Oily Long-Term Anti-Icing Coating Based on Hydrophobic Cross-Linking Composite Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

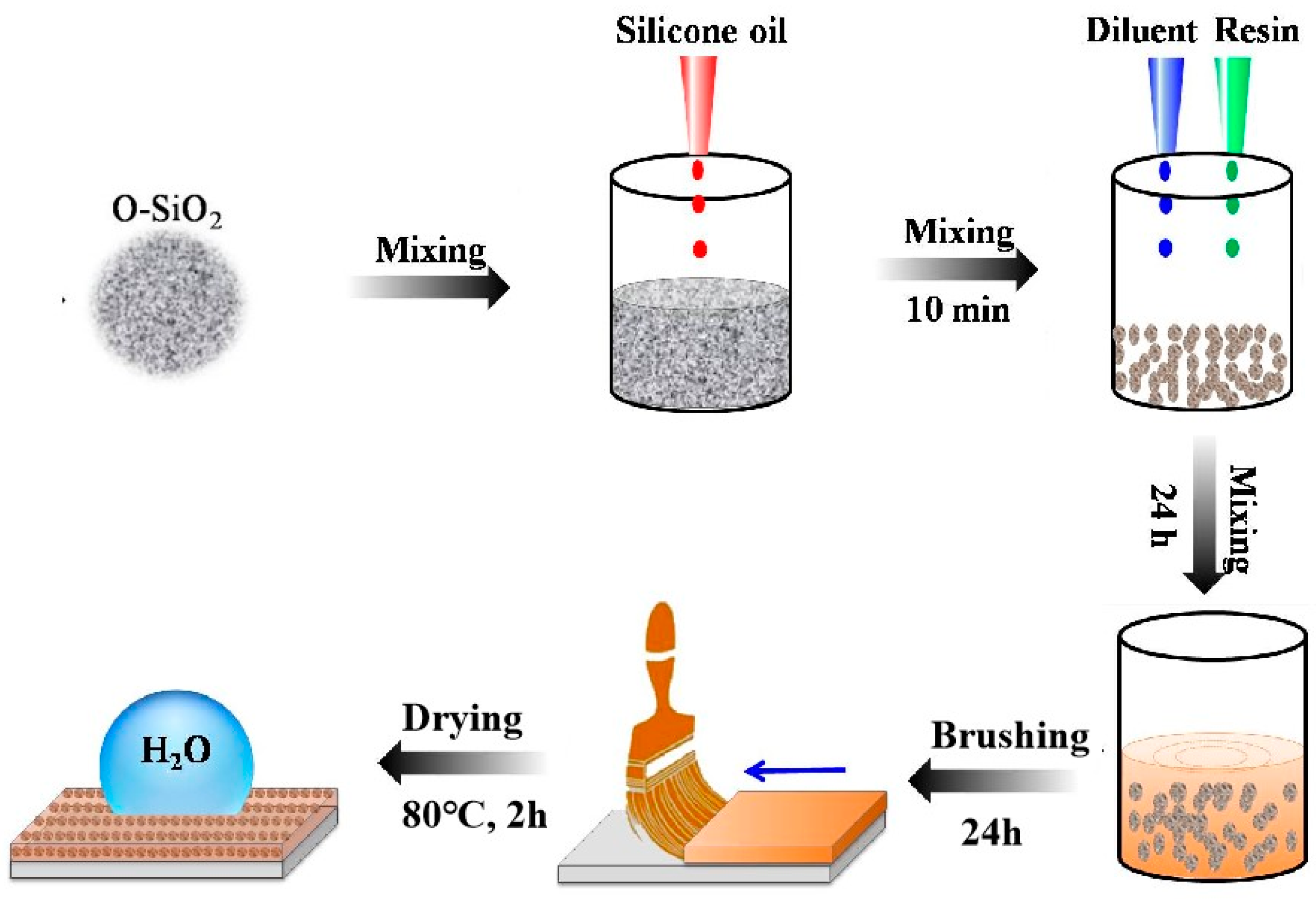

2.2. Preparation of Interfacial Lubricating Coatings

2.3. Characterization and Testing

3. Results and Discussion

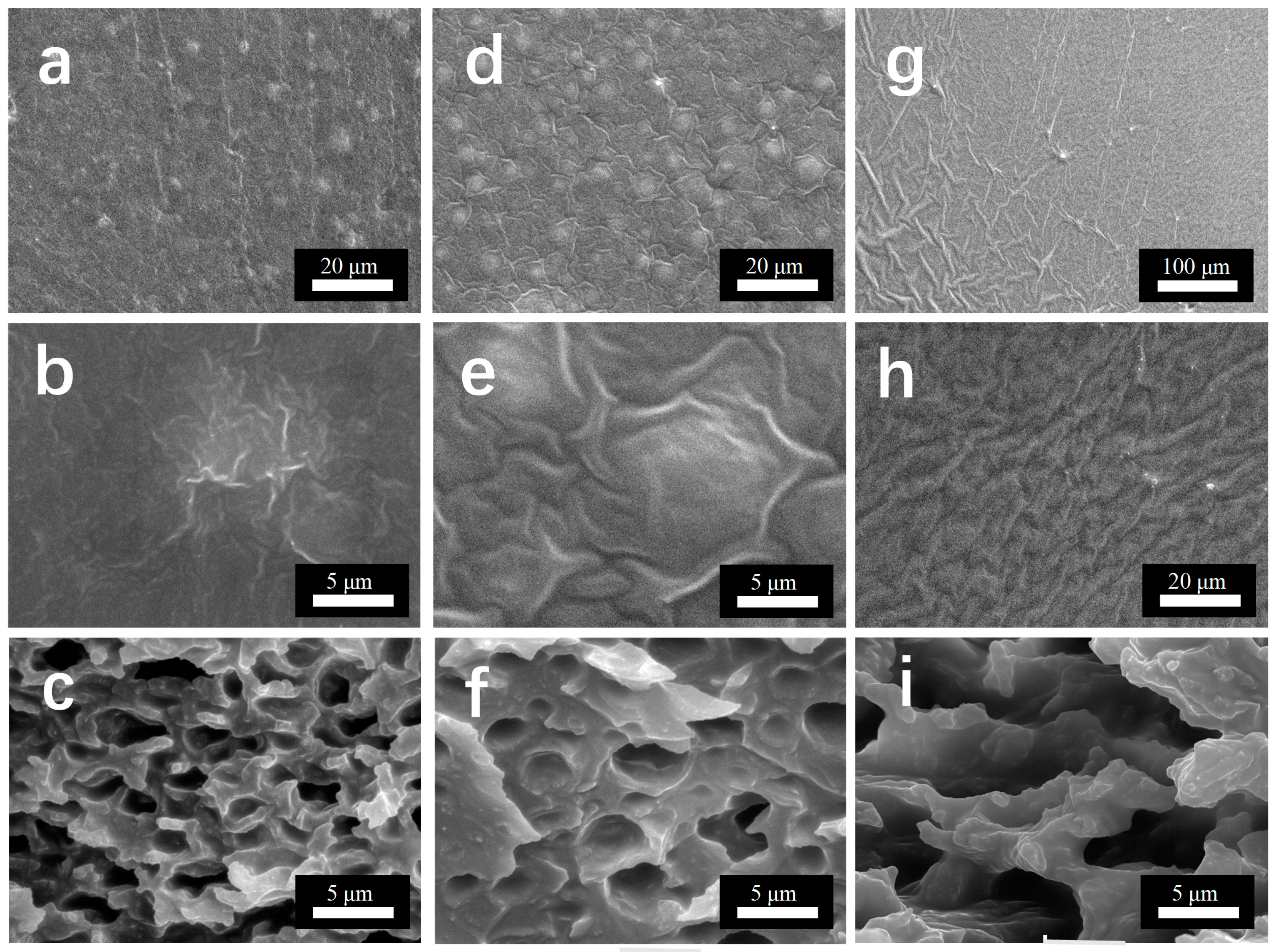

3.1. Subsection Surface Layered Structure of the Coating

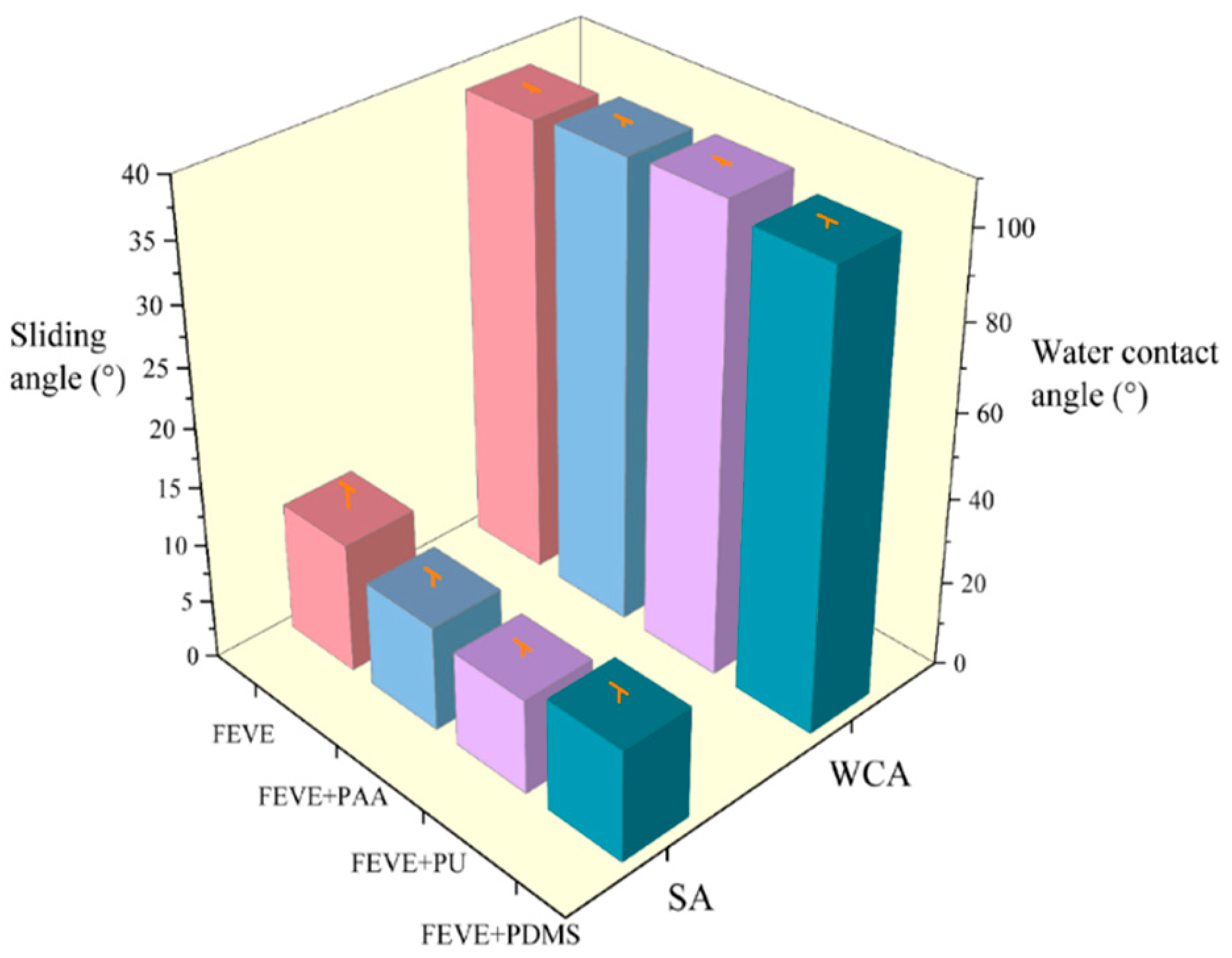

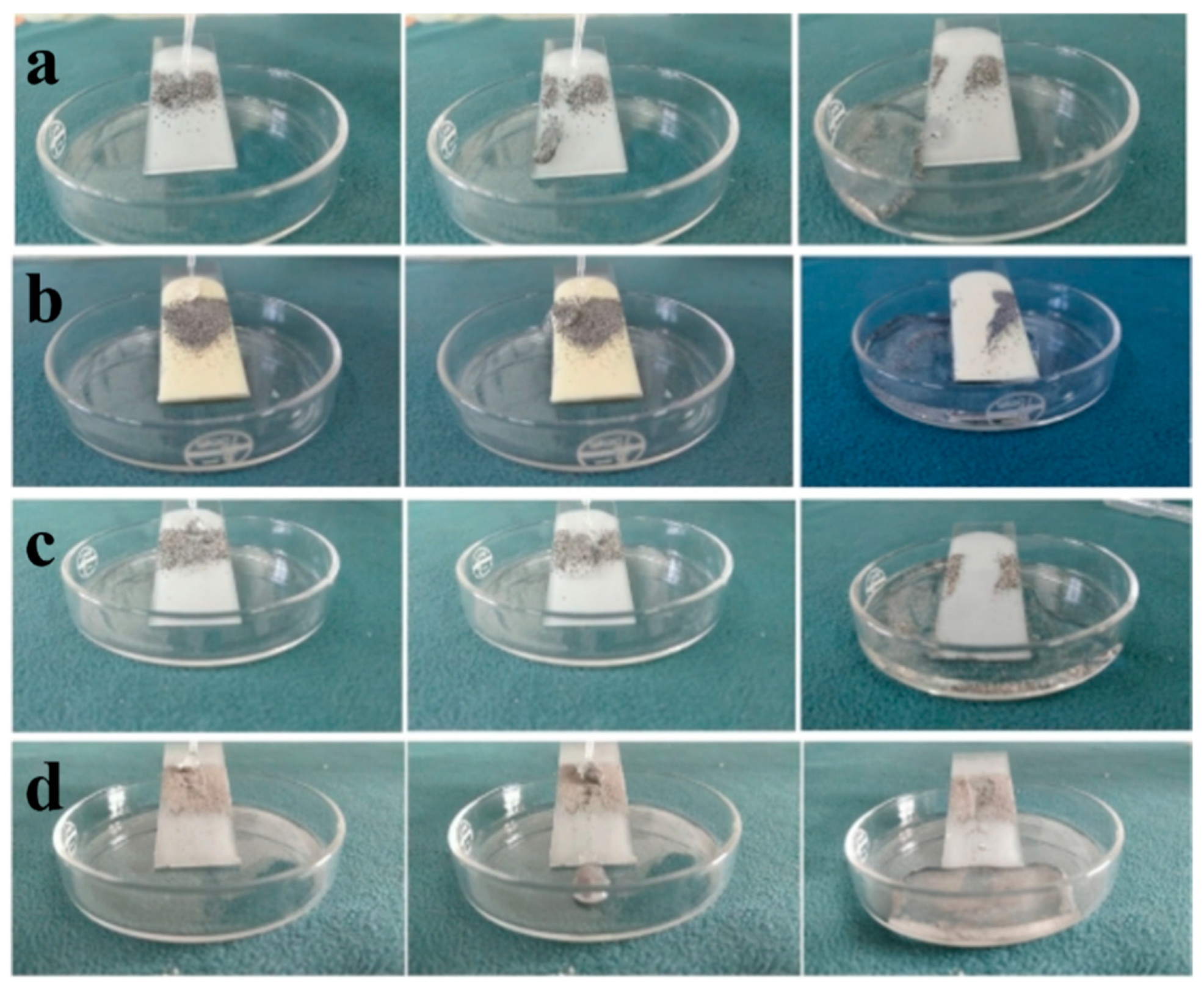

3.2. Surface Wettability and Self-Cleaning of Composite Coatings

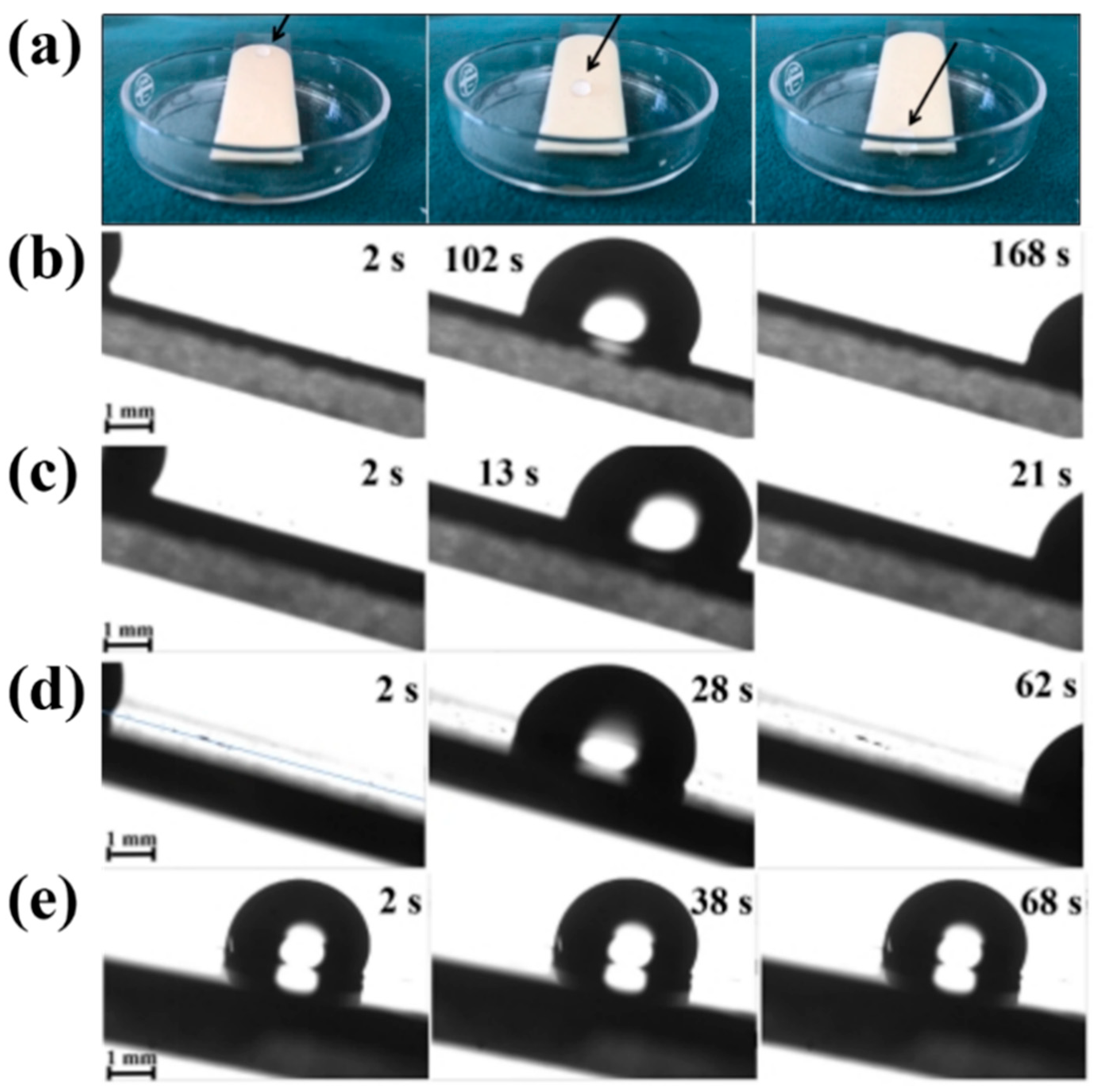

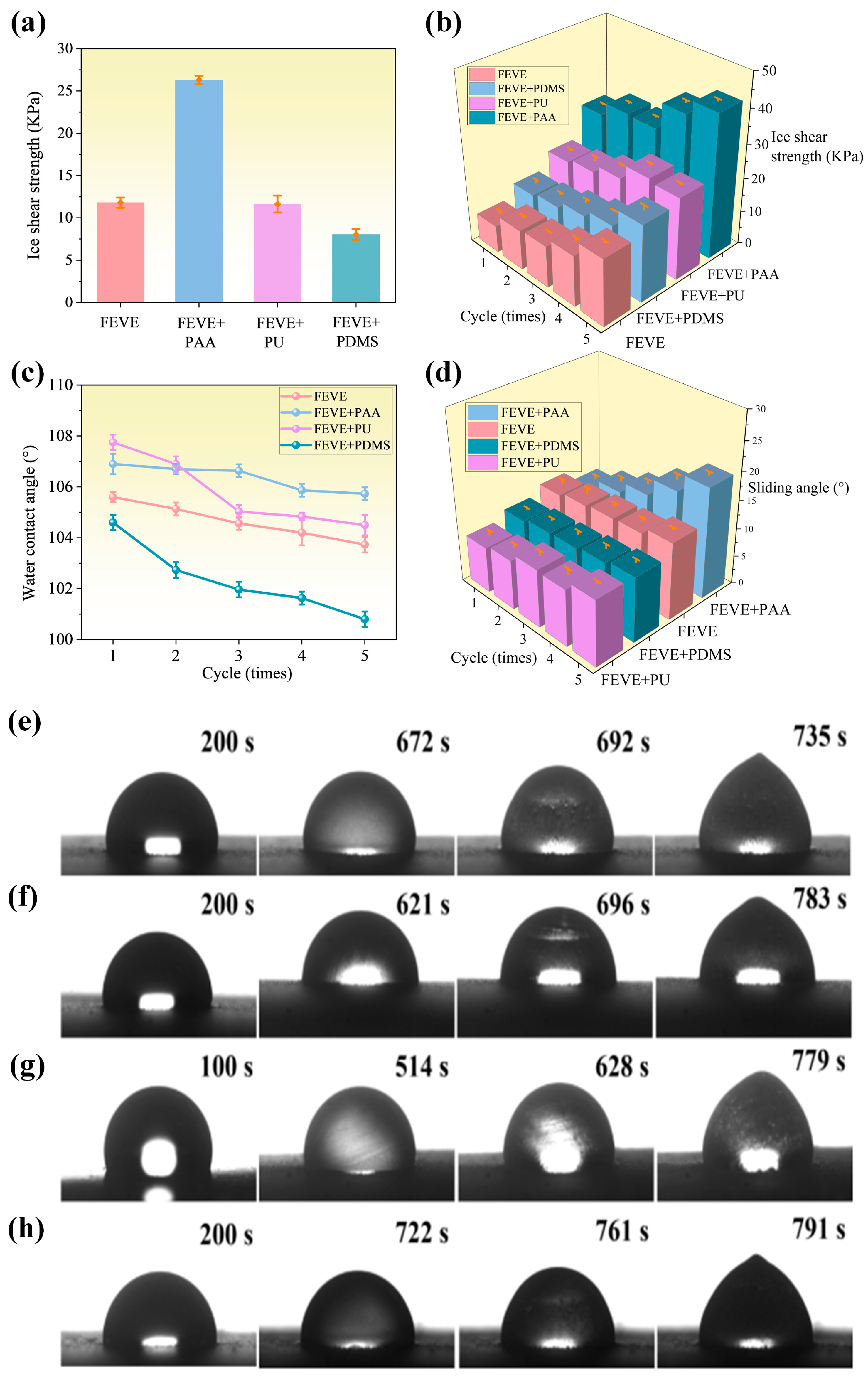

3.3. Long-Term Anti-Icing Behavior and Mechanisms of Action

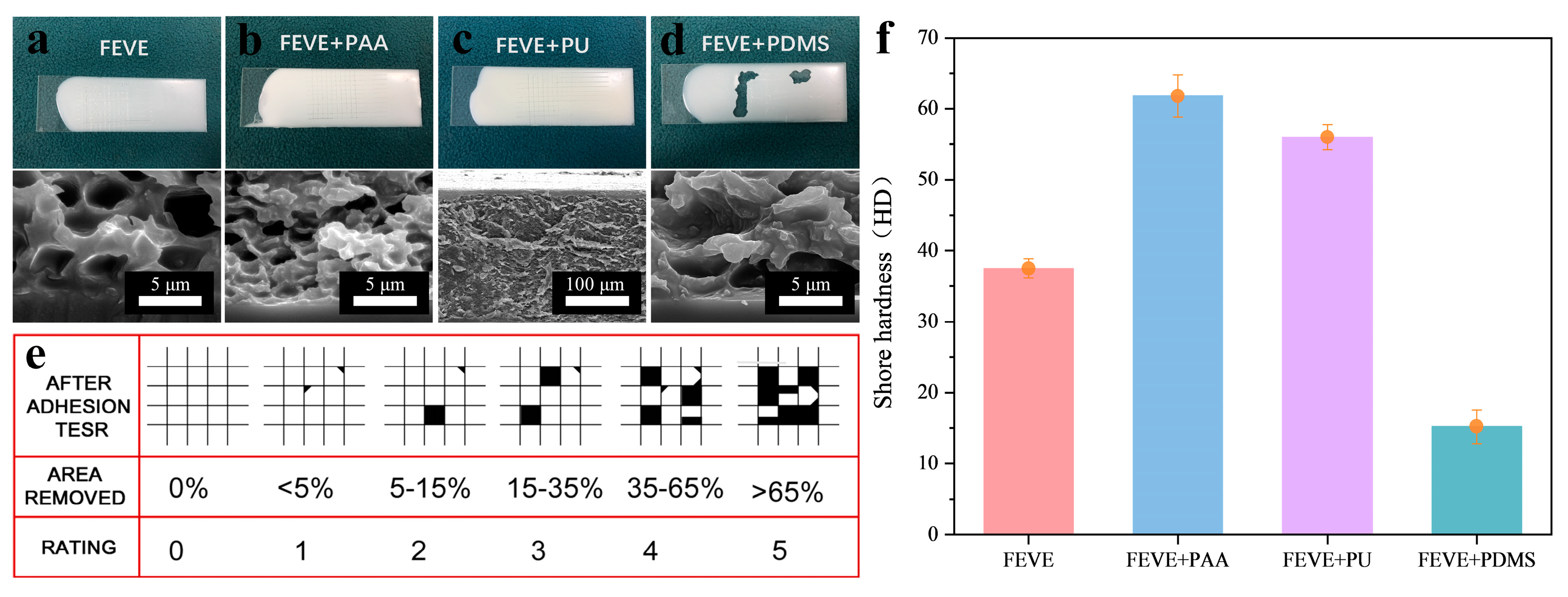

3.4. Mechanical Stability

3.4.1. Mechanical Properties

3.4.2. Durability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shen, Y.; Wu, X.; Tao, J.; Zhu, C.; Lai, Y.; Chen, Z. Icephobic materials: Fundamentals, performance evaluation, and applications. Prog. Mater. Sci. 2019, 103, 509–557. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, F.; Zhang, Z.; Li, G.; Fu, H.; Huang, J.; Wang, Y.; Lei, Z.; Qian, X.; Lai, Y. An electroless nickel plating fabric coated with photothermal Chinese ink for powerful passive anti-icing/icephobic and fast active deicing. Chem. Eng. J. 2022, 450, 138328. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, Q.; Lin, T.; Cheng, P. A review of recent literature on icing phenomena: Transport mechanisms, their modulations and controls. Int. J. Heat Mass Transf. 2020, 159, 120074. [Google Scholar]

- Cong, Q.; Qin, X.; Chen, T.; Jin, J.; Liu, C.; Wang, M. Research Progress of Superhydrophobic Materials in the Field of Anti-/De-Icing and Their Preparation: A Review. Materials 2023, 16, 5151. [Google Scholar] [CrossRef]

- Zhu, J.; Li, W.; Wang, T.; Feng, H.; Cheng, J.; Lin, C.; Wang, X.; Wang, W.; Chen, S. Robust photothermal self-healing superhydrophobic composite coating for durable anti/de-icing applications. Chem. Eng. J. 2025, 505, 159218. [Google Scholar] [CrossRef]

- Qin, X.; Cong, Q.; Xu, J.; Chen, T.; Jin, J.; Liu, C.; Wang, M. Photothermal superhydrophobic coupled functional surface with active anti/de-icing performance. Appl. Therm. Eng. 2025, 260, 125031. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, C.; Tu, J. Robust Slippery Coating with Superior Corrosion Resistance and Anti-Icing Performance for AZ31B Mg Alloy Protection. ACS Appl. Mater. Interfaces 2017, 9, 11247–11257. [Google Scholar] [CrossRef]

- Heydarian, S.; Jafari, R.; Momen, G. Recent progress in the anti-icing performance of slippery liquid-infused surfaces. Prog. Org. Coat. 2021, 151, 106096. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Wei, D.; Shi, Y.; Lu, T.; Zhang, Z.; Han, Z.; Liu, Y. A fluorine-free bioinspired multifunctional slippery coating for ultra-long-term anticorrosion of Mg alloy, static/dynamic anti-icing, antibacterial and antifouling. Chem. Eng. J. 2024, 500, 157516. [Google Scholar] [CrossRef]

- Jiang, X.; Zhou, H.; He, K.; Yang, Z.; Hu, Y. Anti-icing Performance Degradation for Wind Blades with Superhydrophobic Coatings. Gaodianya Jishu/High Volt. Eng. 2019, 45, 167–172. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, C.; Jiang, B.; Lei, Y.; Li, Z.; Sun, K.; Zhang, Y. A robust photothermal superhydrophobic anti/de-icing composite coating fabricated from BP/SiO2 on a modified fluorocarbon coating base. Prog. Org. Coat. 2024, 196, 108725. [Google Scholar] [CrossRef]

- Huang, W.; Huang, J.; Guo, Z.; Liu, W. Icephobic/anti-icing properties of superhydrophobic surfaces. Adv. Colloid Interface Sci. 2022, 304, 102658. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Z.; Gao, L.; Liu, Y.; Hu, H. An exploratory study on using Slippery-Liquid-Infused-Porous-Surface (SLIPS) for wind turbine icing mitigation. Renew. Energy 2020, 162, 2344–2360. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, Z.; Zheng, Q.; Wang, K.; Zhou, F.; Yang, Q.; Wang, X.; Ye, L.; Chen, Y.; Liu, H.; et al. Waxberry-liked micro-nanostructured, superhydrophobic surfaces with enhanced photothermal de-icing and passive anti-icing properties. Chem. Eng. J. 2025, 503, 158358. [Google Scholar] [CrossRef]

- Veronesi, F.; Boveri, G.; Mora, J.; Corozzi, A.; Raimondo, M. Icephobic properties of anti-wetting coatings for aeronautical applications. Surf. Coat. Technol. 2021, 421, 127363. [Google Scholar] [CrossRef]

- Wan, Y.; Liu, Y.; Liu, Y.; Sun, C.; Feng, K.; Wu, Y.; Zhou, F. Flexible Electrothermal Hydrophobic Self-Lubricating Tape for Controllable Anti-icing and De-icing. ACS Appl. Eng. Mater. 2023, 1, 669–678. [Google Scholar] [CrossRef]

- Park, G.D.; Lee, Y.S.; Lee, S.J. Superior anti-icing performance of a silicone-based slippery gel coating with a self-replenishing lubricant layer under airflow. Appl. Surf. Sci. 2025, 681, 161478. [Google Scholar] [CrossRef]

- Shamshiri, M.; Jafari, R.; Momen, G. Icephobic properties of aqueous self-lubricating coatings containing PEG-PDMS copolymers. Prog. Org. Coat. 2021, 161, 106466. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, Y.; Huang, M.; Zhou, Y.; Liu, Y.; Liang, X. Durability of a lubricant-infused Electrospray Silicon Rubber surface as an anti-icing coating. Appl. Surf. Sci. 2015, 346, 68–76. [Google Scholar] [CrossRef]

- Xiao, Z.; Chen, C.; Liu, S.; Liu, C.; Liu, W.; Cheng, Z.; Yu, X.; Lu, Y.; Zhang, Y. Endowing durable icephobicity by combination of a rough powder coating and a superamphiphobic coating. Chem. Eng. J. 2024, 482, 149001. [Google Scholar] [CrossRef]

- Corsaro, C.; Orlando, G.; Costa, G.; Latino, M.; Barreca, F.; Mezzasalma, A.M.; Neri, F.; Fazio, E. Wetting Behavior Driven by Surface Morphology Changes Induced by Picosecond Laser Texturing. Materials 2024, 17, 1719. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Fu, C.; Li, J.; Tang, W.; Gao, X.; Zhang, J. Fabrication and Experimental Study of Micro/Sub-Micro Porous Copper Coating for Anti-Icing Application. Materials 2023, 16, 3774. [Google Scholar] [CrossRef]

- Liu, W.; Wang, S.; Wang, G.; Xiao, Z.; Zhou, C.; Gao, S. Wettability, Self-Cleaning Property, and Mechanical Durability of A390 Aluminum Alloy with the Major Effect of Si Phases. Langmuir 2022, 38, 15303–15315. [Google Scholar] [CrossRef]

- Li, P.; Wang, S.; Yu, K.; Zhang, L.; Jiang, Y.; Wang, G. Superhydrophobic biomimetic microstructures prepared by laser-ablation for drag reduction. Colloids Surf. A Physicochem. Eng. Asp. 2024, 686, 133381. [Google Scholar] [CrossRef]

- Chen, T.; Cong, Q.; Li, Y.; Jin, J.; Choy, K.-L. Utilizing swelling force to decrease the ice adhesion strength. Cold Reg. Sci. Technol. 2018, 146, 122–126. [Google Scholar] [CrossRef]

- Chen, J.; Li, K.; Wu, S.; Liu, J.; Liu, K.; Fan, Q. Durable Anti-Icing Coatings Based on Self-Sustainable Lubricating Layer. ACS Omega 2017, 2, 2047–2054. [Google Scholar] [CrossRef]

- Golovin, K.; Kobaku, S.P.R.; Lee, D.H.; DiLoreto, E.T.; Mabry, J.M.; Tuteja, A. Designing durable icephobic surfaces. Sci. Adv. 2016, 2, e1501496. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.; Du, M.; Li, P.; Liu, J.; Tian, X.; Cheng, Z.; Wang, S. Oily Long-Term Anti-Icing Coating Based on Hydrophobic Cross-Linking Composite Resin. Materials 2025, 18, 1558. https://doi.org/10.3390/ma18071558

Xiao Z, Du M, Li P, Liu J, Tian X, Cheng Z, Wang S. Oily Long-Term Anti-Icing Coating Based on Hydrophobic Cross-Linking Composite Resin. Materials. 2025; 18(7):1558. https://doi.org/10.3390/ma18071558

Chicago/Turabian StyleXiao, Zhen, Mingyang Du, Peining Li, Jingyu Liu, Xiaoyu Tian, Zhi Cheng, and Shouren Wang. 2025. "Oily Long-Term Anti-Icing Coating Based on Hydrophobic Cross-Linking Composite Resin" Materials 18, no. 7: 1558. https://doi.org/10.3390/ma18071558

APA StyleXiao, Z., Du, M., Li, P., Liu, J., Tian, X., Cheng, Z., & Wang, S. (2025). Oily Long-Term Anti-Icing Coating Based on Hydrophobic Cross-Linking Composite Resin. Materials, 18(7), 1558. https://doi.org/10.3390/ma18071558