Abstract

The assignment problem is a problem that takes many forms in optimization and graph theory, and by changing some of the constraints or interpreting them differently and adding other constraints, it can be converted to routing, distribution, and scheduling problems. Showing such correlations is one of the aims of this paper. For some of the derived problems having exponential time complexity, the question arises of their solvability for larger instances. Instead of the traditional approach based on the use of approximate or stochastic heuristic methods, we focus here on the direct use of mixed integer programming models in the GAMS environment, which is now capable of solving instances much larger than in the past and does not require complex parameter settings or statistical evaluation of the results as in the case of stochastic heuristics because the computational core of software tools, nested in GAMS, is deterministic in nature. The source codes presented may be an aid because this tool is not yet as well known as the MATLAB Optimisation Toolbox. Benchmarks of the permutation flow shop scheduling problem with the informally derived MIP model and the traveling salesman problem are used to present the limits of the software’s applicability.

1. Introduction

The Assignment Problem (abbreviated to AP) [1] and its mathematical model is a problem that is the basis of the field of combinatorial optimization [2,3]. The problem in its basic form has been successfully handled by the discovery of Harold Kuhn, who proved that his method [4], derived from the results of the theoretical work of the Hungarian mathematicians Dénes König and Jenö Egerváry and dubbed the Hungarian method in their honor, finds a solution in polynomial time [5] in an efficient implementation.

However, this does not make the assignment problem less interesting because it has many analogs in bipartite graph matching problems of the graph theory [5,6].

The assignment problem is most extensively addressed in [5,7], where we find theoretical foundations for the existence of perfect matching, implementation details for the Hungarian method, and a number of other related problems such as the k-cardinality assignment problem, the semi-assignment problem, the bottleneck assignment problem, the algebraic assignment problem, quadratic assignment problems, and multi-index assignment problems.

These are still variants closely related in meaning to the basic version of the matching problem, although the time complexity may no longer be polynomial, and, in the case of the quadratic matching problem, it is a non-linear problem.

In this paper, however, we focus on similarities of a different kind, namely in the mathematical model, where a completely different relationship to the underlying problem may be found because it allows, often with small modifications, for expressing problems from a different application domain, to switch between linear, mixed integer, and even non-linear problem classes, thus changing its computational complexity and solvability.

Perhaps the most well-known combinatorial optimization problem, the Travelling Salesman Problem [8], is a slight modification of this, with the Vehicle Routing Problem [9] also stemming from this. On the other hand, from the assignment problem, with other modifications, we can easily move to logistic distribution operations [10], agricultural applications [11], set covering problems [12] with many interesting applications in telecommunications [13], and scheduling problems [14].

Concerning two selected problems of exponential complexity, the Travelling Salesman Problem (TSP) and the Permutation Flow Shop Scheduling Problem (PFSSP) [15], we will also deal with their solvability. We have very good experience in solving sets covering problems of complexity [13] using GAMS (General Algebraic Modelling System), where it is possible to find the optimal solution in the available time even for instances with matrices of hundreds of rows and thousands of columns, and it has also proven itself in solving the problem of finding the Steiner minimum tree in networks, which also has exponential time complexity.

Since the two problems mentioned above are permutational in nature with the factorial time complexity, they are more challenging than the set covering problems.

For extremely large TSP instances (many hundreds of cities), heuristics must be used, e.g., differential evolution [16], genetic algorithm [17,18,19,20], memetic search [21], simulated annealing [22], neural network [23], and improved neighbourhood search algorithms [24,25].

Many stochastic heuristics are inspired by the behaviour of animals in nature, e.g., deer [26], spider monkey [27], hyena [28], wolf [29], cuckoo [30,31], sparrow [32], frog [33], and ant colony [34].

On the other hand, stochastic heuristic methods are not suitable for TSP instances up to 100 cities because they may not find the optimal solution and the convergence time is often unsure, as, e.g., shown in the comparison of different methods in [28].

However, there are also approaches based on deterministic methods such as cutting plane [35], branch and bound [36] and branch and cut [37,38].

According to listings in the GAMS environment, the latter method is in some way incorporated into GAMS and, therefore, it makes sense to explore its limits of applicability. These, together with the GAMS source code, are discussed in detail in Section 6.

Scheduling problems seem far from the assignment problem. But one of them, the PFSSP, shares with the assignment problem a permutational nature in the ordering of jobs, where each job (with its operations) is assigned to exactly one position and each position can contain only one job (with its operations), which corresponds in the assignment problem to the fact that each task is assigned to a single worker and each worker solves only one task. There are additional constraints, and the aim is to minimize the total scheduling time (makespan), but we can still say that the derived PFSSP model is related to the assignment problem.

As in the case of the TSP, heuristic methods are used for large instances of different variants of flow shop scheduling problems, e.g., differential evolution [39], genetic algorithm [40,41], genetic programming [42], memetic algorithm [43], tabu-search [44], harmony search [45], iterated greedy algorithms [46,47,48], multi-local search [49], hybrid metaheuristics [50,51], reinforcement learning [52], fireworks algorithm [53], and also nature-inspired algorithms, e.g., ant colony optimization [54], firefly particle swarm optimization [55], migrating birds optimization [56] and whale swarm algorithm [57].

However, the exact methods [58,59], linear programming approach [60] and branch and bound [61], are also applicable so we will again focus on the usability of the GAMS tool.

2. The Assignment Problem Model

In most common problem formulation, we have n workers who need to be assigned n tasks in such a way that each worker is assigned a single task and each task is solved by a single worker.

For each worker-task pair, we know the time it takes the worker to complete the task. The task is to find an assignment that minimizes the total time to complete all tasks.

Let denote the time taken by the ith worker for the jth task. The decision variables are binary, if the ith worker is assigned the jth task, in the opposite case. Then, the problem can be formulated as follows:

subject to

Equation (2) ensures that each task is assigned to a single worker, and Equation (3) ensures that each worker is assigned a single task.

The assignment problem can also be viewed as a problem of finding a permutation

where ith worker is assigned to task and

Since the number of different permutations of n elements is , it is not possible to find the optimal solution for large instances in the available time by enumerating all possibilities. However, due to the Hungarian method mentioned above, we no longer use this approach.

3. Routing Problems

With a different interpretation of the variables and a possible extension of the constraints, the assignment problem changes into a series of other problems. In this section, we consider two routing problems.

3.1. Travelling Salesman Problem

The Travelling Salesman Problem (TSP) [8,62] is mathematically similar to the assignment problem model, differing only in one additional constraint, but the meaning of the decision variables is different. It is formulated as follows: Given n cities and distances among them, the objective is to find a round trip through all cities with a minimum length (alternatively, with a minimum total transportation cost).

Since the starting city 1 is fixed, the number of routes is given by the permutations of cities 2, 3, …, n, and is therefore equal to . If there are no one-way segments anywhere in the transportation between cities, routes in reverse order of cities do not affect the length, and then we can reduce the number of routes to , but still the time complexity of exploring all routes is .

If we denote by the distance between cities i and j (alternatively, the price of transportation between cities i and j), a binary decision variable that takes the value 1 when city j on the route immediately follows city i, otherwise it takes the value 0, is the order of city i on the route, then the Travelling Salesman Problem can be formulated as follows:

subject to

Constraints (6) and (7) ensure that each city (vertex of the graph) is traversed exactly once (entered and left exactly once); the system of subtour elimination constraints (8), referred to in the English literature by Miller, Tucker, and Zemlin as MTZ constraints, prevents the formation of subtours, as we will show below in Theorem 1.

Equation (8) follows from the following reasoning:

(i) If , then j is the immediate successor of i, and if , then . Hence, .

(ii) If , then and this difference in the order of the cities in the route for can be at most equal to .

From (i) and (ii), a common conclusion already follows, which, for all combinations of feasible values of i and j, is expressed by inequality (8).

Without the constraint (8), constraints (6) and (7) are satisfied by splitting the route into several subtours, e.g., for 15 vertices, the two conditions mentioned above are satisfied by the subtours , and .

Theorem 1.

Proof.

Suppose that satisfies the subtour elimination constraints but does not form a Hamiltonian circle. Then due to (6) and (7) form at least two subtours, one containing the initial vertex 1 and another without it. Let S be a subtour that does not contain vertex 1 and let be the set of edges in S. Summing the conditions over the edges of we get:

since the values of and eliminate each other in this subtour, we get

which is a contradiction.

Assume now that forms a Hamiltonian circle. If 1 is the initial vertex of this circle, and for each vertex , , if i is the kth vertex of the Hamiltonian circle, then it is clear that the conditions (8) are satisfied. □

3.2. Vehicle Routing Problem

A generalization of the Travelling Salesman Problem is the Vehicle Routing Problem (VRP) [9,63,64,65,66] where a desired quantity of goods needs to be delivered from a central depot to customers by vehicles of a certain capacity.

We are looking for closed routes of individual vehicles that start and end at the depot, each customer is served exactly once by exactly one vehicle, the requirements of all customers are met and the total transport costs are minimal.

Consider the following notation:

number of customers

depot (start and end of each vehicle’s route)

number of (identical) vehicles

request of the jth customer (for depot )

vehicle capacity

the cost of transport from i to j ()

binary decision variable equal to 1 if j is immediately followed by i on the route,

otherwise

the load left in the vehicle after visiting customer i.

subject to

In the model, (11) and (12) ensure that exactly one vehicle arrives at each customer (11) and exactly one vehicle leaves it (12). Equations (13) and (14) ensure that all K vehicles return to the depot (13) and all K vehicles leave the depot (14).

Equation (16) is analogous to the MTZ constraints in the Travelling Salesman Problem preventing the formation of partial circuits and at the same time ensuring that the requirements of customers i and j can be met when traveling from i to j [67].

The Vehicle Routing Problem has many other specific formulations, e.g., there may be a larger number of depots available, and customers are only ready to receive delivery of goods at certain time intervals. For more details, see the sources listed at the beginning of this section.

4. Distribution Problems

Distribution problems have many different formulations, first, we consider the classical Hitchcock’s Transportation/Transshipment Problem with m suppliers (sources, warehouses) and n customers (consumers), where we assume the transportation of a single type of material (goods) with an objective to minimize the total cost of transporting the material [68].

Assume the following notation:

… capacity (stocks) of suppliers,

… customer requirements,

… the matrix of rates for the transport of a unit quantity between the ith supplier and the jth customer,

…the sought quantity transported between the ith supplier and the jth customer.

If total stocks are equal to total requirements, this means:

we are talking about a balanced distribution problem, where all stocks are exhausted and all demands are met, and the following mathematical model corresponds to this:

subject to

Equation (20) corresponds to the stock drawdown, and Equation (21) expresses the fulfillment of requirements.

Obviously, the assignment problem is a special case of the balanced transportation problem, where:

However, the balanced case is rare in practice, usually, total stocks exceed total requirements, i.e.,

In this case, all requirements can be met, but not every stock will be used up. The model then changes as follows:

subject to

In the case of material shortages, the opposite situation may occur, where the total stock is insufficient for the total requirements, i.e.,

This means that stocks are used up but not all requirements can be met. The model must then be modified as follows:

subject to

4.1. Container Transportation Problem

The Container Transportation Problem is a special case of Hitchcock’s transportation problem, where we assume that materials from suppliers to customers are transported only in containers of a certain capacity. Instead of rates per unit of material transported, there are prices per container transported, being fixed even if the container is not completely full.

From the previous three possibilities for the sum of all stocks and the sum of all requirement relations, the case of the stocks being sufficient to meet all the requirements is given here.

Assume that K is the capacity of the container and gives the number of containers needed for the quantity of material . Obviously, must be integers, the last container to reach the quantity need not be full.

Then, the container transportation problem for all requirements met can be formulated as the following model:

subject to

4.2. Allocation Problem

For the transportation problem described in Section 4, it was possible to provide the required quantity by composing partial quantities from different suppliers (from different warehouses) when fulfilling the requirements.

However, in the Allocation Problem, it is required that the required quantity is provided from a single location so the mathematical model of the transportation problem has to be modified by [10] to account for this condition. With the same notation used for the symbols, the meaning of the decision variables is now different. They only assume binary values and if the quantity required by the jth customer is sourced from the ith supplier, if not, .

If more than one customer receives the required quantity from the same supplier, the sum of their requirements must not exceed the capacity of that supplier (stock).

The model of the allocation problem with these conditions then takes the following form:

subject to

4.3. Location Problem

The Location Problem is an extension of the allocation problem [12]. For clarity, let us first summarize all the symbols used.

Consider m locations with capacities that can be used to operate warehouses supplying n customers with demands . The operation of the warehouse at the ith location requires a cost for the given period. Let be the cost of the jth customer being assigned to get the required quantity from the ith location.

The aim is to decide in which locations to operate the warehouses and to find the assignment of customers to the operated warehouses so that the value of the total cost of operating the system is minimal. Like in the allocation problem, we assume that the demands of each consumer must be covered from a single warehouse.

Therefore, the meaning of the binary decision variables is analogous to the allocation problem, , if the quantity required by the jth customer is provided from the warehouse at the ith location, if not, .

In addition, there are other binary decision variables , where means that the warehouse at the ith location will be operated and, if , it will not be operated there.

The model of the location problem with these conditions has the following form:

subject to

As in the allocation problem, the condition (44) means that each customer takes the entire requested quantity from a single location, the condition (46) monitors the non-overstocking of individual locations by customers receiving the requested quantity from the same location.

Let us have a look at condition (45). The left and right sides are binary variables with the inequality satisfied for the combinations , and , but not for the combination . This ensures that no customer can get anything from a location where the warehouse will not be operated.

It is clear that, for all combinations of indices i and j, (45) represents a system of conditions. Expressing this for the values of the indices j, we get:

Summing up the previous inequalities, we get:

and hence

4.4. Capacitated Network Area Coverage

Let us consider two finite sets I and J, where I is the set of service centers , and J is the set of customer locations .

Further, means that customer location j is in a reachable distance to service center i, means that it does not satisfy it, and expresses the weights of service centers (since it is the minimization problem, the greater the weights are, the smaller the coefficient must be).

Similarly, means that service centre i is selected, while means that it is not selected.

Finally, —capacity of service centre i, —demand of customer location j, —customer from location j is assigned or is not assigned to service centre i.

In [13], we derived the following model for a capacitated network area coverage:

subject to

A necessary precondition for finding a solution is that the sum of all capacities is sufficient to cover all demands, i.e., , with each customer having a reachable distance to at least one center, i.e., .

In [13], we then modified the previous model for the domain of telecommunication signals considering signal interference and its nonlinear version linearized as follows:

subject to

Another possible modification of the model is to meet the demand by composing parts of the capacities of several centers, but with a fragmentation not lower than a certain threshold. This new approach will be presented in detail in a separate paper.

4.5. Transportation Problem with Supply from Primary Source

Consider now a transportation network where, in addition to locations with warehouse stocks and customer requirements, there will also be a primary source, which can represent the location of the transported commodity or a global warehouse, and customers can be supplied both from local warehouses and directly from the primary source.

Assume the constraints and denotations from the location problem and two types of transportation equipment, one with a larger capacity from the primary source to local warehouses and a cost per 1 km of travel, and the other with a smaller capacity to customers and a cost per 1 km. Denoting the distance from the primary source to the ith local storage by , and the distance from the primary source to the jth customer by , we add binary decision variables to indicate whether the jth customer receives the desired quantity directly from the primary source (in the positive case , otherwise ), the model with primary source and transportation technique information has the following form:

subject to

The fractions in the objective function according to (69) indicate how many times the distance must be traveled for the customer to receive the required quantity. Since the fractions may have non-integer values, they must be rounded up to integers, the corresponding capacity may not be fully used for the last trip. The expression with the first summation in the objective function corresponds to the total cost of moving material from the primary source directly to customers, and the expression with the double summation in the objective function corresponds to the total cost of moving material from the primary source to local warehouses and from there on to the customers.

If, instead of the conditions of the location problem, the simpler conditions of the allocation problem were assumed (i.e., dropping the decision as to whether or not to use a location for storage), the previous model would be simplified, the conditions (71) and (74) would be dropped and would be omitted in the last term of the objective function (i.e., the fixed costs of all locations would be included).

4.6. Crop Problem

In plant production, an important task is to find a method of sowing the land with agricultural crops (cultures) in such a way that, given the expected yield of crops on the land and the profit from the sale of individual crops, the total profit is maximised.

Assume the following notation:

… grounds,

… area of grounds (plays the role of available capacities),

… agricultural crops (cultures),

… profit from 1 ha of ground , sown with culture

… number of hectares of ground sown with crop .

The mathematical model of the Crop Problem is similar to the basic version of the transportation problem with unbalanced capacities (the ground areas may not be fully used), but it lacks a set of constraints corresponding to the fulfillment of the requirements with the difference that the problem being a maximization one. It takes the following form:

subject to

Equation (77) expresses the use of grounds, which corresponds to the drawdown of supplier stocks in the distribution problem.

If we required each crop j to be sown on some minimum area , then the problem would become an example of the maximization version of the generalized distribution problem and the model would be modified as follows:

subject to

5. Scheduling Problems

Scheduling problems are numerous and varied. They arise in diverse areas such as flexible manufacturing systems, production planning, computer design, logistics, timetabling, communication, etc. [14].

Here we focus on one of them, the Permutation Flow Shop Scheduling Problem (PFSSP), which, like the Assignment problem and the Traveling Salesman Problem, is permutational in nature.

It can be briefly described as follows: There are a set of m machines (processors) and a set of n jobs. Each job comprises a set of m operations which must be done on different machines. All jobs have the same processing operation order when passing through the machines. There are no precedence constraints among operations of different jobs. Operations cannot be interrupted, and each machine can process only one operation at a time. The problem is to find the job sequences on the machines which minimizes the makespan (i.e., the maximum completion times of all operations).

Mathematical Model of PFSSP

Consider three finite sets J, M, O where J is a set of jobs , M is a set of machines , and O is a set of operations .

Denote:

… the ith job in the permutation of jobs

… processing time of the job on machine k

Define the following decision variables:

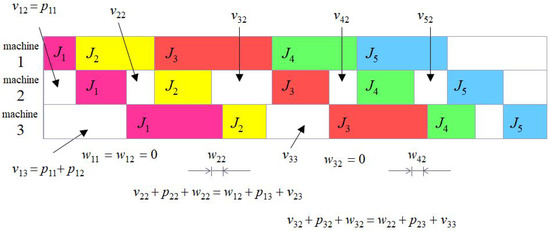

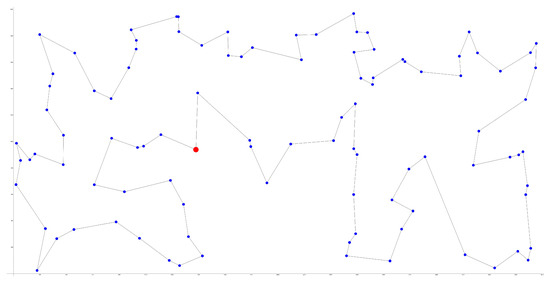

Figure 1 illustrates the use of the variables and on an example with 5 jobs and 3 machines.

Figure 1.

Meaning of the variables and .

From Figure 1, we can draw some more general conclusions:

- The first task in a permutation can always continue the next operation on the next machine without delay because it does not wait for the completion of any other operation.

- It follows from the previous conclusion that waiting times to start the operation of the first task in the permutation on the second and subsequent machines are given by the sum of the durations of the operations of that task on the previous machines.

- Equalities of 3 addition terms in Figure 1 can be generalized into a Gantt chart between all pairs of neighboring machines.

- The duration of the entire schedule (makespan) is given by the sum of the waiting times for the start of operations on the last machine and the duration of these operations.

All verbal conclusions are expressed formally by the following system of equations:

6. Computational Results

From the above problems, we select two, TSP and PFSSP, that are NP-hard in the decision versions [69,70].

To give an idea of the cardinality of the search space of these permutation problems, we present a few factorials as follows:

10! = 3628800 ≈ 3.6 × 10

20! = 2432902008176640000 ≈ 2.4 × 10

30! = 265252859812191058636308480000000 ≈ 2.6 × 10

40! = 815915283247897734345611269596115894272000000000 ≈ 8.1 × 10

50! ≈ 3 × 10

…

100! ≈ 9.3 × 10

The traditional approaches to such problems are based on computations using heuristic methods [71,72] for large instances such as genetic algorithms, simulated annealing, tabu search, differential evolution [73], firefly algorithm, particle swarm optimization, and ant colony optimization. Then, statistical tests are applied to examine at a certain significance level (e.g., ), to what extent the mean value of the results obtained by different methods and different settings of their parameters at a larger number of runs is the same or different (and, therefore, one of the methods gives better results). For the t-test, we assume that the sets of values have a normal distribution. However, this assumption may be false, and then one of the non-parametric tests, such as the Wilcoxon test, must be used.

Since, given the validity of the No Free Lunch Theorem [74,75], one should not expect a general conclusion that any of the heuristics for each problem instance gives better results than other heuristics.

In this paper, we do not explore heuristics using instead a mixed integer programming model with software tools built as solvers in the GAMS environment [76,77] to find an exact solution by deterministic computation.

Statistical evaluations are, therefore, meaningless here. What can be said, however, is that the power of this software today is considerably greater than it was 20 years ago, when, in our experience, for a problem with a complexity of , the system ended up with a runtime error and the message “insufficient space to update U-factor …”. The performance of GAMS has been steadily increasing over the years, although the source code of the solvers is not freely available, from [78] it can at least be seen that it includes, among others, CPLEX, GUROBI, Lindo, and the results of the work of academic departments of Princeton University, Stanford University, and Zuse Institute Berlin. Today, GAMS calculates the exact solution for PFSSP with 20 jobs on a laptop with Intel(R) Core(TM) i5-10210U CPU @ 1.60 GHz 2.11 GHz processor, 8 GB operational memory and 64-bit operating system in less than 3 min, as shown in the following subsection.

Of course, with a computer of better technical parameters for the same time limit we get results for larger instances of the problem, but it seems to be better to use a heuristic beyond this boundary, e.g., our GA ’war elimination’ modification [79].

Since PFSSP has a more complex model than TSP, we start with it and include its complete GAMS code.

6.1. PFSSP Computational Results

For PFSSP with 10 jobs, 6 machines, processing times from the TABLE section (it corresponds to the first benchmark in Table 1) and the model given by Equations (84)–(89), the program code in GAMS can be, e.g., as follows:

Table 1.

GAMS computational results ( corresponds to 10 jobs and 6 machines, etc.; t-l-e = time limit exceeded).

* Permutation flow shop scheduling problem

$TITLE permutation flow shop scheduling problem

$OFFSYMXREF

$OFFUELLIST

$OFFUELXREF

OPTION ITERLIM=200,000

* ITERLIM number of iterations

OPTION OPTCR=0.00001

*OPTION OPTCR=0.001

* OPTCR stopping in MIP in case the best solution is within the limits

* 100*OPTCR% of the global~extreme

* section defining indexes

SETS

I jobs /1*10/

K machines /1*6/;

ALIAS(I,J);

* J - position of the job in the permutation

ALIAS(K,R);

* input data section

PARAMETERS

N,M;

N=CARD(I);

M=CARD(K);

TABLE P(I,K)

1 2 3 4 5 6 1 333 991 996 123 145 234 2 333 111 663 456 785 532 3 252 222 222 789 214 586 4 222 204 114 876 752 532 5 255 477 123 543 143 142 6 555 566 456 210 698 573 7 558 899 789 124 532 12 8 888 965 876 537 145 14 9 889 588 543 854 247 527 10 999 889 210 632 451 856;

*variables section (decision variables and objective function)

VARIABLES

X(I,J) is 1 if job j is assigned to position i in the permutation, 0, otherwise

V(I,K) waiting time on machine k before the start of job i in the permutation

W(I,K) waiting time of job i in the permutation after finishing processing

* on machine k, while machine k+1 becomes free

Cmax total processing time for all tasks (makespan);

BINARY VARIABLE X;

NONNEGATIVE VARIABLE V;

NONNEGATIVE VARIABLE W;

*section describing the system of (in)equalities

EQUATIONS

EQ1(I)

EQ2(J)

EQ3(K)

EQ4(K)

EQ5(I,K)

OBJFCE(K);

EQ1(I) .. SUM(J,X(I,J)) =E= 1;

EQ2(J) .. SUM(I,X(I,J)) =E= 1;

EQ3(K)$(ORD(K) LE (M-1)) .. W(“1”,K) =E= 0;

EQ4(K)$(ORD(K) GE 2)

.. V(“1”,K) =E= SUM((R,I)$(ORD(R) LE (ORD(K)-1)),P(I,R)*X(“1”,I));

EQ5(I,K)$((ORD(I) LE (N-1)) AND (ORD(K) LE (M-1)))

.. V(I+1,K)+SUM(J,P(J,K)*X(I+1,J))+W(I+1,K) =E=

W(I,K)+SUM(J,P(J,K+1)*X(I,J))+V(I+1,K+1);

OBJFCE(K)$(ORD(K) EQ M) .. Cmax =E= SUM(I,V(I,K)+SUM(J,P(J,K)*X(I,J)));

*description of the model, running the solver, and displaying the results

MODEL FLOWSHOP /ALL/;

SOLVE FLOWSHOP USING MIP MINIMIZING Cmax;

DISPLAY X.L, V.L, W.L, Cmax.L;

The ability to compute optimal solutions was checked using standard benchmarks from OR-Library (OR = Operations Research) accessible at Brunel University London [80], originally described in [81]. The computational results are summarised in Table 1. For instances with 30 or more jobs, GAMS does not find the optimal solution in the 1000 s time limit, but only a “close” approximation, which, however, differs by less than 10% even for the last instance , where the optimal value is unknown due to the huge size of the search space and is only estimated by the interval. For such cases, we at least suggest a solution method using the genetic algorithm [82].

To do this, we will need a model that builds an appropriate schedule for the permutation. The genetic algorithm will then select a promising part of the search space of permutations in which a good approximation of the optimum can be found in a reasonable amount of time.

If we have processing times for job i on machine j, and a job permutation , then we can calculate the completion times as follows:

As the genetic algorithms [79] are well known, we only summarise parameter settings and describe only the problem-specific operators in more detail.

The fitness function is inversely proportional to the makespan, the smaller the makespan, the higher the value of the fitness function.

The number of individuals in the population was set to 50 and the number of iterations to . The initial population was generated randomly, and the parents for the crossover operation were determined by binary tournament selection.

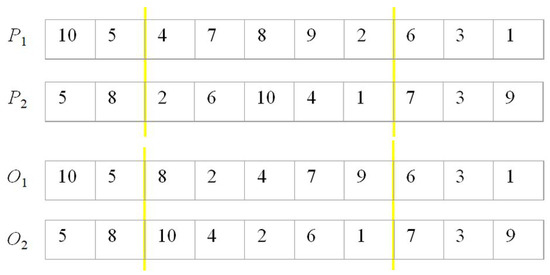

As to the crossover operation, we cannot use the traditional two-point crossover, because it would lead to infeasible solutions. If we change the middle parts of the parent chromosomes and in Figure 2, we will obtain offspring (10,5,2,6,10,4,1,6,3,1) and (5,8,4,7,8,9,2,6,3,1) that correspond to no permutations, because some jobs are duplicated or omitted. We used what is called crossover in a partially mapped representation where the genes in the middle part of one chromosome are ordered in its offspring by their occurrence in the second parent chromosome.

Figure 2.

Modified two-point crossover.

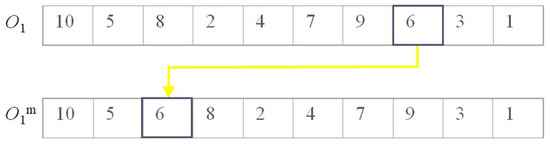

From the possible mutation operations, we have selected the shift mutation, which removes a value at one position and puts it at another position), see Figure 3.

Figure 3.

Shift mutation.

The offspring of the parents replaced two randomly selected individuals with below-average fitness function values.

With the above parameter settings, the results for the last 4 instances in Table 1 were obtained as shown in Table 2. The average values from 30 runs are presented here, as well as the best values obtained from them, which for these large instances are better than the values obtained from GAMS when the 1000 s timeout expires. All these results were achieved in less than 10 s because of the small number of iterations of the genetic algorithm.

Table 2.

GA computational results—average and the best result from 30 runs, optimum.

6.2. TSP Implementation in GAMS

In describing the source code in GAMS and verifying its computational abilities, we use three benchmarks from the TSPlib library [83] with 24, 52, and 100 cities, or positions in the map given by coordinates.

The following code is written for the gr24.tsp benchmark. Since the adjacency matrix is symmetric, only the data of the lower triangular matrix are entered with the remaining data calculated. The EQUATIONS section is a rewrite of the TSP model and its Equations (5)–(8). The binary domain, corresponding to Equation (9), is given by the declaration that precedes this section.

$TITLE Travelling Salesman Problem

OPTION ITERLIM=10000000;

OPTION OPTCR=0;

SETS

I /1*24/;

ALIAS (I,J);

PARAMETERS

N;

N=CARD(I);

TABLE C(I,J) adjacency matrix

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 0 2 257 0 3 87 196 0 4 91 228 158 0 5 150 112 96 120 0 6 80 196 88 77 63 0 7 130 167 59 101 56 25 0 8 134 154 63 105 34 29 22 0 9 243 209 286 159 190 216 229 225 0 10 185 86 124 156 40 124 95 82 207 0 11 214 223 49 185 123 115 86 90 313 151 0 12 70 191 121 27 83 47 64 68 173 119 148 0 13 272 180 315 188 193 245 258 228 29 159 342 209 0 14 219 83 172 149 79 139 134 112 126 62 199 153 97 0 15 293 50 232 264 148 232 203 190 248 122 259 227 219 134 0 16 54 219 92 82 119 31 43 58 238 147 84 53 267 170 255 0 17 211 74 81 182 105 150 121 108 310 37 160 145 196 99 125 173 0 18 290 139 98 261 144 176 164 136 389 116 147 224 275 178 154 190 79 0 19 268 53 138 239 123 207 178 165 367 86 187 202 227 130 68 230 57 86 0 20 261 43 200 232 98 200 171 131 166 90 227 195 137 69 82 223 90 176 90 0 21 175 128 76 146 32 76 47 30 222 56 103 109 225 104 164 99 57 112 114 134 0 22 250 99 89 221 105 189 160 147 349 76 138 184 235 138 114 212 39 40 46 136 96 0 23 192 228 235 108 119 165 178 154 71 136 262 110 74 96 264 187 182 261 239 165 151 221 0 24 121 142 99 84 35 29 42 36 220 70 126 55 249 104 178 60 96 175 153 146 47 135 169 0;

SET C2(I,J);

C2(I,J)$(NOT SAMEAS(I,J)) = yes;

C(C2(I,J)) = MAX(C(I,J),C(J,I));

VARIABLES

X(I,J)

delta(I)

Z;

BINARY VARIABLE X(I,J);

EQUATIONS

EQ1(J) each city is entered exactly once

EQ2(I) each city is left exactly once

EQ3(I,J) subtour elimination constraints

EQ4 objective function;

EQ1(J) .. SUM(I,X(I,J)$(ORD(I) NE ORD(J))) =E= 1;

EQ2(I) .. SUM(J,X(I,J)$(ORD(I) NE ORD(J))) =E= 1;

EQ3(I,J)$((ORD(I) GE 2) AND (ORD(J) GE 2) AND (ORD(I) NE ORD(J)))

.. delta(I)-delta(J)+N*X(I,J) =L= N-1;

EQ4 .. Z =E= SUM((I,J),C(I,J)*X(I,J));

MODEL TSP/ALL/;

SOLVE TSP USING MIP MINIMIZING Z;

DISPLAY X.L, Z.L;

The total length of the route is 1272, the decision variables have a value of 1 in the following order: , , , , , , , , , , , , , , , , , , , , , , , , and, thus, the circuitous route passes through cities 1, 16, 11, 3, 7, 6, 24, 8, 21, 5, 10, 17, 22, 18, 19, 15, 2, 20, 14, 13, 9, 23, 4, 12, 1, which is in agreement with the published result for the gr24 benchmark. The calculation time was 0.36 s.

The data for the berlin52.tsp benchmark are entered differently, namely as a matrix with 52 rows and 2 columns, where the 1st column is the value of the x-coordinate and the 2nd column is the value of the y-coordinate. The adjacency matrix in this case is obtained by calculating the Euclidean distances between all pairs of positions. This part of the code takes the following form, the rest is the same as in the previous code.

SETS

I /1*52/;

ALIAS (I,J);

PARAMETERS

N;

N=CARD(I);

TABLE XY(I,*)

1 2 1 565.0 575.0 2 25.0 185.0 3 345.0 750.0 4 945.0 685.0 5 845.0 655.0 6 880.0 660.0 7 25.0 230.0 8 525.0 1000.0 9 580.0 1175.0 10 650.0 1130.0 11 1605.0 620.0 12 1220.0 580.0 13 1465.0 200.0 14 1530.0 5.0 15 845.0 680.0 16 725.0 370.0 17 145.0 665.0 18 415.0 635.0 19 510.0 875.0 20 560.0 365.0 21 300.0 465.0 22 520.0 585.0 23 480.0 415.0 24 835.0 625.0 25 975.0 580.0 26 1215.0 245.0 27 1320.0 315.0 28 1250.0 400.0 29 660.0 180.0 30 410.0 250.0 31 420.0 555.0 32 575.0 665.0 33 1150.0 1160.0 34 700.0 580.0 35 685.0 595.0 36 685.0 610.0 37 770.0 610.0 38 795.0 645.0 39 720.0 635.0 40 760.0 650.0 41 475.0 960.0 42 95.0 260.0 43 875.0 920.0 44 700.0 500.0 45 555.0 815.0 46 830.0 485.0 47 1170.0 65.0 48 830.0 610.0 49 605.0 625.0 50 595.0 360.0 51 1340.0 725.0 52 1740.0 245.0;

PARAMETERS C(I,J);

SET C2(I,J);

C2(I,J)$(NOT SAMEAS(I,J)) = yes;

C(C2(I,J)) = ROUND(SQRT(SQR(XY(I,’1’)-XY(J,’1’))+SQR(XY(I,’2’)-XY(J,’2’))));

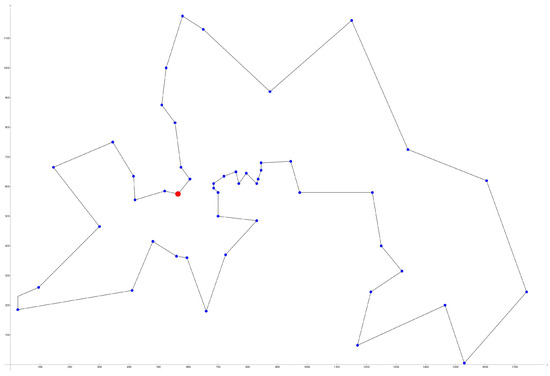

The total length of the route is 7542, the calculation time was 1.45 s and the circuitous route passes through positions 1, 49, 32, 45, 19, 41, 8, 9, 10, 43, 33, 51, 11, 52, 14, 13, 47, 26, 27, 28, 12, 25, 4, 6, 15, 5, 24, 48, 38, 37, 40, 39, 36, 35, 34, 44, 46, 16, 29, 50, 20, 23, 30, 2, 7, 42, 21, 17, 3, 18, 31, 22, 1. The optimal route can be seen in Figure 4.

Figure 4.

The optimal route for the berlin52.tsp benchmark.

Finally, GAMS for the kroA100.tsp benchmark stopped the computation at 1000.02 s by exceeding the time limit, but the intermediate result of the path length 21282 and its traversal through positions 1, 47, 93, 28, 67, 58, 61, 51, 87, 25, 81, 69, 64, 40, 54, 2, 44, 50, 73, 68, 85, 82, 95, 13, 76, 33, 37, 5, 52, 78, 96, 39, 30, 48, 100, 41, 71, 14, 3, 43, 46, 29, 34, 83, 55, 7, 9, 57, 20, 12, 27, 86, 35, 62, 60, 77, 23, 98, 91, 45, 32, 11, 15, 17, 59, 74, 21, 72, 10, 84, 36, 99, 38, 24, 18, 79, 53, 88, 16, 94, 22, 70, 66, 26, 65, 4, 97, 56, 80, 31, 89, 42, 8, 92, 75, 19, 90, 49, 6, 63, 1 corresponds to the known optimal solution for this benchmark. The optimal route is in Figure 5.

Figure 5.

The optimal route for the kroA100.tsp benchmark.

For instances with more than 100 positions, it would be necessary to search for an approximation of the optimum using one of the heuristic methods.

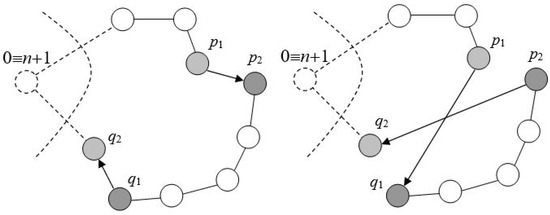

One of the first was the use of the so-called Lin-2-Opt change operator [8], see Figure 6. Here, two elements are added to the permutation of n cities to visit (into positions 0 and ), and then the starting city is assigned to those positions to simulate a cyclic tour. Two ’edges’ (pairs of neighbouring elements in permutation) are randomly chosen and say), the inner elements , are swapped and the elements between and are reversed.

Figure 6.

Lin-2-Opt change neighbourhood operation.

Positions 0 and with the fixed value of the starting city can also be used to expand the individuals in the population of the genetic algorithm and then apply the operations presented for the PFSSP.

However, we no longer investigate this for extremely large instances of the TSP problem because heuristics do not guarantee finding an optimal solution, which often is not even known here, and the aim was to find bounds for which we still obtain the precise solution in reasonable time using a ’normal’ computer. In the case of GAMS, this bound is an instance with 100 cities.

6.3. Data, Changes in Time, Uncertainty

Data from OR-Library and TSPLIB are related to a specific point in time, in reality they may change over time or may not be completely known.

A more general case of the Travelling Salesman Problem is the Canadian Traveller Problem (CTP) [84,85]. Here, the distance matrix may change over time due to the occurrence of events that make some parts of the route inaccessible so that an adaptive strategy must be found. These events are random in nature, which corresponds to the problems of robot navigation in environments where the distribution of obstacles is only discovered as the robot moves through the environment; moreover, the obstacles may move, and thus the locations of potential collisions change dynamically.

In transport tasks, the values of some parameters can change over time, the fuel price is not constant, and the vehicle consumption can only be estimated because it can change according to the traffic situation and the season, which will affect, e.g., the calculation of the objective function (69). Similarly, in the crop problem, we can only estimate crop yields.

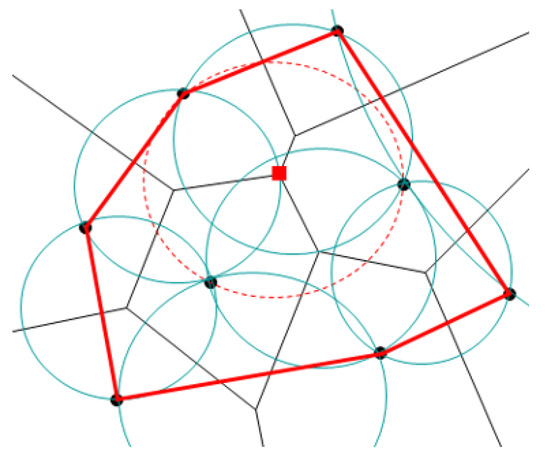

In location-based tasks, the problem may arise of adding another center to an existing network of centers to improve the coverage of an area. An example might be an expansion of the existing supermarket network of a chain store. Here it is suggested to use one of the properties of the Voronoi diagram [86,87], a data structure known from computational geometry: Assume a Voronoi diagram with its sites represented by the current centers. The point q is the vertex of the Voronoi diagram if and only if the largest empty circle contains three (or more in a degenerate case) sites on its boundary and none inside. Among these circles, we determine the one with the largest diameter, and its center is then the optimal position for the location of the new center, see Figure 7.

Figure 7.

Finding a new location using the largest empty circles.

In fact, the calculated position may not be available, the cost of building here may be too high, thus a suitable nearby location must be found, or the center of one of the other empty circles must be chosen in descending order of diameters.

Another issue is the amount of inventory in logistics operations. The stock changes over time according to demand and needs to be replenished accordingly. We speak about inventory management and the resulting sustainability [88,89,90,91]. However, demands are stochastic in nature and, in addition, inventory management must take into account the cost of maintaining inventory and losses from premature depletion of inventory for undelivered goods.

In [92], a new mathematical model is derived, the properties of the profit function are proved, and the profitability in a two-channel production system considering carbon emissions and green technology is numerically verified on specific data.

While artificial neural networks (ANN) have very little application in combinatorial optimization, their main use is in cluster analysis, pattern recognition, image processing and prediction, in [93] the authors present an efficient implementation of ANNs in an inventory management model under uncertainty and inflation.

In [94] the unreliability of the supply chain and methods to eliminate this unreliability are explored, and the required mathematical equations are derived and verified by numerical experiments, including sensitivity analysis.

However, all these aspects are beyond the scope of this paper and can be the subject of separate texts as also evidenced by the papers mentioned.

7. Conclusions

This paper studies the assignment problem and its modifications with logistics applications, in routing, distribution, and scheduling tasks. Its first contribution is the correlation of the problem models, which are often distant in nature and time complexity.

It has also shown how the described models can be directly transferred to the GAMS environment. NP-hard Permutation Flow Shop Scheduling Problem (PFSSP) and the Travelling Salesman Problem are used to show that the optimal solution can be determined in the available time of a few minutes for instances with 20 jobs on 10 machines in the case of PFSSP, and for 100 cities in the case of TSP.

Previously, these boundaries were inaccessible with mixed integer programming solvers, but with the new version of GAMS, they have been significantly extended. This of course means first to build the appropriate model (and this is not always a simple matter, as the informal derivation of the PFSSP model in Section 5 showed) and then, for instance, for benchmark libraries (e.g., OR-Library or TSPLIB), to search individually for the appropriate bounds. The findings from PFSSP and TSP are not isolated examples of the successful application of GAMS in solving large instances of optimization versions of NP-complete/NP-hard problems. We have already validated it in [13] in solving the covering problem with matrices of hundreds of thousands of elements, and more recently in solving the Steiner problem in graphs in [95], where first using the terminology of network flows a mixed integer programming model was derived, then modified for GAMS, and finally exact results for a representative class of benchmarks from OR-Library were obtained.

Another goal of this paper was to introduce code generation in GAMS on non-trivial tasks because in the manuals [76,77] we can find only a description of individual elements of this tool, but not the codes of complete task models. In MATLAB, running the computation of an optimization program means writing just a single command (intlinprog or linprog with the appropriate parameters). Similarly, when solving differential equations, e.g., to calculate the differential equation with initial condition , it is enough to enter dsolve(’Dy=4*x*y+x3’,’y(4)=2’,’x’). In MATHEMATICA, too, to obtain the impulse function of the system described by a differential equation, it is enough to rewrite it in the form of a Laplace transfer and use a single command InverseLaplaceTransform. In contrast, the code notation in GAMS is similar to code in programming languages with the definition of constants, the declaration of variables, and the body of the program. Again, there are assignment statements, conditional statements, and loop statements. For example, the binary values of the reachability matrix A from the distance matrix D and the defined reachable distance threshold are determined in GAMS as follows:

LOOP(I,

LOOP(J,

IF (D(I,J) <= Dmax,

A(I,J)=1;

ELSE

A(I,J)=0;

);

);

);

The only disadvantage of GAMS is that it has no graphical tools, and the results of the calculations are only in text form. This requires exporting them to a suitable program and postprocessing. In [13] we used MATLAB, here Figure 4 and Figure 5 are generated in the MATHEMATICA environment.

Only where for extremely large instances of problems of exponential complexity we cannot obtain an exact solution using GAMS in a reasonable amount of time (e.g., no more than in tens of minutes), do we use one of the many heuristic methods. Given the No Free Lunch Theorem [74,75], none of them can be recommended as the best in the general case, since finding the optimal solution is not guaranteed and the result is always an approximation of the optimum, so our modification of the genetic algorithm, implemented in Java and described in more detail in [79], can be used without loss of generality.

One-point heuristics (hill climbing, tabu search, simulated annealing) in solving problems where in each iteration the neighborhood operation often generates tens of infeasible solutions and it is necessary to use a repair operator for them (here it concerns the coverage problem), and slow down the computation considerably, so in these cases we prefer, e.g., a genetic algorithm that generates only two new solutions in each iteration.

The model in Section 4.4 is original with another possible modification proposed at the end. Its model has already been built and verified on smaller-scale instances so far and will be investigated in more complex cases.

In future research, we expect to focus on the Quadratic Assignment Problem, the Vehicle Routing Problem and its solvability using GAMS, and applications in agriculture with consideration of data uncertainty using probabilistic models or fuzzy modeling, since yields can only be estimated. Although the Quadratic Assignment Problem has a non-linear objective function with quadratic terms, it can be converted to a mixed integer programming problem using Lawler’s linearization [7] and the MIP solver of GAMS can be used again.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AP | Assignment Problem |

| TSP | Travelling Salesman Problem |

| VRP | Vehicle Routing Problem |

| PFSSP | Permutation Flow Shop Scheduling Problem |

| GAMS | General Algebraic Modelling System |

| GA | Genetic Algorithm |

| ANN | Artificial Neural Network |

References

- Gass, S.I. Linear Programming. Methods and Applications; Dover Books on Computer Science; Courier Corporation: North Chelmsford, MA, USA, 2010. [Google Scholar]

- Du, D.Z.; Pardalos, P.M. Handbook of Combinatorial Optimization. Volume A; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1999. [Google Scholar]

- Du, D.Z.; Pardalos, P.M. Handbook of Combinatorial Optimization. Volume B; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Kuhn, H.W. The Hungarian Method for the Assignment Problem. Nav. Res. Logist. 1955, 2, 83–97. [Google Scholar] [CrossRef]

- Burkard, R.; Dell’Amico, M.; Martello, S. Assignment Problems; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2009. [Google Scholar]

- Diestel, R. Graph Theory; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Burkard, R.E.; Cela, E.; Pardalos, P.M.; Pitsoulis, L.S. The Quadratic Assignment Problem; Report; Graz University of Technology: Graz, Austria, 1998; p. 71. [Google Scholar]

- Gutin, G.; Punnen, A.P. The Traveling Salesman Problem and Its Variations; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Nalepa, J. Smart Delivery Systems. Solving Complex Vehicle Routing Problems; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Ganesh, K.; Malaijaran, R.A.; Mohapatra, S.; Punniyamoorthy, M. Resource Allocation Problems in Supply Chains; Emerald Group Publishing Limited: Bingley, UK, 2015. [Google Scholar]

- Bohle, C.; Maturana, S.; Vera, J. A Robust Optimization Approach to Wine Grape Harvesting Scheduling. Eur. J. Oper. Res. 2010, 200, 245–252. [Google Scholar] [CrossRef]

- Church, R.L.; Murray, A. Location Covering Models; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Seda, P.; Seda, M.; Hosek, J. On Mathematical Modelling of Automated Coverage Optimization in Wireless 5G and beyond Deployments. Appl. Sci. 2020, 10, 8853. [Google Scholar] [CrossRef]

- Błażewicz, J.; Ecker, K.H.; Schmidt, G.; Wȩglarz, J. Scheduling Computer and Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Rossit, D.; Vásquez, Ó.C.; Tohmé, F.; Frutos, M.; Safe, M. A Combinatorial Analysis of the Permutation and Non-Permutation Flow Shop Scheduling Problems. Eur. J. Oper. Res. 2021, 289, 841–854. [Google Scholar] [CrossRef]

- Ali, I.; Essam, D.; Kasmarik, K. A Novel Design of Differential Evolution for Solving Discrete Traveling Salesman Problems. Swarm Evol. Comput. 2020, 52, 100607. [Google Scholar] [CrossRef]

- Dong, X.; Cai, Y. A Novel Genetic Algorithm for Large Scale Colored Balanced Traveling Salesman Problem. Future Gener. Comput. Syst. 2019, 95, 727–742. [Google Scholar] [CrossRef]

- Placido, A.D.; Archetti, C.; Cerrone, C. A Genetic Algorithm for the Close-Enough Traveling Salesman Problem with Application to Solar Panels Diagnostic Reconnaissance. Comput. Oper. Res. 2022, 145, 105831. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, J.; Tian, Z.; Sun, S.; Li, J.; Yang, J. A Genetic Algorithm with Jumping Gene and Heuristic Operators for Traveling Salesman Problem. Appl. Soft Comput. 2022, 127, 109339. [Google Scholar] [CrossRef]

- Mahrach, M.; Miranda, G.; León, C.; Segredo, E. Comparison between Single and Multi-Objective Evolutionary Algorithms to Solve the Knapsack Problem and the Travelling Salesman Problem. Mathematics 2020, 8, 2018. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, Y.; Fu, Z.H. Knowledge-Guided Two-Stage Memetic Search for the Pickup and Delivery Traveling Salesman Problem with FIFO Loading. Knowl.-Based Syst. 2022, 242, 108332. [Google Scholar] [CrossRef]

- Larasati, M.R.; Wang, I.L. An Integrated Integer Programming Model with a Simulated Annealing Heuristic for the Carrier Vehicle Traveling Salesman Problem. Procedia Comput. Sci. 2022, 197, 301–308. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Y. The Neural Network Methods for Solving Traveling Salesman Problem. Procedia Comput. Sci. 2022, 199, 681–686. [Google Scholar] [CrossRef]

- Karakostas, P.; Sifaleras, A. A Double-Adaptive General Variable Neighborhood Search Algorithm for the Solution of the Traveling Salesman Problem. Appl. Soft Comput. 2022, 121, 108746. [Google Scholar] [CrossRef]

- Schmidt, J.; Irnich, S. New Neighborhoods and an Iterated Local Search Algorithm for the Generalized Traveling Salesman Problem. EURO J. Comput. Optim. 2022, 10, 100029. [Google Scholar] [CrossRef]

- Kanna, S.; Sivakumar, K.; Lingaraj, N. Development of Deer Hunting Linked Earthworm Optimization Algorithm for Solving Large Scale Traveling Salesman Problem. Knowl.-Based Syst. 2021, 227, 107199. [Google Scholar] [CrossRef]

- Akhand, M.; Ayon, S.; Shahriyar, S.; Siddique, N.; Adel, H. Discrete Spider Monkey Optimization for Travelling Salesman Problem. Appl. Soft Comput. 2020, 86, 105887. [Google Scholar] [CrossRef]

- Krishna, M.; Panda, N.; Majhi, S. Solving Traveling Salesman Problem Using Hybridization of Rider Optimization and Spotted Hyena Optimization Algorithm. Expert Syst. Appl. 2021, 183, 115353. [Google Scholar] [CrossRef]

- Panwar, K.; Deep, K. Discrete Grey Wolf Optimizer for Symmetric Travelling Salesman Problem. Appl. Soft Comput. 2021, 105, 107298. [Google Scholar] [CrossRef]

- Reda, M.; Onsy, A.; Elhosseini, M.A.; Haikal, A.Y.; Badawy, M. A Discrete Variant of Cuckoo Search Algorithm to Solve the Travelling Salesman Problem and Path Planning for Autonomous Trolley inside Warehouse. Knowl.-Based Syst. 2022, 252, 109290. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J. A Discrete Cuckoo Search Algorithm for Traveling Salesman Problem and Its Application in Cutting Path Optimization. Comput. Ind. Eng. 2022, 169, 108157. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, Y. Discrete Sparrow Search Algorithm for Symmetric Traveling Salesman Problem. Appl. Soft Comput. 2022, 118, 108469. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, X.N.; You, X. A Discrete Shuffled Frog-Leaping Algorithm Based on Heuristic Information for Traveling Salesman Problem. Appl. Soft Comput. 2021, 102, 107085. [Google Scholar] [CrossRef]

- Stodola, P.; Otřísal, P.; Hasilová, K. Adaptive Ant Colony Optimization with Node Clustering Applied to the Travelling Salesman Problem. Swarm Evol. Comput. 2022, 70, 101056. [Google Scholar] [CrossRef]

- Land, A. The Solution of Some 100-City Travelling Salesman Problems. EURO J. Comput. Optim. 2021, 9, 100017. [Google Scholar] [CrossRef]

- Dell’Amico, M.; Montemanni, R.; Novellani, S. Algorithms Based on Branch and Bound for the Flying Sidekick Traveling Salesman Problem. Omega 2021, 104, 102493. [Google Scholar] [CrossRef]

- Pereira, A.; Mateus, G.; Urrutia, S. Valid Inequalities and Branch-and-Cut Algorithm for the Pickup and Delivery Traveling Salesman Problem with Multiple Stacks. Eur. J. Oper. Res. 2022, 300, 207–220. [Google Scholar] [CrossRef]

- Yuan, Y.; Cattaruzza, D.; Ogier, M.; Semet, F. A Branch-and-Cut Algorithm for the Generalized Traveling Salesman Problem with Time Windows. Eur. J. Oper. Res. 2020, 286, 849–866. [Google Scholar] [CrossRef]

- Morais, M.; Ribeiro, M.; da Silva, R.; Mariani, V.; Coelho, L. Discrete Differential Evolution Metaheuristics for Permutation Flow Shop Scheduling Problems. Comput. Ind. Eng. 2022, 166, 107956. [Google Scholar] [CrossRef]

- Qiao, Y.; Wu, N.; He, Y.; Li, Z.; Chen, T. Adaptive Genetic Algorithm for Two-Stage Hybrid Flow-Shop Scheduling with Sequence-Independent Setup Time and No-Interruption Requirement. Expert Syst. Appl. 2022, 208, 118068. [Google Scholar] [CrossRef]

- Wu, X.; Cao, Z. An Improved Multi-Objective Evolutionary Algorithm Based on Decomposition for Solving Re-Entrant Hybrid Flow Shop Scheduling Problem with Batch Processing Machines. Comput. Ind. Eng. 2022, 169, 108236. [Google Scholar] [CrossRef]

- Song, H.B.; Lin, J. A Genetic Programming Hyper-Heuristic for the Distributed Assembly Permutation Flow-Shop Scheduling Problem with Sequence Dependent Setup Times. Swarm Evol. Comput. 2021, 60, 100807. [Google Scholar] [CrossRef]

- Wang, J.J.; Wang, L. A Cooperative Memetic Algorithm with Feedback for the Energy-Aware Distributed Flow-Shops with Flexible Assembly Scheduling. Comput. Ind. Eng. 2022, 168, 108126. [Google Scholar] [CrossRef]

- Harbaoui, H.; Khalfallah, S. Tabu-Search Optimization Approach for No-Wait Hybrid Flow-Shop Scheduling with Dedicated Machines. Procedia Comput. Sci. 2020, 176, 706–712. [Google Scholar] [CrossRef]

- Doush, I.; Al-Betar, M.; Awadallah, M.; Alyasseri, Z.; Makhadmeh, S.; El-Abd, M. Island Neighboring Heuristics Harmony Search Algorithm for Flow Shop Scheduling with Blocking. Swarm Evol. Comput. 2022, 74, 101127. [Google Scholar] [CrossRef]

- Brum, A.; Ruiz, R.; Ritt, M. Automatic Generation of Iterated Greedy Algorithms for the Non-Permutation Flow Shop Scheduling Problem with Total Completion Time Minimization. Comput. Ind. Eng. 2022, 163, 107843. [Google Scholar] [CrossRef]

- Miyata, H.; Nagano, M. An Iterated Greedy Algorithm for Distributed Blocking Flow Shop with Setup Times and Maintenance Operations to Minimize Makespan. Comput. Ind. Eng. 2022, 171, 108366. [Google Scholar] [CrossRef]

- Schulz, S.; Neufeld, J.; Buscher, U. Multi-Objective Iterated Local Search Algorithm for Comprehensive Energy-Aware Hybrid Flow Shop Scheduling. J. Clean. Prod. 2019, 224, 421–434. [Google Scholar] [CrossRef]

- Shao, W.; Shao, Z.; Pi, D. Multi-Local Search-Based General Variable Neighborhood Search for Distributed Flow Shop Scheduling in Heterogeneous Multi-Factories. Appl. Soft Comput. 2022, 125, 109138. [Google Scholar] [CrossRef]

- Pereira, M.; Nagano, M. Hybrid Metaheuristics for the Integrated and Detailed Scheduling of Production and Delivery Operations in No-Wait Flow Shop Systems. Comput. Ind. Eng. 2022, 170, 108255. [Google Scholar] [CrossRef]

- Umam, M.; Mustafid, M.; Suryono, S. A Hybrid Genetic Algorithm and Tabu Search for Minimizing Makespan in Flow Shop Scheduling Problem. J. King Saud Univ. Comput. Inf. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Brammer, J.; Lutz, B.; Neumann, D. Permutation Flow Shop Scheduling with Multiple Lines and Demand Plans Using Reinforcement Learning. Eur. J. Oper. Res. 2022, 299, 75–86. [Google Scholar] [CrossRef]

- Pang, X.; Xue, H.; Tseng, M.L.; Lim, M.; Liu, K. Hybrid Flow Shop Scheduling Problems Using Improved Fireworks Algorithm for Permutation. Appl. Sci. 2020, 10, 1174. [Google Scholar] [CrossRef]

- Engin, O.; Güclü, A. A New Hybrid Ant Colony Optimization Algorithm for Solving the No-Wait Flow Shop Scheduling Problems. Appl. Soft Comput. 2018, 72, 166–176. [Google Scholar] [CrossRef]

- Gümüsçü, A.; Kaya, S.; Tenekeci, M.; Karaçizmeli, I.; Aydilek, I. The Impact of Local Search Strategies on Chaotic Hybrid Firefly Particle Swarm Optimization Algorithm in Flow-Shop Scheduling. J. King Saud Univ. Comput. Inf. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Deng, G.; Xu, M.; Zhang, S.; Jiang, T.; Su, Q. Migrating Birds Optimization with a Diversified Mechanism for Blocking Flow Shops to Minimize Idle and Blocking Time. Appl. Soft Comput. 2022, 114, 107834. [Google Scholar] [CrossRef]

- Zhang, C.; Tan, J.; Peng, K.; Gao, L.; Shen, W.; Lian, K. A Discrete Whale Swarm Algorithm for Hybrid Flow-Shop Scheduling Problem with Limited Buffers. Robot. Comput.-Integr. Manuf. 2021, 68, 102081. [Google Scholar] [CrossRef]

- Croce, F.; Salassa, F.; T’Kindt, V. Exact Solution of the Two-Machine Flow Shop Problem with Three Operations. Comput. Oper. Res. 2022, 138, 105595. [Google Scholar] [CrossRef]

- Ho, M.; Hnaien, F.; Dugardin, F. Exact Method to Optimize the Total Electricity Cost in Two-Machine Permutation Flow Shop Scheduling Problem under Time-of-Use Tariff. Comput. Oper. Res. 2022, 144, 10578. [Google Scholar] [CrossRef]

- Oujana, S.; Yalaoui, F.; Amodeo, L. A Linear Programming Approach for Hybrid Flexible Flow Shop with Sequence-Dependent Setup Times to Minimise Total Tardiness. IFAC PapersOnLine 2021, 54-1, 1162–1167. [Google Scholar] [CrossRef]

- Schaller, J.; Valente, J. Branch-and-Bound Algorithms for Minimizing Total Eearliness and Tardiness in a Two-Machine Permutation Flow Shop with Unforced Idle Allowed. Comput. Oper. Res. 2019, 109, 1–11. [Google Scholar] [CrossRef]

- Liu, M.; Li, Y.; Huo, Q.; Li, A.; Zhu, M.; Qu, N.; Chen, L.; Xia, M. A Two-Way Parallel Slime Mold Algorithm by Flow and Distance for the Travelling Salesman Problem. Appl. Sci. 2020, 10, 6180. [Google Scholar] [CrossRef]

- Golden, B.; Raghavan, S.; Wasil, E. The Vehicle Routing Problem: Latest Advances and New Challenges; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Toth, P.; Vigo, D. The Vehicle Routing Problem; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2002. [Google Scholar]

- Soto-Mendoza, V.; García-Calvillo, I.; Ruiz-y Ruiz, E.; Pérez-Terrazas, J. Comparison between Single and Multi-Objective Evolutionary Algorithms to Solve the Knapsack Problem and the Travelling Salesman Problem. Algorithms 2020, 13, 96. [Google Scholar] [CrossRef]

- Ochelska-Mierzejewska, J.; Poniszewska-Marańda, A.; Marańda, W. Selected Genetic Algorithms for Vehicle Routing Problem Solving. Electronics 2021, 10, 3147. [Google Scholar] [CrossRef]

- Desrochers, M.; Laporte, G. Improvements and Extensions to the Miller-Tucker-Zemlin Subtour Elimination Constraints. Oper. Res. Lett. 1991, 10, 27–36. [Google Scholar] [CrossRef]

- Stroh, M.B. A Practical Guide to Transportation and Logistics; Logistics Network: Burr Ridge, IL, USA, 2006. [Google Scholar]

- Garey, M.R.; Johnson, D.S. Computers and Intractability: A Guide to the Theory of NP-Completeness, 19th ed.; W.H. Freeman and Company: New York, NY, USA, 1997. [Google Scholar]

- Ausiello, G.; Crescenzi, P.; Gambosi, G.; Kann, V.; Marchetti-Spaccamela, A.; Protasi, M. Complexity and Approximation: Combinatorial Optimization Problems and their Approximability Properties; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Reeves, C.R. Modern Heuristic Techniques for Combinatorial Problems; Blackwell Scientific Publications: Oxford, UK, 1993. [Google Scholar]

- Michalewicz, Z.; Fogel, D.B. How to Solve It: Modern Heuristics; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Onwubolu, G.; Davendra, D. Differential Evolution. A Handbook for Global Permutation-Based Combinatorial Optimization; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Wolpert, D.H.; McReady, W.G. No Free Lunch Theorems for Optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Wolpert, D.H.; McReady, W.G. Coevolutionary Free Lunches. IEEE Trans. Evol. Comput. 2005, 9, 721–735. [Google Scholar] [CrossRef]

- Brooke, A.; Kendrick, D.; Meeraus, A. GAMS Release 2.25. A User’s Guide; The Scientific Press. Boyd & Fraser Publishing Company: Boston, MA, USA, 1992. [Google Scholar]

- Rosenthal, R.E. GAMS—A User’s Guide; GAMS Development Corporation: Washington, DC, USA, 2016. [Google Scholar]

- GAMS. Solver Manuals. Report, GAMS Development Corporation. Available online: https://www.gams.com/latest/docs/S_MAIN.html (accessed on 6 September 2022).

- Seda, P.; Mark, M.; Su, K.W.; Seda, M.; Hosek, J.; Leu, J. The Minimization of Public Facilities With Enhanced Genetic Algorithms Using War Elimination. IEEE Access 2019, 7, 9395–9405. [Google Scholar] [CrossRef]

- Beasley, J.E. OR-Library. Report, Brunel University London. 2018. Available online: http://people.brunel.ac.uk/~mastjjb/jeb/info.html (accessed on 6 September 2022).

- Beasley, J.E. OR-Library: Distributing Test Problems by Electronic Mail. J. Oper. Res. Soc. 1990, 41, 1069–1072. [Google Scholar] [CrossRef]

- Michalewicz, Z. Genetic Algorithms + Data Structures = Evolution Programs; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Reinelt, G. MP-TESTDATA—The TSPLIB Symmetric Traveling Salesman Problem Instances; Report; Heidelberg University: Heidelberg, Germany, 2013; Available online: http://elib.zib.de/pub/mp-testdata/tsp/tsplib/tsp (accessed on 6 September 2022).

- Alkaya, A.F.; Yildirim, S.; Aksakalli, V. Heuristics for the Canadian Traveler Problem with Neutralizations. Comput. Ind. Eng. 2019, 159, 107488. [Google Scholar] [CrossRef]

- Liao, C.S.; Huang, Y. The Covering Canadian Traveller Problem. Theor. Comput. Sci. 2014, 530, 80–88. [Google Scholar] [CrossRef]

- Aurenhammer, F. Voronoi Diagrams. A Survey of a Fundamental Geometric Data Structure. ACM Comput. Surv. 1991, 23, 345–405. [Google Scholar] [CrossRef]

- de Berg, M.; Cheong, O.; van Kreveld, M.; Overmars, M. Computational Geometry: Algorithms and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Becerra, P.; Mula, J.; Sanchis, R. Green Supply Chain Quantitative Models for Sustainable Inventory Management: A Review. J. Clean. Prod. 2021, 328, 129544. [Google Scholar] [CrossRef]

- Forkan, M.; Rizvi, M.M.; Chowdhury, M.A.M. Multiobjective Reverse Logistics Model for Inventory Management with Eenvironmental Impacts: An Application in Industry. Intell. Syst. Appl. 2022, 14, 200078. [Google Scholar]

- Teerasoponpong, S.; Sopadang, A. Decision Support System for Adaptive Sourcing and Inventory Management in Small- and Medium-Sized Enterprises. Robot. Comput.-Integr. Manuf. 2022, 73, 102226. [Google Scholar] [CrossRef]

- Xiong, X.; Li, Y.; Yang, W.; Shen, H. Data-Driven Robust Dual-Sourcing Inventory Management under Purchase Price and Demand Uncertainties. Transp. Res. Part E 2022, 160, 102671. [Google Scholar] [CrossRef]

- Sarkar, B.; Kar, S.; Basu, K.; Guchhait, R. A Sustainable Managerial Decision-Making Problem for a Substitutable Product in a Dual-Channel under Carbon Tax Policy. Comput. Ind. Eng. 2022, 172, 108635. [Google Scholar] [CrossRef]

- Sarkar, A.; Guchhait, R.; Sarkar, B. Application of the Artificial Neural Network with Multithreading within an Inventory Model under Uncertainty and Inflation. Int. J. Fuzzy Syst. 2022, 24, 2318–2332. [Google Scholar] [CrossRef]

- Guchhait, R.; Sarkar, B. Economic and Environmental Assessment of an Unreliable Supply Chain Management. RAIRO Oper. Res. 2021, 55, 3153–3170. [Google Scholar] [CrossRef]

- Seda, M. Steiner Tree Problem in Graphs and Mixed Integer Linear Programming-Based Approach in GAMS. WSEAS Trans. Comput. 2022, 21, 257–262. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).