Experimental Investigation on Freeze–Thaw Durability of Polyacrylonitrile Fiber-Reinforced Recycled Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Experimental Parameters

2.3. Concrete Mix Proportion

2.4. Program of Basic Mechanical Tests and Frost Durability Tests

3. Results

3.1. Analysis of Basic Mechanical Test Results

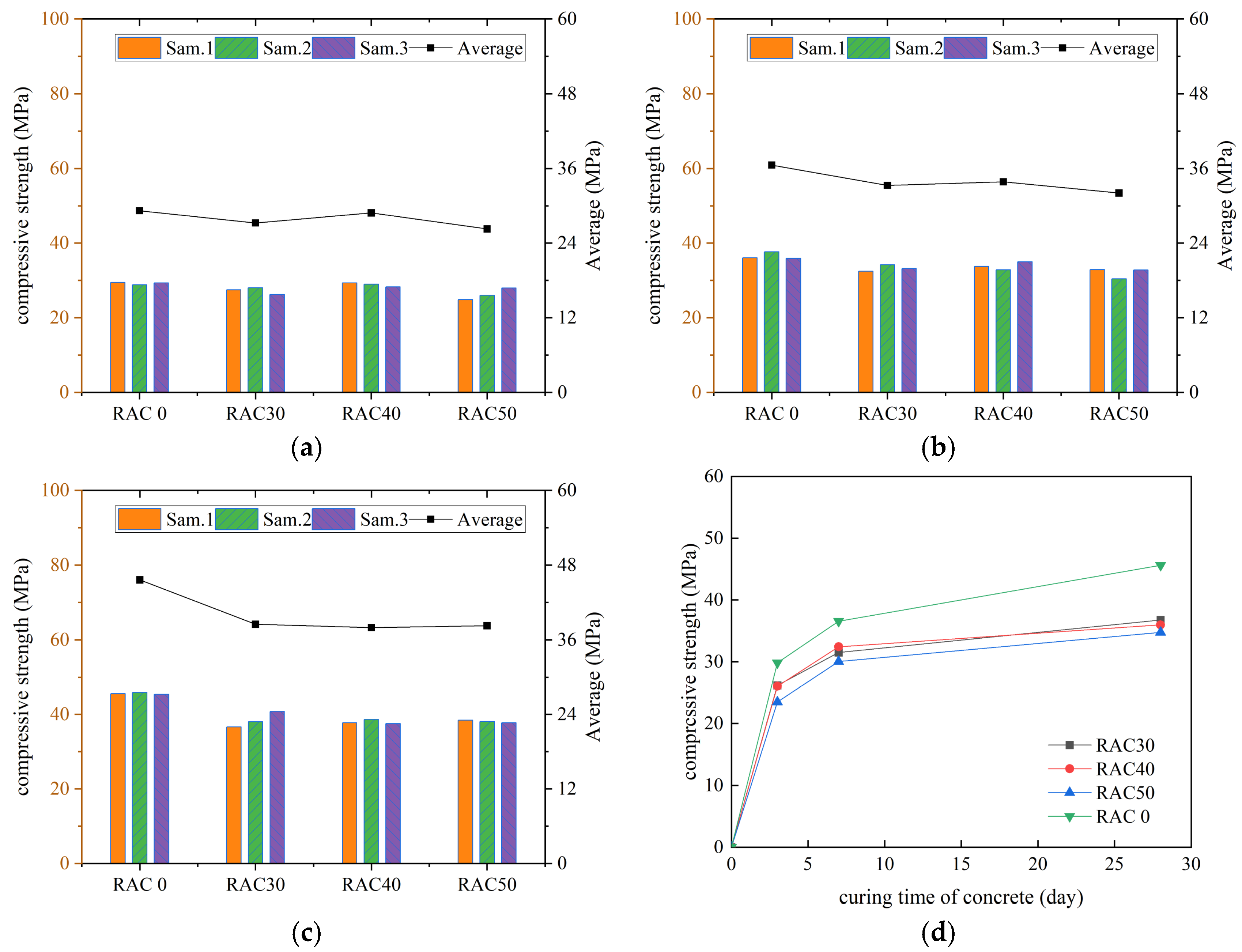

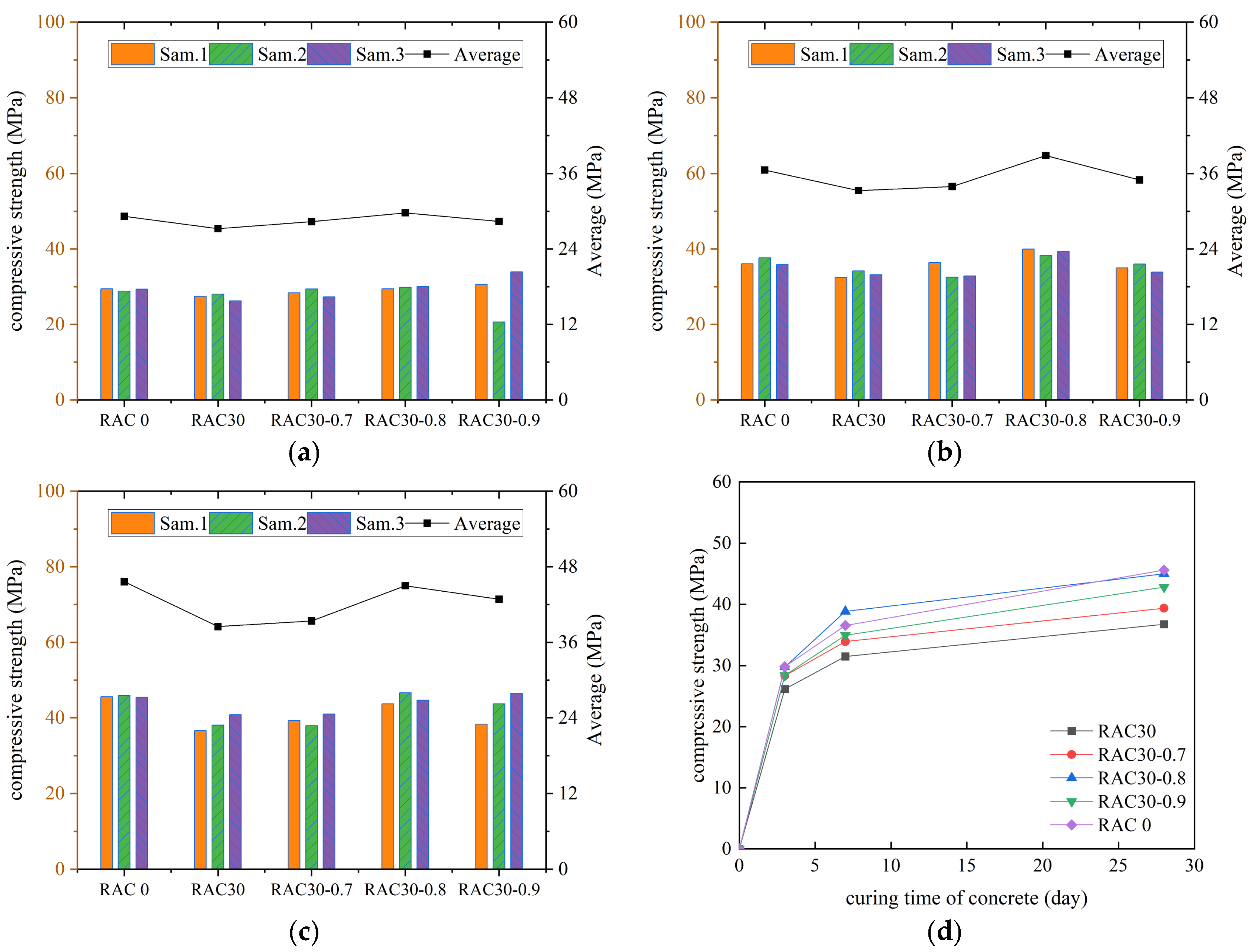

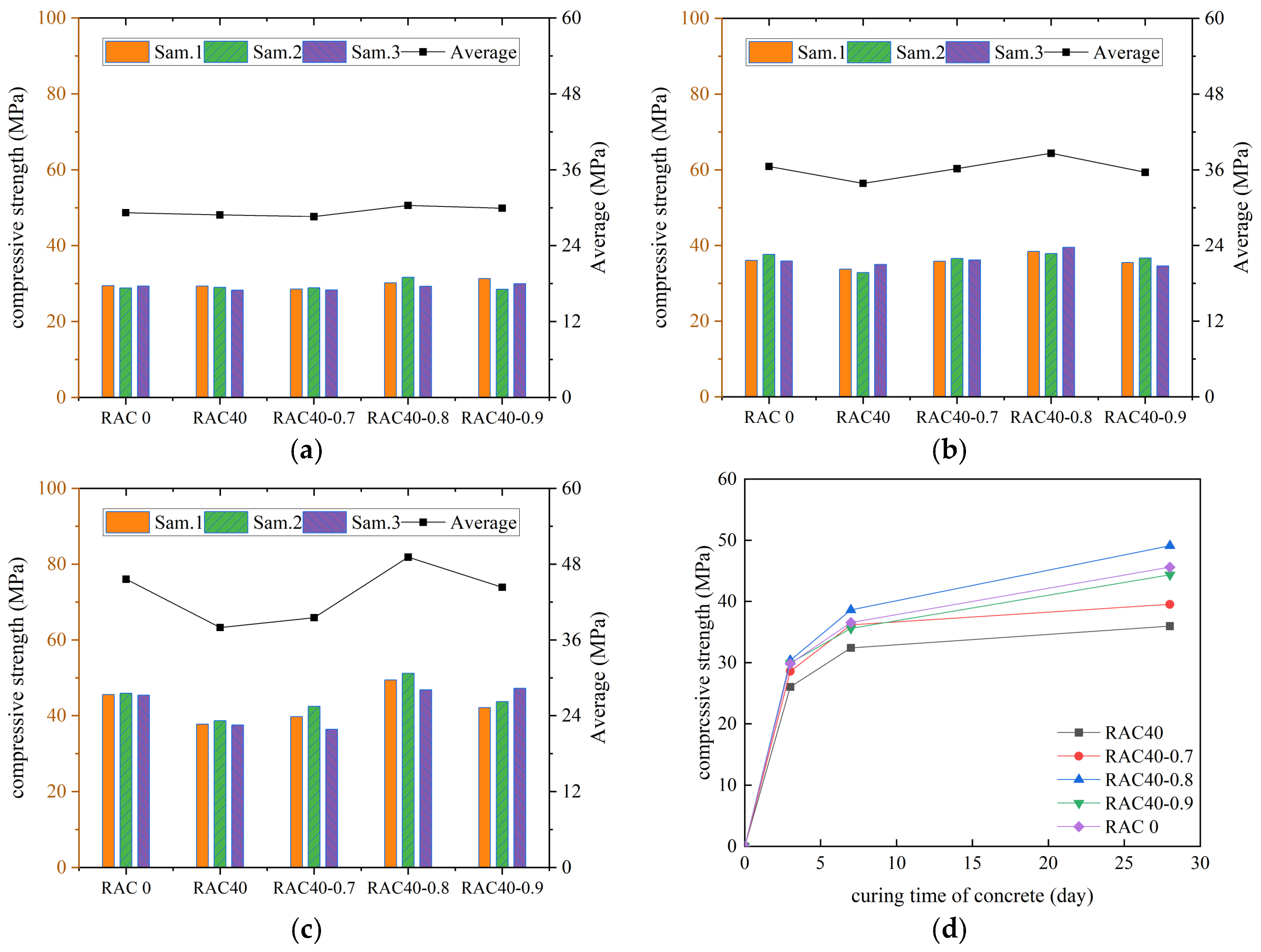

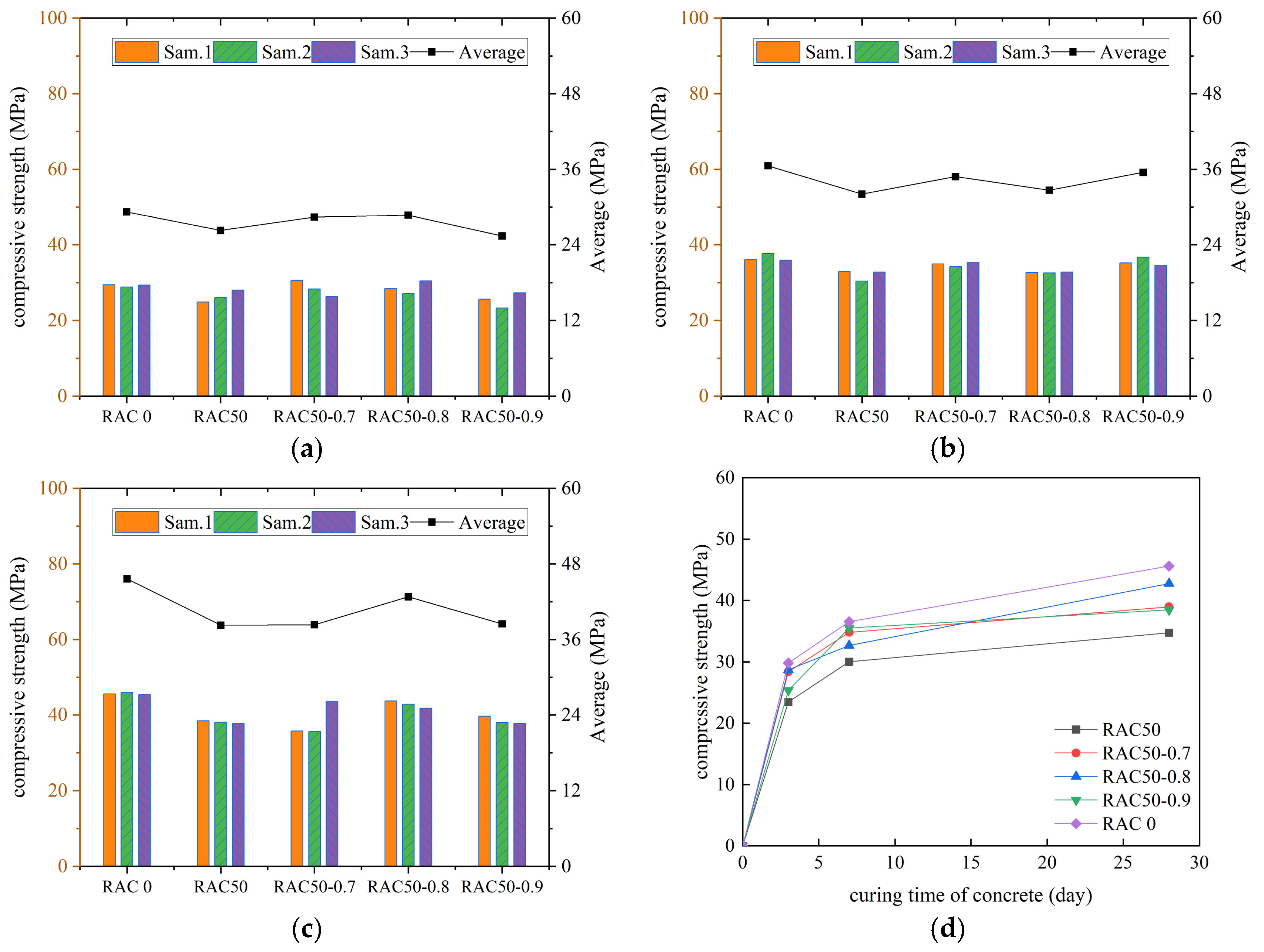

3.1.1. Analysis of Compressive Test Results

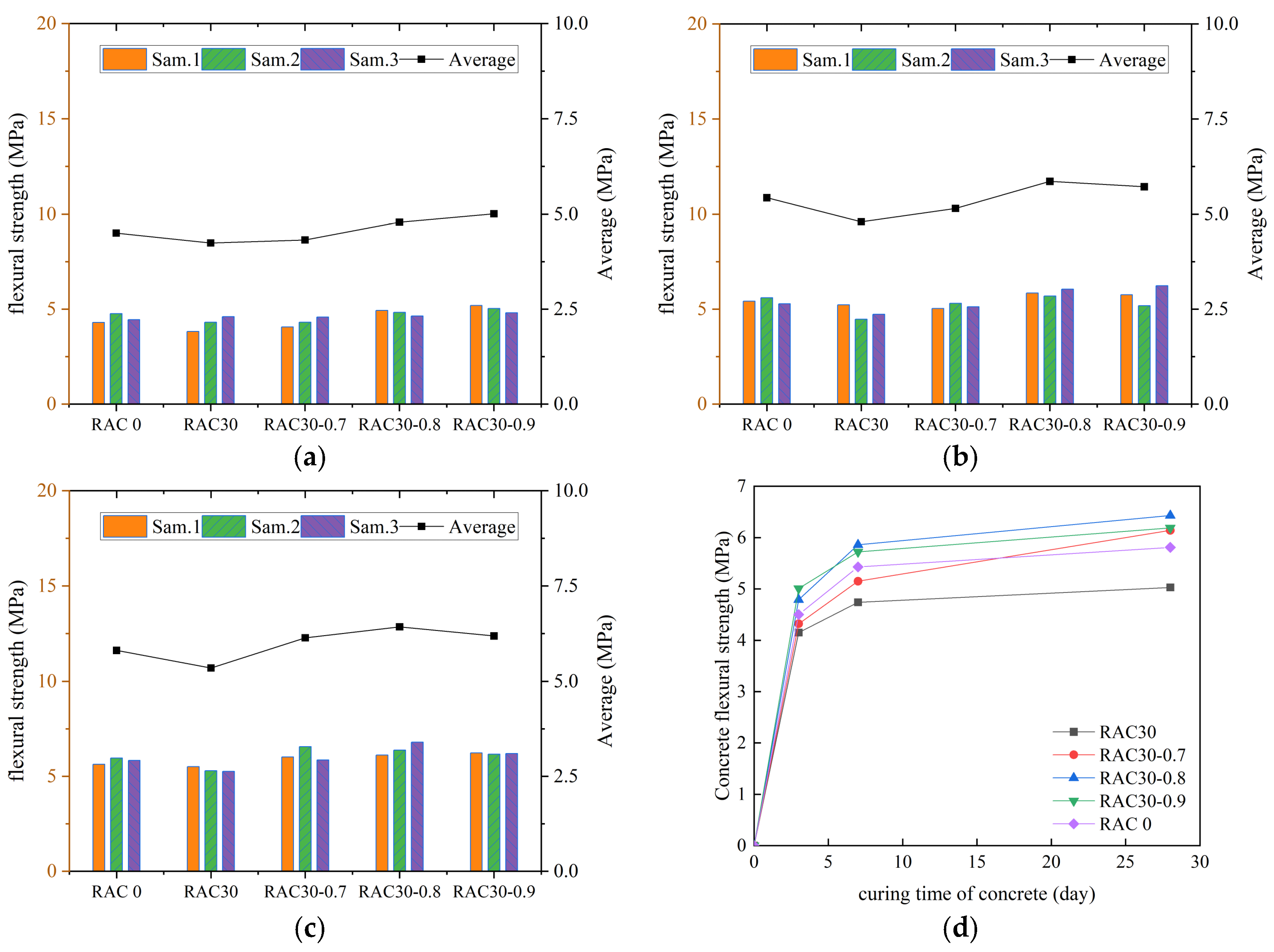

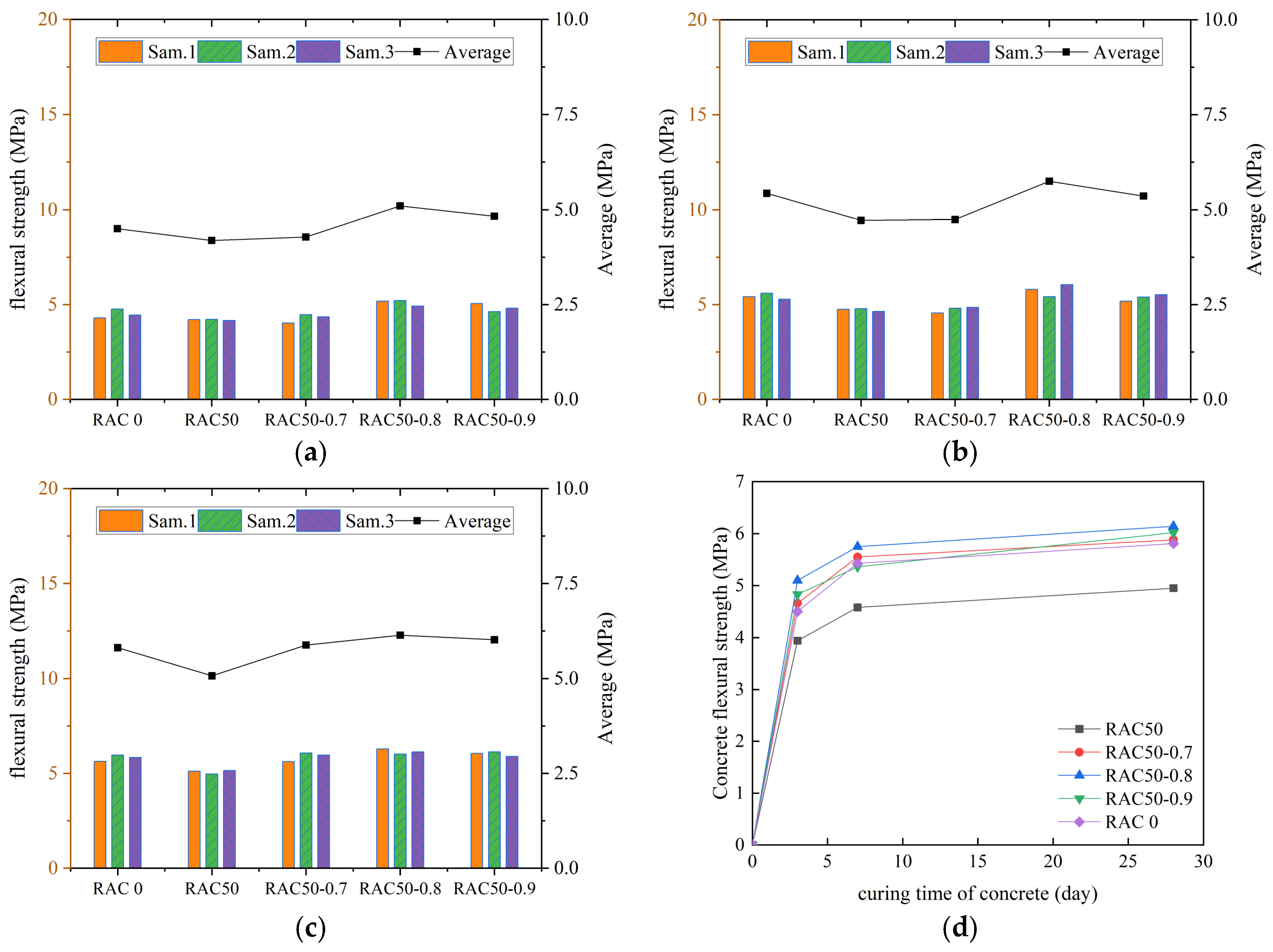

3.1.2. Analysis of Flexural Test Results

3.2. Analysis of Frost Durability Test Results

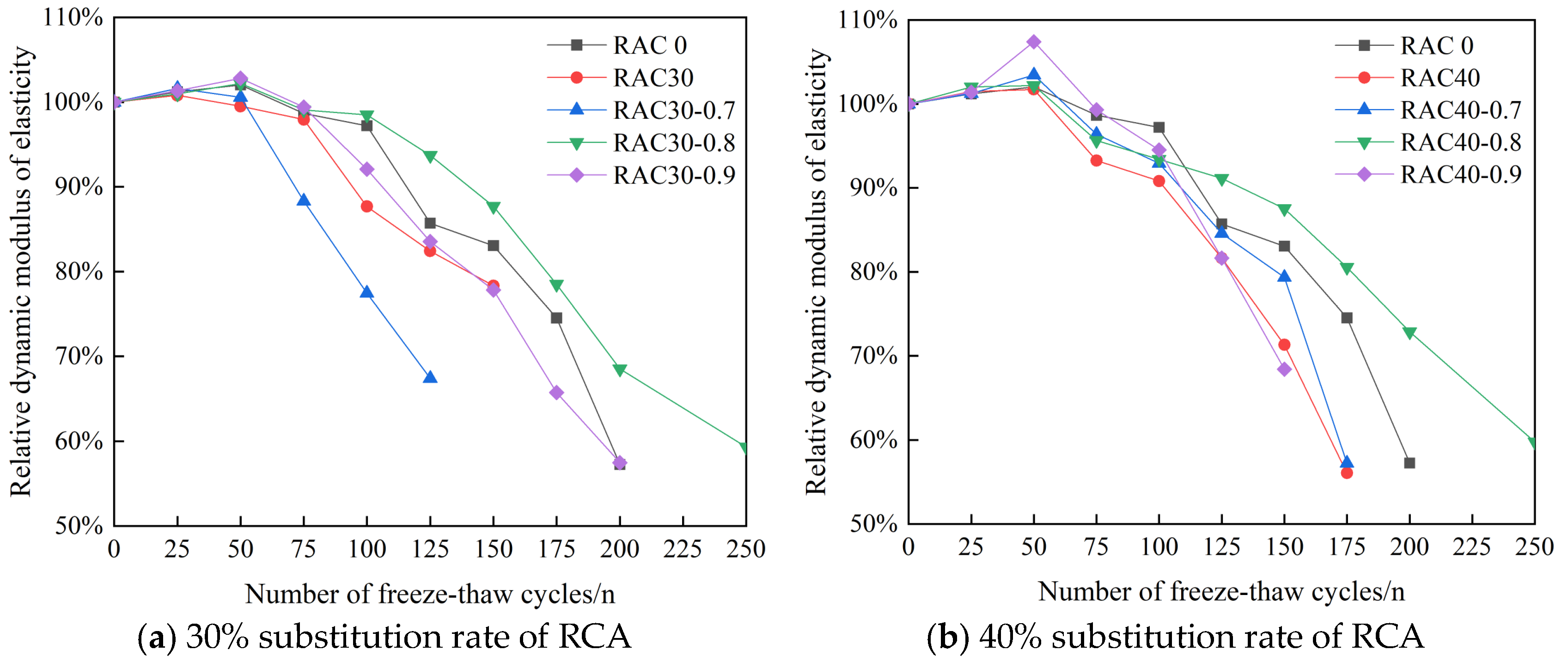

3.2.1. Analysis of Dynamic Elastic Modulus Test Results

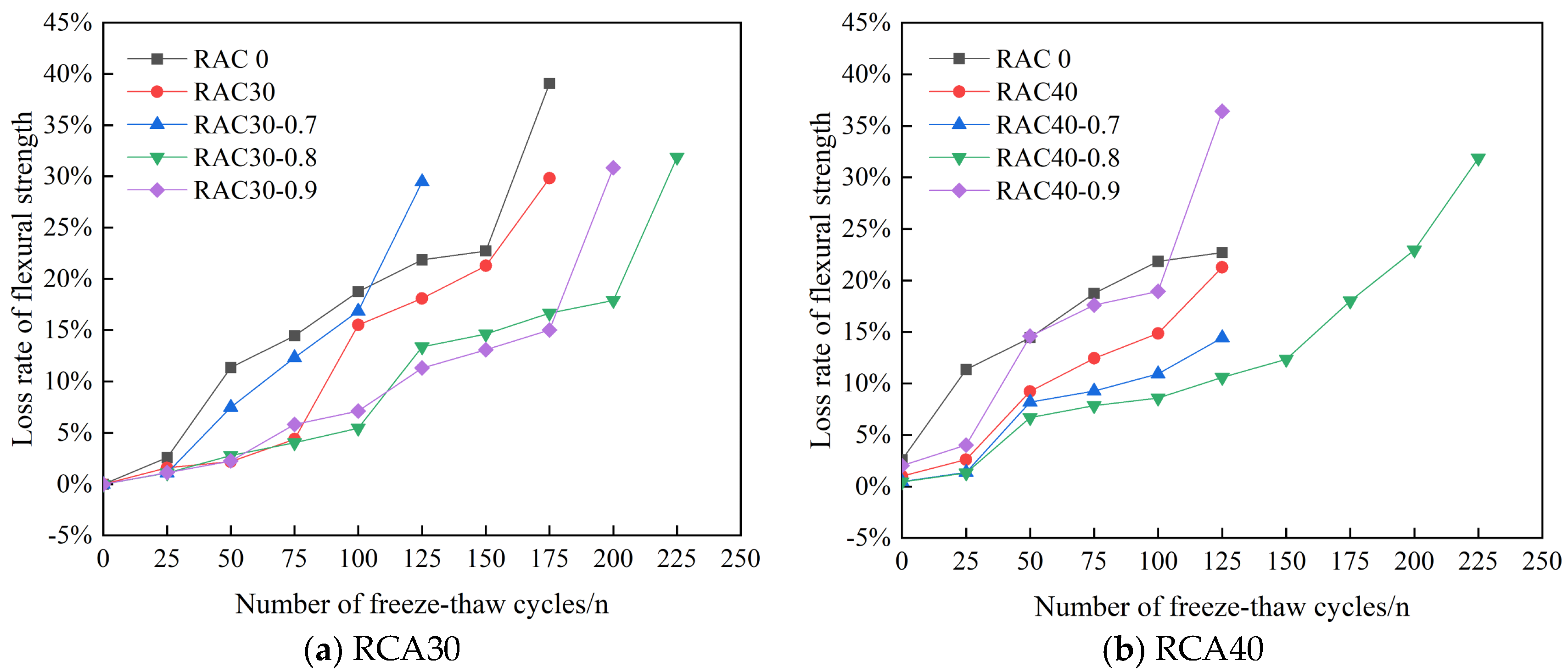

3.2.2. Analysis of Flexural Strength Test Results

4. Freeze–Thaw Damage Model of PAN-RC

4.1. Effect of Substitution Rate of RCA on Frost Durability of RC

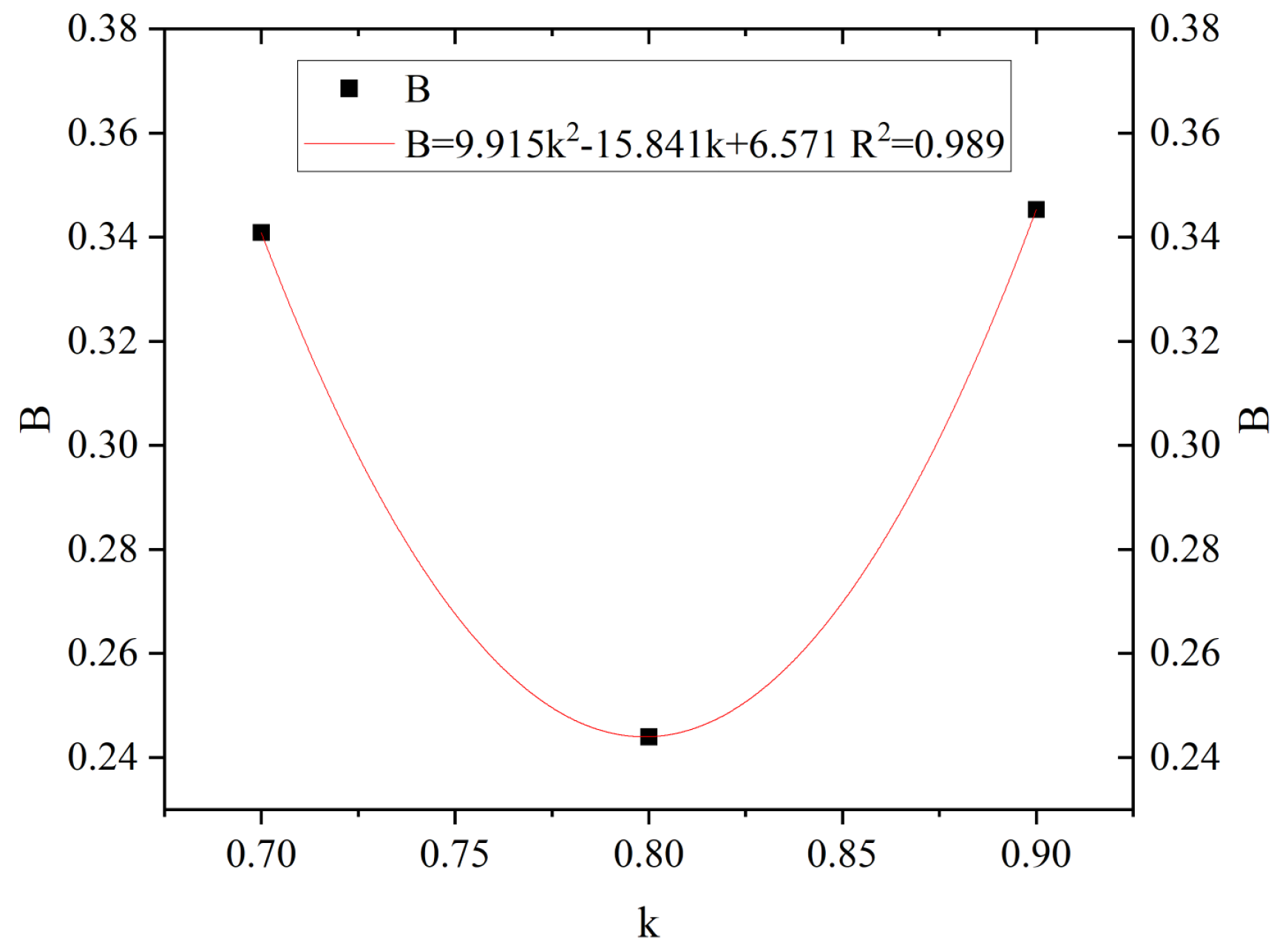

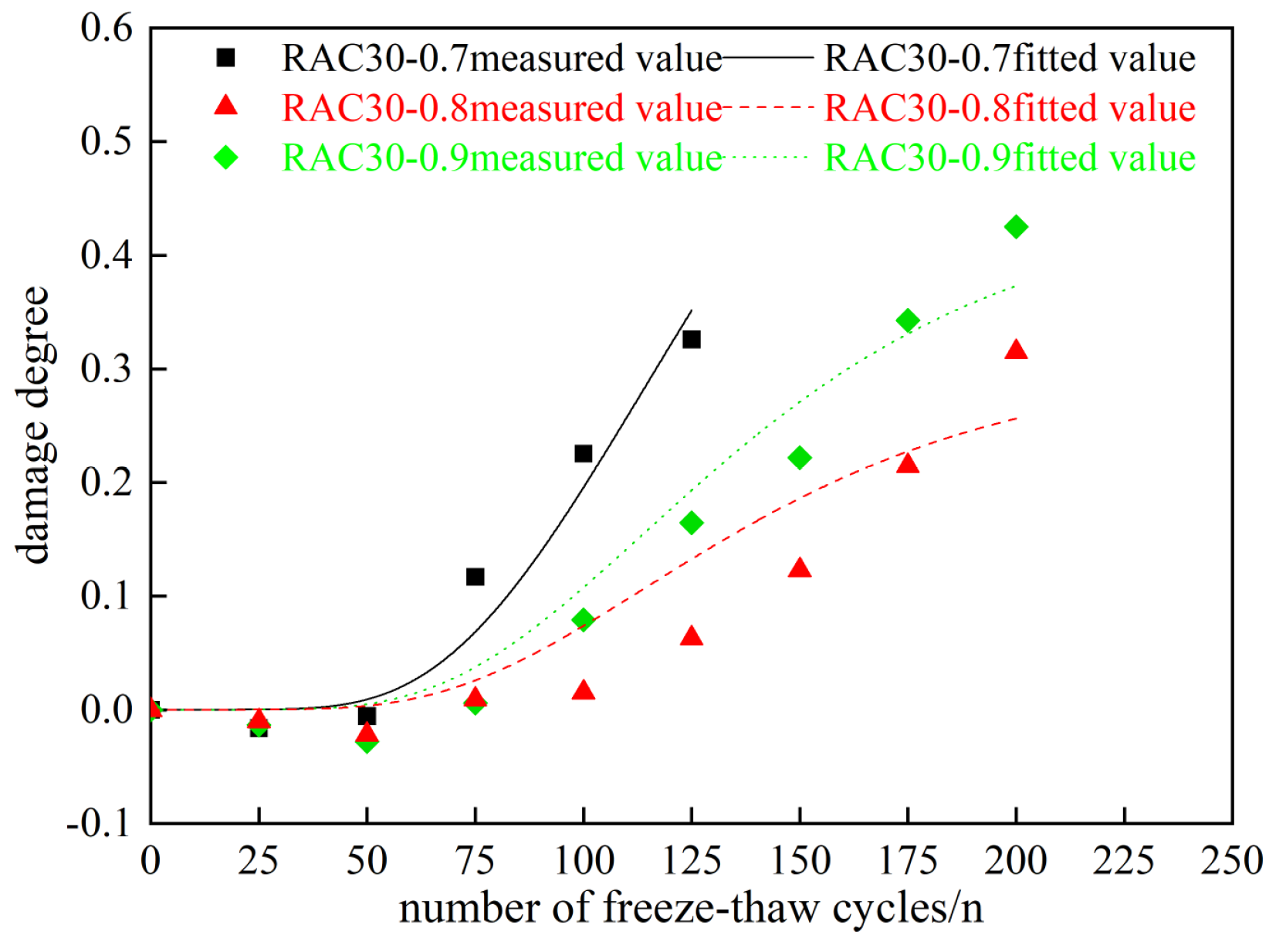

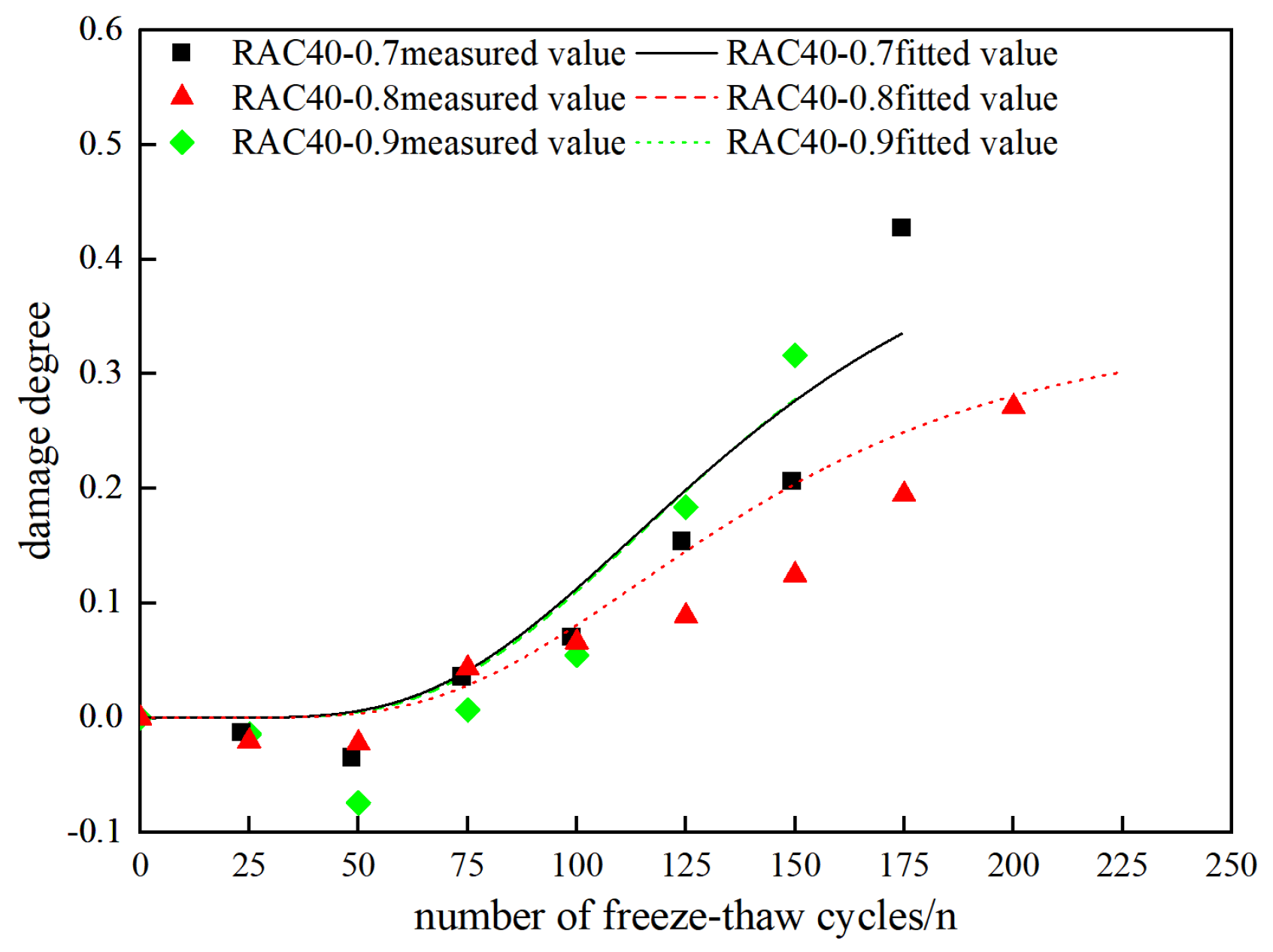

4.2. Consequence of the Mixing Content of PANF on the Frost Durability of RC

5. Conclusions

- (1)

- The mechanical test results indicate that both the compressive and flexural strength of RC decrease as the substitution rate of RCA increases. Conversely, with an increase in the mixing content of PANF, the mechanical properties of RC initially improve before subsequently declining. Notably, the optimal mechanical properties were achieved with a 40% substitution rate of RCA and a PANF content of 0.8 kg/m3.

- (2)

- The freeze–thaw cycle test results indicate that PANF may enhance the frost durability of RC. The improvement effect increases with the fiber content up to a certain point and then decreases. The material achieves optimal freeze–thaw durability at a PANF content of 0.8 kg/m3. These findings suggest that the incorporation of PANF not only improves mechanical properties but also contributes significantly to the material’s resistance to freeze–thaw cycles.

- (3)

- A freeze–thaw damage model for PAN-RC, using the substitution rate of RCA and PANF as independent variables, was developed. This model can predict the freeze–thaw damage degree of fiber-reinforced RC under various replacement rates of RCA and different dosages of PANF. And the model can assess the damage degree of PAN-RC. The findings hold both theoretical value and practical significance for the application of RC in high-altitude cold regions, particularly in infrastructure projects where resistance to severe weather conditions is critical.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B. A comprehensive review on the use of natural fibers in cement/geopolymer concrete: A step towards sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; de Brito, J. Physical–chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef]

- Porras-Amores, C.; Garcia, P.M.; Sáez, P.V.; Merino, M.d.R.; Vitielo, V. Assessing the Energy Efficiency Potential of Recycled Materials with Construction and Demolition Waste: A Spanish Case Study. Appl. Sci. 2021, 11, 7809. [Google Scholar] [CrossRef]

- Shan, M.; Hwang, B.-G.; Zhu, L. A Global Review of Sustainable Construction Project Financing: Policies, Practices, and Research Efforts. Sustainability 2017, 9, 2347. [Google Scholar] [CrossRef]

- Behún, M.; Behúnová, A. Advanced Innovation Technology of BIM in a Circular Economy. Appl. Sci. 2023, 13, 7989. [Google Scholar] [CrossRef]

- Sumikura, Y.; Katsumi, T. Material reuse and recycling in construction works in Japan. J. Mater. Cycles Waste Manag. 2022, 24, 1216–1227. [Google Scholar] [CrossRef]

- Lederer, J.; Gassner, A.; Kleemann, F.; Fellner, J. Potentials for a circular economy of mineral construction materials and demolition waste in urban areas: A case study from Vienna. Resour. Conserv. Recycl. 2020, 161, 104942. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J. Recycled Aggregates Produced from Construction and Demolition Waste for Structural Concrete: Constituents, Properties and Production. Materials 2021, 14, 5748. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, A.; Negro, C. Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review. Materials 2021, 14, 2408. [Google Scholar] [CrossRef]

- Wang, Z.; Tao, L.; Liu, Y.; Yunhui, J. Temperature Control Measures and Temperature Stress of Mass Concrete during Construction Period in High-Altitude Regions. Adv. Civ. Eng. 2018, 2018, 9249382. [Google Scholar] [CrossRef]

- Liu, M.; Wen, Z.; Su, H. A multipoint prediction model for the deformation of concrete dams considering climatic features of high-altitude regions. Eng. Struct. 2024, 319, 118845. [Google Scholar] [CrossRef]

- Liu, K.; Fu, K.; Sang, Y.; Yang, Y.; Zou, C.; Xie, T.; Zhao, X. Frost resistance of recycled aggregate concrete: A critical review. J. Build. Eng. 2024, 90, 109450. [Google Scholar] [CrossRef]

- Sadati, S.; Khayat, K.H. Can Concrete Containing High-Volume Recycled Concrete Aggregate Be Durable? ACI Mater. J. 2018, 115, 471–480. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete. Sustainability 2020, 12, 9399. [Google Scholar] [CrossRef]

- Xiao, Q.H.; Cao, Z.Y.; Guan, X.; Li, Q.; Liu, X.L. Damage to recycled concrete with different aggregate substitution rates from the coupled action of freeze-thaw cycles and sulfate attack. Constr. Build. Mater. 2019, 221, 74–83. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Kan, W.; Yang, Z.; Yu, L. Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete. Appl. Sci. 2022, 12, 3823. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, X.; Meng, Y.; Chen, Z. Durability of concrete containing fly ash and silica fume against combined freezing-thawing and sulfate attack. Constr. Build. Mater. 2017, 147, 398–406. [Google Scholar] [CrossRef]

- Fan, S.-J. Mechanical and Durability Performance of Polyacrylonitrile Fiber Reinforced Concrete. Mater. Res. 2015, 18, 1298–1303. [Google Scholar] [CrossRef][Green Version]

- Wang, R.; Cao, Z.; Li, Y.; Shi, Q. The influence of fiber on salt frost resistance of hydraulic face slab concrete. Struct. Concr. 2023, 24, 521–535. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Y.; Ren, B. Experimental study on frost resistance of hybrid fiber fly ash concrete. AIP Adv. 2023, 13, 0150754. [Google Scholar] [CrossRef]

- Saberian, M.; Tajaddini, A.; Li, J.; Zhang, G.; Wang, L.; Sun, D.; Maqsood, T.; Roychand, R. Mechanical properties of polypropylene fibre reinforced recycled concrete aggregate for sustainable road base and subbase applications. Constr. Build. Mater. 2023, 405, 133352. [Google Scholar] [CrossRef]

- Yang, W.; Huang, Y.; Li, C.; Tang, Z.; Quan, W.; Xiong, X.; He, J.; Wu, W. Damage prediction and long-term cost performance analysis of glass fiber recycled concrete under freeze-thaw cycles. Case Stud. Constr. Mater. 2024, 21, e03795. [Google Scholar] [CrossRef]

- Guan, T.; Zhang, L.; Zheng, Y.; Guan, J.; Zhang, Y.; Zhang, Y. Frost resistance and damage evolution model of basalt fiber-reinforced recycled concrete based on recycled coarse aggregate strengthening and vibration mixing processes. J. Build. Eng. 2024, 91, 109627. [Google Scholar] [CrossRef]

- Duan, M.; Qin, Y.; Li, Y.; Zhou, H. Durability and damage model of polyacrylonitrile fiber reinforced concrete under freeze–thaw and erosion. Constr. Build. Mater. 2023, 394, 132238. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, D.; Yang, F.; Mei, J.; Yao, Y.; Deng, Y. Freeze–thaw damage analysis and life prediction of modified pervious concrete based on Weibull distribution. Case Stud. Constr. Mater. 2024, 20, e03305. [Google Scholar] [CrossRef]

- Yu, H.; Ma, H.; Yan, K. An equation for determining freeze-thaw fatigue damage in concrete and a model for predicting the service life. Constr. Build. Mater. 2017, 137, 104–116. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Qiu, J.; Zhou, Y.; Vatin, N.I.; Guan, X.; Sultanov, S.; Khemarak, K. Damage constitutive model of coal gangue concrete under freeze-thaw cycles. Constr. Build. Mater. 2020, 264, 120720. [Google Scholar] [CrossRef]

- Rong, X.; Li, L.; Zheng, S.; Wang, F.; Huang, W.; Zhang, Y.; Lu, D. Freeze—thaw damage model for concrete considering a nonuniform temperature field. J. Build. Eng. 2023, 72, 106747. [Google Scholar] [CrossRef]

- Jaskulski, R.; Supera, M.; Kubissa, W.; Koteš, P.; Brodňan, M. The influence of RCA addition on selected parameters of concrete. MATEC Web Conf. 2018, 196, 02018. [Google Scholar] [CrossRef][Green Version]

- Yang, G.; Li, Q.; Guo, Y.; Liu, H.; Zheng, S.; Chen, M. Study on the Mechanical Properties and Durability of Recycled Aggregate Concrete under the Internal Curing Condition. Materials 2022, 15, 5914. [Google Scholar] [CrossRef]

- DB11/T 803-2011; Code for Design of Recycled Concrete Structure. China Architecture & Building Press: Beijing, China, 2011.

- Slebi-Acevedo, C.J.; Lastra-González, P.; Castro-Fresno, D.; Vega-Zamanillo, Á. Experimental evaluation and recyclability potential of asphalt concrete mixtures with polyacrylonitrile fibers. Constr. Build. Mater. 2022, 317, 125829. [Google Scholar] [CrossRef]

- Zhang, W.J.; Bao, C.C.; Kong, X.Q.; Qu, Y.D.; Liu, H.X. Experimental Study on Mechanical Properties of Hybrid Fiber Basic of Recycled Concrete. Sience Technol. Eng. 2016, 16, 106–112+123. [Google Scholar]

- Zeng, Z.; Li, C.; Chen, Z.; Ke, L. Study on Mechanical Properties and Optimum Fiber Content for Basalt/Polyacrylonitrile Hybrid Fiber Reinforced Concrete. Adv. Mater. Sci. Eng. 2022, 2022, 1–11. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Fiber Reinforced Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- JGJ55-2011; Design Code for Ordinary Concrete Mix Ratio. China Architecture & Building Press: Beijing, China, 2011.

- EN 12620:2013; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2013.

- JIS A 5021:2011; Recycled Aggregate for Concrete. Japanese Industrial Standards Committee: Tokyo, Japan, 2011.

- Fib Model Code 2010: Model Code for Concrete Structures; International Federation for Structural Concrete: Lausanne, Switzerland, 2010.

- ACI 544.1R-96; Report on Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1996.

- GB/T50082-2009; Standard for Test Methods for Long-Term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2009.

- Liu, Y.Y. Frost Resistance Durability of Concrete in High Altitude Cold Area; Xi’an Technological University: Xi’an, China, 2021. [Google Scholar] [CrossRef]

- Deng, X.-H.; Liang, K.-X.; Wang, R.; Liu, Y.-Y.; Yang, Y.-W. Experimental study on the frost resistance durability of concrete in high altitude and cold regions. Eng. Mech. 2023, 40, 37–47. [Google Scholar] [CrossRef]

- Gao, X.Y. Experimental Study on Frost Resistance and Durability of Air-Entrained Recycled Concrete Pavement; Xi’an Technological University: Xi’an, China, 2020. [Google Scholar] [CrossRef]

- Liu, C.X.; Wang, Z.Q. Decay patterns in the endurance life of dam concrete. J. Chang. River Sci. Res. Inst. 2000, 17, 18–21. [Google Scholar]

- Li, B.; Huang, W.; Li, C.N.; Dong, K.L. Study on damage constitutive model of steel fiber recycleed brick aggregate concrete. J. Huazhong Univ. Sci. Technol. 2017, 45, 17–23. [Google Scholar] [CrossRef]

- Luo, D. Dynamic Constitutive Model Analysis of High Parameter Steel Fiber Reinforced Concrete. Symmetry 2019, 11, 377. [Google Scholar] [CrossRef]

| Item | Fineness (%) | Setting Time (h) | Stability | |

|---|---|---|---|---|

| Initial Setting≥ | Final Setting≤ | |||

| Standard Requirements | ≤10 | 1.5 | 10 | - |

| Test data | 4.3 | 4.5 | 8.6 | Pass |

| Technical Specification | Unit | Test Value | Technical Requirements |

|---|---|---|---|

| Modulus of fineness | - | 2.98 | 2.0–3.7 |

| Mud content | % | 2.5 | ≤1 |

| Apparent density | kg/m3 | 2835 | ≥2500 |

| Porosity | % | 42.75 | ≤45 |

| Bulk accumulation density | kg/m3 | 1475 | ≥1400 |

| Technical Specification | Unit | Test Value | Technical Requirements |

|---|---|---|---|

| Crushing value | % | 8.4 | ≤18 |

| Water absorption rate | % | 0.4 | ≤1 |

| Apparent density | g/cm3 | 2738 | ≥2500 |

| Mud content | % | 0.3 | ≤0.5 |

| Technical Specification | Unit | Test Value | Technical Requirements |

|---|---|---|---|

| Crushing value | % | 12.6 | ≤20 |

| Water absorption rate | % | 2.8 | ≤10 |

| Apparent density | g/cm3 | 2469 | ≥2400 |

| Mud content | % | 1.6 | ≤2.0 |

| Specimen No. | Cement | Water | Sand | Coarse Aggregate | Additional Water | Fiber Content | Water Reducer | Air-Entraining Agent | |

|---|---|---|---|---|---|---|---|---|---|

| Natural | Recycled | ||||||||

| RAC0 | 417 | 171 | 753 | 1039 | 0 | 0 | 0 | 3.12 | 0.02 |

| RAC30 | 417 | 171 | 753 | 727 | 312 | 8.7 | 0 | 3.12 | 0.02 |

| RAC30-0.7 | 0.7 | ||||||||

| RAC30-0.8 | 0.8 | ||||||||

| RAC30-0.9 | 0.9 | ||||||||

| RAC40 | 417 | 171 | 753 | 623 | 416 | 11.6 | 0 | 3.12 | 0.02 |

| RAC40-0.7 | 0.7 | ||||||||

| RAC40-0.8 | 0.8 | ||||||||

| RAC40-0.9 | 0.9 | ||||||||

| RAC50 | 417 | 171 | 753 | 519.5 | 519.5 | 14.5 | 0 | 3.12 | 0.02 |

| RAC50-0.7 | 0.7 | ||||||||

| RAC50-0.8 | 0.8 | ||||||||

| RAC50-0.9 | 0.9 | ||||||||

| Technical Specification | Unit | Test Value | Technical Requirements |

|---|---|---|---|

| Inorganic Salts | % | 2.6 | ≤5 |

| Petroleum Ether Soluble | % | 0.9 | ≤1.5 |

| Moisture | % | 1.8 | ≤3.0 |

| PH Value | - | 9.4 | 8.0–10.5 |

| Specimen No. | Number of Freeze–Thaw Cycles | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | |

| RAC0 | 37.35 | 37.80 | 38.11 | 36.85 | 36.31 | 32.01 | 31.02 | 27.83 | 21.38 | - |

| RAC30 | 36.43 | 36.72 | 36.25 | 35.68 | 31.94 | 30.02 | 28.53 | - | - | - |

| RAC30-0.7 | 35.22 | 35.79 | 35.42 | 31.10 | 27.28 | 23.74 | - | - | - | - |

| RAC30-0.8 | 38.30 | 38.68 | 39.14 | 37.95 | 37.72 | 35.89 | 33.59 | 30.07 | 26.24 | 22.72 |

| RAC30-0.9 | 35.93 | 36.41 | 36.94 | 35.72 | 33.09 | 30.01 | 27.96 | 23.62 | 20.65 | - |

| RAC40 | 35.94 | 36.47 | 36.56 | 33.52 | 32.64 | 29.34 | 25.63 | 20.15 | - | - |

| RAC40-0.7 | 36.01 | 36.46 | 37.25 | 34.71 | 33.46 | 30.46 | 28.57 | 20.61 | - | - |

| RAC40-0.8 | 36.63 | 37.37 | 37.43 | 35.04 | 34.21 | 33.38 | 32.06 | 29.50 | 26.69 | 21.89 |

| RAC40-0.9 | 31.96 | 32.41 | 34.33 | 31.74 | 30.21 | 26.09 | 21.86 | - | - | - |

| Specimen No. | Number of Freeze–Thaw Cycles | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | |

| RAC0 | 5.81 | 5.66 | 5.15 | 4.97 | 4.72 | 4.54 | 4.49 | 3.54 | - | - |

| RAC30 | 5.03 | 4.95 | 4.92 | 4.81 | 4.25 | 4.12 | 3.96 | 3.53 | - | - |

| RAC30-0.7 | 6.41 | 6.34 | 5.93 | 5.62 | 5.33 | 4.52 | - | - | - | - |

| RAC30-0.8 | 6.43 | 6.36 | 6.25 | 6.17 | 6.08 | 5.57 | 5.49 | 5.36 | 5.28 | 4.38 |

| RAC30-0.9 | 6.19 | 6.12 | 6.05 | 5.83 | 5.75 | 5.49 | 5.38 | 5.26 | 4.28 | - |

| RAC40 | 4.98 | 4.93 | 4.85 | 4.52 | 4.36 | 4.24 | 3.92 | 3.51 | - | - |

| RAC40-0.7 | 6.58 | 6.55 | 6.49 | 6.04 | 5.97 | 5.86 | 5.63 | 4.89 | - | - |

| RAC40-0.8 | 6.88 | 6.85 | 6.79 | 6.42 | 6.34 | 6.29 | 6.15 | 6.03 | 5.64 | 5.3 |

| RAC40-0.9 | 5.96 | 5.84 | 5.72 | 5.09 | 4.91 | 4.83 | 3.79 | - | - | - |

| Concrete Type | Mf | A | α | R2 |

|---|---|---|---|---|

| RAC 0 | 0 | 0.009 | 0.2 | 0.959 |

| RAC30 | 0.3 | 0.012 | 0.2 | 0.941 |

| RAC40 | 0.4 | 0.013 | 0.2 | 0.968 |

| Concrete Type | A | B | α | β | R2 |

|---|---|---|---|---|---|

| RAC30-0.7 | 0.012 | 0.453 | 0.02 | 9.80 | 0.892 |

| RAC30-0.8 | 0.324 | 0.862 | |||

| RAC30-0.9 | 0.459 | 0.889 |

| Mixing Content of PANF (kg/m3) | k |

|---|---|

| 0.7 | 0.7 |

| 0.8 | 0.8 |

| 0.9 | 0.9 |

| Concrete Type | Mf | k | α | β | R2 |

|---|---|---|---|---|---|

| RAC30-0.7 | 0.3 | 0.7 | 0.02 | 9.80 | 0.882 |

| RAC30-0.8 | 0.8 | 0.844 | |||

| RAC30-0.9 | 0.9 | 0.891 | |||

| RAC40-0.7 | 0.4 | 0.7 | 0.02 | 9.80 | 0.853 |

| RAC40-0.8 | 0.8 | 0.832 | |||

| RAC40-0.9 | 0.9 | 0.874 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Qiao, Z.; Deng, X.; Shen, X.; Yang, Y.; Wang, P.; Zhang, J. Experimental Investigation on Freeze–Thaw Durability of Polyacrylonitrile Fiber-Reinforced Recycled Concrete. Materials 2025, 18, 1548. https://doi.org/10.3390/ma18071548

Wang R, Qiao Z, Deng X, Shen X, Yang Y, Wang P, Zhang J. Experimental Investigation on Freeze–Thaw Durability of Polyacrylonitrile Fiber-Reinforced Recycled Concrete. Materials. 2025; 18(7):1548. https://doi.org/10.3390/ma18071548

Chicago/Turabian StyleWang, Rui, Zhonglin Qiao, Xianghui Deng, Xiaolin Shen, Yiwen Yang, Pingan Wang, and Jinzeng Zhang. 2025. "Experimental Investigation on Freeze–Thaw Durability of Polyacrylonitrile Fiber-Reinforced Recycled Concrete" Materials 18, no. 7: 1548. https://doi.org/10.3390/ma18071548

APA StyleWang, R., Qiao, Z., Deng, X., Shen, X., Yang, Y., Wang, P., & Zhang, J. (2025). Experimental Investigation on Freeze–Thaw Durability of Polyacrylonitrile Fiber-Reinforced Recycled Concrete. Materials, 18(7), 1548. https://doi.org/10.3390/ma18071548