Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications

Highlights

- Strategies for improving Si3N4 slurries by particle size gradation, surface oxidation and resin modification.

- Multiphase compositing and polymer-derived ceramics of Si3N4-based ceramics via VPP.

- Printing, debinding/sintering process and predictive models.

- Type and proportion of sintering aids for enhancing the densification of VPP-based Si3N4 ceramics.

- Typical components and applications of VPP-based Si3N4 ceramics.

Abstract

:1. Introduction

2. Principles of Ceramic 3D Printing via Vat Photopolymerization

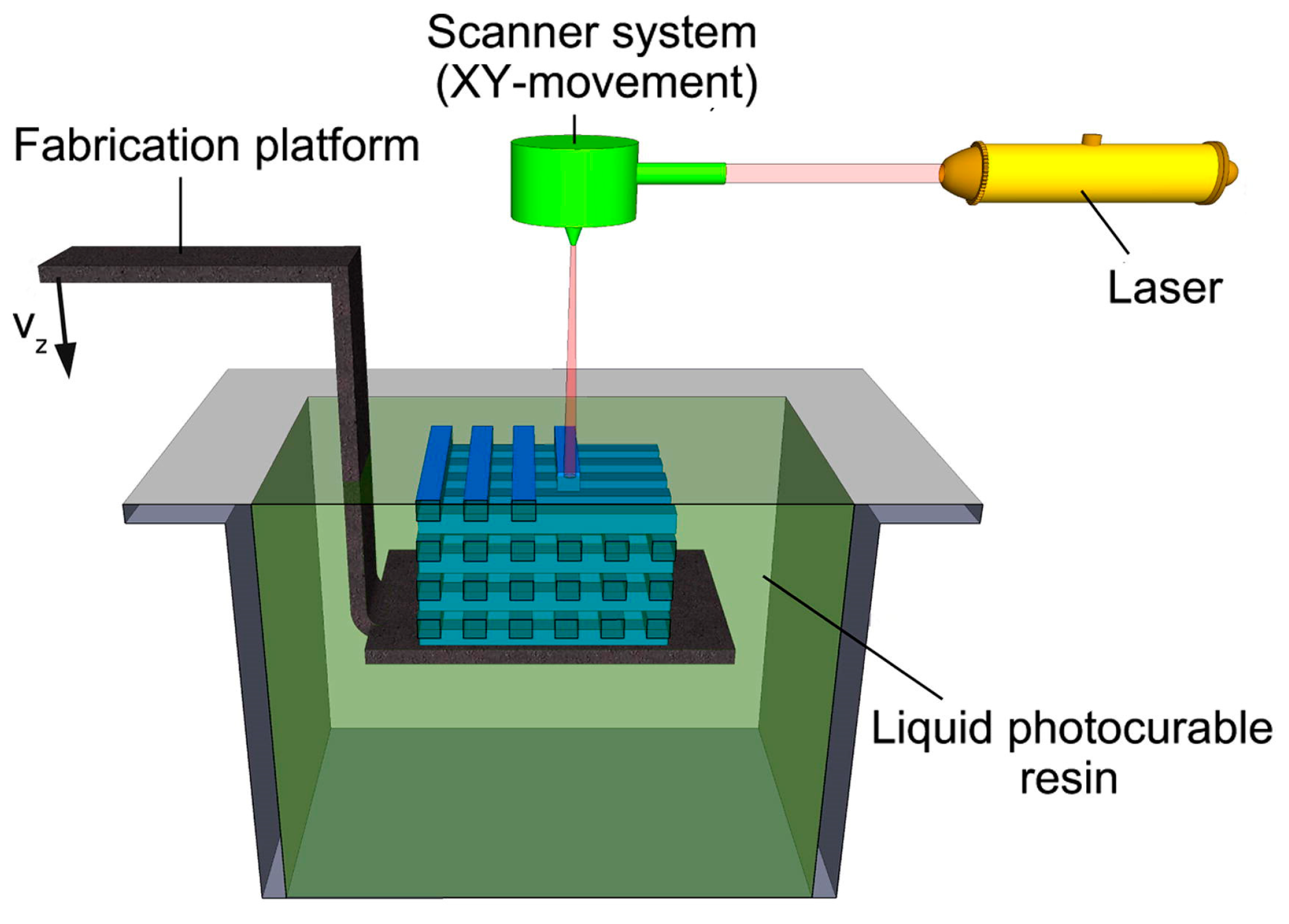

2.1. Stereolithography (SLA)

2.2. Digital Light Processing (DLP)

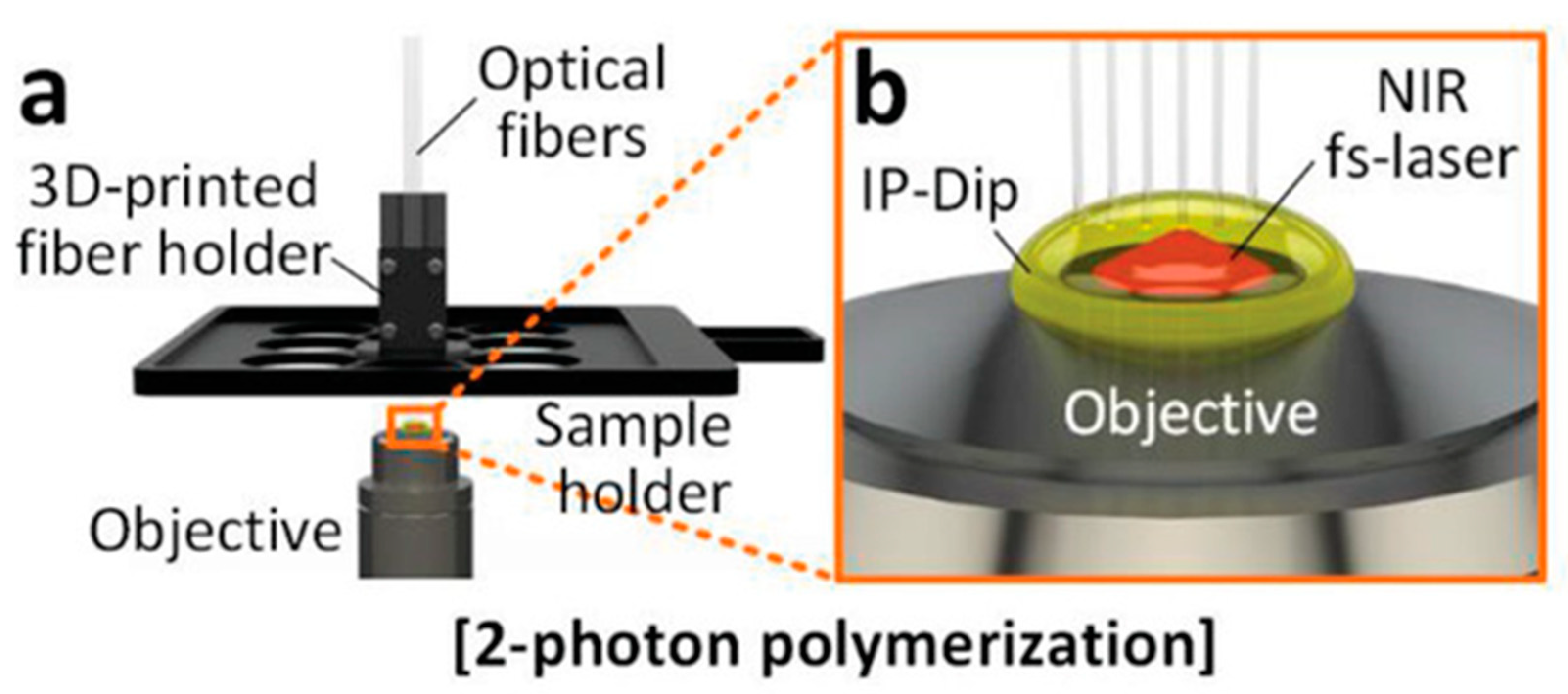

2.3. Two-Photon Polymerization (TPP)

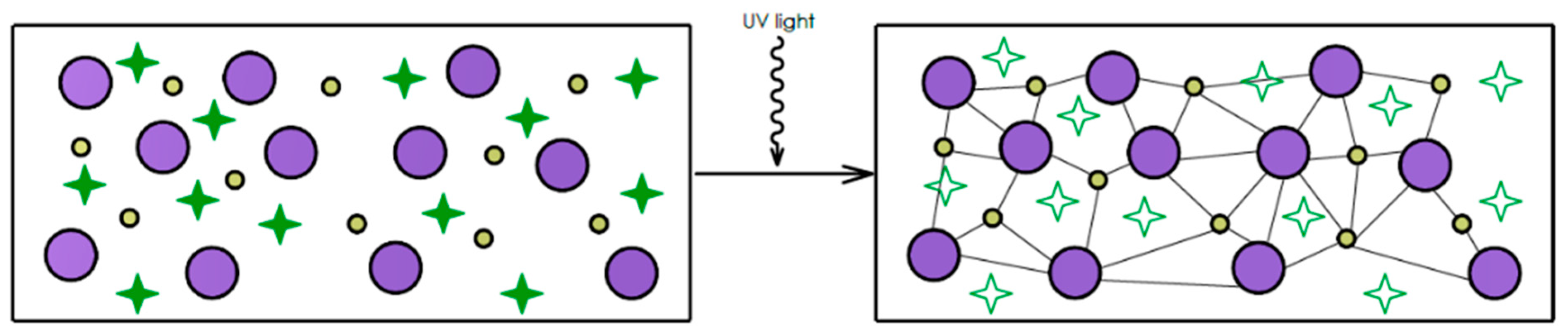

2.4. Photopolymerization Mechanisms

3. Strategies for Improving Si3N4 Ceramic Slurries

3.1. Particle Size Optimization

3.2. Resin and Dispersant Selection

| Resin | D50 (μm) | Dispersant | Solid Loading (vol.%) | Viscosity (Pa·s) | Curing Depth (μm) | Ref. |

|---|---|---|---|---|---|---|

| HDDA | 0.5 | BYK-103 (3 wt.%) | 42 | 2.8 at 100 s−1 | 38 | [47] |

| HEMA:HDDA:TMPTA = 3:4:3 (vol.%) | 0.5 | BYK-110 (1 wt.%) | 48 | 2.09 at 30 s−1 | 80 | [81] |

| HDDA:ACMO:POE = 5:2:3 (wt.%) | 0.45 | KD1 (2.5 wt.%) + CC42 (0.5 wt.%) | 40 | 1.9 at 6.4 s−1 | 38 | [83] |

| OPPEA:ACMO:HDDA:POE = 2:1:4:3 (wt.%) | 0.45 | KD1 (2.5 wt.%) + CC42 (0.5 wt.%) | 40 | 4.3 at 6.4 s−1 | <45 | [84] |

| PPTTA:OPPEA = 4:3 (wt.%) | 0.813 | Solsperse 85000 (3 wt.%) | 20 | 4.19 at 1.18 s−1 | 60.75 | [85] |

| HDDA + TMP3EOTA | 0.83 | Solsperse 41000 | 40 | <1.5 at 60 s−1 | 61.6 | [86] |

3.3. Surface Modification

3.4. Multiphase Ceramics

3.5. Polymer-Derived Ceramics

4. Debinding/Sintering Process and Optimization for Si3N4 via VPP

4.1. Debinding Process

4.2. Sintering Process

4.3. Influence of Sintering Additives

| Ceramic Powder | Solid Loading (vol.%) | Relative Density (%) | Flexural Strength (MPa) | Hardness (GPa) | Fracture Toughness (MPa·m1/2) | Linear Shrinkage Range (%) | Ref. |

|---|---|---|---|---|---|---|---|

| 92Si3N4 + 2.47MgO + 5.53Y2O3 | - | 99.4 | 879 ± 37 | 15 ± 0.4 | - | - | [147] |

| 95Si3N4 + 2.5Y2O3 + 2.5Al2O3 | 45 | 84.2 ± 10.0 | 540.63 ± 10.05 | 12.88 ± 0.52 | 4.92 ± 0.07 | - | [150] |

| Si3N4 + CeO2 | - | 95.8 | - | HV10/10 1347.9 ± 2.4 | 6.57 ± 0.07 | - | [151] |

| 90Si3N4 + 3La2O3 + 7MgO | 45 | 95.94 | 577 ± 16.28 | - | 5.84 ± 0.17 | 21.75–25.45 | [152] |

| 90Si3N4 + 6Y2O3 + 4Al2O3 | 60 | 98.24 ± 0.36 | 865.87 ± 54.35 | 16.70 ± 0.34 | - | 15.38–18.61 | [90] |

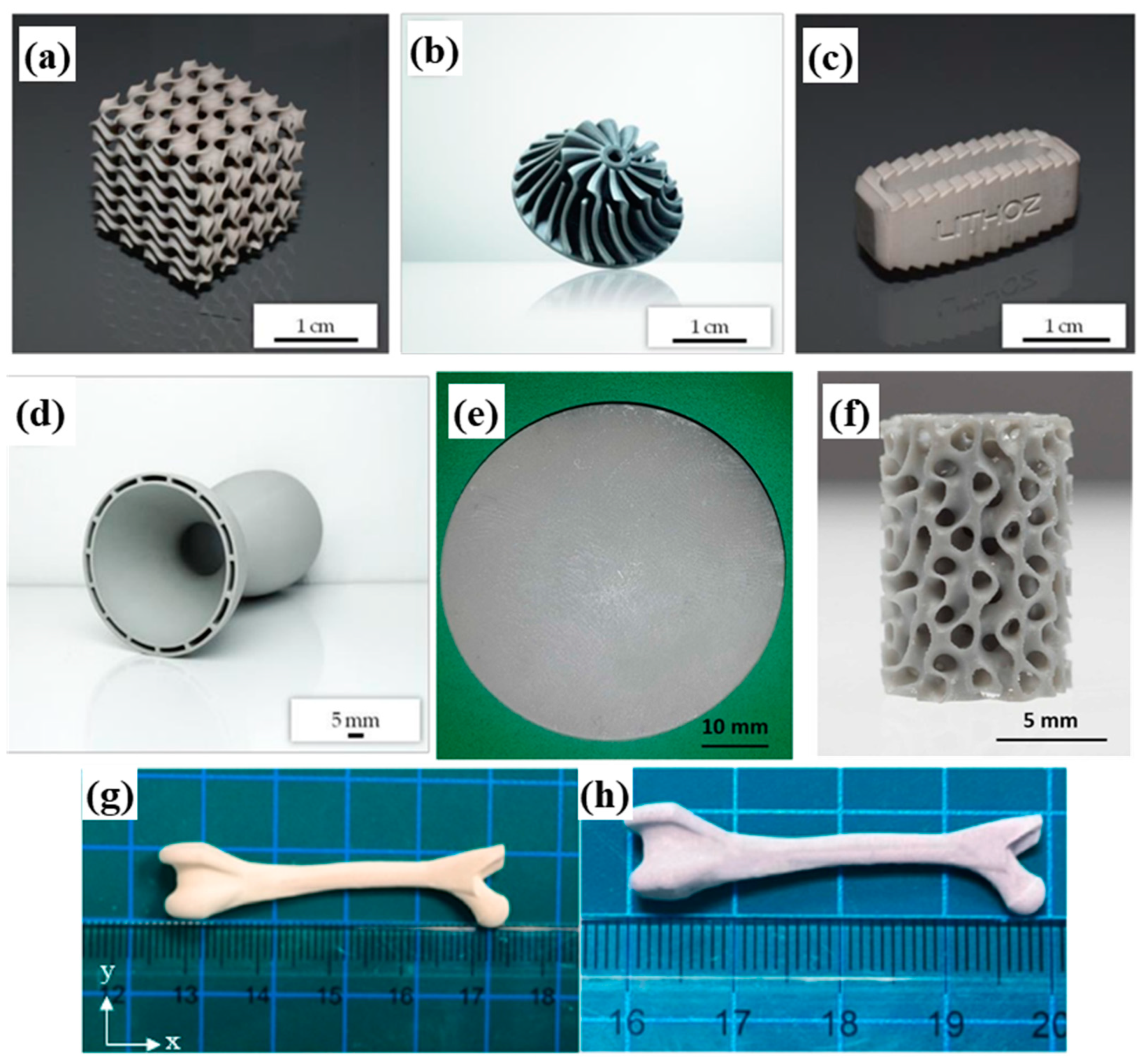

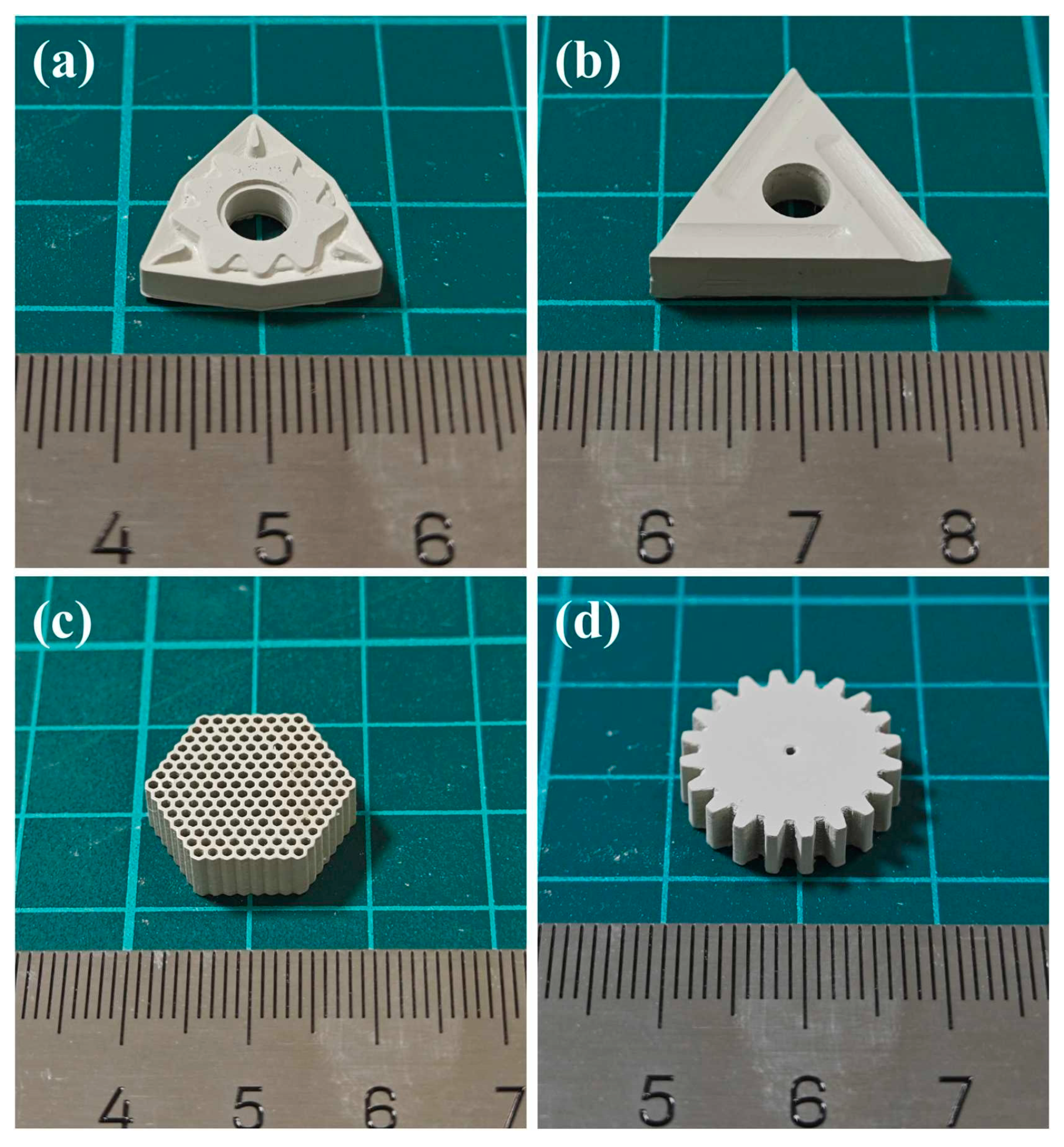

5. Typical Components and Structures of Photopolymerization-Based Si3N4 Ceramics

6. Future Opportunities and Challenges

- (1)

- Creating stable and high-quality Si3N4 ceramic slurries requires balancing multiple factors. Achieving an optimal slurry solid loading of typically 50–60% ceramic content is critical—a low solid concentration causes weak interlayer bonding and defects like cracks, while excessive solid loading leads to poor resin flow, particle clumping, and uneven curing [164,165]. Photopolymer resins must also chemically “wrap around” ceramic particles without separating, demanding precise dispersants and viscosity modifiers. Limited UV penetration in concentrated Si3N4 slurries further complicates uniform curing, risking incomplete layers or structural weaknesses.

- (2)

- Every step of the printing process demands tight calibration. Exposure time, layer thickness, and light intensity must align perfectly to avoid over-curing (brittle parts) or under-curing (collapsed features). Support structures for complex geometries often leave surface marks or require tedious post-removal refinishing. Additionally, slight variations in ambient temperature or resin aging can alter curing behavior, demanding constant monitoring. For multi-material designs, mismatched thermal expansion between Si3N4 and other materials risks delamination during subsequent heat treatments.

- (3)

- Removing organic binders through various debinding techniques requires ultra-slow heating to prevent cracks from trapped gases, while sintering must balance high temperatures of 1700–1800 °C with nitrogen atmospheres to avoid the decomposition of silicon nitride. Even minor deviations in these steps can introduce voids, warping, or weakened grain boundaries. Secondary processes like polymer infiltration (PIP) increase additional costs and complexity but remain quite necessary to achieve full densification in critical applications.

- (4)

- In high-precision industries like aerospace and those of biomedical implants, vat photopolymerization-based Si3N4 ceramics face challenges in controlling dimensional shrinkage and surface roughness due to inherent material behavior during manufacturing. Anisotropic shrinkage from photopolymerization and sintering, combined with phase transformations, causes structural inaccuracies in critical components. Addressing these issues requires optimizing materials and post-processing techniques to align Si3N4 ceramics with the precision demands of advanced technologies.

7. Conclusions

- (1)

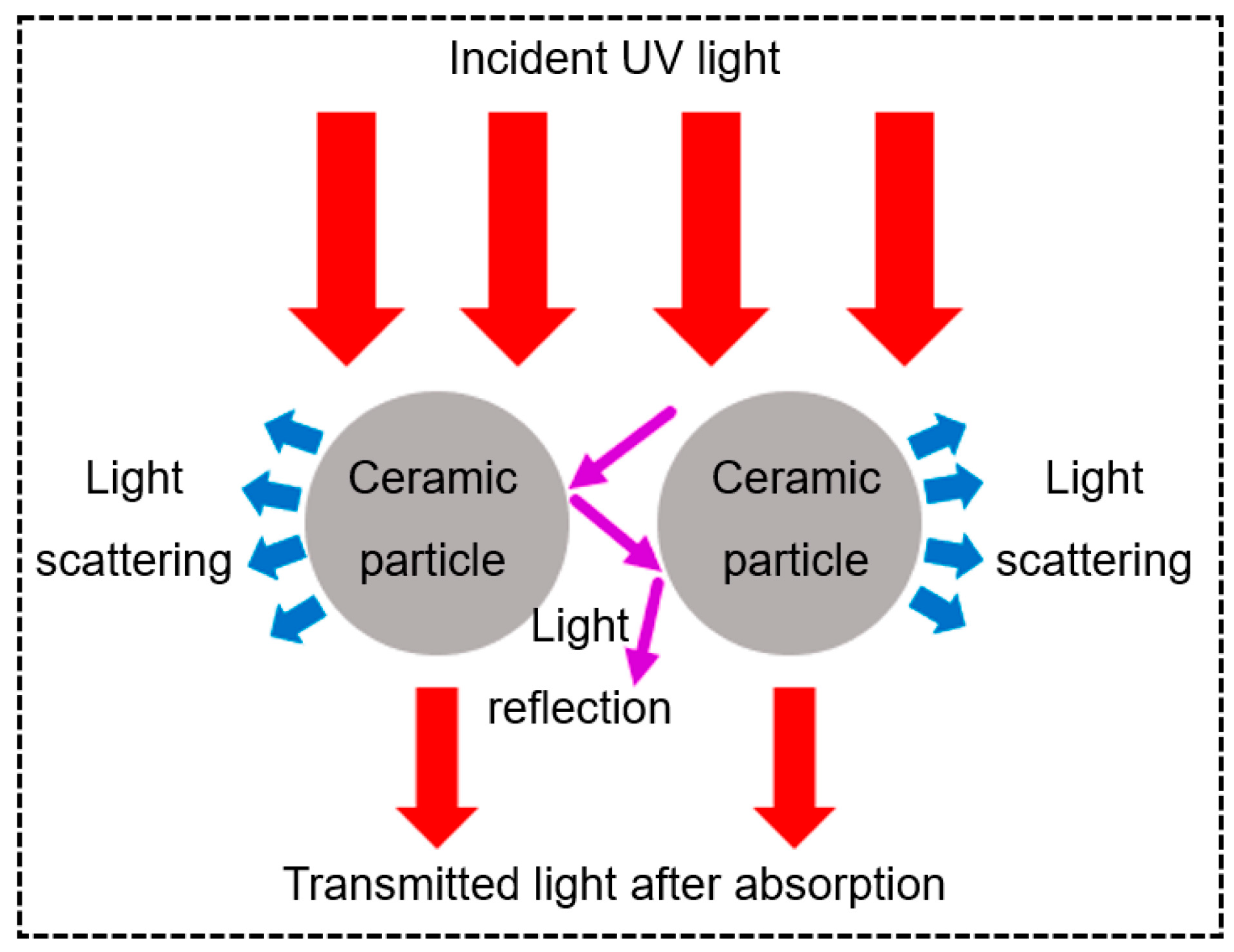

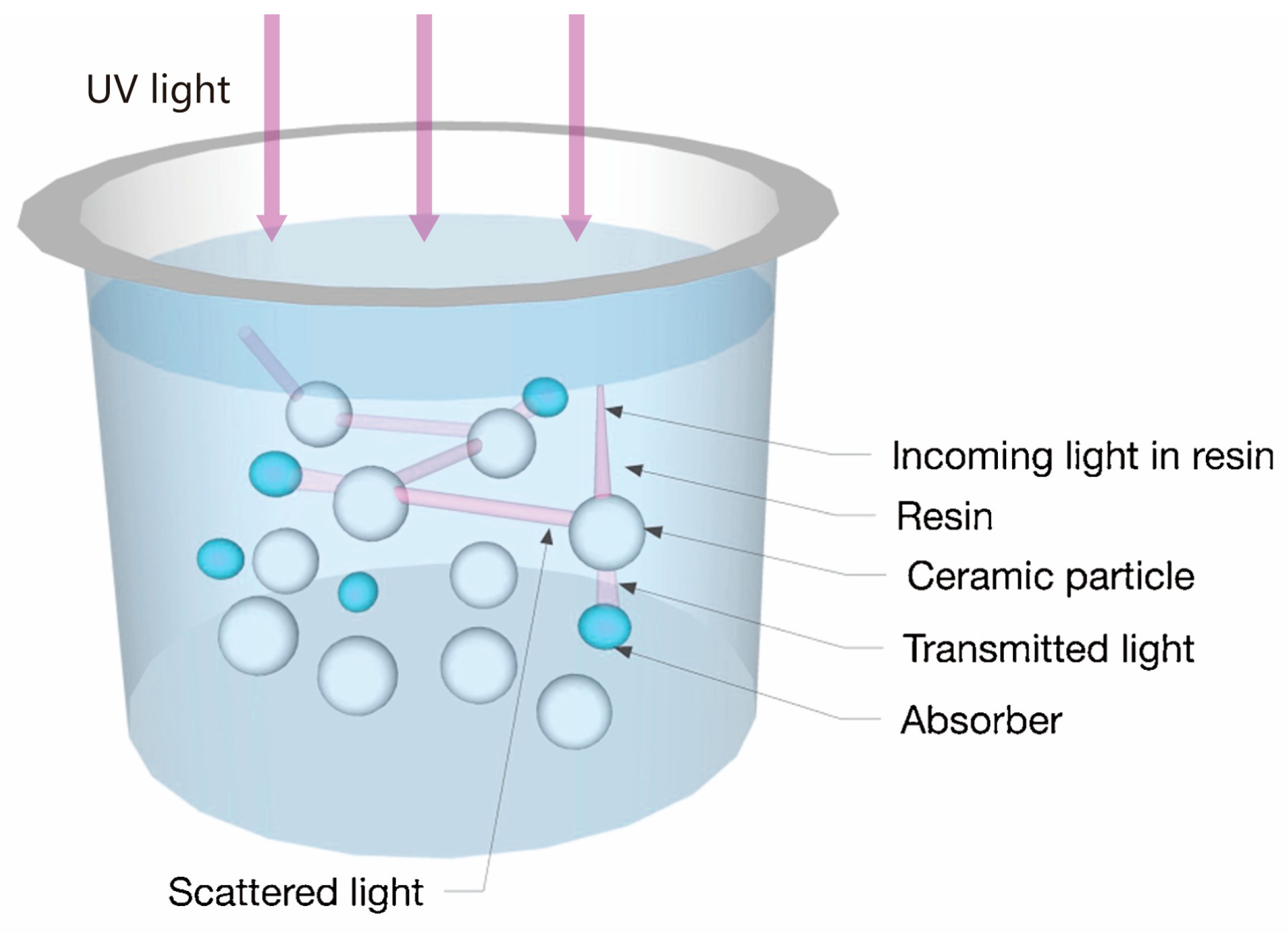

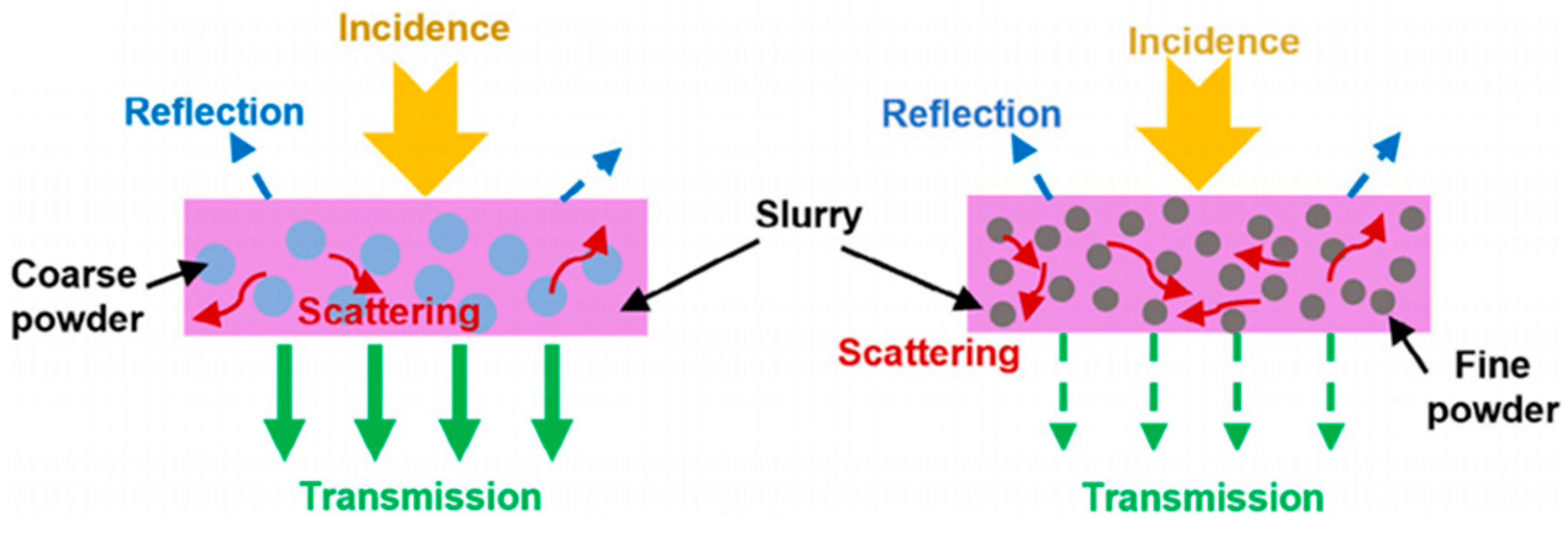

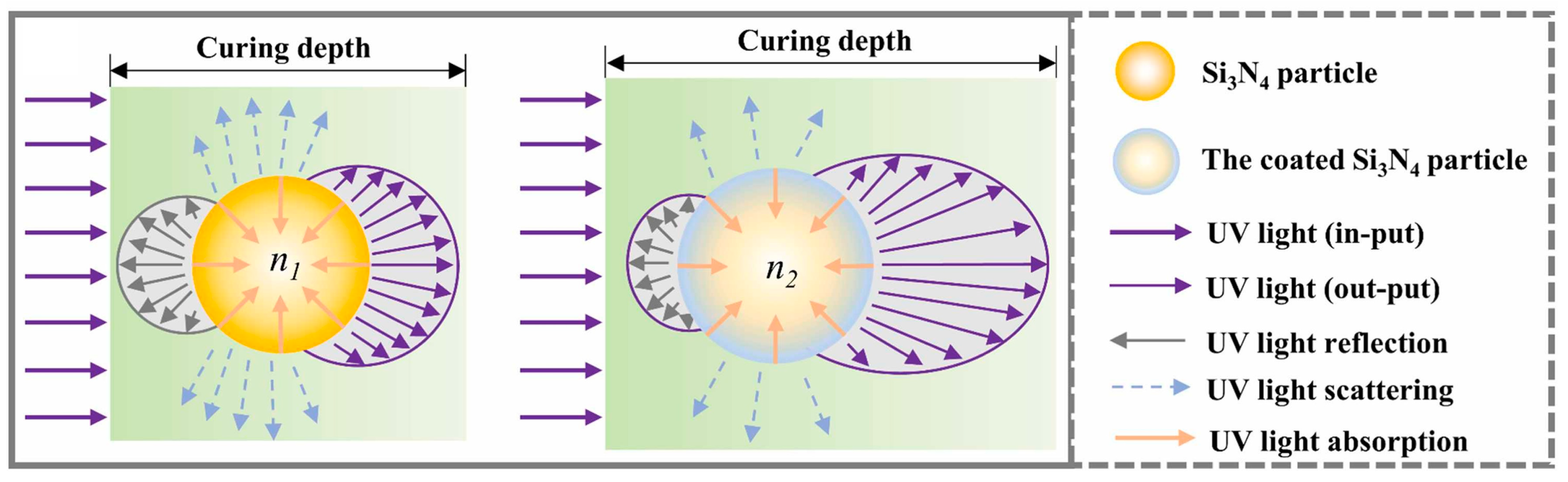

- The mechanisms of vat photopolymerization rely on UV light to selectively cure photopolymer resins mixed with ceramic powders. However, due to the refractive index difference between ceramics and resins, light scattering limits curing depth and resolution at high solid loadings, which reduces print fidelity. In addition, polymerization shrinkage induces internal stresses, which causes delamination or microcracks in green bodies during debinding and sintering.

- (2)

- This review highlights the interplay between material properties, printing parameters, and post-processing protocols. Key advancements include optimizing ceramic slurries through particle size gradation, refractive index matching, and surface modifications to mitigate challenges posed by the high refractive index of Si3N4 and UV absorption. Strategies such as bimodal particle distributions and high-refractive-index resins enhance the slurry stability, curing depth, and mechanical performance.

- (3)

- The integration of composite reinforcements, such as whiskers and fibers, can enhance the mechanical properties of VPP-based Si3N4 ceramics. PDCs also offer a unique pathway to ceramic fabrication via 3D printing techniques such as VPP, bypassing the need for sintering aids.

- (4)

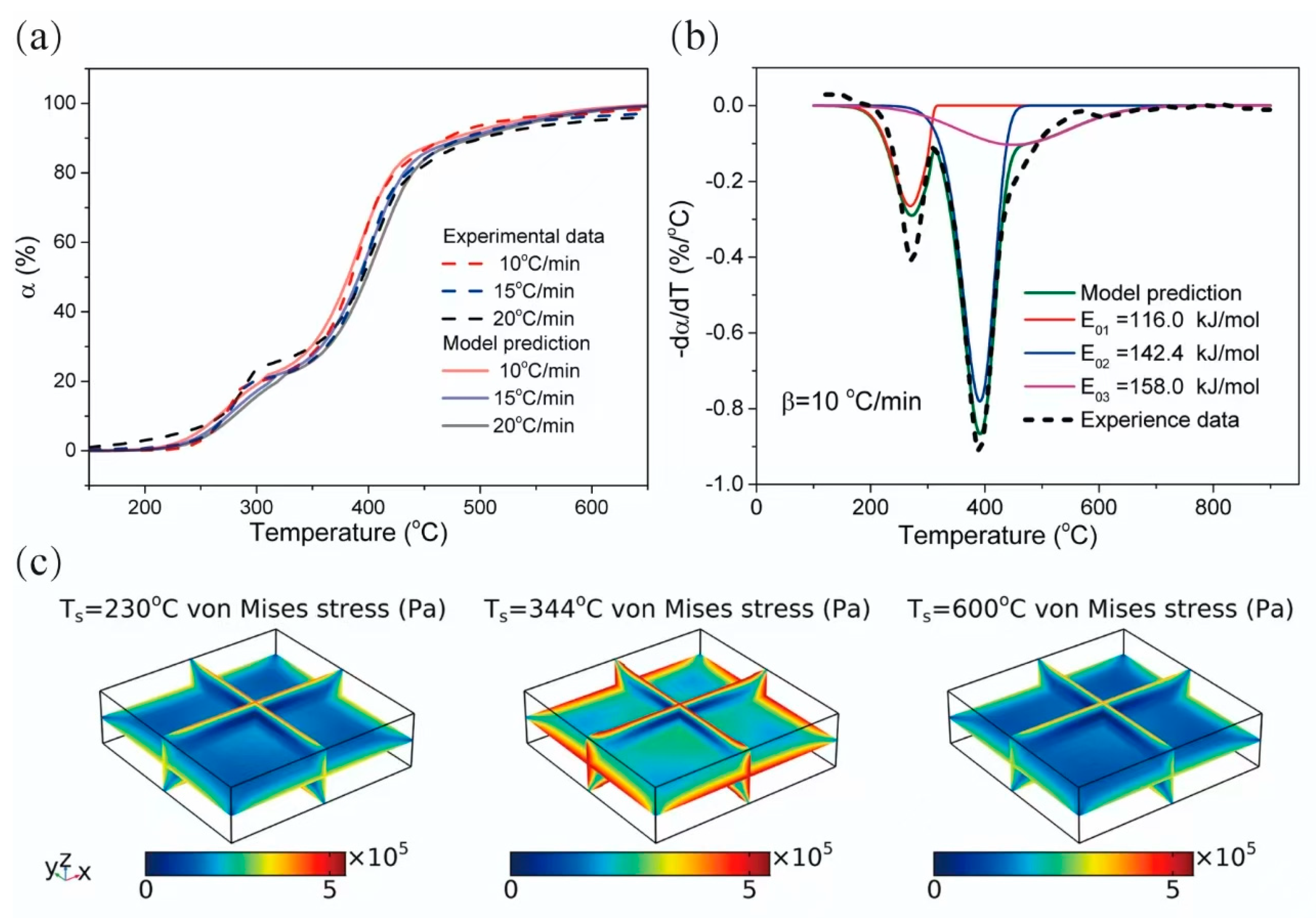

- Debinding and sintering processes are tailored to minimize defects, with innovations like nitrogen-hydrogen atmospheres and pressure-assisted sintering achieving a relative density of higher than 95%. The thermal debinding process of ceramics via VPP can be optimized by establishing predictive models. Future studies should couple the pyrolysis kinetics of cured resin with heat/mass transfer processes. Controlling the type and proportion of the sintering additive can improve the performance of VPP-printed Si3N4 ceramic structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Danzer, R. On the relationship between ceramic strength and the requirements for mechanical design. J. Eur. Ceram. Soc. 2014, 34, 3435–3460. [Google Scholar]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2011, 47, 535–552. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H.; Matovic, B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Mater. Sci. Eng. A 2010, 527, 1314–1338. [Google Scholar]

- Riley, F.L. Silicon Nitride and Related Materials. J. Am. Ceram. Soc. 2004, 83, 245–265. [Google Scholar]

- Heimann, R.B. Silicon Nitride, a Close to Ideal Ceramic Material for Medical Application. Ceramics 2021, 4, 208–223. [Google Scholar] [CrossRef]

- Zhang, C.; Ye, F.; Cheng, L.; Li, M.; Zhou, J.; Zhang, Q. Electromagnetic wave-transparent porous silicon nitride ceramic prepared by gel-casting combined with In-Situ nitridation reaction. J. Eur. Ceram. Soc. 2021, 41, 7620–7629. [Google Scholar] [CrossRef]

- Opila, E.J.; Nguyen, Q.N. Oxidation of Chemically-Vapor-Deposited Silicon Carbide in Carbon Dioxide. J. Am. Ceram. Soc. 2005, 81, 1949–1952. [Google Scholar]

- Duan, W.; Li, S.; Wang, G.; Dou, R.; Wang, L.; Zhang, Y.; Li, H.; Tan, H. Thermal conductivities and mechanical properties of AlN ceramics fabricated by three dimensional printing. J. Eur. Ceram. Soc. 2020, 40, 3535–3540. [Google Scholar]

- He, Z.X.; Mao, G.X.; Wu, J.M.; Zhang, G.Z.; Shi, Y.S. Effects of CuO additive on properties of high-performance (Ba0.85Ca0.15) (Ti0.9Zr0.1)O3 piezoceramics obtained by vat photopolymerization. Ceram. Int. 2023, 49, 38973–38981. [Google Scholar]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 200256. [Google Scholar]

- Kantaros, A.; Petrescu, F.I.T.; Ganetsos, T. From Stents to Smart Implants Employing Biomimetic Materials: The Impact of 4D Printing on Modern Healthcare. Biomimetics 2025, 10, 125. [Google Scholar] [CrossRef] [PubMed]

- Hagen, A.; Chisling, M.; House, K.; Katz, T.; Abelseth, L.; Fraser, I.; Bradley, S.; Kirsch, R.; Morris, J.; Giles, J.W.; et al. 3D Printing for Medical Applications: Current State of the Art and Perspectives during the COVID-19 Crisis. Surgeries 2021, 2, 244–259. [Google Scholar] [CrossRef]

- Zhu, C.H.; Li, T.Y.; Mohideen, M.M.; Hu, P.; Gupta, R.; Ramakrishna, S.; Liu, Y. Realization of Circular Economy of 3D Printed Plastics: A Review. Polymers 2021, 13, 744. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Douros, P.; Soulis, E.; Brachos, K.; Ganetsos, T.; Peppa, E.; Manta, E.; Alysandratou, E. 3D Imaging and Additive Manufacturing for Original Artifact Preservation Purposes: A Case Study from the Archaeological Museum of Alexandroupolis. Heritage 2025, 8, 80. [Google Scholar] [CrossRef]

- Hu, H.; Cao, X.X.; Zhang, T.; Chen, Z.F.; Xie, J.L. Three-Dimensional Printing Materials for Cultural Innovation Products of Historical Buildings. Buildings 2022, 12, 624. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Szwedziak, K.; Lusiak, T.; Babel, R.; Winiarski, P.; Podsedek, S.; Dolezal, P.; Niedbala, G. Wind Tunnel Experiments on an Aircraft Model Fabricated Using a 3D Printing Technique. J. Manuf. Mater. Process. 2022, 6, 12. [Google Scholar] [CrossRef]

- Qi, H.; He, C.; Zhang, P.; Han, W.; Guo, F.; Wu, F.; Du, M. Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties. Materials 2019, 12, 2717. [Google Scholar] [CrossRef]

- Wang, K.J.; Bao, C.G.; Zhang, C.Y.; Li, Y.H.; Liu, R.Z.; Xu, H.M.; Ma, H.Q.; Man, J.Y.; Song, S.C. Preparation of high-strength Si3N4 antenna window using selective laser sintering. Ceram. Int. 2022, 48, 2903–2911. [Google Scholar]

- Duan, W.Y.; Yin, X.W.; Cao, F.X.; Jia, Y.L.; Xie, Y.; Greil, P.; Travitzky, N. Absorption properties of twinned SiC nanowires reinforced Si3N4 composites fabricated by 3D-prining. Mater. Lett. 2015, 159, 257–260. [Google Scholar]

- Li, X.M.; Zhang, L.T.; Yin, X.W. Effect of chemical vapor infiltration of Si3N4 on the mechanical and dielectric properties of porous Si3N4 ceramic fabricated by a technique combining 3-D printing and pressureless sintering. Scr. Mater. 2012, 67, 380–383. [Google Scholar] [CrossRef]

- Tu, Y.; Bao, C.; Liu, R.; Li, S.; Xu, H. Influence of the dispersants and sintering process on the properties of Si2N2O ceramics via digital light processing. Ceram. Int. 2025, 51, 4318–4328. [Google Scholar] [CrossRef]

- Faria, M.S.; Alves, M.F.R.P.; Cintra, R.; Oliveira, F.J.; Fernandes, C.M.; Figueiredo, D.; Olhero, S.M. Influence of ink rheology and post processing in the structural performance of silicon nitride-based ceramics fabricated by robocasting. Ceram. Int. 2023, 49, 20968–20979. [Google Scholar] [CrossRef]

- Sainz, M.A.; Serena, S.; Belmonte, M.; Miranzo, P.; Osendi, M.I. Protein adsorption and In Vitro behavior of additively manufactured 3D-silicon nitride scaffolds intended for bone tissue engineering. Mater. Sci. Eng. C 2020, 115, 110734. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yang, Z.; Duan, X.; He, P.; Cai, D.; Jia, D.; Zhou, Y. Large-size Si3N4 ceramic fabricated by additive manufacturing using long-term stable hydrogel-based suspensions. Addit. Manuf. 2023, 69, 103534. [Google Scholar] [CrossRef]

- Furong, N.; Xiaole, Y.; Yuanbing, L.; Jinyu, G.; Peng, L.; Zhipeng, X.; Xianfeng, Y. Fused deposition modeling of Si3N4 ceramics: A cost-effective 3D-printing route for dense and high performance non-oxide ceramic materials. J. Eur. Ceram. Soc. 2022, 42, 7369–7376. [Google Scholar] [CrossRef]

- Zeng, X.; Sipaut, C.S.; Ismail, N.M.; Liu, Y.; Farm, Y.Y.; Peng, B.; He, J. Preparation of 3D printed silicon nitride bioceramics by microwave sintering. Sci. Rep. 2024, 14, 15824. [Google Scholar] [CrossRef]

- Zeng, X.; Sipaut, C.S.; Ismail, N.M.; Liu, Y.; Farm, Y.Y.; Peng, B.; He, J. Fabrication of 3D printed Si3N4 bioceramics with superior comprehensive performance through ZnO nanowires doping. Ceram. Int. 2024, 50, 34457–34466. [Google Scholar] [CrossRef]

- Aleni, A.H.; Kretzschmar, N.; Jansson, A.; Ituarte, I.F.; St-Pierre, L. 3D printing of dense and porous TiO2 structures. Ceram. Int. 2020, 46, 16725–16732. [Google Scholar] [CrossRef]

- Rosen, D.; Kim, S. Design and Manufacturing Implications of Additive Manufacturing. J. Mater. Eng. Perform. 2021, 30, 6426–6438. [Google Scholar] [CrossRef]

- Minasyan, T.; Liu, L.; Aghayan, M.; Kollo, L.; Kamboj, N.; Aydinyan, S.; Hussainova, I. A novel approach to fabricate Si3N4 by selective laser melting. Ceram. Int. 2018, 44, 13689–13694. [Google Scholar]

- Rasaki, S.A.; Xiong, D.; Xiong, S.; Su, F.; Idrees, M.; Chen, Z. Photopolymerization-based additive manufacturing of ceramics: A systematic review. J. Adv. Ceram. 2021, 10, 442–471. [Google Scholar]

- Tian, X.; Li, D.; Lian, Q.; Wang, L.; Lu, Z.; Huang, K.; Wang, F.; Liang, Q.; Zhang, H.; Meng, Z.; et al. Additive Manufacturing of Integrated Micro/Macro Structures Driven by Diversified Functions—30 years of Development of Additive Manufacturing in Xi’an Jiaotong University. Addit. Manuf. Front. 2024, 3, 200140. [Google Scholar]

- Han, Z.; Liu, S.; Qiu, K.; Liu, J.; Zou, R.; Wang, Y.; Zhao, J.; Liu, F.; Wang, Y.; Li, L. The enhanced ZrO2 produced by DLP via a reliable plasticizer and its dental application. J. Mech. Behav. Biomed. Mater. 2023, 141, 105751. [Google Scholar]

- Fan, L.S.; Huang, C.Z.; Liu, H.L.; Wang, Z.; Xu, L.H.; Huang, S.Q.; Qu, M.N.; Xu, Z.K.; Li, S.J.; Xu, S.L. The effect of ZrO2 particle size and solid loading on the rheological properties of highly thixotropic ZrO2 ceramic slurries applied in photopolymerization 3D printing. Ceram. Int. 2025, 51, 6669–6678. [Google Scholar]

- Li, Y.H.; Chen, Y.; Wang, M.L.; Li, L.; Wu, H.D.; He, F.P.; Wu, S.H. The cure performance of modified ZrO2 coated by paraffin via projection based stereolithography. Ceram. Int. 2019, 45, 4084–4088. [Google Scholar]

- Xu, X.; Zhou, S.; Wu, J.; Zhang, C.; Liu, X. Inter-particle interactions of alumina powders in UV-curable suspensions for DLP stereolithography and its effect on rheology, solid loading, and self-leveling behavior. J. Eur. Ceram. Soc. 2021, 41, 2763–2774. [Google Scholar]

- Wu, H.D.; Liu, W.; Lin, L.F.; Chen, Y.; Xu, Y.R.; Wu, S.H.; Sun, Z.Z.; An, D.; Wei, S.; Xie, Z.P. Realization of complex-shaped and high-performance alumina ceramic cutting tools via Vat photopolymerization based 3D printing: A novel surface modification strategy through coupling agents aluminic acid ester and silane coupling agent. J. Eur. Ceram. Soc. 2023, 43, 1051–1063. [Google Scholar]

- Zhang, J.; Yu, K.-B.; Wu, J.-M.; Ye, C.-S.; Zheng, W.; Liu, H.; Wen, S.-F.; Yan, C.-Z.; Shi, Y.-S. Effects of ZrSiO4 content on properties of SiO2-based ceramics prepared by digital light processing. Ceram. Int. 2023, 49, 9584–9591. [Google Scholar]

- Wang, Y.Y.; Wang, Z.Y.; Liu, S.H.; Qu, Z.B.; Han, Z.Q.; Liu, F.T.; Li, L. Additive manufacturing of silica ceramics from aqueous acrylamide based suspension. Ceram. Int. 2019, 45, 21328–21332. [Google Scholar]

- Li, M.; Huang, H.-L.; Wu, J.-M.; Wu, Y.-R.; Shi, Z.-A.; Zhang, J.-X.; Shi, Y.-S. Preparation and properties of Si3N4 ceramics via digital light processing using Si3N4 powder coated with Al2O3-Y2O3 sintering additives. Addit. Manuf. 2022, 53, 102713. [Google Scholar] [CrossRef]

- Sha, Q.; Xie, J.; Duan, Y.; Tang, W.; Zhang, J. Preparation and optimization of silicon nitride slurries for digital light processing. Int. J. Appl. Ceram. Technol. 2024, 22, e14888. [Google Scholar]

- Lin, L.; Wu, H.; Ni, P.; Chen, Y.; Huang, Z.; Li, Y.; Lin, K.; Sheng, P.; Wu, S. Additive manufacturing of complex-shaped and high-performance aluminum nitride-based components for thermal management. Addit. Manuf. 2022, 52, 102671. [Google Scholar]

- Wang, C.; Tang, J.; Wang, Z.; She, Y.; Huang, Z.; Yang, Y. Tuning the microstructure of porous SiCnw/SiC fabricated by vat photopolymerization 3D printing for electromagnetic wave absorption. Ceram. Int. 2024, 50, 7745–7757. [Google Scholar]

- Zhang, H.; Yang, Y.; Hu, K.H.; Liu, B.; Liu, M.; Huang, Z.R. Stereolithography-based additive manufacturing of lightweight and high-strength Cf/SiC ceramics. Addit. Manuf. 2020, 34, 101199. [Google Scholar]

- Shi, Z.A.; Wu, J.M.; Fang, Z.Q.; Shi, Y.S. Influence of high-temperature oxidation of SiC powders on curing properties of SiC slurry for digital light processing. J. Adv. Ceram. 2023, 12, 169–181. [Google Scholar]

- Li, X.; Zhang, J.; Duan, Y.; Liu, N.; Jiang, J.; Ma, R.; Xi, H.; Li, X. Rheology and Curability Characterization of Photosensitive Slurries for 3D Printing of Si3N4 Ceramics. Appl. Sci. 2020, 10, 6438. [Google Scholar] [CrossRef]

- de Hazan, Y.; Penner, D. SiC and SiOC ceramic articles produced by stereolithography of acrylate modified polycarbosilane systems. J. Eur. Ceram. Soc. 2017, 37, 5205–5212. [Google Scholar]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar]

- Griffith, M.L.; Halloran, J.W. Freeform Fabrication of Ceramics via Stereolithography. J. Am. Ceram. Soc. 2005, 79, 2601–2608. [Google Scholar]

- Miao, W.-J.; Wang, S.-Q.; Wang, Z.-H.; Wu, F.-B.; Zhang, Y.-Z.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants 2025, 13, 112. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar]

- Tan, B.; Dou, J.; Wen, Y.; Duan, B.; Mo, H.; Wei, Z.; Zhang, J.; Pan, Y.; Ding, X.; Liu, N. 3D Printing for Explosives and Propellants Applications. Addit. Manuf. Front. 2024, 3, 200151. [Google Scholar]

- Billiet, T.; Vandenhaute, M.; Schelfhout, J.; Van Vlierberghe, S.; Dubruel, P. A review of trends and limitations in hydrogel-rapid prototyping for tissue engineering. Biomaterials 2012, 33, 6020–6041. [Google Scholar] [PubMed]

- Pan, Y.Y.; Zhou, C.; Chen, Y. A Fast Mask Projection Stereolithography Process for Fabricating Digital Models in Minutes. J. Manuf. Sci. Eng. 2012, 134, 051011. [Google Scholar]

- Ge, Q.; Li, Z.Q.; Wang, Z.L.; Kowsari, K.; Zhang, W.; He, X.N.; Zhou, J.L.; Fang, N.X. Projection micro stereolithography based 3D printing and its applications. Int. J. Extrem. Manuf. 2020, 2, 022004. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Mamatha, S.; Biswas, P.; Johnson, R. Digital light processing of ceramics: An overview on process, materials and challenges. Prog. Addit. Manuf. 2022, 8, 1083–1102. [Google Scholar]

- Zhou, W.; Li, D.; Wang, H. A novel aqueous ceramic suspension for ceramic stereolithography. Rapid Prototyp. J. 2010, 16, 29–35. [Google Scholar]

- Lemma, E.D.; Spagnolo, B.; De Vittorio, M.; Pisanello, F. Studying Cell Mechanobiology in 3D: The Two-Photon Lithography Approach. Trends Biotechnol. 2019, 37, 358–372. [Google Scholar]

- Kim, J.A.; Wales, D.J.; Thompson, A.J.; Yang, G.Z. Fiber-Optic SERS Probes Fabricated Using Two-Photon Polymerization For Rapid Detection of Bacteria. Adv. Opt. Mater. 2020, 8, 1901934. [Google Scholar]

- Marschner, D.E.; Pagliano, S.; Huang, P.-H.; Niklaus, F. A methodology for two-photon polymerization micro 3D printing of objects with long overhanging structures. Addit. Manuf. 2023, 66, 103474. [Google Scholar]

- Li, H.; Shi, X.B.; Liu, X.G.; Li, X. Synthesis of novel, visible-light driven S,N-doped NaTaO3 catalysts with high photocatalytic activity. Appl. Surf. Sci. 2020, 508, 145306. [Google Scholar]

- Fiedor, P.; Pilch, M.; Szymaszek, P.; Chachaj-Brekiesz, A.; Galek, M.; Ortyl, J. Photochemical Study of a New Bimolecular Photoinitiating System for Vat Photopolymerization 3D Printing Techniques under Visible Light. Catalysts 2020, 10, 284. [Google Scholar] [CrossRef]

- Gao, X.; Chen, J.; Chen, X.; Wang, W.; Li, Z.; He, R. How to Improve the Curing Ability during the Vat Photopolymerization 3D Printing of Non-Oxide Ceramics: A Review. Materials 2024, 17, 2626. [Google Scholar] [CrossRef] [PubMed]

- Griffith, M.L.; Halloran, J.W. Scattering of ultraviolet radiation in turbid suspensions. J. Appl. Phys. 1997, 81, 2538–2546. [Google Scholar]

- Gentry, S.P.; Halloran, J.W. Depth and width of cured lines in photopolymerizable ceramic suspensions. J. Eur. Ceram. Soc. 2013, 33, 1981–1988. [Google Scholar]

- Bürger, R.; Wendland, W.L. Sedimentation and suspension flows: Historical perspective and some recent developments. J. Eng. Math. 2001, 41, 101–116. [Google Scholar] [CrossRef]

- Jin, J.; Ni, M.; Wang, S.H. Structure and Properties Study of Porous Silicon Carbide Pomposite Based on SLA. Adv. Mater. Res. 2011, 194–196, 1590–1593. [Google Scholar]

- Huang, C.; Zheng, L.; Tian, Z.; Shi, L.; Li, B. A warpage-free Si3N4 slurry strategy for vat photopolymerization. J. Adv. Ceram. 2025, 14, 9221016. [Google Scholar] [CrossRef]

- Ding, G.; He, R.; Zhang, K.; Xie, C.; Wang, M.; Yang, Y.; Fang, D. Stereolithography-based additive manufacturing of gray-colored SiC ceramic green body. J. Am. Ceram. Soc. 2019, 102, 7198–7209. [Google Scholar]

- Liu, Y.; Zhan, L.; Wen, L.; Cheng, L.; He, Y.; Xu, B.; Wu, Q.; Liu, S. Effects of particle size and color on photocuring performance of Si3N4 ceramic slurry by stereolithography. J. Eur. Ceram. Soc. 2021, 41, 2386–2394. [Google Scholar]

- Huang, S.; Li, Y.; Yang, P.; Sheng, P.; Ou, J.; Ning, T.; Wu, S. Cure behaviour and mechanical properties of Si3N4 ceramics with bimodal particle size distribution prepared using digital light processing. Ceram. Int. 2023, 49, 12166–12172. [Google Scholar]

- Zhao, J.; Chu, W.; Song, T.; Bi, L.; Liu, J.; Han, Z.; Wang, Y.; Zhou, Q.; Li, L. Digital light processing of high-strength Si3N4 ceramics: Role of particle grading on slurries curing and mechanical properties. Ceram. Int. 2024, 50, 22722–22732. [Google Scholar]

- De Pablos, A.; Osendi, M.I.; Miranzo, P. Correlation between microstructure and toughness of hot pressed Si3N4 ceramics seeded with β-Si3N4 particles. Ceram. Int. 2003, 29, 757–764. [Google Scholar]

- Hirosaki, N.; Akimune, Y.; Mitomo, M. Effect of Grain Growth of β-Silicon Nitride on Strength, Weibull Modulus, and Fracture Toughness. J. Am. Ceram. Soc. 1993, 76, 1892–1894. [Google Scholar]

- Wang, X.; Duan, W.; Li, S.; Huang, Z.; Liu, B.; Wang, G.; Chen, F. Preparation of high-strength Si3N4 ceramics via vat photopolymerization: A bi-phase particle size gradation strategy. J. Am. Ceram. Soc. 2024, 108, e20229. [Google Scholar] [CrossRef]

- Mao, G.-X.; Wu, J.-M.; Tian, C.; Liu, C.-L.; Lin, X.; Wang, F.; Xu, H.-S.; Shi, Y.-S. Improved mechanical properties of porous Si3N4 ceramics strengthened by β-Si3N4 seeds fabricated by vat photopolymerization. Ceram. Int. 2024, 50, 49058–49065. [Google Scholar] [CrossRef]

- Li, Y.; Sheng, P.; Lin, L.; Wang, L.; Lu, D.; Lin, K.; Wu, H.; Wu, S. Vat Photopolymerization Versus Conventional Colloidal Processing Methods in Structural Ceramics: Progress, Challenges, and Future Perspectives. Addit. Manuf. Front. 2024, 3, 200110. [Google Scholar]

- Chung, K.; Nenov, N.S.; Park, S.; Park, S.; Bae, C.-J. Design of Optimal Organic Materials System for Ceramic Suspension-Based Additive Manufacturing. Adv. Eng. Mater. 2019, 21, 1900445. [Google Scholar]

- Shen, M.; Fu, R.; Liu, H.; Liu, Y.; Hu, Y.; Zhang, Y.; Liu, X.; Li, M.; Zhao, Z. Photosensitive Si3N4 slurry with combined benefits of low viscosity and large cured depth for digital light processing 3D printing. J. Eur. Ceram. Soc. 2023, 43, 881–888. [Google Scholar] [CrossRef]

- Lin, L.; Wu, H.; Huang, Z.; Wu, S. Effect of monomers with different functionalities on stability, rheology, and curing behavior of ceramic suspensions. Mater. Chem. Phys. 2022, 275, 125243. [Google Scholar] [CrossRef]

- Wu, X.; Xu, C.; Zhang, Z. Preparation and optimization of Si3N4 ceramic slurry for low-cost LCD mask stereolithography. Ceram. Int. 2021, 47, 9400–9408. [Google Scholar] [CrossRef]

- Wu, X.; Xu, C.; Zhang, Z. Development and analysis of a high refractive index liquid phase Si3N4 slurry for mask stereolithography. Ceram. Int. 2022, 48, 120–129. [Google Scholar] [CrossRef]

- Zou, W.; Yang, P.; Lin, L.; Li, Y.; Wu, S. Improving cure performance of Si3N4 suspension with a high refractive index resin for stereolithography-based additive manufacturing. Ceram. Int. 2022, 48, 12569–12577. [Google Scholar] [CrossRef]

- Zhou, F.-L.; Wu, J.-M.; Tian, C.; Li, W.-K.; Guo, L.; Qin, X.-Y.; Lin, X.; Wang, F.; Xu, H.-S.; Shi, Y.-S. Effect of thermosetting resin coating modification on the properties of Si3N4 ceramics prepared by vat photopolymerization. J. Eur. Ceram. Soc. 2024, 44, 7465–7473. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, W.; Zhao, C.; Wang, X.; Jin, B.; Hu, C.; Jia, Q.; Li, S.; Liu, B.; Wang, G.; et al. Mechanical and dielectric properties of Si3N4/β-SiAlON composite ceramics fabricated by vat photopolymerization 3D printing technology. Ceram. Int. 2024, 50, 32549–32560. [Google Scholar] [CrossRef]

- Huang, R.-J.; Jiang, Q.-G.; Wu, H.-D.; Li, Y.-H.; Liu, W.-Y.; Lu, X.-X.; Wu, S.-H. Fabrication of complex shaped ceramic parts with surface-oxidized Si3N4 powder via digital light processing based stereolithography method. Ceram. Int. 2019, 45, 5158–5162. [Google Scholar] [CrossRef]

- Li, Y.; Huang, S.; Wang, S.; Zhang, X.; Wang, Y.; Lu, B.; Luo, Y.; He, F.; Liu, W.; Wu, S. Research on the effects of surface modification of ceramic powder on cure performance during digital light processing (DLP). Ceram. Int. 2022, 48, 3652–3658. [Google Scholar] [CrossRef]

- Lu, D.; Lin, K.; He, X.; Gao, Y.; Huang, N.; Lin, L.; Wu, S. A synergistic dispersion strategy for high volume fraction slurry and high performance silicon nitride sintered components in digital light processing (DLP)-based vat photopolymerization. Addit. Manuf. 2024, 86, 104182. [Google Scholar]

- Li, Y.; Nie, G.; Sheng, P.; Wang, L.; Chen, X.; Liu, Y.; Deng, X.; Wu, S. Effects of ceramic powder coating treatment on the curing behavior, mechanical properties, and microstructure of 3D printed silicon nitride ceramics. J. Eur. Ceram. Soc. 2025, 45, 116952. [Google Scholar] [CrossRef]

- Wang, Q.-W.; Shi, Z.-A.; Guo, L.; Cai, W.-H.; Wu, J.-M.; Tian, C.; Lin, X.; Xu, H.-S.; Wang, F.; Shi, Y.-S. Effect of Al2O3 coating on the properties of Si3N4 ceramics prepared by vat photopolymerization. Ceram. Int. 2024, 50, 49041–49050. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, L.; Li, H.; Li, Q.; Shi, Y.; Liu, F.; Wu, Q.; Liu, S. Formation mechanism of stereolithography of Si3N4 slurry using silane coupling agent as modifier and dispersant. Ceram. Int. 2020, 46, 14583–14590. [Google Scholar] [CrossRef]

- Yang, P.; Sun, Z.; Huang, S.; Ou, J.; Jiang, Q.; Li, D.; Wu, S. Digital light processing 3D printing of surface-oxidized Si3N4 coated by silane coupling agent. J. Asian Ceram. Soc. 2022, 10, 69–82. [Google Scholar] [CrossRef]

- Sun, N.; Wang, T.; Du, Y.; Ma, X.; Xin, W.; Dang, H.; Xie, X.; Wei, T.; Li, Q. Effect of TMAH as a modifier on the performance of Si3N4 stereolithography pastes. Ceram. Int. 2024, 50, 15502–15512. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R. Effect of ultrasonic nanocrystal surface modification temperature: Microstructural evolution, mechanical properties and tribological behavior of silicon carbide manufactured by additive manufacturing. Surf. Coat. Technol. 2021, 425, 127688. [Google Scholar] [CrossRef]

- Wang, Q.-W.; Wu, J.-M.; Tian, C.; Shi, Z.-A.; Liu, C.-L.; Lin, X.; Xu, H.-S.; Wang, F.; Shi, Y.-S. Preparation and properties of Si3N4 ceramics via vat photopolymerization using Si3N4 powders coated with bowl-like boehmite. Addit. Manuf. 2024, 84, 104137. [Google Scholar]

- Li, W.-K.; Zhang, R.-Z.; Wu, J.-M.; Guo, L.; Cai, W.-H.; Lin, X.; Xu, H.-S.; Wang, F.; Shi, Y.-S. Optimizing AlN hydrolysis process to fabricate coated modified powders for improving the properties of Si3N4/SiAlON ceramics prepared by Vat Photopolymerization. Addit. Manuf. 2024, 94, 104460. [Google Scholar]

- Li, T.T.; Chen, Y.Y.; Hu, X.Y.; Li, Y.B.; Wang, L.F. Exploiting negative Poisson’s ratio to design 3D-printed composites with enhanced mechanical properties. Mater. Des. 2018, 142, 247–258. [Google Scholar] [CrossRef]

- Xiao, S.; Mei, H.; Han, D.; Yuan, W.; Cheng, L. Porous (SiCw-Si3N4w)/(Si3N4-SiC) composite with enhanced mechanical performance fabricated by 3D printing. Ceram. Int. 2018, 44, 14122–14127. [Google Scholar]

- Cheng, Z.; Ye, F.; Liu, Y.; Qiao, T.; Li, J.; Qin, H.; Cheng, L.; Zhang, L. Mechanical and dielectric properties of porous and wave-transparent Si3N4-Si3N4 composite ceramics fabricated by 3D printing combined with chemical vapor infiltration. J. Adv. Ceram. 2019, 8, 399–407. [Google Scholar]

- Mao, G.-X.; Wu, J.-M.; Tian, C.; Liu, C.-L.; Guo, L.; Cai, W.-H.; Zhang, Y.-Z.; Lin, X.; Wang, F.; Xu, H.-S.; et al. ZrO2 reinforced porous Si3N4-based ceramics with improved mechanical properties fabricated via vat photopolymerization (VPP). Addit. Manuf. 2024, 91, 104327. [Google Scholar] [CrossRef]

- Li, W.-K.; Wu, J.-M.; Tian, C.; Zhang, R.-Z.; Zhou, F.-L.; Lin, X.; Wang, F.; Xu, H.-S.; Shi, Y.-S. Effect of AlN content on microstructure and properties of SiAlON ceramics prepared via vat photopolymerization. Ceram. Int. 2024, 50, 24347–24357. [Google Scholar]

- Qin, Y.; Zhao, C.; Huang, Y.; Dong, J.; Yang, X.; Shi, C. Preparation of porous β-Si3N4/Si5AlON7 composite ceramics for digital light processing and study of mechanical and dielectric properties. Ceram. Int. 2024, 50, 41299–41306. [Google Scholar]

- Vidakis, N.; Petousis, M.; Michailidis, N.; David, C.; Saltas, V.; Sagris, D.; Spiridaki, M.; Argyros, A.; Mountakis, N.; Papadakis, V. Interpretation of the optimization course of Silicon Nitride nano-powder content in biomedical resins for vat photopolymerization additive manufacturing. Ceram. Int. 2024, 50, 14919–14935. [Google Scholar]

- Wang, X.; Li, S.; Duan, W.; Li, Y.; Liu, B.; Wang, G.; Cui, C.; Li, W.; Chen, F. Preparation of Cf/Si3N4 composites based on vat photopolymerization combined with precursor infiltration and pyrolysis. Int. J. Appl. Ceram. Technol. 2025, 22, e14956. [Google Scholar]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Huang, C.; Hu, Y. Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. J. Eur. Ceram. Soc. 2020, 40, 5797–5809. [Google Scholar]

- Wang, X.; Duan, W.; Li, S.; Liu, B.; Wang, G.; Chen, F. Preparation of Si3N4f/Si3N4 wave-transparent composites by vat photopolymerization combined with chemical vapor infiltration. Addit. Manuf. 2024, 95, 104540. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, X.; Zhang, L.; Zheng, L.; Wang, R.; Wu, L.; Weng, Z. Preparation of high thermal conductivity vat photopolymerization used UV-curable resin synergistically enhanced by silicon nitride and boron nitride. Ceram. Int. 2024, 50, 23441–23450. [Google Scholar]

- Eckel, Z.C.; Zhou, C.Y.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. 3D PRINTING Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar]

- Bernardo, E.; Fiocco, L.; Parcianello, G.; Storti, E.; Colombo, P. Advanced Ceramics from Preceramic Polymers Modified at the Nano-Scale: A Review. Materials 2014, 7, 1927–1956. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Liu, D.Q.; Cheng, H.F.; Jia, Y.; Zhou, S.; Zu, M. Carbon nanotubes as light absorbers in digital light processing three-dimensional printing of SiCN ceramics from preceramic polysilazane. Ceram. Int. 2020, 46, 19393–19400. [Google Scholar]

- O’Masta, M.R.; Stonkevitch, E.; Porter, K.A.; Bui, P.P.; Eckel, Z.C.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramic matrix composites. J. Am. Ceram. Soc. 2020, 103, 6712–6723. [Google Scholar]

- Huang, M.; Wu, Y.; Ou, J.; Huang, Y.; Wang, J.; Wu, S. 3D-printing of polymer-derived SiCN ceramic matrix composites by digital light processing. J. Eur. Ceram. Soc. 2022, 42, 5476–5483. [Google Scholar]

- Li, S.; Zhang, Y.; Zhao, T.; Han, W.; Duan, W.; Wang, L.; Dou, R.; Wang, G. Additive manufacturing of SiBCN/Si3N4w composites from preceramic polymers by digital light processing. RSC Adv. 2020, 10, 5681–5689. [Google Scholar]

- Wang, M.; Xie, C.; He, R.; Ding, G.; Zhang, K.; Wang, G.; Fang, D. Polymer-derived silicon nitride ceramics by digital light processing based additive manufacturing. J. Am. Ceram. Soc. 2019, 102, 5117–5126. [Google Scholar]

- Wang, K.; Qiu, M.B.; Jiao, C.; Gu, J.J.; Xie, D.Q.; Wang, C.J.; Tang, X.B.; Wei, Z.; Shen, L.D. Study on defect-free endebinding green body of ceramic formed by DLP technology. Ceram. Int. 2020, 46, 2438–2446. [Google Scholar]

- Li, H.; Liu, Y.S.; Liu, Y.S.; Zeng, Q.F.; Hu, K.H.; Lu, Z.G.; Liang, J.J. Effect of debinding temperature under an argon atmosphere on the microstructure and properties of 3D-printed alumina ceramics. Mater. Charact. 2020, 168, 110548. [Google Scholar]

- Coats, A.; Redfern, j. Kinetic Parameters from Thermogravimetric Data. Nature 1964, 201, 68–69. [Google Scholar]

- Yan, X.K.; Wang, C.; Xiong, W.; Hou, T.W.; Hao, L.; Tang, D.N. Thermal debinding mass transfer mechanism and dynamics of copper green parts fabricated by an innovative 3D printing method. RSC Adv. 2018, 8, 10355–10360. [Google Scholar]

- Lin, Y.; Chen, Z.H.; Dai, M.Q.; Fang, S.W.; Liao, Y.F.; Yu, Z.S.; Ma, X.Q. Co-pyrolysis kinetics of sewage sludge and bagasse using multiple normal distributed activation energy model (M-DAEM). Bioresour. Technol. 2018, 259, 173–180. [Google Scholar] [PubMed]

- Li, J.; Zhang, C.F.; Yin, R.M.; Zhang, W.H. DAEM kinetics analysis and finite element simulation of thermal debinding process for a gelcast SiAlON green body. Ceram. Int. 2019, 45, 8166–8174. [Google Scholar]

- Cui, M.M.; Wang, T.; Zhao, Y.; Zhang, Z.; Wang, X.; Hou, X.; Sun, W.X.; Liu, H.X. Research on crack mechanism and kinetic model of alumina ceramic in the degreasing stage based on stereolithography. Int. J. Appl. Ceram. Technol. 2023, 20, 3419–3435. [Google Scholar]

- Li, J.; Huang, J.D.; Yin, R.M. Multistage kinetic analysis of DMAA/MBAM polymer removal from gelcast ceramic parts using a multi-stage parallel reaction model and model-free method. RSC Adv. 2019, 9, 27305–27317. [Google Scholar] [PubMed]

- Li, J.; Huang, J.D. Thermal Debinding Kinetics of Gelcast Ceramic Parts via a Modified Independent Parallel Reaction Model in Comparison with the Multiple Normally Distributed Activation Energy Model. Acs Omega 2022, 7, 20219–20228. [Google Scholar]

- Bhandari, S.; Manière, C.; Sedona, F.; De Bona, E.; Sglavo, V.M.; Colombo, P.; Fambri, L.; Biesuz, M.; Franchin, G. Ultra-rapid debinding and sintering of additively manufactured ceramics by ultrafast high-temperature sintering. J. Eur. Ceram. Soc. 2024, 44, 328–340. [Google Scholar]

- Gu, J.H.; Qiao, L.; Cai, W.; Zheng, J.W.; Ying, Y.; Yu, J.; Li, W.C.; Che, S.L. Effects of heating rate in thermal debinding on the microstructure and property of sintered NiCuZn ferrite prepared by powder injection molding. J. Magn. Magn. Mater. 2021, 530, 167931. [Google Scholar]

- Goswami, A.; Srivastava, G.; Umarji, A.M.; Madras, G. Thermal degradation kinetics of poly(trimethylol propane triacrylate)/poly(hexane diol diacrylate) interpenetrating polymer network. Thermochim. Acta 2012, 547, 53–61. [Google Scholar]

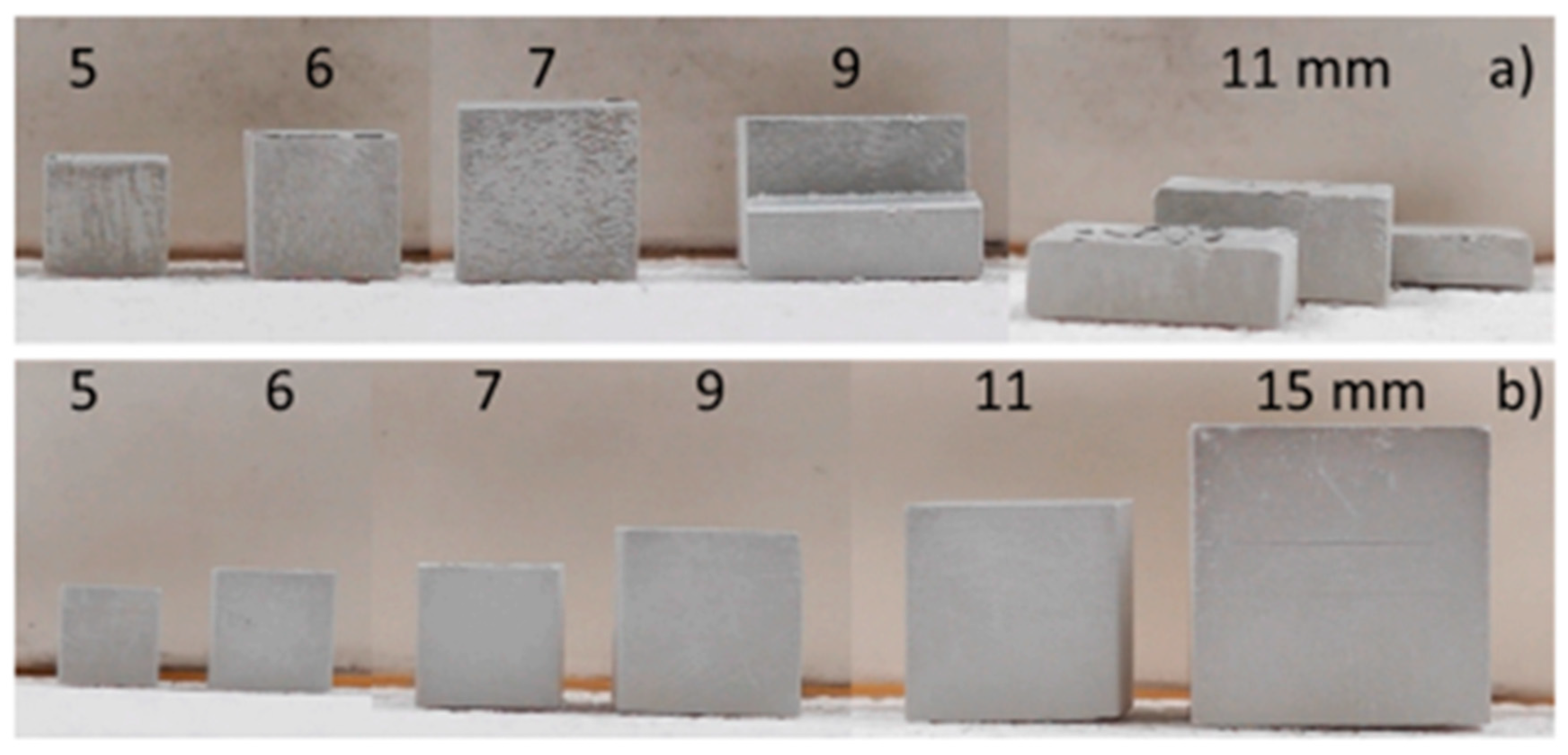

- Marie, T.; Du, Z.; Gan, C.L.; Marinel, S.; Sridharan, V.S.; Manière, C. Debinding and sintering optimization of stereolithography based silicon nitride parts for attaining centimetric wall-thickness shapes. J. Eur. Ceram. Soc. 2025, 45, 116911. [Google Scholar]

- Shen, M.; Fu, R.; Zhang, Y.; Sun, K.; Xu, W.; Jiang, Y.; Zhao, Z.; Liu, M. Defect-free Si3N4 ceramics by vat photopolymerization 3D printing with nitrogen-hydrogen debinding atmosphere. Ceram. Int. 2024, 50, 42709–42720. [Google Scholar]

- Jin, B.; Bian, Y.; Shen, Y.; Xing, B.; Li, M.; Zhao, Z. Improved Flexural Strength in Digital-Light-Processing-Printed Si3N4 Ceramics by Removing Carbon Residue. J. Ceram. Sci. Technol. 2022, 13, 99–106. [Google Scholar]

- Wang, X.; Duan, W.; Chen, Z.; Li, S.; Liu, B.; Wang, G.; Chen, F. Uniform rate debinding for Si3N4 vat photopolymerization 3D printing green parts using a specific-stage stepwise heating process. Addit. Manuf. 2024, 84, 104119. [Google Scholar] [CrossRef]

- Kim, J.; Gal, C.W.; Choi, Y.J.; Park, H.; Yoon, S.Y.; Yun, H.S. Effect of non-reactive diluent on defect-free debinding process of 3D printed ceramics. Addit. Manuf. 2023, 67, 103475. [Google Scholar] [CrossRef]

- Bae, C.J.; Halloran, J.W. Influence of Residual Monomer on Cracking in Ceramics Fabricated by Stereolithography. Int. J. Appl. Ceram. Technol. 2011, 8, 1289–1295. [Google Scholar] [CrossRef]

- Hernandez-Cuevas, G.; Mendoza, J.R.L.; García-Casillas, P.E.; González, C.A.R.; Hernandez-Paz, J.F.; Herrera-Pérez, G.; Fuentes-Cobas, L.; de la Torre, S.D.; Raymond-Herrera, O.; Camacho-Montes, H. Effect of the sintering technique on the ferroelectric and d33 piezoelectric coefficients of Bi0.5(Na0.84K0.16)0.5TiO3 ceramic. J. Adv. Ceram. 2019, 8, 278–288. [Google Scholar] [CrossRef]

- Liu, Y.; Zhan, L.; He, Y.; Zhang, J.; Hu, J.; Cheng, L.; Wu, Q.; Liu, S. Stereolithographical fabrication of dense Si3N4 ceramics by slurry optimization and pressure sintering. Ceram. Int. 2020, 46, 2063–2071. [Google Scholar] [CrossRef]

- Schwarzer-Fischer, E.; Zschippang, E.; Kunz, W.; Koplin, C.; Löw, Y.M.; Scheithauer, U.; Michaelis, A. CerAMfacturing of silicon nitride by using lithography-based ceramic vat photopolymerization (CerAM VPP). J. Eur. Ceram. Soc. 2023, 43, 321–331. [Google Scholar] [CrossRef]

- Tian, C.; Wang, Q.-W.; Wu, J.-M.; Liu, C.-L.; Shi, Z.-A.; Huang, H.-L.; Lin, X.; Shi, Y.-S. Microstructure and properties of porous Si3N4 ceramics fabricated by digital light processing combined with spark plasma sintering. Ceram. Int. 2023, 49, 40814–40820. [Google Scholar] [CrossRef]

- Wang, L.; Wang, L.; Hao, Z.; Tang, W.; Dou, R. Microstructure and properties of silicon nitride ceramics fabricated by vat photopolymerization in combination with pressureless sintering. Ceram. Int. 2024, 50, 10485–10496. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Liu, B.; Li, S.; Duan, W.; Wang, G.; Chen, F. Preparation of Si3N4 ceramic based on digital light processing 3D printing and precursor infiltration and pyrolysis. Int. J. Appl. Ceram. Technol. 2022, 20, 1017–1027. [Google Scholar] [CrossRef]

- Chen, R.; Duan, W.; Wang, G.; Liu, B.; Zhao, Y.; Li, S. Preparation of broadband transparent Si3N4-SiO2 ceramics by digital light processing (DLP) 3D printing technology. J. Eur. Ceram. Soc. 2021, 41, 5495–5504. [Google Scholar] [CrossRef]

- Dong, X.; Wu, J.; Zhou, Q.; Wang, W.; Zhang, X.; Zhang, L.; He, R. Mechanical and dielectric properties of Si3N4-SiO2 ceramics prepared by digital light processing based 3D printing and oxidation sintering. Ceram. Int. 2023, 49, 29699–29708. [Google Scholar]

- Safronova, N.A.; Kryzhanovska, O.S.; Dobrotvorska, M.V.; Balabanov, A.E.; Yavetskiy, R.P.; Parkhomenko, S.V.; Brodskii, R.Y.; Baumer, V.N.; Kosyanov, D.Y.; Shichalin, O.O.; et al. Influence of sintering temperature on structural and optical properties of Y2O3-MgO composite SPS ceramics. Ceram. Int. 2020, 46, 6537–6543. [Google Scholar]

- Chen, Z.; Duan, W.; Zhang, D.; Wang, X.; Li, T.; Zhao, C.; Li, Q.; Li, S.; Liu, B.; Wang, G. Fabrication of broadband wave-transparent Si3N4 ceramics with octet-truss lattice structure by vat photopolymerization 3D printing technology. J. Eur. Ceram. Soc. 2024, 44, 2026–2036. [Google Scholar]

- Duan, W.; Fan, Z.; Wang, H.; Zhang, J.; Qiao, T.; Yin, X. Electromagnetic interference shielding and mechanical properties of Si3N4–SiOC composites fabricated by 3D-printing combined with polymer infiltration and pyrolysis. J. Mater. Res. 2017, 32, 3394–3401. [Google Scholar]

- Bordia, R.K.; Kang, S.J.L.; Olevsky, E.A. Current understanding and future research directions at the onset of the next century of sintering science and technology. J. Am. Ceram. Soc. 2017, 100, 2314–2352. [Google Scholar] [CrossRef]

- Li, Y.; Wu, H.; Chen, X.; Huang, P.; Huang, Z.; Wu, S. Vat photopolymerization of complex-shaped silicon nitride ceramics with high mechanical and thermal performance by optimization sintering aids and kinetics. J. Eur. Ceram. Soc. 2025, 45, 117014. [Google Scholar]

- German, R.; Suri, P.; Park, S. Review: Liquid phase sintering. J. Mater. Sci. 2009, 44, 1–39. [Google Scholar]

- Liu, W.; Tong, W.X.; Lu, X.X.; Wu, S.H. Effects of different types of rare earth oxide additives on the properties of silicon nitride ceramic substrates. Ceram. Int. 2019, 45, 12436–12442. [Google Scholar]

- Qin, Q.; Han, L.; Xiong, G.; Guo, Z.; Huang, J.; Zhang, Y.; Shen, Z.; Ge, C. Impact of Sintering Aid Type and Content on the Mechanical Properties of Digital Light Processing 3D-Printed Si3N4 Ceramics. Materials 2024, 17, 5830. [Google Scholar] [CrossRef]

- Rao, W.-d.; Liu, Y.; Cheng, L.-j.; Liu, S.-j. Densification mechanism of stereolithographical dense Si3N4 ceramics with CeO2 as sintering additive by field assisted sintering. J. Cent. South Univ. 2021, 28, 1233–1243. [Google Scholar]

- Zhou, Q.; Wang, Y.; Han, Z.; Liu, J.; Zhao, J.; Chu, W.; Zhao, Z.; Li, J.; Cheng, Z.; Li, L.; et al. Effect of La2O3-MgO ratio on the microstructure and properties of Si3N4 ceramics fabricated via digital light processing. Ceram. Int. 2024, 50, 51289–51296. [Google Scholar]

- Yang, Y.; Yang, Z.; He, P.; Duan, X.; Cai, D.; Jia, D.; Zhou, Y. Si3N4 ceramics with embedded microchannel structures fabricated by high-precision additive manufacturing based on computational fluid dynamics simulations. Addit. Manuf. 2022, 60, 103271. [Google Scholar]

- Zanocco, M.; Boschetto, F.; Zhu, W.; Marin, E.; McEntire, B.J.; Bal, B.S.; Adachi, T.; Yamamoto, T.; Kanamura, N.; Ohgitani, E.; et al. 3D-additive deposition of an antibacterial and osteogenic silicon nitride coating on orthopaedic titanium substrate. J. Mech. Behav. Biomed. Mater. 2020, 103, 103557. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Wang, C.; Chen, Z.; Qiu, Z.; Chu, C.; Cheng, Y.; Zeng, T.; Sun, A. Additive manufacturing of broadband electromagnetic wave absorbing materials: Polymer-derived SiC/Si3N4 composites with triply periodic minimal surface meta-structure. Chem. Eng. J. 2024, 483, 149185. [Google Scholar]

- Altun, A.A.; Prochaska, T.; Konegger, T.; Schwentenwein, M. Dense, Strong, and Precise Silicon Nitride-Based Ceramic Parts by Lithography-Based Ceramic Manufacturing. Appl. Sci. 2020, 10, 996. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, L.Y.; Yuan, J.; Guo, H.; Wang, H.; Ye, P.; Du, Z.; Zhao, Y.; Zhang, H.; Gan, C.L. Stereolithography 3D printing of Si3N4 cellular ceramics with ultrahigh strength by using highly viscous paste. Ceram. Int. 2023, 49, 6984–6995. [Google Scholar]

- Zeng, X.; Sipaut, C.S.; Ismail, N.M.; Liu, Y.; Farm, Y.Y.; He, J. Mechanical properties and biological activity of 3D printed silicon nitride materials. Ceram. Int. 2024, 50, 16704–16713. [Google Scholar]

- Zhang, P.; He, R. 3D-printed silicon nitride ceramic implants for clinical applications: The state of the art and prospects. RSC Adv. 2025, 15, 406–419. [Google Scholar]

- Huang, S.; Yang, P.; Sheng, P.; Ning, T.; Wu, S. Additive manufacturing of complex-shaped and porous silicon nitride-based components for bionic bones. Ceram. Int. 2023, 49, 25025–25034. [Google Scholar]

- Zou, R.; Bi, L.; Huang, Y.; Wang, Y.; Wang, Y.; Li, L.; Liu, J.; Feng, L.; Jiang, X.; Deng, B. A biocompatible silicon nitride dental implant material prepared by digital light processing technology. J. Mech. Behav. Biomed. Mater. 2023, 141, 105756. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Zhang, R.; Ren, G.; Yang, X.; Cui, X.; Liu, W.; Wang, D.; Hou, Y.; Wen, G.; Zhang, L.; et al. Vat photopolymerization-engaged fabrication of high-performance, complex Si3N4 implants under rapid debinding efficiency. Ceram. Int. 2024, 50, 17646–17656. [Google Scholar]

- Lu, X.; Liu, G.; Lu, J. Development of Ceramic 3D/4D Printing in China. Addit. Manuf. Front. 2024, 3, 200158. [Google Scholar]

- Zhang, K.Q.; Meng, Q.Y.; Cai, N.J.; Qu, Z.L.; He, R.J. Effects of solid loading on stereolithographic additive manufactured ZrO2 ceramic: A quantitative defect study by X-ray computed tomography. Ceram. Int. 2021, 47, 24353–24359. [Google Scholar]

- Zhang, K.Q.; Meng, Q.Y.; Zhang, X.Q.; Qu, Z.L.; He, R.J. Quantitative characterization of defects in stereolithographic additive manufactured ceramic using X-ray computed tomography. J. Mater. Sci. Technol. 2022, 118, 144–157. [Google Scholar]

| Surface Modification Methods | D50 (μm) | Solid Loading (vol.%) | Viscosity (Pa·s) | Curing Depth (μm) | Sd (μm) | Ed (mJ/cm2) | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Surface oxidation | 800 °C 24 h | 0.5 | 25 | 0.068 at 30 s−1 | 52 | - | - | [42] |

| 1200 °C 1 h | 0.6 | 50 | 7.268 at 100 s−1 | 80 | - | - | [87] | |

| 1200 °C 1.5 h | 0.7 | 35 | - | 100 | - | - | [89] | |

| 1200 °C 3 h | 0.2 | - | - | 68 | - | - | [88] | |

| Surface modifier | KH560 | 0.83 | 40 | 45 | [72] | |||

| KMT-3331(2 wt.%) | 0.7 | 50 | 3.1 at 30 s−1 | - | 8.39 | - | [90] | |

| Surface coating | YAG via NCP a | 0.7 | 30 | - | - | 9.42 | 3.28 | [91] |

| Bowl-like boehmite(6 wt.%) | 1.25 | 40 | <2 at 30 s−1 | 40 | 21.4 | 4.85 | [92] | |

| Thermosetting resin E51(5 wt.%) | 0.83 | 40 | 2 at 30 s−1 | 61.6 | - | - | [86] | |

| Sintering Methods | D50 (μm) | Solid Loading (vol.%) | Density | Flexural Strength (MPa) | Hardness (GPa) | Fracture Toughness (MPa·m1/2) | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Dry-pressed sintering | 1750 °C 5 MPa 2 h 10 °C/min | 0.8 | 45 | 95% | - | 14.63 ± 0.45 | 5.82 ± 0.42 | [136] |

| 1775 °C 5 MPa 2 h | 0.5 | 40 | 99 ± 0.05% | 847 | - | - | [137] | |

| SPS | N2 1700 °C 5 min 100 °C/min | 1.19 | - | - | 249.5 ± 4.0 (Porous structure) | - | - | [138] |

| Pressureless sintering | N2 1750 °C 2 h 5 °C/min | 0.84 | 48 | 3.09 g/cm3 | 613.3 ± 53.1 | 12.6 ± 0.4 | 7.5 ± 0.3 | [139] |

| N2 1800 °C 2 h | 0.7 | 43 | 98.88% | 833.74 | 15.75 ± 0.20 | 5.17 ± 0.25 | [91] | |

| 1825 °C 4 h | 0.7 | 40 | 3.21 g/cm3 | 701.66 | 13.81 | 5.34 | [94] | |

| PIP | 8 infiltration cycles | 0.84 | 55 | 2.64 g/cm3 | 162.35 | - | - | [140] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.-H.; Zhang, Y.-Z.; Miao, W.-J.; Wu, F.-B.; Wang, S.-Q.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications. Materials 2025, 18, 1556. https://doi.org/10.3390/ma18071556

Wang Z-H, Zhang Y-Z, Miao W-J, Wu F-B, Wang S-Q, Ouyang J-H, Wang Y-M, Zou Y-C. Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications. Materials. 2025; 18(7):1556. https://doi.org/10.3390/ma18071556

Chicago/Turabian StyleWang, Zi-Heng, Yun-Zhuo Zhang, Wei-Jian Miao, Fan-Bin Wu, Shu-Qi Wang, Jia-Hu Ouyang, Ya-Ming Wang, and Yong-Chun Zou. 2025. "Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications" Materials 18, no. 7: 1556. https://doi.org/10.3390/ma18071556

APA StyleWang, Z.-H., Zhang, Y.-Z., Miao, W.-J., Wu, F.-B., Wang, S.-Q., Ouyang, J.-H., Wang, Y.-M., & Zou, Y.-C. (2025). Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications. Materials, 18(7), 1556. https://doi.org/10.3390/ma18071556