The Technological, Economic, and Strength Aspects of High-Frequency Buried Arc Welding Using the GMAW Rapid HF Process

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

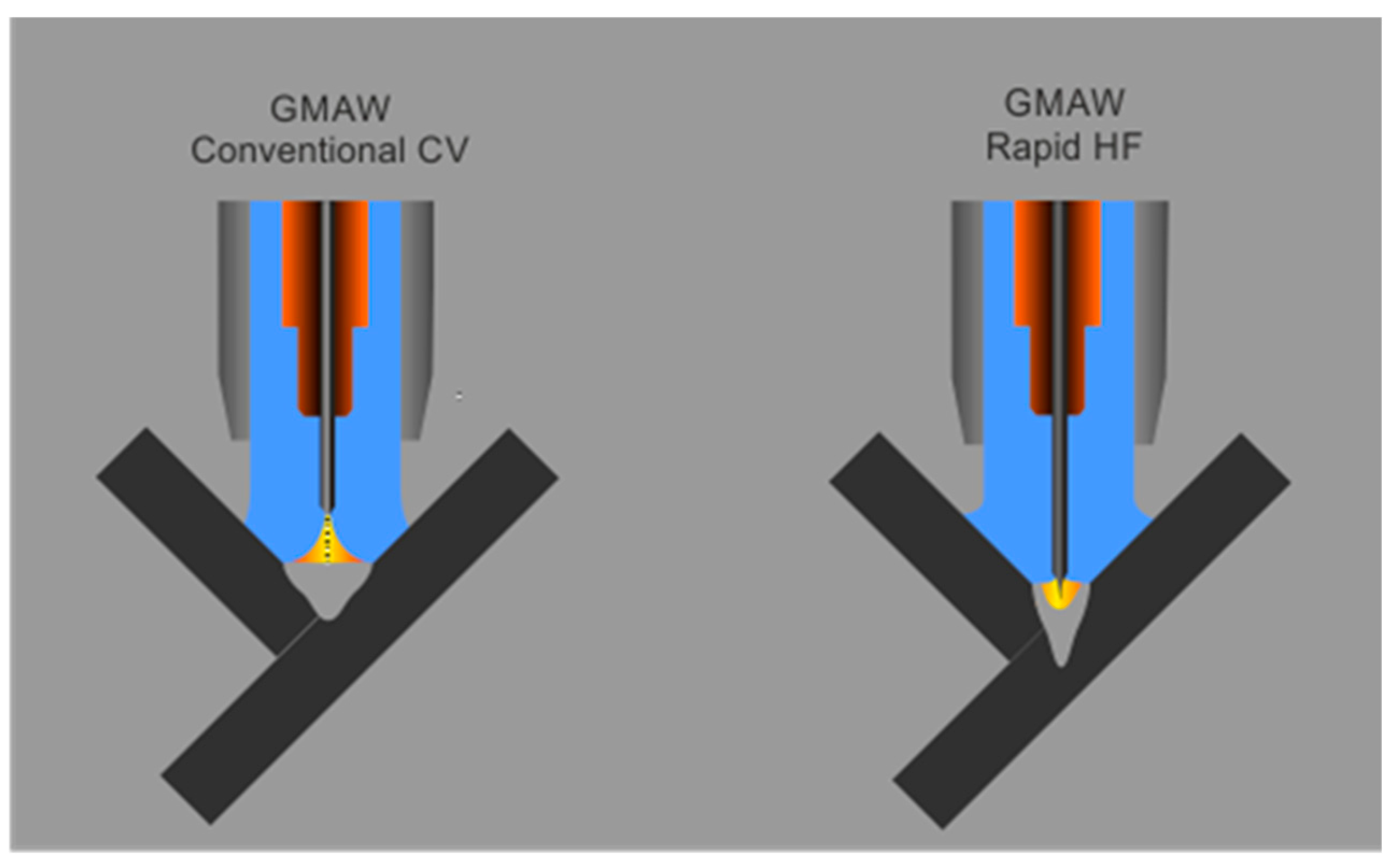

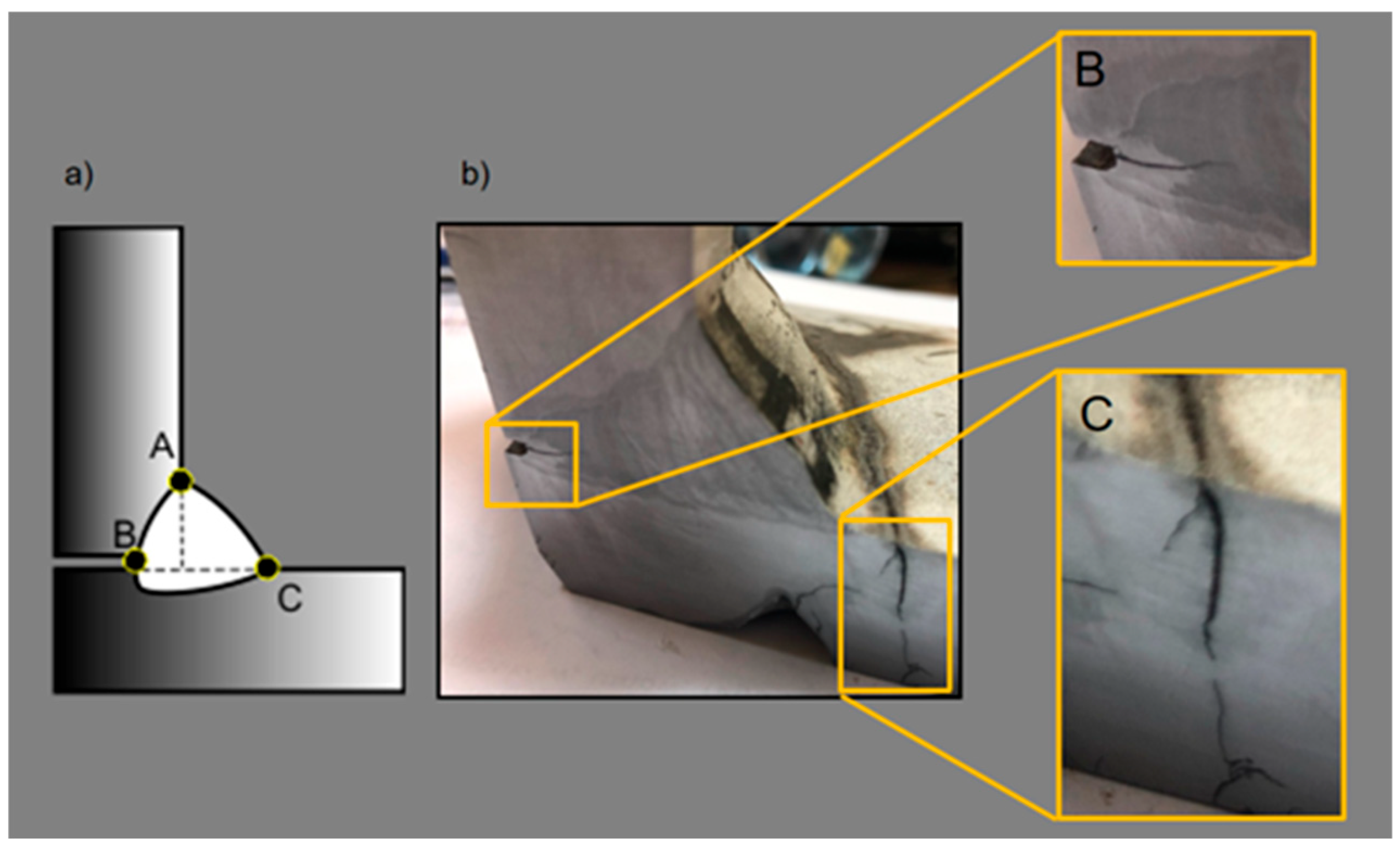

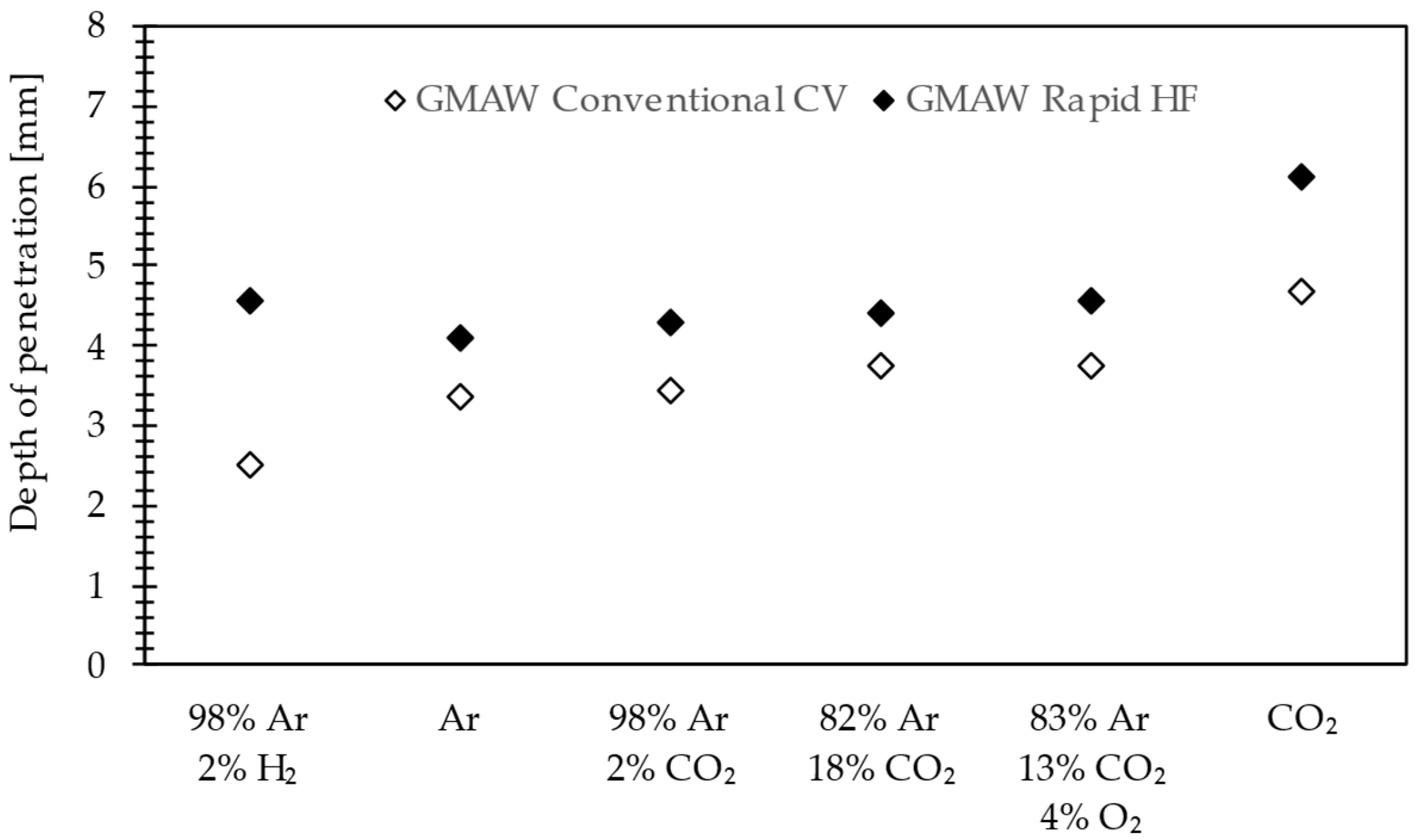

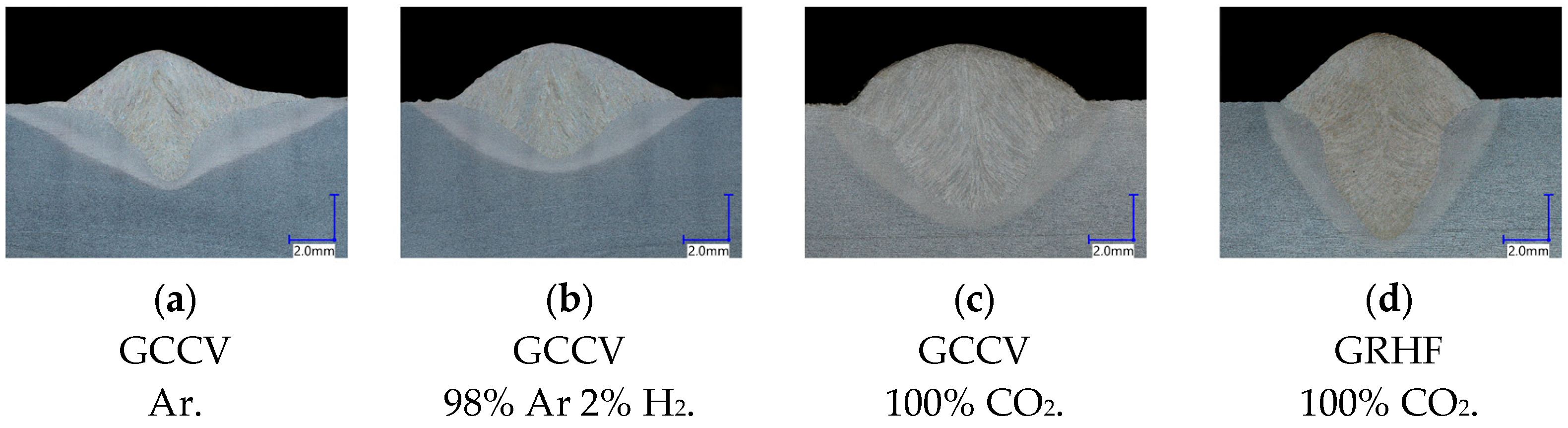

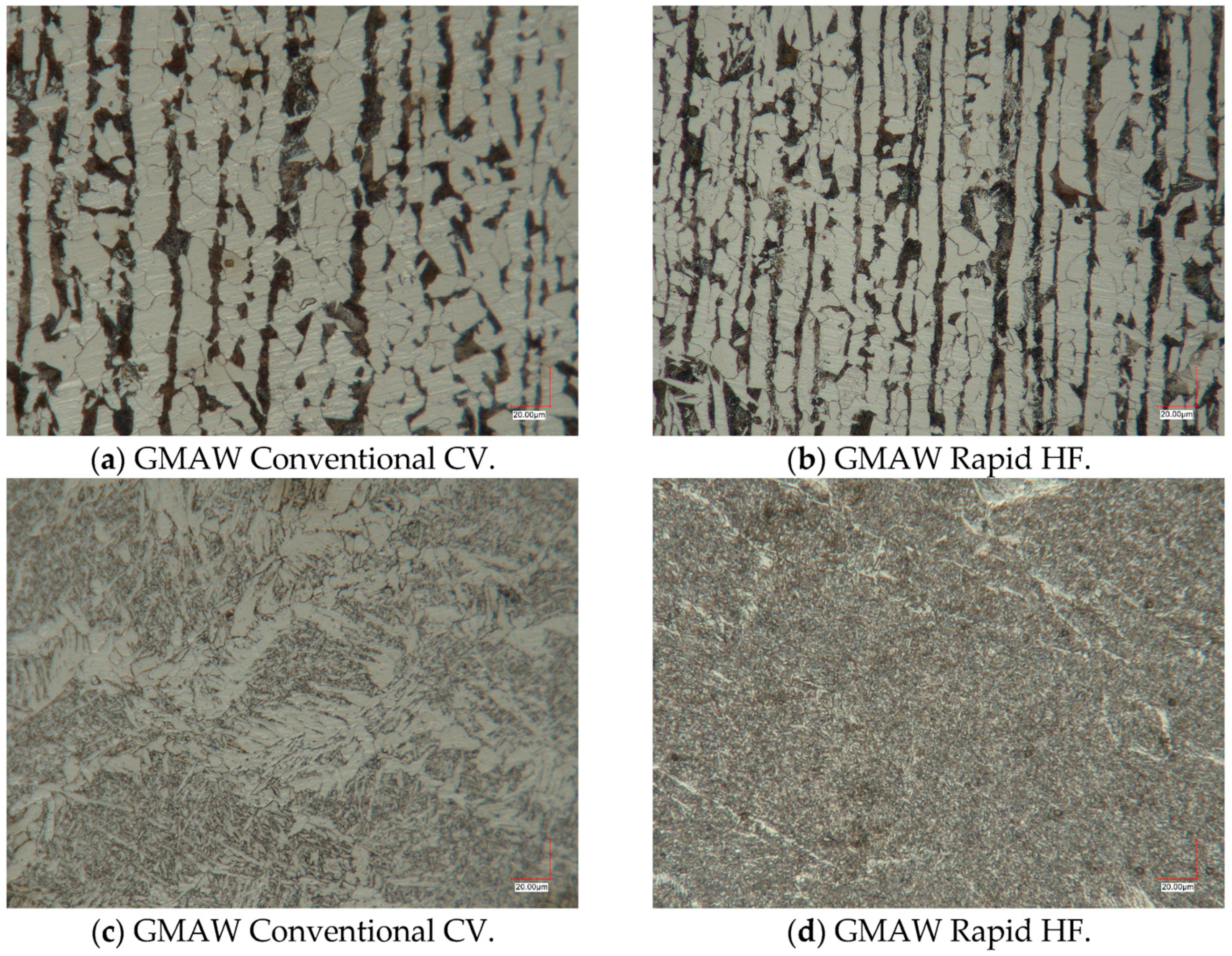

3.1. Effect of the Impact of a High-Frequency Pulsation on the Weld Pool and Penetration on the Base Material

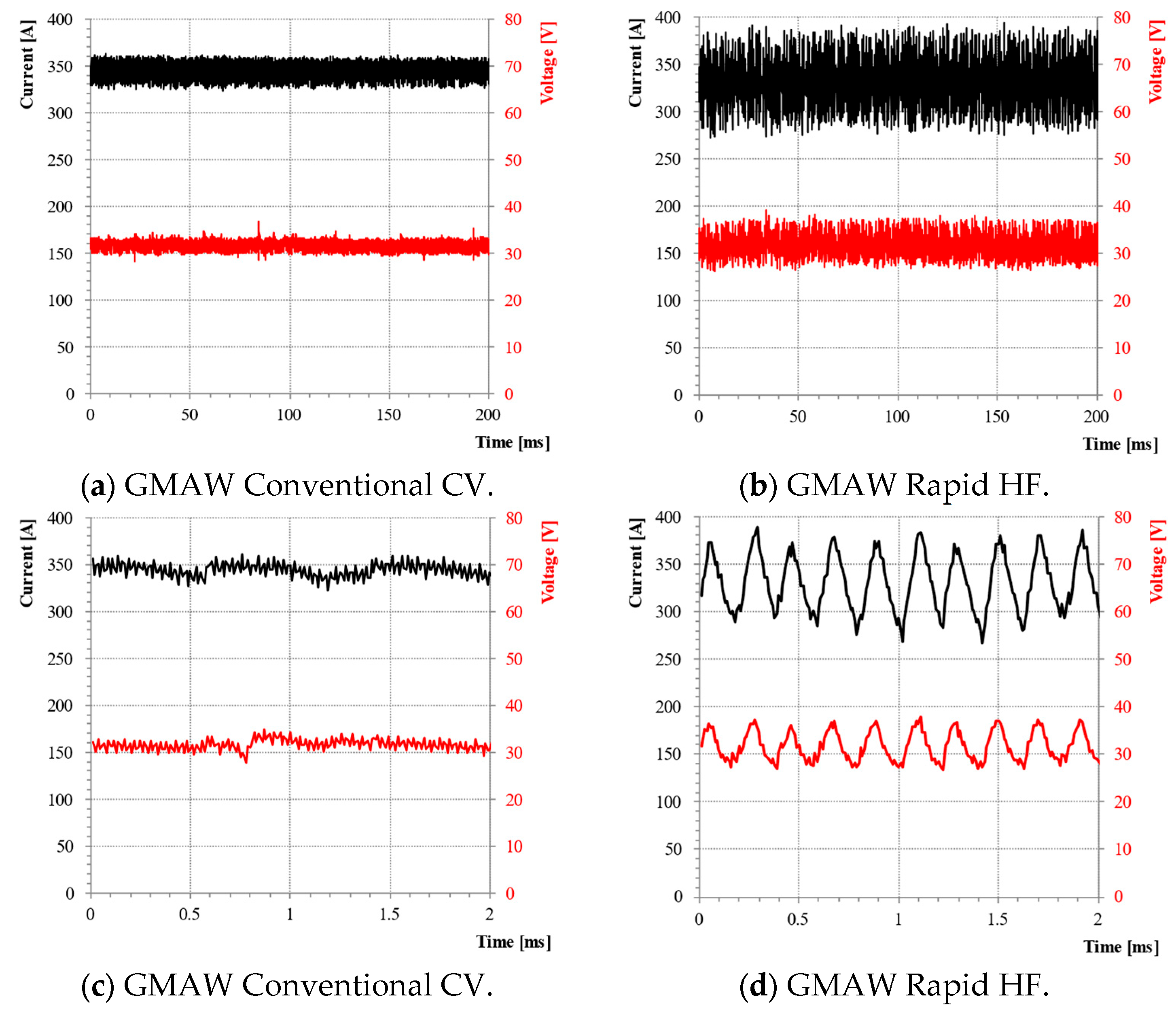

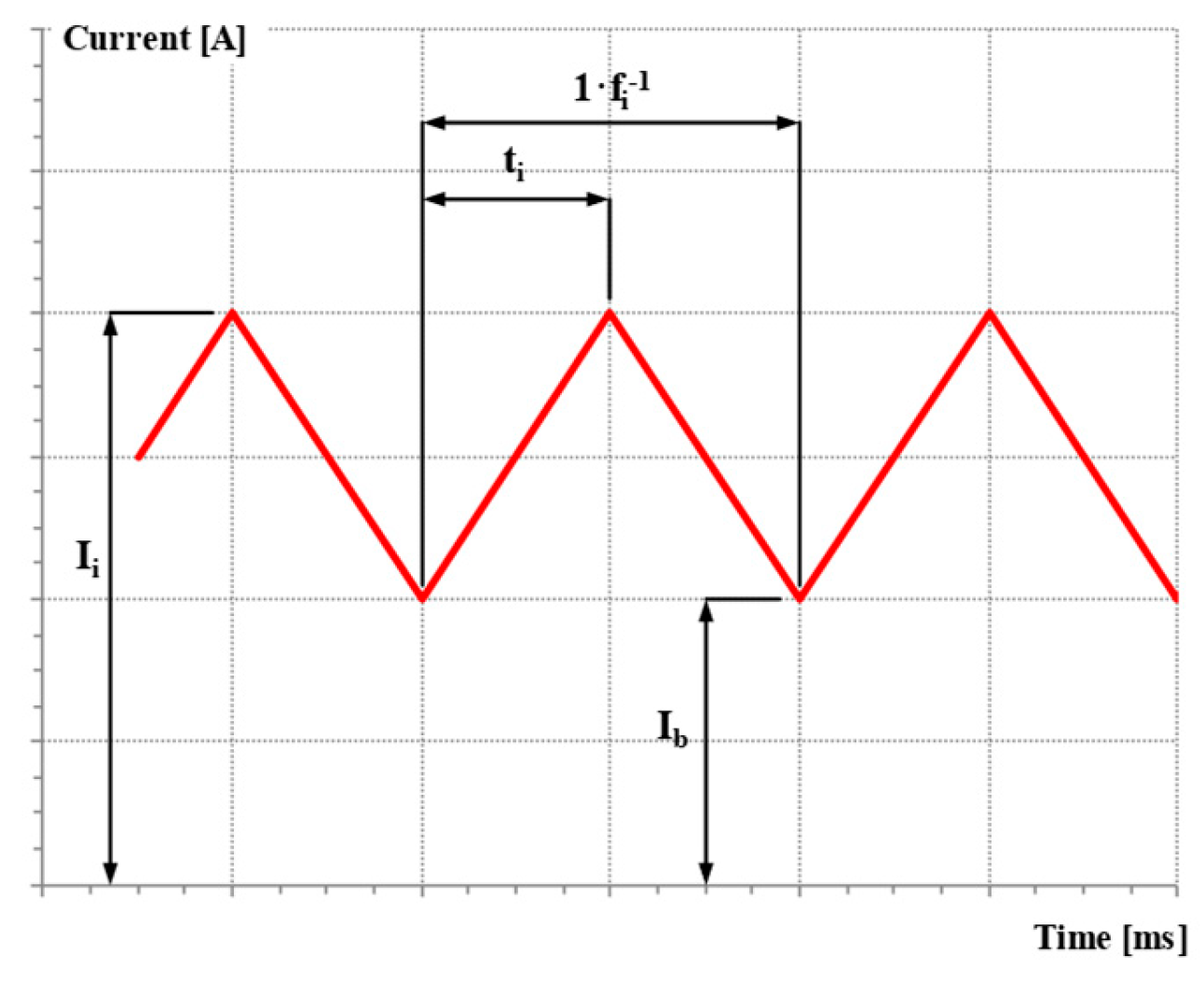

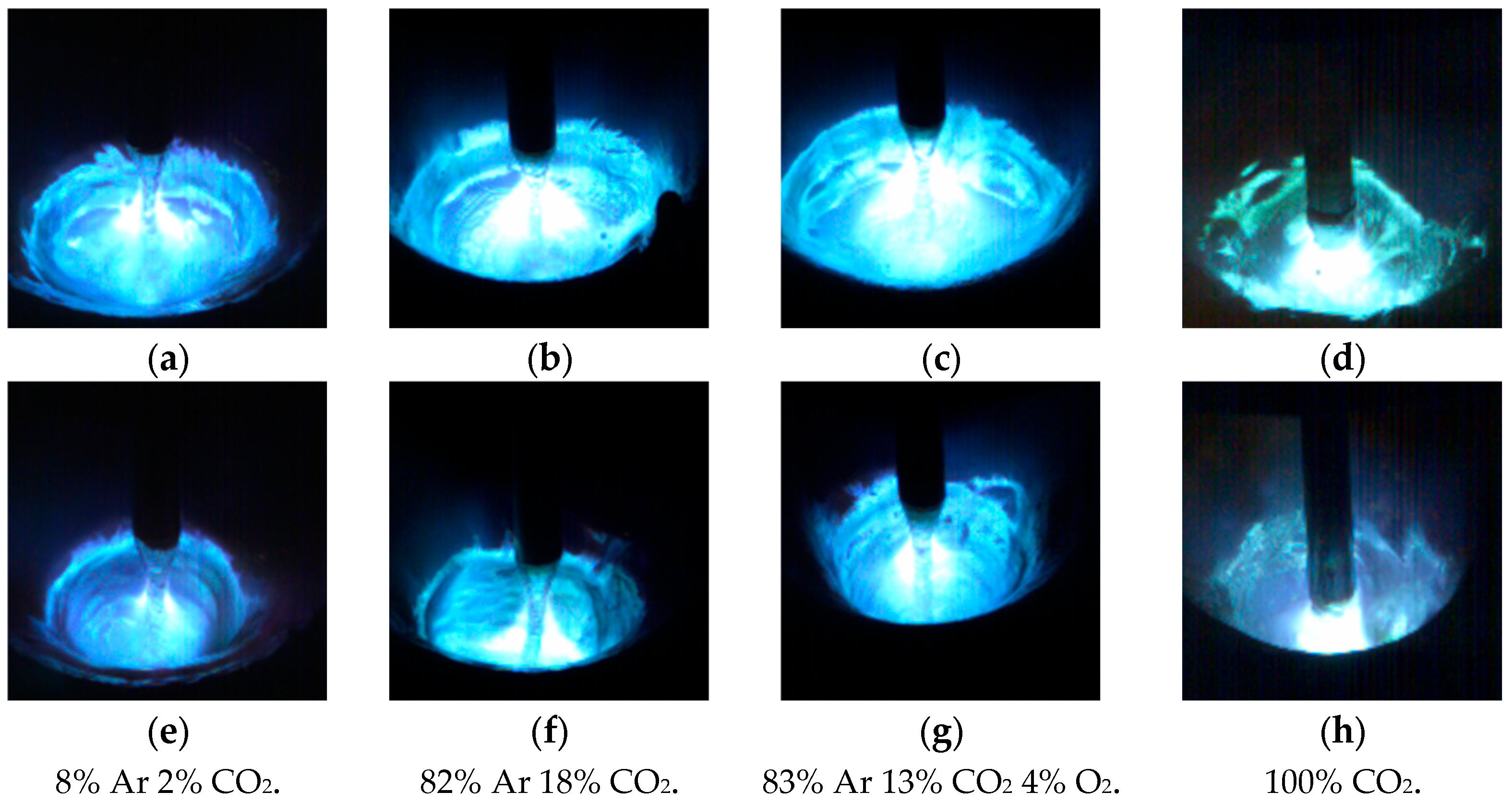

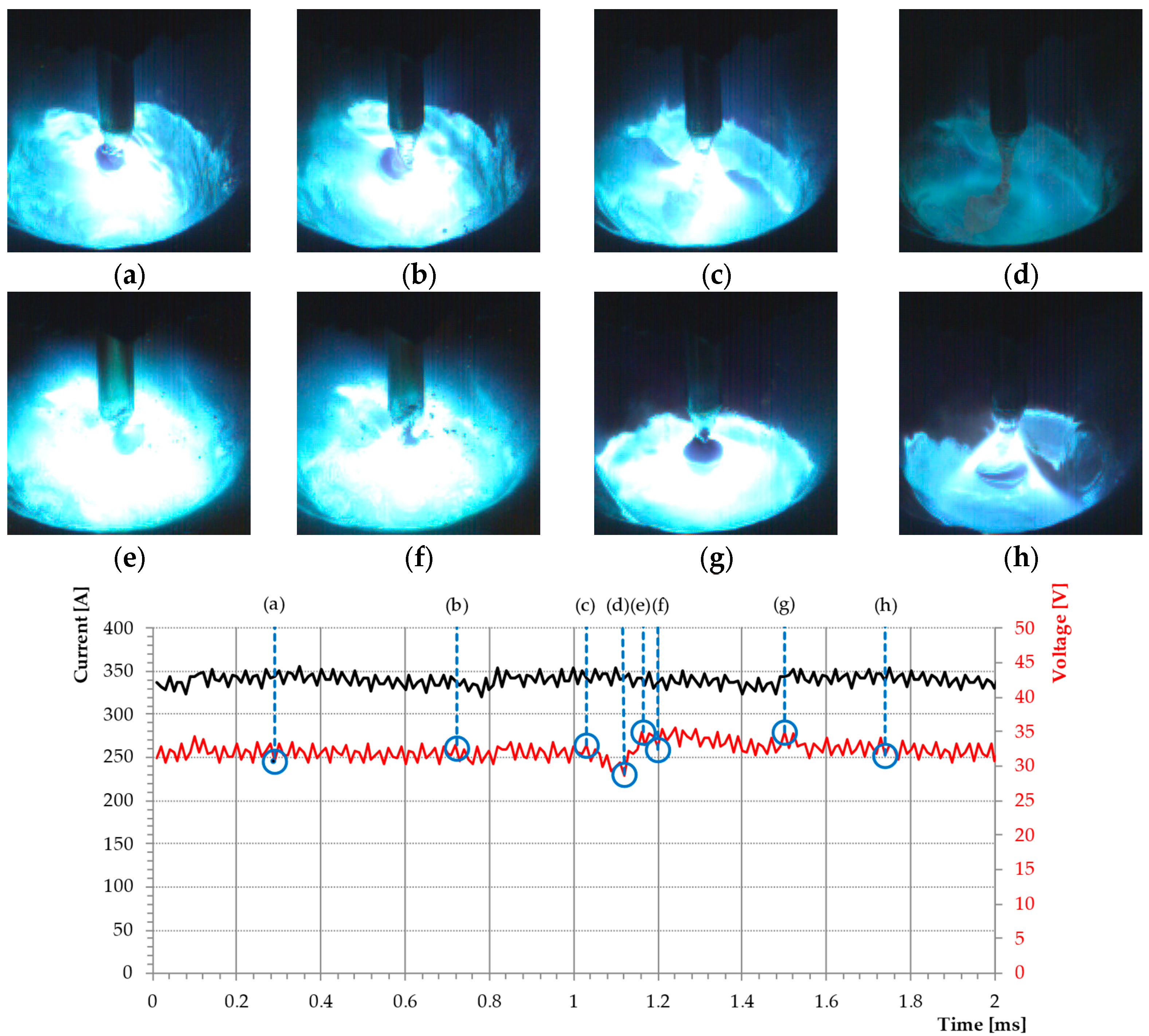

3.2. The Effect of the Impact of High-Frequency Pulsation on the Stabilization of a Buried Welding Arc

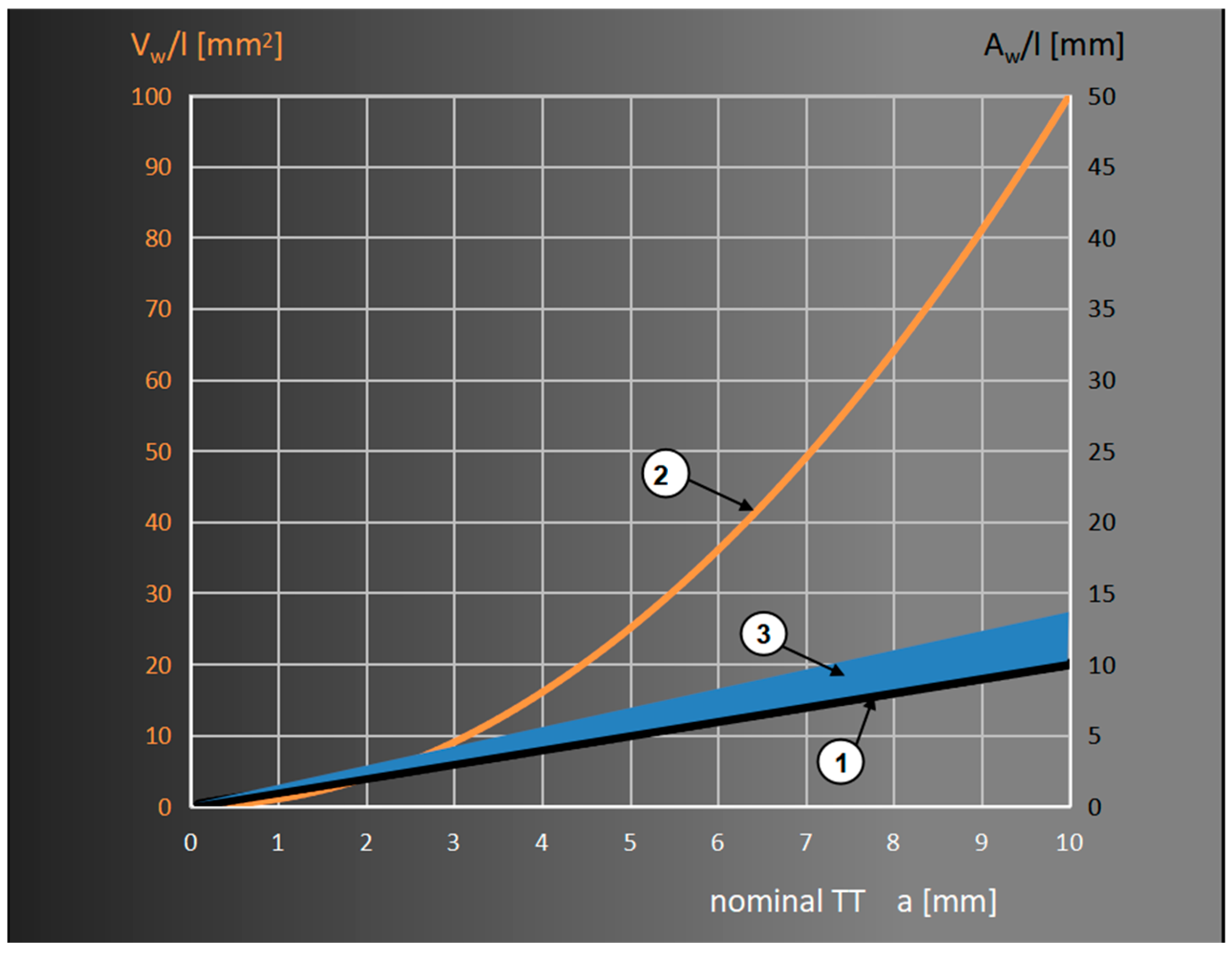

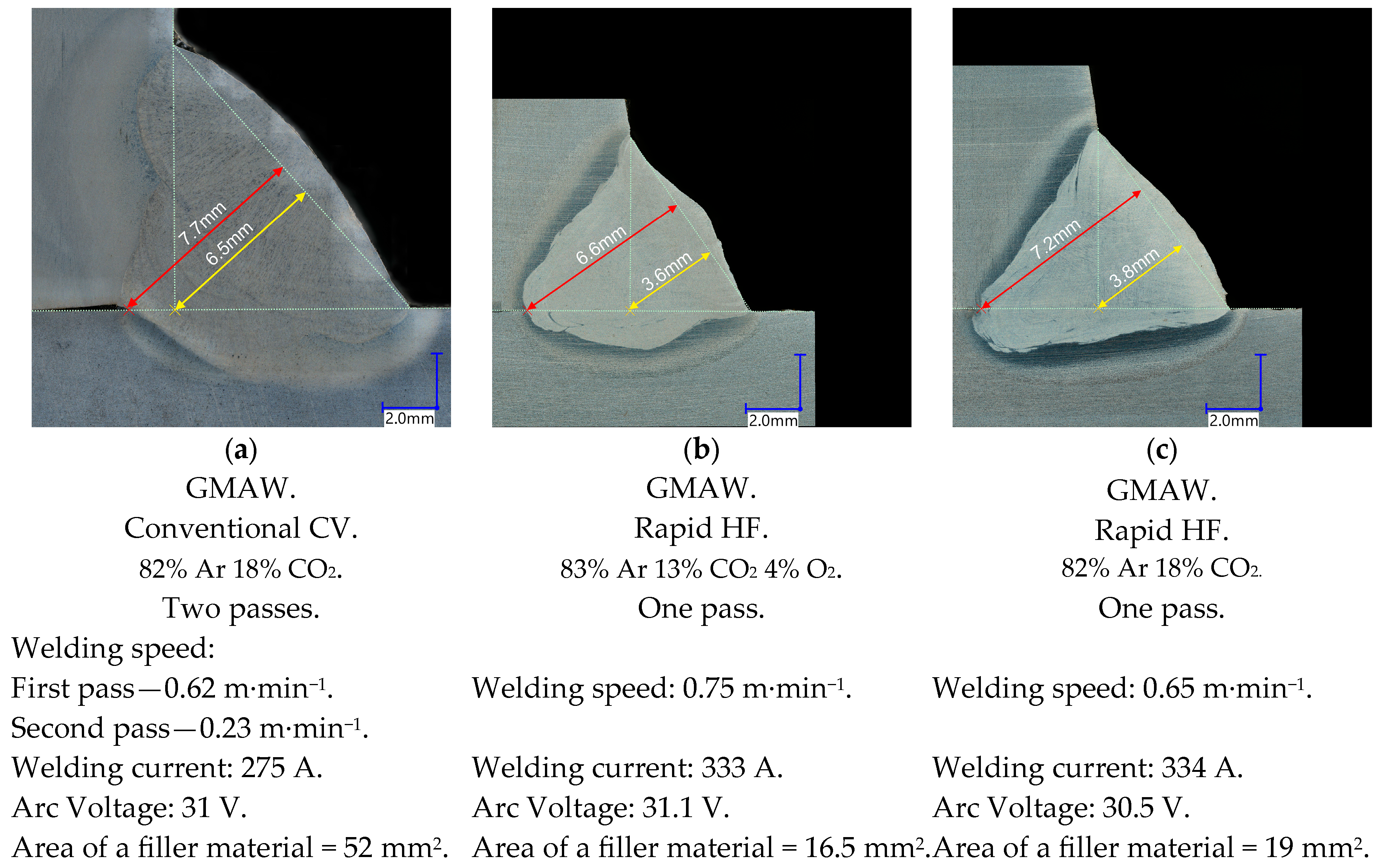

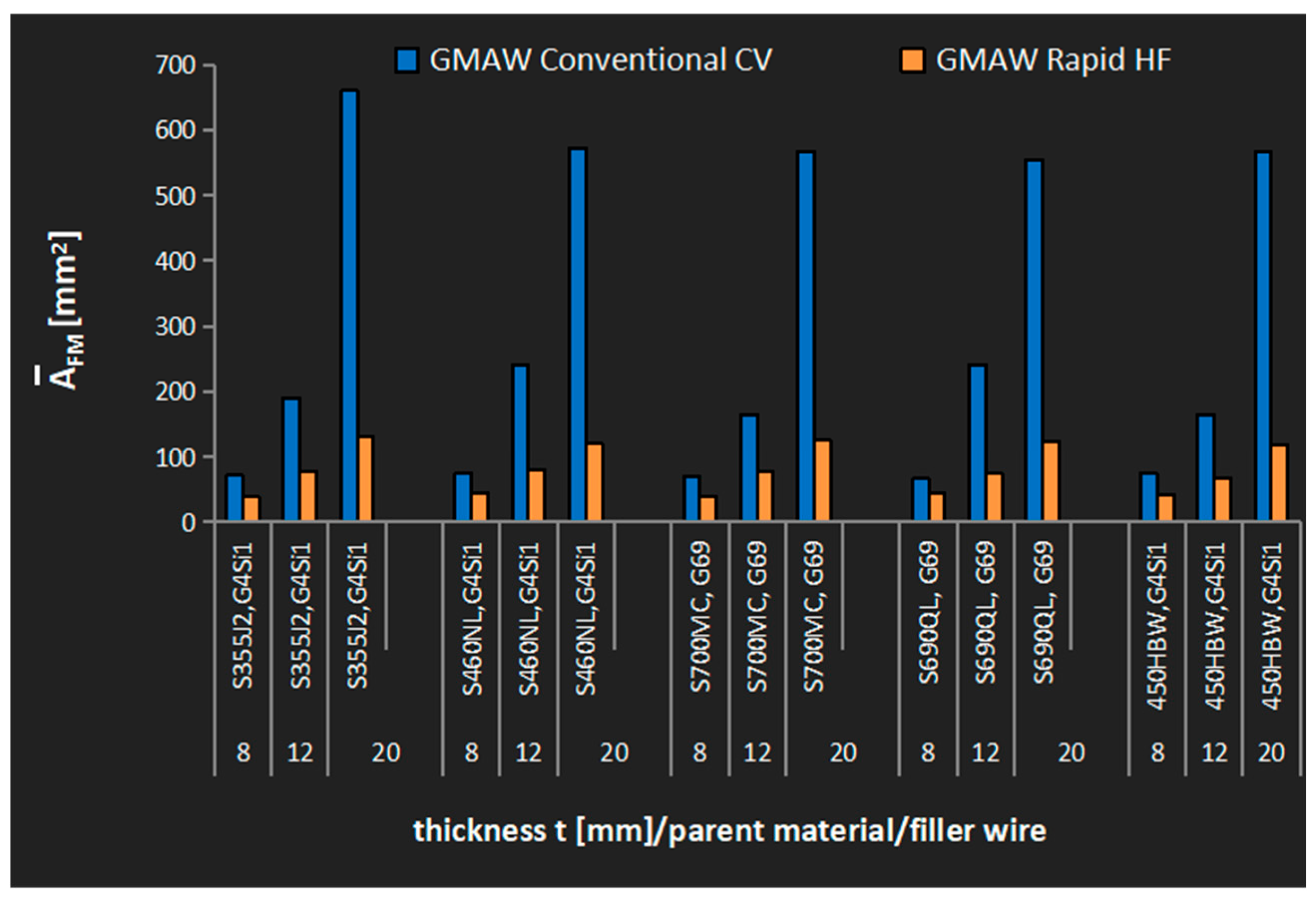

3.3. The Assessment of the Effectiveness of Welding with the Application of the Rapid HF Process

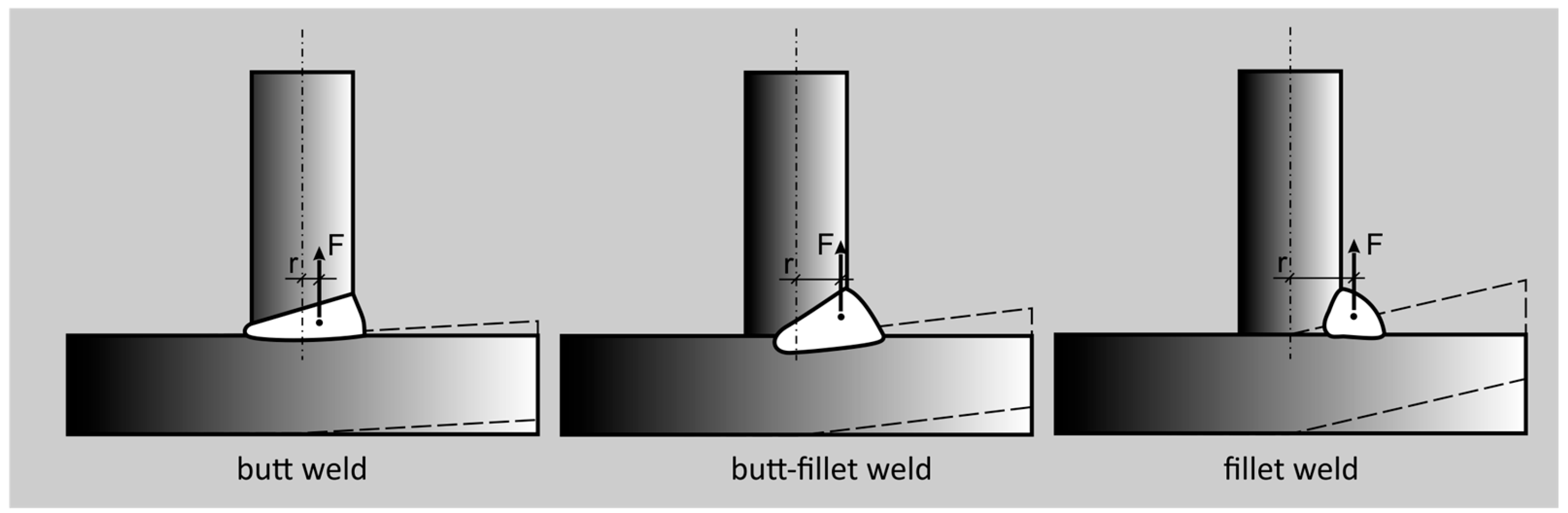

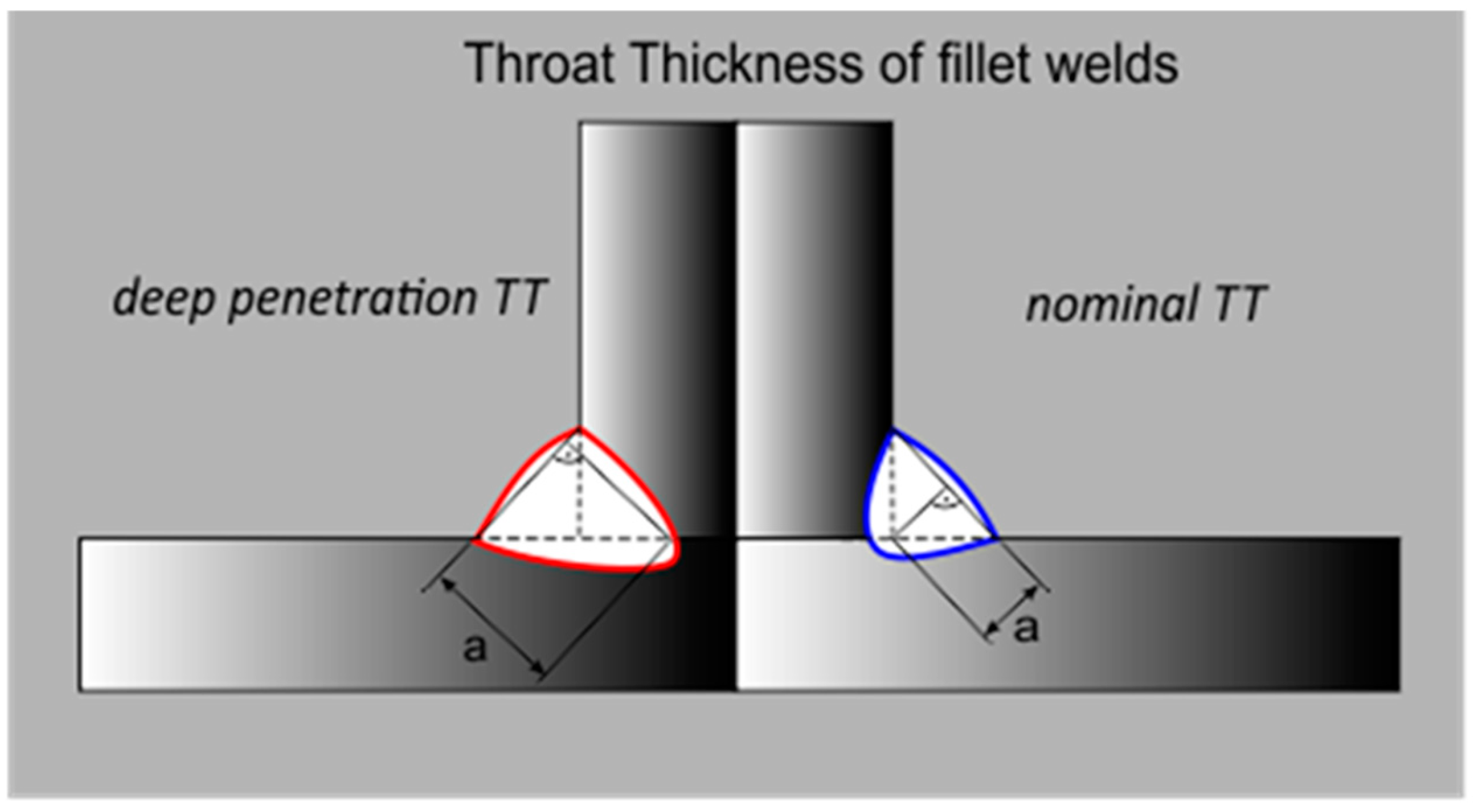

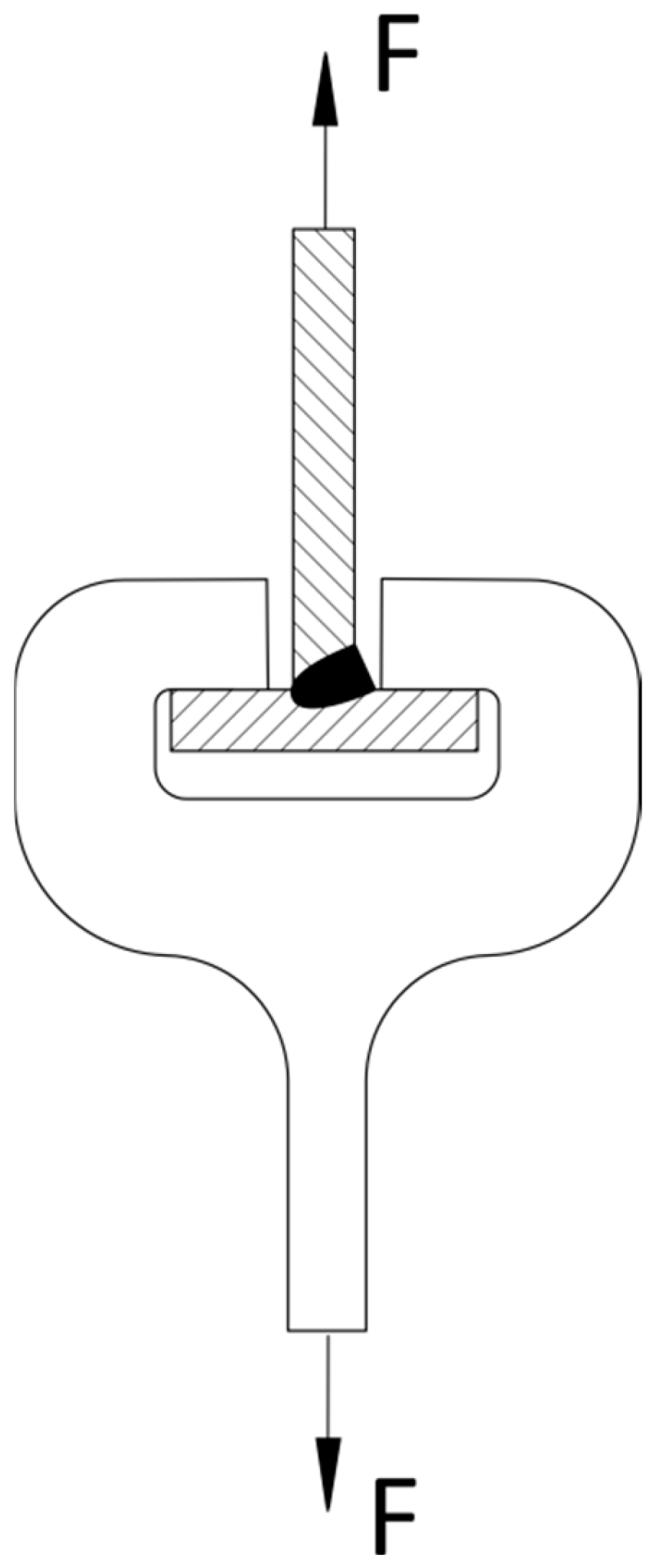

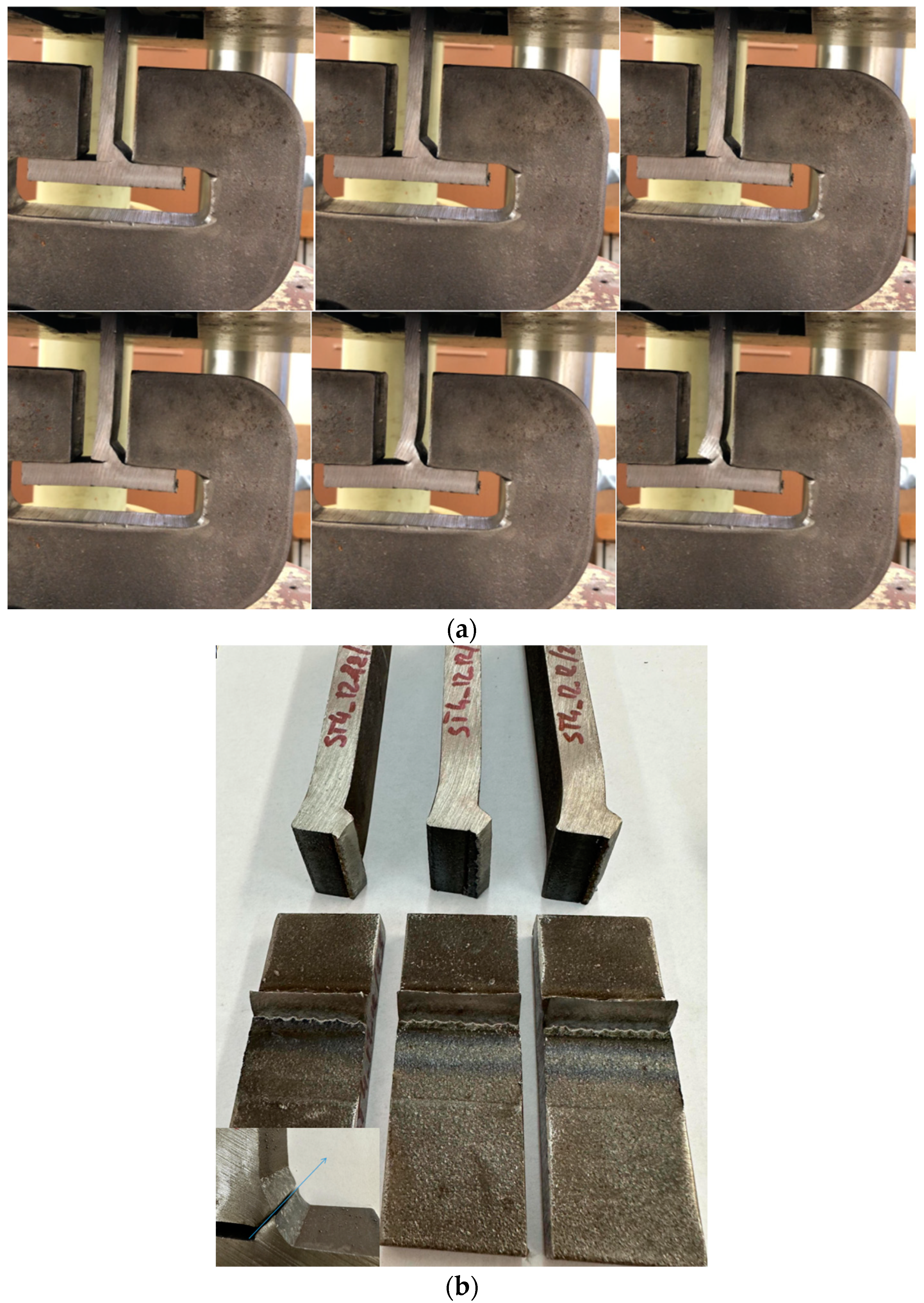

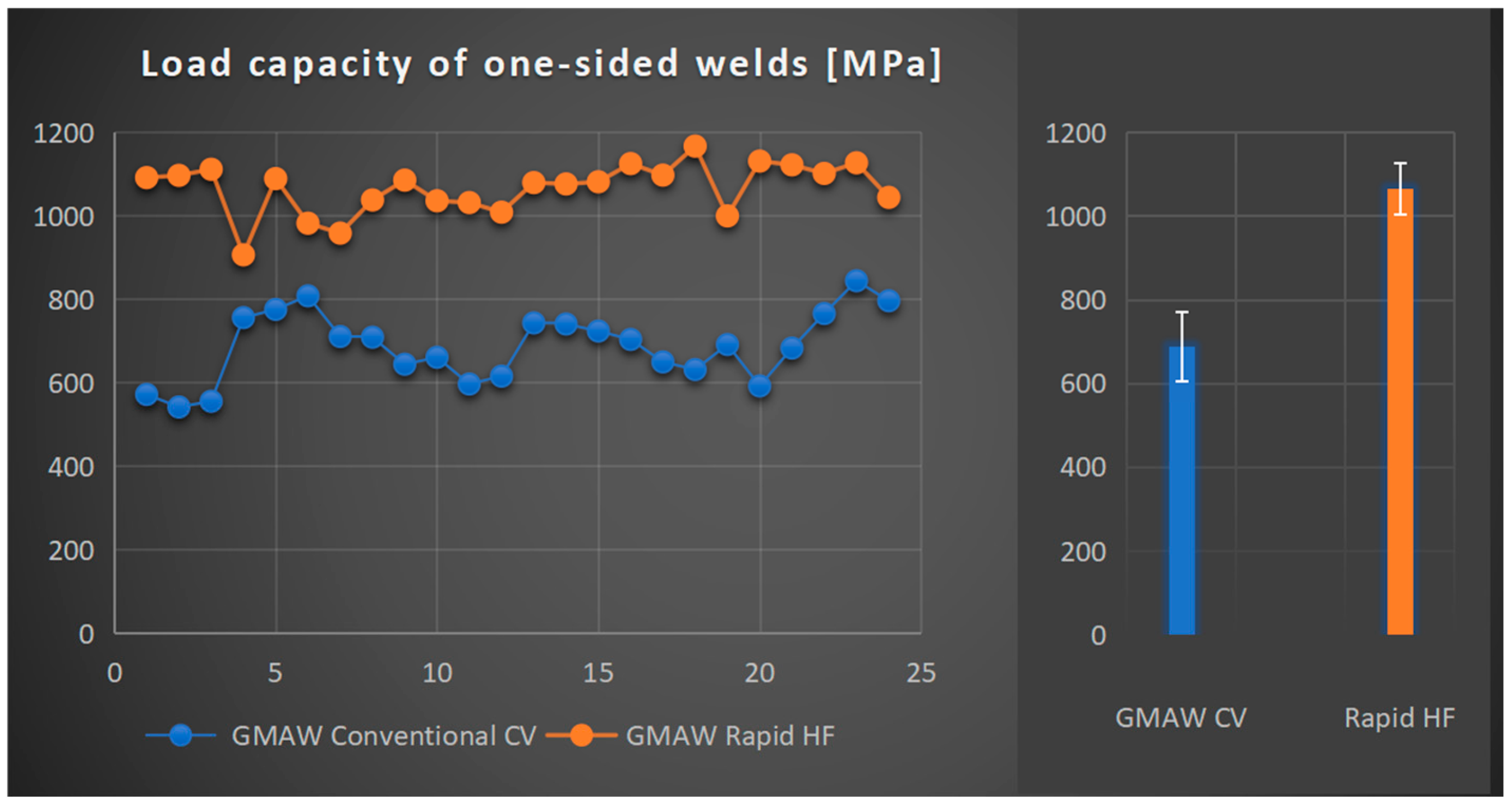

3.4. Analysis of the Load-Carrying Capacity of One-Side Fillet Welds/Fillet–Butt Welds Made with the Application of the GMAW Rapid HF Process

- F force acts axially along the web of a T-joint (Figure 18);

- The field of load-bearing cross-section welds in mm2 is as follows:where a is the throat thickness calculated for fillet welds/fillet–butt welds (mm), and l is the length of fillet welds/fillet–butt welds (mm);

- Welds (in accordance with the results of research) undergo destruction starting from the root point—on the axis of the joints in the direction of the weld face (Figure 19a);

- Welds have the same transverse dimension on the entire length of welds.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EN 1993-1-8:2005; Design of Steel Structures—Part 1–8: Design of Joints. European Committee for Standardization: Brussels, Belgium, 2005.

- Baba, H.; Kadota, K.; Era, T.; Ueyama, T.; Maeshima, M.; Kadoi, K.; Inoue, H.; Tanaka, M. Single-pass full-penetration welding for thick stainless steel using high-current GMAW. Weld. Int. 2021, 35, 240–253. [Google Scholar] [CrossRef]

- Silva, J.H.G.; Dutra, J.C.; Schwedersky, M.B.; Marques, C.; Riffel, K.C.; Bernard, R.A. Dynamically-Flexible Arc—A Novel Interpretation for the High Performance GMAW. In Proceedings of the 29th International Ocean and Polar Engineering Conference (ISOPE 2019), Honolulu, HI, USA, 19–21 June 2019. [Google Scholar]

- Szczesny, M. Shielded Arc Welding Process and Device. EP1640100B1, 24 September 2004. [Google Scholar]

- Komen, H.; Baba, H.; Kadota, K.; Era, T.; Tanaka, M.; Terasaki, H. Three-dimensional particle simulation of buried space formation process during high current gas metal arc welding. J. Adv. Join. Process. 2020, 1, 100019. [Google Scholar] [CrossRef]

- ISO 2553:2019; Welding and Allied Processes—Symbolic Representation on Drawings—Welded Joints. International Organization for Standardization: Geneva, Switzerland, 2019.

- AWS A3.0M/A3.0:2010; Standard Welding Terms and Definitions Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying 12th Edition. American Welding Society: Miami, FL, USA, 2009.

- ISO 17659:2002; Welding—Multilingual Terms for Welded Joints with Illustrations. International Organization for Standardization: Geneva, Switzerland, 2002.

- Uzunali, U.Y.; Cuvalci, H. Review of the definition of weld penetration, depth of fusion and throat thickness on fillet welds. Gazi Univ. J. Sci. 2023, 36, 1746–1757. [Google Scholar] [CrossRef]

- Kudła, K.; Wojsyk, K. The rational use of fillet welds and butt-fillet welds in welded structures. Weld. Tech. Rev. 2019, 91, 7–13. [Google Scholar]

- Mikkola, E.; Murakami, Y.; Marquis, G. Fatigue life assessment of welded joints by the equivalent crack length method. Procedia Mater. Sci. 2014, 3, 1822–1827. [Google Scholar] [CrossRef]

- Tso-Liang, T.; Chin-Ping, F.; Peng-Hsiang, C.; Wei-Chun, Y. Analysis of residual stresses and distortions in T-joint fillet welds. Int. J. Pres. Ves. Pip. 2001, 78, 523–538. [Google Scholar] [CrossRef]

- Barsoum, Z.; Lundbäck, A. Simplified FE welding simulation of fillet welds—3D effects on the deformation residual stress. Eng. Fail. Anal. 2009, 16, 2281–2289. [Google Scholar] [CrossRef]

- Yang, L.; Cui, Y.; Wei, X.; Li, M.; Zhang, Y. Strength of duplex stainless steel fillet welded connections. J. Constr. Steel Res. 2019, 152, 246–260. [Google Scholar] [CrossRef]

- Torabian, S.; Xiao, F.; Haws, R.B.; Schafer, B.W. Design of transverse fillet welds in the lapped joints of thin steel plates. Int. J. Steel Struct. 2018, 18, 337–348. [Google Scholar] [CrossRef]

- Dundu, M. Mathematical model to determine the weld resistance factor of asymmetrical strength results. Structures 2017, 12, 298–305. [Google Scholar] [CrossRef]

- Wojsyk, K.; Nawrocki, J. Study of the impact of lack of fusion in the fillet weld on its fatigue strength under various load combinations. Weld. Tech. Rev. 2019, 91, 17–24. [Google Scholar]

- Grimsmo, E.L.; Daehli, L.E.; Hopperstad, O.S.; Aalberg, A.; Langseth, M.; Clausen, A.H. Numerical study of fillet welds subjected to quasi-static and impact loading. Sciences 2017, 131–132, 1092–1105. [Google Scholar] [CrossRef]

- Khurshid, M.; Barsoum, Z.; Mumtaz, N.A. Ultimate strength and failure modes for fillet welds in high strength steels. Mater. Des. 2012, 40, 36–42. [Google Scholar] [CrossRef]

- Mellor, B.G.; Rainey, R.C.T.; Kirk, N.E. The static strength of end and T fillet weld. Mater. Des. 1999, 20, 193–205. [Google Scholar] [CrossRef]

- Perić, M.; Tonković, Z.; Rodić, A.; Surjak, M.; Garasić, I.; Boras, I.; Svaić, S. Numerical analysis and experimental investigation of welding residual stresses and distortions in a T-joint fillet weld. Mater. Des. 2014, 53, 1052–1063. [Google Scholar]

- ISO 9018:2016-01; Destructive Tests on Welds in Metallic Materials—Tensile Test on Cruciform and Lapped Joints. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 14341:2020; Welding Consumables—Wire Electrodes and Weld Deposits for Gas Shielded Metal Arc Welding of non Alloy and Fine Grain Steels—Classification. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 16834:2025; Welding Consumables—Wire Electrodes, Wires, Rods and Deposits for Gas Shielded Arc Welding of High Strength Steels—Classification. International Organization for Standardization: Geneva, Switzerland, 2025.

- ISO/TR 17671-1:2002; Welding—Recommendations for Welding of Metallic Materials. Part 1: General Guidance for Arc Welding. International Organization for Standardization: Geneva, Switzerland, 2002.

- Lancaster, J.F. The Physics of Welding, 2nd ed.; Pergamon Press: Oxford, UK, 1986. [Google Scholar]

- Lin, M.A.; Eagar, T.W. Pressures Produced by Gas Tungsten Arcs. Metall. Trans. B 1986, 17, 601–607. [Google Scholar] [CrossRef]

- Matsunawa, A.; Yamamoto, H.; Hiramoto, S. Pulsed arc welding. Q. J. Jap. Weld. Soc. 1984, 53, 284–322. [Google Scholar]

- Krivtsun, I.; Demchenko, V.; Krikent, I.; Reisgen, U.; Mokrov, O.; Sharma, R. Characteristics of high-frequency pulsed current arc with refractory cathode. Paton Weld. J. 2022, 13, 9–18. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, H.; Qi, B.; Yang, Z. Effect of arc behavior on Ti-6Al-4V welds during high frequency pulsed arc welding. J. Materi. Process. Technol. 2017, 243, 9–15. [Google Scholar] [CrossRef]

- Yamazaki, K.; Suzuki, R.; Shimizu, H.; Koshiishi, F. Spatter and fume reduction in CO2 Gas-Shielded Arc Welding by regulated globular transfer. Weld. World 2012, 56, 12–19. [Google Scholar] [CrossRef]

- Liskevych, O.; Scotti, A. Influence of the CO2 content on operational performance of short-circuit GMAW. Weld. World 2015, 59, 217–224. [Google Scholar] [CrossRef]

- Zielinska, S.; Pellerin, S.; Valensi, F.; Dzierzega, K.; Musiol, K.; Izarra, C.; Briand, F. Gas influence on the arc shape in MIG-MAG welding. Eur. Phys. J. Appl. Phys. 2008, 43, 111–122. [Google Scholar] [CrossRef]

- Tusek, J.; Suban, M. Experimental research of the effect of hydrogen in argon as a shielding gas in arc welding of high-alloy stainless steel. Int. J. Hydrog. Energy. 2000, 25, 369–376. [Google Scholar] [CrossRef]

- Baba, H.; Era, T.; Ueyama, T.; Tanaka, M. Single pass full penetration joining for heavy plate steel using high current GMA process. Weld. World 2017, 61, 963–969. [Google Scholar] [CrossRef]

- Bryła, S. Electrically welded iron bridge over the Słudwia River in Poland. Weld. Tech. Rev. 1929, 2, 186–194. [Google Scholar]

- Śledziewski, E. Projektowanie Stalowych Konstrukcji Spawanych, 1st ed.; WNT: Warsaw, Poland, 1972. [Google Scholar]

- Kudła, K.; Wojsyk, K. Method for analytical computation of stresses in fillet joints for complex load states—According to Eurocode 3. Weld. Tech. Rev. 2014, 86, 8–14. [Google Scholar]

- Ferenc, K.; Ferenc, J. Konstrukcje Spawane, 1st ed.; WNT: Warsaw, Poland, 2006. [Google Scholar]

- Wichtowski, B. Calculation of static and fatigue load capacity of welds in Eurocode 3. Weld. Tech. Rev. 2011, 83, 15–22. [Google Scholar]

| Element | G4Si 1 | G69 2 | S355J2 | S460NL | S700MC | S690QL | 450HBW |

|---|---|---|---|---|---|---|---|

| C | 0.071 | 0.08 | 0.130 | 0.176 | 0.066 | 0.141 | 0.200 |

| Si | 0.91 | 0.60 | 0.018 | 0.455 | 0.034 | 0.288 | 0.350 |

| Mn | 1.63 | 1.70 | 1.49 | 1.68 | 1.90 | 1.10 | 1.32 |

| P | 0.070 | - | 0.150 | 0.011 | 0.008 | 0.010 | 0.015 |

| S | 0.014 | - | 0.050 | 0.0009 | 0.0005 | 0.0003 | 0.001 |

| Cr | 0.021 | 0.25 | 0.089 | 0.035 | 0.028 | 0.330 | 0.980 |

| Ni | 0.033 | 1.5 | 0.046 | 0.014 | 0.011 | 0.190 | 0.040 |

| Al | 0.002 | - | 0.068 | 0.020 | 0.054 | 0.057 | 0.087 |

| Cu | 0.106 | - | 0.052 | 0.011 | 0.011 | 0.295 | 0.020 |

| Nb | - | - | 0.025 | 0.002 | 0.047 | 0.023 | 0.030 |

| Ti | 0.009(Zr + Ti) | - | 0.001 | 0.002 | 0.143 | 0.021 | 0.010 |

| V | 0.001 | - | 0.002 | 0.109 | 0.008 | 0.005 | 0.010 |

| B | - | - | 0.0000 | 0.0002 | 0.0002 | 0.0026 | 0.0030 |

| Mo | 0.013 | 0.3 | 0.010 | 0.011 | 0.004 | 0.167 | 0.170 |

| N | - | - | 0.006 | 0.025 | 0.000 | 0.0048 | 0.0400 |

| Process | Wire Feed Rate [m·min−1] | Welding Speed [m·min−1] | CTWD [mm] | Pulse Frequency [Hz] | Thickness PM [mm] | Welding Current [A] | Arc Voltage [V] | Heat Input [kJ·mm−1] |

|---|---|---|---|---|---|---|---|---|

| GCCV | 8.2 | 0.50 | 15 | - | 8 | 240 | 27.4 | 0.63 |

| GCCV | 8.0 | 0.15 | 15 | - | 12 | 250 | 20.0 | 1.60 |

| 8.8 (1P) | 0.60 | 15 | - | 254 | 30.9 | 0.63 | ||

| GCCV | 8.8 (2P) | 0.15 | 15 | - | 20 | 252 | 31.0 | 2.50 |

| 8.0 (3P) | 0.15 | 15 | - | 235 | 22.5 | 1.69 | ||

| GRHF | 16 | 0.90 | 14 | 5000 | 8 | 430 | 34.0 | 0.78 |

| GRHF | 16 | 0.54 | 16 | 5000 | 12 | 430 | 36.0 | 1.38 |

| GRHF | 16 | 0.55 | 16 | 5000 | 20 | 430 | 39.0 | 1.46 |

| Process | Wire Feed Rate [m·min−1] | Pulse Frequency [Hz] | Peak Current [A] | Pulse Time [ms] | Base Current [A] | Response Rate [A·ms−1] | Welding Current [A] | Arc Voltage [V] |

|---|---|---|---|---|---|---|---|---|

| GCCV | 11 | - | - | - | - | - | 340 | 31.5 |

| GRHF | 11 | 5000 | 380 | 0.1 | 280 | 1000 | 330 | 28.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kudła, K.; Makles, K.; Iwaszko, J. The Technological, Economic, and Strength Aspects of High-Frequency Buried Arc Welding Using the GMAW Rapid HF Process. Materials 2025, 18, 1490. https://doi.org/10.3390/ma18071490

Kudła K, Makles K, Iwaszko J. The Technological, Economic, and Strength Aspects of High-Frequency Buried Arc Welding Using the GMAW Rapid HF Process. Materials. 2025; 18(7):1490. https://doi.org/10.3390/ma18071490

Chicago/Turabian StyleKudła, Krzysztof, Krzysztof Makles, and Józef Iwaszko. 2025. "The Technological, Economic, and Strength Aspects of High-Frequency Buried Arc Welding Using the GMAW Rapid HF Process" Materials 18, no. 7: 1490. https://doi.org/10.3390/ma18071490

APA StyleKudła, K., Makles, K., & Iwaszko, J. (2025). The Technological, Economic, and Strength Aspects of High-Frequency Buried Arc Welding Using the GMAW Rapid HF Process. Materials, 18(7), 1490. https://doi.org/10.3390/ma18071490