A Heuristic Algorithm for the Routing and Scheduling Problem with Time Windows: A Case Study of the Automotive Industry in Mexico

Abstract

1. Introduction

2. Literature Review

3. Importance of the Problem

- It is ranked as the second most important activity in manufacturing after the food industry

- Because its exports were ranked fourth in the world in 2014

- When demanding inputs to carry out its production, it generates impacts on 157 economic activities out of a total of 259, according to the input-output matrix

4. Problem Definition and Mathematical Model

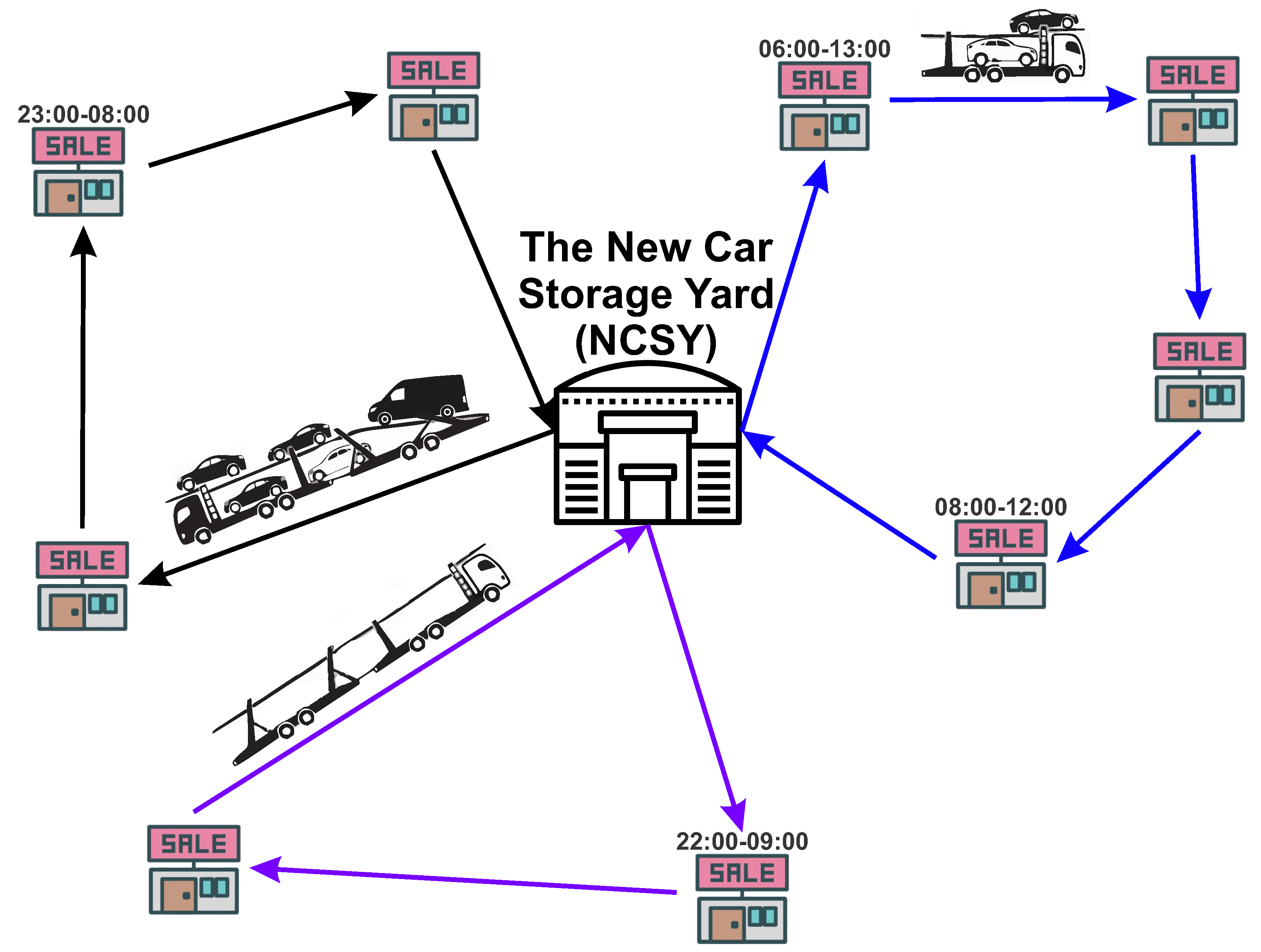

given a heterogeneous fleet of auto-carriers based at a NCSY and a set of dealerships each requiring a set of vehicles, the loading of the vehicles into the auto-carriers and route the auto-carriers through the road network to deliver all dealerships with minimum cost (total number of kilometers traveled) that start and ends in the NCSY, considering the restrictions of time windows, a LIFO policy for the loading/unloading of vehicles and maximizing the total use of the capacity of each auto-carrier

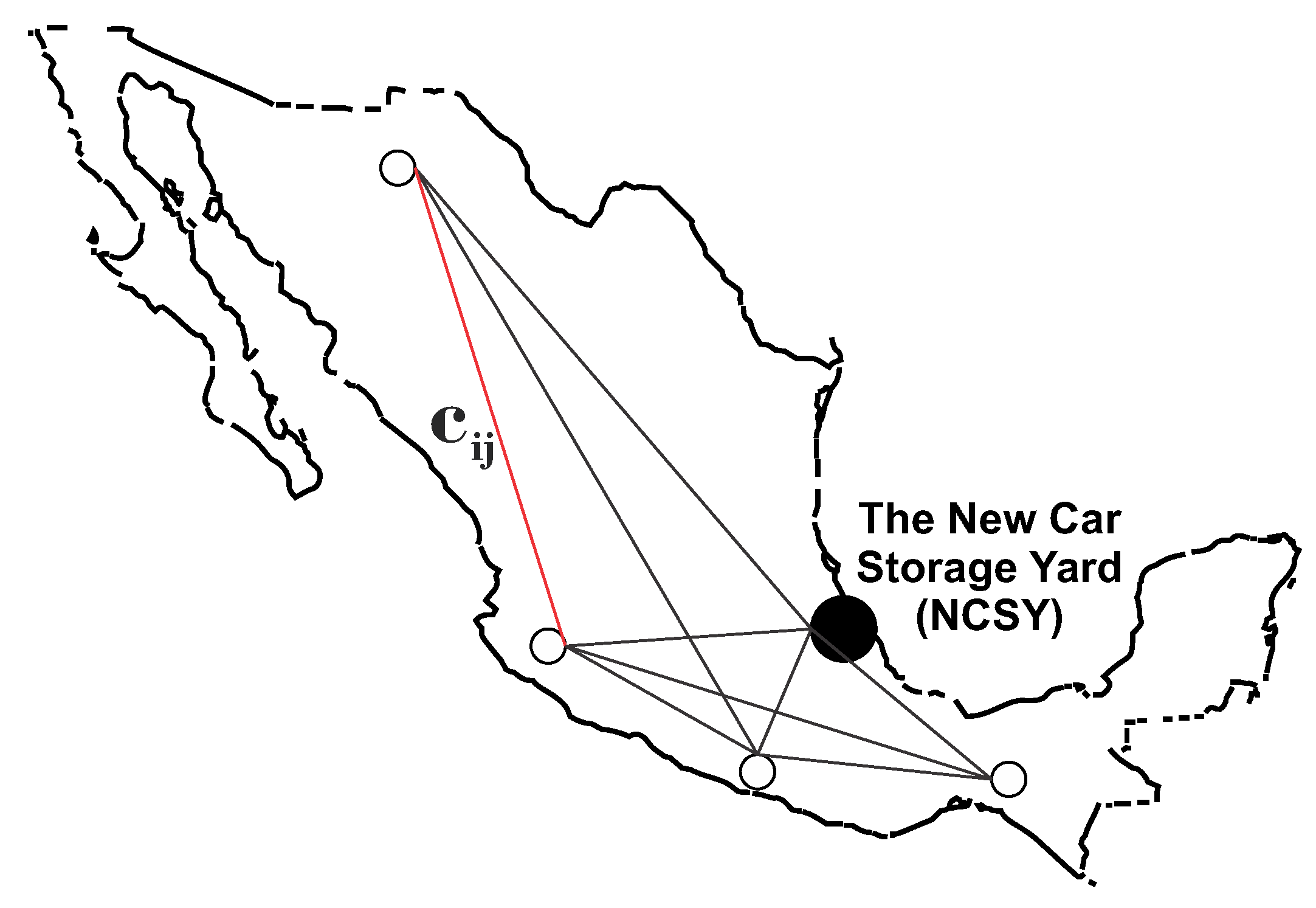

- Network: Given a complete graph , where is the set of vertices and E the set of edges connecting each vertex pair. Vertex 0 corresponds to the NCSY, whereas vertices correspond to the n dealerships to be served. The edge is connecting vertices i and j is denoted by and has an associated routing cost shown in Figure 2. The distance and times matrices are symmetric.

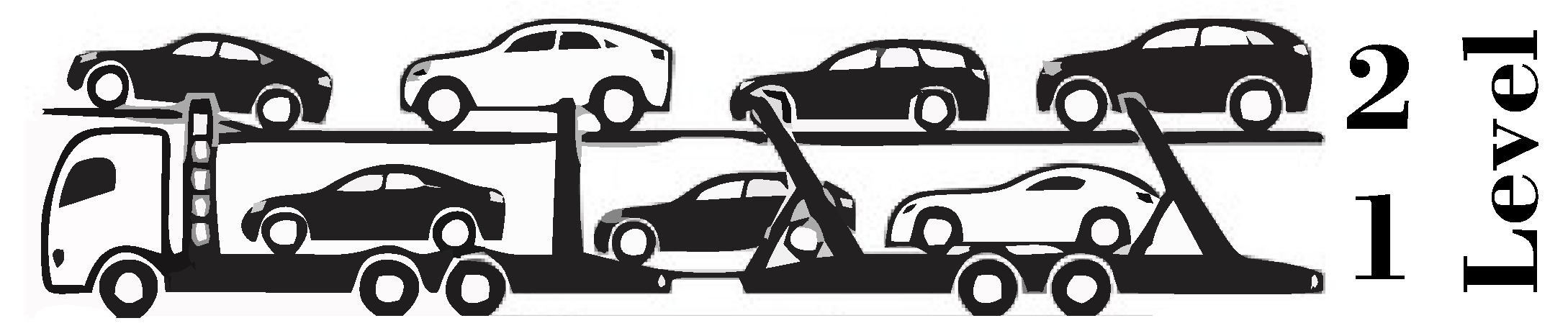

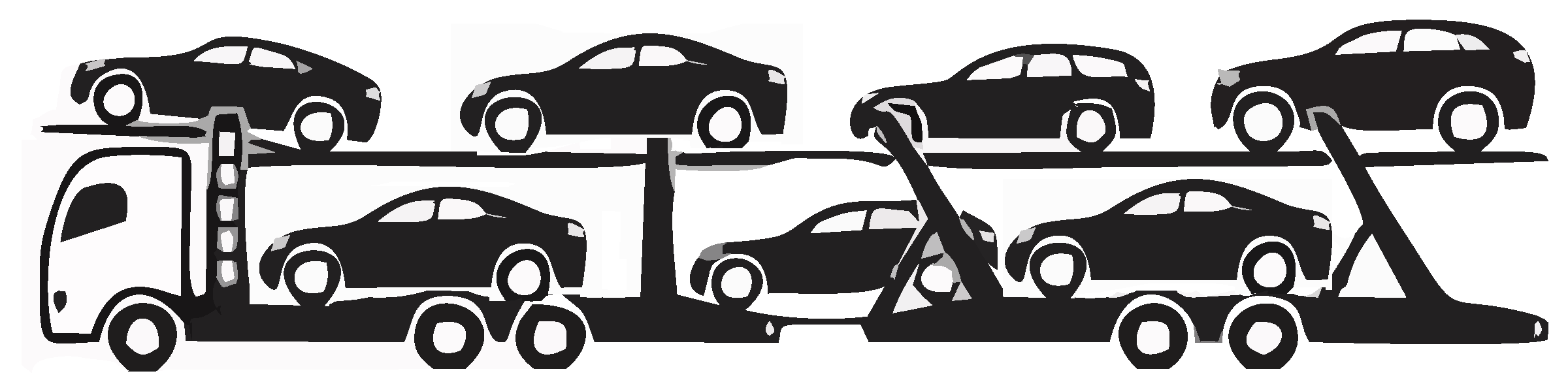

- Fleet: Given a heterogeneous fleet of auto-carriers, composed by a set T of auto-carrier types. Each auto-carrier type has a maximum vehicles capacity and is formed by loading platforms (levels, shown in Figure 3). There are auto-carriers available for each type t.

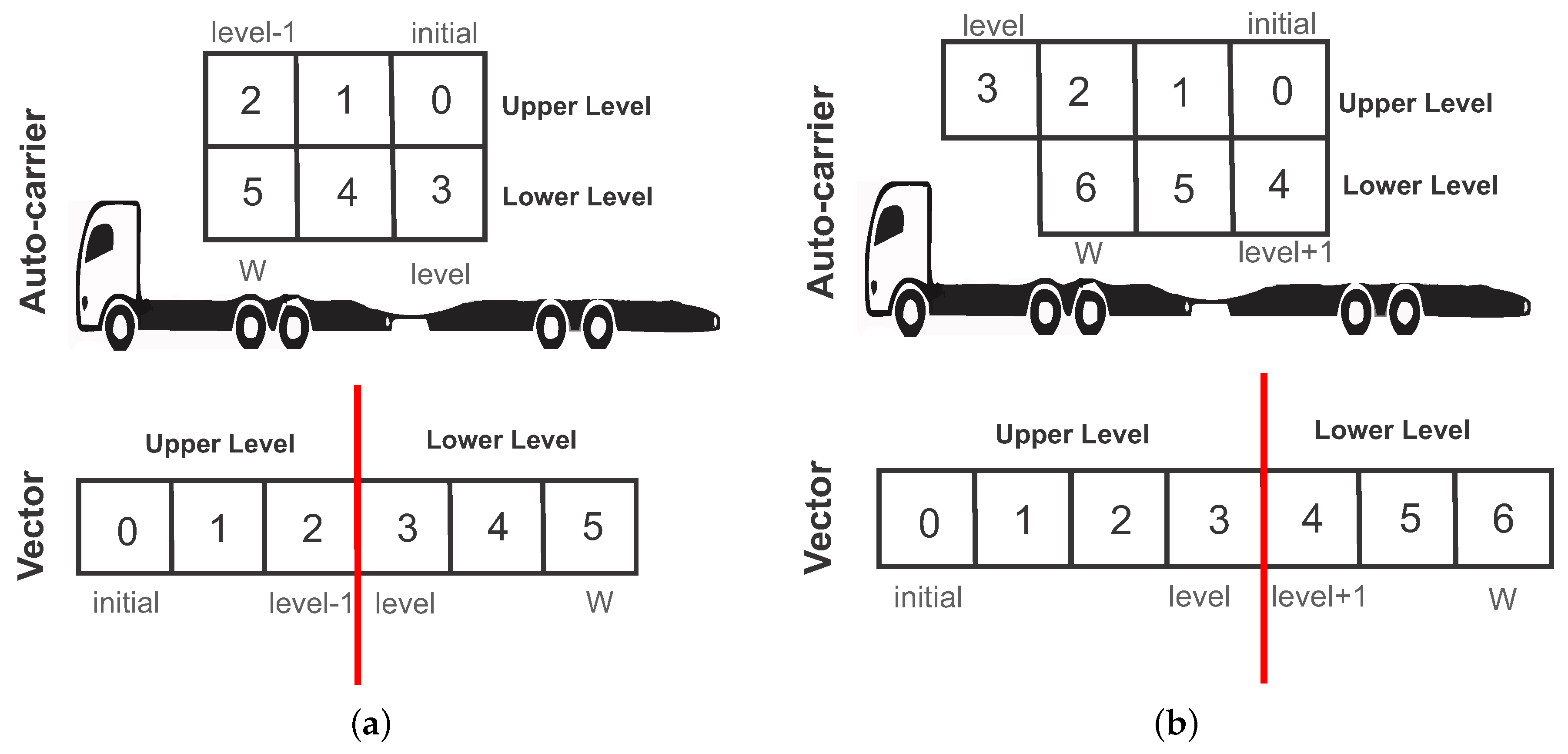

- Demand: The demand of dealership i consists of a set M of vehicles . Each vehicle demanded by dealership i belongs to a vehicle type (or vehicle model) shown in Figure 4, which is defined by a height and a vehicle identification number (VIN).

5. Methodology

5.1. Heuristic Approach

- Vehicle m: It uses three spaces of the capacity of the auto-carrier k, i.e., a space in level and two spaces on level , this is shown in Figure 5. To maximize the use of the capacity of the auto-carrier, another allocation is to occupy one space above () and two below ().

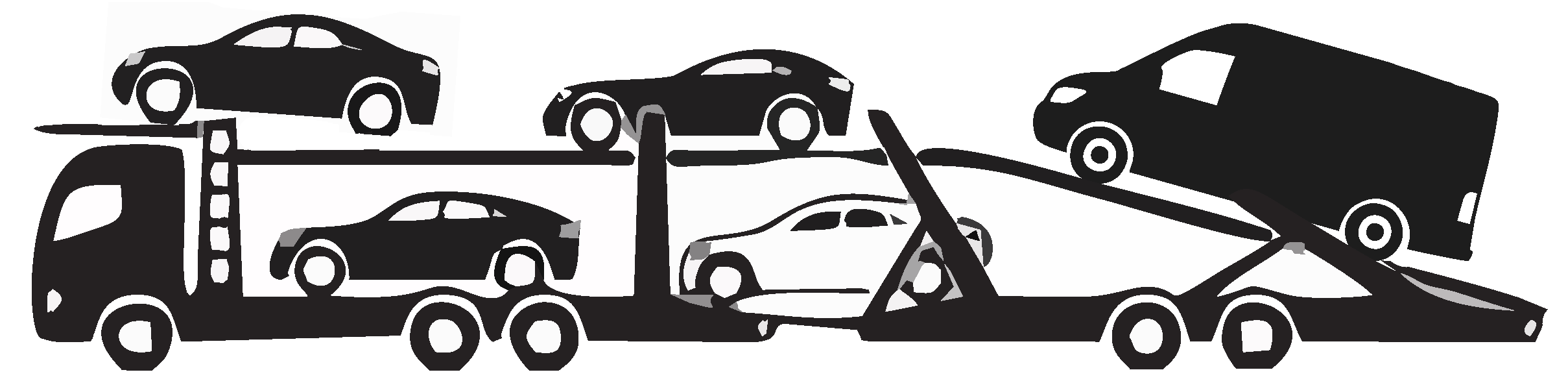

- Vehicle m m: It uses a space of the capacity of the auto-carrier k and can only be assigned in level , as shown in Figure 6.

- Vehicle m: It uses a space of the capacity of the auto-carrier k and can be assigned in any available space to it, as shown in Figure 7.

- Policy Last In First Out (LIFO): Last vehicle loaded, first vehicle unloaded. For example, if the first dealership to visit is on the current route, the vehicles of should be the last to be loaded on the auto-carrier.

5.2. Development of the Two-Phase Heuristic

| Algorithm 1: Two-phase heuristic |

| Data: M (), K (auto-carriers). Output: The K auto-carriers with arrangement, route and delivery schedules. A vector with the remaining M, if any. 1 begin 2 get from demand; 3 get ; 4 while and do 5 Initialization a new route ; 6 get from k; 7 generate a new arrangement with capacity ; 8 get to visit from U; 9 while and do 10 while do 11 if then 12 Update demand M, capacity and route ; 13 end 14 end 15 get to visit and update U; 16 end 17 if and then 18 Get from M; 19 end 20 Add to , 21 end 22 end |

| Algorithm 2: Allocation |

| Data: (vehicle), (arrangement). Output: The arrangement with assigned if it is feasible. 1 begin 2 size of ; 3 ; 4 for do 5 if and and then 6 if and and then 7 Allocate vehicle to spaces and 8 else 9 if and and then 10 Allocate vehicle to spaces and 11 end 12 end 13 else 14 if and and then 15 Allocate vehicle to spaces and 16 else 17 if and and then 18 Allocate vehicle to spaces and 19 end 20 end 21 end 22 if and and and then 23 Allocate vehicle in space 24 end 25 if and then 26 Allocate vehicle in space 27 end 28 end 29 return 30 end |

6. Results and Analysis

6.1. Experimental Results

- Random Dealerships with Time Windows (RDTW)—context in which most of the dealerships (34 of 44) were set different time windows for vehicle unloading.

- Main Dealerships with Time Windows (MDTW)—context that corresponds to the case of the logistics company, only the dealerships (14 of 44) that are located in the main cities of the country establish a time window for the unloading of vehicles.

6.2. Analysis of the Results

7. Conclusions and Future Research Works

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bonassa, A.C.; Cunha, C.B.; Isler, C.A. An exact formulation for the multi-period auto-carrier loading and transportation problem in Brazil. Comput. Ind. Eng. 2019, 129, 144–155. [Google Scholar] [CrossRef]

- Asociación Mexicana de la Industria Automotriz. AMIA-BOLETIN DE PRENSA/HISTORICO/BOLETIN HISTORICO/2005 2018; AMIA: Ciudad de México, Mexico, 2018; Available online: http://www.amia.com.mx/descargarb.html (accessed on 22 July 2018).

- Secretaría de Comunicaciones y Transportes. PROYECTO de Norma Oficial Mexicana PROY-NOM-012-SCT-2-2017; DOF—Diario Oficial de la Federación/SCT: México city, Mexico, 2017; Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=5508944&fecha=26/12/2017 (accessed on 15 March 2018).

- Ghiani, G.; Laporte, G.; Musmanno, R. Introduction to Logistics Systems Planning and Control; Online Edition; John Wiley & Sons Ltd: Chichester, UK, 2004; pp. 273–278. ISBN 0-470-84916-9. [Google Scholar]

- Dantzig, G.; Fulkerson, R.; Johnson, S. Solution of a large-scale traveling-salesman problem. J. Op. Res. Soc. Am. 1954, 2, 393–410. [Google Scholar] [CrossRef]

- Połap, D.; Woźniak, M.; Damaševičius, R.; Maskeliūnas, R. Bio-inspired voice evaluation mechanism. Appl. Soft Comput. 2019, 80, 342–357. [Google Scholar] [CrossRef]

- Arnau, Q.; Juan, A.A.; Serra, I. On the Use of Learnheuristics in Vehicle Routing Optimization Problems with Dynamic Inputs. Algorithms 2018, 11, 208. [Google Scholar] [CrossRef]

- Cassettari, L.; Demartini, M.; Mosca, R.; Revetria, R.; Tonelli, F. A Multi-Stage Algorithm for a Capacitated Vehicle Routing Problem with Time Constraints. Algorithms 2018, 11, 69. [Google Scholar] [CrossRef]

- Zhao, M.; Lu, Y. A Heuristic Approach for a Real-World Electric Vehicle Routing Problem. Algorithms 2019, 12, 45. [Google Scholar] [CrossRef]

- Stodola, P. Using Metaheuristics on the Multi-Depot Vehicle Routing Problem with Modified Optimization Criterion. Algorithms 2018, 11, 74. [Google Scholar] [CrossRef]

- Połap, D.; Woźniak, M. Polar Bear Optimization Algorithm: Meta-Heuristic with Fast Population Movement and Dynamic Birth and Death Mechanism. Symmetry 2017, 9, 203. [Google Scholar] [CrossRef]

- Chen, S.; Chen, R.; Gao, J. A Monarch Butterfly Optimization for the Dynamic Vehicle Routing Problem. Algorithms 2017, 10, 107. [Google Scholar] [CrossRef]

- Ahmed, A.K.M.F.; Sun, J.U. Bilayer Local Search Enhanced Particle Swarm Optimization for the Capacitated Vehicle Routing Problem. Algorithms 2018, 11, 31. [Google Scholar] [CrossRef]

- Desrochers, M.; Desrosiers, J.; Solomon, M. A New Optimization Algorithm for the Vehicle Routing Problem with Time Windows. Oper. Res. 1992, 40, 342–354. [Google Scholar] [CrossRef]

- Tan, K.C.; Lee, L.H.; Zhu, Q.L.; Ou, K. Heuristic methods for vehicle routing problem with time windows. Artif. Intell. Eng. 2001, 15, 281–295. [Google Scholar] [CrossRef]

- Yu, B.; Yang, Z.Z.; Yao, B.Z. A hybrid algorithm for vehicle routing problem with time windows. Expert Syst. Appl. 2011, 38, 435–441. [Google Scholar] [CrossRef]

- Taner, F.; Galić, A.; Carić, T. Solving Practical Vehicle Routing Problem with Time Windows Using Metaheuristic Algorithms. Promet-Traffic Transp. 2012, 24, 343–351. [Google Scholar] [CrossRef][Green Version]

- Sripriya, J.; Ramalingam, A.; Rajeswari, K. A hybrid genetic algorithm for vehicle routing problem with time windows. In Proceedings of the 2015 International Conference on Innovations in Information, Embedded and Communication Systems (ICIIECS), Coimbatore, India, 19–20 March 2015; pp. 1–4. [Google Scholar]

- Tadei, R.; Perboli, G.; Della, F. A Heuristic Algorithm for the Auto-Carrier Transportation Problem. Transp. Sci. 2002, 36, 55–62. [Google Scholar] [CrossRef]

- Miller, B.M. Auto Carrier Transporter Loading and Unloading Improvement. Master’s Thesis, Air Force Institute of Technology, Air University, Montgomery, AL, USA, March 2003. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a413017.pdf (accessed on 25 May 2018).

- Dell’Amico, M.; Falavigna, S.; Iori, M. Optimization of a Real-World Auto-Carrier Transportation Problem. Transp. Sci. 2014, 49, 402–419. [Google Scholar] [CrossRef]

- Tran, T.H.; Nagy, G.; Nguyen, T.B.T.; Wassan, N.A. An efficient heuristic algorithm for the alternative-fuel station location problem. Eur. J. Op. Res. 2018, 269, 159–170. [Google Scholar] [CrossRef]

- Hosseinabadi, A.A.R.; Siar, H.; Shamshirband, S.; Shojafar, M.; Nasir, M.H.N.M. Using the gravitational emulation local search algorithm to solve the multi-objective flexible dynamic job shop scheduling problem in Small and Medium Enterprises. Ann. Op. Res. 2015, 229, 451–474. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística y Geografía, Asociación Mexicana de la Industria Automotriz. Estadísticas a Propósito de...la Industria Automotriz; INEGI: México city, Mexico, 2016; Available online: http://www.dapesa.com.mx/dan-a-conocer-inegi-y-la-amia-libro-estadistico-de-la-industria-automotriz/ (accessed on 3 June 2018).

- Morawska, L.; Moore, M.R.; Ristovski, Z.D. Desktop Literature Review and Analysis: Health Impacts of Ultrafine Particles; Technical Report; Department of the Environment and Heritage, Australian Government: Canberra, Australia, 2004. Available online: http://www.environment.gov.au/system/files/resources/00dbec61-f911-494b-bbc1-adc1038aa8c5/files/health-impacts.pdf (accessed on 17 July 2018).

- Jiménez, M. Wastes to Reduce Emissions from Automotive Diesel Engines. J. Waste Manag. 2014, 2014, 1–5. [Google Scholar] [CrossRef][Green Version]

- Sajeevan, A.C.; Sajith, V. Diesel Engine Emission Reduction Using Catalytic Nanoparticles: An Experimental Investigation. J. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Cordeau, J.F.; Laporte, G.; Savelsbergh, M.W.P.; Vigo, D. Chapter 6. Vehicle Routing. In Handbooks in Operations Research and Management Science; Elsevier: Amsterdam, The Netherlands, 2007; Volume 14, pp. 367–428. [Google Scholar]

- Bräysy, O.; Gendreau, M. Vehicle Routing Problem with Time Windows, Part I: Route Construction and Local Search Algorithms. Transp. Sci. 2005, 39, 104–118. [Google Scholar] [CrossRef]

- Solomon, M.M. Algorithms for the Vehicle Routing and Scheduling Problems with Time Window Constraints. Op. Res. 1987, 35, 254–265. [Google Scholar] [CrossRef]

- El-Sherbeny, N.A. Vehicle routing with time windows: An overview of exact, heuristic and metaheuristic methods. J. King Saud Univ. Sci. 2010, 22, 123–131. [Google Scholar] [CrossRef]

| Dealership | |||||

|---|---|---|---|---|---|

| 0 | 885 | 1373 | ... | 114 | |

| 885 | 0 | 498 | ... | 752 | |

| 1373 | 498 | 0 | ... | 1245 | |

| ⋮ | ⋮ | ⋮ | 0 | ⋮ | |

| 114 | 752 | 1245 | ... | 0 |

| Dealership | |||||

|---|---|---|---|---|---|

| 0 | 568 | 880 | ... | 92 | |

| 568 | 0 | 319 | ... | 490 | |

| 880 | 319 | 0 | ... | 829 | |

| ⋮ | ⋮ | ⋮ | 0 | ⋮ | |

| 92 | 490 | 829 | ... | 0 |

| 00:00 | 23:59 | |

| 06:00 | 13:00 | |

| 08:00 | 12:00 | |

| ⋮ | ⋮ | |

| 22:00 | 09:00 | |

| Parameter | Value |

|---|---|

| Algorithm 1 | |

| mu | 1 |

| alpha | 0.9 |

| lamda | 1 |

| time_unloading | 15 |

| k | 1 |

| Algorithm 2 | |

| initial | 0 |

| It depends on the auto-carrier K | |

| level | |

| parity | It depends on the auto-carrier K |

| Instance | Demand Size | Cars | Partners | Managers |

|---|---|---|---|---|

| 1 | 20 | 6 | 14 | 0 |

| 2 | 50 | 46 | 1 | 3 |

| 3 | 100 | 32 | 66 | 2 |

| 4 | 200 | 108 | 87 | 5 |

| 5 | 500 | 206 | 270 | 24 |

| 6 | 1000 | 456 | 502 | 42 |

| 7 | 1500 | 654 | 767 | 79 |

| 8 | 2000 | 941 | 974 | 85 |

| 9 | 2500 | 1164 | 1224 | 112 |

| 10 | 3000 | 1433 | 1431 | 136 |

| 11 | 3884 | 1810 | 1906 | 168 |

| Auto-Carrier with | Auto-Carrier with | |||||

|---|---|---|---|---|---|---|

| Instance | Routes (K) | Distance (Km) | Time (Min) | Routes (K) | Distance (Km) | Time (Min) |

| 1 | 4 | 19,263 | 12,660 | 4 | 19,263 | 12,660 |

| 2 | 7 | 18,329 | 12,481 | 7 | 18,338 | 12,493 |

| 3 | 18 | 71,366 | 48,256 | 14 | 62,571 | 41,809 |

| 4 | 24 | 81,429 | 55,950 | 21 | 71,231 | 48,997 |

| 5 | 69 | 148,588 | 102,617 | 59 | 130,604 | 87,928 |

| 6 | 137 | 323,696 | 213,737 | 118 | 270,872 | 179,242 |

| 7 | 195 | 417,909 | 277,747 | 170 | 364,385 | 241,743 |

| 8 | 254 | 550,555 | 367,032 | 220 | 471,456 | 312,449 |

| 9 | 318 | 681,336 | 458,476 | 278 | 585,245 | 389,968 |

| 10 | 366 | 794,553 | 525,284 | 323 | 696,878 | 459,669 |

| 11 | 478 | 1,037,633 | 686,562 | 418 | 900,562 | 597,259 |

| Random Dealerships | Main Dealerships | |||||

|---|---|---|---|---|---|---|

| Instance | Routes (K) | Distance (Km) | Time (Min) | Routes (K) | Distance (Km) | Time (Min) |

| 1 | 4 | 17,458 | 11,416 | 5 | 25,649 | 16,875 |

| 2 | 10 | 27,626 | 18,854 | 9 | 22,964 | 15,622 |

| 3 | 26 | 94,510 | 62,905 | 22 | 91,525 | 61,156 |

| 4 | 32 | 111,317 | 75,206 | 37 | 124,226 | 84,035 |

| 5 | 95 | 240,376 | 160,016 | 102 | 199,158 | 134,659 |

| 6 | 180 | 436,777 | 284,208 | 190 | 446,823 | 294,392 |

| 7 | 278 | 563,385 | 367,985 | 278 | 572,442 | 381,464 |

| 8 | 350 | 724,204 | 476,686 | 350 | 764,601 | 511,309 |

| 9 | 444 | 932,767 | 611,969 | 450 | 933,942 | 623,494 |

| 10 | 490 | 1,091,345 | 710,645 | 495 | 1,049,780 | 696,274 |

| 11 | 655 | 1,389,356 | 907,976 | 660 | 1,416,358 | 943,464 |

| VIN | Vehicle | VIN | Vehicle |

|---|---|---|---|

| 1 | 2.52 m | 10 | 1.47 m |

| 2 | 1.47 m | 11 | 1.47 m |

| 3 | 1.47 m | 12 | 1.47 m |

| 4 | 1.47 m | 13 | 1.47 m |

| 5 | 1.47 m | 14 | 1.47 m |

| 6 | 1.47 m | 15 | 1.47 m |

| 7 | 2.52 m | 16 | 1.47 m |

| 8 | 1.87 m | 17 | 1.47 m |

| 9 | 1.47 m | 18 | 1.47 m |

| Auto-Carrier (Capacity) | Main Dealerships | ||

|---|---|---|---|

| Routes (K) | Distance (Km) | Time (Min) | |

| 3 | 2043 | 4,146,291.8 | 2,720,157 |

| 6 | 936 | 2,018,547.9 | 1,332,574 |

| 7 | 688 | 1,488,546.3 | 980,416 |

| 10 | 478 | 1,037,633.2 | 686,562 |

| 11 | 418 | 900,562.8 | 597,259 |

| 3, 6, 7, 10 & 11 | 660 | 1,416,358.8 | 943,464 |

| Dealership | Arrival | Departure | Unloaded Vehicles |

|---|---|---|---|

| d0 | –:– | 18:19 | 0 |

| d44 | 22:59 | 23:14 | 6 |

| d35 | 08:21 | 08:36 | 5 |

| d0 | 21:55 | –:– | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juárez Pérez, M.A.; Pérez Loaiza, R.E.; Quintero Flores, P.M.; Atriano Ponce, O.; Flores Peralta, C. A Heuristic Algorithm for the Routing and Scheduling Problem with Time Windows: A Case Study of the Automotive Industry in Mexico. Algorithms 2019, 12, 111. https://doi.org/10.3390/a12050111

Juárez Pérez MA, Pérez Loaiza RE, Quintero Flores PM, Atriano Ponce O, Flores Peralta C. A Heuristic Algorithm for the Routing and Scheduling Problem with Time Windows: A Case Study of the Automotive Industry in Mexico. Algorithms. 2019; 12(5):111. https://doi.org/10.3390/a12050111

Chicago/Turabian StyleJuárez Pérez, Marco Antonio, Rodolfo Eleazar Pérez Loaiza, Perfecto Malaquias Quintero Flores, Oscar Atriano Ponce, and Carolina Flores Peralta. 2019. "A Heuristic Algorithm for the Routing and Scheduling Problem with Time Windows: A Case Study of the Automotive Industry in Mexico" Algorithms 12, no. 5: 111. https://doi.org/10.3390/a12050111

APA StyleJuárez Pérez, M. A., Pérez Loaiza, R. E., Quintero Flores, P. M., Atriano Ponce, O., & Flores Peralta, C. (2019). A Heuristic Algorithm for the Routing and Scheduling Problem with Time Windows: A Case Study of the Automotive Industry in Mexico. Algorithms, 12(5), 111. https://doi.org/10.3390/a12050111