Mechanical Properties and Fracture Analysis of Advanced Nickel-Based Nanomembranes

Abstract

1. Introduction

- How does a change in the process parameters from 1000 °C/170 MPa to 950 °C/250 MPa affect the strength of the nickel-based nanomembranes?

- How do the fracture mechanisms differ between perpendicular and parallel loading of the raft structure?

- To what extent do inhomogeneities in the microstructure influence the strength under parallel loading of the raft structure and what could be the possible mechanism of origin?

2. Materials and Methods

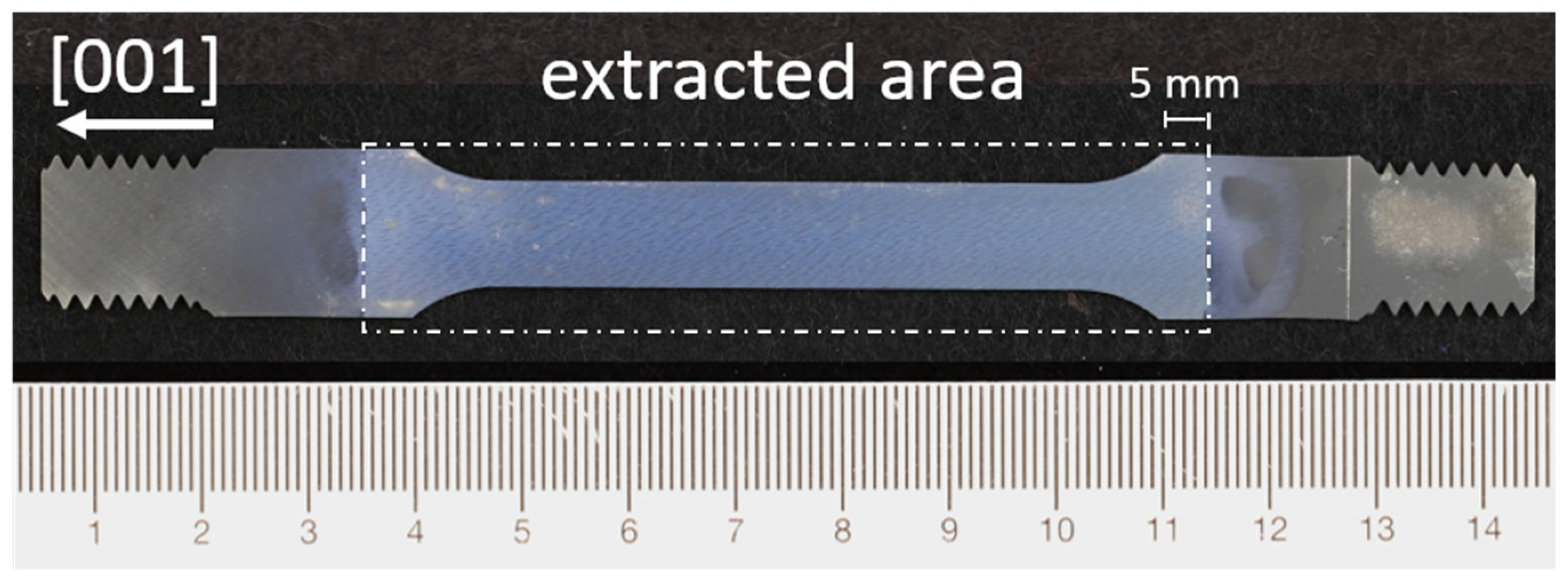

2.1. Creep Test Samples and Sample Preparation

2.2. Tensile Tests

2.3. Microstructure Analysis

2.4. Fracture Analysis

2.5. Electron Backscatter Diffraction—EBSD

3. Results

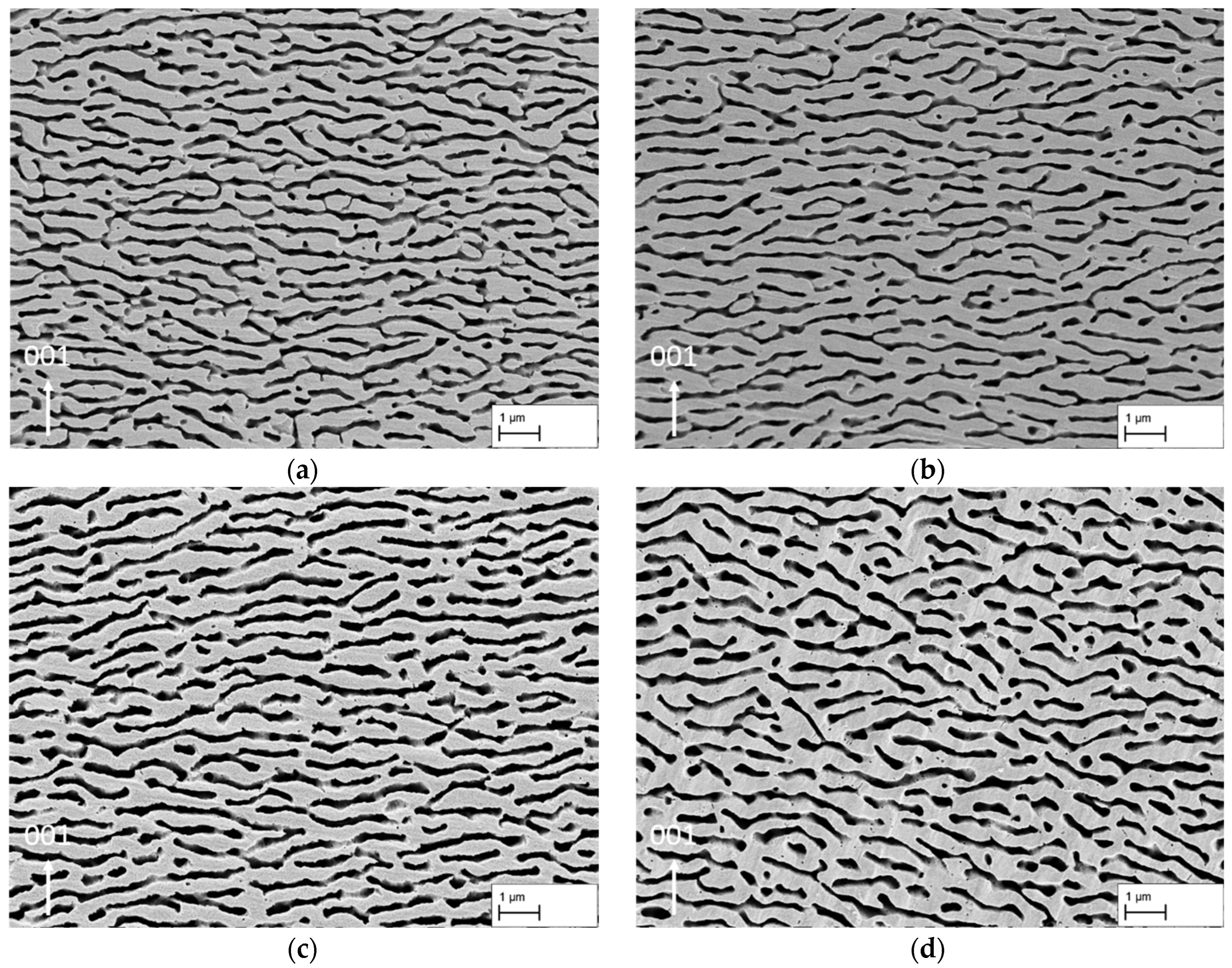

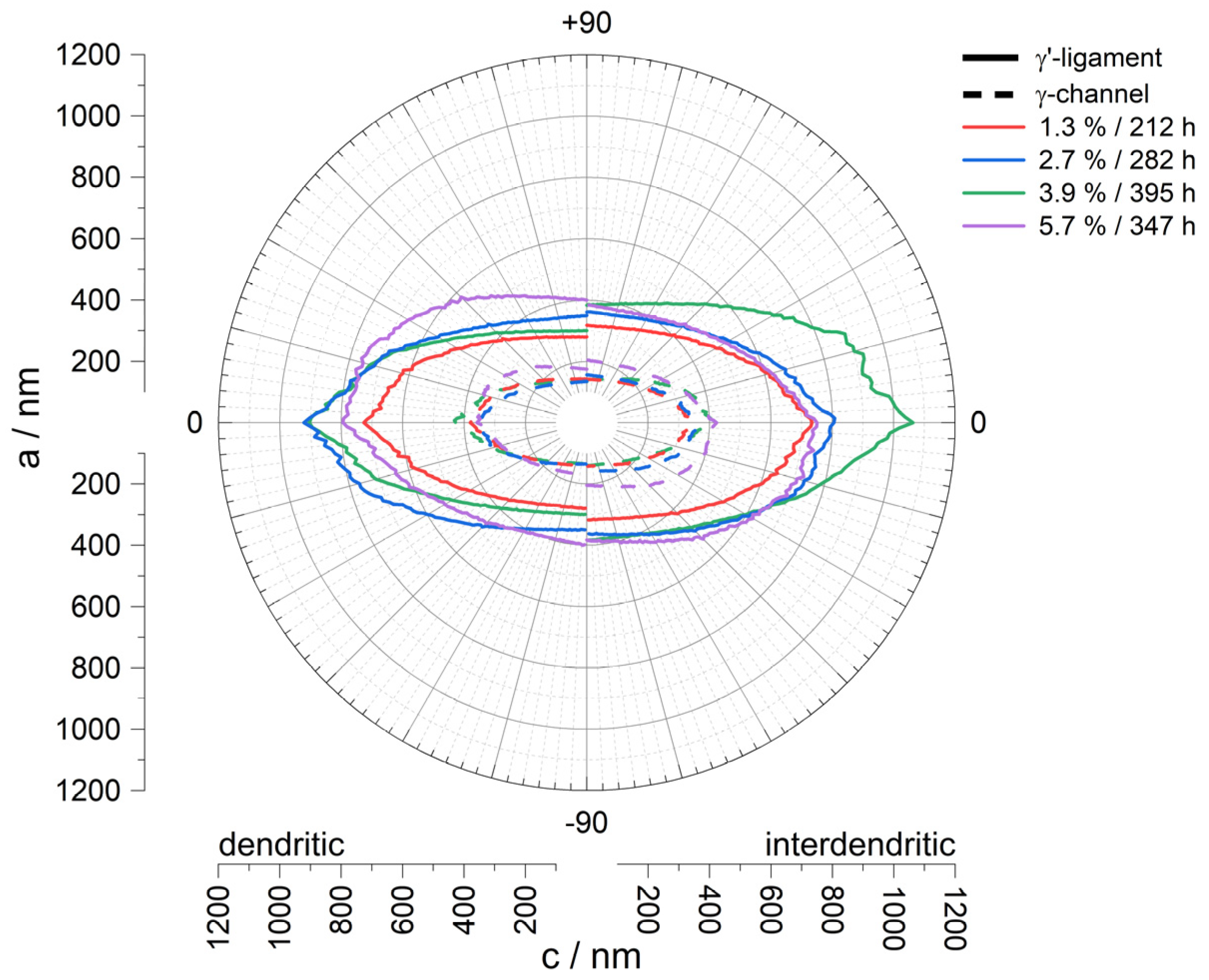

3.1. Pore Size and Structural Comparison

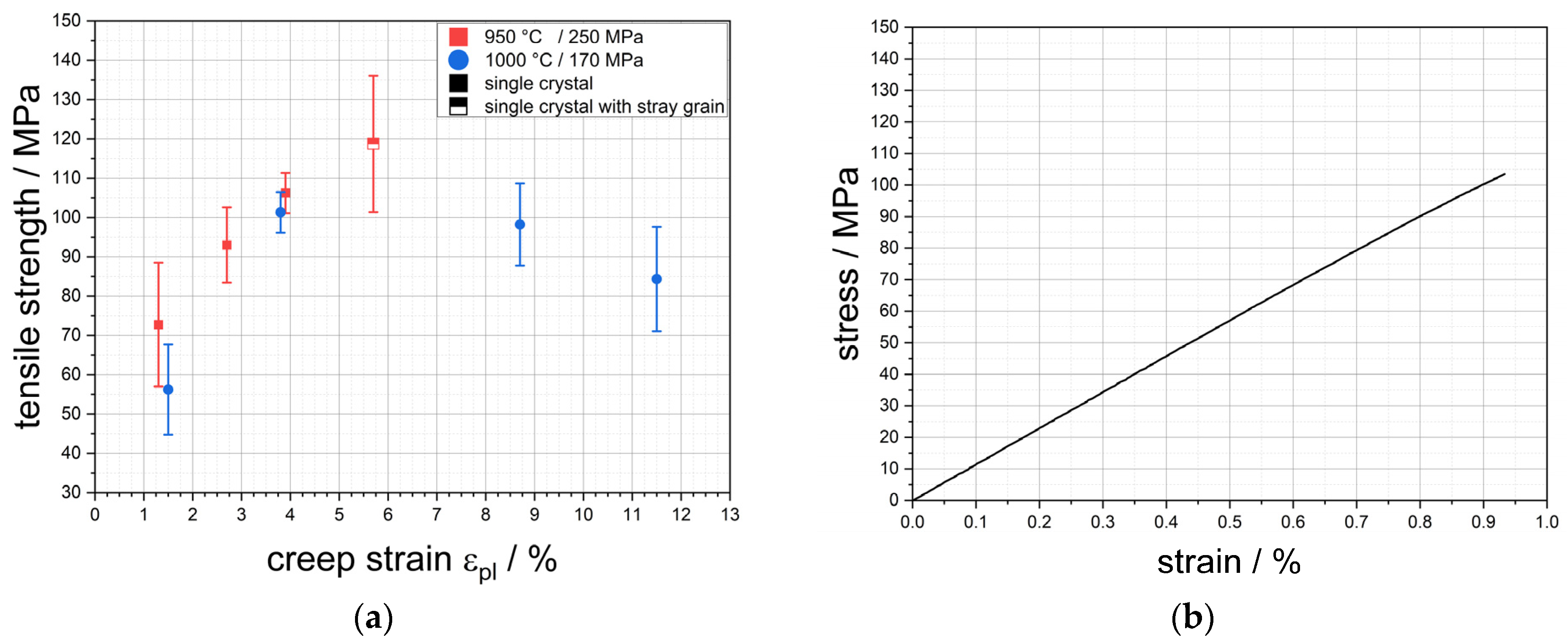

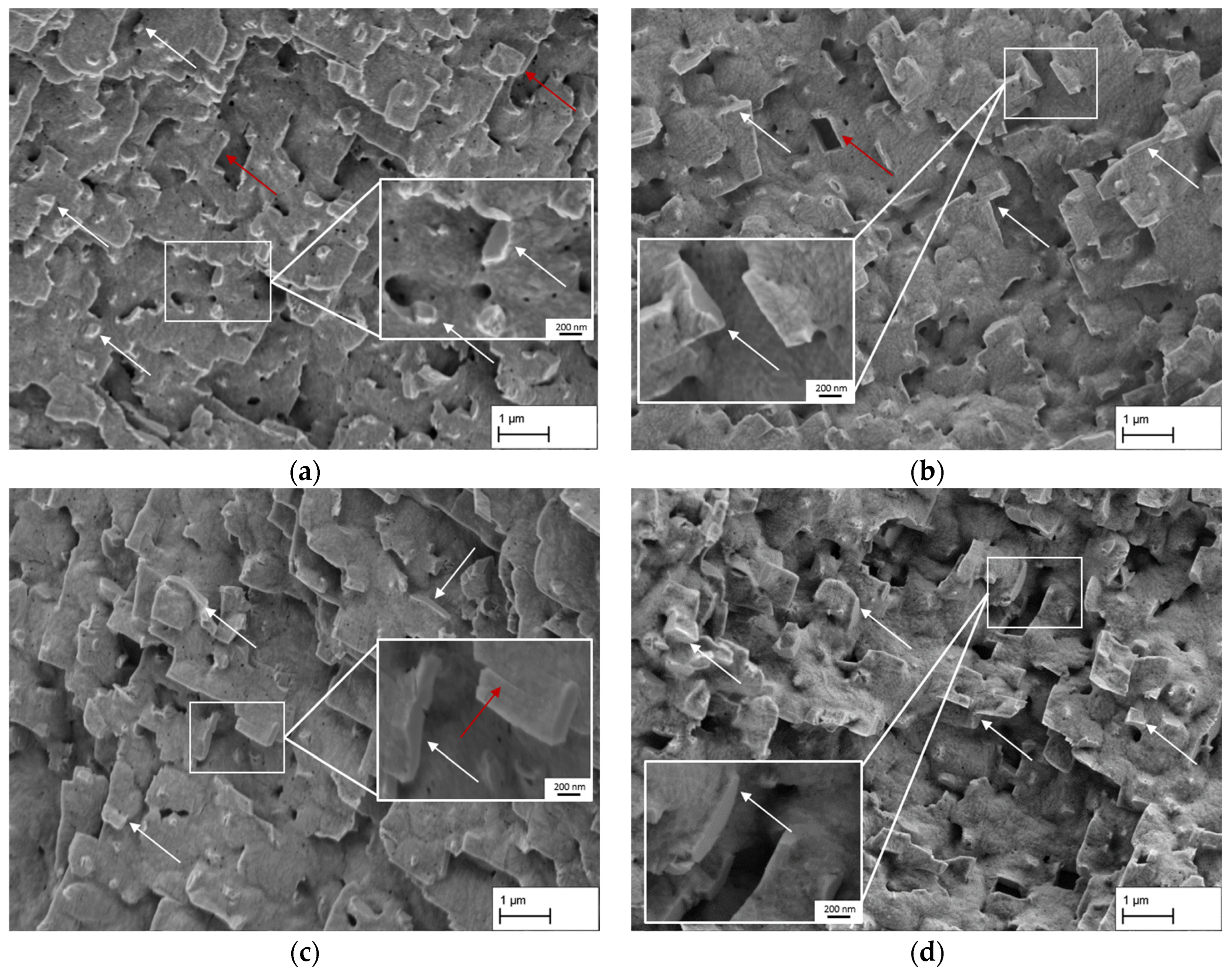

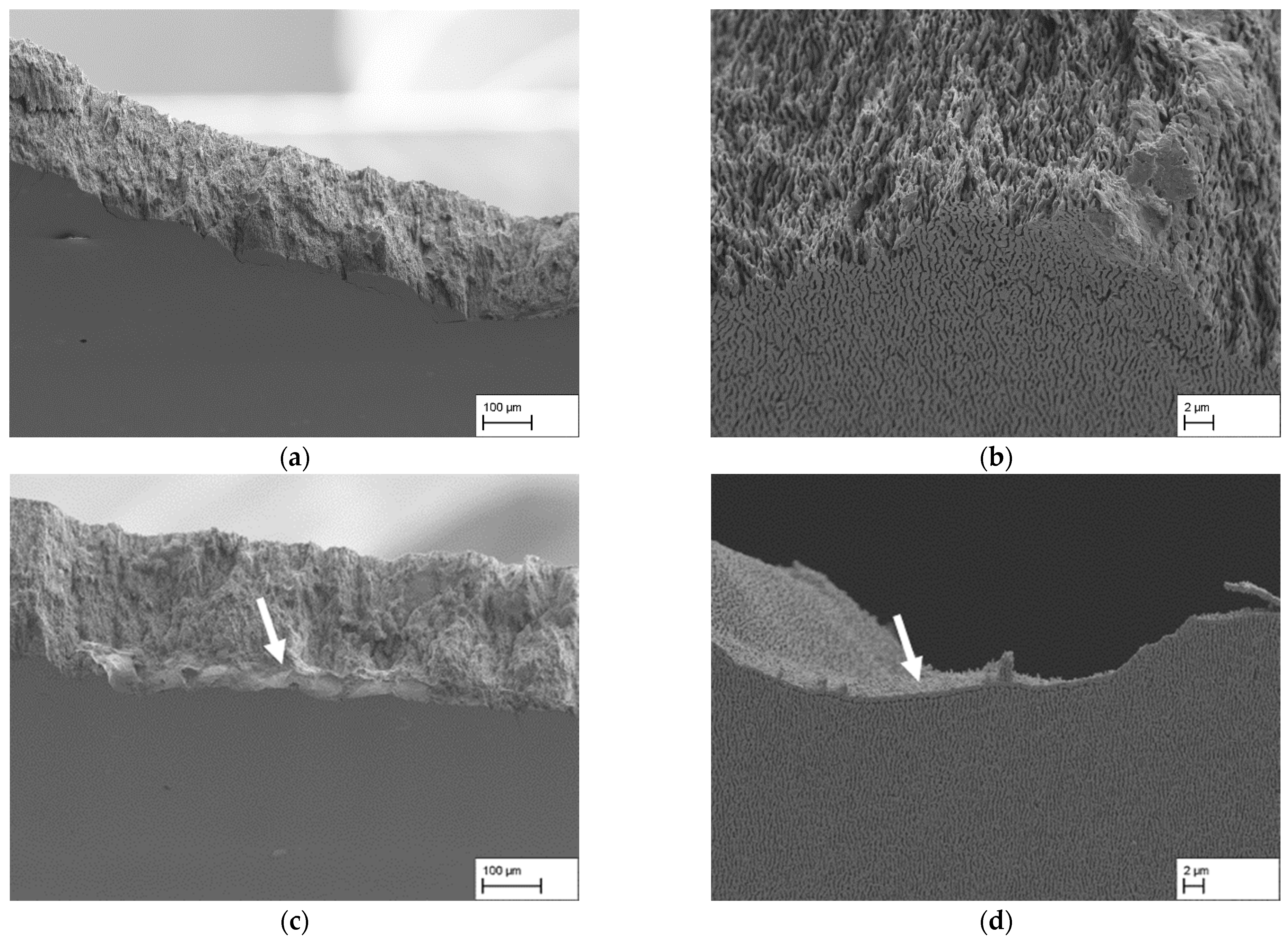

3.2. Tensile Test Perpendicular to the γ′-Raft Structure

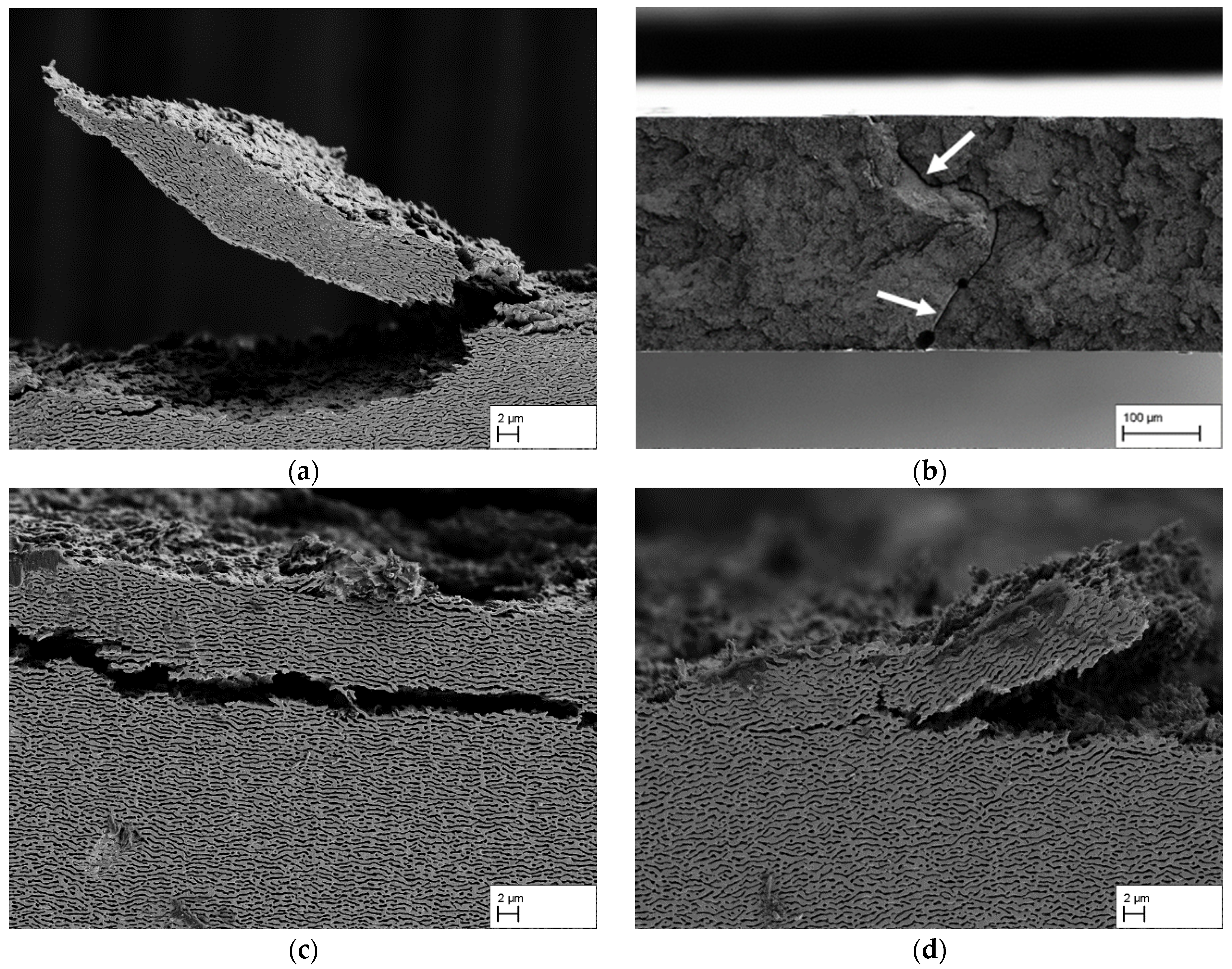

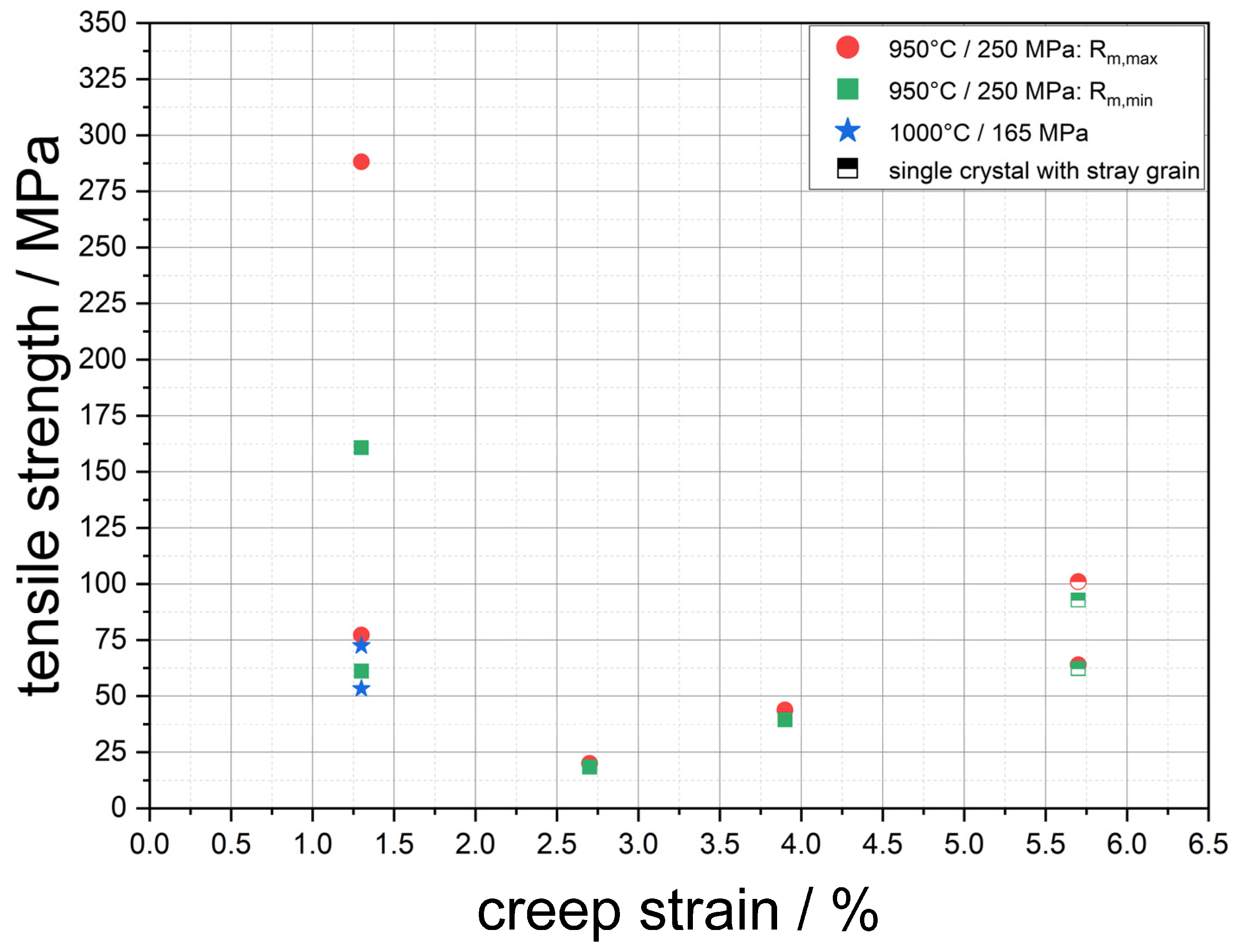

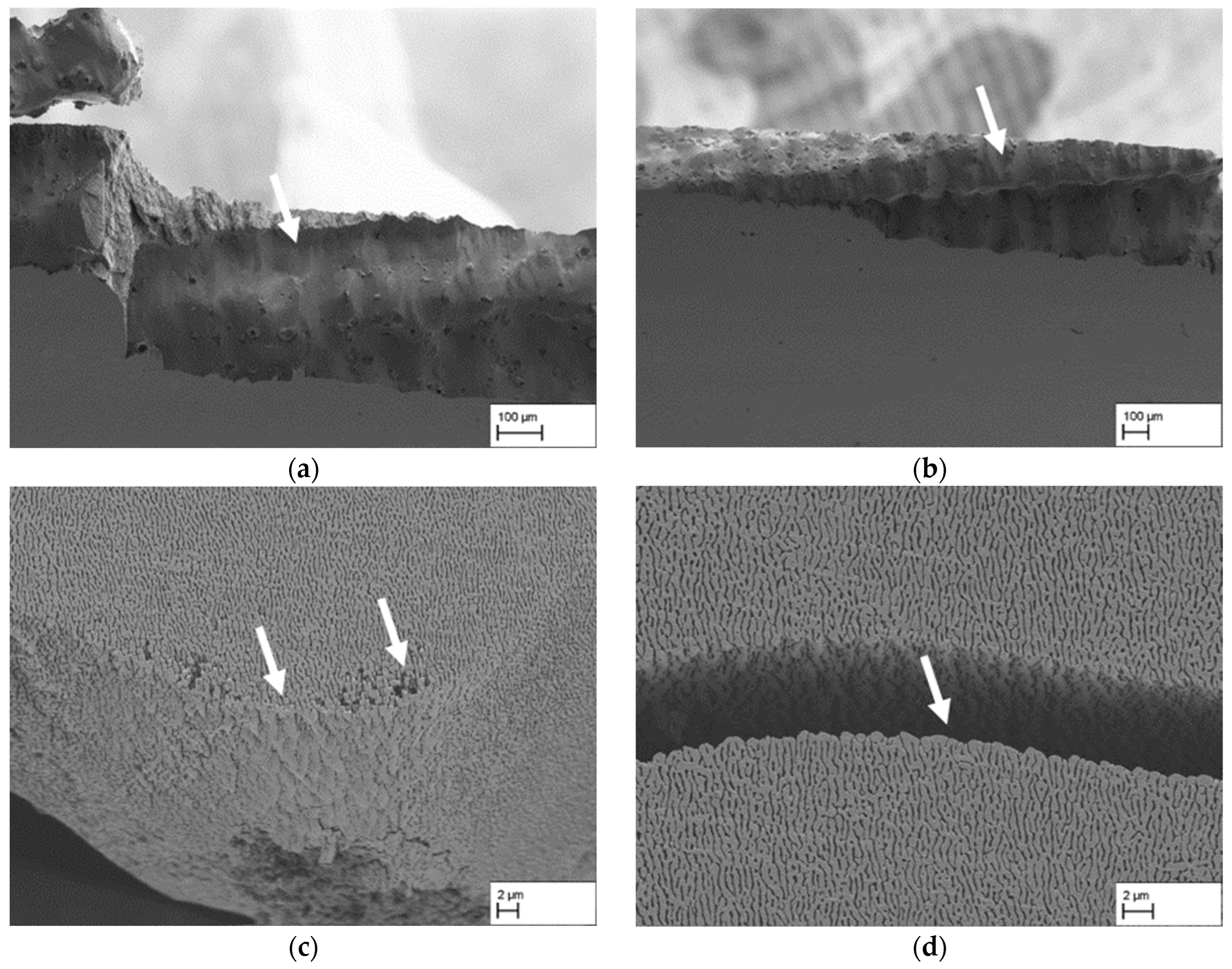

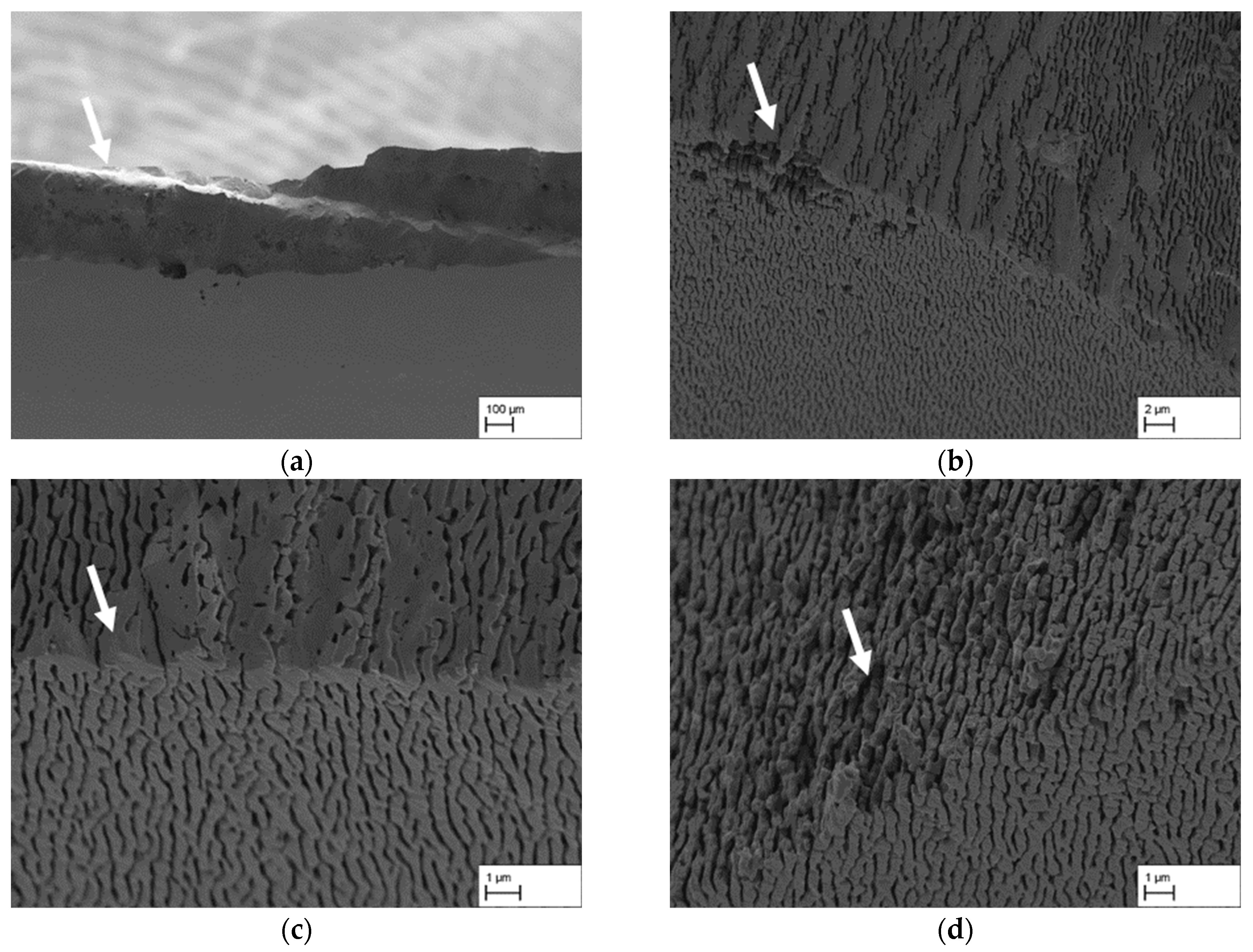

3.3. Tensile Tests Parallel to the γ′-Raft Structure

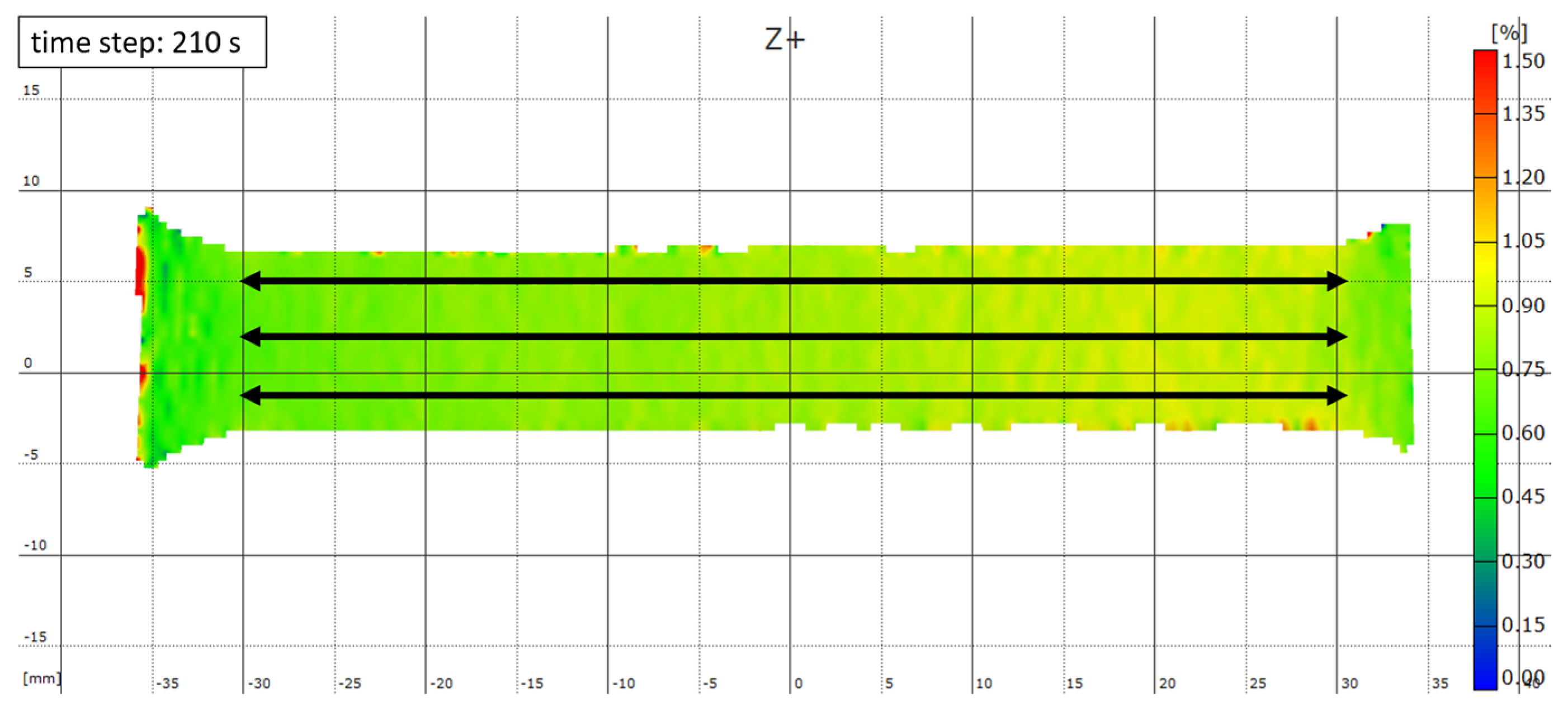

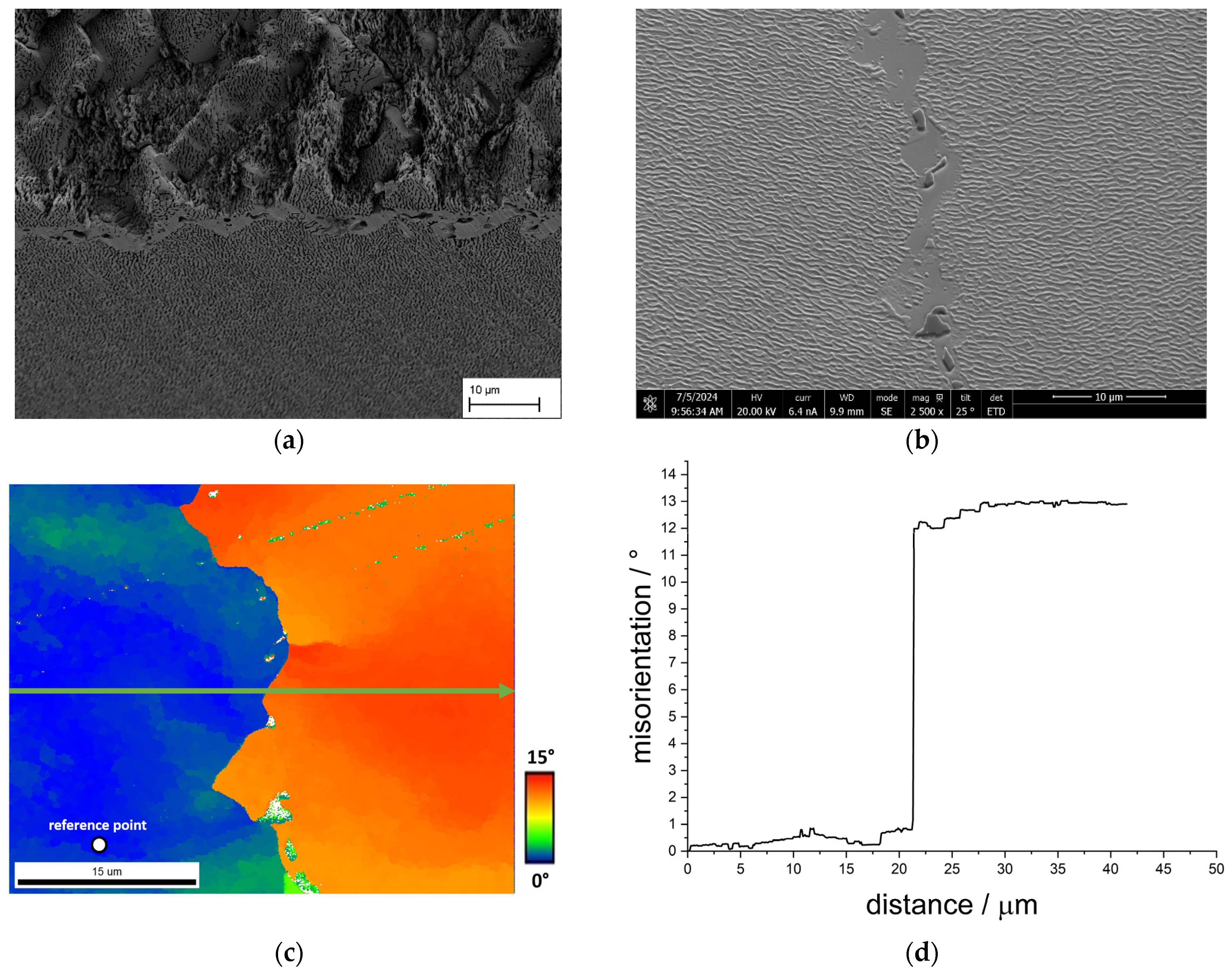

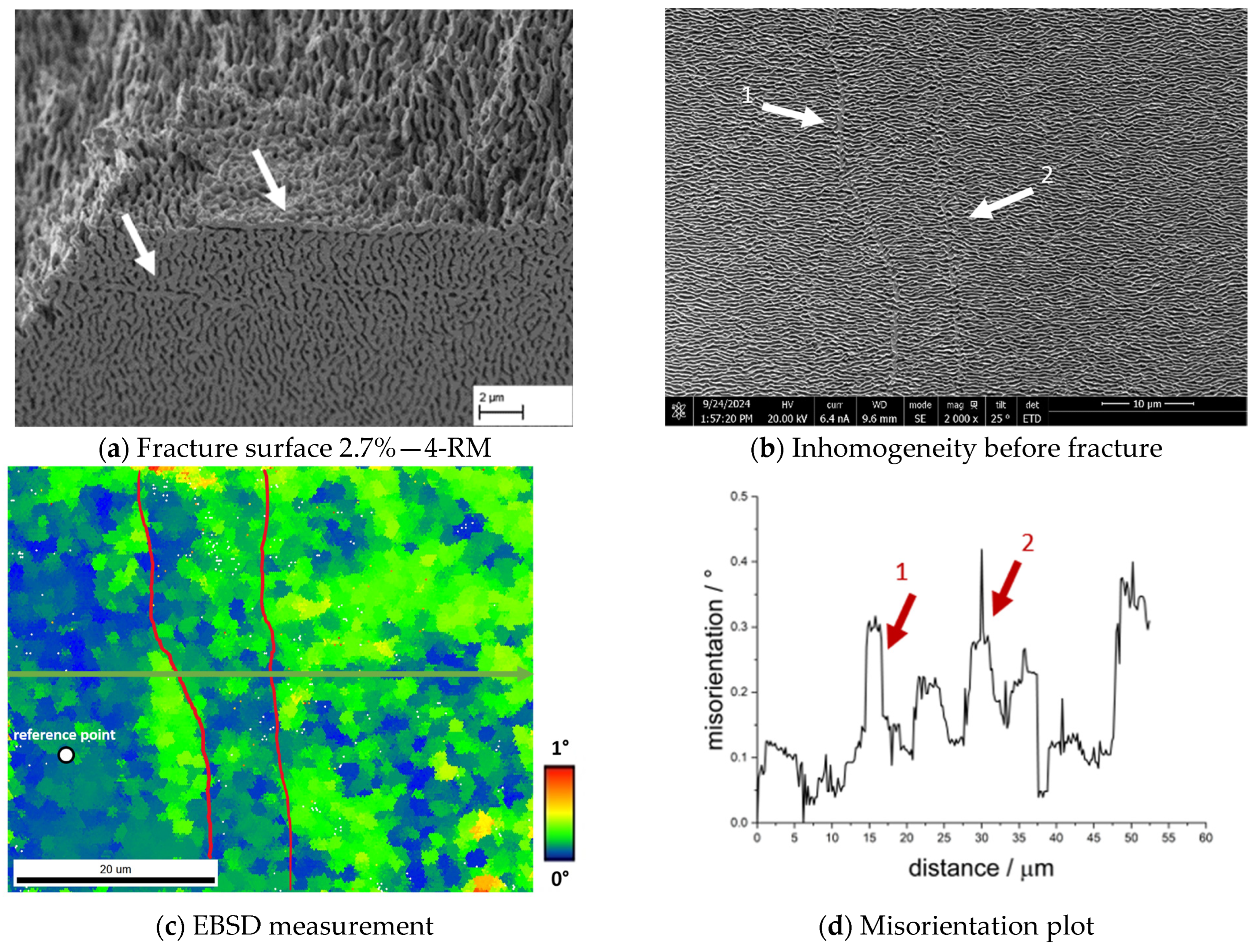

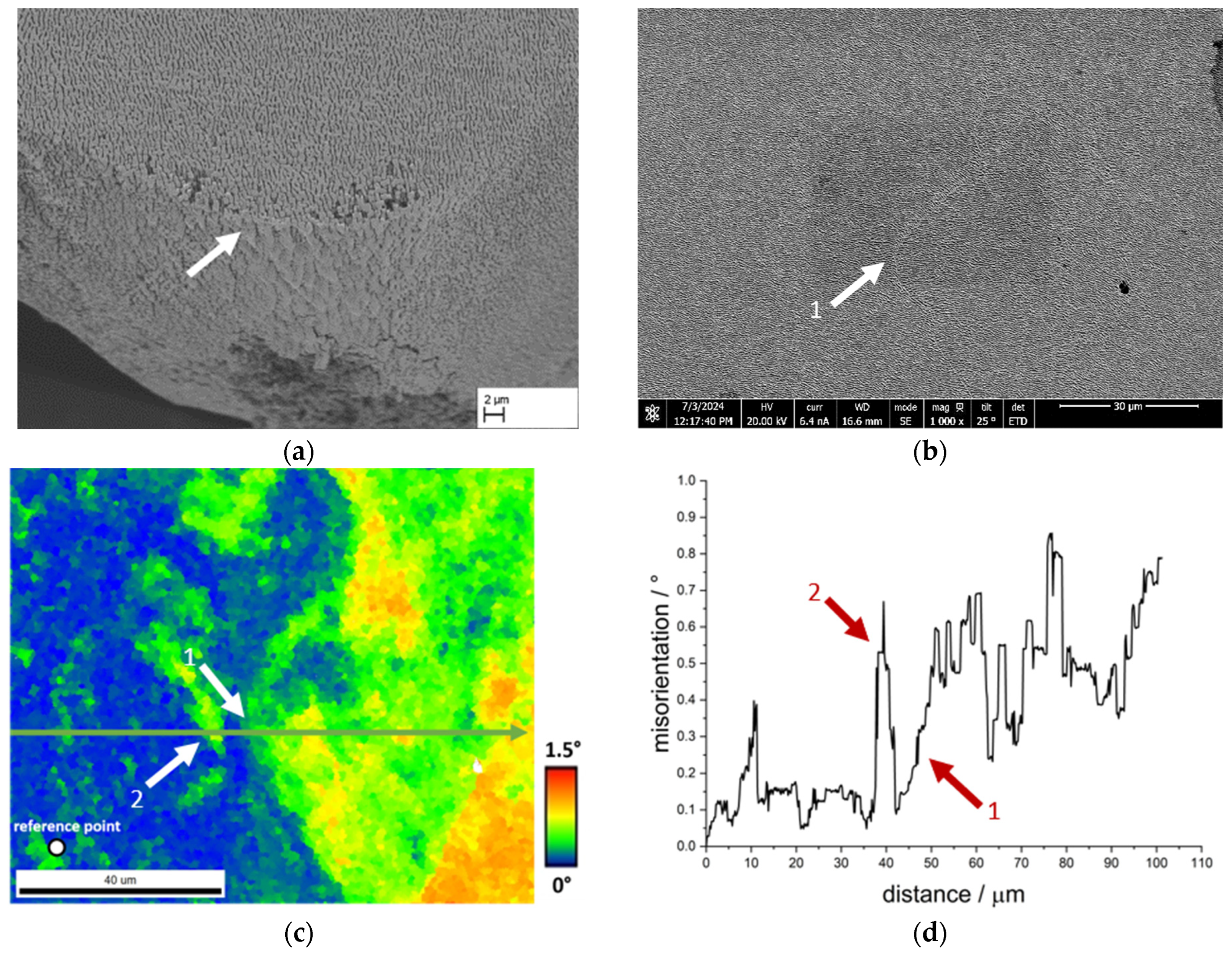

3.4. EBSD Measurements on γ′-Inhomogeneities

4. Discussion

4.1. Pore Structure and Mechanical Strength Perpendicular to the Rafting Structure

4.2. Mechanical Strength Parallel to the Raft Structure and Orientation Analysis

5. Conclusions

- The mechanical strength of nanomembranes strongly depends on the cross-linking of the γ′-rafting structure. The creep strain plays an important role, generally leading to higher tensile strengths during perpendicular loading of the raft structure with increasing creep strain due to a continuous cross-linking process. The orientation of the fractured rafts itself indicates that the failure of the rafts is mainly caused by shear stresses.

- The mechanical strength of nanomembranes during parallel loading of the raft structure strongly depends on the homogeneity of the microstructure. Orientation measurements using EBSD indicate that the formation of γ′-inhomogeneities originates from local orientation deviations between dendrites. The γ′-inhomogeneities can reduce the membrane strength due to a reduced cross-linking between areas with orientation deviations, leading to preferred crack progression during tensile testing.

- In the context of the later premix membrane emulsification application, a creep strain of approximately 4% combines a good mechanical strength with a small pore size in both dendritic and interdendritic areas.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kohnke, M.; Finke, J.; Kwade, A.; Rösler, J. Investigation of Nanoporous Superalloy Membranes for the Production of Nanoemulsions. Metals 2018, 8, 361. [Google Scholar] [CrossRef]

- Lück, J.M.; Rösler, J. Reducing the γ′-Particle Size in CMSX-4 for Membrane Development. Materials 2022, 15, 1320. [Google Scholar] [CrossRef]

- Lück, J.M.; Rösler, J. New Approach in the Determination of a Suitable Directionally Coarsened Microstructure for the Fabrication of Nanoporous Superalloy Membranes Based on CMSX-4. Materials 2023, 16, 3715. [Google Scholar] [CrossRef]

- Rösler, J.; Näth, O. Mechanical behaviour of nanoporous superalloy membranes. Acta Mater. 2010, 58, 1815–1828. [Google Scholar] [CrossRef]

- Harris, K.; Erickson, G.L.; Sikkenga, S.L.; Brentnall, W.D.; Aurrecoechea, J.M.; Kubarych, K.G. Development of two rhenium- containing superalloys for single-crystal blade and directionally solidified vane applications in advanced turbine engines. J. Mater. Eng. Perform. 1993, 2, 481–487. [Google Scholar] [CrossRef]

- 3M. 3MTM Eloxier-Abdeckband 8985L. Available online: https://www.3mdeutschland.de/3M/de_DE/p/d/b5005097131/ (accessed on 2 December 2024).

- Rösler, J.; Mukherji, D. Design of Nanoporous Superalloy Membranes for Functional Applications. Adv. Eng. Mater. 2003, 5, 916–918. [Google Scholar] [CrossRef]

- Rösler, J.; Näth, O.; Jäger, S.; Schmitz, F.; Mukherji, D. Fabrication of nanoporous Ni-based superalloy membranes. Acta Mater. 2005, 53, 1397–1406. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Arganda-Carreras, I.; Kaynig, V.; Rueden, C.; Eliceiri, K.W.; Schindelin, J.; Cardona, A.; Sebastian Seung, H. Trainable Weka Segmentation: A machine learning tool for microscopy pixel classification. Bioinformatics 2017, 33, 2424–2426. [Google Scholar] [CrossRef]

- Epishin, A.; Link, T.; Nazmy, M.; Staubli, M.; Klingelhffer, H.; Nolze, G. Microstructural Degradation of CMSX-4: Kinetics and Effect on Mechanical Properties. In Superalloys 2008, Proceedings of the 11th Int’l Symposium Superalloys 2008, Champion, PA, USA, 14–18 September 2008; TMS: Pittsburgh, PA, USA, 2008; pp. 725–731. ISBN 978-0-87339-728-5. [Google Scholar]

- Kamaraj, M. Rafting in single crystal nickel-base superalloys—An overview. Sadhana 2003, 28, 115–128. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in nickel-base single crystals with high volume fractions of coherent precipitates. Acta Metall. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Nabarro, F.R.N. Rafting in Superalloys. Met. Mater. Trans. A 1996, 27, 513–530. [Google Scholar] [CrossRef]

- Epishin, A.; Link, T.; Klingelhöffer, H.; Fedelich, B.; Brückner, U.; Portella, P.D. New technique for characterization of microstructural degradation under creep: Application to the nickel-base superalloy CMSX-4. Mater. Sci. Eng. A 2009, 510–511, 262–265. [Google Scholar] [CrossRef]

- Durand-Charre, M. The Microstructure of Superalloys; Routledge: London, UK, 2017; ISBN 9780203736388. [Google Scholar]

- Müller, M.; Böttger, B.; Schleifer, F.; Fleck, M.; Glatzel, U. 3D Minimum Channel Width Distribution in a Ni-Base Superalloy. Integr. Mater. Manuf. Innov. 2023, 12, 27–40. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Yu, Z.; Ding, X.; Zheng, Y.; Cao, L.; Feng, Q. Misorientation effect of grain boundary on the formation of discontinuous precipitation in second and third generation single crystal superalloys. MATEC Web Conf. 2014, 14, 11006. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, H.; Li, J.; Zhang, Y.; Liu, J.; Liu, T. An innovative approach towards forming the serrated grain boundaries and refining the γ′ precipitates in nickel-based superalloys. J. Alloys Compd. 2022, 908, 164570. [Google Scholar] [CrossRef]

- Tang, Y.T.; Karamched, P.; Liu, J.; Haley, J.C.; Reed, R.C.; Wilkinson, A.J. Grain boundary serration in nickel alloy inconel 600: Quantification and mechanisms. Acta Mater. 2019, 181, 352–366. [Google Scholar] [CrossRef]

- Mitchell, R.J.; Li, H.Y.; Huang, Z.W. On the formation of serrated grain boundaries and fan type structures in an advanced polycrystalline nickel-base superalloy. J. Mater. Process. Technol. 2009, 209, 1011–1017. [Google Scholar] [CrossRef]

- Koul, A.K.; Gessinger, G.H. On the mechanism of serrated grain boundary formation in Ni-based superalloys. Acta Metall. 1983, 31, 1061–1069. [Google Scholar] [CrossRef]

- Xu, W.; Wang, F.; Ma, D.; Zhu, X.; Li, D.; Bührig-Polaczek, A. Sliver defect formation in single crystal Ni-based superalloy castings. Mater. Des. 2020, 196, 109138. [Google Scholar] [CrossRef]

- Aveson, J.; Reinhart, G.; Nguyen-Thi, H.; Mangelinck-Noël, N.; Tandjaoui, A.; Billia, B.; Goodwin, K.; Lafford, T.; Baruchel, J.; Stone, H.; et al. Dendrite Bending during Directional Solidification. In Superalloys 2012, Proceedings of the Twelfth International Symposium), Champion, PA, USA, 9–13 September 2012; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Aveson, J.W.; Reinhart, G.; Goddard, C.J.L.; Nguyen-Thi, H.; Mangelinck-Noël, N.; Tandjaoui, A.; Davenport, J.R.; Warnken, N.; Di Gioacchino, F.; Lafford, T.A.; et al. On the Deformation of Dendrites During Directional Solidification of a Nickel-Based Superalloy. Met. Mater. Trans. A 2019, 50, 5234–5241. [Google Scholar] [CrossRef]

- Yu, X.; Xuan, W.; Zhang, C.; Zhang, X.; Wang, X.; Zhao, Y.; Wang, B.; Li, H.; Bao, J.; Ren, Z. An insight into the creep failure mechanism of sliver defect in the second-generation nickel-based single crystal superalloy CMSX-4. Eng. Fract. Mech. 2024, 307, 110307. [Google Scholar] [CrossRef]

- Reed, R.C.; Cox, D.C.; Rae, C.M.F. Kinetics of rafting in a single crystal superalloy: Effects of residual microsegregation. Mater. Sci. Technol. 2007, 23, 893–902. [Google Scholar] [CrossRef]

| Specimen-ID | Cross Section/mm2 | Stress σ/MPa | Creep Strain εpl/% | Duration/h |

|---|---|---|---|---|

| CMSX-4/1.3/212 | 112.0 | 250 | 1.3 | 212 |

| CMSX-4/2.7/282 | 112.0 | 2.7 | 282 | |

| CMSX-4/3.9/395 | 100.8 | 3.9 | 395 | |

| CMSX-4/5.7/347 * | 112.0 | 5.7 | 347 |

| CMSX-4/1.3/212 | CMSX-4/2.7/282 | CMSX-4/3.9/395 | CMSX-4/5.7/347 | |

|---|---|---|---|---|

| cd,γ-channel | 379 (310) | 376 (273) | 427 (351) | 358 (270) |

| cid,γ-channel | 341 (298) | 361 (270) | 411 (348) | 423 (336) |

| ad,γ-channel | 142 (44) | 134 (42) | 134 (39) | 174 (55) |

| aid,γ-channel | 141 (48) | 156 (58) | 140 (44) | 204 (65) |

| cd,γ′-ligament | 726 (596) | 921 (725) | 904 (755) | 794 (588) |

| cid,γ′-ligament | 733 (623) | 805 (599) | 1063 (857) | 750 (596) |

| ad,γ′-ligament | 280 (128) | 350 (170) | 300 (146) | 400 (212) |

| aid,γ‘-ligament | 318 (158) | 360 (191) | 383 (191) | 383 (206) |

| (c/a)d,γ-channel | 2.67 | 2.80 | 3.19 | 2.06 |

| (c/a)id,γ-channel | 2.42 | 2.31 | 2.94 | 2.07 |

| (c/a)d,γ′-ligament | 2.59 | 2.63 | 3.01 | 1.99 |

| (c/a)id,γ′-ligament | 2.31 | 2.24 | 2.78 | 1.96 |

| Specimen-ID | Creep Strain εpl/% | Thickness t/mm | Width w/mm | Cross-Sectional Area/mm2 | Rm/ MPa | Mean Rm/ MPa | SD Rm/ MPa | E*/ GPa | Mean E*/ GPa | SD E*/ GPa | Mean A/% | Stdv. A/% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CMSX-4/1.3/212-1 | 1.3 | 0.30 | 10 | 3.0 | 52 | 72.75 | 15.75 | 8.3 | 8.9 | 0.9 | 0.63 | 0.01 |

| CMSX-4/1.3/212-3 | 0.29 | 10 | 2.9 | 85 | 9.6 | 0.91 | 0.01 | |||||

| CMSX-4/1.3/212-5 | 0.29 | 10 | 2.9 | 85 | 9.8 | 0.88 | 0.01 | |||||

| CMSX-4/1.3/212-9 | 0.30 | 10 | 3.0 | 69 | 8.1 | 0.85 | 0.01 | |||||

| CMSX-4/2.7/282-3 | 2.7 | 0.30 | 10 | 3.0 | 82 | 93.00 | 9.55 | 13.6 | 13.9 | 0.7 | 0.60 | 0.00 |

| CMSX-4/2.7/282-5 | 0.30 | 10 | 3.0 | 97 | 13.4 | 0.74 | 0.01 | |||||

| CMSX-4/2.7/282-7 | 0.30 | 10 | 3.0 | 104 | 14.9 | 0.71 | 0.00 | |||||

| CMSX-4/2.7/282-9 | 0.29 | 10 | 2.9 | 89 | 13.8 | 0.79 | 0.01 | |||||

| CMSX-4/3.9/395-1 | 3.9 | 0.30 | 10 | 3.0 | 104 | 106.25 | 5.12 | 11.5 | 11.6 | 0.3 | 0.93 | 0.01 |

| CMSX-4/3.9/395-3 | 0.30 | 10 | 3.0 | 101 | 11.8 | 0.88 | 0.01 | |||||

| CMSX-4/3.9/395-5 | 0.30 | 10 | 3.0 | 107 | 11.2 | 0.99 | 0.01 | |||||

| CMSX-4/3.9/395-7 | 0.30 | 10 | 3.0 | 113 | 11.8 | 1.00 | 0.01 | |||||

| CMSX-4/5.7/347-1 | 5.7 | 0.30 | 10 | 3.0 | 137 | 118.75 | 17.34 | 16.7 | 15.9 | 0.8 | 0.84 | 0.00 |

| CMSX-4/5.7/347-3 | 0.28 | 10 | 2.8 | 106 | 15.8 | 0.68 | 0.01 | |||||

| CMSX-4/5.7/347-5 | 0.29 | 10 | 2.9 | 102 | 16.1 | 0.64 | 0.00 | |||||

| CMSX-4/5.7/347-7 | 0.28 | 10 | 2.8 | 130 | 14.9 | 0.89 | 0.01 |

| Specimen-ID | Creep Strain εpl/% | Thickness t/mm | Min. Width wmin/mm | Max. Width wmax/mm | Rm,min/MPa | Rm,max/MPa |

|---|---|---|---|---|---|---|

| CMSX-4/1.3/212-4-R | 1.3 | 0.33 | 12.02 | 15.17 | 61 | 77 |

| CMSX-4/1.3/212-6-LM | 1.3 | 0.28 | 8.23 | 14.76 | 160 | 288 |

| CMSX-4/2.7/282-4-RM | 2.7 | 0.33 | 14.03 | 15.26 | 18 | 20 |

| CMSX-4/3.9/395-4-RM | 3.9 | 0.29 | 12.97 | 14.38 | 39 | 43 |

| CMSX-4/5.7/347-8-LM | 5.7 | 0.30 | 13.80 | 15.03 | 92 | 101 |

| CMSX-4/5.7/347-8-L | 5.7 | 0.30 | 14.18 | 14.58 | 62 | 63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the Lithuanian University of Health Sciences. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lück, J.M.; Rösler, J. Mechanical Properties and Fracture Analysis of Advanced Nickel-Based Nanomembranes. Materials 2025, 18, 1961. https://doi.org/10.3390/ma18091961

Lück JM, Rösler J. Mechanical Properties and Fracture Analysis of Advanced Nickel-Based Nanomembranes. Materials. 2025; 18(9):1961. https://doi.org/10.3390/ma18091961

Chicago/Turabian StyleLück, Janik Marius, and Joachim Rösler. 2025. "Mechanical Properties and Fracture Analysis of Advanced Nickel-Based Nanomembranes" Materials 18, no. 9: 1961. https://doi.org/10.3390/ma18091961

APA StyleLück, J. M., & Rösler, J. (2025). Mechanical Properties and Fracture Analysis of Advanced Nickel-Based Nanomembranes. Materials, 18(9), 1961. https://doi.org/10.3390/ma18091961