Surface Modification and Crystal Quality Improvement of 4H-SiC Film via Laser Treatment: Comparison of Continuous Wave and Femtosecond Pulse Laser

Abstract

1. Introduction

2. Materials and Methods

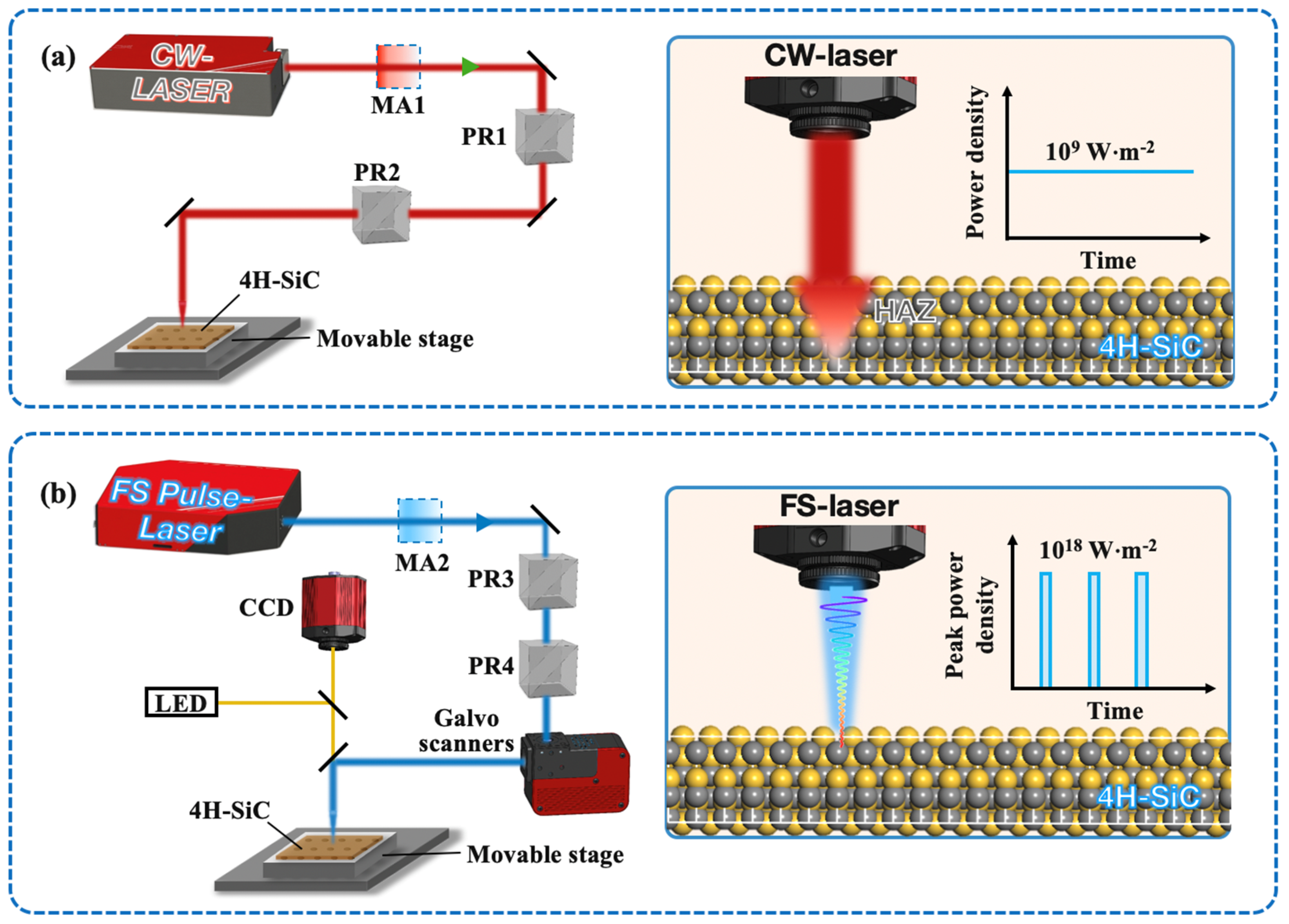

2.1. Laser Treatment Procedures

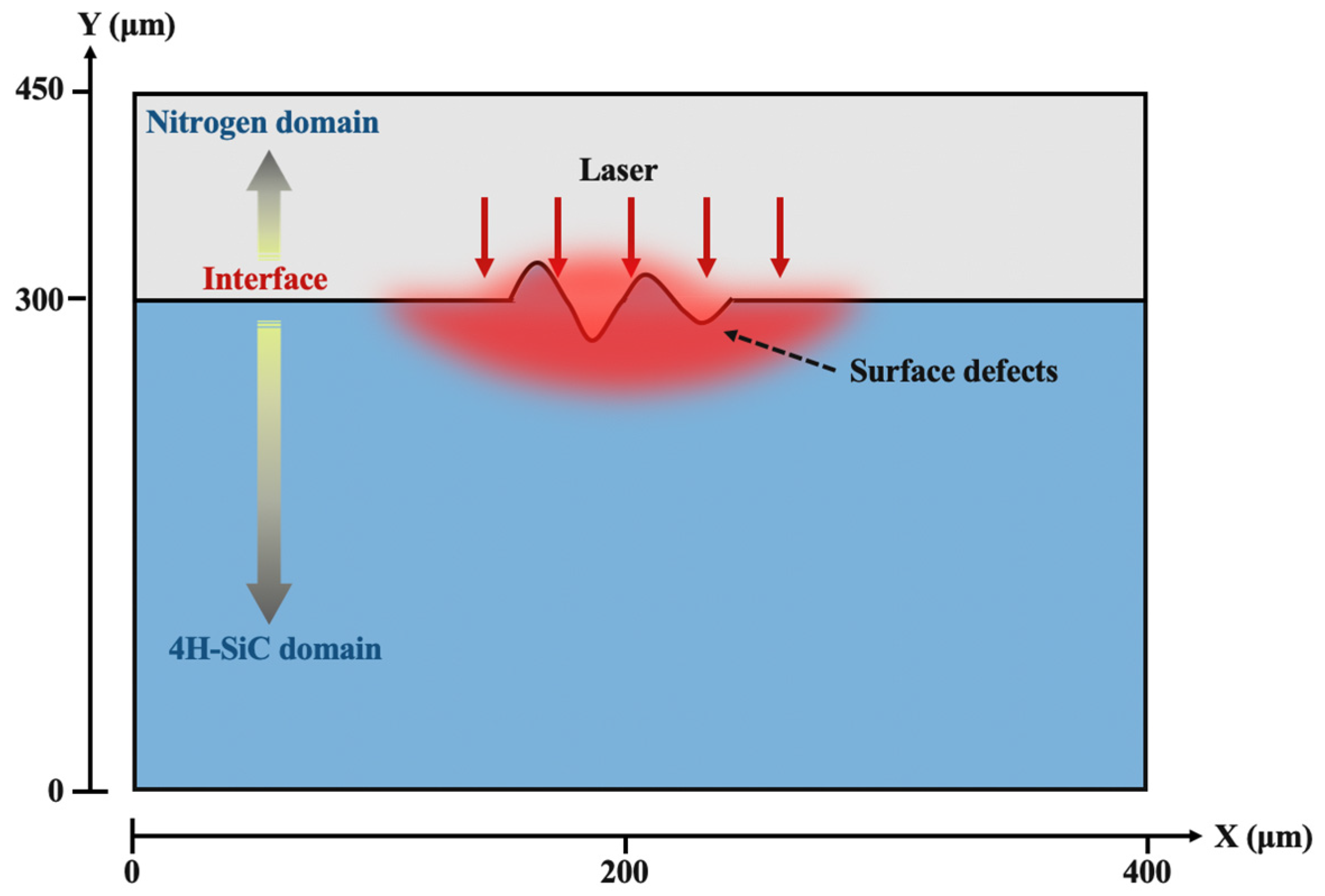

2.2. Modeling and Simulation

- CW Laser Treatment of 4H-SiC

- 2.

- FS pulse laser treatment of 4H-SiC

3. Results and Discussion

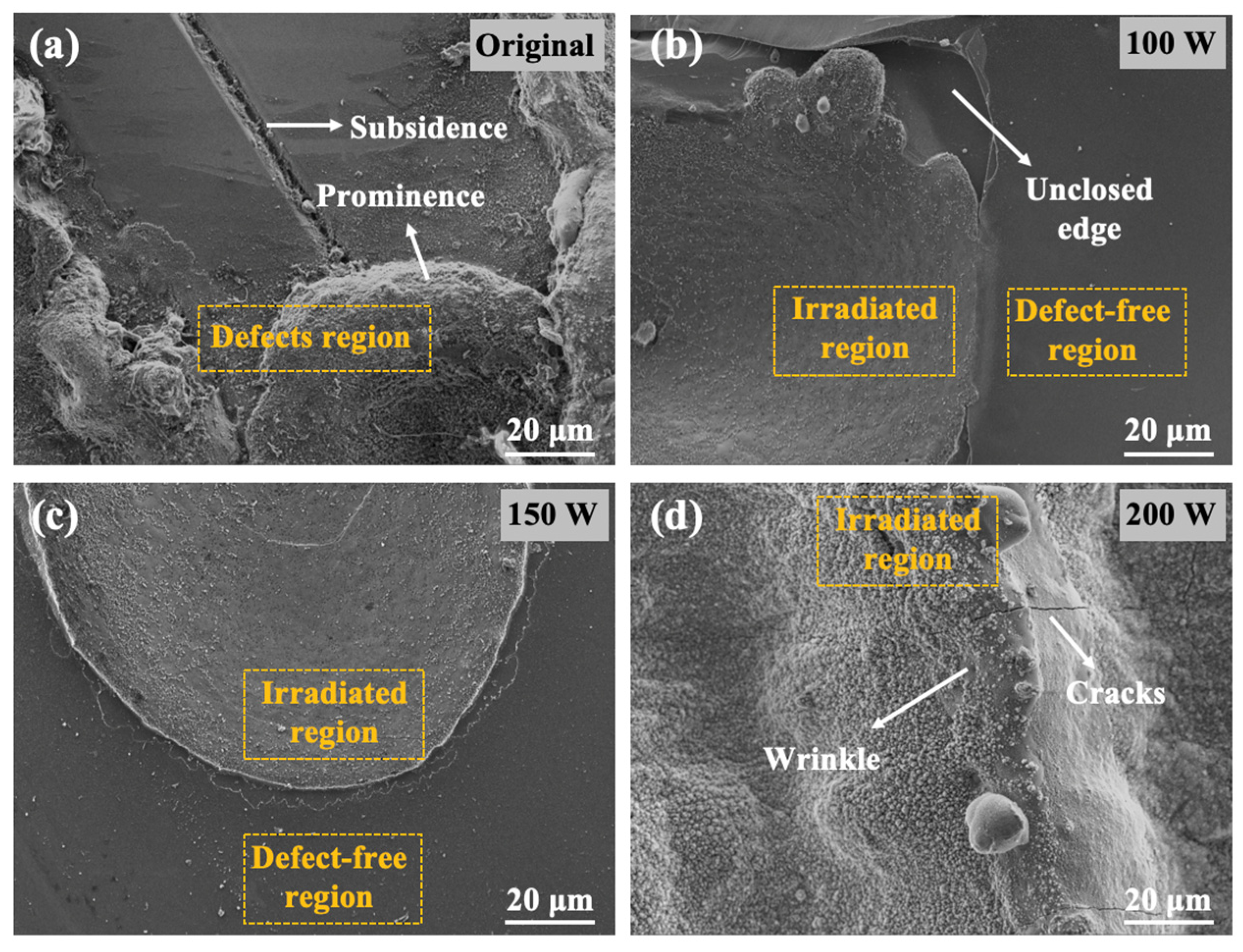

3.1. Surface Morphology

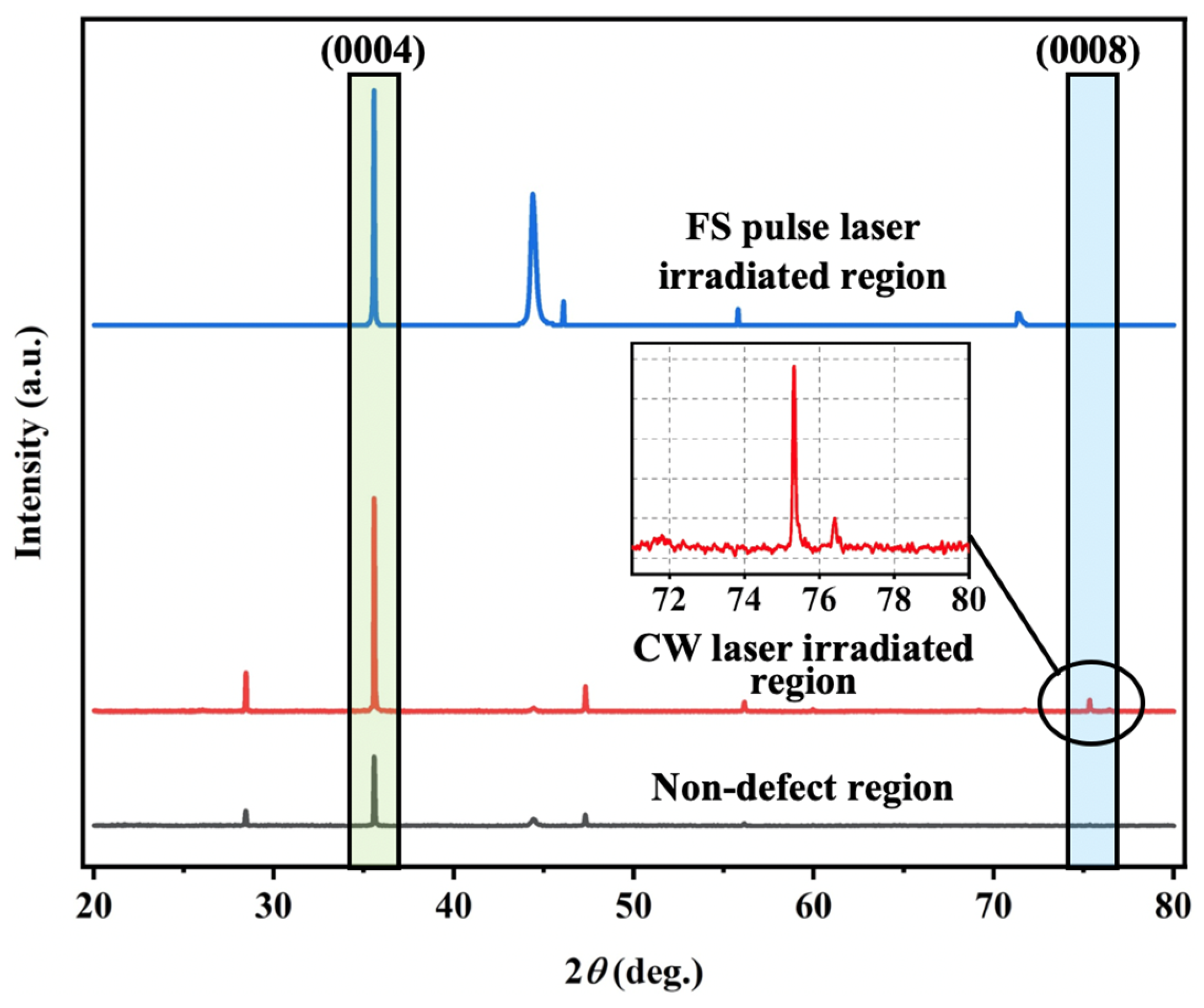

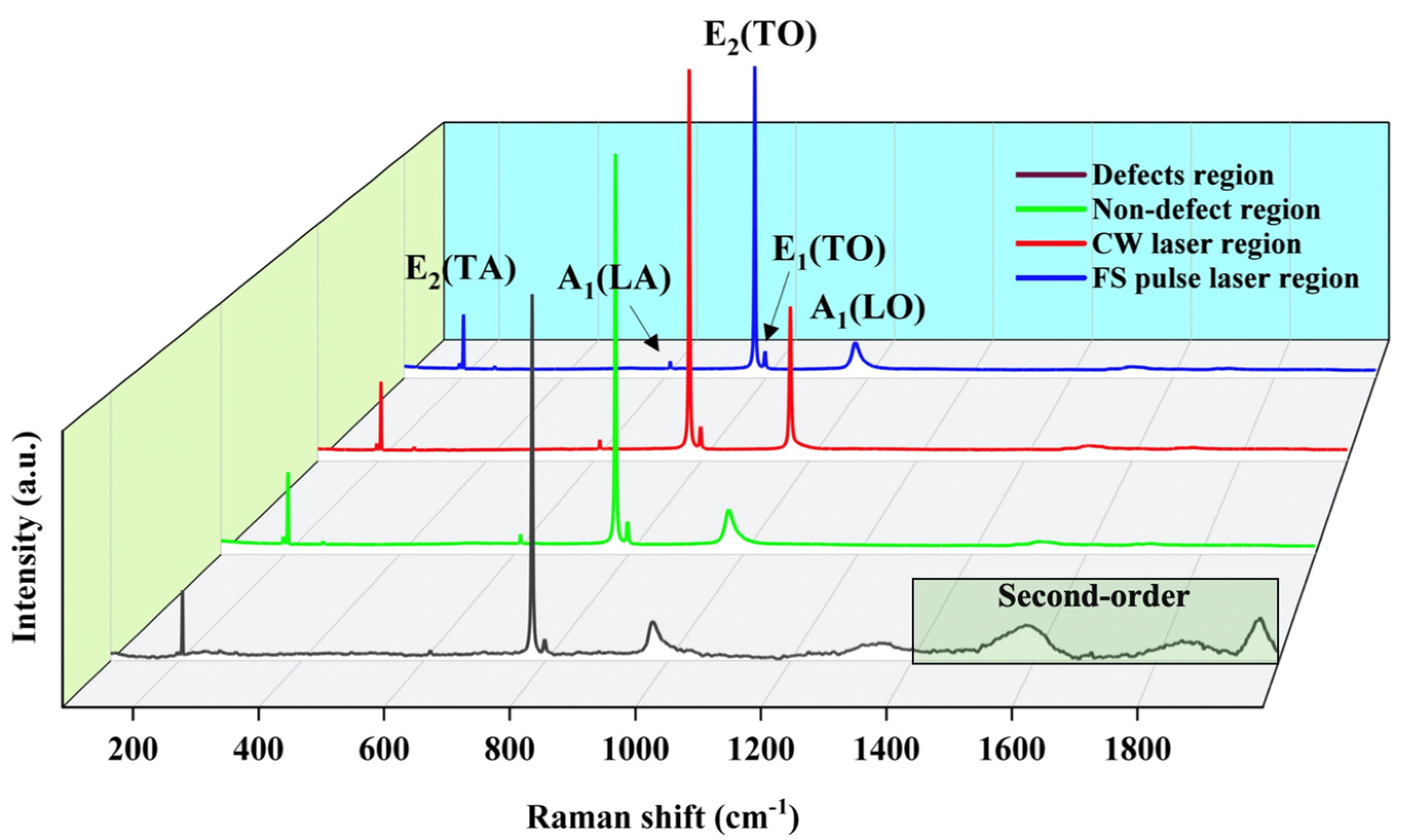

3.2. Phase Changing

3.3. Laser Treatment Mechanisms

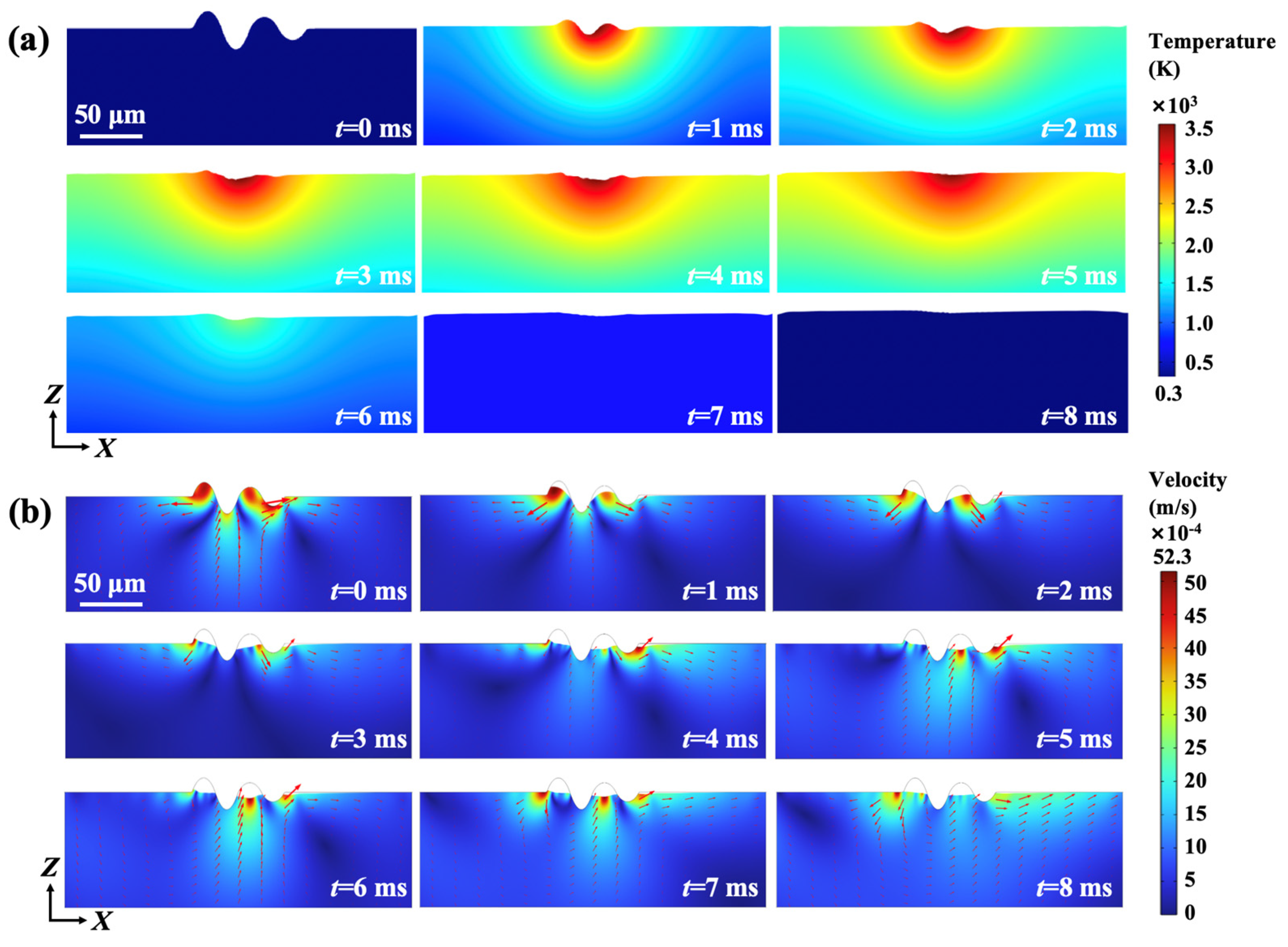

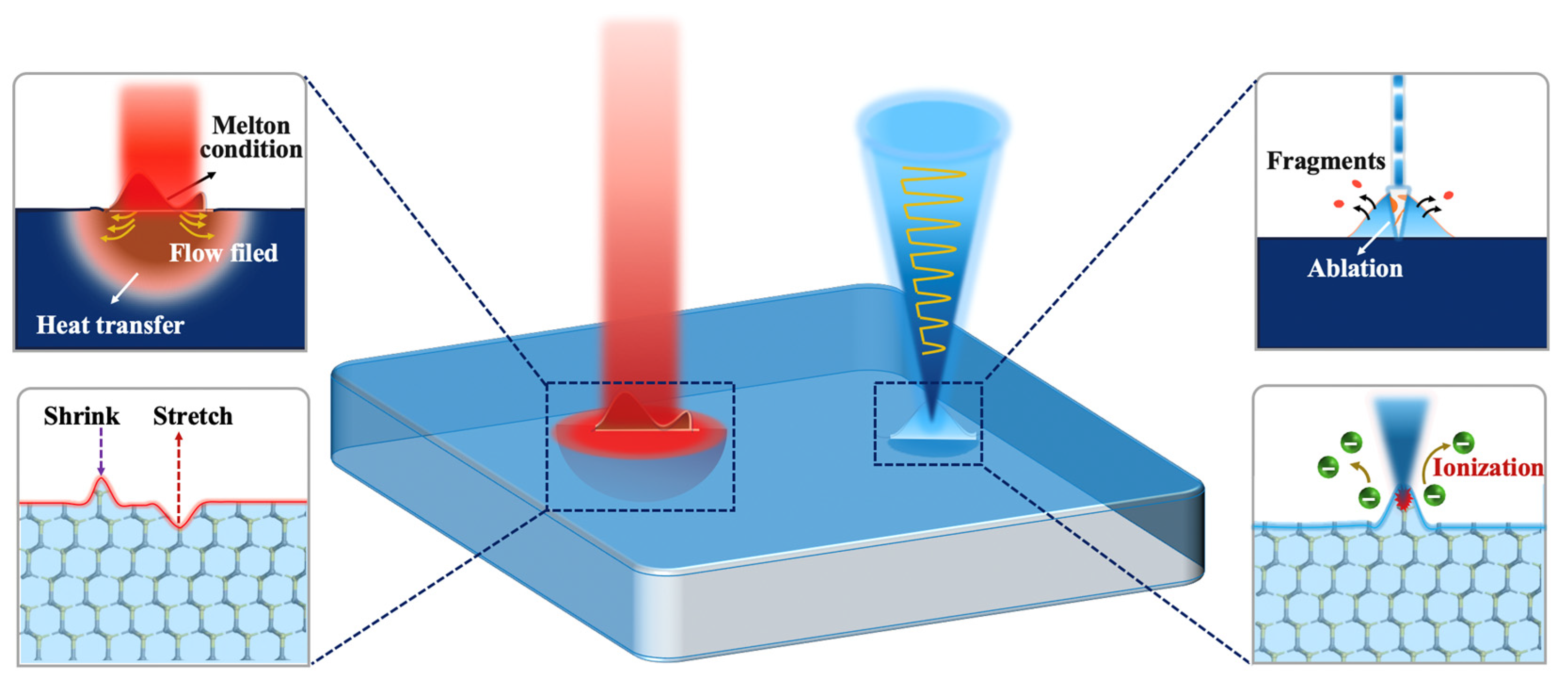

- CW laser treatment of 4H-SiC

- 2.

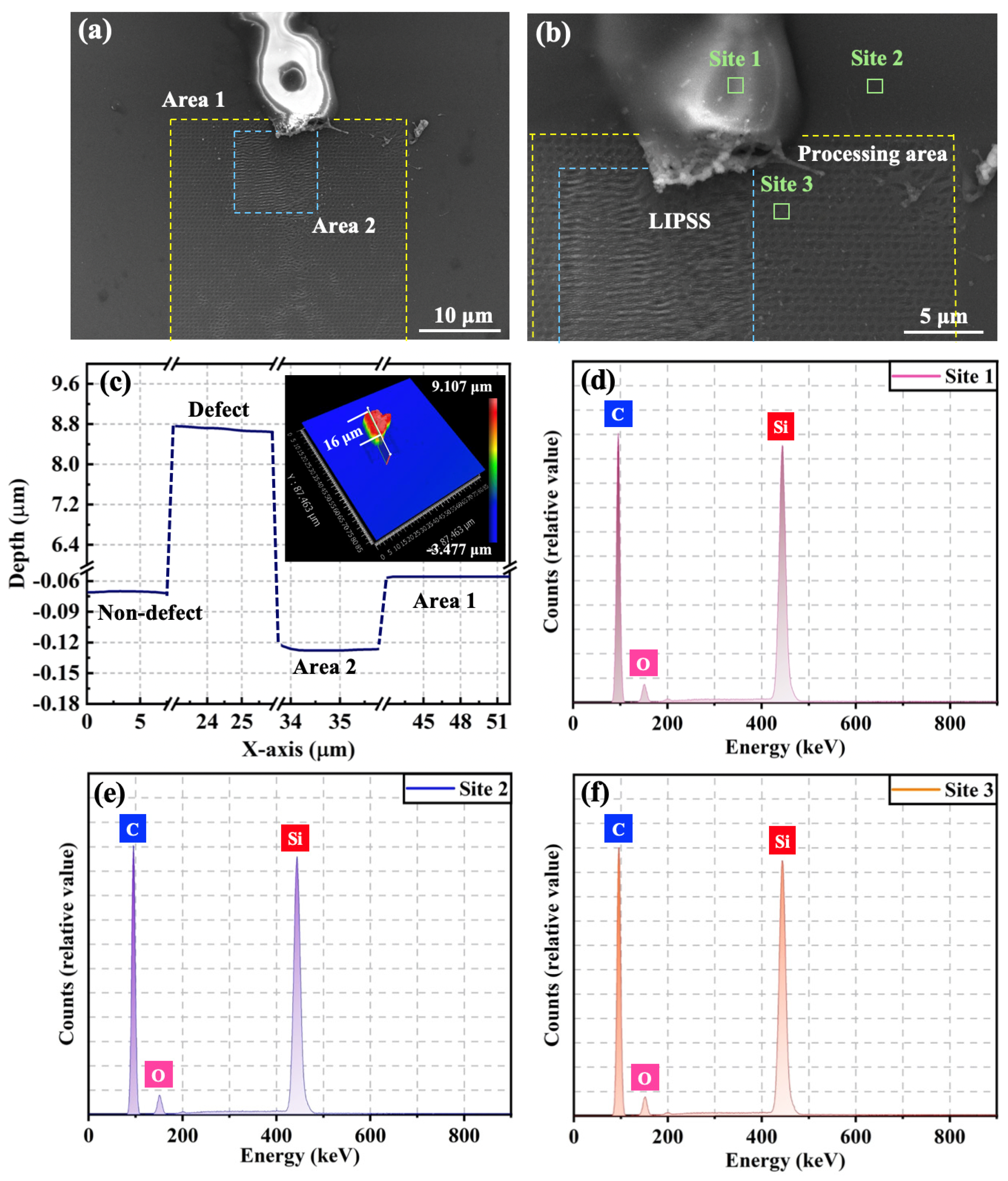

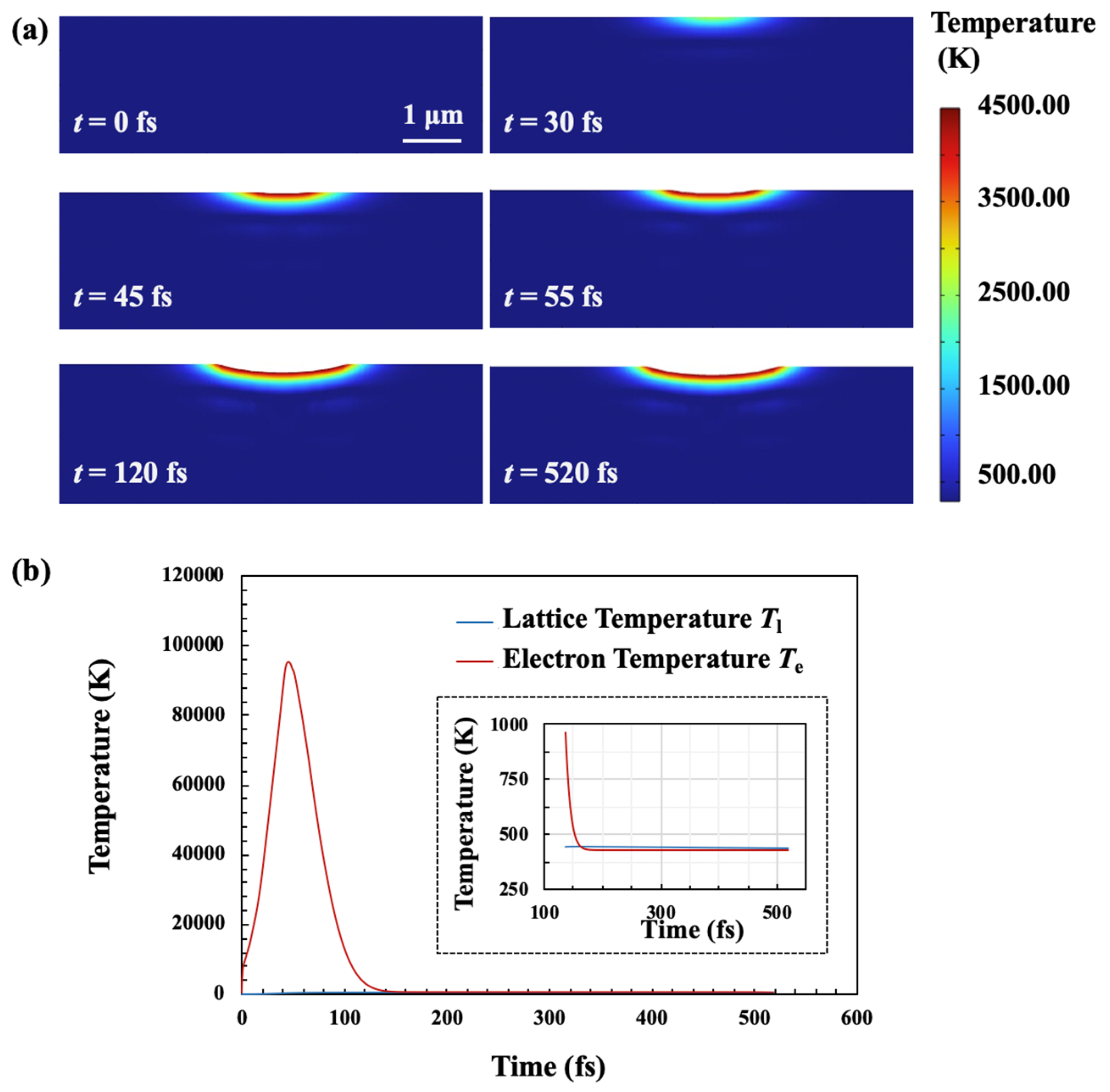

- FS pulse laser defect ablation

3.4. Comparison of CW and FS Pulse Laser Modification

4. Conclusions

- (1)

- Under the optimized process parameters, both CW and FS pulse lasers significantly improve the morphology of the defect region and greatly reduce the surface roughness. The CW laser reduces the surface roughness to less than 0.071 µm, while the FS pulse laser can control the maximum surface profile peak height to about 0.015 µm. Laser treatment maintains the structural integrity of 4H-SiC and enhances overall quality according to XRD patterns.

- (2)

- The CW laser remelting mechanism partially retains the structure caused by surface defects. In contrast, the FS pulse laser removes defect structures more thoroughly and can improve crystal quality more effectively. Benefiting from the ultrashort pulse duration and high-energy focal region, the irradiated area exhibits minimal thermal diffusion.

- (3)

- Combined with FEM simulation, this reveals that the upper-surface temperature of the 4H-SiC crystal elevates rapidly to the melting point under the heating of the CW laser beam. The material flows from the crest to the trough, largely ascribed to the surface tension and Marangoni force, improving surface flatness. With FS pulse laser irradiation, rapid electron heating occurs via localized thermal effects. Under such a mechanism, the FS pulse laser eliminates surface defects at the microlevel.

- (4)

- In general, the CW laser is suitable for processing complex surfaces with defects in both protrusions and grooves. The FS pulse laser is particularly well suited for treating surfaces with protruding defects or residual material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazumder, S.K.; Voss, L.F.; Dowling, K.M. Overview of wide/ultrawide bandgap power semiconductor devices for distributed energy resources. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 3957–3982. [Google Scholar] [CrossRef]

- Ma, P.; Ni, J.; Sun, J. Three-dimensional detection and quantification of defects in SiC by optical coherence tomography. Appl. Opt. 2020, 59, 1746–1755. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Huang, A.Q. Extreme high efficiency enabled by silicon carbide (SiC) power devices. Mater. Sci. Semicond. Process. 2024, 172, 108052. [Google Scholar] [CrossRef]

- Deng, X.C.; Liu, R.; Li, S.J.; Li, L.; Wu, H.; Li, X. SiC fin-shaped gate trench MOSFET with integrated Schottky diode. Materials 2021, 14, 7096. [Google Scholar] [CrossRef]

- Wang, H.; Lai, P.; Islam, M.Z. A review of silicon carbide CMOS technology for harsh environments. Mater. Sci. Semicond. Process. 2024, 178, 108422. [Google Scholar] [CrossRef]

- La, V.F.; Alquier, D.; Giannazzo, F. Emerging SiC applications beyond power electronic devices. Micromachines 2023, 14, 1200. [Google Scholar] [CrossRef]

- Wang, X.; Liu, E.; Li, W. A new route to fabricate high-quality double-side-polished freestanding diamond film. Vacuum 2023, 218, 112645. [Google Scholar] [CrossRef]

- Yu, J.; Yu, Y.; Bai, Z. Morphological and microstructural analysis of triangular defects in 4H-SiC homoepitaxial layers. CrystEngComm 2022, 24, 1582–1589. [Google Scholar] [CrossRef]

- Luo, M.; Zhang, Y.; Wang, Y. Study of leakage current degradation based on stacking faults expansion in irradiated SiC junction barrier Schottky diodes. Chin. Phys. B 2024, 33, 108401. [Google Scholar] [CrossRef]

- Ma, J.; Li, J.; Tan, X. Effect of the diffusion annealing process and cooling rate on the microstructure of Zr/Ti layered materials. Mater. Charact. 2023, 197, 112667. [Google Scholar] [CrossRef]

- Guo, J.; Wu, D.; Niu, L. Investigation on flatness and surface integrity of pure copper processed by electrochemical mechanical polishing. Procedia CIRP 2020, 95, 721–725. [Google Scholar] [CrossRef]

- Salter, P.S.; Booth, M.J. Adaptive optics in laser processing. Light 2019, 8, 110. [Google Scholar] [CrossRef] [PubMed]

- Mitsuoki, H.; Naohoki, K.; Kentaro, M.; Tatsuya, O.; Takashi, N. Highly productive laser annealing manufacturing method using continuous blue WBC (wavelength beam combining) technology. Materials 2024, 17, 5399. [Google Scholar] [CrossRef]

- Antonowicz, J.; Zalden, P.; Sokolowski, T.K. Devitrification of thin film Cu–Zr metallic glass via ultrashort pulsed laser annealing. J. Alloys Compd. 2021, 887, 161437. [Google Scholar] [CrossRef]

- Lu, G.; Li, X.; Yan, D. Influence of parameters on the surface roughness of the CO2 laser polished fused silica glass. Optik 2021, 248, 168044. [Google Scholar] [CrossRef]

- Komlenok, M.; Pashinin, V.; Sedov, V. Femtosecond and nanosecond laser polishing of rough polycrystalline diamond. Laser Phys. 2022, 32, 084003. [Google Scholar] [CrossRef]

- Wang, S.; Wang, L.; Zhang, S. A low-damage copper removal process by femtosecond laser for integrated circuits. Vacuum 2022, 203, 111273. [Google Scholar] [CrossRef]

- Yu, M.; Mo, Z.; Yu, X. Effects of fictive temperature on mid-frequency waviness in laser polishing of glass. Appl. Opt. 2022, 61, 7315–7322. [Google Scholar] [CrossRef]

- Rihakova, L.; Chmelickova, H. Laser micromachining of glass, silicon, and ceramics. Adv. Mater. Sci. Eng. 2015, 2015, 584952. [Google Scholar] [CrossRef]

- Ibenskas, A.; Galdikas, A.; Grigonis, A. Kinetic modeling of laser annealing processes in a-C: H films. Vacuum 2011, 86, 124–130. [Google Scholar] [CrossRef]

- Lv, P.; Chen, Z.; Zhang, A.H.X. Effect of laser annealing on amorphous silicon carbide films prepared by PECVD. In Proceedings of the 4th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Shenzhen, China, 5 June 2009. [Google Scholar] [CrossRef]

- Zheng, Q.; Mei, X.; Jiang, G. Influence of surface morphology and processing parameters on polishing of silicon carbide ceramics using femtosecond laser pulses. Surf. Interfaces 2023, 36, 102528. [Google Scholar] [CrossRef]

- Hildebrand, J.; Hecht, K.; Bliedtner, J. Laser beam polishing of quartz glass surfaces. Phys. Procedia 2011, 12, 452–461. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, H.; Luo, R.E.F. In-situ doped and laser annealing of PECVD SiC thin film. In Proceedings of the 2nd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Bangkok, Thailand, 23 April 2007. [Google Scholar] [CrossRef]

- Wei, R.; Song, S.; Yang, K. Thermal conductivity of 4H-SiC single crystals. J. Appl. Phys. 2013, 113, 053503. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Liu, F. Ultrafast pulsed laser stealth dicing of 4H-SiC wafer: Structure evolution and defect generation. J. Manuf. Process. 2022, 81, 562–570. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, Y.; Li, J. Femtosecond laser surface modification of 4H-SiC improves machinability. Appl. Surf. Sci. 2023, 615, 156436. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, J.; Tian, Z. Improving the crystal quality of AlN films by nanosecond laser annealing. J. Manuf. Process. 2022, 84, 1519–1525. [Google Scholar] [CrossRef]

- Zhou, N.; Yuan, S.; Gao, M.; Zhang, W.; Zhang, J.; Hu, T. Investigation on the oxidation behavior and removal mechanism of SiC/SiC composites by multi-pulse femtosecond laser ablation. J. Mater. Res. Technol. 2023, 26, 3408–3425. [Google Scholar] [CrossRef]

- Zhou, T.; Kraft, S.; Perrie, W.; Schille, J.; Loschner, U.; Edwardson, S.; Dearden, G. Backward flux re-deposition patterns during multi-spot ablation of stainless steel with picosecond and femtosecond pulses in air. Materials 2021, 14, 2243. [Google Scholar] [CrossRef]

- Wu, C.; Fang, X.; Kang, Q. Crystal cleavage, periodic nanostructure and surface modification of SiC ablated by femtosecond laser in different media. Surf. Coat. Technol. 2021, 424, 127652. [Google Scholar] [CrossRef]

- Feng, Z.C.; Rohatgi, A.; Tin, C.C. Structural, optical, and surface science studies of 4H-SiC epilayers grown by low pressure chemical vapor deposition. J. Electron. Mater. 1996, 25, 917–923. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, J. Microstrain and grain-size analysis from diffraction peak width and graphical derivation of high-pressure thermomechanics. J. Appl. Crystallogr. 2008, 41, 1095–1108. [Google Scholar] [CrossRef]

- Jung, H.; Jeong, S.; Park, Y. X-ray diffraction analysis of damaged layer during polishing of silicon carbide. Int. J. Precis. Eng. Manuf. 2023, 24, 25–32. [Google Scholar] [CrossRef]

- Yin, T.Y.; Ru, H. Raman analysis of defects in n-type 4H-SiC. Chin. Phys. B 2008, 17, 3459. [Google Scholar] [CrossRef]

- Nakashima, S.; Kitamura, T.; Mitani, T. Raman scattering study of carrier-transport and phonon properties of 4 H-Si C crystals with graded doping. Phys. Rev. B—Condens. Matter Mater. Phys. 2007, 76, 245208. [Google Scholar] [CrossRef]

- Sugie, R.; Uchida, T. Determination of stress components in 4H-SiC power devices via Raman spectroscopy. J. Appl. Phys. 2017, 122, 195703. [Google Scholar] [CrossRef]

- Han, S.; Yu, H.; He, C. Laser slicing of 4H-SiC wafers based on picosecond laser-induced micro-explosion via multiphoton processes. Opt. Laser Technol. 2022, 154, 108323. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, J.; Zhao, Y. Numerical analysis of coupling dynamics of keyhole and molten pool in vertical-up laser mirror welding of 2219 aluminum alloy. Int. J. Therm. Sci. 2023, 192, 108390. [Google Scholar] [CrossRef]

- Semak, V.; Matsunawa, A. The role of recoil pressure in energy balance during laser materials processing. J. Phys. D Appl. Phys. 1997, 30, 2541. [Google Scholar] [CrossRef]

- Ai, Y.; Liu, X.; Huang, Y. Numerical analysis of the influence of molten pool instability on the weld formation during the high speed fiber laser welding. Int. J. Heat Mass Transf. 2020, 160, 120103. [Google Scholar] [CrossRef]

- Chen, L.; Richter, B.; Zhang, X. Modification of surface characteristics and electrochemical corrosion behavior of laser powder bed fused stainless-steel 316L after laser polishing. Addit. Manuf. 2020, 32, 101013. [Google Scholar] [CrossRef]

- Jia, H.; Cao, L.; Fu, S. Numerical simulation and experiment for the dynamic behavior of molten pool in ultrasonic-assisted MIG welding. Int. J. Heat Mass Transf. 2023, 215, 124469. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, Z.; Hu, J. Numerical simulation and experimental analysis on nanosecond laser ablation of titanium alloy. J. Manuf. Process. 2023, 99, 138–151. [Google Scholar] [CrossRef]

- Dong, F.; Han, X.; Cai, X. Periodic surface micro-nanostructures on GaN films induced by femtosecond laser irradiation. J. Manuf. Process. 2024, 123, 142–149. [Google Scholar] [CrossRef]

- Lenzner, M.; Krüger, J.; Sartania, S. Femtosecond optical breakdown in dielectrics. Phys. Rev. Lett. 1998, 80, 4076. [Google Scholar] [CrossRef]

- Stuart, B.C.; Feit, M.D.; Herman, S. Nanosecond-to-femtosecond laser-induced breakdown in dielectrics. Phys. Rev. B 1996, 53, 1749. [Google Scholar] [CrossRef]

- Yadav, A.; Kbashi, H.; Kolpakov, S. Stealth dicing of sapphire wafers with near infra-red femtosecond pulses. Appl. Phys. A 2017, 123, 369. [Google Scholar] [CrossRef]

- Orazi, L.; Romoli, L.; Schmidt, M. Ultrafast laser manufacturing: From physics to industrial applications. CIRP Ann. 2021, 70, 543–566. [Google Scholar] [CrossRef]

- Norman, G.E.; Starikov, S.V.; Stegailov, V.V. Atomistic Modeling of Warm Dense Matter in the Two-Temperature State. Contrib. Plasma Phys. 2013, 53, 129–139. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, L.; Yang, W. Laser punching of soft magnetic Fe-based amorphous ribbons. Scr. Mater. 2024, 240, 115839. [Google Scholar] [CrossRef]

| Parameters (Unit) | Symbol | Value |

|---|---|---|

| Melting temperature (K) | Tmelt | 2973 |

| Initial temperature (K) | T0 | 293.15 |

| Thermal conductivity (W·m−1·K−1) | k | 2.67 × 105T−1.26 |

| Solid specific heat (J·g−1·K−1) | cp | 0.48 + 0.0023exp(T/262) |

| Solid density (kg·m−3) | ρs | 3210 |

| Latent heat of fusion (J·kg−1) | Lm | 3.6 × 105 |

| Emissivity | ε | 0.8 − 0.4exp(−T/600) |

| Absorption coefficient (m−1) | α | 7.3 × 107 |

| Reflectivity | R | 0.224 |

| Electron specific heat capacity (J·m−3·K−1) | Ce | 78.300 |

| Lattice specific heat capacity (J·m−3·K−1) | Cl | 1.659 × 105 |

| Electronic thermal conductivity (W·m−1·K−1) | ke | 27.300 |

| Lattice thermal conductivity (W·m−1·K−1) | kl | 1.480 |

| Electron–lattice coupling coefficient | G | 1.120 × 1017 |

| Measured Region | Omega (°) | Intensity (a.u.) | FWHM (°) |

|---|---|---|---|

| Non-defect region | 35.581 | 1310 | 0.053 |

| CW laser-irradiated region | 35.540 | 4049 | 0.068 |

| FS pulse laser-irradiated region | 35.569 | 4960 | 0.047 |

| Measured Region | E2(TO) (Raman Peak at 777 cm−1) | E1(TO) (Raman Peak at 798 cm−1) |

|---|---|---|

| Defect region | 2.43 ± 0.05 | 2.86 ± 1.31 |

| Non-defect region | 2.38 ± 0.02 | 1.85 ± 0.35 |

| CW laser treatment region | 2.43 ± 0.02 | 2.48 ± 0.37 |

| FS pulse laser treatment region | 2.42 ± 0.01 | 2.31 ± 0.40 |

| Elements | Spectrum 1 | Spectrum 2 | Spectrum 3 |

|---|---|---|---|

| wt. % | wt. % | wt. % | |

| Si | 53.58 | 54.32 | 52.92 |

| C | 37.10 | 39.91 | 38.36 |

| O | 9.31 | 5.77 | 8.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Zhou, J.; Li, R.; Wang, S.; Dong, F.; Sun, C.; Liu, S. Surface Modification and Crystal Quality Improvement of 4H-SiC Film via Laser Treatment: Comparison of Continuous Wave and Femtosecond Pulse Laser. Materials 2025, 18, 1781. https://doi.org/10.3390/ma18081781

Han X, Zhou J, Li R, Wang S, Dong F, Sun C, Liu S. Surface Modification and Crystal Quality Improvement of 4H-SiC Film via Laser Treatment: Comparison of Continuous Wave and Femtosecond Pulse Laser. Materials. 2025; 18(8):1781. https://doi.org/10.3390/ma18081781

Chicago/Turabian StyleHan, Xu, Jiantao Zhou, Rui Li, Shizhao Wang, Fang Dong, Chengliang Sun, and Sheng Liu. 2025. "Surface Modification and Crystal Quality Improvement of 4H-SiC Film via Laser Treatment: Comparison of Continuous Wave and Femtosecond Pulse Laser" Materials 18, no. 8: 1781. https://doi.org/10.3390/ma18081781

APA StyleHan, X., Zhou, J., Li, R., Wang, S., Dong, F., Sun, C., & Liu, S. (2025). Surface Modification and Crystal Quality Improvement of 4H-SiC Film via Laser Treatment: Comparison of Continuous Wave and Femtosecond Pulse Laser. Materials, 18(8), 1781. https://doi.org/10.3390/ma18081781