Effect of Silane-Modified Nano-Al2O3-Reinforced Vinyl Ester Resin on the Flexural Properties of Basalt Fiber Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

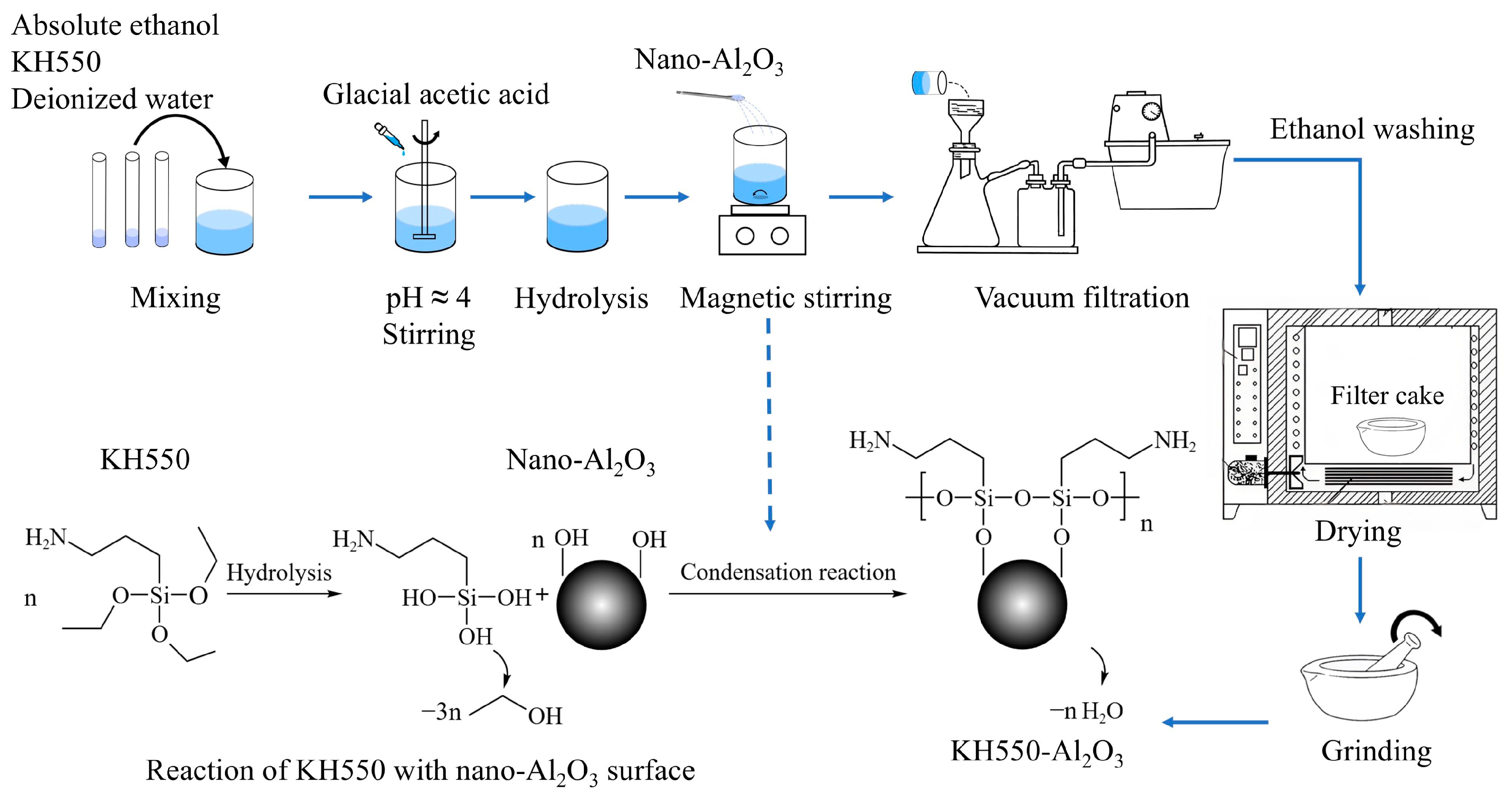

2.2. Surface Modification of Nano-Al2O3

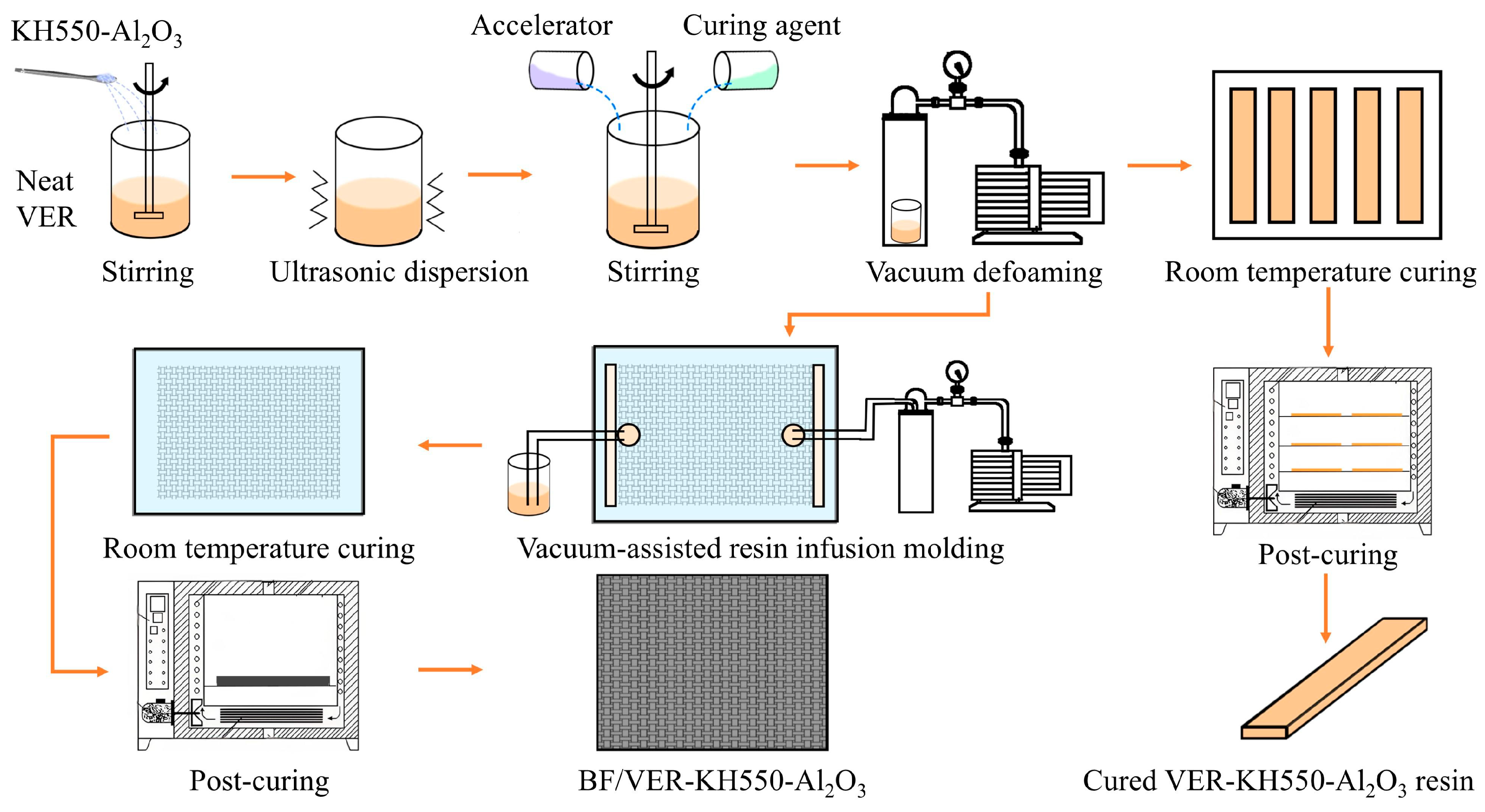

2.3. Preparation of Modified VERs

2.4. Preparation of BF/VER Composites

2.5. Elevated Temperature Aging of BF/VER Composites

2.6. Characterization

2.6.1. Fourier Transform Infrared Spectrum Tests

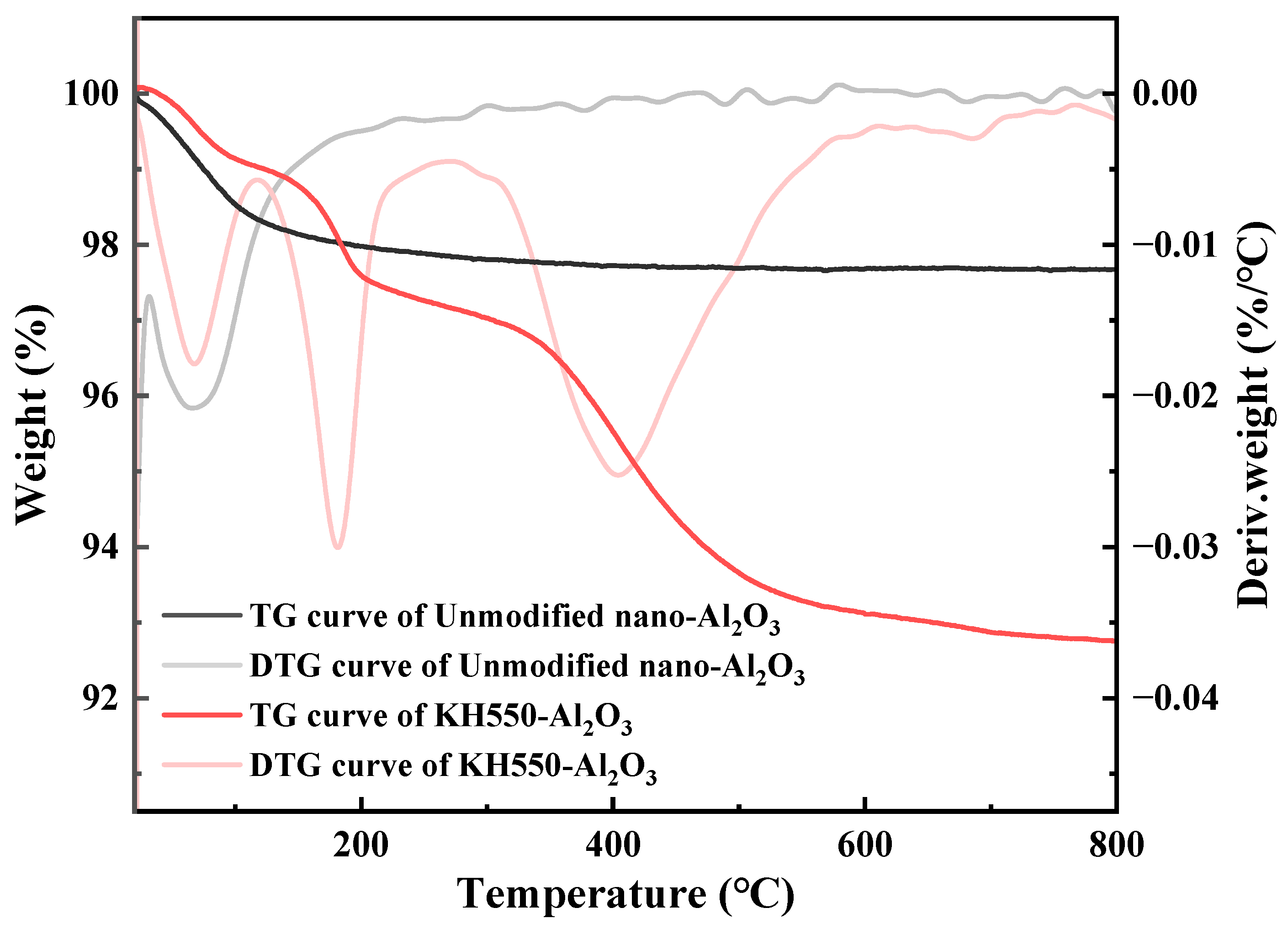

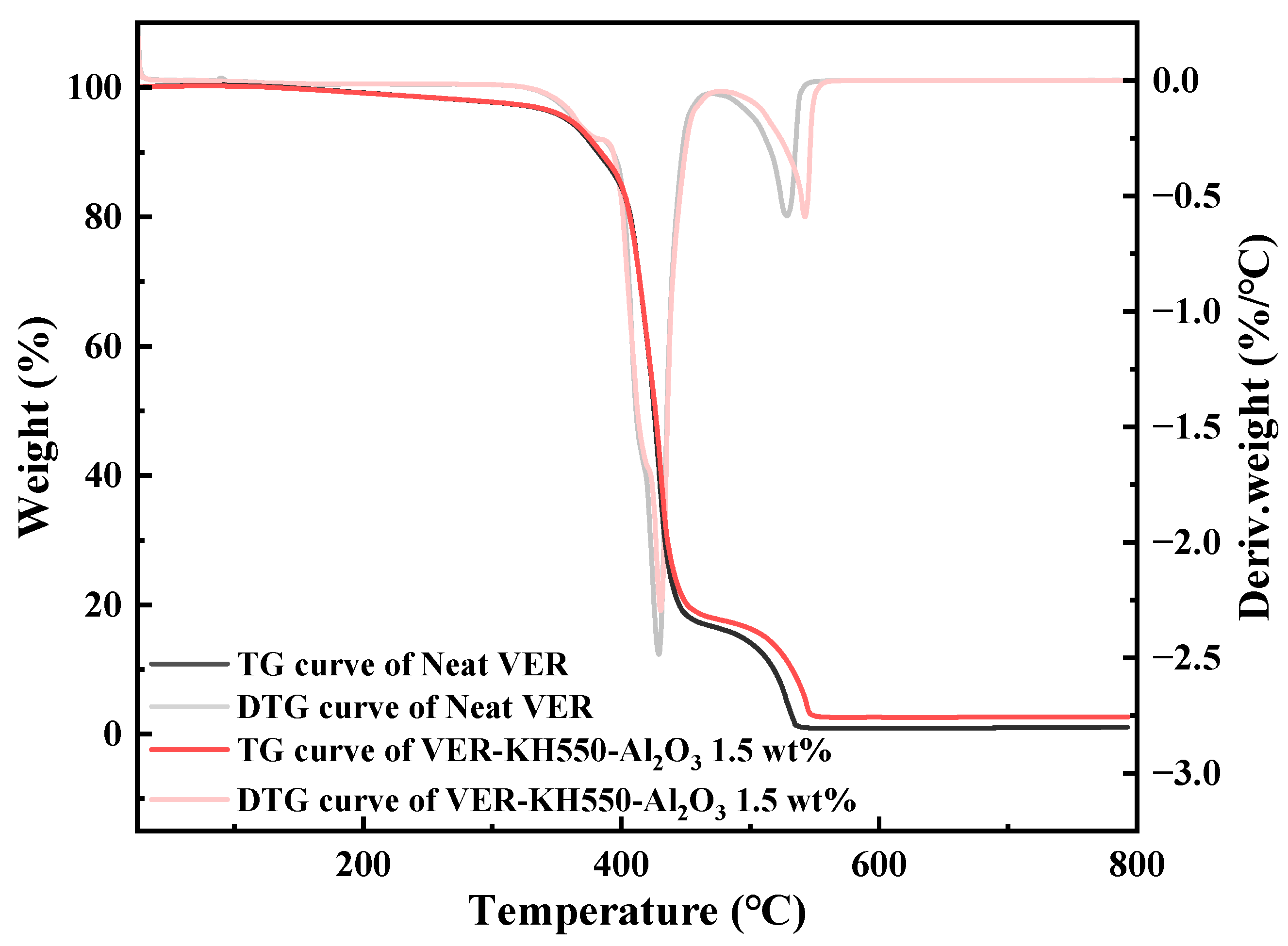

2.6.2. Thermogravimetric Tests

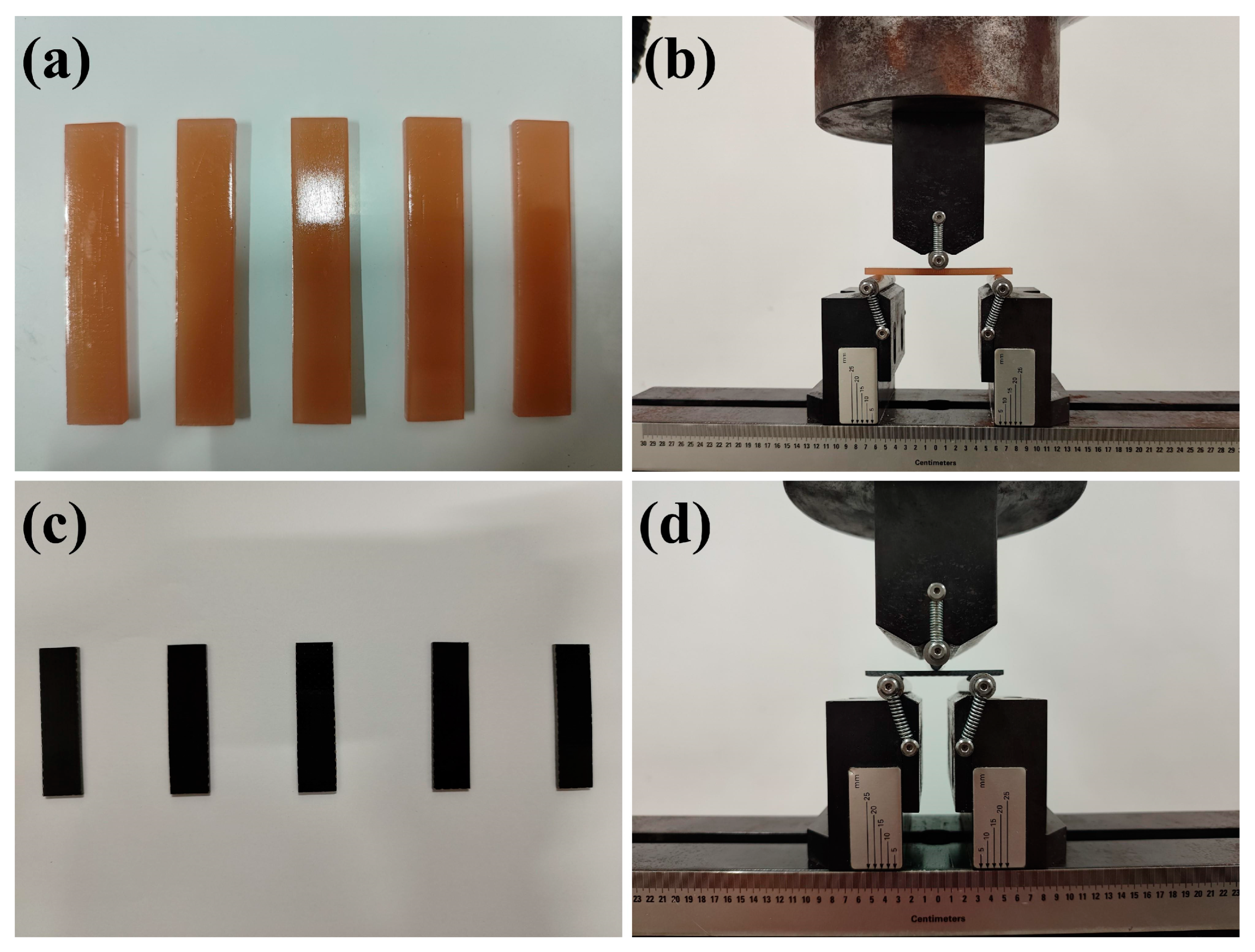

2.6.3. Three-Point Bending Tests

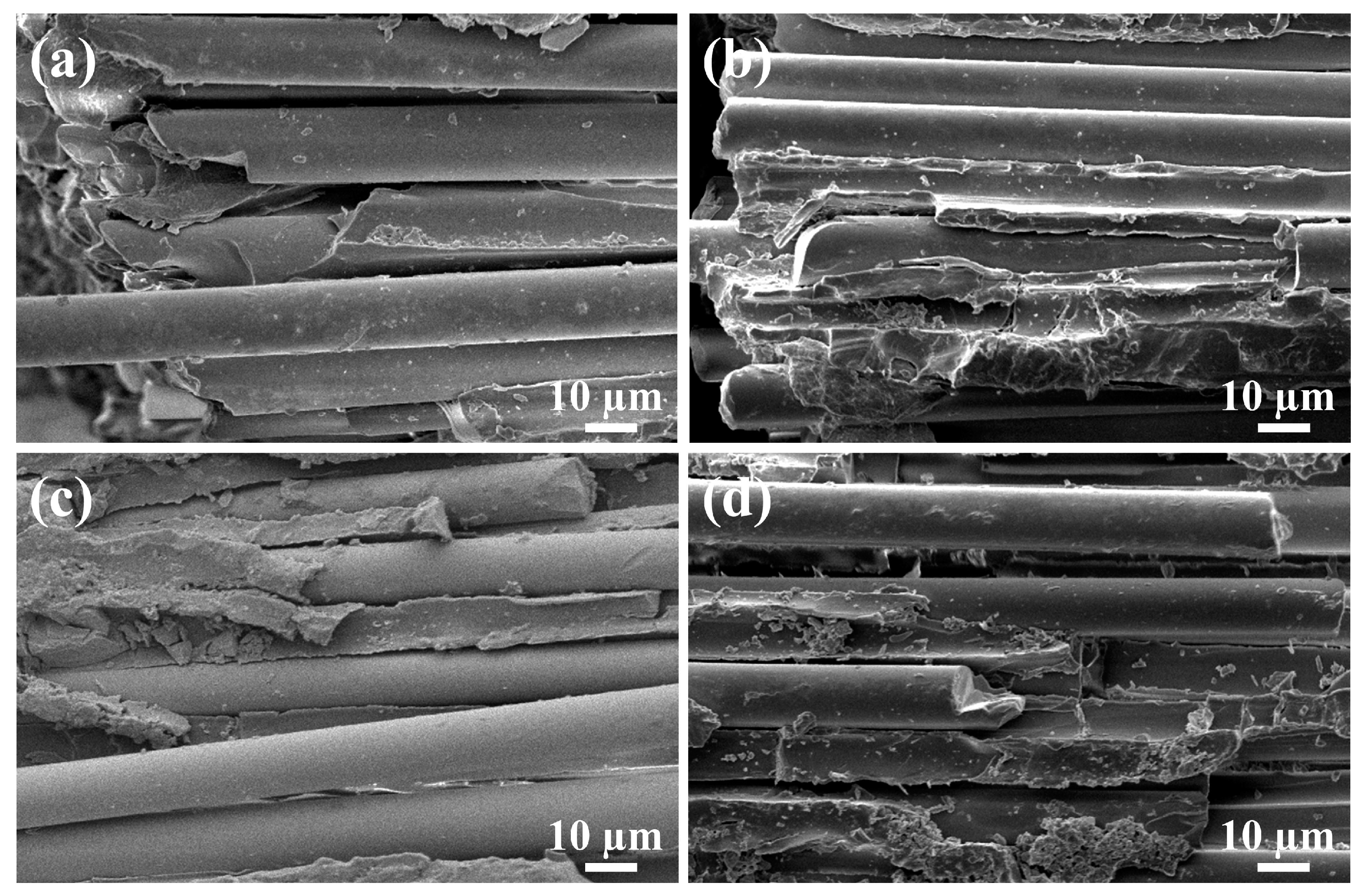

2.6.4. Scanning Electron Microscope Imaging

2.6.5. Dynamic Mechanical Analysis Tests

3. Results

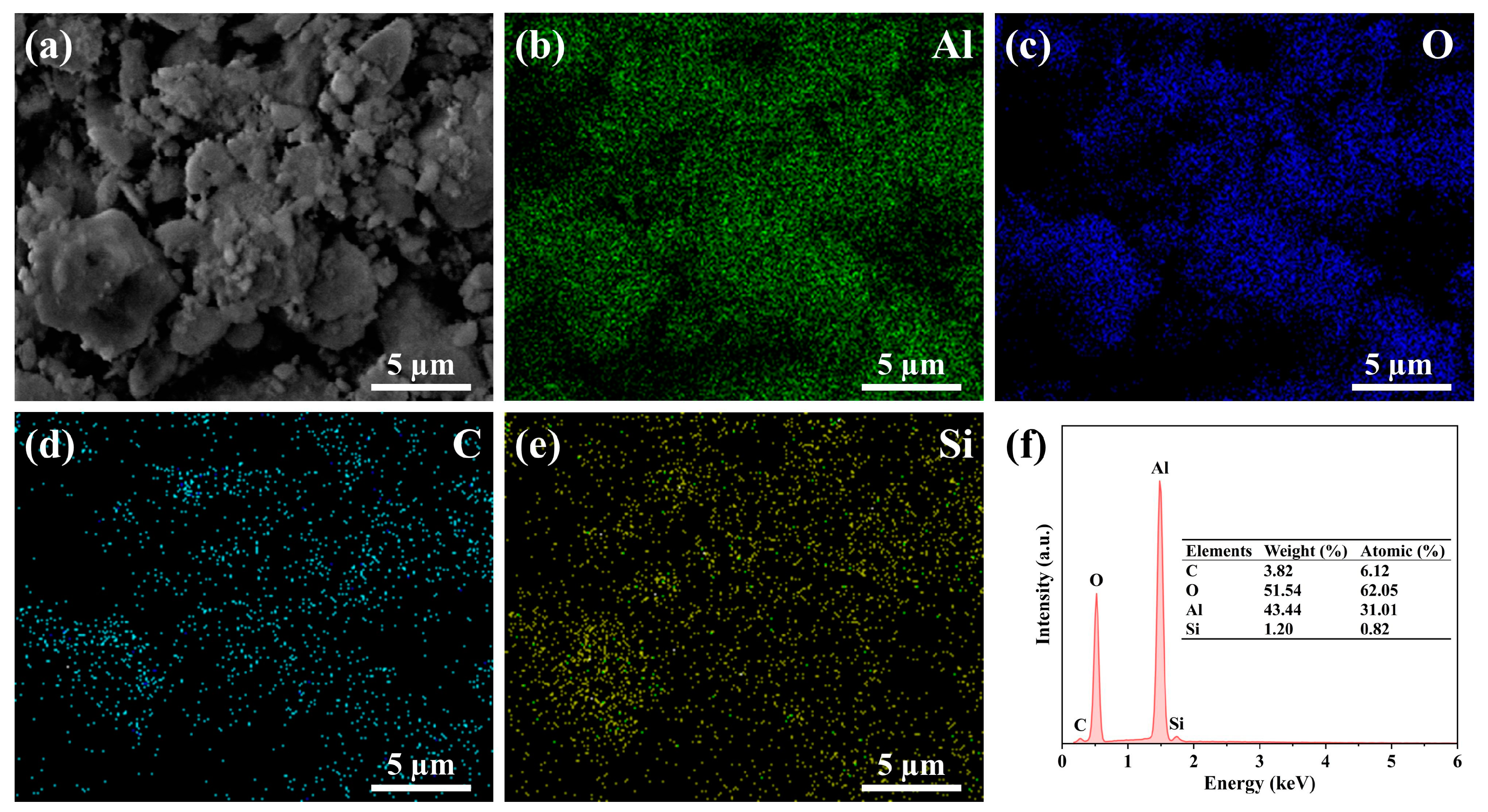

3.1. Characterization of KH550-Al2O3

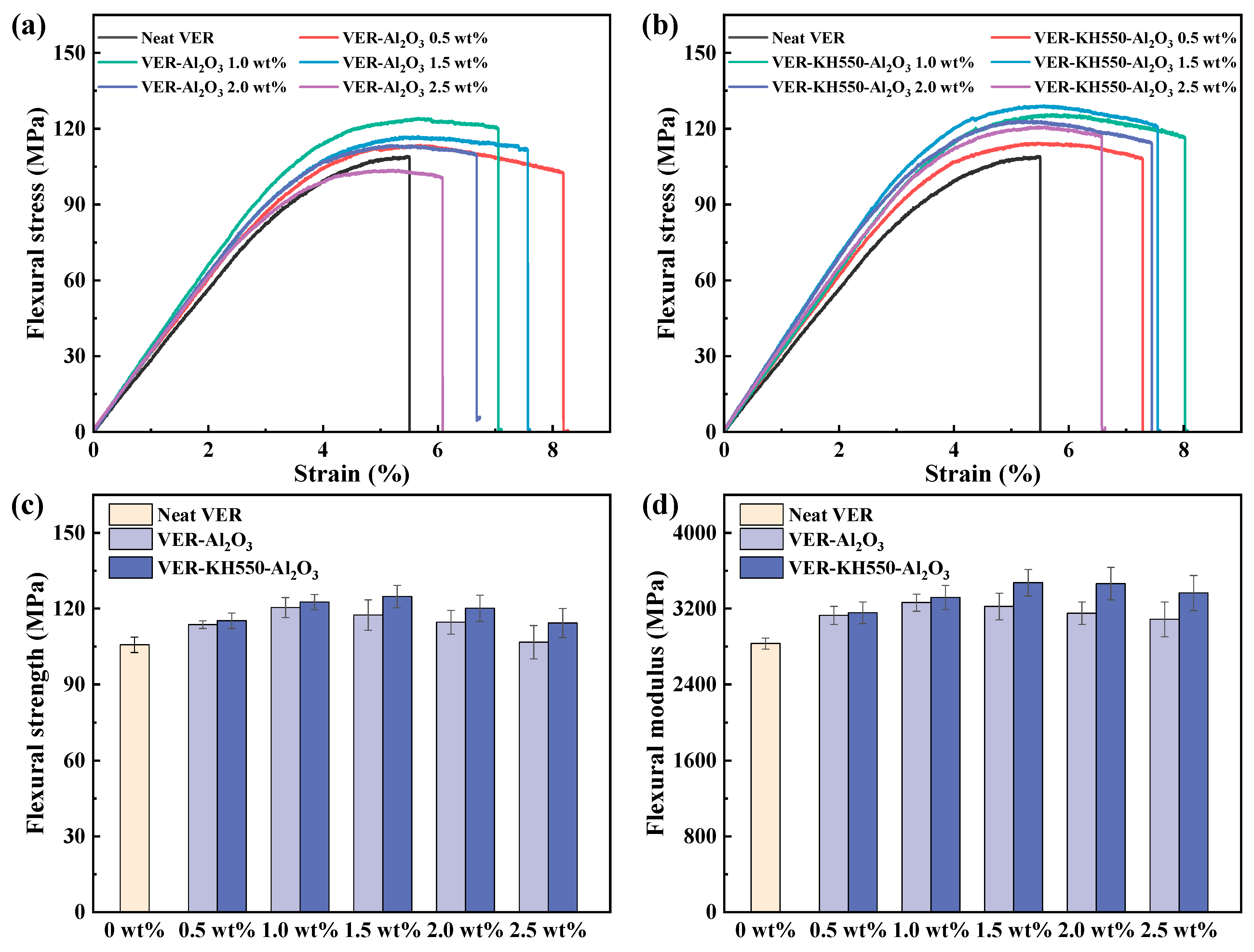

3.2. Flexural Properties of VERs

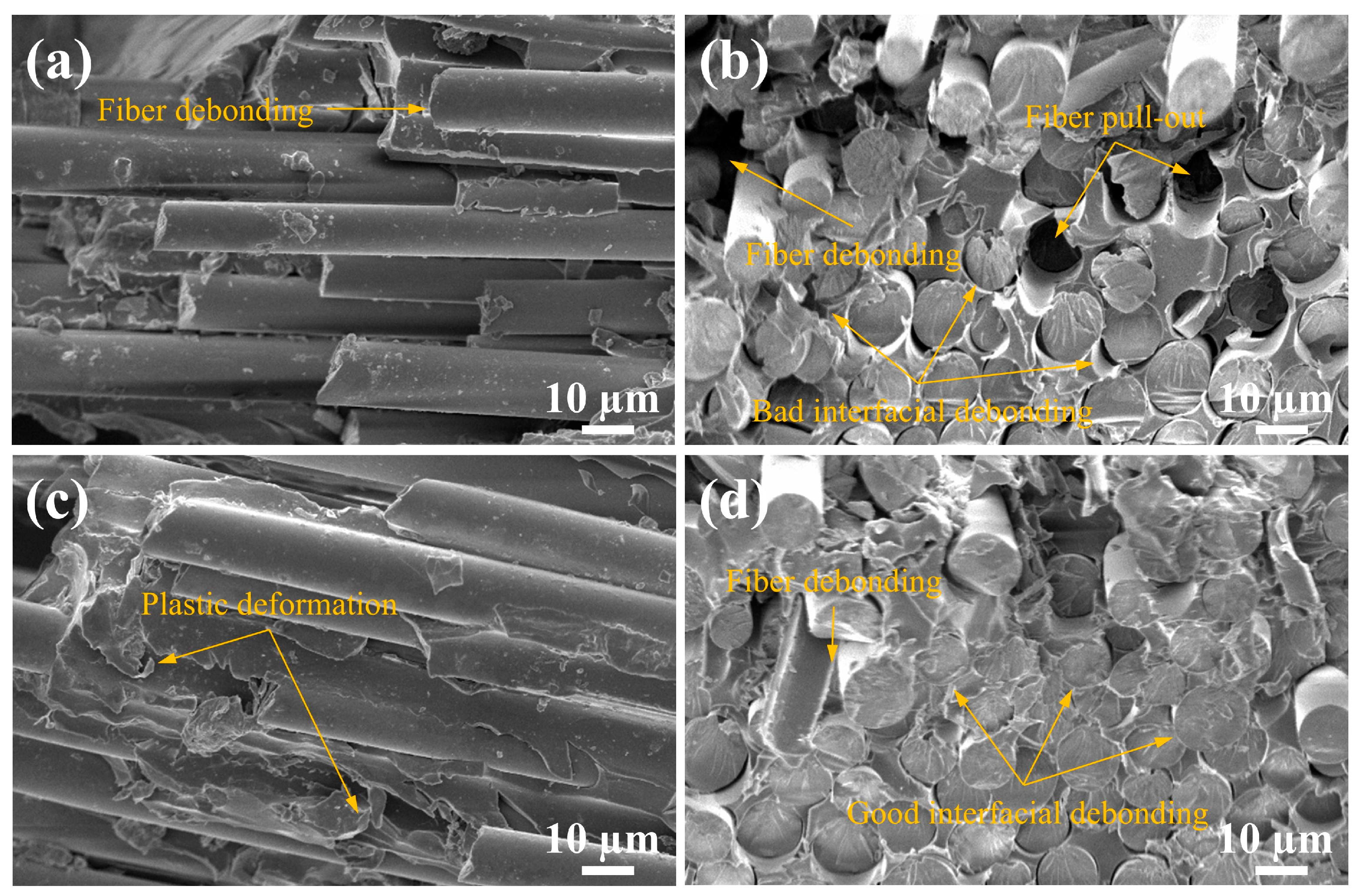

3.3. Flexural Properties of BF/VER Composites

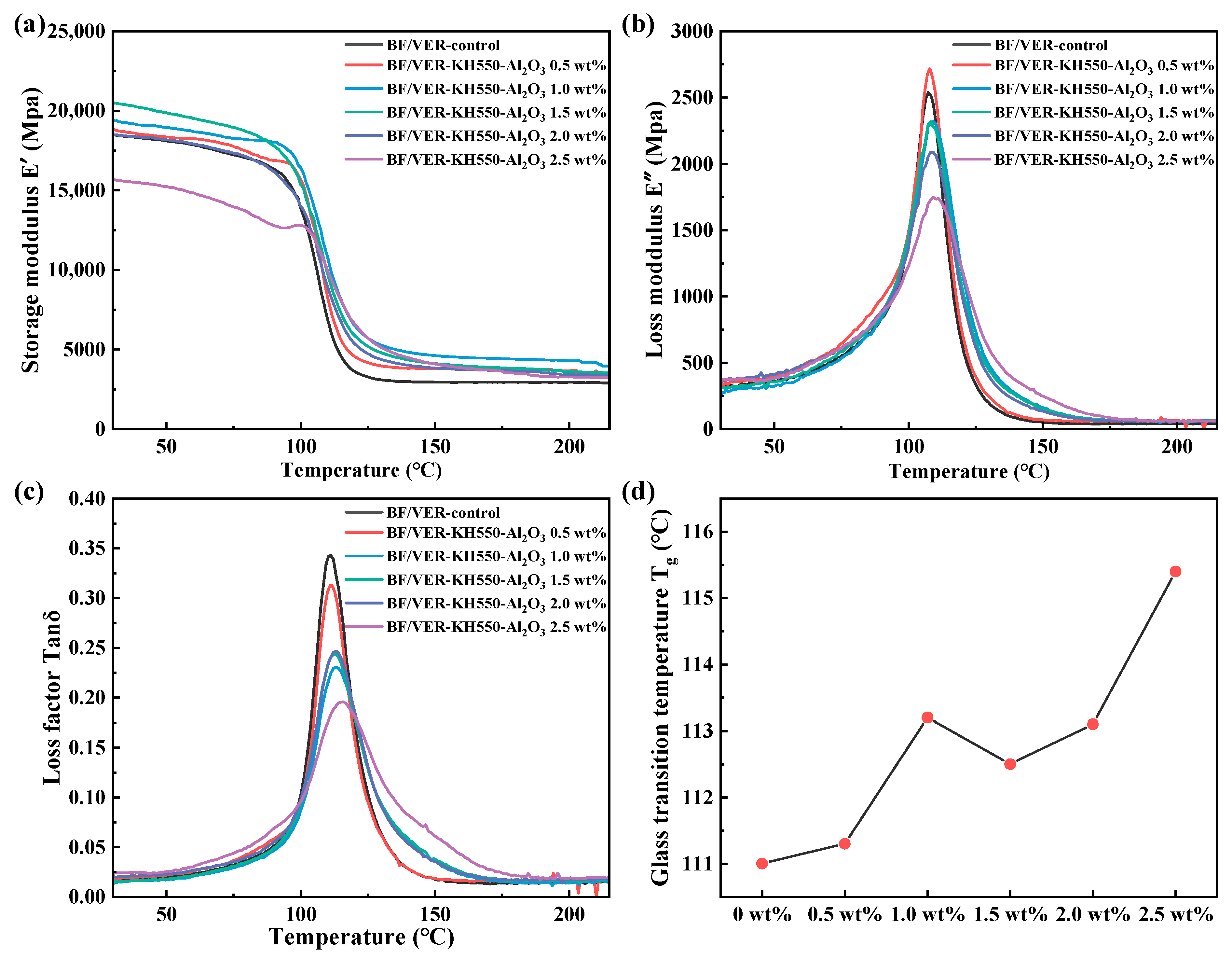

3.4. Dynamic Mechanical Properties of BF/VER Composites

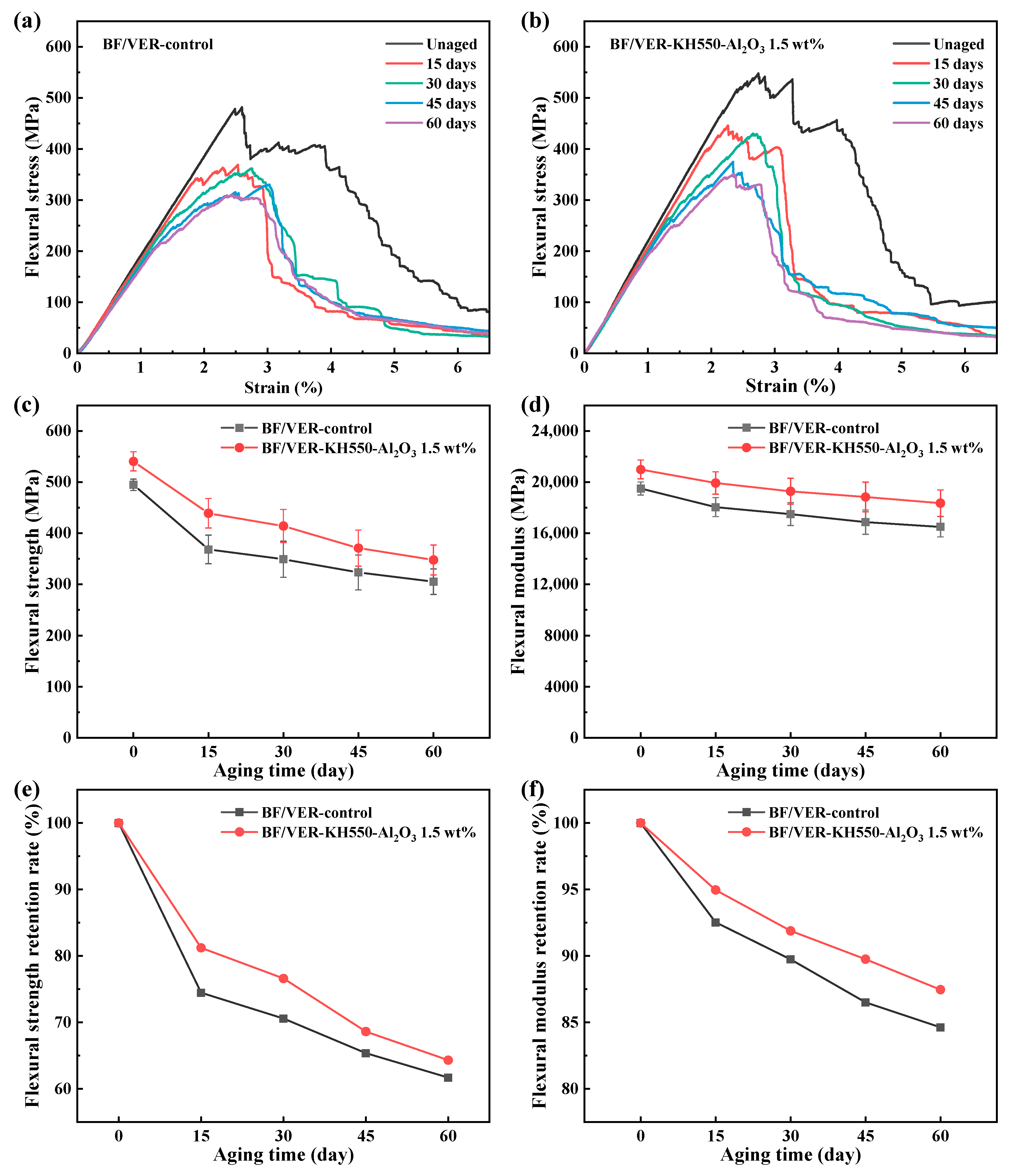

3.5. Flexural Properties of BF/VER Composites After Long-Term Elevated Temperature Aging

4. Conclusions

- Silane coupling agent KH550 surface modification can effectively reduce the agglomeration of nano-Al2O3 in the VER, but the formation of excessive polysiloxane weakens the positive effect of surface modification. The main effects of whether or not nano-Al2O3 was modified and the effects of its loading on the flexural properties of VER were statistically significant. Still, the interaction between the two factors did not reach the level of significance for the flexural strength or flexural modulus. Unmodified nano-Al2O3 and KH550-Al2O3 enhanced the flexural properties of the VER, primarily through crack deflection and crack pinning mechanisms. At 1.5 wt% KH550-Al2O3 filler loading, the VER attained peak flexural strength and modulus values, showing 18.1% and 22.7% increases, respectively.

- The flexural properties of BF/VER composites were enhanced by both matrix reinforcement and improved fiber–resin interfacial bonding. At 1.5 wt% KH550-Al2O3 filler loading, the BF/VER composites attained peak flexural strength and modulus values, showing 9.3% and 7.6% increases, respectively.

- Adding a certain amount of KH550-Al2O3 increased the storage modulus and Tg of the BF/VER composites but reduced the peak loss modulus. At 1.5 wt% KH550-Al2O3 filler loading, the storage modulus at 30 °C improved by 11.5%, while Tg increased from 111.0 °C to 112.5 °C.

- The addition of 1.5 wt% KH550-Al2O3 enabled the BF/VER composites to maintain higher flexural properties during long-term elevated temperature aging at 120 °C. The thermal stability of the VER remained unaffected, with the property degradation of the BF/VER composites attributed to both matrix degradation caused by thermal oxidation and the physical aging phenomenon. After 60 days of aging, the flexural strength and modulus retention rates of the composites were 64.3% and 87.4% of those before aging, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Khandelwal, S.; Rhee, K.Y. Recent advances in basalt-fiber-reinforced composites: Tailoring the fiber-matrix interface. Compos. Part B Eng. 2020, 192, 108011. [Google Scholar] [CrossRef]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and fatigue characterisation of new basalt fibre reinforced composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Fan, Y.; Guo, J.; Wang, X.; Xia, Y.; Han, P.; Shangguan, L.; Zhang, M. Comparative Failure Study of Different Bonded Basalt Fiber-Reinforced Polymer (BFRP)-AL Joints in a Humid and Hot Environment. Polymers 2021, 13, 2593. [Google Scholar] [CrossRef]

- Sun, W.; Wu, Z.; Huang, C.; Wang, Z.; Huang, R.; Gong, L.; Nishimura, A.; Zhou, Y.; Li, L. Investigation on cryogenic mechanical properties of basalt fiber-reinforced epoxy composites. Cryogenics 2023, 132, 103684. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, H.; Feng, Q.; Zheng, Y. Improvement of basalt fiber dispersion and its effect on mechanical characteristics of oil well cement. J. Build. Eng. 2023, 76, 107244. [Google Scholar] [CrossRef]

- Zhang, S.; Zhong, T.; Xu, Q.; Su, Z.; Jiang, M.; Liu, P. The effects of chemical grafting 1,6-hexanediol diglycidyl ether on the interfacial adhesion between continuous basalt fibers and epoxy resin as well as the tensile strength of composites. Constr. Build. Mater. 2022, 323, 126563. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, A.; Li, X.; Lin, H.L.; Ni, K.; Bian, J.; Jing, S.; Yang, K.C.; Yang, S.; Liu, C.; et al. Synergetic control of multi-level interface structure of basalt fibers by plasma and chemical functionalization to enhance the mechanical, thermal and interfacial performances of PBZ composites. Polym. Compos. 2024, 45, 16806–16822. [Google Scholar] [CrossRef]

- Xiang, D.; Qiu, T.; Sun, H.; Zhao, C.; Wang, B.; Li, H.; Liu, Y.; Pan, Y.; Wu, Y. In situ growth of polysiloxane nanowires on basalt fibers and interfacial enhancement with epoxy resin. Mater. Lett. 2024, 357, 135728. [Google Scholar] [CrossRef]

- Olhan, S.; Behera, B.K. Development of GNP nanofiller based textile structural composites for enhanced mechanical, thermal, and viscoelastic properties for automotive components. Adv. Compos. Hybrid Mater. 2024, 7, 25. [Google Scholar] [CrossRef]

- Hiremath, A.; Nayak, S.Y.; Heckadka, S.S.; Pramod, J.J. Mechanical behavior of basalt-reinforced epoxy composites modified with biomass-derived seashell powder. Biomass Convers. Biorefin. 2023, 14, 26281–26291. [Google Scholar] [CrossRef]

- Venu, H.; Anand Chairman, C.; Ravichandran, M.; Sieh Kiong, T.; Kannan, S.; Razali, N.M.; Fouly, A. Analysis of mechanical properties of basalt fabric reinforced fly ash filled vinyl ester composites using multi criteria decision making technique. Therm. Sci. Eng. Prog. 2024, 54, 102869. [Google Scholar] [CrossRef]

- Li, S.; Chen, D.; Gao, C.; Yuan, Y.; Wang, H.; Liu, X.; Hu, B.; Ma, J.; Liu, M.; Wu, Z. Epoxy-functionalized polysiloxane/Nano-SiO2 synergistic reinforcement in cryogenic mechanical properties of epoxy and carbon fiber reinforced epoxy laminate. Compos. Sci. Technol. 2020, 198, 108292. [Google Scholar] [CrossRef]

- Wu, Y.; Tang, B.; Liu, K.; Zeng, X.; Lu, J.; Zhang, T.; Shen, X. Enhanced flexural properties of aramid fiber/epoxy composites by graphene oxide. Nanotechnol. Rev. 2019, 8, 484–492. [Google Scholar] [CrossRef]

- Pathak, A.K.; Borah, M.; Gupta, A.; Yokozeki, T.; Dhakate, S.R. Improved mechanical properties of carbon fiber/graphene oxide-epoxy hybrid composites. Compos. Sci. Technol. 2016, 135, 28–38. [Google Scholar] [CrossRef]

- Qin, G.; Na, J.; Mu, W.; Tan, W. Effect of thermal cycling on the degradation of adhesively bonded CFRP/aluminum alloy joints for automobiles. Int. J. Adhes. Adhes. 2019, 95, 102439. [Google Scholar] [CrossRef]

- Khajeh, A.; Mustapha, F.; Sultan, M.T.H.; Bánhegyi, G.; Karácsony, Z.; Baranyai, V. The Effect of Thermooxidative Aging on the Durability of Glass Fiber-Reinforced Epoxy. Adv. Mater. Sci. Eng. 2015, 2015, 372354. [Google Scholar] [CrossRef]

- Srivastava, C.; Alcock, B.; Strandlie, A.; Grammatikos, S.A. Comparison of the effect of thermal and hygrothermal sub-Tg aging on the durability and appearance of multilayered filament wound composite structure. Polym. Test. 2024, 131, 108326. [Google Scholar] [CrossRef]

- Barile, C.; Paramsamy Kannan, V.; Del Core, L.; Casavola, C. Tensile and shear behavior of plain weave fabric carbon fiber reinforced polymer at elevated temperatures. Polym. Compos. 2022, 43, 6536–6547. [Google Scholar] [CrossRef]

- Haque, M.H.; Upadhyaya, P.; Roy, S.; Ware, T.; Voit, W.; Lu, H. The changes in flexural properties and microstructures of carbon fiber bismaleimide composite after exposure to a high temperature. Compos. Struct. 2014, 108, 57–64. [Google Scholar] [CrossRef]

- Fan, W.; Li, J.-L.; Zheng, Y.-Y. Improved thermo-oxidative stability of three-dimensional and four-directional braided carbon fiber/epoxy hierarchical composites using graphene-reinforced gradient interface layer. Polym. Test. 2015, 44, 177–185. [Google Scholar] [CrossRef]

- Su, C.; Wang, X.; Ding, L.; Wu, Z. Enhancement of mechanical behavior of FRP composites modified by silica nanoparticles. Constr. Build. Mater. 2020, 262, 120769. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Demirci, M.T.; Tarakçıoğlu, N.; Avcı, A.; Akdemir, A.; Demirci, İ. Fracture toughness (Mode I) characterization of SiO2 nanoparticle filled basalt/epoxy filament wound composite ring with split-disk test method. Compos. Part B Eng. 2017, 119, 114–124. [Google Scholar] [CrossRef]

- Prabhu, P.; Karthikeyan, B.; Ravi Raja Malar Vannan, R.; Balaji, A. Dynamic mechanical analysis of Silk and Glass (S/G/S)/Pineapple and Glass (P/G/P)/Flax and Glass (F/G/F) reinforced Lannea coromandelica blender hybrid nano composites. J. Mater. Res. Technol. 2021, 15, 2484–2496. [Google Scholar] [CrossRef]

- Saleem, H.; Edathil, A.; Ncube, T.; Pokhrel, J.; Khoori, S.; Abraham, A.; Mittal, V. Mechanical and Thermal Properties of Thermoset–Graphene Nanocomposites. Macromol. Mater. Eng. 2016, 301, 231–259. [Google Scholar] [CrossRef]

- Vinay, S.S.; Sanjay, M.R.; Siengchin, S.; Venkatesh, C.V. Effect of Al2O3 nanofillers in basalt/epoxy composites: Mechanical and tribological properties. Polym. Compos. 2020, 42, 1727–1740. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Demir, O.; Şahin, Ö.S.; Avcı, A. Effects of alumina nanoparticles on dynamic impact responses of carbon fiber reinforced epoxy matrix nanocomposites. Eng. Sci. Technol. Int. J. 2018, 21, 399–407. [Google Scholar] [CrossRef]

- Mahato, K.K.; Dutta, K.; Chandra Ray, B. Assessment of mechanical, thermal and morphological behavior of nano-Al2O3 embedded glass fiber/epoxy composites at in-situ elevated temperatures. Compos. Part B Eng. 2019, 166, 688–700. [Google Scholar] [CrossRef]

- Ozen, M.; Demircan, G.; Kisa, M.; Acikgoz, A.; Ceyhan, G.; Işıker, Y. Thermal properties of surface-modified nano-Al2O3/Kevlar fiber/epoxy composites. Mater. Chem. Phys. 2022, 278, 125689. [Google Scholar] [CrossRef]

- Demircan, G.; Kisa, M.; Ozen, M.; Aktas, B. Surface-modified alumina nanoparticles-filled aramid fiber-reinforced epoxy nanocomposites: Preparation and mechanical properties. Iran. Polym. J. 2020, 29, 253–264. [Google Scholar] [CrossRef]

- Islam, M.S.; Benninger, L.F.; Pearce, G.; Wang, C.-H. Toughening carbon fibre composites at cryogenic temperatures using low-thermal expansion nanoparticles. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106613. [Google Scholar] [CrossRef]

- Islam, M.S.; Chang, W.; Sha, Z.; Wang, J.; Wu, S.; Rose, L.R.F.; Kinloch, A.J.; Wang, C.H. Mitigating cryogenic microcracking in carbon-fibre reinforced polymer composites using negative thermal-expansion nanoparticles functionalized by a polydopamine coating. Compos. Part B Eng. 2023, 257, 110676. [Google Scholar] [CrossRef]

- Baghdadi, Y.N.; Youssef, L.; Bouhadir, K.; Harb, M.; Mustapha, S.; Patra, D.; Tehrani-Bagha, A.R. Thermal and mechanical properties of epoxy resin reinforced with modified iron oxide nanoparticles. J. Appl. Polym. Sci. 2021, 138, e50533. [Google Scholar] [CrossRef]

- Jiang, T.; Kuila, T.; Kim, N.H.; Lee, J.H. Effects of surface-modified silica nanoparticles attached graphene oxide using isocyanate-terminated flexible polymer chains on the mechanical properties of epoxy composites. J. Mater. Chem. A 2014, 2, 10557–10567. [Google Scholar] [CrossRef]

- Bian, W.; Yao, T.; Chen, M.; Zhang, C.; Shao, T.; Yang, Y. The synergistic effects of the micro-BN and nano-Al2O3 in micro-nano composites on enhancing the thermal conductivity for insulating epoxy resin. Compos. Sci. Technol. 2018, 168, 420–428. [Google Scholar] [CrossRef]

- Li, C.; Liao, H.; Gao, H.; Cheng, F. Enhancing interface compatibility in high-filled coal gangue/polyethylene composites through silane coupling agent-mediated interface modification. Compos. Sci. Technol. 2024, 251, 110546. [Google Scholar] [CrossRef]

- Li, J.; Peng, C.; Li, Z.; Wu, Z.; Li, S. The improvement in cryogenic mechanical properties of nano-ZrO2/epoxy composites via surface modification of nano-ZrO2. RSC Adv. 2016, 6, 61393–61401. [Google Scholar] [CrossRef]

- Sun, T.; Fan, H.; Wang, Z.; Liu, X.; Wu, Z. Modified nano Fe2O3-epoxy composite with enhanced mechanical properties. Mater. Des. 2015, 87, 10–16. [Google Scholar] [CrossRef]

- Thomason, J.; Xypolias, G. Hydrothermal Ageing of Glass Fibre Reinforced Vinyl Ester Composites: A Review. Polymers 2023, 15, 835. [Google Scholar] [CrossRef]

- Nodehi, M. Epoxy, polyester and vinyl ester based polymer concrete: A review. Innov. Infrastruct. Solut. 2021, 7, 64. [Google Scholar] [CrossRef]

- Jaswal, S.; Gaur, B. New trends in vinyl ester resins. Rev. Chem. Eng. 2014, 30, 567–581. [Google Scholar] [CrossRef]

- Wang, L.; Sun, Y.; Chen, F.; Zhang, G.; Yi, S.; Zuo, D. Investigating the mechanical properties of epoxy resin composites modified by polyamide and nano-Al2O3. J. Appl. Polym. Sci. 2023, 140, e53624. [Google Scholar] [CrossRef]

- Derakhshani, K.; Alimohammadi, M.; Eslami-Farsani, R. The mechanical behavior of silane-modified nano–Al2O3/basalt fiber/polymer composite materials. J. Mater. Sci. 2024, 59, 15270–15282. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Lai, Q.; Huang, C.; Chen, Q.; Fu, X.; Shi, Z. Preparation and characterization of UV curable Al2O3 suspensions applying for stereolithography 3D printing ceramic microcomponent. Powder Technol. 2018, 338, 153–161. [Google Scholar] [CrossRef]

- Brochier Salon, M.-C.; Bayle, P.-A.; Abdelmouleh, M.; Boufi, S.; Belgacem, M.N. Kinetics of hydrolysis and self condensation reactions of silanes by NMR spectroscopy. Colloids Surf. A Physicochem. Eng. Asp. 2008, 312, 83–91. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Li, H. Effects of elevated temperatures on the mechanical properties of basalt fibers and BFRP plates. Constr. Build. Mater. 2016, 127, 1029–1036. [Google Scholar] [CrossRef]

- GB/T 2567-2021; Test Methods for Properties of Resin Casting Body. Standards Press of China: Beijing, China, 2021.

- GB/T 1449-2005; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. Standards Press of China: Beijing, China, 2005.

- Kim, J.; Seidler, P.; Wan, L.S.; Fill, C. Formation, structure, and reactivity of amino-terminated organic films on silicon substrates. J. Colloid Interface Sci. 2009, 329, 114–119. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Liu, X. Novel Functionalized BN Nanosheets/Epoxy Composites with Advanced Thermal Conductivity and Mechanical Properties. ACS Appl. Mater. Interfaces 2020, 12, 6503–6515. [Google Scholar] [CrossRef]

- Yuan, P.; Southon, P.D.; Liu, Z.W.; Green, M.E.R.; Hook, J.M.; Antill, S.J.; Kepert, C.J. Functionalization of Halloysite Clay Nanotubes by Grafting with γ-Aminopropyltriethoxysilane. J. Phys. Chem. C 2008, 112, 15742–15751. [Google Scholar] [CrossRef]

- Silvestro, L.; Spat Ruviaro, A.; Ricardo de Matos, P.; Pelisser, F.; Zambelli Mezalira, D.; Jean Paul Gleize, P. Functionalization of multi-walled carbon nanotubes with 3-aminopropyltriethoxysilane for application in cementitious matrix. Constr. Build. Mater. 2021, 311, 125358. [Google Scholar] [CrossRef]

- Zhou, Y.; Xie, H.; Zhou, W.; Ren, Z. Enhanced antioxidation and microwave absorbing properties of SiO2 -coated flaky carbonyl iron particles. J. Magn. Magn. Mater. 2018, 446, 143–149. [Google Scholar] [CrossRef]

- Li, H.; Xu, J.; Wang, J.; Yang, J.; Bai, K.; Lu, J.; Zhang, Y.; Yin, D. Seed-free synthesis of highly permeable zeolite NaA membranes through deposition of APTES-functionalized alumina particles on macroporous supports. J. Membr. Sci. 2014, 471, 84–93. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Lv, H.; Yang, B. Enhancement of interface performance between shape memory alloy fiber and polymer matrix using silane coupling agent KH550 and Al2O3 nanoparticles. Polym. Compos. 2017, 39, 3040–3047. [Google Scholar] [CrossRef]

- Jajam, K.C.; Tippur, H.V. Quasi-static and dynamic fracture behavior of particulate polymer composites: A study of nano- vs. micro-size filler and loading-rate effects. Compos. Part B Eng. 2012, 43, 3467–3481. [Google Scholar] [CrossRef]

- Yang, J.; Wang, H.; Liu, X.; Fu, S.; Song, P. A nano-TiO2/regenerated cellulose biohybrid enables simultaneously improved strength and toughness of solid epoxy resins. Compos. Sci. Technol. 2021, 212, 108884. [Google Scholar] [CrossRef]

- Sukur, E.F.; Elimsa, S.; Eskizeybek, V.; Avci, A. Damage tolerance of basalt fiber reinforced multiscale composites: Effect of nanoparticle morphology and hygrothermal aging. Compos. Part B Eng. 2024, 273, 111234. [Google Scholar] [CrossRef]

- Thadathil Varghese, J.; Cho, K.; Raju; Farrar, P.; Prentice, L.; Prusty, B.G. Effect of silane coupling agent and concentration on fracture toughness and water sorption behaviour of fibre-reinforced dental composites. Dent. Mater. 2023, 39, 362–371. [Google Scholar] [CrossRef]

- Lu, N.; Oza, S. Thermal stability and thermo-mechanical properties of hemp-high density polyethylene composites: Effect of two different chemical modifications. Compos. Part B Eng. 2013, 44, 484–490. [Google Scholar] [CrossRef]

- Hossain, M.K.; Hossain, M.E.; Dewan, M.W.; Hosur, M.; Jeelani, S. Effects of carbon nanofibers (CNFs) on thermal and interlaminar shear responses of E-glass/polyester composites. Compos. Part B Eng. 2013, 44, 313–320. [Google Scholar] [CrossRef]

- Machello, C.; Bazli, M.; Santos, J.; Rajabipour, A.; Arashpour, M.; Hassanli, R. Tensile strength retention of fibre-reinforced polymer composites exposed to elevated temperatures: A meta-analysis review. Constr. Build. Mater. 2024, 438, 137150. [Google Scholar] [CrossRef]

- Sharifianjazi, F.; Zeydi, P.; Bazli, M.; Esmaeilkhanian, A.; Rahmani, R.; Bazli, L.; Khaksar, S. Fibre-Reinforced Polymer Reinforced Concrete Members under Elevated Temperatures: A Review on Structural Performance. Polymers 2022, 14, 472. [Google Scholar] [CrossRef] [PubMed]

- Pei, X.; Han, W.; Ding, G.; Wang, M.; Tang, Y. Temperature effects on structural integrity of fiber-reinforced polymer matrix composites: A review. J. Appl. Polym. Sci. 2019, 136, 48206. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G. Combined effects of sustained tensile loading and elevated temperatures on the mechanical properties of pultruded BFRP plates. Constr. Build. Mater. 2017, 150, 310–320. [Google Scholar] [CrossRef]

- Li, C.X.; Kalfon-Cohen, E.; Lee, J.; Furtado, C.; Patel, P.; Kopp, R.; Hank, T.J.; Magato, J.; Kinsella, M.; Kessler, S.S.; et al. Interlaminar reinforcement of carbon fiber reinforced polyimide composites using vertically aligned carbon nanotubes. Compos. Part B Eng. 2025, 292, 112098. [Google Scholar] [CrossRef]

- Arrieta, J.S.; Richaud, E.; Fayolle, B.; Nizeyimana, F. Thermal oxidation of vinyl ester and unsaturated polyester resins. Polym. Degrad. Stab. 2016, 129, 142–155. [Google Scholar] [CrossRef]

- Hao, L.C.; Yu, W.D. Evaluation of thermal protective performance of basalt fiber nonwoven fabrics. J. Therm. Anal. Calorim. 2009, 100, 551–555. [Google Scholar] [CrossRef]

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 1234.752 | 9 | 137.195 | 6.289 | 0.000 |

| Intercept | 683,949.332 | 1 | 683,949.332 | 31,354.057 | 0.000 |

| Modified or unmodified | 292.626 | 1 | 292.626 | 13.415 | 0.001 |

| Filler loading | 860.335 | 4 | 215.084 | 9.860 | 0.000 |

| Modified or unmodified × Filler loading | 81.790 | 4 | 20.448 | 0.937 | 0.452 |

| Error | 872.550 | 40 | 21.814 | ||

| Total | 686,056.633 | 50 | |||

| Corrected Total | 2107.302 | 49 |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 862,628.222 | 9 | 95,847.580 | 4.862 | 0.000 |

| Intercept | 532,072,910.5 | 1 | 532,072,910.5 | 26,991.195 | 0.000 |

| Modified or unmodified | 425,230.109 | 1 | 425,230.109 | 21.571 | 0.000 |

| Filler loading | 259,792.559 | 4 | 64,948.140 | 3.295 | 0.020 |

| Modified or unmodified × Filler loading | 177,605.554 | 4 | 44,401.389 | 2.252 | 0.080 |

| Error | 788,513.302 | 40 | 19,712.833 | ||

| Total | 533,724,052.1 | 50 | |||

| Corrected Total | 1,651,141.524 | 49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Miao, Y.; Ma, L.; Tian, W.; Zhu, C. Effect of Silane-Modified Nano-Al2O3-Reinforced Vinyl Ester Resin on the Flexural Properties of Basalt Fiber Composites. Materials 2025, 18, 1727. https://doi.org/10.3390/ma18081727

Wei Y, Miao Y, Ma L, Tian W, Zhu C. Effect of Silane-Modified Nano-Al2O3-Reinforced Vinyl Ester Resin on the Flexural Properties of Basalt Fiber Composites. Materials. 2025; 18(8):1727. https://doi.org/10.3390/ma18081727

Chicago/Turabian StyleWei, Yuehai, Yongda Miao, Leilei Ma, Wei Tian, and Chenyan Zhu. 2025. "Effect of Silane-Modified Nano-Al2O3-Reinforced Vinyl Ester Resin on the Flexural Properties of Basalt Fiber Composites" Materials 18, no. 8: 1727. https://doi.org/10.3390/ma18081727

APA StyleWei, Y., Miao, Y., Ma, L., Tian, W., & Zhu, C. (2025). Effect of Silane-Modified Nano-Al2O3-Reinforced Vinyl Ester Resin on the Flexural Properties of Basalt Fiber Composites. Materials, 18(8), 1727. https://doi.org/10.3390/ma18081727