Effect of Transition Layers on the Microstructure and Properties of CMT Additively Manufactured Steel/Copper Specimens

Abstract

1. Introduction

2. Experimental Procedures

2.1. Testing Materials

2.2. Testing Equipment

3. Results and Discussions

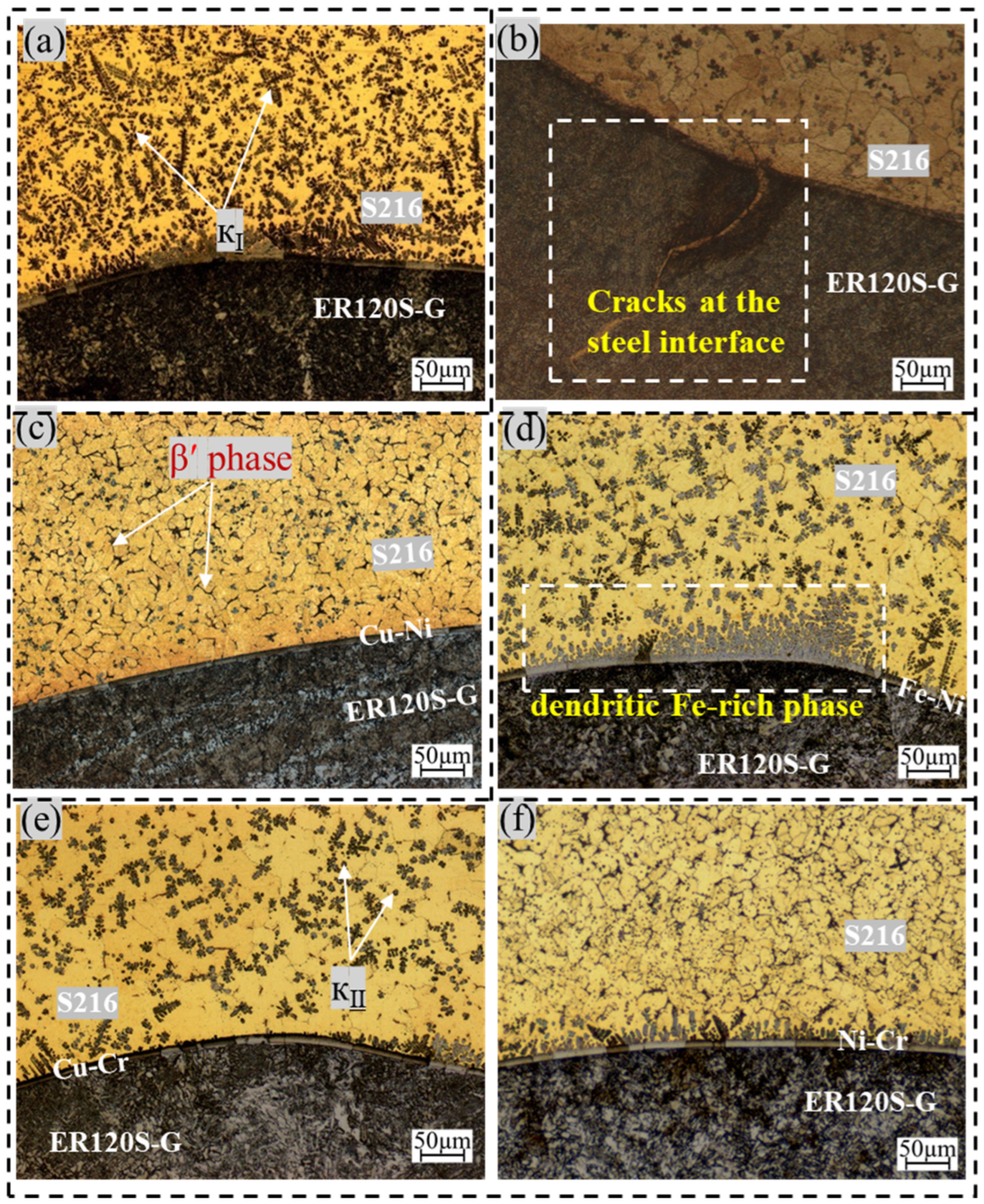

3.1. Microstructure Evolution Analysis

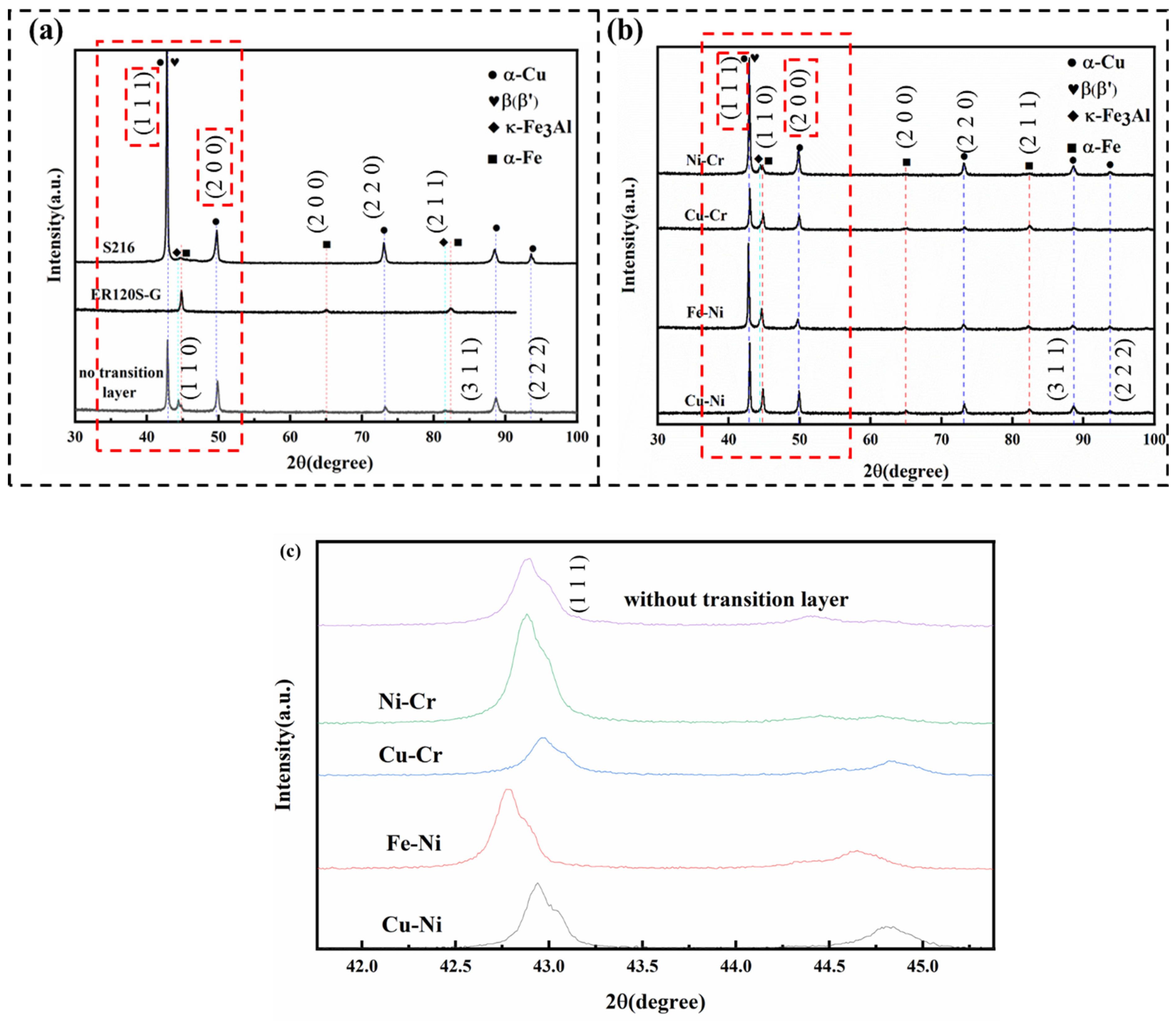

3.2. Phase Composition Analysis

3.2.1. XRD Analysis

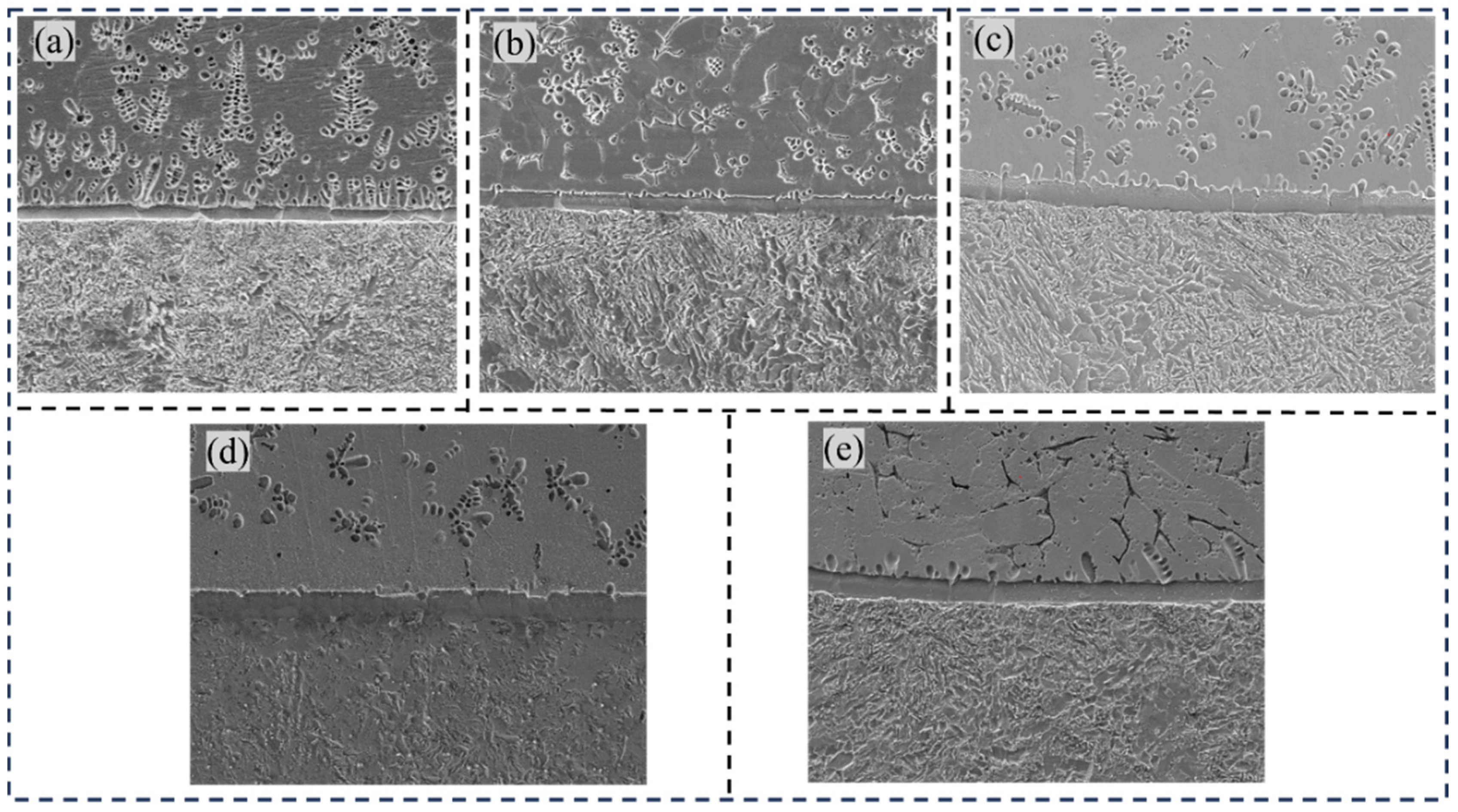

3.2.2. EDS Analysis

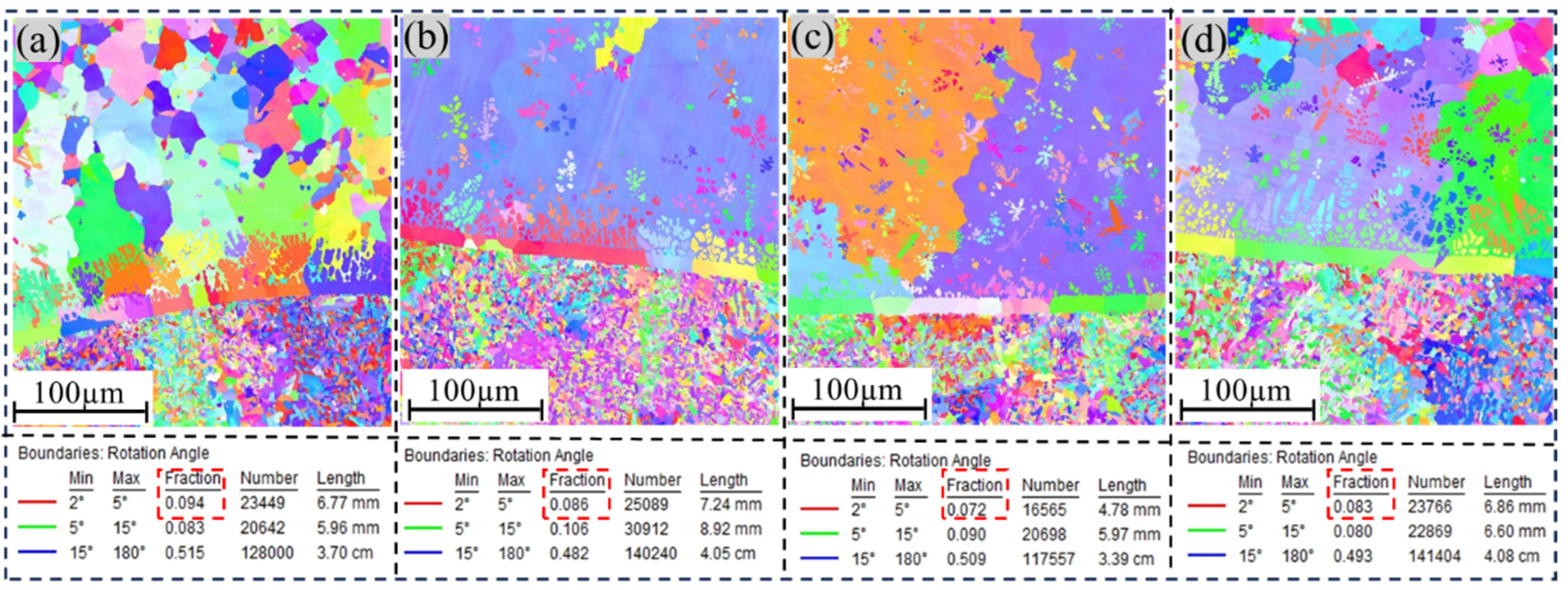

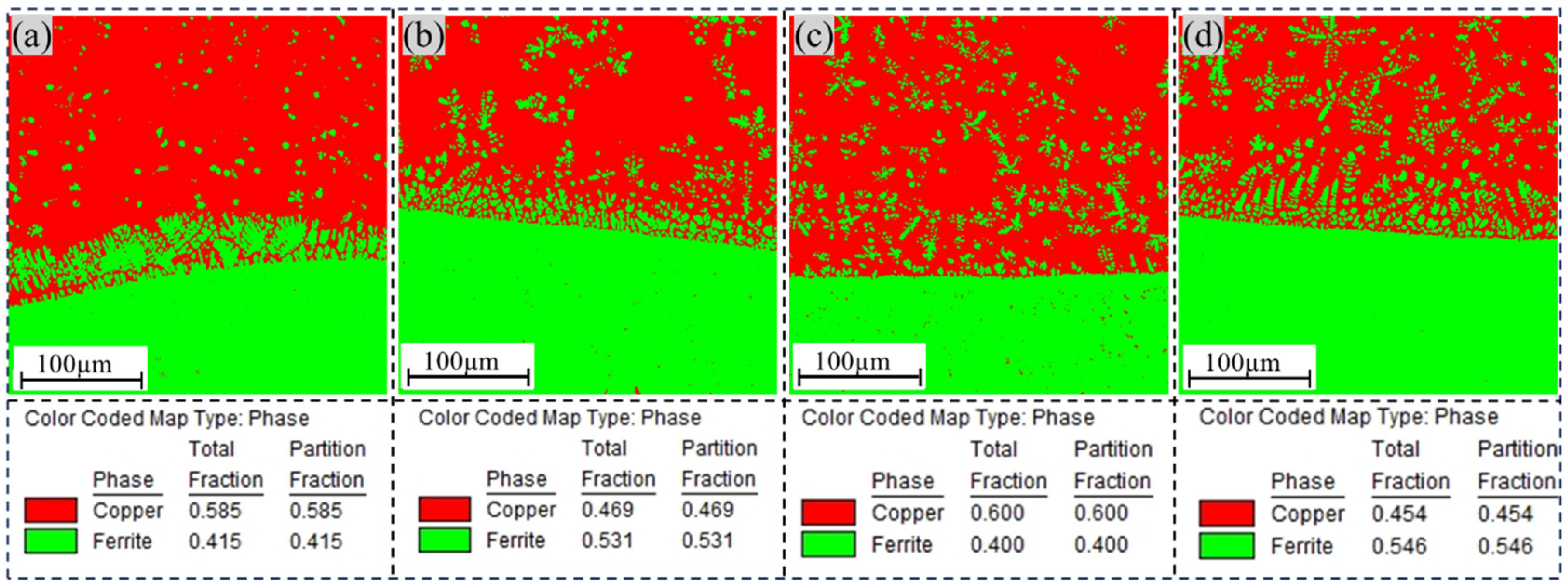

3.2.3. EBSD Analysis

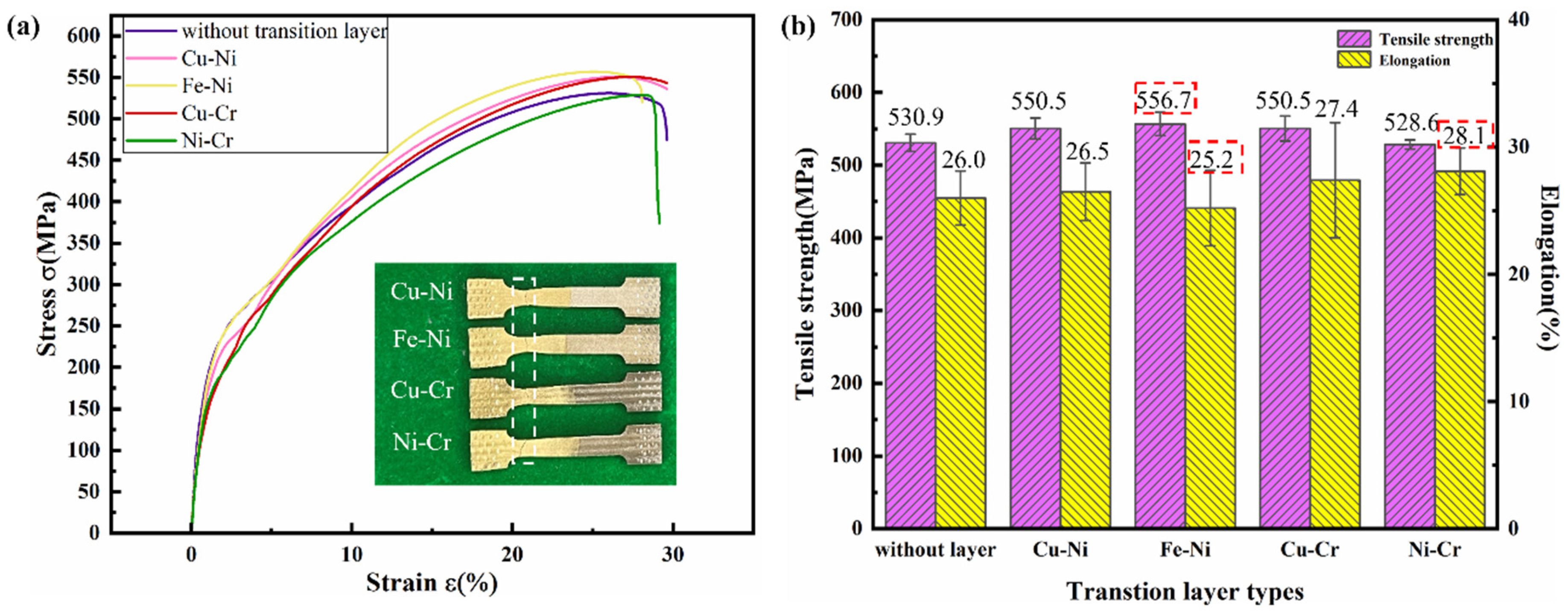

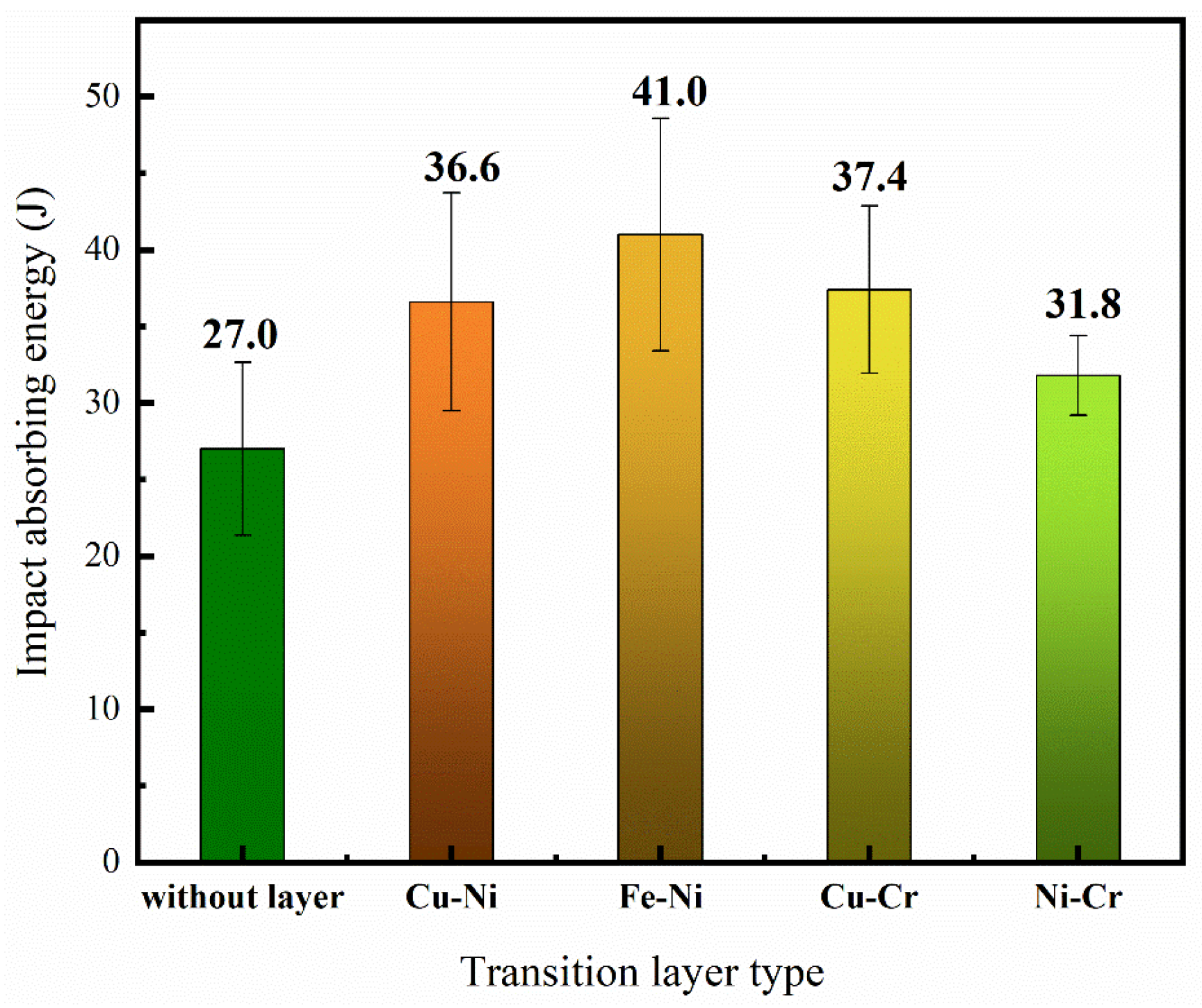

3.3. Comparative Analysis of Mechanical Properties

3.3.1. Comparison of Hardness

3.3.2. Comparison of Tensile Properties

3.3.3. Comparison of Impact Properties

4. Conclusions

- (1)

- In the absence of a transition layer in the sample, flower-shaped iron-rich precipitates (κⅠ) and spherical iron-rich phases (κⅡ) were dispersed near the copper side of the interface, while cracks formed at the steel/copper interface. After the transition layer was introduced, the fusion line at the interface was clearly delineated, and the Fe-enriched phase, β phase, and α-Cu phase were more evenly distributed. The number of iron-rich phases at the copper/steel interface decreased as the distance from the interface increased, effectively suppressing the diffusion of iron and reducing interfacial penetration cracks. Specifically, the Ni-Cr and Fe-Ni transition layers demonstrated a weaker suppression of iron diffusion, resulting in a higher concentration of iron-rich phase compounds at the interface.

- (2)

- The phase composition of the four samples showed no significant changes after the transition layer was added, consisting primarily of the α-Cu phase, β′ phase, and κFe3Al phase. EDS analysis revealed that the addition of the transition layer altered the element distribution at the interface. The transition layer promoted the interdiffusion of Fe, Ni, Cu and other elements.

- (3)

- Hardness tests revealed a gradual increase in hardness from the copper side to the steel side across all samples, with the Fe-Ni transition layer sample exhibiting the highest average hardness. With the help of iron-rich phases, the samples showed enhanced tensile strength and impact absorption energy. In particular, the Fe-Ni transition layer sample demonstrated a tensile strength increase of approximately 4.8% and a 52% improvement in impact absorption energy. However, the iron-rich phase’s inherent brittleness simultaneously compromised the material′s plasticity, ultimately diminishing its elongation capacity. The elongation of the Fe-Ni transition layer was 3.1% lower than that of the sample without a transition layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nemani, A.V.; Ghaffari, M.; Bokati, K.S.; Valizade, N.; Afshari, E.; Nasiri, A. Advancements in additive manufacturing for copper-based alloys and composites: A comprehensive review. J. Manuf. Mater. Process. 2024, 8, 54. [Google Scholar] [CrossRef]

- Müller, A.; Böswirth, B.; Cerri, V.; Greuner, H.; Neu, R.; Siefken, U.; Visca, E.; You, J.H. Application of tungsten–copper composite heat sink materials to plasma-facing component mock-ups. Phys. Scr. 2020, 2020, 014015. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Q.; Jiang, H. New research progress on copper/aluminium bimetallic composites. Mater. Rep. A 2020, 34, 7115–7122. [Google Scholar]

- Zhang, H.; Jiao, K.X.; Zhang, J.L.; Liu, J. Microstructure and mechanical properties investigations of copper-steel composite fabricated by explosive welding. Mater. Sci. Eng. A 2018, 731, 278–287. [Google Scholar] [CrossRef]

- Bai, Q.L.; Zhang, L.J.; Xie, M.X.; Yang, H.-X.; Zhang, J.-X. An investigation into the inhomogeneity of the microstructure and mechanical properties of explosive welded H62-brass/Q235B-steel clad plates. Int. J. Adv. Manuf. Technol. 2017, 90, 1351–1363. [Google Scholar] [CrossRef]

- Zhang, H.; Jiao, K.X.; Zhang, J.L.; Liu, J. Comparisons of the microstructures and micro-mechanical properties of copper/steel explosive-bonded wave interfaces. Mater. Sci. Eng. A 2019, 756, 430–441. [Google Scholar] [CrossRef]

- Chen, J.; Bi, G.; Zhao, D.; Wang, D.; Zhang, M.; Xiao, Y. Subsequent enhancement of mechanical properties using heat treatment of steel/copper bimetallic structures manufactured by laser powder bed fusion. J. Mater. Res. Technol. 2024, 33, 8944–8957. [Google Scholar] [CrossRef]

- Chen, Z.; Cun, C.; Pei, L.I.; Lu, T.-X.; Yang, F.; Guo, Z.-M. Microstructure and properties of Cu–Fe alloys prepared by powder metallurgy. Powder Metall. Technol. 2022, 40, 139–144. [Google Scholar] [CrossRef]

- Tang, Z.J.; Liu, W.W.; Wang, Y.W.; Saleheen, K.M.; Liu, Z.-C.; Peng, S.-T.; Zhang, Z.; Zhang, H.-C. A review on in situ monitoring technology for directed energy deposition of metals. Int. J. Adv. Manuf. Technol. 2020, 108, 3437–3463. [Google Scholar] [CrossRef]

- Lee, K.; Doddapaneni, V.K.; Mirzababaei, S.; Pasebani, S.; Chang, C.-H.; Paul, B.K. Synthesis of a 316L stainless steel-copper composite by laser melting. Addit. Manuf. Lett. 2022, 3, 100058. [Google Scholar] [CrossRef]

- Wang, C.; Zhong, W.; Ping, W.; Lin, Z.; Wang, R.; Dai, J.; Guo, M.; Xiong, W.; Zhao, J.; Hu, L. Rapid synthesis and sintering of metals from powders. Adv. Sci. 2021, 8, 2004229. [Google Scholar] [CrossRef] [PubMed]

- Teimouri, M.; Gao, W.; Godfrey, A. Microstructure and mechanical properties of a copper–stainless-steel dual-phase system prepared by spark plasma sintering. Mater. Sci. Technol. 2020, 36, 1364–1371. [Google Scholar] [CrossRef]

- Cheng, Z.; Huang, J.; Ye, Z.; Chen, Y.; Yang, J.; Chen, S. Microstructures and mechanical properties of copper-stainless steel butt-welded joints by MIG-TIG double-sided arc welding. J. Mater. Process. Technol. 2019, 265, 87–98. [Google Scholar] [CrossRef]

- Yang, J.N.; Zhang, L.J.; Ning, J.; Bai, Q.-L.; Yin, X.-Q.; Zhang, J.-X. Single pass laser-MIG hybrid welding of 8-mm thick pure copper (T2) without preheating: Microstructure and properties. Appl. Therm. Eng. 2017, 126, 867–883. [Google Scholar] [CrossRef]

- Ramachandran, S.; Lakshminarayanan, A.K. An insight into microstructural heterogeneities formation between weld subregions of laser welded copper to stainless steel joints. Trans. Nonferrous Met. Soc. China 2020, 30, 727–745. [Google Scholar] [CrossRef]

- Meng, Y.; Li, X.; Gao, M.; Zeng, X. Microstructures and mechanical properties of laser-arc hybrid welded dissimilar pure copper to stainless steel. Opt. Laser Technol. 2019, 111, 140–145. [Google Scholar] [CrossRef]

- Wang, T.; Shukla, S.; Nene, S.S.; Frank, M.; Wheeler, R.W.; Mishra, R.S. Towards obtaining sound butt joint between metallurgically immiscible pure Cu and stainless steel through friction stir welding. Metall. Mater. Trans. A 2018, 49, 2578–2582. [Google Scholar] [CrossRef]

- Bellamkonda, N.P.; Dwivedy, M.; Addanki, R. Cold metal transfer technology—A review of recent research developments. Results Eng. 2024, 23, 102423. [Google Scholar] [CrossRef]

- Das, B.; Panda, B.N.; Sharma, F.; Dixit, U.S. Recent Developments in Cladding and Coating Using Cold Metal Transfer Technology. J. Mater. Eng. Perform. 2023, 33, 3130–3147. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Tan, Q.; Yin, Y.; Liu, S.; Li, M.; Li, M.; Liu, Q.; Zhou, Y.; Wu, T.; et al. Additive manufacturing of high strength copper alloy with heterogeneous grain structure through laser powder bed fusion. Acta Mater. 2021, 220, 117311. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L/CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- ZainElabdeen, I.H.; Ismail, L.; Mohamed, O.F.; Khan, K.A.; Schiffer, A. Recent advancements in hybrid additive manufacturing of similar and dissimilar metals via laser powder bed fusion. Mater. Sci. Eng. A 2024, 909, 146833. [Google Scholar] [CrossRef]

- Haines, M.P.; List, F., III; Carver, K.; Leonard, D.; Plotkowski, A.; Fancher, C.; Dehoff, R.; Babu, S. Role of scan strategies and heat treatment on grain structure evolution in Fe-Si soft magnetic alloys made by laser-powder bed fusion. Addit. Manuf. 2022, 50, 102578. [Google Scholar] [CrossRef]

- Chen, K.; Wang, C.; Hong, Q.; Wen, S.; Zhou, Y.; Yan, C.; Shi, Y. Selective laser melting 316L/CuSn10 multi-materials: Processing optimization, interfacial characterization and mechanical property. J. Mater. Process. Technol. 2020, 283, 116701. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Astafurova, E.G.; Chumaevskii, A.V.; Kalashnikov, K.N.; Astafurov, S.V.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Tarasov, S.Y.; et al. Gradient transition zone structure in “steel–copper” sample produced by double wire-feed electron beam additive manufacturing. J. Mater. Sci. 2020, 55, 9258–9272. [Google Scholar] [CrossRef]

- Zhang, X.C.; Sun, C.; Pan, T.; Flood, A.; Zhang, Y.; Li, L.; Liou, F. Additive manufacturing of copper-H13 tool steel bi-metallic structures via Ni-based multi-interlayer. Addit. Manuf. 2020, 36, 101474. [Google Scholar] [CrossRef]

- Liu, Y.; Li, B.; Zhang, W.; Liu, Z.; Jiang, M. Interfacial Behavior of Copper/Steel Bimetallic Composites Fabricated by CMT-WAMM. Coatings 2024, 14, 803. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.; Du, M.; Zhang, S.; Lei, L. Experimental characterization and microstructural evaluation of silicon bronze-alloy steel bimetallic structures by additive manufacturing. Metall. Mater. Trans. A 2021, 52, 4664–4674. [Google Scholar] [CrossRef]

- Liu, L.; Zhuang, Z.; Liu, F.; Zhu, M. Additive manufacturing of steel–bronze bimetal by shaped metal deposition: Interface characteristics and tensile properties. Int. J. Adv. Manuf. Technol. 2013, 69, 2131–2137. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, W.; Xiao, H.; Zhu, H.; Yang, H.; Wang, Y.; Chen, B. QCr0.8 Cu alloy/S06 stainless steel bimetal structure via In718 multi-interlayer fabricated by laser powder hybrid additive manufacturing. J. Mater. Res. Technol. 2023, 24, 1034–1042. [Google Scholar] [CrossRef]

| Material | C | Mn | Si | S | P | Fe | Al | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| Q235 | 0.14 | 1.01 | 0.32 | 0.01 | 0.04 | Balance | / | / | / |

| S216 | / | 0.014 | 0.03 | / | / | 0.88 | 8.84 | 0.005 | Balance |

| ER120S-G | 0.08 | 1.76 | 0.78 | 0.008 | 0.007 | Balance | / | 2.25 | / |

| Transition Layer | Ni | Mn | Si | Cu | Fe | Cr | Mo |

|---|---|---|---|---|---|---|---|

| Cu-Ni | 30 | 2 | 3 | Balance | 5 | 4 | 2 |

| Fe-Ni | 30 | 2 | 4 | 4 | Balance | 4 | 2 |

| Cu-Cr | / | 1 | 2 | Balance | 4 | 20 | 2 |

| Ni-Cr | Balance | 1 | 2 | / | 4 | 22 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Xu, Y.; Li, J.; Zhang, C. Effect of Transition Layers on the Microstructure and Properties of CMT Additively Manufactured Steel/Copper Specimens. Materials 2025, 18, 1734. https://doi.org/10.3390/ma18081734

Guo X, Xu Y, Li J, Zhang C. Effect of Transition Layers on the Microstructure and Properties of CMT Additively Manufactured Steel/Copper Specimens. Materials. 2025; 18(8):1734. https://doi.org/10.3390/ma18081734

Chicago/Turabian StyleGuo, Xuyang, Yulang Xu, Jingyong Li, and Cheng Zhang. 2025. "Effect of Transition Layers on the Microstructure and Properties of CMT Additively Manufactured Steel/Copper Specimens" Materials 18, no. 8: 1734. https://doi.org/10.3390/ma18081734

APA StyleGuo, X., Xu, Y., Li, J., & Zhang, C. (2025). Effect of Transition Layers on the Microstructure and Properties of CMT Additively Manufactured Steel/Copper Specimens. Materials, 18(8), 1734. https://doi.org/10.3390/ma18081734