

The SCOPUS and Web of Science databases were chosen to locate studies related to the research topic. The rationale for this choice is that these databases are world leaders in peer-reviewed journal ranking and evaluation [16]. They are two global and multidisciplinary databases that have the highest score in the visibility index. This means that the quality of the research results is already guaranteed because there is a demanding process to review articles published in journals within these databases.

This search was conducted at three main times: January, July, and December 2021, starting with a pilot test to define the most appropriate keywords used in the literature to approach this topic. The search was then limited, and the databases were asked to search for the following equation in Title–Abstract–Keywords: ((scheduling) AND (“learning effect” OR “deterioration effect”)), this search equation was used together with SCOPUS and Web of science. In addition, inclusion and exclusion criteria were defined as follows:

- Only papers written in English were included.

- Book chapters and conference papers were not considered.

- Review papers, editorial notes, letters to the editor or similar documents were not included. Review papers were nevertheless useful in providing information on progress on this topic and were taken as a starting point for the development of this paper.

- Only papers explicitly defining a system configuration (e.g., single machine, flowshop, etc.) were included.

- Papers had to address a scheduling problem.

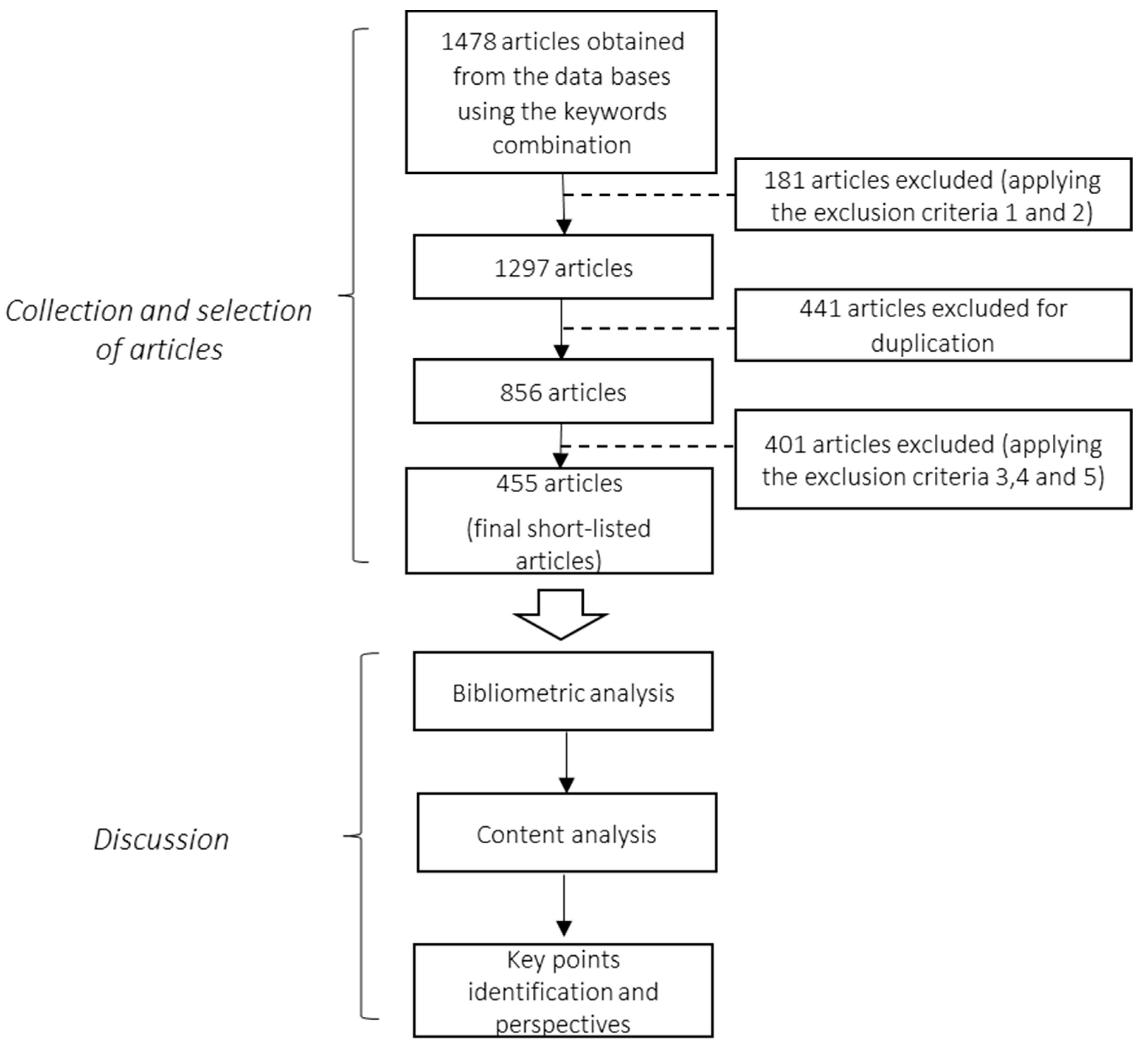

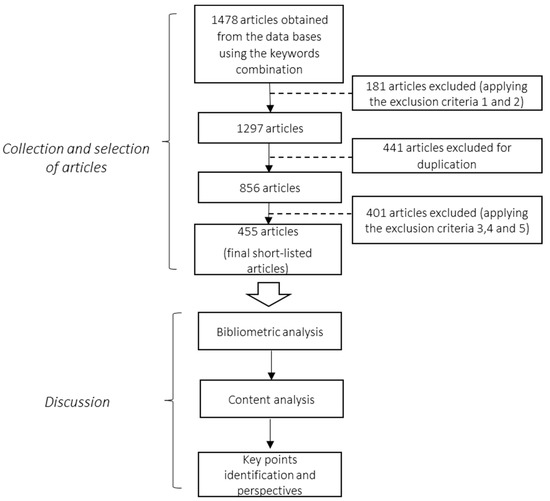

As shown in Figure 1, the process of paper collection and selection consisted of four main phases. The output of combining the keywords string produced a set of 1478 documents. After filtering by papers written in English and excluding conference papers and book chapters, a set of 1297 research articles was evaluated. In a third step, duplicated articles were removed. Finally, titles and abstracts were read in detail to remove papers that were not within the scope of this review, in addition to those not dealing with scheduling problems or not explicitly presenting a shop configuration as well as literature review articles. Hence, a total of 455 research papers were short-listed for further analysis and classification. The complete short-listed articles can be found as Supplementary Material.

Figure 1.

Flowchart of the sequence followed for the literature review.

2.3. Analysis and Presentation of Results

A preliminary bibliometric analysis was conducted for the short-listed articles. VOSviewer software was used to find and develop a co-occurrence analysis of author countries and possible thematic trends. The final set of 455 research papers was analyzed in detail and key information was abstracted. The results are summarized and classified considering descriptive information such as (1) journal and year of publication, (2) type of system configuration under study, (3) objective function(s), (4) proposed solution method, and (5) effects on the processing time (learning and/or deterioration). The proposed analysis is intended to answer the previous research question. The analysis steps followed and sections in this paper are listed in Table 1 (following a similar format used by Parente et al. [17]).

Table 1.

Approaches to address the research questions.

3. Results

3.1. Bibliometric Analysis

The first interesting output of this review is related to a bibliometric study in order to build on a high-level perspective of the publications in terms of the most discussed topics, authors’ nationality, and journals. Bibliometrics consists of the use of quantitative research methods to analyze bibliographic material, with a view of mapping research works [18,19,20]. Bibliometric analysis also serves to evaluate research performance (per country, university, etc.) and allows us to understand relations between scientists. From an academic point of view, applying bibliometric analysis to map research works on scheduling with learning and deteriorating effects in processing times will help both researchers and practitioners better understand the advances and trends in the field, as well as enable them to make decisions and take action in a more informed way [21].

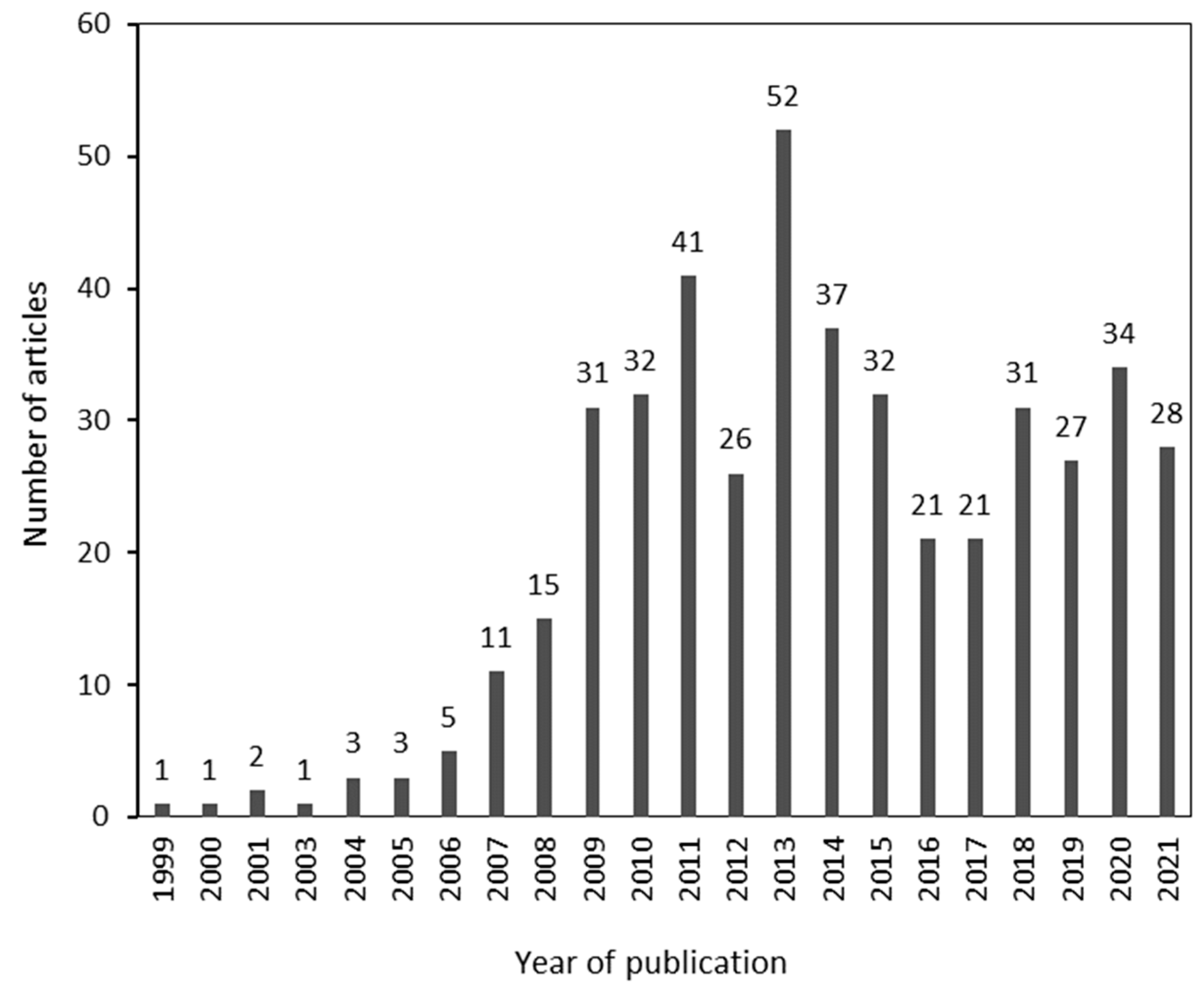

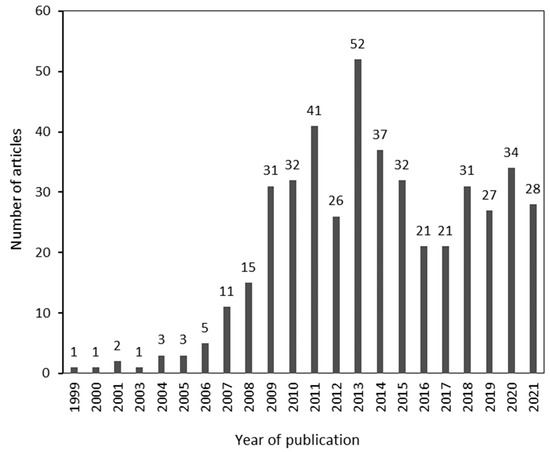

From a static perspective (i.e., printing year) on the proposed analysis strategy, this literature review includes articles published from 1999 (first official publication on the topic) to December 2021. Biskup [6] published the first study. His paper can be considered the starting point of research activities related to this field. The number of articles has since grown, with a peak in 2013 (see Figure 2). There has been a rising trend in this area since 2009, with an average of 32 articles per year in the period 2009–2021. This result may be explained by the fact that around 2011, the concept of the fourth industrial revolution appeared. Despite the high levels of automation, this has brought the challenge of integrating humans into production systems and redefining their roles.

Figure 2.

Frequency of publications per year.

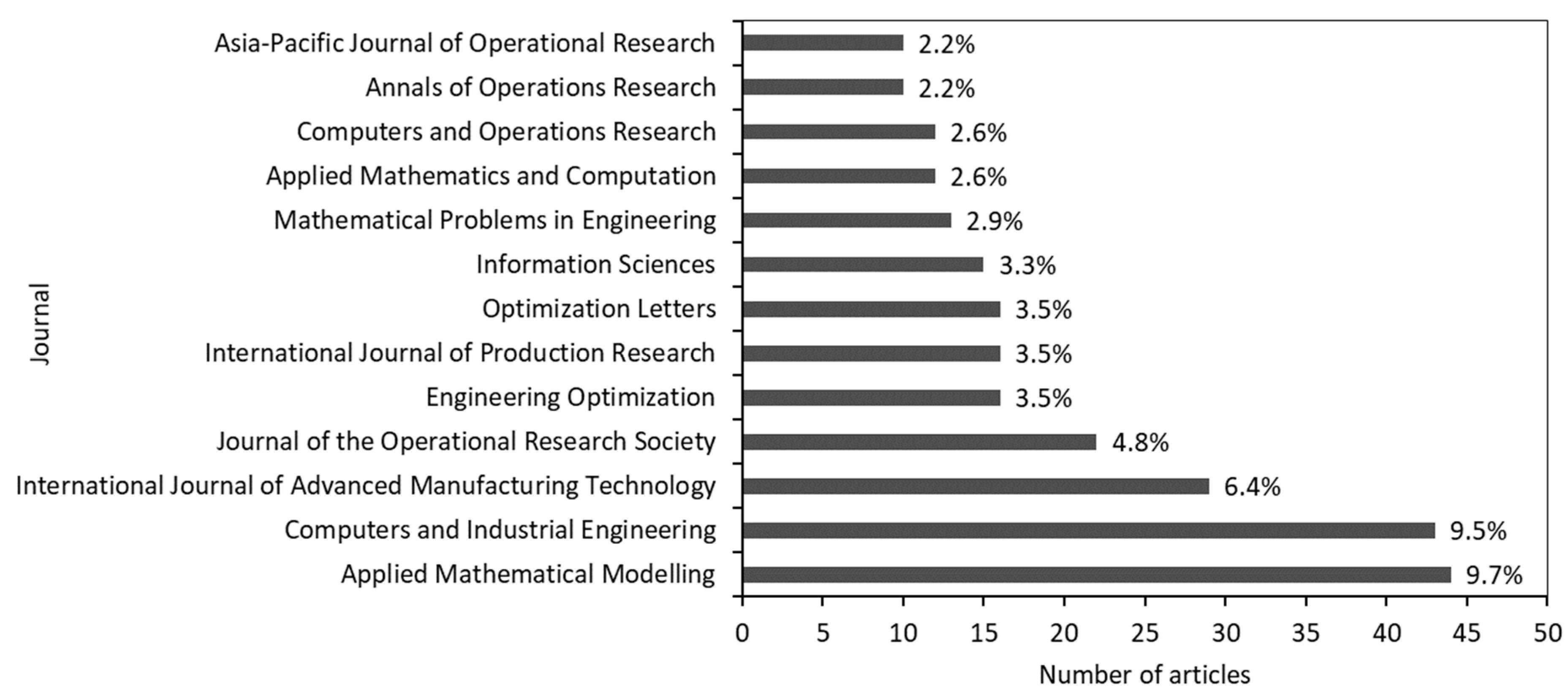

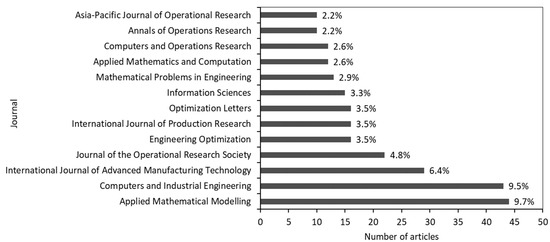

We note that all short-listed articles are distributed in 95 journals, 32 of which contain 80% of all publications.

Figure 3 presents the most relevant journals in this area by the number of publications. Each of these journals published ten or more articles, meaning 56.7% of the total number of publications. Applied Mathematical Modelling (9.7%), Computers and Industrial Engineering (9.5%), and International Journal of Advanced Manufacturing Technology (6.4%) are the journals with the highest number of articles.

Figure 3.

Frequency per journal (journal with ten contributions or more).

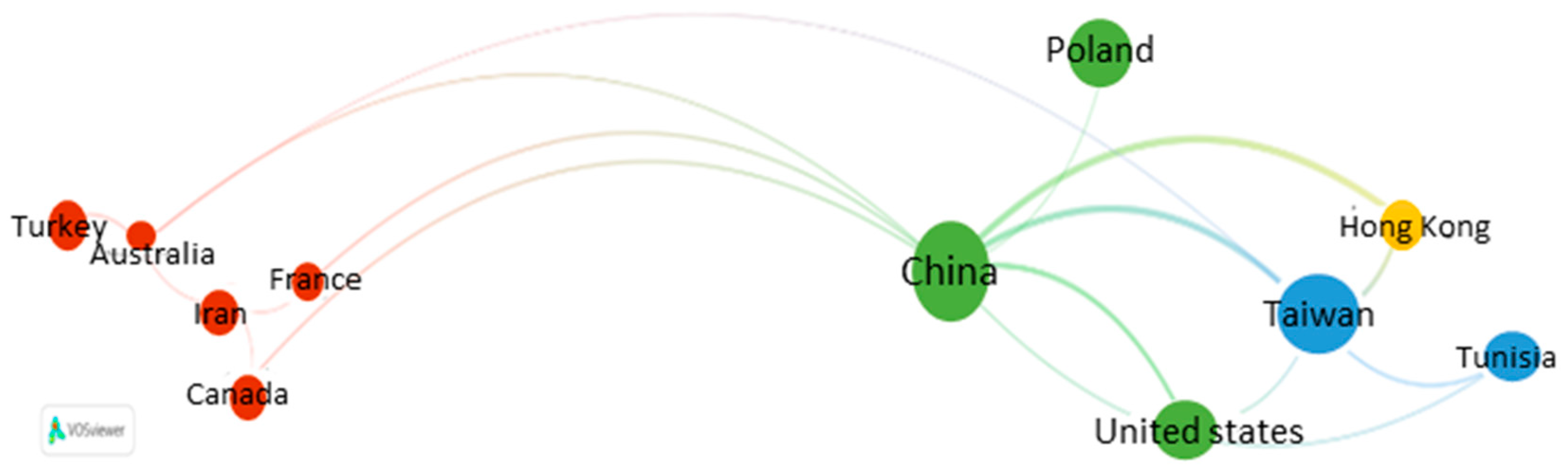

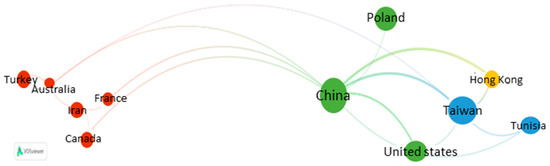

To deepen our investigation of the short-listed papers, we used VOSviewer software [22] to analyze the co-occurrences of a country’s authors.

Figure 4 shows the most productive countries in this field (with five or more articles), of which China is in the lead, with 220 articles. There are four clusters, the green cluster (China, USA, and Poland), the red cluster (Turkey, Iran, Canada, France, and Australia), the blue cluster (Taiwan and Tunisia), and finally, Hong Kong in yellow. In general, the Asian countries are interested in research in this field (even given the thick lines, high levels of cooperation between China-Taiwan and China-Hong Kong can be deduced). A possible cause for this might be that a large proportion of short-listed articles focus on the proposal of approximation algorithms, with the definition of dominant rules and bounds, a subject in which Asian countries have demonstrated considerable interest and progress. Moreover, the interest shown by Asian countries in such subjects may be explained by the fact that they have developed a strong manufacturing industry; it is of great benefit to understand and measure worker productivity in hand intensive tasks.

Figure 4.

Co-authorship countries (source: VOSviewer).

3.2. Classification of Papers Related to Problem Characteristics

After a preliminary paper scan was conducted to exclude papers that were not related to the scheduling problem (exclusion criteria 5), the final screening of the preselected articles was performed manually. Read first was the title, the abstract and then the methods for retrieving detailed information. We present an analysis and classification of all short-listed articles, regarding the system configuration, the type of objective functions, and the phenomena of learning and/or deterioration effect on processing time. Each subsection follows this classification and analyzes the findings.

3.2.1. System Configuration

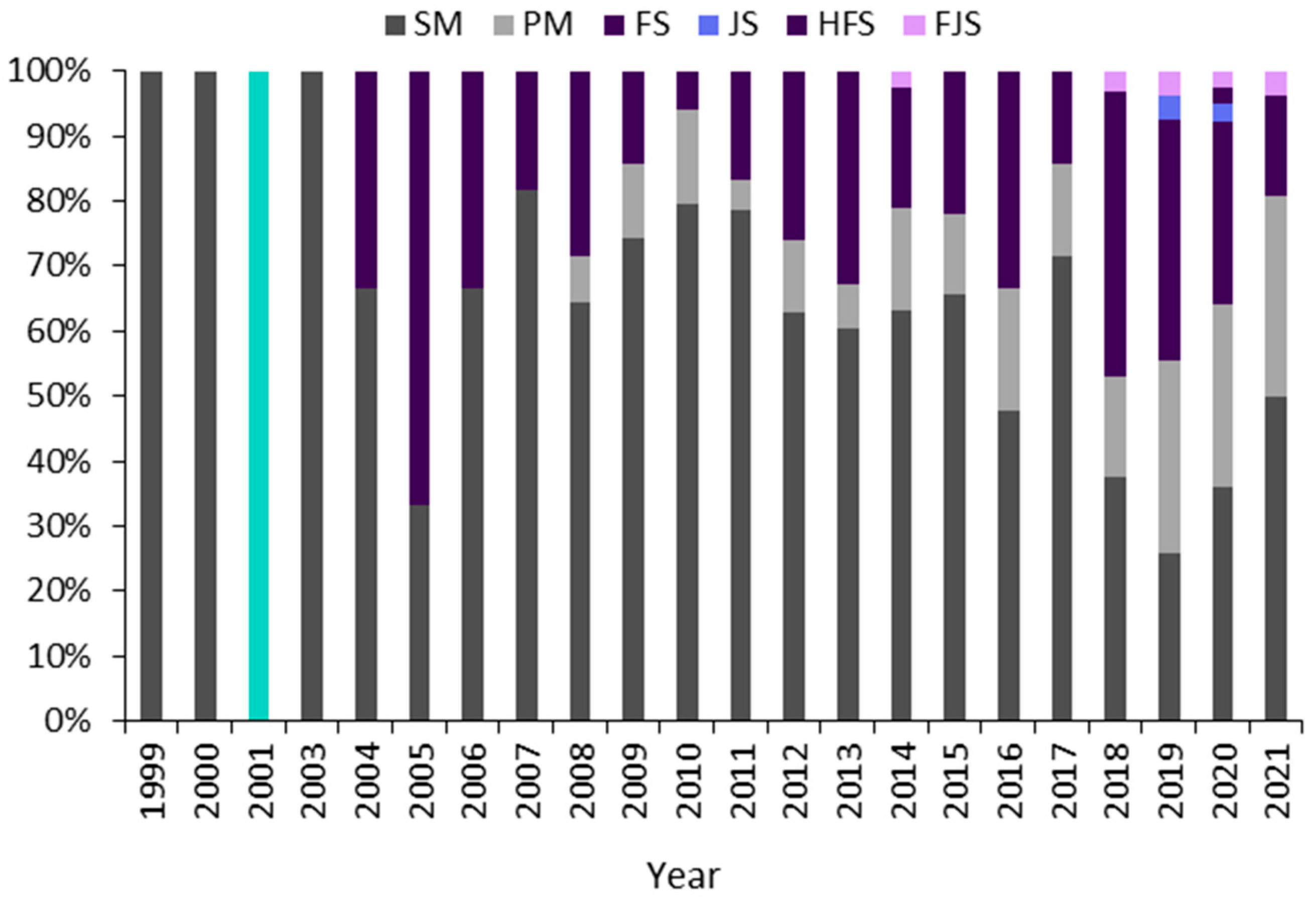

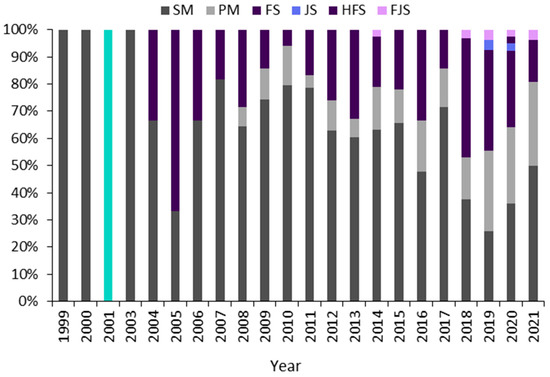

The first classification is based on the system configuration studied in each paper. The output of this analysis allows six (6) categories to be identified, from the simplest single machine configuration to more complex configurations such as hybrid production systems. The single machine configuration with 293 articles (60.5%) has the highest frequency of works, followed by 104 articles that consider the flowshop system (20.4%) and 70 articles that study the parallel machine configuration (14.4%). Finally, the three least common configurations are the hybrid flowshop with 11 articles, the flexible job shop with 5 articles (3.4%), and 2 articles related to the job shop configuration (1.3%). There are significant contributions related to the single machine scheduling problem. This may be because the single machine configuration makes it possible to understand and conceptualize the problem and to extrapolate solution alternatives to other shop configurations. In addition, this problem is particularly important because, as Pinedo [1] explains, scheduling problems in complex configurations could be decomposed into single machine sub-problems. Figure 5 summarizes the percentage of articles per system configuration and per year. This means that the single machine configuration was the most studied. Despite its utility for decomposing more complex problems, it is replaced by other configurations which may better represent the configurations of the real production systems.

Figure 5.

Distribution of short-listed articles according to the system configuration and year of publication. SM: single machine; PM: parallel machine; FS: flowshop; JS: job shop; HFS: hybrid flowshop; FJS: flexible job shop.

In general, scheduling problems are considered in a deterministic environment, but some authors have managed scheduling under uncertainty using stochastic parameters or fuzzy sets. The stochastic approach used to calculate processing times is found in 1.8% of short-listed articles, in single-machine configurations [23,24,25,26,27,28,29], parallel machine shops [30], and flowshop [31]. The fuzzy approach is employed in 2.2% of the articles to model the job processing time. The single machine configuration appears in the majority of contributions [32,33,34,35], followed by the parallel machine configuration [36,37,38,39,40].

3.2.2. Objective Function

Our findings show that most short-listed research papers (71.2%) focus on a single optimization criterion, while 28.8% deal with the optimization of multi-criteria objective functions. We see that 59.5% of total contributions, including two or more objective functions, use the weighted sum of criteria as a solution approach. In recent years, scheduling problems dealing with multi-criteria objective functions have become popular because of the more complex industrial environments [41].

Related to the classical criteria considered in scheduling problems, the most studied objective functions are the minimization of makespan (279 articles), the minimization of total completion time (170 articles), and the minimization of weighted completion time (87 articles). As the authors consider workers, machines, or both as resources, some objective function criteria such as machine hiring costs, maintenance costs and total energy consumption could be found.

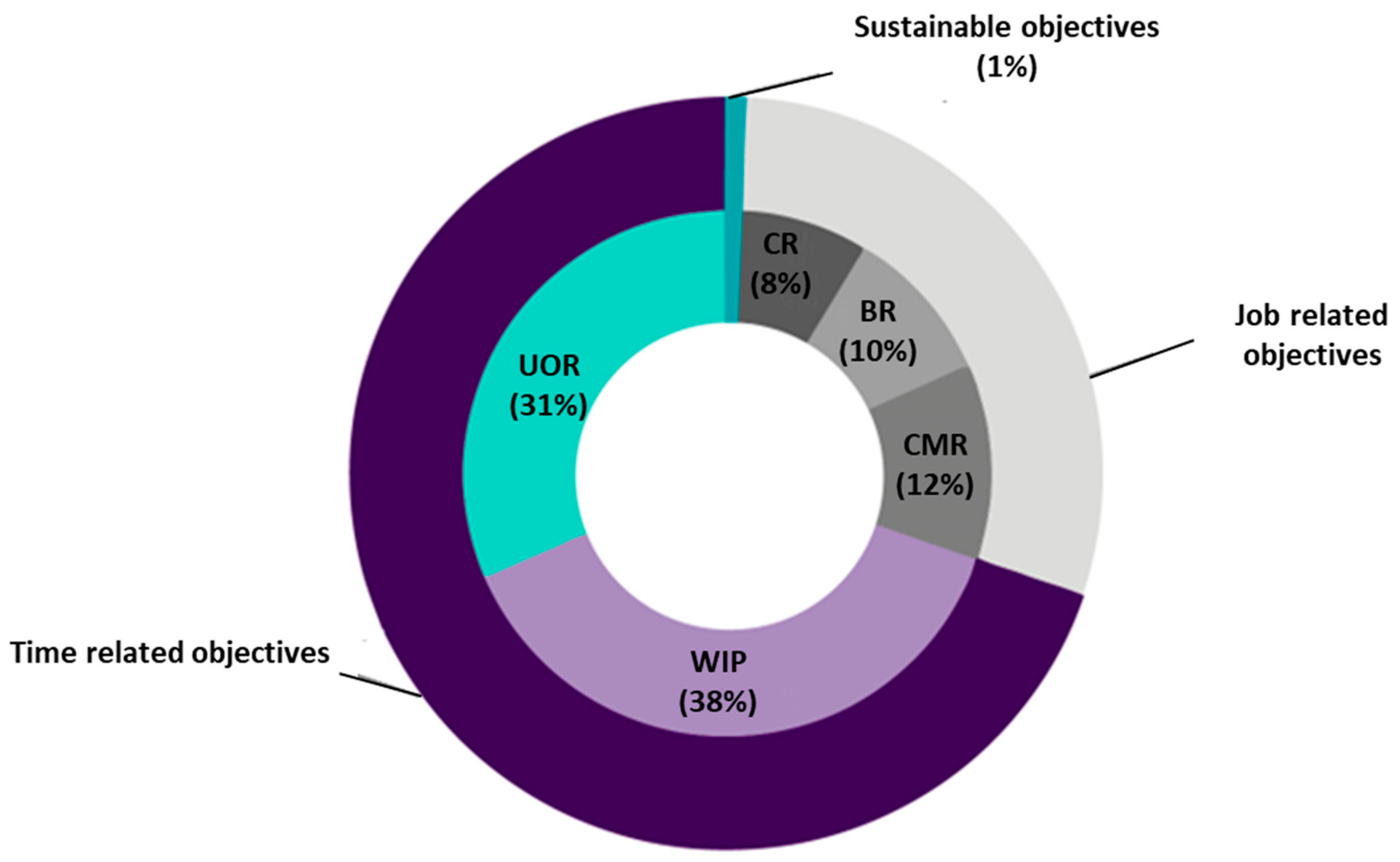

Since more than 30 objective functions criteria were identified in the short-listed articles, a grouping is proposed, taking as a reference the taxonomies suggested by [42,43,44]. The objective functions are classified as time-related objectives (TRO), job-related objectives (JRO), cost-related, and environmental objectives. The first category includes the utilization of resources and work-in-process. The second category covers objectives related to customer satisfaction and work balancing. The third and fourth categories, respectively, group together functions that evaluate costs and sustainability criteria (which include environmental and social criteria). Appendix A shows the objective functions; however, variations concerning the original equations may occur depending on the configuration of the system studied.

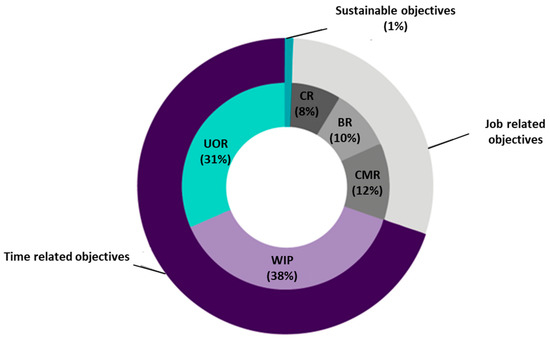

The criteria that belong to the category TRO—work in progress are more frequent, appearing 389 times. Then comes TRO—utilization of resources criteria appear 313 times. In third, fourth and fifth place are JRO—customer-related, JRO—balancing-related, and cost-related, with 122, 97 and 87, respectively. Finally, sustainable objectives are rarely considered (8 times). As shown in Figure 6, most studies have been oriented towards traditional scheduling criteria, as these mean an economic benefit to the system.

Figure 6.

Distribution by objective function categories. UOR: utilization of resources; WIP: work in process; CMR: costumer related; BR: balancing related; CR: cost related.

In recent years, there has, however, been growing interest in working with sustainable systems, which has led to the integration of sustainability criteria into objective functions. In this last category, we include the criteria aimed at minimizing energy consumption [45,46,47,48], as well as criteria pertaining to socially-oriented objective functions such as minimization of the average rate of workers’ deterioration [49] and of the noise levels to which workers are exposed [50].

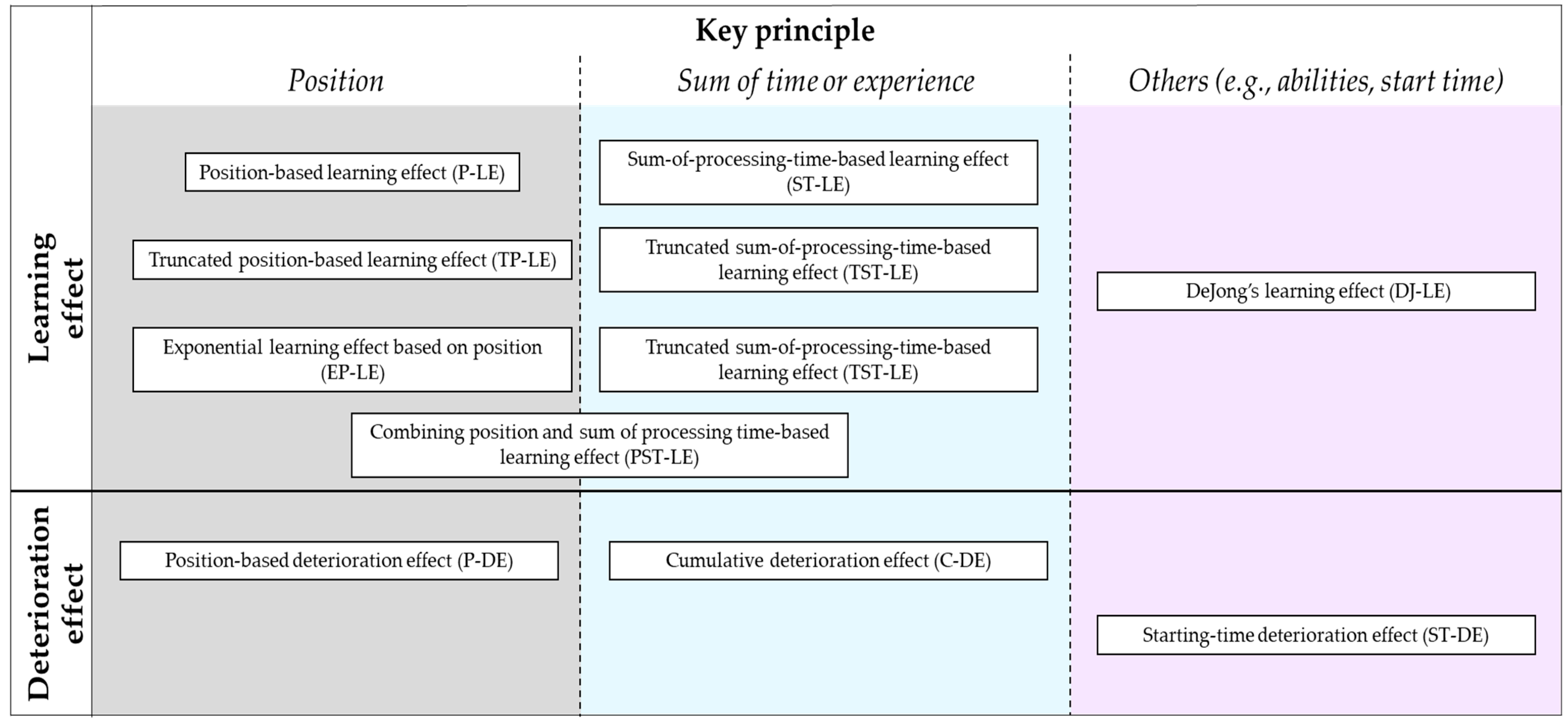

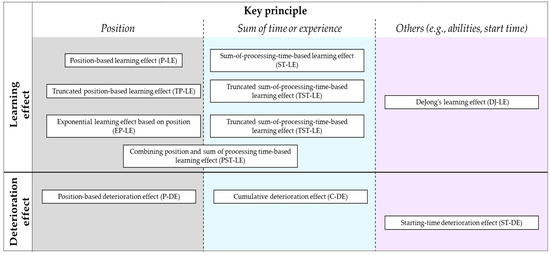

3.3. Modeling Approaches for Learning and Deteriorating Effects

As pointed out above, since production resources are not static and unchangeable over time, job processing times could increase when a resource deteriorates, or decrease when a resource improves in terms of productivity. When humans carry out tasks, many characteristics can have an effect and can be grouped into two categories known as learning effects and deterioration effects [1,51]. The learning effect category includes characteristics that reduce processing times, such as the learning process, motivation, and recovery, among others. The deterioration effect category includes the aging and forgetting effect, for example. Figure 7 shows the classification of the approaches of learning and deterioration effect identified in this review. The categories are regrouped according to the key principle from which the model is developed. This section provides a summary and description of approaches to model the learning and deterioration effects of scheduling problems.

Figure 7.

Taxonomy visualization.

3.3.1. Learning Effect

The learning effect in manufacturing systems was introduced in the work of Wright [5], who stated the increase in productivity as a function of the number of units completed. Thus, monotonous activities have the potential to be improved to achieve a high level of productivity thanks to practical experience [52]. As a result of the invention of the learning equation, certain models were proposed, enhanced, and brought closer to reality. The first study of scheduling with learning effects did not appear until 1999, with the seminal work of Biskup [6] and then Cheng and Wang [53], whose articles have become the baseline on the subject.

Several models have been proposed in the literature and have been grouped together for their analysis. Biskup [8] classified them in two approaches: (i) position-based learning effects, and (ii) sum-of-the-processing-time learning. Azzouz et al. [11] subsequently updated this classification and analyzed some works on the topic up to 2017. The current paper presents an analysis of articles that parts of the one proposed by Azzouz et al. [11], with some modifications. The definition and certain reference models for each category are described below.

Position-Based Learning Effect (P-LE)

In this approach, the learning effect is affected by the number of jobs processed previously [8]. Job processing time therefore decreases with the number of repetitions rather than accumulated time [11]. In 1999, Biskup [6] demonstrated that the single machine scheduling problem can be solved in polynomial time and introduced the equation to calculate the actual job processing time:

where is the processing time of the job located in position of the schedule. The constant learning index is ( Even though some authors have modified Biskup’s equation or proposed their own equations, they are all based on the principle of the number of repetitions. This approach is the one most commonly used in the short-listed articles.

Truncated Position-Based Learning Effect (TP-LE)

This phenomenon is intended to bring the learning effect closer to reality. For a truncated position learning effect, the processing time of the job depends on its position and a control parameter, which indicates the learning limitation. In the work of Cheng and Wang [53] the existence of a learning threshold value is already mentioned. An approach in a single machine scheduling problem, where the actual processing time of a job is defined according to Equation (2). is a parameter of learning effect ( is a control parameter for learning truncation with . The latter parameter introduces a lower bound on the processing time.

Some variations have been proposed, such as the one reported by [54], incorporating the consumption of convex resources. In their equation, is the job-dependent learning factor, is a positive constant [55,56], and is the amount of resource that can be allocated to job .

Exponential Learning Effect Based on Position (EP-LE)

Unlike position-based approaches, the exponential learning effect based on position explains a learning process where the job processing time decreases progressively, thus ensuring the quality of the products. Equation (4) shows the model proposed in a flowshop scheduling problem by Cheng [57], where denotes the actual processing time of job on the r-th position of the machine or worker i.

Zhang et al. [58] also defined the actual processing time of a job in a single machine scheduling problem according to the start time of its processing, as well as the position of the job within the sequence, as computed in Equation (5). In their equation, and are the learning and deterioration rate, respectively. These values can be estimated empirically, such that 0 < ≤ 1, 0 < < 1.

Sum-of-Processing-Time-Based Learning Effect (ST-LE)

The model presented by Kuo and Yang [59] in a single machine scheduling problem is based on the proposition that the more a worker performs a task, the higher their performance will be. From this point of view, the learning effect is expressed in terms of the total processing time of the previously completed jobs. The actual job processing time is defined by Equation (6), where 0 is a constant learning rate.

An alternative approach to this model was developed by Liang et al. [60], who, keeping in mind that learning is a declining phenomenon, proposed a sum-of-logarithm-processing-times-based learning effect. These authors studied a flowshop scheduling problem. The equation is given as:

where is the job processing time (without learning effect) and 0 is the learning rate.

Truncated Sum-of-Processing-Time-Based Learning Effect (TST-LE)

The use of the truncated function can indeed be justified since the learning is limited. For this model, the actual job processing time depends on the sum of processing times of jobs processed previously and a control parameter [61]. Therefore, for the case of a single machine as studied by these authors, the actual processing time of a job is defined as follows:

Another approach is proposed by Wu et al. [62] as below:

where is the learning index, and the truncated parameter with and 0 < < 1.

Exponential Learning Effect Based on Sum-of-Processing-Time (EST-LE)

Some authors have included a learning effect based on an exponential sum of processing time. For instance, Wang et al. [63] described this phenomenon using the following example: if human interactions have a significant impact during the processing of a job, workers will gain experience. The job processing time in a single machine scheduling problem is then as shown in Equation (10).

Wang et al. [64] proposed that the actual processing time of a job be defined by an exponential function of the sum of the logarithm of the processing times of the jobs processed previously.

where , and are parameters obtained empirically, and . They use Pegel’s learning curve [65] as a starting point.

Combining Position and Sum of Processing Time-Based Learning Effect (PST-LE)

This type of model mixes both phenomena, combining the position-based learning effect to model machine learning effects with the sum-of-processing time [11]. In the case of Cheng et al. [66], the actual processing time of a job in the single machine problem is a function of the normal total processing time of previously processed jobs, as well as the position. The model is presented below.

where and indicate the learning rate, with and . On the other hand, Lu et al. [67] propose a complex model for the job processing time in a single machine problem. This involves several approaches, and the authors define it as exponential sum-of-logarithm-processing-times-based and position-based learning effects, as in Equation (13).

where is a truncation parameter with 0 < < 1, and are learning rates, , are parameters obtained empirically [65], and .

DeJong’s Learning Effect (DJ-LE)

The DeJong model [68] takes into account the residual skills resulting from previous experiences and implies that part of the process cannot be improved. This model has been viewed as having great relevance in real life [11,69]. The DeJong learning curve follows the equation below:

where the parameter M represents the part of job processing time that is limited by some conditions and cannot be shortened (it represents the “factor of incompressibility”). Different values of M are recommended in the literature. For example, in a single machine problem, the DeJong model suggests M = 0.25 for labor-intensive jobs and M = 0.5 for machine-intensive jobs [69].

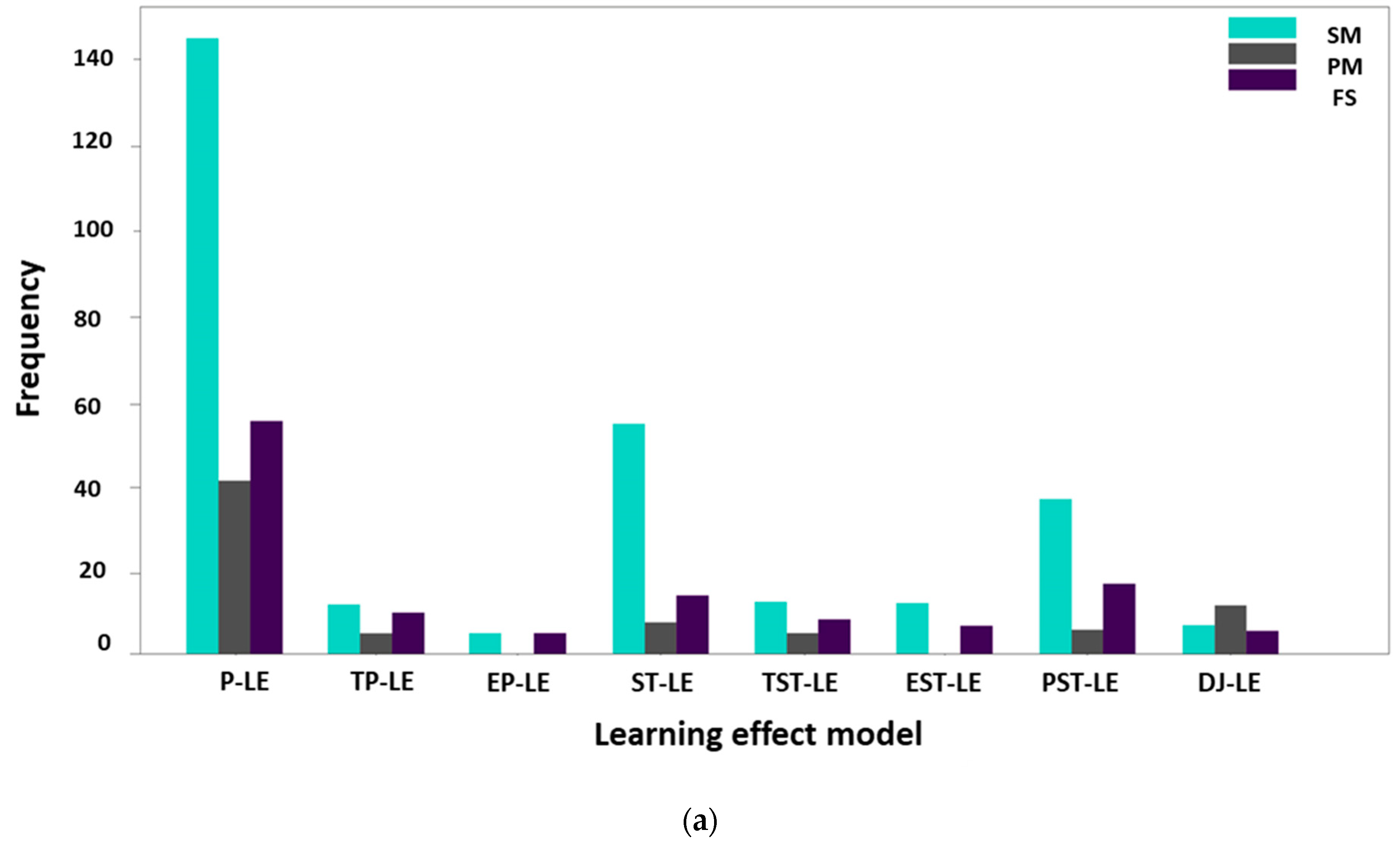

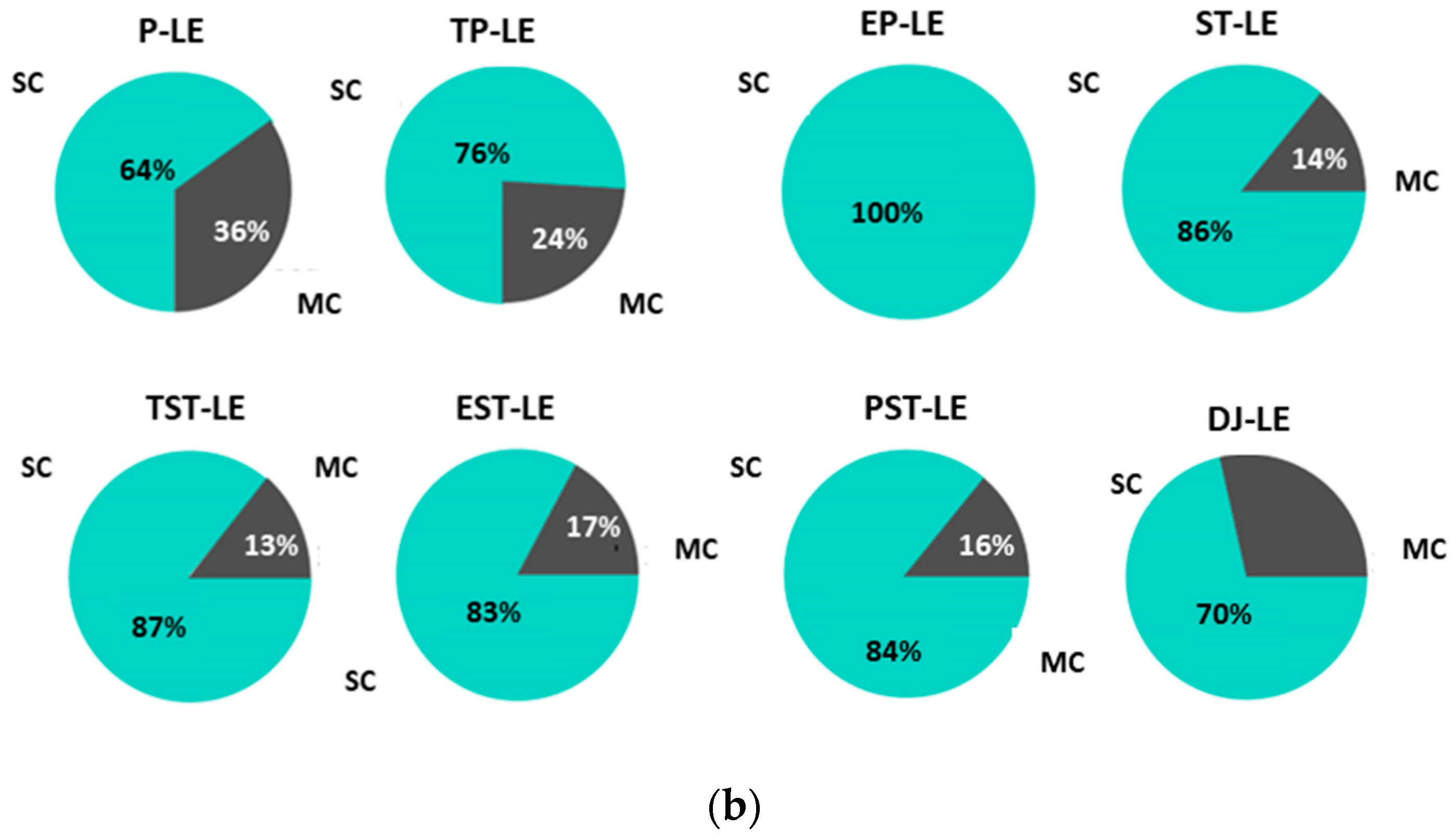

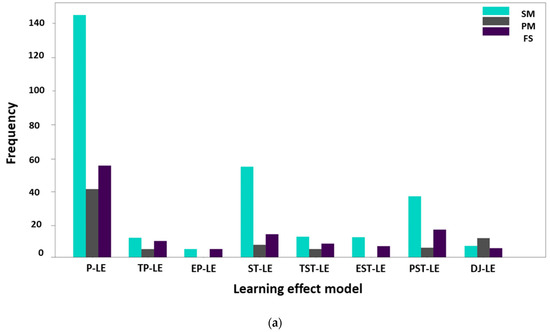

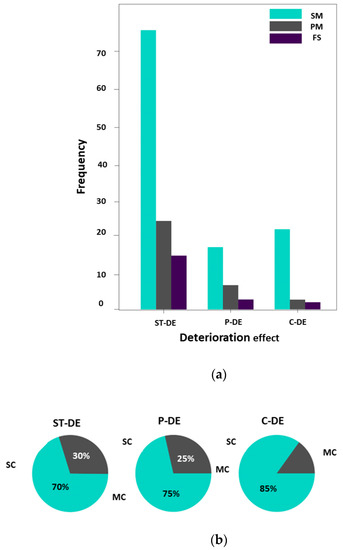

Figure 8a presents the frequency by the system configuration (two or three more common ones) according to each learning effect approach (in Figure 8a: SM: single machine; PM: parallel machine; FS: flowshop). Figure 8b shows the percentage of objective function types per each learning effect approach (in Figure 8b: SC: single-criteria objective function; MC: multi-criteria objective function).

Figure 8.

(a) System configuration vs. learning effect approach. (b) Learning effect approach vs. objective function types.

Given the nature of the learning process, many aspects must be taken into consideration. Some authors, therefore, attempt to include them in their models without being limited to the principles of position and time. These aspects include, for example, previous experience [70], skills [71], the initial capability, learning ability and job difficulty [50]. In addition, we identified alternative approaches to model the learning effect, using a perceptron neural network learning algorithm [72]. We also found some articles corresponding to the inclusion of rate-modifying activities (RMA) [73,74,75,76,77,78,79,80], which changes the processing conditions in a system and adjusts the production rate of a resource. Two examples are maintenance activities or rest periods, which usually increase production rates.

3.3.2. Deterioration Effect

In the real world, processing times could increase if producers and resources become less efficient over time. The literature refers to this phenomenon as the deterioration of the job or resources. The categories in which deterioration effects are grouped in the present review correspond to those mentioned by Li et al. [81] and Strusevich and Rustogi [51], such as (i) starting-time deterioration effect, (ii) positional deterioration effect, and (iii) cumulative deterioration effect. The first relates mainly to job deterioration, while the last two refer to resource deterioration. With respect to workers, the deterioration effect may include aging and forgetting, for example.

Starting-Time Deterioration Effect (ST-DE)

In this case, jobs deteriorate. Browne and Yechiali [82] introduced the case where jobs deteriorate while waiting for a service, and their processing times increase while waiting. An example of job deterioration is when an ingot is waiting to be inserted into the rolling machine. The ingot cools down and has to be heated before rolling. Similarly, the time and effort required to control a fire increases when the wait to put out the fire is longer [83]. Wu et al. [84] proposed the following equation for a linear deterioration. They applied the model to a flowshop problem.

where is the job processing time, is the deterioration ratio of job , and is the starting time.

Position-Based Deterioration Effect (P-DE)

This model attempts to address the real context in which machines and equipment deteriorate with the number of jobs handled [85]. For a flowshop scheduling problem, Lee et al. [86] used a position-dependent deterioration model defined in (16) where is the deterioration factor.

Lee and Yang [87] consider two different models in a parallel machine scheduling problem. One of them is a declining convex model by which the actual processing time is given by 17, where is the amount of resource allocated to the job , and is a positive constant (see Monma et al. [55]).

This category also includes the aging effect, as this is a type of deterioration. Janiak and Rudek [88] defined the actual job processing time in a single machine as:

where denotes various aging ratios provided by individual jobs, is the number of performed jobs (or position), and and are the aging threshold and aging ratio of job j.

Cumulative Deterioration Effect (C-DE)

The job processing time is an increasing function of the total processing time, load or difficulty related to the completion of previously scheduled works [81]. For instance, Abedi et al. [45] focus on a job-shop scheduling problem and define the work processing time, taking into account the cumulative deterioration effect of the speed-scaling machines.

is the actual processing time of the operation of job , and is the selected speed level of the machine for the operation. and are constants related to the deterioration of the machine, and refers to the volume of work that the machine has carried out just before the task and since the last maintenance activity. This approach incorporates speed as a key point, as one of their objectives is to minimize energy consumption (and it is true that the higher the speed, the more energy is needed).

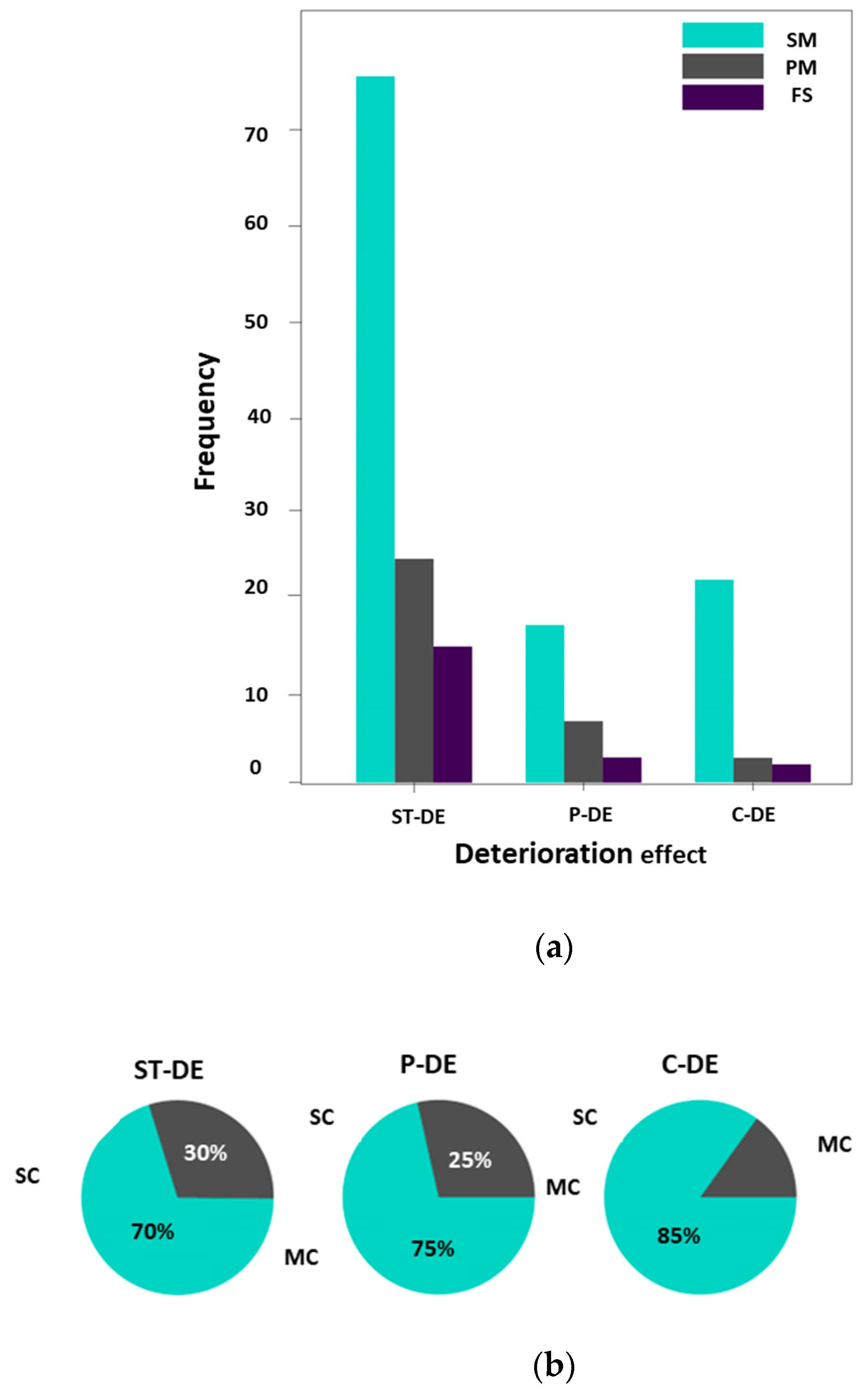

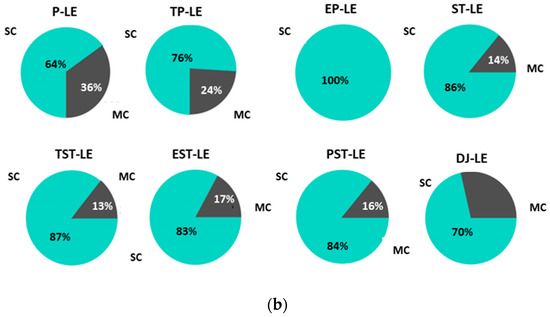

Figure 9a summarizes the frequency by the system configuration (two or three more common ones) according to each deterioration effect approach (in Figure 9a: SM: single machine; PM: parallel machine; FS: flowshop). Figure 9b shows the percentage of objective function types per each deterioration effect approach (in Figure 9b: SC: single-criteria objective function; MC: multi-criteria objective function).

Figure 9.

(a) System configuration vs. deterioration effect approach. (b) Deterioration effect approach vs. objective function types.

As with the learning effect, these summarized approaches are the ones most commonly employed in the literature, though some other modeling approaches have been proposed. For example, Wu et al. [84] employed the step-deterioration effect model to determine the actual processing time, where the job’s processing time is described by an upper-bounded piecewise function. Although most short-listed articles use the term “deterioration effect” referring to job deterioration, few authors have employed the terms fatigue or forgetting [49,71,89,90,91,92,93].

Note that there is a group of works that have simultaneously taken into consideration the effects of learning and deterioration (26.2% of short-listed papers). Most of these effects (over 70%) were studied in a single machine configuration.

We can see that the learning and deterioration approaches are mainly based on the principle of position and sum-of-processing time. However, if models are mainly focused on the scheduling problem of hand-intensive tasks, they should be complemented by characteristics that address human behavior (e.g., experience, forgetting, fatigue).

3.4. Solution Methods

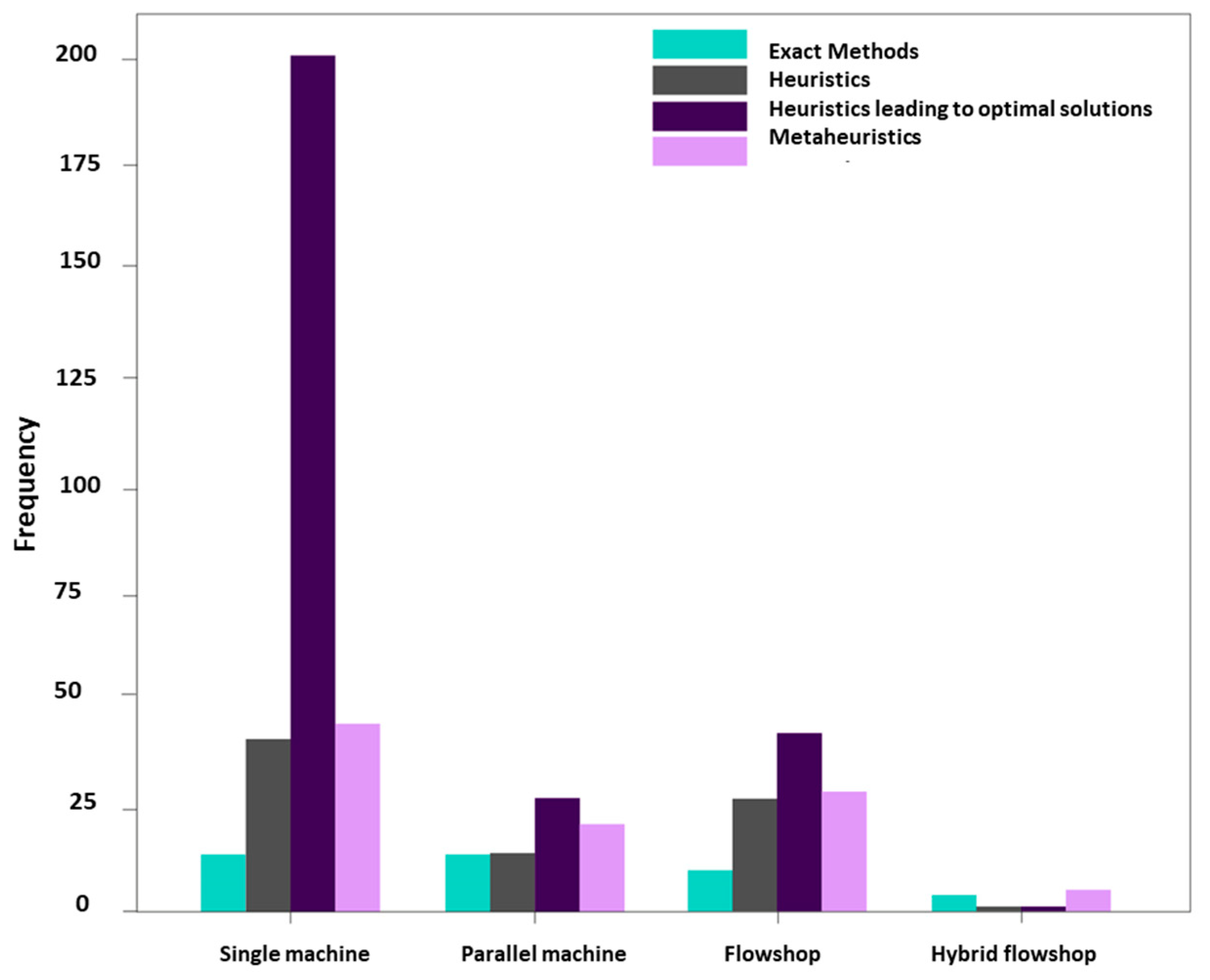

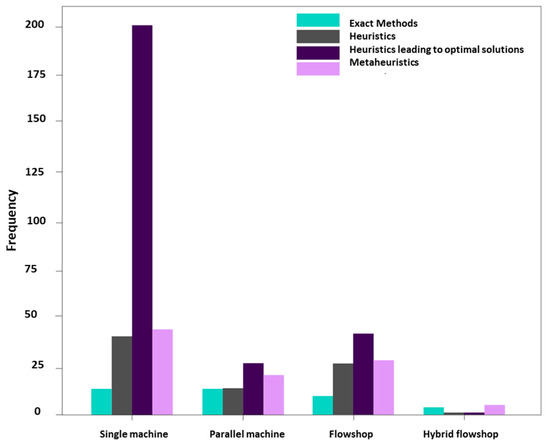

A variety of solution methods has been identified in the literature. For the purposes of our analysis, solution approaches were grouped into categories: metaheuristic, heuristic, exact methods, and heuristic leading to optimal solutions. The last category includes only works proposing heuristic algorithms achieving the optimal solution for polynomial-solved special cases. Figure 10 summarizes the solution methods employed by the type of system configuration studied (for the four most frequent configurations).

Figure 10.

Solution method vs. system configuration.

3.4.1. Exact Methods

In general, the NP-hardness of these scheduling problems makes it difficult to find exact methods to find solutions in polynomial time. Moreover, exact methods are usually proposed to mathematically formalize the problems and to solve small-sized instances. Similarly, they have been used to evaluate the performance of approximation algorithms. Modeling has mainly used mixed-integer linear programming (MILP), mixed-integer programming (MIP), mixed-integer non-linear programming (MINLP) or fuzzy mixed-integer non-linear programming (FMINLP) [94]. In general, the solvers used to deal with these models are CPLEX (e.g., Bai et al. [95]), GAMS (e.g., Eren [96]) and LINGO (e.g., Ghodratnama et al. [97]). Almost 11.2% of short-listed articles propose an exact method. However, in the 1970s, the research community found that some of the optimization problems, including scheduling problems, were difficult to resolve. The first scheduling problem listed was minimizing the total weighted completion time on a single machine. Similarly, problems related to complex machine environments and time-changing effects have become computationally complex. Thus, the use of non-accurate methods to resolve them is more popular every day, as seen below.

3.4.2. Heuristics Leading to Optimal Solutions

Even though the general case of the scheduling problem with learning and deterioration effect belongs to the family of NP-hard problems, research has also focused on finding special cases for which optimal solutions can be achieved in polynomial or pseudo-polynomial time. It is worth noting that with the beginning of the study of scheduling problems with learning and deterioration effects, some of the first approaches that address this issue suggested pseudo-polynomial and polynomial algorithms. For example, the paper of Mosheiov [94] introduces polynomial solutions to the problem into single and parallel machine environments. This category is typically called approximation algorithms and is an intermediary point between exact methods and heuristics. In this case, the algorithms known as “heuristics with a guarantee” or “not-quite-exact” algorithms ensure the possibility of finding the optimal solution in certain cases [98]. This category also includes work that deals with dominance rules and defines upper and lower bounds, with almost 74.7%.

Some of the methods included in this category are based on the branch and bound (B&B) algorithm, based on dispatching rules or specific algorithms adapted to each problem. Another method, rarely used but also reported, is the bounds-based nested partition (BBNP) method applied by Liu et al. [99] and He [100], and studies related to worst-case and lower-bound definitions are also addressed. Despite the high frequency of use of heuristics leading to optimal solutions, these methods are not suitable for solving large-instance problems, or situations with specific characteristics of human behavior such as experience, fatigue, forgetting, etc., that constitute real problems (due to the uncertainty involved).

3.4.3. Heuristics

Heuristic procedures are widely used due to the NP-hard nature of the scheduling problem, considering learning or deterioration effects. More than 21.5% of the short-listed papers propose heuristics to solve large instances. The results obtained from the use of heuristics depend on the system configuration: single machine problem (14.3%), parallel machine problem (25.7%), and flowshop problem (40.3%). Dispatching rules are the most frequently employed e.g., earliest due date (EDD), shortest processing time (SPT), weighted shortest processing time (WSPT), as well as the Framinan and Leisten (FL) and Nawaz, Enscore, Ham (NEH)-based heuristics [101,102]. Note that most of the authors tested the performance of the heuristics against each other. Likewise, heuristic algorithms have regularly been used to obtain the initial solution for the implementation of some metaheuristics. Constructive methods have great relevance to solving problems with variable job processing time. The case of the NEH algorithm is known, which showed good performance with problems with a high number of machines [103] and minimized the makespan as an objective function (among the most common objective functions).

3.4.4. Metaheuristics

Since metaheuristics have proved to be good methods to solve NP-hard combinatorial problems, this literature review identifies a wide variety of procedures to solve scheduling problems with learning and deteriorating effects. A set of 134 articles including metaheuristics show that they are used in 16% of works dealing with scheduling problems of a single machine, 41.4% of parallel machines, 44.3% of a flowshop and 81.8% of a hybrid flowshop. Furthermore, all the articles on job shop and flexible job shop scheduling problems use metaheuristics. The genetic algorithm (GA) is the most widely used metaheuristic for resolving this type of problem, followed by simulated annealing (SA) and tabu search (TS).

Research on metaheuristic algorithms started around the 1950s, and new methods continue to appear frequently. Sophisticated approaches have emerged in recent years, and some of these new metaheuristics, such as artificial bee colony (ABC), invasive weed optimizer (IWO), grey wolf optimizer (GWO), whale optimization algorithm (WOA), league champions algorithms (LCA), and artificial-based-molecule chemical reaction optimization (ACRO), started to be applied in this field since 2019, and cat swarm optimization (CSO) was the first used in 2020.

An overview of the evolution of metaheuristics can be found in the work of Sörensen [98]. The use of hybrid metaheuristics has, moreover, recently also become very popular. Hybrid procedures are a combination of algorithms to take advantage of their individual characteristics and performances simultaneously. These approaches are presented in more than 40% of the short-listed papers that use metaheuristics. In this review, we found several authors who hybridize genetic algorithms with other methods such as tabu search [104,105,106], simulated annealing [107], variable neighborhood search [108,109], kangaroo algorithm [110] and differential evolution [111]. Among other approaches, we found the particle swarm optimization hybridized with local search [38], a hybrid CS-JADE algorithm combining improved cuckoo search algorithms and self-adaptive differential evolution [38], a hybrid SC-VNS mixing society and civilization algorithm with variable neighborhood search [112], and a hybrid VNS–ASHLO algorithm incorporating variable neighborhood search and adaptive simplified human learning optimization [113].

Multi-criteria problems are usually solved using metaheuristics or hybrid metaheuristics, each with its special characteristics. The following are some of the approaches proposed by the authors: Deliktaş [114] to minimize makespan and total tardiness, Abedi et al. [45] to minimize total weighted tardiness and total energy consumption, and Wang et al. [115] to minimize the weighted sum of makespan and total completion time, used a memetic multi-objective algorithm to obtain a set of solutions. First, the authors develop a non-dominated sorting method, and second, the authors appeal to the Pareto front.

Wu et al. [116] presented a multi-objective Hybrid Pigeon Inspired Optimization and Simulated Annealing Algorithm to minimize the makespan and the total energy consumption in a flexible job-shop scheduling problem considering deterioration effects. In the same way, to minimize the makespan and total tardiness in a hybrid flowshop, Pargar et al. [117] developed algorithms by hybridizing water flow-like algorithms (WFA) with non-dominated sorting and ranking concepts. Pakzad-Moghaddam [39] developed a novel metaheuristic called lévy flight embedded particle swarm optimization (LFEPSO) to solve a multi-objective problem (minimizing the makespan and machine hiring cost). Yue et al. [118] proposed a novel hybrid Pareto artificial bee colony algorithm (HPABC), in which the advantage of using the Pareto front was to prioritize the obtained solutions, minimizing the makespan and the total weight tardiness simultaneously.

Some methods referred to in the literature are based on genetic algorithms, such as those by Bektur [119], Shokoufi et al. [120] and Tigane et al. [47], who developed non-dominated sorting-based multi-objective algorithm (NSGA-II)-based approaches. Marichelvam et al. [71] hybridized a variable neighborhood search (VNS) with the particle swarm optimization (PSO) algorithm. Finally, Peng et al. [50] proposed a hybrid discrete multi-objective imperial competition algorithm (HDMICA), where a simulated annealing algorithm (SA) is embedded in an imperialist competitive algorithm (ICA). Their article is particularly interested in three objective functions that are seldom mixed, such as the makespan, power consumption and noise level.

3.4.5. Other Methods

Alternative approaches have been adopted in certain articles, such as the hypothetical analysis based on simulation. Li [23], for instance, uses the monte Carlo (MC) simulation, Ostermeier [49,121] employees discrete event simulation, and Expósito-Izquierdo et al. [122] work with a multi-agent simulation approach. In addition, there is growing interest in incorporating the multi-agent scheduling problem [123,124] when there is more than one criterion to optimize. Each agent then aims for an objective, and they compete to improve their performance. The most frequent in the short-listed papers (with 18 papers) is the two-competing-agents approach [125,126,127,128,129,130,131,132,133,134,135,136,137,138].

In contrast, some contributions have focused on explaining and demonstrating the degree of complexity of such problems rather than solving them. Rudek has explored the subject in depth [2,70,139,140,141], showing that the single machine scheduling problem with learning effects becomes strongly NP-hard [140]. In the same way, there are also complexity studies in other types of configuration such as the flowshop [142], in which they have shown that due to the complexity of the two-machine-flowshop scheduling problem, the Jhonson’s rule does not guarantee an optimal solution [143].

It appears that the articles that use exact methods and heuristics leading to optimal solutions lean towards these methods because they have focused on simplified versions of problems and used experimental data sets. This is in part because few articles support real data or include case studies.

4. Discussion

This literature review provides an overview of studies related to scheduling problems with learning and deteriorating effects. The discussion is offered in two phases. The first one answers the questions put forward in Section 2.1, which enable us to understand the progress in this field. The second one, identifying opportunities and challenges.

Giving the answer to RQ1, the findings suggest that research related to the scheduling problem with learning and deteriorating effects has generated much interest in recent years. It was noted that the number of articles has increased significantly since 1999. The majority of short-listed articles focused on managing the problem by studying the complexity and developing algorithms that can be comparable in their performance with others already proposed. This implied continuing to maintain classic objective functions, which are sometimes far from being the criteria of interest for stakeholders today. Thus, interaction with business partners would allow us to bring the problems closer to reality, thus ensuring sustainability, taking into account economic, social, and environmental dimensions.

In terms of RQ2, various types of configurations have been studied, with the most studied one being the single machine system. However, more recently, authors have been exploring more complex configurations such as the flowshop and the hybrid flowshop [144,145]. They involve multiple types of resources (machines, workers, etc.), which must be managed as well as possible [146], in addition to the fact that they correspond to the most common and realistic configurations in the industry [42,147]

Regarding RQ3, in most cases, the approach considered a single objective, with only 28.8% combining two or more criteria in the objective function. The most recurrent categories of criteria are those involving TRO—work in progress and TRO—utilization of resources, as per the taxonomy of Botta-Genoulaz [42], Akbar and Irohara [43], and Lee and Loong [44]. This shows the authors’ preference to orient towards economic objectives. In this category, the makespan is the most well-studied criterion. In the sustainable category, social orientation criteria are not often included, but they have begun to emerge on a large scale (e.g., noise levels).

In the matter of RQ4, findings show that the learning effect has been modeled primarily by the equation in terms of the number of jobs previously processed or the sum of the processing times. These basic models have been improved by adding truncation parameters, for example. Another important finding is the treatment of the deterioration effect in the literature. This term is typically used for job deterioration (111 articles) but has also been used by some authors for deteriorating resources. In the latter case, the effect may result from the number of jobs previously processed or the cumulative effect of the deterioration. Recently, the combination of learning and deterioration has become increasingly common in the literature.

Concerning RQ5, this present study has shown that the solution method employed to solve the problem is highly dependent on the type of configuration under study. The development of algorithms for the optimal solution in polynomial time is regularly applied in single machine systems. For other configurations such as job shops, flowshops, hybrid flowshops and flexible job shops, methods such as heuristic and metaheuristics become relevant. There is a trend towards proposing novel methods for optimization [98] or using hybrid metaheuristics, in response to the computational complexity that these problems involve, by taking advantage of the characteristics of different metaheuristics operating simultaneously [148]. In recent years, tools such as simulation and multi-agents have garnered increasing interest, particularly when parameter uncertainty is included. Extensive use has also been made of the competitive agent approaches, where two or more criteria need to be optimized. These approaches generally are accompanied by the use of any metaheuristic.

Despite significant progress in these areas, many research opportunities can still be identified. Table 2 provides an overview of the opportunities and challenges.

Table 2.

Opportunities and challenges for the scheduling problem with learning and deterioration effects.

Additionally, they are described in depth below.

- The current results show that the literature is oriented toward the development of models, the analysis of complexity, and the design and implementation of a solution method, instead of representing the real conditions more accurately. This encourages multidisciplinary collaboration to integrate scheduling theory with human factors, experts, ergonomics, psychological issues, etc.

- There are few published articles dealing with the balance between economic and sustainable criteria (particularly as regards social orientation). It might be helpful to propose the study of scheduling problems with learning and deteriorating effects in which multiple criteria are evaluated, including social criteria.

- There are opportunities for developing studies that address the estimation of parameters such as learning, deterioration or truncation. In general, the values of these parameters are based on the literature benchmark. However, there are few articles that are strictly dedicated to estimating parameters adjusted to the problem in question.

- Every learning and deterioration model is based on one principle, such as job position or time. However, in the real world, there are other types or variables that could impact human behavior (e.g., environment, cognition, worker abilities, difficulty of work) [10,50]. The development of multivariate models for predicting worker performance, which may be incorporated into scheduling problems, is therefore relevant.

- As few articles include variables such as previous experience and task complexity in learning models [50], there is the possibility to deepen the topic to integrate these variables in models based on the position and the sum-of-processing-time. With regard to the approaches pertaining to deterioration, there is evidence of the need to integrate fatigue by addressing it through the inclusion of physiological variables, as pointed out in the literature [12]. There is likewise a need to study the effect that rest periods or rate-modifying activities (RMA) may have on performance.

- Most of the works evaluate modeling and solution approaches using theoretical problems, while few papers provide case studies [2,49,71,85]. Verification of the proposed assumptions and models for addressing the learning and deterioration effect in real-life production environments is an interesting area of research [13]. Thus, for example, collaboration with a business stakeholder makes it possible to study industrial problems with real constraints and to validate the proposed optimization methods.

- Although it is true that learning and workers’ aging or deteriorating health have a clear effect on job processing time, it is also true that there are other effects on the system performance such as errors. There are opportunities to include such factors in the scheduling problem, for example, by replacing the classical objective functions with some criteria oriented towards productivity optimization based on the minimization of faulty jobs.

5. Conclusions

Through a systematic literature review, this paper dealt with the scheduling problem with learning and deterioration effects. The main contribution has been to present a framework of published works on this subject and thus to identify trends and research opportunities. The review included 455 research articles published between 1999 and 2021. The purpose was to show and analyze the current state of research on the inclusion of learning and deterioration effects in scheduling problems. To obtain a global analysis, short-listed papers were classified according to certain characteristics such as system configuration, objective function, solution methods, and modeling approach for learning and deterioration effect. This review showed a growing body of research on this subject, as well as the different approaches to model the learning and deterioration effects.

Much effort has gone into analyzing the complexity of the problem and developing efficient techniques based on heuristics and metaheuristics. As far as objective functions are concerned, most studies are mainly related to a single economic optimization criterion. Finally, the evolution of production systems is a challenge for the active integration of the human factor in problems addressed from the perspective of operational research. This integration is essential to achieve a balance between economic and social objectives.

In practice, in recent years, production systems have undergone enormous changes because of predictable factors such as technological advances and changes in consumer needs. However, other unanticipated factors, such as post-pandemic effects and geopolitical issues, have had a strong influence on production systems. Thus, scheduling problems with learning and deteriorating effects are fully relevant because adaptability and maximum utilization of resources (which guarantees the welfare of workers and productivity standards) is decisive for the survival of productive systems—a complex problem that requires an approach that integrates algorithms and human factor disciplines to provide an integral solution.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/a15110439/s1.

Author Contributions

Conceptualization, Y.A.P.-A., J.R.M.-T. and V.B.-G.; methodology, Y.A.P.-A., J.R.M.-T. and V.B.-G.; validation Y.A.P.-A., J.R.M.-T. and V.B.-G.; investigation, Y.A.P.-A.; resources, Y.A.P.-A.; writing—original draft preparation, Y.A.P.-A.; writing—review and editing, Y.A.P.-A., J.R.M.-T. and V.B.-G.; visualization, Y.A.P.-A.; supervision, J.R.M.-T. and V.B.-G.; project administration Y.A.P.-A., J.R.M.-T. and V.B.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was carried out thanks to research scholarship from Universidad de La Sabana (grant number INGPhD-45-2021), a Mobility Grant by the French Embassy in Colombia for a cotutelle thesis call 2021 and by Eiffel Excellence Scholarship—PhD stream awarded to the first author by the French Government of Europe and Foreign Affairs.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Below we present the notation for parameters, variables and objective functions used as conventions in Table A1.

Table A1.

Categories for objective functions criteria.

Table A1.

Categories for objective functions criteria.

| Time related objectives (TRO) | Utilization of resources | Makespan | |

| Total resource consumption | |||

| Total load | |||

| Total idle time | |||

| Work in process | Total completion time | ||

| Total weighted completion time | |||

| Discounted total weighted completion time | |||

| Total absolute differences in completion times | |||

| The sum of the kth powers of completion times | |||

| The sum of the quadratic job completion times | |||

| Total flow time | |||

| Total absolute differences in waiting time. | |||

| Total waiting times | |||

| Cycle time | CT | ||

| Job related Objectives (JRO) | Costumer related | Maximum tardiness | |

| Maximum lateness | |||

| Maximum earliness | |||

| The number of tardy jobs | |||

| Number of just-intime jobs | |||

| Balancing related | Total tardiness | ||

| Total weighted tardiness | |||

| Total earliness | |||

| Total lateness | |||

| Cost related | Tardiness cost (penalties) | ||

| Earliness cost (penalties) | |||

| Maintenance cost or machine deterioration | |||

| Machine hiring cost | |||

| Total resources consumption cost | |||

| Sustainable objectives | Total energy consumption | ||

| Noise level | 10 * Log | ||

References

- Pinedo, M.L. Scheduling: Theory, Algorithms, and Systems; Springer: Berlin/Heidelberg, Germany, 2016; Volume 1. [Google Scholar]

- Rudek, R. Scheduling problems with position dependent job processing times: Computational complexity results. Ann. Oper. Res. 2012, 196, 491–516. [Google Scholar] [CrossRef]

- Moray, N.; Dessouky, M.I.; Kijowski, B.A.; Adapathya, R. Strategic behavior, workload, and performance in task scheduling. Hum. Factor 1991, 33, 607–629. [Google Scholar] [CrossRef]

- Dessouky, M.I.; Moray, N.; Kijowski, B. Taxonomy of scheduling systems as a basis for the study of strategic behavior. Hum. Factor 1995, 37, 443–472. [Google Scholar] [CrossRef]

- Wright, T.P. Factors Affecting the Cost of Airplanes Presented. J. Aeronaut. Sci. 1936, 3, 122–128. [Google Scholar] [CrossRef]

- Biskup, D. Single-machine scheduling with learning functions. Eur. J. Oper. Res. 1999, 115, 173–178. [Google Scholar] [CrossRef]

- Gupta, J.N.D.; Gupta, S.K. Single facility scheduling with nonlinear processing times. Comput. Ind. Eng. 1988, 14, 387–393. [Google Scholar] [CrossRef]

- Biskup, D. A state-of-the-art review on scheduling with learning effects. Eur. J. Oper. Res. 2008, 188, 315–329. [Google Scholar] [CrossRef]

- Anzanello, M.J.; Fogliatto, F.S. Alocação de modelos de produtos a equipes de trabalhadores baseada em modelos de curvas de aprendizagem. Production 2005, 15, 221–234. [Google Scholar] [CrossRef][Green Version]

- Lodree, E.J.; Geiger, C.D.; Jiang, X. Taxonomy for integrating scheduling theory and human factors: Review and research opportunities. Int. J. Ind. Ergon. 2009, 39, 39–51. [Google Scholar] [CrossRef]

- Azzouz, A.; Ennigrou, M.; Ben Said, L. Scheduling problems under learning effects: Classification and cartography. Int. J. Prod. Res. 2018, 56, 1642–1661. [Google Scholar] [CrossRef]

- Xu, S.; Hall, N.G. Fatigue, personnel scheduling and operations: Review and research opportunities. Eur. J. Oper. Res. 2021, 295, 807–822. [Google Scholar] [CrossRef]

- Glock, C.H.; Grosse, E.H.; Jaber, M.Y.; Smunt, T.L. Applications of learning curves in production and operations management: A systematic literature review. Comput. Ind. Eng. 2019, 131, 422–441. [Google Scholar] [CrossRef]

- Badger, D.; Nursten, J.; Williams, P.; Woodward, M. Should all literature reviews be systematic? Eval. Res. Educ. 2000, 14, 220–230. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, W. A tale of two databases: The use of Web of Science and Scopus in academic papers. Scientometrics 2020, 123, 321–335. [Google Scholar] [CrossRef]

- Parente, M.; Figueira, G.; Amorim, P.; Marques, A. Production scheduling in the context of Industry 4.0: Review and trends. Int. J. Prod. Res. 2020, 58, 5401–5431. [Google Scholar] [CrossRef]

- Merigó, J.M.; Yang, J.B. A bibliometric analysis of operations research and management science. Omega 2017, 73, 37–48. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Muñoz-Villamizar, A.; Mejia-Argueta, C. Mapping research in logistics and supply chain management during COVID-19 pandemic. Int. J. Logist. Res. Appl. 2021, 1–21. [Google Scholar] [CrossRef]

- Noyons, E.C.M.; Moed, H.F.; Luwel, M. Combining mapping and citation analysis for evaluative bibliometric purposes: A bibliometric study. J. Am. Soc. Inf. Sci. 1999, 50, 115–131. [Google Scholar] [CrossRef]

- Gaviria-Marin, M.; Merigó, J.M.; Baier-Fuentes, H. Knowledge management: A global examination based on bibliometric analysis. Technol. Forecast. Soc. Chang. 2019, 140, 194–220. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Li, H. Stochastic Single-Machine Scheduling With Learning Effect. IEEE Trans. Eng. Manag. 2017, 64, 94–102. [Google Scholar] [CrossRef]

- Roohnavazfar, M.; Manerba, D.; Fotio Tiotsop, L.; Pasandideh, S.H.R.; Tadei, R. Stochastic single machine scheduling problem as a multi-stage dynamic random decision process. Comput. Manag. Sci. 2021, 18, 267–297. [Google Scholar] [CrossRef]

- Shen, J. Uncertain Single-Machine Scheduling with Deterioration and Learning Effect. J. Math. 2020, 2020, 7176548. [Google Scholar] [CrossRef]

- Soroush, H.M. Stochastic bicriteria single machine scheduling with sequence-dependent job attributes and job-dependent learning effects. Eur. J. Ind. Eng. 2014, 8, 421–456. [Google Scholar] [CrossRef]

- Soroush, H.M. Scheduling in bicriteria single machine systems with past-sequence- dependent setup times and learning effects. J. Oper. Res. Soc. 2014, 65, 1017–1036. [Google Scholar] [CrossRef]

- Wei, W. Single machine scheduling with stochastically dependent times. J. Sched. 2019, 22, 677–689. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, X.; Zhou, X. Stochastic scheduling problems with general position-based learning effects and stochastic breakdowns. J. Sched. 2013, 16, 331–336. [Google Scholar] [CrossRef]

- Shen, J. An uncertain parallel machine problem with deterioration and learning effect. Comput. Appl. Math. 2019, 38, 3. [Google Scholar] [CrossRef]

- Fu, Y.; Ding, J.; Wang, H.; Wang, J. Two-objective stochastic flow-shop scheduling with deteriorating and learning effect in Industry 4.0-based manufacturing system. Appl. Soft Comput. J. 2018, 68, 847–855. [Google Scholar] [CrossRef]

- Ahmadizar, F.; Hosseini, L. Single-machine scheduling with a position-based learning effect and fuzzy processing times. Int. J. Adv. Manuf. Technol. 2011, 56, 693–698. [Google Scholar] [CrossRef]

- Ahmadizar, F.; Hosseini, L. Minimizing makespan in a single-machine scheduling problem with a learning effect and fuzzy processing times. Int. J. Adv. Manuf. Technol. 2013, 65, 581–587. [Google Scholar] [CrossRef]

- Asadi, H. Apply Fuzzy Learning Effect with Fuzzy Processing Times for Single Machine Scheduling Problems. J. Manuf. Syst. 2017, 42, 244–261. [Google Scholar] [CrossRef]

- Toksan, M.D.; Ank, O.A. Single machine scheduling problems under position-dependent fuzzy learning effect with fuzzy processing times. J. Manuf. Syst. 2017, 45, 159–179. [Google Scholar]

- Arık, O.A.; Toksarı, M.D. A genetic algorithm approach to parallel machine scheduling problems under effects of position-dependent learning and linear deterioration: Genetic algorithm to parallel machine scheduling problems. Int. J. Appl. Metaheuristic Comput. 2021, 12, 195–211. [Google Scholar] [CrossRef]

- Geyik, F.; Elibal, K. A linguistic approach to non-identical parallel processor scheduling with fuzzy processing times. Appl. Soft Comput. J. 2017, 55, 63–71. [Google Scholar] [CrossRef]

- Li, K.; Chen, J.; Fu, H.; Jia, Z.; Wu, J. Parallel machine scheduling with position-based deterioration and learning effects in an uncertain manufacturing system. Comput. Ind. Eng. 2020, 149, 106858. [Google Scholar] [CrossRef]

- Pakzad-Moghaddam, S.H. A Lévy flight embedded particle swarm optimization for multi-objective parallel-machine scheduling with learning and adapting considerations. Comput. Ind. Eng. 2016, 91, 109–128. [Google Scholar] [CrossRef]

- Rostami, M.; Pilerood, A.E.; Mazdeh, M.M. Multi-objective parallel machine scheduling problem with job deterioration and learning effect under fuzzy environment. Comput. Ind. Eng. 2015, 85, 206–215. [Google Scholar] [CrossRef]

- Jeong, B.; Han, J.H.; Lee, J.Y. Metaheuristics for a Flow Shop Scheduling Problem with Urgent Jobs and Limited Waiting Times. Algorithms 2021, 14, 323. [Google Scholar] [CrossRef]

- Botta, V. Planning & Scheduling Flow Shop Organizations with Constraints—Towards a Decision Engineering System for Production Planning & Production Activity Control. Ph.D. Thesis, Computer Engineering, Université Claude Bernard—LYON 1, Villeurbanne, France, 1996; 170. [Google Scholar]

- Akbar, M.; Irohara, T. Scheduling for sustainable manufacturing: A review. J. Clean. Prod. 2018, 205, 866–883. [Google Scholar] [CrossRef]

- Lee, T.S.; Loong, Y.T. A review of scheduling problem and resolution methods in flexible flow shop. Int. J. Ind. Eng. Comput. 2019, 10, 67–88. [Google Scholar] [CrossRef]

- Abedi, M.; Chiong, R.; Noman, N.; Zhang, R. A multi-population, multi-objective memetic algorithm for energy-efficient job-shop scheduling with deteriorating machines. Expert Syst. Appl. 2020, 157, 113348. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, X.; Zhang, R. An enhanced MOPSO algorithm for energy-efficient single-machine production scheduling. Sustainability 2019, 11, 5381. [Google Scholar] [CrossRef]

- Tigane, M.; Dahane, M.; Boudhar, M. Multiobjective approach for deteriorating jobs scheduling for a sustainable manufacturing system. Int. J. Adv. Manuf. Technol. 2019, 101, 1939–1957. [Google Scholar] [CrossRef]

- Soleimani, H.; Ghaderi, H.; Tsai, P.-W.; Zarbakhshnia, N.; Maleki, M. Scheduling of unrelated parallel machines considering sequence-related setup time, start time-dependent deterioration, position-dependent learning and power consumption minimization. J. Clean. Prod. 2020, 249, 119428. [Google Scholar] [CrossRef]

- Ostermeier, F.F. On the trade-offs between scheduling objectives for unpaced mixed-model assembly lines. Int. J. Prod. Res. 2020, 60, 866–893. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, H.; Tang, H.; Feng, Y.; Yin, W. Research on flexible job-shop scheduling problem in green sustainable manufacturing based on learning effect. J. Intell. Manuf. 2021, 33, 1725–1746. [Google Scholar] [CrossRef]

- Strusevich, V.; Rustogi, K. Scheduling with Time-Changing Effects and Rate-Modifying Activities; Springer International: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Arditi, D.; Tokdemir, O.B.; Suh, K. Effect of learning on line-of-balance scheduling. Int. J. Proj. Manag. 2001, 19, 265–277. [Google Scholar] [CrossRef]

- Cheng, T.C.E.; Wang, G. Single Machine Scheduling with Learning Effect Considerations. Ann. Oper. Res. 2000, 98, 273–290. [Google Scholar] [CrossRef]

- Wang, J.-B.; Lv, D.-Y.; Xu, J.; Ji, P.; Li, F. Bicriterion scheduling with truncated learning effects and convex controllable processing times. Int. Trans. Oper. Res. 2021, 28, 1573–1593. [Google Scholar] [CrossRef]

- Monma, C.L.; Schrijver, A.; Todd, M.J.; Wei, V.K. Convex resource allocation problems on directed acyclic graphs: Duality, complexity, special cases, and extensions. Math. Oper. Res. 1990, 15, 736–748. [Google Scholar] [CrossRef]

- Shabtay, D.; Steiner, G. A survey of scheduling with controllable processing times. Discret. Appl. Math. 2007, 155, 1643–1666. [Google Scholar] [CrossRef]

- Cheng, M. Flowshop scheduling problems with a position-dependent exponential learning effect. Math. Probl. Eng. 2013, 2013, 753123. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, G.; Huang, W.; Tang, G. Single-machine scheduling problems with time and position dependent processing times. Ann. Oper. Res. 2011, 186, 345–356. [Google Scholar] [CrossRef]

- Kuo, W.H.; Yang, D.L. Minimizing the makespan in a single machine scheduling problem with a time-based learning effect. Inf. Process Lett. 2006, 97, 64–67. [Google Scholar] [CrossRef]

- Liang, X.X.; Zhang, B.; Wang, J.B.; Yin, N.; Huang, X. Study on flow shop scheduling with sum-of-logarithm-processing-times-based learning effects. J. Appl. Math. Comput. 2019, 61, 373–388. [Google Scholar] [CrossRef]

- Wu, C.C.; Yin, Y.; Wu, W.H.; Cheng, S.R. Some polynomial solvable single-machine scheduling problems with a truncation sum-of-processing-times based learning effect. Eur. J. Ind. Eng. 2012, 6, 441–453. [Google Scholar] [CrossRef]

- Wu, C.C.; Yin, Y.; Cheng, S.R. Some single-machine scheduling problems with a truncation learning effect. Comput. Ind. Eng. 2011, 60, 790–795. [Google Scholar] [CrossRef]

- Wang, J.-B.; Wang, D.; Wang, L.-Y.; Lin, L.; Yin, N.; Wang, W.-W. Single machine scheduling with exponential time-dependent learning effect and past-sequence-dependent setup times. Comput. Math. Appl. 2009, 57, 9–16. [Google Scholar] [CrossRef][Green Version]

- Wang, J.-B.; Sun, L.; Sun, L. Single machine scheduling with exponential sum-of-logarithm-processing-times based learning effect. Appl. Math. Model. 2010, 34, 2813–2819. [Google Scholar] [CrossRef]

- Pegels, C.C. On startup or learning curves: An expanded view. AIIE Trans. 1969, 1, 216–222. [Google Scholar] [CrossRef]

- Cheng, T.C.E.; Wu, C.C.; Lee, W.C. Some scheduling problems with sum-of-processing-times-based and job-position-based learning effects. Inf. Sci. 2008, 178, 2476–2487. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Teng, F.; Feng, Z.X. Scheduling jobs with truncated exponential sum-of-logarithm-processing-times based and position-based learning effects. Asia-Pac. J. Oper. Res. 2015, 32, 1857–1873. [Google Scholar] [CrossRef]

- Jong, J.R. The Effects Of Increasing Skill On Cycle Time And Its Consequences For Time Standards. Ergonomics 1957, 1, 51–60. [Google Scholar] [CrossRef]

- Ji, M.; Yao, D.; Yang, Q.; Cheng, T.C.E. Machine scheduling with DeJong’s learning effect. Comput. Ind. Eng. 2015, 80, 195–200. [Google Scholar] [CrossRef]

- Janiak, A.; Rudek, R. The learning effect: Getting to the core of the problem. Inf. Process Lett. 2007, 103, 183–187. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Geetha, M.; Tosun, Ö. An improved particle swarm optimization algorithm to solve hybrid flowshop scheduling problems with the effect of human factors—A case study. Comput. Oper. Res. 2020, 114, 104812. [Google Scholar] [CrossRef]

- Fazlollahtabar, H.; Hassanzadeh, R.; Mahdavi, I.; Mahdavi-Amiri, N. A genetic optimization algorithm and perceptron learning rules for a bi-criteria parallel machine scheduling. J. Chin. Inst. Ind. Eng. 2012, 29, 206–218. [Google Scholar] [CrossRef]

- Arigliano, A.; Ghiani, G.; Grieco, A.; Guerriero, E. Single-machine time-dependent scheduling problems with fixed rate-modifying activities and resumable jobs. 4or 2017, 15, 201–215. [Google Scholar] [CrossRef]

- Chung, T.; Gupta, J.N.D.; Qiu, M. Single machine scheduling problem with batch setups involving positional deterioration effects and multiple rate-modifying activities. Eng. Optim. 2019, 51, 1743–1760. [Google Scholar] [CrossRef]

- Rustogi, K.; Strusevich, V.A. Single machine scheduling with time-dependent linear deterioration and rate-modifying maintenance. J. Oper. Res. Soc. 2015, 66, 500–515. [Google Scholar] [CrossRef]

- Rustogi, K.; Strusevich, V.A. Combining time and position dependent effects on a single machine subject to rate-modifying activities. Omega 2014, 42, 166–178. [Google Scholar] [CrossRef]

- Sun, L.; Wu, B.; Ning, L. Parallel-Machine Scheduling with DeJong’s Learning Effect, Delivery Times, Rate-Modifying Activity, and Resource Allocation. Shock. Vib. 2021, 2021, 6687525. [Google Scholar] [CrossRef]

- Wang, J.-B.; Hu, Y.; Zhang, B. Common due-window assignment for single-machine scheduling with generalized earliness/tardiness penalties and a rate-modifying activity. Eng. Optim. 2021, 53, 496–512. [Google Scholar] [CrossRef]

- Zhao, C.; Tang, H. Single machine scheduling with a learning effect and a rate-modifying activity. Asia-Pac. J. Oper. Res. 2011, 28, 511–521. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, L.; Chu, F.; Liu, M. Due-window assignment and scheduling with multiple rate-modifying activities under the effects of deterioration and learning. Math. Probl. Eng. 2011, 2011, 151563. [Google Scholar] [CrossRef]

- Li, S.-S.; Chen, R.-X.; Feng, Q.; Jiao, C.-W. Parallel-machine scheduling with job-dependent cumulative deterioration effect and rejection. J. Comb. Optim. 2019, 38, 957–971. [Google Scholar] [CrossRef]

- Browne, S.; Yechiali, U. Scheduling deteriorating jobs on a single processor. Oper. Res. 1990, 38, 495–498. [Google Scholar] [CrossRef]

- Xingong, Z.; Guangle, Y. Single-machine group scheduling problems with deteriorated and learning effect. Appl. Math. Comput. 2010, 216, 1259–1266. [Google Scholar] [CrossRef]

- Wu, C.-C.; Azzouz, A.; Chung, I.-H.; Lin, W.-C.; Ben Said, L. A two-stage three-machine assembly scheduling problem with deterioration effect. Int. J. Prod. Res. 2019, 57, 6634–6647. [Google Scholar] [CrossRef]

- Rostami, M.; Nikravesh, S.; Shahin, M. Minimizing total weighted completion and batch delivery times with machine deterioration and learning effect: A case study from wax production. Oper. Res. 2020, 20, 1255–1287. [Google Scholar] [CrossRef]

- Lee, H.-T.; Yang, D.-L.; Yang, S.-J. Multi-machine scheduling with deterioration effects and maintenance activities for minimizing the total earliness and tardiness costs. Int. J. Adv. Manuf. Technol. 2013, 66, 547–554. [Google Scholar] [CrossRef]

- Lee, H.-T.; Yang, S.-J. Parallel machines scheduling with deterioration effects and resource allocations. J. Chin. Inst. Ind. Eng. 2012, 29, 534–543. [Google Scholar] [CrossRef]

- Janiak, A.; Rudek, R. Scheduling jobs under an aging effect. J. Oper. Res. Soc. 2010, 61, 1041–1048. [Google Scholar] [CrossRef]

- Pan, E.; Wang, G.; Xi, L.; Chen, L.; Han, X. Single-machine group scheduling problem considering learning, forgetting effects and preventive maintenance. Int. J. Prod. Res. 2014, 52, 5690–5704. [Google Scholar] [CrossRef]

- Seidgar, H.; Abedi, M.; Rad, S.T. A new mathematical model for scheduling flexible flow shop problem with learning and forgetting effects of workers. Int. J. Ind. Syst. Eng. 2015, 21, 534–549. [Google Scholar] [CrossRef]

- Yang, W.H.; Chand, S. Learning and forgetting effects on a group scheduling problem. Eur. J. Oper. Res. 2008, 187, 1033–1044. [Google Scholar] [CrossRef]

- Wu, C.-H.; Lai, P.-J.; Lee, W.-C. A note on single-machine scheduling with sum-of-processing-time-based learning and forgetting effects. Appl. Math. Model. 2015, 39, 415–424. [Google Scholar] [CrossRef]

- Wu, C.-H.; Lee, W.-C.; Lai, P.-J.; Wang, J.-Y. Some single-machine scheduling problems with elapsed-time-based and position-based learning and forgetting effects. Discret. Optim. 2016, 19, 1–11. [Google Scholar] [CrossRef]

- Mosheiov, G. Scheduling problems with a learning effect. Eur. J. Oper. Res. 2001, 132, 687–693. [Google Scholar] [CrossRef]

- Bai, D.; Bai, X.; Yang, J.; Zhang, X.; Ren, T.; Xie, C.; Liu, B. Minimization of maximum lateness in a flowshop learning effect scheduling with release dates. Comput. Ind. Eng. 2021, 158, 107309. [Google Scholar] [CrossRef]

- Eren, T. Human and machine effects in a just-in-time scheduling problem. Hum. Factors Ergon. Manuf. 2009, 19, 294–299. [Google Scholar] [CrossRef]