Abstract

Grade 14.9 superhigh-strength bolts (SHTBs) are a type of high-strength steel bolt with a nominal tensile strength of 1400 MPa, which is significantly higher than the commonly used Grade 10.9 high-strength bolt (HSB), which has a nominal tensile strength of 1000 MPa. The use of an SHTB can reduce the number of bolts required in connections or joints, leading to material savings and improved construction efficiency. However, like HSB, the mechanical properties of an SHTB can be significantly degraded at high temperatures, though the extent of this reduction may differ. In this study, the authors designed and conducted experiments on SHTBs under elevated temperatures including both vibration and tensile coupon tests. Based on the test data, the stress–strain curves and key mechanical properties such as the Young’s modulus, yield stress, ultimate stress, ultimate strain, percentage elongation, cross-sectional area reduction, and failure strain were obtained and analyzed for various high-temperature conditions. Furthermore, a new three-stage model was proposed to describe the stress–strain relationship of SHTBs under fire conditions. Additionally, empirical formulae were developed to predict the mechanical properties of SHTBs under elevated temperatures, providing valuable insights for engineering applications and fire safety design.

1. Introduction

Connections are essential for transferring loads within structures and ensuring their stability. The failure of connections may undermine the structural integrity and significantly increase the risk of collapse [1,2]. The importance of robust connections is further heightened in the case of fire conditions [3]. Welding and bolt connections are commonly used connection methods for steel structures. Bolt connections can avoid the influence of the heat-affected zone [4,5,6,7] generated by welding on the performance of the joint, but the equal-strength connections may require a large number of bolts, especially for high-strength steel structures. Using Grade 14.9 super-high-strength bolts (SHTBs) can significantly reduce the number of bolts and improve the efficiency because their nominal ultimate stress is 1400 MPa, which is much higher than the 1000 MPa of the commonly used Grade 10 high-strength bolts (HSBs). SHTBs are now commercially available, enhancing the options for robust structural connections in key markets such as Japan [8,9], the United States [10,11,12], and China [13,14].

The mechanical properties of materials are pivotal for assessing the safety of structures in the event of fire hazards. Extensive research has explored the behavior of various structural steels under elevated temperatures, including S235 [15,16], S355 [17,18,19,20,21,22], S460 [23,24,25,26], S690 [27,28,29,30,31,32], and ultra-high-strength steels [33,34,35,36], each with specific temperature thresholds beyond which their properties degrade [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36]. However, due to the different material grades and manufacturing, the mechanical properties of steel bolts are also different from structural steel. Sakumoto et al. [37] and others have shown that for F10T bolts (Grade 10.9), the ultimate stress and Young’s modulus experience rapid declines at temperatures above 400 °C. Kirby [38] reported the tensile and shear tests of Grade 8.8 bolts under high temperatures, and their results indicated that both the tensile and shear capacity of the bolts significantly decreased when the temperature exceeded 300 °C. Li et al. [39] reported the results of a series of high-temperature tensile tests of 20MnTiB (used to fabricate Grade 10.9 high-strength bolts in China). They also emphasized that the ultimate stress and Young’s modulus decreased rapidly when the temperature exceeded 300 °C. Yu et al. [40,41] conducted high-temperature double shear tests of A325 and A490 bolts (Grade 8.8 and 10.9 bolts, respectively). The results showed that the shear capacity of the A325 and A490 bolts also decreased obviously when the temperature was over 300 °C. G and Lange [42] reported a series of high-temperature tensile tests on Grade 10.9 bolts. The results also showed that the capacity was significantly less when the temperature was over 300 °C. Kodur et al. [3] conducted tests to investigate the effect of temperature on the thermal and mechanical properties of the high-strength steel used in A325 and A490 bolts. They emphasized that temperature had a significant influence on the thermal and mechanical properties of the high-strength steel used in bolts: the steel in A490 bolts possesses a slightly lower thermal conductivity than that of the A325 bolts; the yield and ultimate stress degrade at a rapid pace when the temperature exceeds 400 °C. Jonathan et al. [43] conducted high-temperature shear tests of A325 and A490 bolts, and data from these tests showed that the shear capacity of both types of bolts decreased significantly when the temperature exceeded 400 °C, but the failure displacement increased. Pang et al. [44] conducted extensive tensile experiments on the steel used for Grades 8.8, 10.9, and 12.9 bolts, respectively. Data from their tests showed that all three types of bolts exhibited a significant strength reduction when the temperature exceeded 300 °C, and when the temperature ranged from 20 to 700 °C, the Grade 12.9 bolt steel processed the maximum ultimate stress. Rezaeian et al. [45] reported the results of a series of high-temperature tensile experiments on the Grade 10.9 materials. Their study showed that the Grade 10.9 bolts experienced a rapid decrease in strength at temperatures exceeding 400 °C. Furthermore, the tension-shear combined strength [46,47], constitutive model [2], and fracture behavior [48,49] of the Grade 8.8 or 10.9 bolts (or material) were also conducted. Huseyin et al. [50] presented a study on the ductile fracture of Grade 8.8 or 10.9 bolts under fire conditions. Based on results from the tension, shear, and combined tension-shear tests, they calibrated the fracture parameters and investigated the influence of displacement at fracture values on the results by a three-bolted inclined shear test. These studies have all contributed valuable insights, but primarily focused on conventional high-strength bolts such as Grades 8.8 and 10.9. The SHTB, which has a higher ultimate stress than its conventional counterparts, has not been the subject of similar high-temperature mechanical property studies. This gap in research is notable, given the absence of data for SHTBs in the current fire resistance design guides, including BS EN 1993-1-2 [51], BS 5950-9 [52], and GB 51249-2017 [53], which limits the application of SHTBs in fire-resistant design practices.

To fill this gap, the authors designed and conducted an experimental study on the mechanical properties and stress–strain relationship of SHTBs under elevated temperatures. The Young’s modulus, yield stress, ultimate stress, ultimate strain, percentage elongation, reduction in cross-sectional area as well as failure strain of the SHTBs under various temperatures were obtained. Then, we quantitatively analyzed the variation in these mechanical properties with the increase in temperature and compared it with the public data of different types of high-strength bolts. Finally, a new three-stage model was proposed to describe the stress–strain relationship of SHTBs under fire conditions.

2. Experimental Investigation

2.1. Materials

The study utilized samples machined from Grade 14.9 SHTB, with a standard bolt size of 16 mm in diameter and 150 mm in length. The chemical composition of the SHTB, in accordance with the quality specifications from the manufacturer (Eagle Metalware Co. Ltd., Dongguan, Guangdong, China), is presented in Table 1.

Table 1.

Chemical composition of the SHTB (%).

2.2. Specimen Design

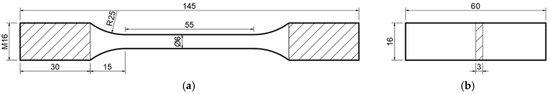

Figure 1 illustrates the dimensions and shapes of the samples utilized in this study, with Figure 1a depicting the tensile test coupon, and Figure 1b showing the vibration test samples. The tensile test coupons were designed according to GB/T 228.1-2021 [54], while the vibration test samples adhered to the guidelines of ASTM E1876-15 [55]. To assess the impact of temperature on the mechanical properties of the SHTB, we conducted a total of twenty-one tensile tests and three vibration tests.

Figure 1.

Dimensions of the test samples (unit: mm). (a) Tensile test sample; (b) vibration test sample.

2.3. Test Setup

2.3.1. Vibration Tests Under Elevated Temperature

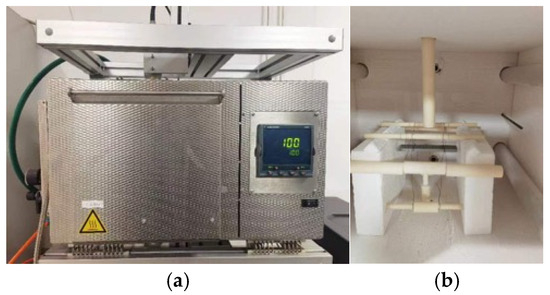

Figure 2a presents the vibration test machine (RFDA HT650, IMCE, Belgium) that was used to measure the Young’s modulus. The machine consisted of a power system, a furnace, and transducers, which convert vibration signals into electrical signals and vice versa. The high-temperature vibration test process is as follows. (1) The sample is suspended in the furnace using two copper wires, as depicted in Figure 2b. (2) The temperature is increased to the pre-selected value and held for 10 min, with a heating rate of 10 °C per minute. (3) The vibration switch is activated to measure the fundamental resonant frequency. (4) Steps 2 and 3 are repeated to measure the fundamental resonant frequency of the material at various temperature levels. Finally, the Young’s modulus is calculated from the measured fundamental resonant frequency using the formulae provided in [55] (see Equations (1) and (2)).

where m is the mass of the test specimen; b, t, and L are the width, thickness, and length of the test sample, respectively; is the fundamental resonant frequency of the specimen in flexure under a temperature of T; is the Poisson’s ratio, which was assumed as 0.3 [25]. However, the maximum operating temperature of the testing machine used in this study was 600 °C, which was the maximum temperature of the vibration tests in this study.

Figure 2.

Test machine and specimen setup: (a) vibration test machine; (b) setup.

2.3.2. Tensile Tests Under Elevated Temperature

Following [3], the steady-state test method was employed to evaluate the high-temperature mechanical properties of the SHTB. The steady-state tensile tests were conducted at nine distinct elevated temperatures: 100, 200, 300, 400, 500, 600, 650, 700, and 750 °C. To ascertain the original mechanical properties of the SHTB, three coupons were also tested without fire exposure. The heating procedure took place in an electric furnace, as depicted in Figure 3. As shown in Figure 4, two clamps were utilized to secure the test specimen to the testing machine, which was a CMT5305 universal testing machine from MTS Industrial Systems (China) Co. Ltd., Shenzhen, China.

Figure 3.

Test equipment.

Figure 4.

Installed specimen and the clamps.

The tensile testing procedure at elevated temperatures was as follows: (1) The test specimen was installed with only the top clamp connected to the test machine to prevent compressive loads due to thermal expansion during heating; (2) the furnace was closed and the test specimen heated to the pre-selected temperature, which was maintained for 10 min (the heating rate is 10 °C/min); (3) the bottom clamp was secured to the test machine and the tensile load applied at a displacement rate of 2 mm/minute until specimen failure [56].

3. Experimental Results

3.1. Overall Behavior

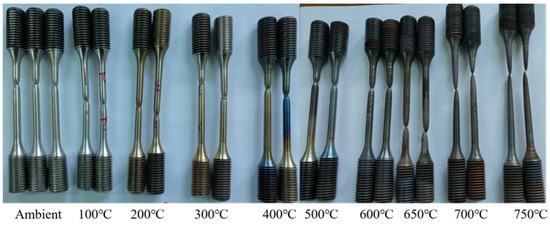

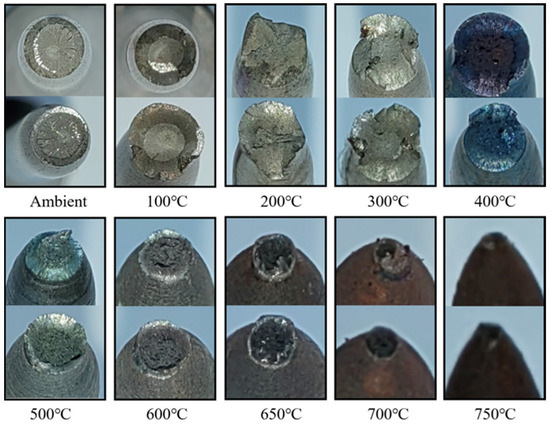

Figure 5 shows the photos of the samples after testing. All specimens failed with a ductile fracture showing a marked necking phenomenon, and the necking became more significant with temperatures larger than 500 °C. Furthermore, with an increase in the tested temperature, the surface of the tested samples gradually changed from silvery at ambient temperature (about 20 °C), to golden yellow at 300 °C, to a mix of golden-yellow and blue at 400 °C, and finally to black at 600~750 °C. Studies [57,58] have shown that oxidation on the bolt surface is the main reason for its color change. At the same time, due to the difference in oxidation products when oxidation occurs in different temperature ranges, the bolts will show different colors after experiencing different temperatures. Moreover Figure 6 presents the failure surfaces of the coupons after being tested at various high temperatures. Visible necking phenomenon and shear lips could be seen from the photos, which became more significant with the increase in temperature, also indicating that the SHTB possessed ductile failure characteristics [2,13].

Figure 5.

The test samples after testing.

Figure 6.

Fracture surfaces of the coupons under various temperatures.

3.2. Stress–Strain Curves

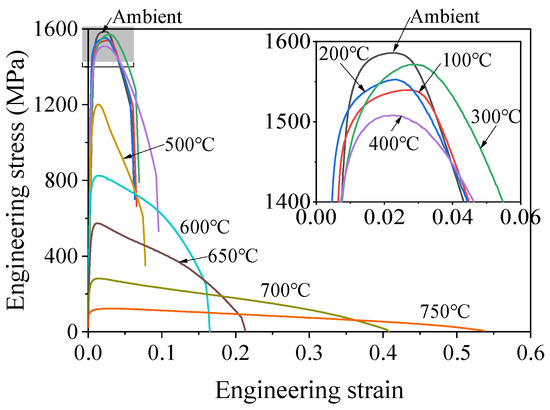

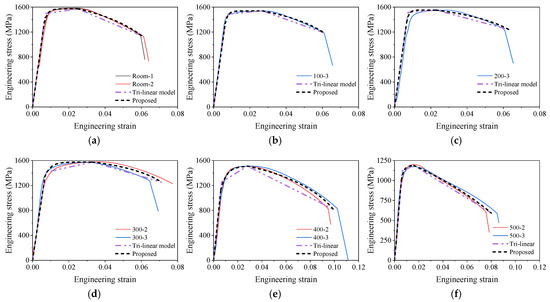

The typical engineering stress–strain curves of the SHTB at various temperatures are summarized in Figure 7. The stress–strain curves exhibited significant elastic and plastic behaviors, and no yield plateau was observed. Furthermore, the coupons were exposed to a temperature equal to or below 400 °C, the shape of the engineering stress–strain curves of coupons were similar, and the engineering strain at fracture changed little. However, when the coupons underwent a temperature exceeding 500 °C, the ultimate stress mark decreased with the increasing temperature, while a reverse trend was observed on the engineering strain. In addition, the yield stress (0.2% proof stress), ultimate stress, and the corresponding strain (ultimate strain) were also obtained from these engineering strain–stress curves.

Figure 7.

Typical stress–strain curves of an SHTB under various temperatures.

3.3. Mechanical Properties

Table 2 summarizes the mechanical properties of the SHTB under various temperatures (the average of coupons in each group) including the Young’s modulus (), proportional limit (), yield stress (), ultimate stress (), ultimate strain (), the percentage elongation after fracture (), the percentage reduction in area (, failure strain (), and corresponding stress (). The percentage reduction in area, an index presenting the ductility of steel, was calculated as the ratio of the maximum reduction in the cross-section area from the initial area of the specimen [59]; the failure strain was calculated using Equation (3) [60], where is the radius of the minimum cross-section of the coupon tested at a temperature of , and is the initial value of .

Table 2.

Summary of the mechanical properties of the SHTB under elevated temperature.

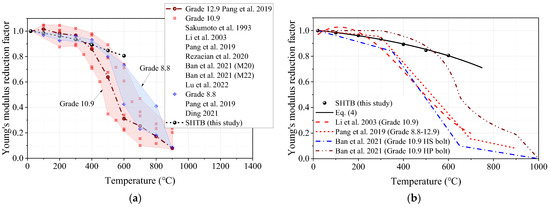

3.3.1. Young’s Modulus

The deterioration of the mechanical properties of the SHTB under elevated temperature is represented by reduction factors. For the Young’s modulus, the reduction factor was defined as the ratio of the Young’s modulus from a specific temperature () to that of the coupons at ambient temperature (). Figure 8a presents the Young’s modulus reduction factor of SHTB in this test, along with that of conventional high-strength bolts (Grades 8.8, 10.9, and 12.9) in the previous literature [2,37,39,44,45,48,49]. It can be found that the Young’s modulus reduction factor of the SHTB decreased with increasing temperature; a similar trend can also be found in the public data. However, when the temperature exceeded 400 °C, the Young’s modulus reduction factor of SHTB was larger than that of the conventional high-strength bolts. Figure 8b illustrates the comparisons of the Young’s modulus reduction factor of the SHTB with the predicted formulae suggested by previous studies. It was found that these existing formulae could not well predict the Young’s modulus reduction factor of the SHTB because these formulae were proposed based on the test data of conventional high-strength bolts. According to Wang et al. [25], an exponent formula was proposed to predict the Young’s modulus reduction factor of the SHTB, as shown in Equation (4). As shown in Figure 8b, the proposed formula could well predict the test data in this study.

Figure 8.

The Young’s modulus reduction factors. (a) Comparison of the public data; (b) comparison of the formulae in the previous study [2,37,39,44,45,48,49].

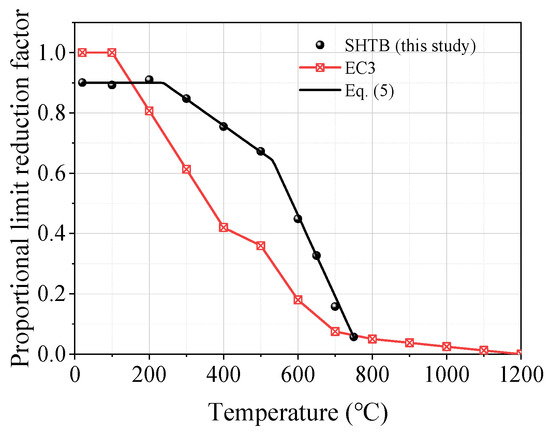

3.3.2. Proportional Limit

The proportional limit reduction factor was defined as the ratio of the proportional limit under a specific temperature level () to the yield stress of the coupons at ambient temperature (). Figure 9 presents the comparisons of the proportional reduction factor from this study and EC3. As shown in Figure 9, there was an obvious difference between the proportional limit reduction factors from this study and EC3. When the temperature was not higher than 100 °C, the proportional limit reduction factors from EC3 were one, significantly larger than the corresponding value of the SHTB; however, both of them decreased with the increase in temperature. However, when the temperature was not lower than 200 °C, the proportional limit reduction factor of the SHTB was larger than that from EC3, but the difference decreased with the increase in temperature. This may have been caused by the difference in delivery conditions of the structural steel and SHTB. Based on the experimental results, the authors’ recommended predictive formulae for the proportional limit reduction factor of the SHTB under various temperatures are proposed, as shown in Equation (5).

Figure 9.

Proportional limit and the corresponding reduction factors.

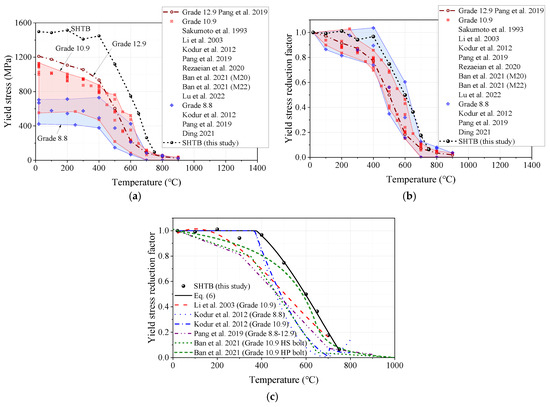

3.3.3. Yield Stress

The yield stress reduction factor was defined as the ratio of the yield stress under elevated temperature level () to that of the coupons at ambient temperature (). Figure 10 presents the comparisons of the yield stress, yield stress reduction factor, and prediction formulae from this study and other public studies. As shown in Figure 10a, it can be found that the SHTB exhibited a much larger yield stress than that of the conventional high-strength bolts under the same temperature. Figure 10b presents the yield stress reduction factor of the SHTB in this test and that of conventional high-strength bolts in previous studies [2,3,37,39,44,45,48,49]. It can be found that the yield stress reduction factor of SHTB was much larger than that of the Grade 12.9 high-strength bolt and close to the upper limit of the data from the Grades 8.8 and 10.9 high-strength bolts. Moreover, the authors also compared the prediction formulae of the yield stress reduction factor from previous studies, as shown in Figure 10c. It can be found that when the temperature was at a level equal to or below 400 °C, the yield stress reduction factor of the Grade 14.9 SHTB was close to the prediction made by the formula suggested by Kodur et al. [3], where the reduction factor maintained a constant of one. However, when the temperature level exceeded 400 °C, the yield stress reduction factor was slightly larger than the prediction made by the formula suggested by Ban et al. [2], which is based on Grade 10.9 high-performance (HP) bolts. Based on the experimental results, the authors’ recommended predictive formulae for the yield stress reduction factor of the SHTB under various temperatures are proposed, as shown in Equation (6).

Figure 10.

Yield stress and the corresponding reduction factors: (a) yield stress; (b) yield stress reduction factors; (c) comparison of different predicted formulae [2,3,37,39,44,45,48,49].

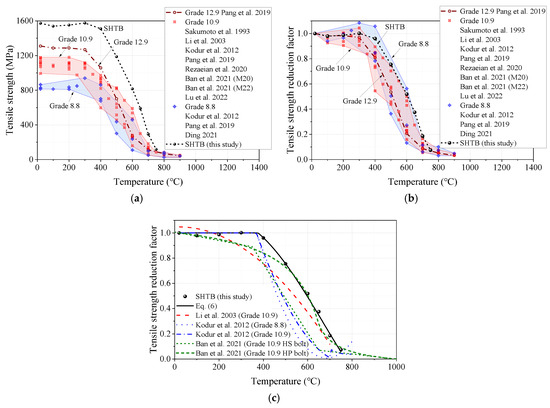

3.3.4. Ultimate Stress

The ultimate stress reduction factor was defined as the ratio of the ultimate stress under a specific temperature level () to that of the coupons at ambient temperature (). Figure 11 presents the comparisons of the ultimate stress, ultimate stress reduction factor, and prediction formulae from this study and other public studies. Similar to the comparisons of the yield stress, the SHTB also exhibited a much larger ultimate stress than that of the conventional high-strength bolts under the same temperature, as shown in Figure 11a. This means that the SHTB can provide a larger capacity than the high-strength bolts when affected by the same fire hazard. Figure 11b presents the ultimate stress reduction factor of the SHTB in this study and that of the conventional high-strength bolts in previous studies [2,3,37,39,44,45,48,49]. It was found that the ultimate stress reduction factor of the SHTB was also much larger than that of the Grade 12.9 high-strength bolt when the temperature exceeded 200 °C, which indicates a marked difference from that of the Grades 8.8 and 10.9 high-strength bolts. In addition, the authors also compared the prediction formulae of the yield stress reduction factor from previous studies, as shown in Figure 11c. It was found that Equation (6) could also well predict the ultimate stress reduction factor of the SHTB.

Figure 11.

Ultimate stress and the corresponding reduction factors: (a) ultimate stress; (b) ultimate stress reduction factors; (c) comparison of different predicted formulae [2,3,37,39,44,45,48,49].

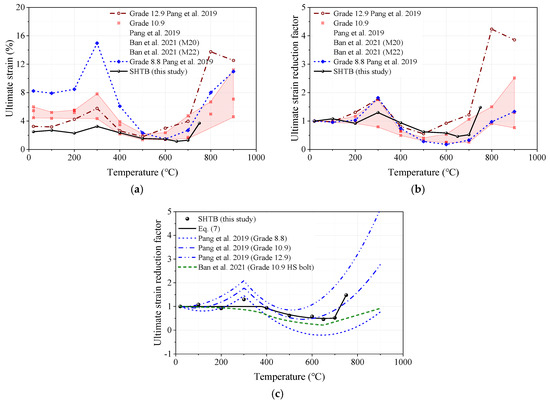

3.3.5. Ultimate Strain

The ultimate strain reduction factor was defined as the ratio of the ultimate strain under a specific temperature level () to that of the coupons at ambient temperature (). Figure 12 presents the comparisons of the ultimate strain, ultimate strain reduction factor, and prediction formulae from this study and other public studies. As shown in Figure 12a, it was found that the ultimate strain of the SHTB was much smaller than that of the high-strength bolts with the same temperature. However, with the increase in temperature, the ultimate strain of the SHTB was steadier than that of the high-strength bolts (exhibited a smaller change). Given the smaller ultimate strain, the ultimate strain reduction factor of the SHTB ranged from the lower and upper results of the data for high-strength bolts, as shown in Figure 12b. As shown in Figure 12c, the existing formulae in previous studies could not well predict the ultimate strain reduction factor of the SHTB. Thus, the use of Equation (7) as the prediction formula for the ultimate strain reduction factor of the SHTB was recommended. This formula is in good agreement with the experimental data.

Figure 12.

Ultimate strain and the corresponding reduction factors: (a) ultimate strain; (b) ultimate strain reduction factors; (c) comparison of different predicted formulae [2,44].

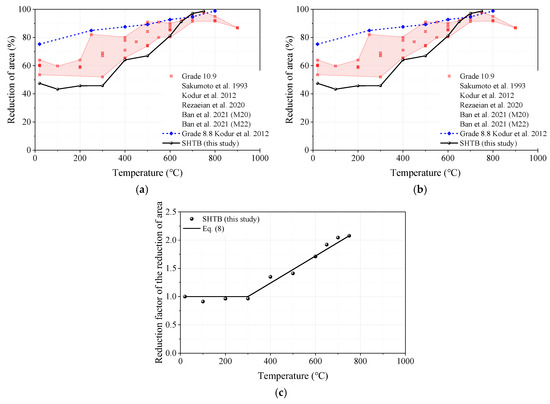

3.3.6. Reduction in Cross-Section Area

The reduction factor of reduction in cross-section area (reduction factor of reduction in area) is defined as the ratio of the reduction in cross-section area (reduction in area) under a specific temperature level () to that of the coupons at ambient temperature (). As shown in Figure 13a, the reduction in area of the SHTB exhibited an increasing trend with the increasing temperature and was much smaller than that of the high-strength bolts when the temperature exceeded 600 °C, but the opposite was true when the temperature exceeded 600 °C. Because of this reason, the reduction factor of the reduction area of the SHTB was much higher than that of the high-strength bolts when the temperature was higher than 600 °C, as shown in Figure 13b. Therefore, Equation (8) is recommended as the prediction formula for the reduction factor of the percentage reduction in area of the SHTB. This formula is in good agreement with the experimental data.

Figure 13.

Reduction factors of reduction in the cross-section area: (a) reduction in the cross-section area; (b) reduction factors of reduction in the cross-section area; (c) prediction formula [2,3,37,45].

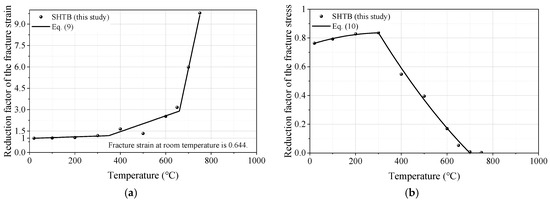

3.3.7. Failure Strain and Stress

Figure 14 presents the reduction factors of the failure strain and stress of the SHTB. The reduction factor of failure strain was defined as the ratio of the failure strain under a specific temperature level () to that of the coupons at ambient temperature (), while the reduction factor of failure stress was defined as the ratio of the failure stress under a specific temperature level () to the yield stress under ambient temperature ().

Figure 14.

Prediction formula of the reduction factors of failure strain and stress: (a) failure strain; (b) failure stress.

From Figure 14a, it can be found that: (1) when the temperature does not exceed 300 °C, the reduction factor of failure strain almost maintained a constant of one; and (2) when the temperature exceeded 300 °C, the reduction factor of failure strain significantly increased with the increase in temperature. Equation (9) was developed to predict the reduction factor of the failure strain of the SHTB, which provided good predictions of the test data. However, the reduction factor of failure stress showed a different trend to the reduction factor of failure strain: the value of the reduction factor of failure stress first increased and then decreased as the temperature increased and reached the maximum value at 300 °C; when the temperature was not lower than 700 °C, the value of the reduction factor of failure stress was almost zero. Based on the fitting analysis, Equation (10) was suggested to predict the reduction factor of the failure stress of the SHTB, as shown in Figure 14b.

4. Stress–Strain Relationship

Uniaxial stress–strain models are commonly used in the component model for structural steel joints [60]. However, to evaluate the mechanical behavior of joints from elastic to failure, a stress–strain model with a descending stage is necessary. Zhu et al. [60] suggested a trilinear model, which can be determined with the yield point, peak point, and failure point, as shown in Equation (11).

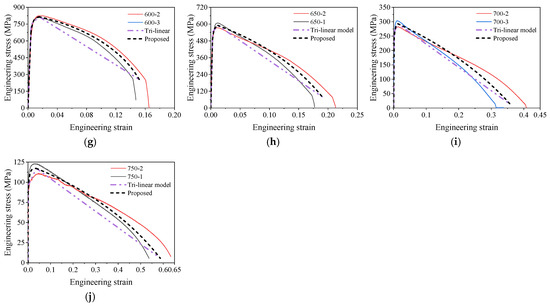

However, the trilinear model is so simplified that it may not accurately describe the stress–strain curve of the SHTB. Therefore, the authors proposed a new three-stage stress–strain model (see Equation (12)): (1) elastic stage (before the proportional limit), in this stage the strain–stress curve is linear; (2) the strain hardening stage (from the proportional limit to the peak stress), in this stage, the curve is assumed to be an exponential curve, where the parameter can be calculated by the strain and stress of the yield point (with a plastic strain of 0.2%); and (3) the descending stage (after peak stress), where the curve is assumed as an arc and the parameter controls the radius of curvature of the curve. Based on the analytical results, the values of parameters and of the SHTB with different temperatures are summarized in Table 3.

Table 3.

Summary of the values of parameters and for the SHTB under various temperatures.

Figure 15 presents the comparisons of the stress–strain curves of the SHTB from the tests, the tri-linear model, and the proposed model. It was found that both the trilinear model and the proposed model described the characteristics of stress–strain curves of the SHTB under various temperatures. However, the curves from the proposed model agreed more with the test data and also showed a difference of proportional limit and proved yield stress at 0.2% plastic strain. Therefore, the proposed model is recommended for component models for structural steel joints, and the trilinear model is more recommended for simplified analysis.

Figure 15.

Comparisons of the stress–strain curves from test and proposed model: (a) room temperature; (b) 100 °C; (c) 200 °C; (d) 300 °C; (e) 400 °C; (f) 500 °C; (g) 600 °C; (h) 650 °C; (i) 700 °C; (j) 750 °C.

5. Conclusions

In this study, a series of vibration tests and tensile tests of Grade 14.9 SHTB coupons were performed at elevated temperatures. The stress–strain curves, Young’s modulus, yield stress, ultimate stress, ultimate strain, percentage elongation, reduction in the cross-section area as well as failure strain were obtained and discussed. Based on the obtained results, the following conclusions can be drawn:

- (1)

- Similar to the conventional high-strength bolts (Grades 8.8, 10.9, and 12.9), the surface states of the SHTB changed to some extent after the test. As the temperature increased, the surface color changed from silvery to black, and the “blue brittle” phenomenon was observed when the temperature was around 400 °C.

- (2)

- When the temperature was below 400 °C, the deterioration in the Young’s modulus of the SHTB was similar to the conventional high-strength bolts, but the SHTB had a larger value when the temperature exceeded 400 °C.

- (3)

- Both the yield stress and ultimate stress of the SHTB were much larger than that of the conventional high-strength bolts under the same temperature. When the temperature did not exceed 400 °C, there were few changes in the yield stress and ultimate stress but exhibited a marked decreasing trend when the temperature exceeded 400 °C.

- (4)

- Both the reduction in the cross-section area and failure strain of the SHTB exhibited an increasing trend with the increase in temperature. However, the failure stress first increased with the temperature increase, and then decreased with the increase in temperature.

- (5)

- Simplified prediction formulae for the reduction factors of the Young’s modulus, proportional limit, yield stress, ultimate tensile stress and strain, failure stress and strain, and the reduction in the cross-section area of the SHTB are suggested. These formulae could well predict the reduction factor of the mechanical properties of the SHTB with the elevated temperature varying from 20 to 750 °C. These formulae can be used to perform future fire safety designs and evaluation.

- (6)

- A three-stage model is suggested to describe the full uniaxial stress–strain curves of the SHTB under various elevated temperatures.

Author Contributions

Conceptualization, L.S. and C.R.; Methodology, M.D.; Software, X.W.; Validation, M.D. and Y.G.; Formal analysis, L.S.; Investigation, C.R. and X.W.; Resources, C.R.; Data curation, C.R.; Writing—original draft preparation, L.S.; Writing—review and editing, M.D. and Y.G.; Visualization, Y.G.; Supervision, X.X.; Project administration, X.X.; Funding acquisition, X.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Foundation of Chongqing Institute of Humanities and Technology (grant number CRKZK2021005) and the Chongqing Education Commission Humanities and social science project (grant number 22SKGH501).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ketabdari, H.; Daryan, A.S.; Hassani, N. Predicting post-fire mechanical properties of grade 8.8 and 10.9 steel bolts. J. Constr. Steel Res. 2019, 162, 105735. [Google Scholar] [CrossRef]

- Ban, H.; Yang, Q.; Shi, Y.; Luo, Z. Constitutive model of high-performance bolts at elevated temperatures. Eng. Struct. 2021, 233, 111889. [Google Scholar] [CrossRef]

- Kodur, V.; Kand, S.; Khaliq, W. Effect of temperature on thermal and mechanical properties of steel bolts. J. Mater. Civ. Eng. 2012, 24, 765–774. [Google Scholar] [CrossRef]

- Chen, C.; Chiew, S.P.; Zhao, M.S.; Lee, C.K.; Fung, T.C. Experimental study of welding effect on grade S690Q high strength steel butt joint. Steel Compos. Struct. 2021, 39, 401–417. [Google Scholar]

- Cai, W.Y.; Wang, Y.B.; Li, G.Q.; Stroetmann, R. Comparative study on strength of TMCP and QT high-strength steel butt-welded joints. J. Constr. Steel Res. 2022, 197, 107447. [Google Scholar] [CrossRef]

- Ghafouri, M.; Amraei, M.; Pokka, A.P.; Bjork, T.; Larkiola, J.; Piili, H.; Zhao, X.L. Mechanical properties of butt-welded ultra-high strength steels at elevated temperatures. J. Constr. Steel Res. 2022, 198, 107499. [Google Scholar] [CrossRef]

- Keränen, L.; Nousiainen, O.; Javaheri, V.; Kaijalainen, A.; Pokka, A.P.; Keskitalo, M.; Niskanen, J.; Kurvinen, E. Mechanical properties of welded ultrahigh-strength S960 steel at low and elevated temperatures. J. Constr. Steel Res. 2022, 198, 107517. [Google Scholar] [CrossRef]

- Kamei, Y.; Ishikawa, M.; Nishimura, N.; Kiryu, S.; Takeuchi, S. Application to Steel Girder Bridges of Super High Tension Bolt. Steel Constr. Eng. 2003, 10, 39–49. [Google Scholar]

- Uno, N.; MKubota; Nagata, M.; Tarui, T.; Kanisawa, H.; Yamasaki, S.; Azuma, K.; Miyagawa, T. Super-High-Strength Bolt, “SHTB®”; Nippon Steel Corporation: Tokyo, Japan, 2008; pp. 95–104. [Google Scholar]

- ASTM F3043-15; Standard Specification for “Twist Off” Type Tension Control Structural Bolt/Nut/Washer Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum Tensile Strength. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM F3111-16; Standard Specification for Heavy Hex Structural Bolt/Nut/Washer Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum Tensile Strength. ASTM International: West Conshohocken, PA, USA, 2016.

- Wood, M.T.; Galitz, C.L.; Shaw, R.E.; Eatherton, M.R. Pretensioning procedures for ASTM F3043 twist-off type tension control bolt assemblies. J. Constr. Steel Res. 2019, 155, 385–394. [Google Scholar] [CrossRef]

- Yang, B.; Wang, F.; Ding, M.; Shen, L.; Elchalakani, M. Experimental study on the post-fire mechanical properties of grade 14.9 superhigh-tension bolt. J. Struct. Eng. 2023, 149, 04023011. [Google Scholar] [CrossRef]

- Gao, H.; Yang, B.; Liu, Z.K.; Elchalakani, M.; Shen, L. Study on Post-Fire Constitutive Model and Fracture Performance of Grade 14.9 Superhigh Tension Bolts. J. Struct. Eng. 2025, accepted. [Google Scholar]

- Laim, L.; Rodrigues, J.P.C.; da Silva, L.S. Experimental analysis on cold-formed steel beams subjected to fire. Thin-Walled Struct. 2014, 74, 104–117. [Google Scholar] [CrossRef]

- Pantousa, D.; Karavasilis, T. Experimental and numerical investigation of the ductile fracture of structural steel at elevated temperatures. J. Constr. Steel Res. 2021, 177, 106444. [Google Scholar] [CrossRef]

- Knobloch, M.; Pauli, J.; Fontana, M. Influence of the strain-rate on the mechanical properties of mild carbon steel at elevated temperatures. Mater. Des. 2013, 49, 553–565. [Google Scholar] [CrossRef]

- Heidarpour, A.; Cevro, S.; Song, Q.Y.; Zhao, X.L. Behaviour of stub columns utilising mild-steel plates and VHS tubes under fire. J. Constr. Steel Res. 2014, 95, 220–229. [Google Scholar] [CrossRef]

- Aziz, E.M.; Kodur, V.K.; Glassman, J.D.; Garlock, M.E.M. Behavior of steel bridge girders under fire conditions. J. Constr. Steel Res. 2015, 106, 11–22. [Google Scholar] [CrossRef]

- Hassler, D.; Hothan, S. Mechanical properties of cold drawn steel S355 at elevated temperatures used for tension rods. Stahlbau 2015, 84, 332–339. [Google Scholar]

- Yuan, G.L.; Shu, Q.J.; Huang, Z.H.; Li, Q. An experimental investigation of properties of Q345 steel pipe at elevated temperatures. J. Constr. Steel Res. 2016, 118, 41–48. [Google Scholar] [CrossRef]

- Wu, Z.L.; Liu, Z.Q.; Li, L.Z.; Lu, Z.D. Experimental and neural networks analysis on elevated-temperature mechanical properties of structural steels. Mater. Today Commun. 2022, 32, 104092. [Google Scholar] [CrossRef]

- Qiang, X.H.; Bijlaard, F.S.K.; Kolstein, H. Deterioration of mechanical properties of high strength structural steel S460N under transient state fire condition. Mater. Des. 2012, 40, 521–527. [Google Scholar] [CrossRef]

- Schneider, R.; Lange, J. Analysis of the time-dependent mechanical behaviour of S460 in case of fire. Stahlbau 2012, 81, 379–390. [Google Scholar] [CrossRef]

- Wang, W.Y.; Liu, B.; Kodur, V. Effect of temperature on strength and elastic modulus of high-strength steel. J. Mater. Civ. Eng. 2013, 25, 174–182. [Google Scholar] [CrossRef]

- Hanus, F.; Caillet, N.; Gaillard, S.; Vassart, O. Strength reduction factors for S355 to S500 steel grades under steady-state and transient-state heating. J. Struct. Fire Eng. 2019, 11, 137–149. [Google Scholar] [CrossRef]

- Qiang, X.H.; Bijlaard, F.; Kolstein, H. Dependence of mechanical properties of high strength steel S690 on elevated temperatures. Constr. Build. Mater. 2012, 30, 73–79. [Google Scholar] [CrossRef]

- Chiew, S.P.; Zhao, M.S.; Lee, C.K. Mechanical properties of heat-treated high strength steel under fire/post-fire conditions. J. Constr. Steel Res. 2014, 98, 12–19. [Google Scholar] [CrossRef]

- Xiong, M.X.; Liew, J.Y.R. Experimental study to differentiate mechanical behaviours of TMCP and QT high strength steel at elevated temperatures. Constr. Build. Mater. 2020, 242, 118105. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Zhao, X.J.; Qi, J.J.; Zhu, W.T.; Feng, Y.; Chen, L.Q.; Wang, G.D. Effect of tempering on the microstructure and properties of a new multi-functional 460 MPa Grade construction structural steel. J. Mater. Res. Technol. 2022, 18, 1092–1104. [Google Scholar] [CrossRef]

- Wang, M.J.; Li, Y.Z.; Li, G.Q.; Wang, W.Y.; Jiang, B.H. Comparative experimental studies of high-temperature mechanical properties of HSSs Q460D and Q690D. J. Constr. Steel Res. 2022, 189, 107065. [Google Scholar] [CrossRef]

- Xiong, M.X.; Pi, P.W.; Gong, W.; Yang, M.F.; Ou, Z.F. Mechanical properties of TMCP high strength steels with different strength grades at elevated temperatures. J. Build. Eng. 2022, 48, 103874. [Google Scholar] [CrossRef]

- Heidarpour; Tofts, N.S.; Korayem, A.H.; Zhao, X.L.; Hutchinson, C.R. Mechanical properties of very high strength steel at elevated temperatures. Fire Saf. J. 2014, 64, 27–35. [Google Scholar] [CrossRef]

- Azhari, F.; Heidarpour, A.; Zhao, X.L.; Hutchinson, C.R. Mechanical properties of ultra-high strength (Grade 1200) steel tubes under cooling phase of a fire: An experimental investigation. Constr. Build. Mater. 2015, 93, 841–850. [Google Scholar] [CrossRef]

- Niu, Q.L.; Ming, W.W.; Chen, M.; Tang, S.W.; Li, P.N. Dynamic mechanical behavior of ultra-high strength steel 30CrMnSiNi2A at high strain rates and elevated temperatures. J. Iron Steel Res. Int. 2017, 24, 724–729. [Google Scholar] [CrossRef]

- Zeng, X.; Wu, W.B.; Zou, J.; Elchalakani, M. Constitutive Model for equivalent stress-plastic strain curves including full-range strain hardening behavior of high-strength steel at elevated temperatures. Materials 2022, 15, 8075. [Google Scholar] [CrossRef] [PubMed]

- Sakumoto, Y.; Keira, K.; Furumura, F.; Ave, T. Tests of fire-resistant bolts and joints. J. Struct. Eng. 1993, 119, 3131–3150. [Google Scholar] [CrossRef]

- Kirby, B.R. The behavior of high-strength grade 8.8 bolts in fire. J. Constr. Steel Res. 1995, 33, 3–38. [Google Scholar] [CrossRef]

- Li, G.Q.; Jiang, S.C.; Yin, Y.Z.; Chen, K.; Li, M.F. Experimental studies on the properties of constructional steel at elevated temperatures. J. Struct. Eng. 2003, 129, 1717–1721. [Google Scholar] [CrossRef]

- Yu, L. Behavior of Bolted Connections During and After a Fire; The University of Texas at Austin: Austin, TX, USA, 2006. [Google Scholar]

- Yu, L.A.; Frank, K.H. Shear behavior of A325 and A490 high-strength bolts in fire and post-fire. Eng. J. 2009, 46, 99–106. [Google Scholar] [CrossRef]

- Lange, J.; González, F. Behavior of high-strength grade 10.9 bolts under fire conditions. Struct. Eng. Int. 2012, 22, 470–475. [Google Scholar] [CrossRef]

- Weigand, J.; Main, J.; Peixoto, R.; Vieira, L. Shear Behavior of High-Strength Bolts at Elevated Temperature: Testing and Formulation of Reduced-Order Model; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1978. [Google Scholar]

- Pang, X.P.; Hu, Y.; Tang, S.L.; Xiang, Z.; Wu, G.; Xu, T.; Wang, X.Q. Physical properties of high-strength bolt materials at elevated temperatures. Results Phys. 2019, 13, 102156. [Google Scholar] [CrossRef]

- Rezaeian, A.; Shafiei, M.; Eskandari, M. Effect of temperature on mechanical properties of steel bolts. J. Mater. Civ. Eng. 2020, 32, 04020239. [Google Scholar] [CrossRef]

- Kawohl, A.K.; Lange, J. Tests on 10.9 bolts under combined tension and shear during and after fire. In Proceedings of the International Conference on Applications of Structural Fire Engineering, Dubrovnik, Croatia, 15–16 October 2015. [Google Scholar]

- Lange, J.; Kawohl, A. Tension-shear interaction of high-strength bolts during and after fire. Steel Constr.-Des. Res. 2019, 12, 124–134. [Google Scholar] [CrossRef]

- Ding, H.M. Study on Fracture Properties of 8.8s Grade High Strength Bolts, in School of Civil Engineering; Chongqing University: Chongqing, China, 2021. [Google Scholar]

- Lu, Y.; Jiang, J.; Chen, Q.; Cai, W.; Chen, W.; Ye, J. Fracture behavior of Grade 10.9 high-strength bolts and T-stub connections in fire. J. Constr. Steel Res. 2022, 199, 107618. [Google Scholar] [CrossRef]

- Saglik, H.; Chen, A.; Ma, R. Ductile fracture of high-strength bolts under combined actions at elevated temperatures. J. Constr. Steel Res. 2024, 213, 108437. [Google Scholar] [CrossRef]

- BS EN 1993-1-2; Eurocode 3: Design of Steel Structures—Part 1–2: General Rules—Structural Fire Design. European Committee for Standardization: Brussels, Belgium, 2005.

- BS 5950-9; Structural Use of Steel Work in Building—Part 8: Code of Practice for Fire Resistance Design. Standards Policy and Strategy Committee: London, UK, 2003.

- GB 51249-2017; Code for Fire Safety of Steel Structures in Buildings. China Planning Press: Beijing, China, 2017.

- GB/T 228.1-2021; Metallic Materials: Tensile Testing: Part 1: Method of Test at Room Temperature. Stand. Press China: Beijing, China, 2021.

- ASTM E1876-15; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2015.

- GB/T 228.2-2015; Metallic Materials-Tensile Testing-Part 2: Method of Test at Elevated Temperature. Stand. Press China: Beijing, China, 2015.

- Wiman, P.; Boonpensin, M.; Saranyachot, P.; Thublaor, T. Approximation in Ellingham diagram and calculation approach using heat capacity of oxides and metals constituent in stainless steels. Mater. Today Proc. 2022, 52, 2539–2542. [Google Scholar] [CrossRef]

- Epifano, E.; Monceau, D. Ellingham diagram: A new look at an old tool. Corros. Sci. 2023, 217, 111113. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Zhu, C.; Rasmussen, K.J.R.; Yan, S. Generalised component model for structural steel joints. J. Constr. Steel Res. 2019, 153, 330–342. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).