Application of Machine Learning in Amorphous Alloys

Abstract

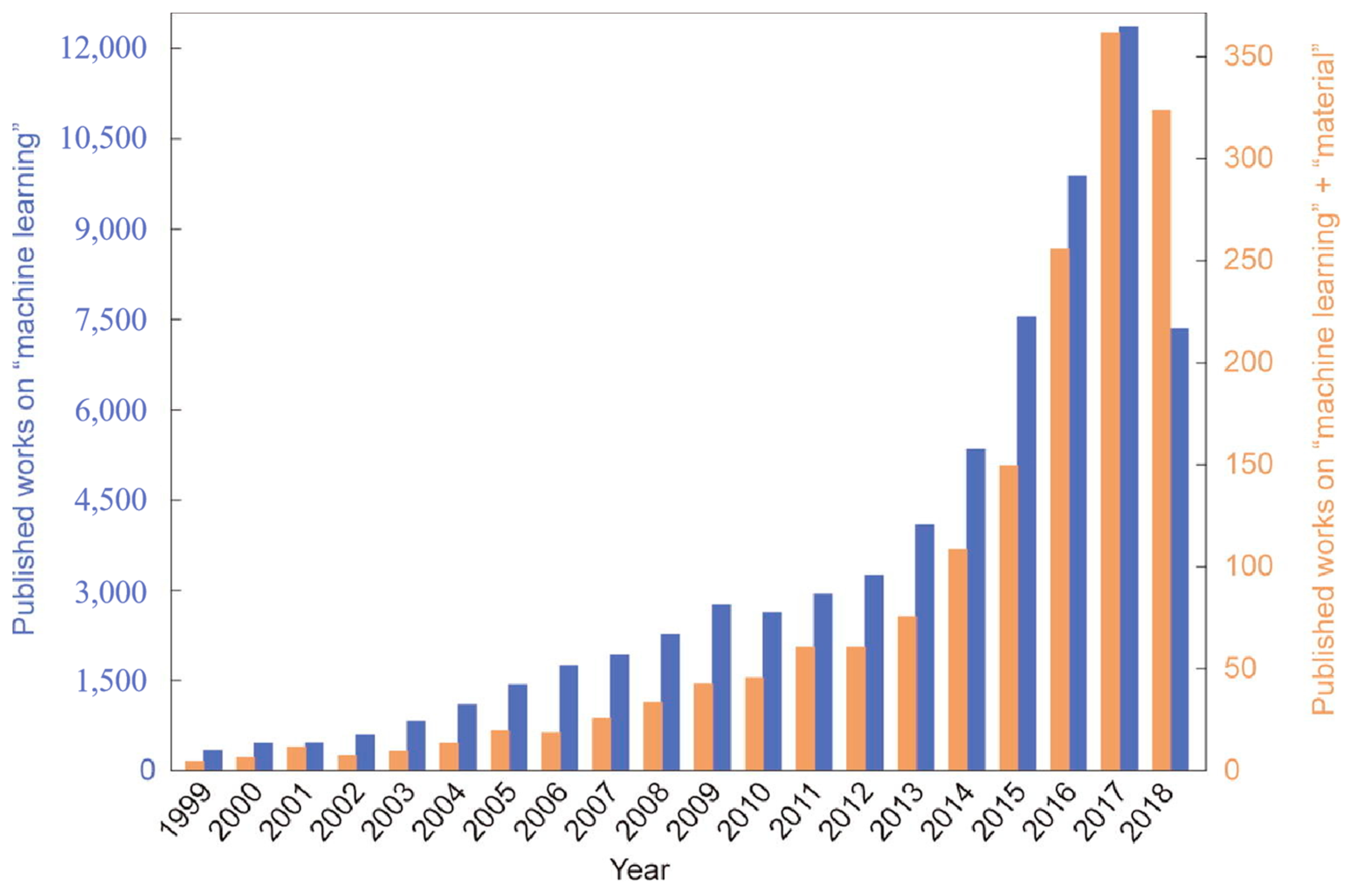

1. Introduction

2. ML for Phase Prediction in Amorphous Alloys

3. ML for the Study of Multi-Principal Element Amorphous Alloy Composites

4. ML for Predicting GFA

5. ML for Predicting Other Properties of Amorphous Alloys

6. Comparison and Analysis

6.1. Phase Prediction and Multi-Principal Element Amorphous Alloy Composites

- (1)

- If the amount of data is too large or too small, the prediction accuracy will decrease. When the number of data points is between 300 and 600, the prediction accuracy is higher.

- (2)

- The lack of unified physical significance in selected parameters often leads to random combinations or an excessive number of features, complicating the selection process. Among them, Sid, δ, ΔHm, and Δχ are the four features that are more important.

- (3)

- Various machine learning algorithms have different advantages and disadvantages, and it is necessary to choose the most suitable machine learning model and the optimal combination of feature parameters.

6.2. Predicting GFA and Predicting Other Properties

- (1)

- Problem Type Clarification. Classification tasks (e.g., predicting amorphous phase formation likelihood): Logistic regression, SVM, random forest, and XGBoost are recommended. Regression tasks (e.g., predicting quantitative GFA metrics such as critical cooling rate or glass-forming parameters): Linear regression, SVR, random forest regression, and XGBoost regression are suitable.

- (2)

- Data Scale and Quality Assessment. Small sample sizes (<1000 samples): Prioritize models with low sample requirements (e.g., SVM, random forest). High-dimensional features: Apply feature selection (random forest-based importance, LASSO) or dimensionality reduction (e.g., PCA). Missing values/noise: Use robust algorithms (e.g., random forest) or implement data imputation/cleaning.

- (3)

- Feature Engineering and Selection. Key features: Elemental composition, atomic size mismatch, thermodynamic parameters (e.g., mixing enthalpy, entropy), and kinetic parameters (e.g., undercooled liquid region width). Preprocessing: Standardization/normalization (critical for SVM/neural networks), generation of interaction/polynomial features.

- (4)

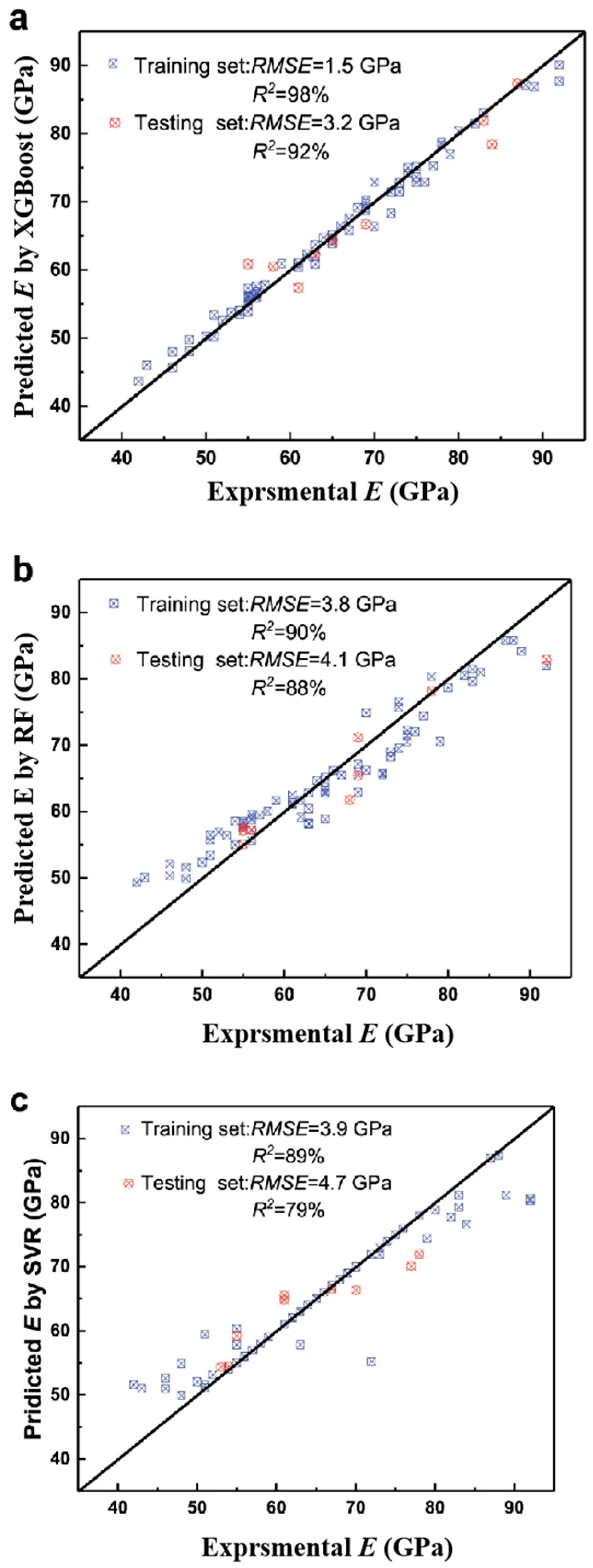

- Model Selection and Optimization. Baseline models: Start with linear models (logistic/linear regression) to establish performance benchmarks. Nonlinear relationships: Random forest or XGBoost, which also enable feature importance analysis. High-dimensional data: SVM (requires hyperparameter tuning for kernel functions and regularization) with standardized inputs. Neural networks: Consider only for large datasets, with careful architecture design and regularization to prevent overfitting. Ensemble methods (e.g., Stacking): Improve performance at the cost of computational resources.

- (5)

- Model Evaluation and Validation. Cross-validation: Use k-fold cross-validation (especially for small datasets) to mitigate overfitting. Metrics: Classification: Accuracy, F1-score (to address class imbalance), ROC–AUC. Regression: MSE, R2 score. Interpretability: Leverage SHAP values or LIME to explain complex models (e.g., XGBoost, neural networks).

7. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Blyskun, P.; Maj, P.; Kowalczyk, M.; Latuch, J.; Kulik, T. Relation of various GFA indicators to the critical diameter of Zr-based BMGs. J. Alloys Compd. 2015, 625, 13–17. [Google Scholar] [CrossRef]

- Qiao, J.; Jia, H.; Liaw, P.K. Metallic glass matrix composites. Mater. Sci. Eng. R-Rep. 2016, 100, 1–69. [Google Scholar] [CrossRef]

- Samuel, A.L. Some studies in machine learning using the game of checkers. IBM J. Res. Dev. 1959, 3, 210. [Google Scholar] [CrossRef]

- Ramprasad, R.; Batra, R.; Pilania, G.; Mannodi-Kanakkithodi, A.; Kim, C. Machine learning in materials informatics: Recent applications and prospects. Npj Comput. Mater. 2017, 3, 54. [Google Scholar] [CrossRef]

- Correa-Baena, J.P.; Hippalgaonkar, K.; van Duren, J.; Shaffiq, J.; Chandrasekhar, V.R.; Stevanovic, V.; Wadia, C.; Guha, S.; Buonassisi, T. Accelerating materials development via automation, machine learning, and high-performance computing. Joule 2018, 2, 1410. [Google Scholar] [CrossRef]

- Zhou, T.; Song, Z.; Sundmacher, K. Big data creates new opportunities for materials research:A review on methods and applications of machine learning for materials design. Engineering 2019, 5, 1017–1026. [Google Scholar] [CrossRef]

- He, Q.F.; Ding, Z.Y.; Ye, Y.F.; Yang, Y. Design of high-entropy alloy: A perspective from nonideal mixing. JOM 2017, 69, 2092–2098. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chan, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Hugh, C.; Olexandr, I.; Aron, W. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef]

- Ren, B.Y.; Long, Z.L.; Deng, R.J. A new criterion for predicting the glass-forming ability of alloys based on machine learning. Comput. Mater. Sci. 2021, 189, 110259. [Google Scholar] [CrossRef]

- Schmidt, J.; Marques, M.; Botti, S.; Miguel, M. Recent advances and applications of machine learning in solid-state materials science. Npj Comput. Mater. 2019, 5, 1–36. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Yang, S.; Evans, J. Revisiting hume-rothery’s rules with artificial neural networks. Acta Mater. 2008, 56, 1094–1105. [Google Scholar] [CrossRef]

- Rupp, M.; Tkatchenko, A.; Müller, K.R.; Lilienfeld, O.V. Fast and accurate modeling of molecular atomization energies with machine learning. Phys. Rev. Lett. 2012, 108, 058301. [Google Scholar] [CrossRef] [PubMed]

- Meredig, B.; Wolverton, C. A hybrid computational-experimental approach for automated crystal structure solution. Nat. Mater. 2013, 12, 123–127. [Google Scholar] [CrossRef]

- Ward, L.; Agrawal, A.; Choudhary, A.; Wolverton, C. A general-purpose machine learning framework for predicting properties of inorganic materials. Npj Comput. Mater. 2016, 2, 16028. [Google Scholar] [CrossRef]

- Hart, G.L.W.; Mueller, T.; Toher, C.; Curtarolo, S. Machine learning for alloys. Nat. Rev. Mater. 2021, 6, 730–755. [Google Scholar] [CrossRef]

- Liu, X.D.; Li, X.; He, Q.F.; Liang, D.D.; Zhou, Z.Q.; Ma, J.; Yang, Y.; Shen, J. Machine learning-based glass formation prediction in multicomponent alloys. Acta Mater. 2020, 201, 182–190. [Google Scholar] [CrossRef]

- Islam, N.; Huang, W.J.; Zhuang, H.L. Machine learning for phase selection in multi-principal element alloys. Comput. Mater. Sci. 2018, 150, 230–235. [Google Scholar] [CrossRef]

- Zhou, Z.Q.; Zhou, Y.J.; He, Q.F.; Ding, Z.Y.; Li, F.C.; Yang, Y. Machine learning guided appraisal and exploration of phase design for high entropy alloys. Npj Comput. Mater. 2019, 5, 128. [Google Scholar] [CrossRef]

- Huang, W.J.; Martin, P.; Zhuang, H.L. Machine-learning phase prediction of high entropy alloys. Acta Mater. 2019, 169, 225–236. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, H.M.; Tao, X.M.; Cai, H.G.; Liu, J.N.; Ouyang, Y.F.; Peng, Q.; Du, Y. Machine learning reveals the importance of the formation enthalpy and atom-size difference in forming phases of high entropy alloys. Mater. Des. 2020, 193, 108835. [Google Scholar] [CrossRef]

- Wu, Q.F.; Wang, Z.J.; Hu, X.B.; Zheng, T.; Yang, Z.S.; He, F.; Li, J.J.; Wang, J.C. Uncovering the eutectics design by machine learning in the Al-Co-Cr-Fe-Ni high entropy system. Acta Mater. 2020, 182, 278–286. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, C.; Wang, C.X.; Antonov, S.; Xue, D.Z.; Bai, Y.; Su, Y.J. Phase prediction in high entropy alloys with a rational selection of materials descriptors and machine learning models. Acta Mater. 2020, 185, 528–539. [Google Scholar] [CrossRef]

- Feng, S.; Fu, H.D.; Zhou, H.Y.; Wu, Y.; Lu, Z.P.; Dong, H.B. A general and transferable deep learning framework for predicting phase formation in materials. Npj Comput. Mater. 2021, 7, 10. [Google Scholar] [CrossRef]

- Ching, W.Y.; San, S.; Brechtl, J.; Sakidja, R.; Zhang, M.Q.; Liaw, P.K. Fundamental electronic structure and multiatomic bonding in 13 biocompatible high-entropy alloys. Npj Comput. Mater. 2020, 6, 45. [Google Scholar] [CrossRef]

- Qu, N.; Chen, Y.C.; Lai, Z.H.; Liu, Y.; Zhu, J.C. The phase selection via machine learning in high entropy alloys. Procedia Manuf. 2019, 37, 299–305. [Google Scholar] [CrossRef]

- Lee, S.Y.; Byeon, S.; Kim, H.S.; Jin, H.Y.; Lee, S.C. Deep learning-based phase prediction of high entropy alloys: Optimization, generation, and explanation. Mater. Des. 2021, 197, 109260. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.L.; Bi, S.R.; Yin, J.Q.; Zhang, G.N.; Eisenbach, M. Robust data-driven approach for predicting the configurational energy of high entropy alloys. Mater. Des. 2020, 185, 108247. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, M.B.; Yang, X. Advanced High-Entropy Alloy Technology; Chemical Industry Press: Beijing, China, 2018. [Google Scholar]

- Yeh, J.W.; Lin, S.J.; Chin, T.S.; Gan, J.W.; Chen, S.K.; Shun, T.T.; Tsau, C.H.; Chou, S.Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Fu, X.L.; Wang, G.; Wu, Y.; Song, W.L.; Shek, C.H.; Zhang, Y.; Shen, J.; Ritchie, R.O. Compressive ductility and fracture resistance in CuZr-based shape-memory metallic-glass composites. Int. J. Plast. 2020, 128, 102687. [Google Scholar] [CrossRef]

- Li, T.X.; Lu, Y.P.; Cao, Z.Q.; Wang, T.M.; Li, T.J. Opportunity and challenge of refractory high-entropy alloys in the field of reactor structural materials. Acta Metall. Sin. 2021, 57, 42–54. [Google Scholar]

- Lu, Z.P.; Lei, Z.F.; Huang, H.L.; Liu, S.F.; Zhang, F.; Duan, D.B.; Cao, P.P.; Wu, Y.; Liu, X.J.; Wang, H. Deformation behavior and toughening of high-entropy alloys. Acta Metall. Sin. 2018, 54, 1553–1566. [Google Scholar]

- Han, Z.D.; Luan, H.W.; Zhao, S.F.; Chen, N.; Peng, R.X.; Shao, Y.; Yao, K. Microstructures and mechanical properties of AlCrFeNiMo0.5Tix high entropy alloys. Chin. Phys. Lett. 2018, 35, 48–52. [Google Scholar] [CrossRef]

- Zhao, S.F.; Wang, P.F.; Chen, X.; Zhang, Y.Q.; Wen, Z.Q.; Zhang, Q.; Yao, K.F.; Chen, N.; Wang, W.H. Anomalous low-temperature transport property of oxygen containing high-entropy Ti-Zr-Hf-Cu-Ni metallic glass thin films. Sci. China Mater. 2019, 62, 907–912. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Sun, S.J.; Lin, H.R.; Zhang, Z.F. Fatigue behavior of CoCrFeMnNi high-entropy alloy under fully reversed cyclic deformation. J. Mater. Sci. Technol. 2019, 35, 334–340. [Google Scholar] [CrossRef]

- Tiwary, C.S.; Pandey, P.; Sarkar, S.; Das, R.; Samal, S.; Biswas, K.; Chattopadhyay, K. Five decades of research on the development of eutectic as engineering materials. Prog. Mater. Sci. 2021, 9, 100793. [Google Scholar] [CrossRef]

- Gargarella, P.; Pauly, S.; Khoshkhoo, M.S. Phase formation and mechanical properties of Ti-Cu-Ni-Zr bulk metallic glass composites. Acta Mater. 2014, 65, 259–269. [Google Scholar] [CrossRef]

- Li, P.Y.; Jia, Y.F.; Yi, J.Y.; Ma, X.D.; Pu, J.; Wang, D. Composition design, microstructure and mechanical properties of novel multiphase Ti-Cu-Ni-Nb complex concentrated alloys. J. Alloys Compd. 2020, 844, 156175. [Google Scholar] [CrossRef]

- Wang, T.R.; Li, J.C.; Shu, W.; Hu, S.L.; Ouyang, R.H.; Li, W.X. Machine-learning adsorption on binary alloy surfaces for catalyst screening. Chin. J. Chem. Phys. 2020, 33, 703–711. [Google Scholar] [CrossRef]

- Xiong, J.; Shi, S.Q.; Zhang, T.Y. A machine-learning approach to predicting and understanding the properties of amorphous metallic alloys. Mater. Des. 2020, 187, 108378. [Google Scholar] [CrossRef]

- Wu, J.Q.; Sun, Y.T.; Wang, W.H.; Mao, Z.L. Application of machine learning approach in disordered materials. Sci. Sin.-Phys. Mech. Astron. 2020, 50, 7–20. [Google Scholar] [CrossRef]

- Sun, Y.T.; Bai, H.Y.; Li, M.Z.; Wang, W.H. Machine learning approach for prediction and understanding of glass-forming ability. J. Phys. Chem. Lett. 2017, 8, 3434–3439. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Zhou, H.Y.; Dong, H.B. Using deep neural network with small dataset to predict material defects. Mater. Des. 2019, 162, 300–310. [Google Scholar] [CrossRef]

- Xue, D.Z.; Balachandran, P.V.; Hogden, J.; Theiler, J.; Xue, D.Q.; Lookman, T. Accelerated search for materials with targeted properties by adaptive design. Nat. Commun. 2016, 7, 11241. [Google Scholar] [CrossRef]

- Ward, L.; Stephanie, C.O.; Stevick, J.; Jelvert, G.R.; Aykol, M.; Wolverton, C. A machine learning approach for engineering bulk metallic glass alloys. Acta Mater. 2018, 159, 102–111. [Google Scholar] [CrossRef]

- Zeng, X.Q.; Xie, T.; Ying, T.; Zhu, H.; Liu, Y.W.; Wang, L.Y.; Ding, W.J. Data-driven structure and performance design of magnesium alloy. Mater. China 2020, 39, 1–11. [Google Scholar]

- Liu, X.J.; Chen, Y.C.; Lu, Y.; Han, J.J.; Xu, W.W.; Guo, Y.H.; Yu, J.X.; Wei, Z.B.; Wang, C.P. Present research situation and prospect of multi-scale design in novel Co-based superalloys:A review. Acta Metall. Sin. 2020, 56, 1–20. [Google Scholar]

- Mitra, R.; Bajpai, A.; Biswas, K. ADASYN-assisted machine learning for phase prediction of high entropy carbides. Comput. Mater. Sci. 2023, 223, 112142. [Google Scholar] [CrossRef]

- Hou, S.; Sun, M.Y.; Bai, M.J.; Dong, L.; Li, Y.J.; Liu, W.W. A hybrid prediction frame for HEAs based on empirical knowledge and machine learning. Acta Mater. 2022, 228, 117742. [Google Scholar] [CrossRef]

- Li, X.; Shan, G.C.; Zhang, J.L.; Shek, C.H. Accelerated design for magnetic high entropy alloys using data-driven multi-objective optimization. J. Mater. Chem. C 2022, 10, 17291. [Google Scholar] [CrossRef]

- Li, X.; Shan, G.C.; Zhao, H.B.; Shek, C.H. Domain knowledge aided achine learning method for properties prediction of soft magnetic metallic glasses. Trans. Nonferrous Met. Soc. China 2023, 33, 209–219. [Google Scholar] [CrossRef]

- Zhou, Z.H. Machine Learning; Tsinghua University Press: Beijing, China, 2016. [Google Scholar]

- Grosan, C.; Abraham, A. Intelligent Systems; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Basak, D.; Pal, S.; Patranabis, D.C. A tutorial support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar]

- Wen, C.; Zhang, Y.; Wang, C.X.; Xue, D.Z.; Bai, Y.; Antonov, S.; Dai, L.H.; Lookman, T.; Su, Y.J. Machine learning assisted design of high entropy alloys with desired property. Acta Mater. 2019, 170, 109–117. [Google Scholar] [CrossRef]

- Dai, D.B.; Xu, T.; Wei, X.; Ding, G.; Xu, Y.; Zhang, J.C.; Zhang, H.R. Using machine learning and feature engineering to characterize limited material datasets of high-entropy alloys. Comput. Mater. Sci. 2020, 175, 109618. [Google Scholar] [CrossRef]

- Roy, A.; Babuska, T.; Krick, B.; Balasubramanian, G. Machine learned feature identification for predicting phase and Young’s modulus of low-, medium- and high-entropy alloys. Scr. Mater. 2020, 185, 152–158. [Google Scholar] [CrossRef]

- Zheng, T.; Hu, X.B.; He, F.; Wu, Q.F.; Han, B.; Da, C.; Li, J.J.; Wang, Z.J.; Wang, J.C.; Kai, J.J.; et al. Tailoring nanoprecipitates for ultra-strong high-entropy alloys via machine learning and prestrain aging. J. Mater. Sci. Technol. 2021, 69, 156–167. [Google Scholar] [CrossRef]

- Dai, F.Z.; Wen, B.; Sun, Y.J.; Ren, Y.X.; Xiang, H.M.; Zhou, Y.C. Grain boundary segregation induced strong UHTCs atelevated temperatures:A universal mechanism from conventional UHTCs to high entropy UHTCs. Journal of Materials Sci. Technol. 2020, 43, 168–174. [Google Scholar] [CrossRef]

- Wang, L.; Li, P.Y.; Zhang, W.; Wan, F.Y.; Wu, J.X.; Yong, L.Q.; Liu, X.D. Prediction of phase selection of amorphous alloys and high entropy alloys by artificial neural network. Comput. Mater. Sci. 2023, 223, 112129. [Google Scholar] [CrossRef]

- Deng, R.J.; Long, Z.L.; Peng, L.; Kuang, D.; Ren, B.Y. A new mathematical expression for the relation between characteristic temperature and glass-forming ability of metallic glasses. J. Non-Cryst. Solids 2020, 533, 119829. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, T.Y.; Shi, S.Q. Machine learning prediction of elastic properties and glass-forming ability of bulk metallic glasses. MRS Commun. 2019, 25, 1–10. [Google Scholar] [CrossRef]

- Deng, B.H.; Zhang, Y.L. Critical feature space for predicting the glass forming ability of metallic alloys revealed by machine learning. Chem. Phys. 2020, 538, 110898. [Google Scholar] [CrossRef]

- Liu, G.N.; Sohn, S.; Kube, S.A.; Raj, A.; Mertz, A.; NAwano, A.; Gilvert, A.; Shattuck, M.D.; O’Hern, C.S.; Schroers, J. Machine learning versus human learning in predicting glass-forming ability of metallic glasses. Acta Mater. 2023, 243, 118497. [Google Scholar] [CrossRef]

- Peng, L.; Long, Z.L.; Zhao, M.S.Z. Determination of glass forming ability of bulk metallic glasses based on machine learning. Comput. Mater. Sci. 2021, 195, 110480. [Google Scholar] [CrossRef]

- Li, Z.; Long, Z.L.; Lei, S.; Zhang, T.; Liu, X.W.; Kuang, D.M. Predicting the glass formation of metallic glasses using machine learning approaches. Comput. Mater. Sci. 2021, 197, 110656. [Google Scholar] [CrossRef]

- Liu, X.W.; Long, Z.L.; Yang, L.M.; ZHANG, W.; Li, Z. Prediction of glass forming ability in amorphous alloys based on different machine learning algorithms. J. Non-Cryst. Solids 2021, 570, 121000. [Google Scholar] [CrossRef]

- Xiong, J.; Shi, S.Q.; Zhnag, T.Y. Machine learning prediction of glass-forming ability in bulk metallic glasses. Comput. Mater. Sci. 2021, 192, 110362. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Xing, G.C.; Sha, Z.D.; Poh, L.H. A two-step fused machine learning approach for the prediction of glass-forming ability of metallic glasses. J. Alloys Compd. 2021, 875, 160040. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Ganguly, S.; Dey, P.; Chattopadhyay, P.P. Evolution of glass forming ability indicator by genetic programming. Comput. Mater. Sci. 2016, 118, 56–65. [Google Scholar] [CrossRef]

- Mastropietro, D.G.; Moya, J.A. Design of Fe-based bulk metallic glasses for maximum amorphous diameter (Dmax) using machine learning models. Comput. Mater. Sci. 2021, 188, 110230. [Google Scholar] [CrossRef]

- Lu, F.; Liang, Y.C.; Wang, X.Y.; Gao, T.H.; Chen, Q.; Liu, Y.C.; Zhou, Y.; Yuan, Y.K.; Liu, Y.T. Prediction of amorphous forming ability based on artificial neural network and convolutional neural network. Comput. Mater. Sci. 2022, 210, 111464. [Google Scholar] [CrossRef]

- Reddy, G.J.; Kandavalli, M.; Saboo, T.; Prasada Rao, A.K. Prediction of glass forming ability of bulk metallic glasses using machine learning. Integr. Mater. Manuf. Innov. 2021, 10, 610–626. [Google Scholar] [CrossRef]

- Liu, X.W.; Long, Z.L.; Zhang, W.; Yang, L.M. Key feature space for predicting the glass-forming ability of amorphous alloys revealed by gradient boosted decision trees model. J. Alloys Compd. 2022, 901, 163606. [Google Scholar] [CrossRef]

- Long, T.; Long, Z.L.; Peng, Z. Rational design and glass-forming ability prediction of bulk metallic glasses via interpretable machine learning. J. Mater. Sci. 2023, 58, 8833–8844. [Google Scholar] [CrossRef]

- Xu, M.J.; Wang, J.F.; Sun, Y.F.; Zhu, S.J.; Zhang, T.; Guan, S.K. Prediction of glass-forming ability in ternary alloys based on machine learning method. J. Non-Cryst. Solids 2023, 616, 122476. [Google Scholar] [CrossRef]

- Hu, J.Y.; Xu, X.; Cui, Y.C.; Xu, M.X.; Gao, X.J.; Ji, X.M. An ensemble learning based amorphous state predictor for multicomponent alloys. J. Non-Cryst. Solids 2023, 607, 122116. [Google Scholar] [CrossRef]

- Xie, J.X.; Liang, Y.C.; Sun, B.; Pu, Y.W.; Wang, M.Q.; Qin, Z.F. Recurrent neural network based on attention mechanism in prediction of glass forming ability by element proportion. Mater. Today Commun. 2024, 38, 107853. [Google Scholar] [CrossRef]

- Yao, Y.; Sullivan, T., IV; Yan, F.; Gong, J.Q.; Li, L. Balancing data for generalizable machine learning to predict glass-forming ability of ternary alloys. Scr. Mater. 2022, 209, 114366. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, C.; Zhou, Y.X.; Zhang, L.T.; Wang, H. An element-wise machine learning strategy to predict glass-forming range of ternary alloys enables by comprehensive data. Scr. Mater. 2023, 229, 115347. [Google Scholar] [CrossRef]

- Samavatian, M.; Gholamipour, R.; Samavatian, V. Discovery of novel quaternary bulk metallic glasses using a developed correlation-based neural network apporach. Comput. Mater. Sci. 2021, 186, 110025. [Google Scholar] [CrossRef]

- Tan, B.F.; Liang, Y.C.; Chen, Q.; Zhang, L.; Ma, J.J. Discovery of a new criterion for predicting glass-forming ability based on symbolic regression and artificial neural network. J. Appl. Phys. 2022, 132, 125104. [Google Scholar] [CrossRef]

- Liu, X.W.; Long, Z.L.; Peng, L. Prediction of Vickers hardness of amorphous alloys based on interpretable machine learning. J. Non-Cryst. Solids 2023, 602, 122095. [Google Scholar] [CrossRef]

- Liu, C.C.; Wang, X.D.; Cai, W.D.; Su, H. Prediction of magnetocaloric properties of Fe-based amorphous alloys based on interpretable machine learning. J. Non-Cryst. Solids 2024, 625, 122749. [Google Scholar] [CrossRef]

- Tang, Y.C.; Wan, Y.; Wang, Z.Q.; Zhang, C.; Han, J.N.; Hu, C.H.; Tang, C.Y. Machine learning and Python assisted design and verification of Fe-based amorphous/nanocrystalline alloy. Mater. Des. 2022, 219, 110726. [Google Scholar] [CrossRef]

- Yang, F.; Li, Z.; Wang, Q.; Jiang, B.B.; Yan, B.J.; Zhang, P.C.; Xu, W.; Dong, C.; Liaw, P.K. Cluster-formula-embedded machine learning for design of multicomponentβ-Ti alloys with low Young’s modulus. npj Comput. Mater. 2020, 6, 101. [Google Scholar] [CrossRef]

- Rohatgi, M.; Kordijazi, A. Application of machine learning to mechanical properties of copper-graphene composites. MRS Commun. 2023, 13, 111–116. [Google Scholar] [CrossRef]

- Hu, J.Y.; Xu, X.; Ji, X.M.; Xu, M.X.; Jiang, D.F.; Wang, J. Machine learning in designing amorphous alloys. Chin. J. Eng. 2023, 45, 1517–1527. [Google Scholar]

- Madanchi, A.; Azek, E.; Zongo, K.; Béland, L.K.; Mousseau, N.; Simine, L. Is the Future of Materials Amorphous? Challenges and Opportunities in Simulations of Amorphous Materials. ACS Phys. Chem Au 2025, 5, 3–16. [Google Scholar] [CrossRef]

| Researcher | Data Volume | Machine Learning Models | Features | Prediction Accuracy |

|---|---|---|---|---|

| Liu et al. [18] | 3227 | ANN (MLP) | 13 features | ACC for multicomponent alloys (n > 3) prediction: 83%. |

| Islam et al. [19] | 118 | Neural network (NN) | (VEC), Sid, δ, ΔHm, and Δχ | Achieved a test set accuracy of 83% (particularly Sid, δ, ΔHm, and Δχ; reduced prediction accuracy by over 7%). |

| Zhou et al. [20] | 601 | ANN, SVM, KNN | 11 features | All three ML algorithms achieved high prediction accuracy. |

| Huang et al. [21] | 401 | KNN, ANN, SVM | (VEC), Sid, δ, ΔHm, and Δχ | The KNN algorithm achieved an accuracy of 68.6%, the SVM algorithm achieved 64.3%, and the ANN algorithm achieved 74.3%. |

| Zhang et al. [22] | 407 | SVM | 4 features | Achieved accuracy of 88.77–94.63% for amorphous phases, 95.67–97.87% for solid solution phases, and 96.03–98.63% for mixed solid solution and intermetallic phases. |

| Wu et al. [23] | 321 | MLP, ANN, GBDT | 9 features | Achieved a test set accuracy of 98.3% |

| Researcher | Data Volume | Machine Learning Models | Forecast Results |

|---|---|---|---|

| Xiong et al. [66] | 442 | SVM | R2 = 0.57 |

| Deng et al. [67] | 442 | Random forest | R2 = 0.64 |

| Xiong et al. [44] | 6471 | Symbolic regression and random forest model | The random forest model achieved the highest R value of 0.85 |

| Ward et al. [49] | 607 | Random forest, decision tree, and ensemble models | The random forest model achieved 89% |

| Liu et al. [68] | 6816 | Random forest | The random forest model achieved 89% |

| Peng et al. [69] | 810 | Random forest | R2 = 0.682 |

| Tripathi et al. [74] | 410 | Genetic algorithm | 95.26% |

| Mastropietro et al. [75] | 480 | Multiple Linear Regression and Tree Boosting Model | R = 0.84 (after integrating two models) |

| Long et al. [79] | 698 | Six algorithms | The determination coefficient R2 of the decision tree model can reach 0.763 |

| Algorithms | Advantages | Limitations | Applicable Scenarios |

|---|---|---|---|

| Traditional linear models (linear regression, logistic regression) |

|

| Preliminary screening of features or baseline models. |

| SVM |

|

| Small and medium-sized datasets, when it is necessary to balance accuracy and complexity. |

| Decision Tree and Random Forest |

|

| Feature importance analysis and medium-sized dataset prediction (such as GFA prediction). |

| Gradient Boosting Machine (XGBoost, LightGBM) |

|

| Scenarios with high precision requirements (such as mechanical property prediction). |

| Neural Networks (NN) and Deep Learning |

|

| Large-scale datasets or combined with transfer learning (such as pre-trained models). |

| Bayesian Optimization and Gaussian Process (GP) |

|

| Experimental parameter optimization or active learning framework. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhang, H.; Ji, B.; Liu, L.; Liu, X.; Chen, D. Application of Machine Learning in Amorphous Alloys. Materials 2025, 18, 1771. https://doi.org/10.3390/ma18081771

Zhang L, Zhang H, Ji B, Liu L, Liu X, Chen D. Application of Machine Learning in Amorphous Alloys. Materials. 2025; 18(8):1771. https://doi.org/10.3390/ma18081771

Chicago/Turabian StyleZhang, Like, Huangyou Zhang, Boyan Ji, Leqing Liu, Xianlan Liu, and Ding Chen. 2025. "Application of Machine Learning in Amorphous Alloys" Materials 18, no. 8: 1771. https://doi.org/10.3390/ma18081771

APA StyleZhang, L., Zhang, H., Ji, B., Liu, L., Liu, X., & Chen, D. (2025). Application of Machine Learning in Amorphous Alloys. Materials, 18(8), 1771. https://doi.org/10.3390/ma18081771