Graining and Texturing of Metal Surfaces by Picosecond Laser Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

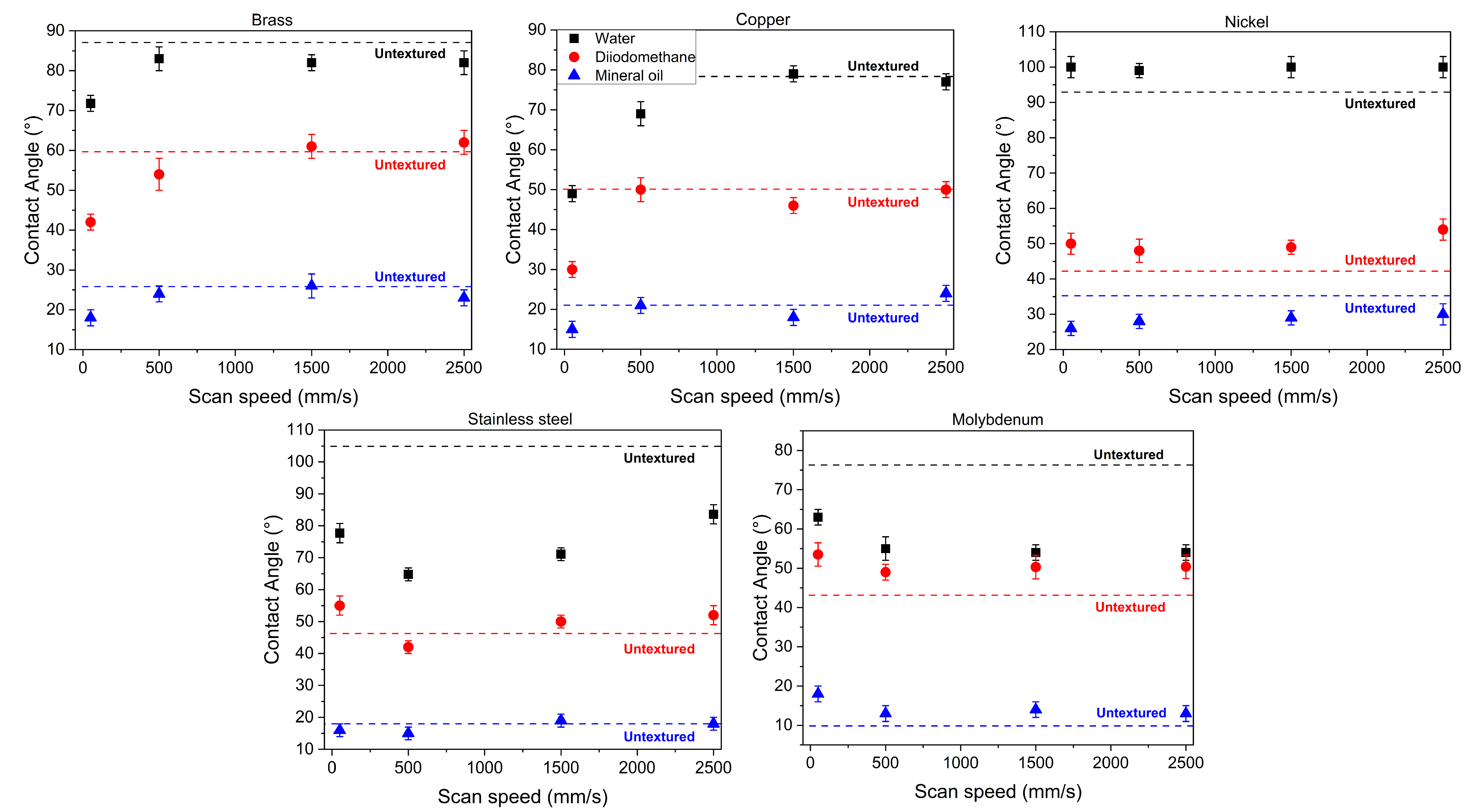

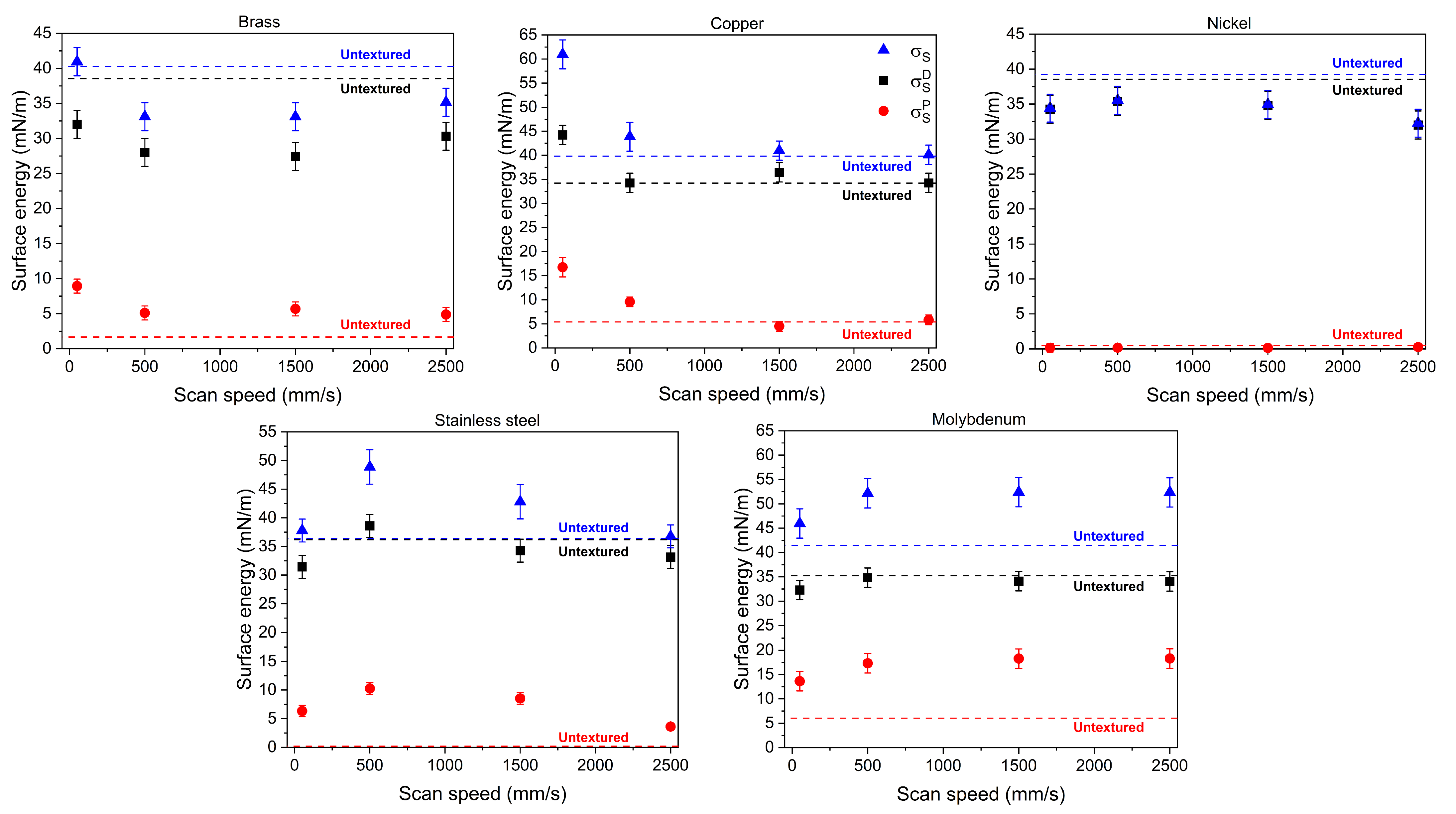

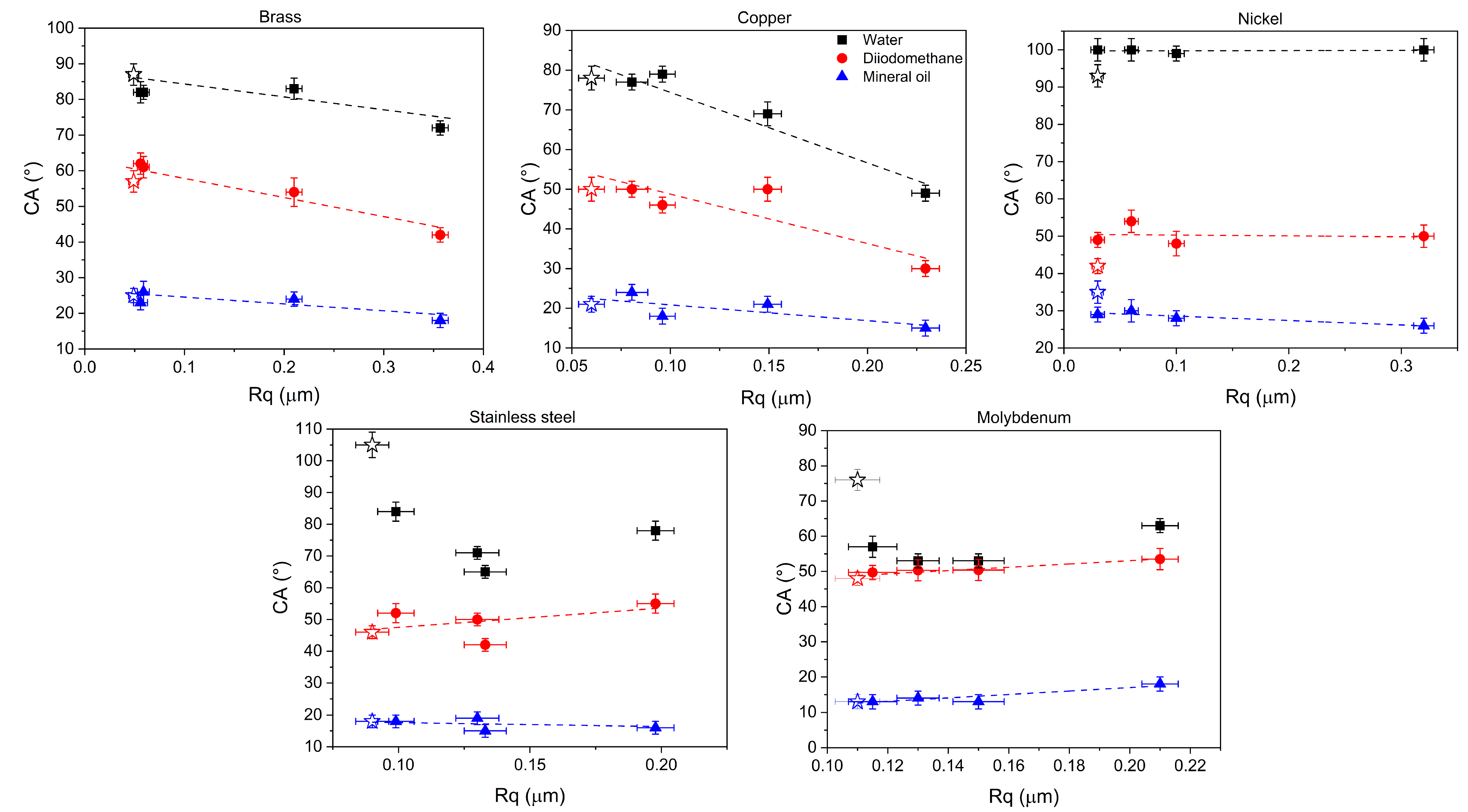

3.1. Contact Angle and Surface Energy

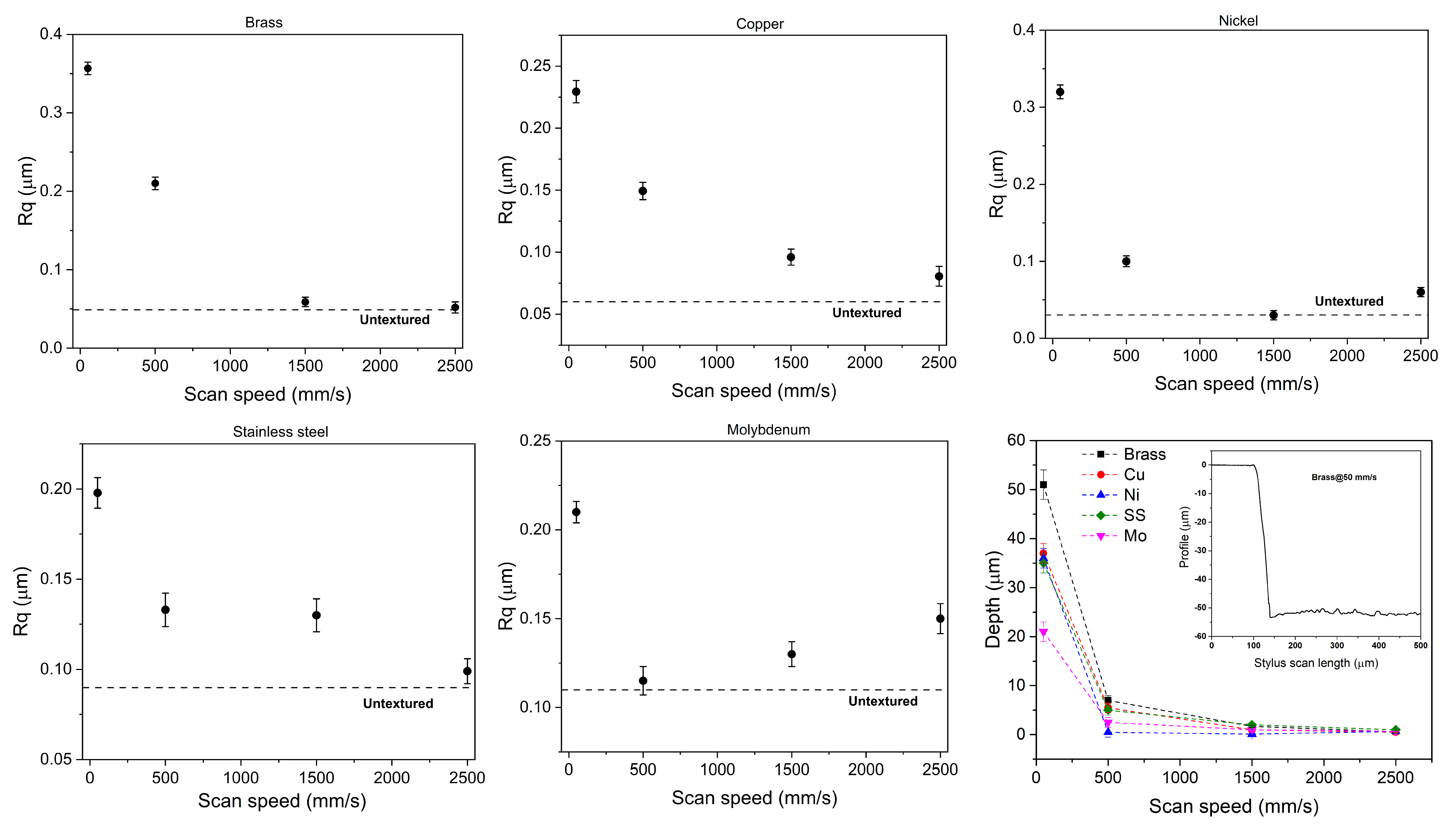

3.2. Roughness

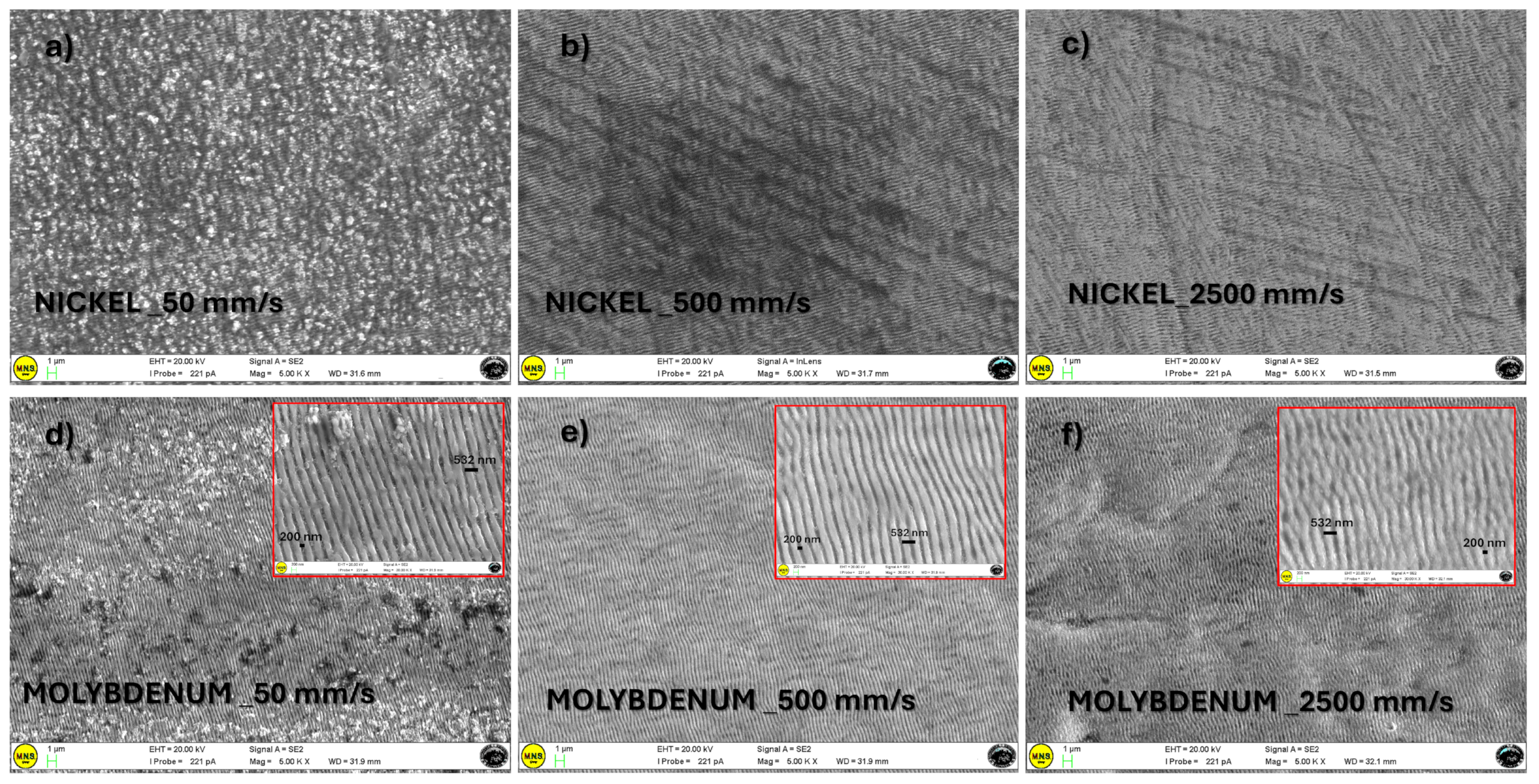

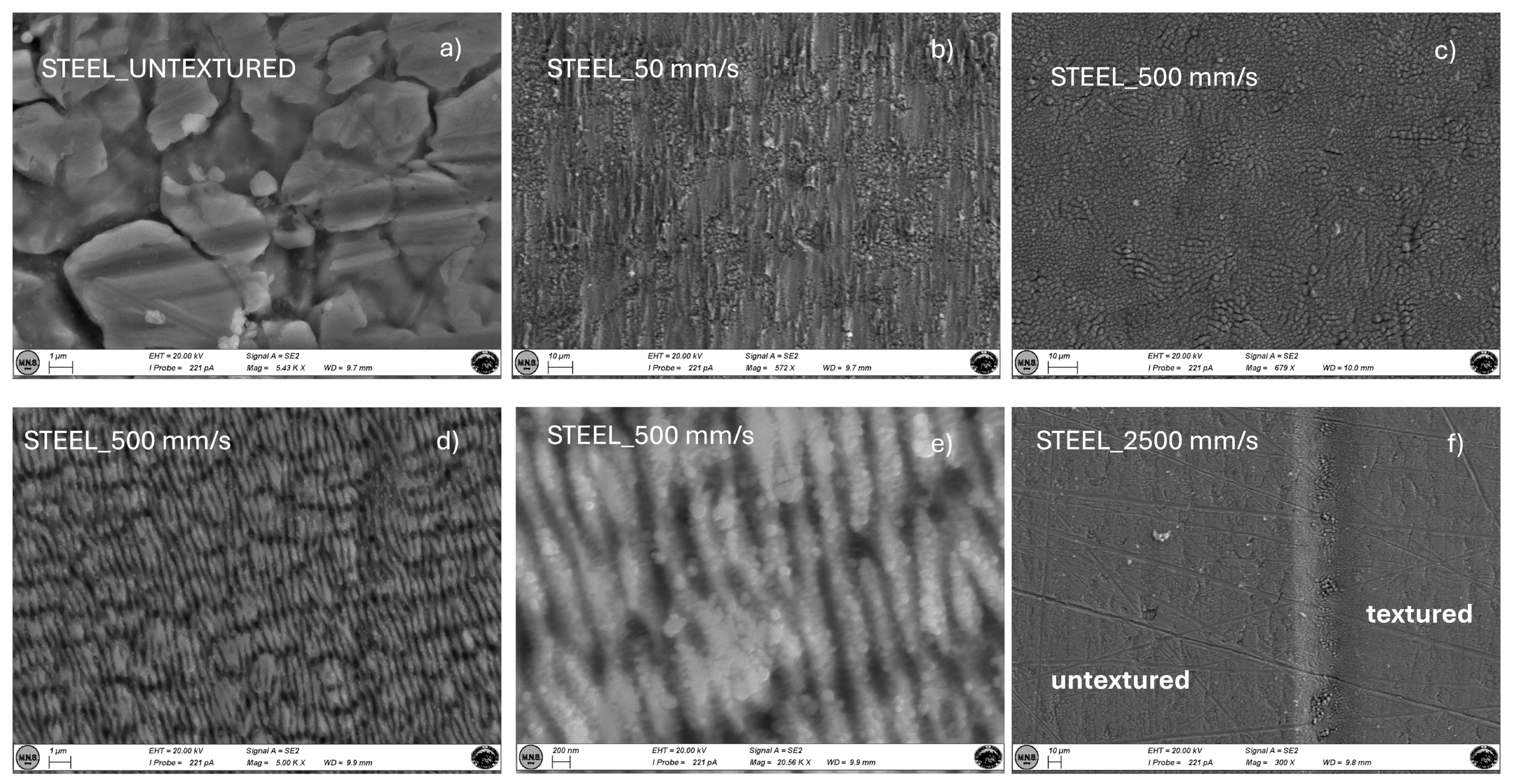

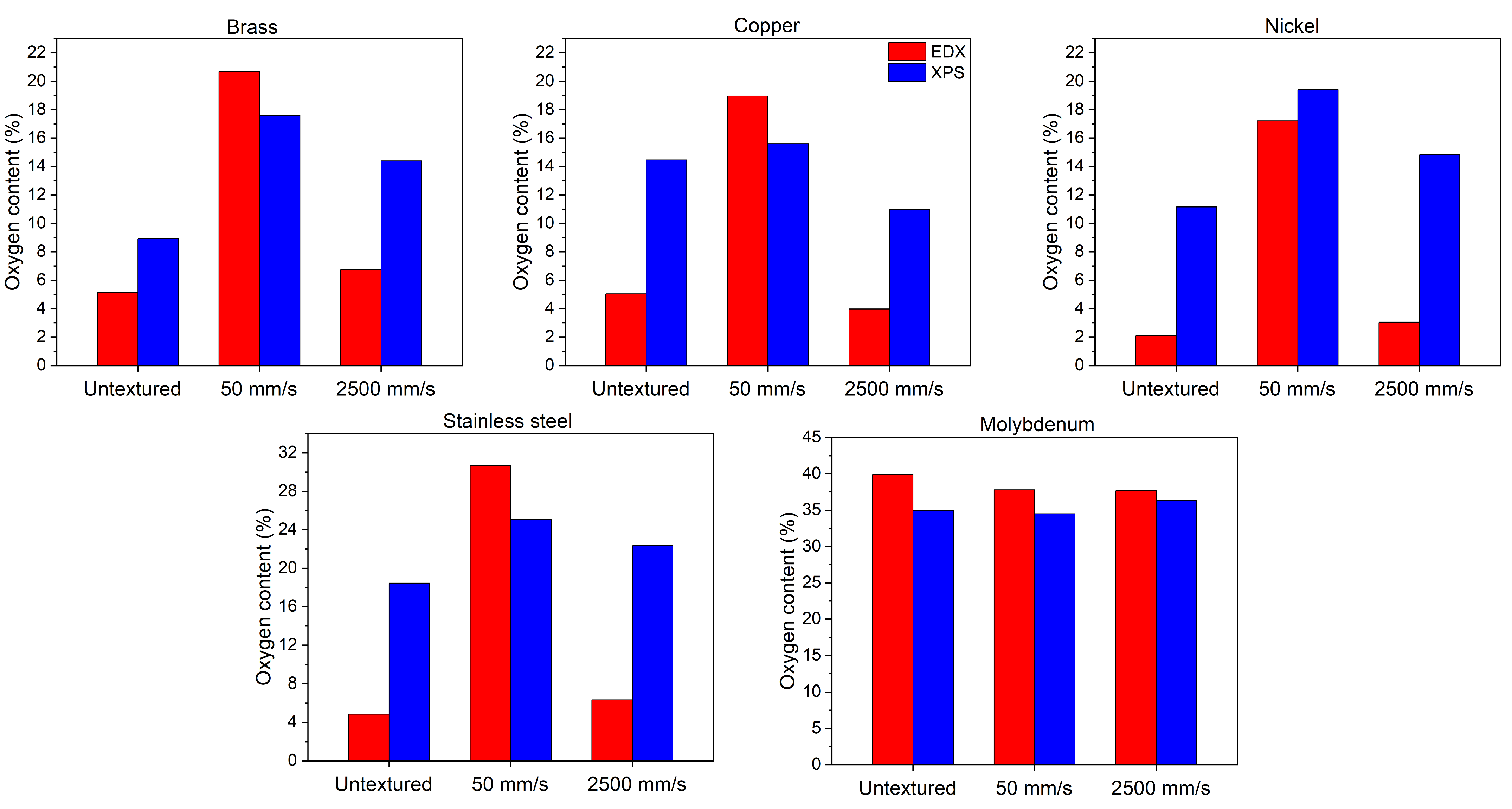

3.3. SEM and EDX Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LIPSS | Laser Induced Periodic Surface Structure |

| CA | Contact Angle |

| SE | Surface Energy |

References

- Joshi, G.; Putignano, C.; Gaudiuso, C.; Stark, T.; Kiedrowski, T.; Ancona, A.; Carbone, G. Effects of the micro surface texturing in lubricated non-conformal point contacts. Tribol. Int. 2018, 127, 296–301. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent progresses and applications in laser-based surface texturing systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Ma, J.; Liu, Y.; Mostaghimi, J.; Zhan, X. Effect of laser-induced texture on lubrication retention and tribological properties of 40Cr alloy surfaces. Tribol. Int. 2023, 187, 108651. [Google Scholar] [CrossRef]

- Etsion, I. Improving Tribological Performance of Mechanical Components by Laser Surface Texturing. Tribol. Lett. 2004, 17, 733–737. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vijayaraghavan, L.; Vasa, N.J. Investigation of Nd3+:YAG Laser Aided Surface Texturing to Improve Tribological Characteristics of Piston Ring. J. Laser Micro/Nanoeng. 2017, 12, 195–202. [Google Scholar] [CrossRef][Green Version]

- Son, M.K.; Choe, H.C. Evaluation of Interfacial Bonding Strength between Laser Textured Metal Coping and Porcelain. Procedia Eng. 2011, 10, 2286–2291. [Google Scholar] [CrossRef]

- Corsaro, C.; Orlando, G.; Costa, G.; Latino, M.; Barreca, F.; Mezzasalma, A.M.; Neri, F.; Fazio, E. Wetting Behavior Driven by Surface Morphology Changes Induced by Picosecond Laser Texturing. Materials 2024, 17, 1719. [Google Scholar] [CrossRef]

- Drelich, J.W.; Boinovich, L.; Chibowski, E.; Della Volpe, C.; Hołysz, L.; Marmur, A.; Siboni, S. Contact angles: History of over 200 years of open questions. Surf. Innov. 2020, 8, 3–27. [Google Scholar] [CrossRef]

- Good, R.J. Contact angle, wetting, and adhesion: A critical review. J. Adhes. Sci. Technol. 1992, 6, 1269–1302. [Google Scholar] [CrossRef]

- Wróblewski, P.; Kachel, S. The concept of the contact angle in the process of oil film formation in internal combustion piston engines. Sci. Rep. 2023, 13, 20715. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The correlation between the surface energy, the contact angle and the spreading parameter, and their relevance for the wetting behaviour of DLC with lubricating oils. Tribol. Int. 2013, 66, 225–233. [Google Scholar] [CrossRef]

- Deng, X.; Zhou, X.; Kamal, M.S.; Hussain, S.M.S.; Mahmoud, M.; Patil, S. A Modified Contact Angle Measurement Process to Suppress Oil Drop Spreading and Improve Precision. Molecules 2022, 27, 1195. [Google Scholar] [CrossRef]

- Butt, H.J.; Liu, J.; Koynov, K.; Straub, B.; Hinduja, C.; Roismann, I.; Berger, R.; Li, X.; Vollmer, D.; Steffen, W.; et al. Contact angle hysteresis. Curr. Opin. Colloid Interface Sci. 2022, 59, 101574. [Google Scholar] [CrossRef]

- Fowkes, F.M. Attractive Forces at Interfaces. Ind. Eng. Chem. 1964, 56, 40–52. [Google Scholar] [CrossRef]

- Kozbial, A.; Li, Z.; Conaway, C.; McGinley, R.; Dhingra, S.; Vahdat, V.; Zhou, F.; D’Urso, B.; Liu, H.; Li, L. Study on the Surface Energy of Graphene by Contact Angle Measurements. Langmuir 2014, 30, 8598–8606. [Google Scholar] [CrossRef]

- Kasman, Ş.; Uçar İbrahim, C.; Ozan, S. Laser Surface Texturing of Co–Cr–Mo Alloy for Biomedical Applications: A Case Study for the Effects of Process Parameters on Surface Properties. J. Bionic Eng. 2023, 20, 1967–1984. [Google Scholar] [CrossRef]

- Li, C.; Zhang, J.; Han, J.; Yao, B. A numerical solution to the effects of surface roughness on water–coal contact angle. Sci. Rep. 2021, 11, 459. [Google Scholar] [CrossRef]

- Huang, J.; Wei, S.; Zhang, L.; Yang, Y.; Yang, S.; Shen, Z. Fabricating the Superhydrophobic Nickel and Improving Its Antifriction Performance by the Laser Surface Texturing. Materials 2019, 12, 1155. [Google Scholar] [CrossRef]

- Huang, J.; Wei, S.; Zhang, L.; Yang, Y.; Yang, S.; Shen, Z. Effect of Laser Texturing Parameters on Wettability of Nickel Surface. J. Mater. Sci. Chem. Eng. 2018, 6, 163–168. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, L.; Wei, S.; Yang, Y.; Yang, S.; Shen, Z. Fabrication of the laser textured nickel surface and its tribological property under the water lubrication. AIP Adv. 2019, 9, 085224. [Google Scholar] [CrossRef]

- Islam, S.A.; Hao, L.; Javaid, Z.; Xiong, W.; Li, Y.; Jamil, Y.; Chen, Q.; Han, G. Surface Roughness of Interior Fine Flow Channels in Selective Laser Melted Ti-6Al-4V Alloy Components. Micromachines 2024, 15, 348. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Boltaev, G.S.; Iqbal, M.; Kim, V.; Ganeev, R.A.; Alnaser, A.S. Ultrafast fiber laser-induced fabrication of superhydrophobic and self-cleaning metal surfaces. Appl. Surf. Sci. 2021, 542, 148560. [Google Scholar] [CrossRef]

- Bonse, J.; Hohm, S.; Kirner, S.V.; Rosenfeld, A.; Kruger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Simões, J.; Riva, R.; Miyakawa, W. High-speed Laser-Induced Periodic Surface Structures (LIPSS) generation on stainless steel surface using a nanosecond pulsed laser. Surf. Coatings Technol. 2018, 344, 423–432. [Google Scholar] [CrossRef]

- Leggio, L.; Di Maio, Y.; Pascale-Hamri, A.; Egaud, G.; Reynaud, S.; Sedao, X.; Mauclair, C. Ultrafast Laser Patterning of Metals Commonly Used in Medical Industry: Surface Roughness Control with Energy Gradient Pulse Sequences. Micromachines 2023, 14, 251. [Google Scholar] [CrossRef]

- Alsaigh, R.A. Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review. Crystals 2024, 14, 353. [Google Scholar] [CrossRef]

- Babadjanov, F.; Specht, U.; Lukasczyk, T.; Mayer, B. Heat Accumulation-Induced Surface Structures at High Degrees of Laser Pulse Overlap on Ti6Al4V Surfaces by Femtosecond Laser Texturing. Materials 2023, 16, 2498. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, D.; Rosenkranz, A.; Zhang, J.; Zhao, L.; Song, C.; Yan, Y.; Sun, T. Laser Surface Texturing of Stainless Steel—Effect of Pulse Duration on Texture’s Morphology and Frictional Response. Adv. Eng. Mater. 2018, 21, 1801016. [Google Scholar] [CrossRef]

- Ahuir-Torres, J.; Arenas, M.; Perrie, W.; de Damborenea, J. Influence of laser parameters in surface texturing of Ti6Al4V and AA2024-T3 alloys. Opt. Lasers Eng. 2018, 103, 100–109. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.K.; Umer, U.; Abdulhameed, O.; Alkhalefah, H. Effects of Laser Fluence and Pulse Overlap on Machining of Microchannels in Alumina Ceramics Using an Nd:YAG Laser. Appl. Sci. 2019, 9, 3962. [Google Scholar] [CrossRef]

- Bartolo, P.; Vasco, J.; Silva, B.; Galo, C. Laser micromachining for mould manufacturing: I. The influence of operating parameters. Assem. Autom. 2006, 26, 227–234. [Google Scholar] [CrossRef]

- Müller, D.W.; Fox, T.; Grützmacher, P.G.; Suarez, S.; Mücklich, F. Applying Ultrashort Pulsed Direct Laser Interference Patterning for Functional Surfaces. Sci. Rep. 2020, 10, 3647. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, J.Z.; Meng, X.K.; Yang, J.N.; Guo, Z.H.; Zhu, M.; Guo, S. Mechanism and threshold fluence of nanosecond pulsed laser paint removal. Rare Met. 2021, 41, 1022–1031. [Google Scholar] [CrossRef]

- Mannion, P.; Magee, J.; Coyne, E.; O’Connor, G.; Glynn, T. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 2004, 233, 275–287. [Google Scholar] [CrossRef]

- Temmler, A.; Willenborg, E.; Wissenbach, K. Laser Polishing. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XVII; Hennig, G., Xu, X., Gu, B., Nakata, Y., Eds.; SPIE: Bellingham, WA, USA, 2012. [Google Scholar] [CrossRef]

- Jaeggi, B.; Remund, S.; Streubel, R.; Gökce, B.; Barcikowski, S.; Neuenschwander, B. Laser Micromachining of Metals with Ultra-Short Pulses: Factors Limiting the Scale-Up Process. J. Laser Micro Nanoeng. 2017, 12, 267–273. [Google Scholar] [CrossRef]

- Kietzig, A.M.; Hatzikiriakos, S.G.; Englezos, P. Patterned Superhydrophobic Metallic Surfaces. Langmuir 2009, 25, 4821–4827. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Calderon, M.; Rodríguez, A.; Dias-Ponte, A.; Morant-Miñana, M.; Gómez-Aranzadi, M.; Olaizola, S. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89. [Google Scholar] [CrossRef]

- Shugaev, M.V.; Wu, C.; Armbruster, O.; Naghilou, A.; Brouwer, N.; Ivanov, D.S.; Derrien, T.J.Y.; Bulgakova, N.M.; Kautek, W.; Rethfeld, B.; et al. Fundamentals of ultrafast laser–material interaction. MRS Bull. 2016, 41, 960–968. [Google Scholar] [CrossRef]

- He, Z.; Lei, L.; Lin, S.; Tian, S.; Tian, W.; Yu, Z.; Li, F. Metal Material Processing Using Femtosecond Lasers: Theories, Principles, and Applications. Materials 2024, 17, 3386. [Google Scholar] [CrossRef] [PubMed]

- Samanta, A.; Wang, Q.; Shaw, S.K.; Ding, H. Roles of chemistry modification for laser textured metal alloys to achieve extreme surface wetting behaviors. Mater. Des. 2020, 192, 108744. [Google Scholar] [CrossRef]

- Long, J.; Zhong, M.; Zhang, H.; Fan, P. Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air. J. Colloid Interface Sci. 2015, 441, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Narula, M.L.; Tare, V.B.; Worrell, W.L. Diffusivity and solubility of oxygen in solid copper using potentiostatic and potentiometric techniques. Metall. Trans. B 1983, 14, 673–677. [Google Scholar] [CrossRef]

- Garruchet, S.; Politano, O.; Arnoux, P.; Vignal, V. Diffusion of oxygen in nickel: A variable charge molecular dynamics study. Solid State Commun. 2010, 150, 439–442. [Google Scholar] [CrossRef]

- Schürmann, A.; Haas, R.; Murat, M.; Kuritz, N.; Balaish, M.; Ein-Eli, Y.; Janek, J.; Natan, A.; Schröder, D. Diffusivity and Solubility of Oxygen in Solvents for Metal/Oxygen Batteries: A Combined Theoretical and Experimental Study. J. Electrochem. Soc. 2018, 165, A3095–A3099. [Google Scholar] [CrossRef]

- Baroutaji, A.; Arjunan, A.; Beal, J.; Robinson, J.; Coroado, J. The Influence of Atmospheric Oxygen Content on the Mechanical Properties of Selectively Laser Melted AlSi10Mg TPMS-Based Lattice. Materials 2023, 16, 430. [Google Scholar] [CrossRef] [PubMed]

- Ezzat, M.; Aniculaesei, C.; Lee, J.W.; Lee, S.K. Effects of Laser Irradiation in High-Speed Gas Flow for Surface Treatments of Copper. Micromachines 2024, 15, 1296. [Google Scholar] [CrossRef]

- Glushkov, D.; Paushkina, K.; Pleshko, A.; Zykov, I.; Orlova, E.; Feoktistov, D. Prospects for the Use of Metal Surfaces Modified by Nanosecond Laser Radiation for Energy Applications. Energies 2023, 16, 7979. [Google Scholar] [CrossRef]

- Velasco-Castro, M.; Hernández-Nava, E.; Figueroa, I.; Todd, I.; Goodall, R. The effect of oxygen pickup during selective laser melting on the microstructure and mechanical properties of Ti–6Al–4V lattices. Heliyon 2019, 5, e02813. [Google Scholar] [CrossRef]

- Conradi, M.; Podgornik, B.; Remškar, M.; Klobčar, D.; Kocijan, A. Tribological Evaluation of Vegetable Oil/MoS2 Nanotube-Based Lubrication of Laser-Textured Stainless Steel. Materials 2023, 16, 5844. [Google Scholar] [CrossRef] [PubMed]

- Yue, H.; Schneider, J.; Deng, J. Laser Surface Texturing for Ground Surface: Frictional Effect of Plateau Roughness and Surface Textures under Oil Lubrication. Lubricants 2024, 12, 22. [Google Scholar] [CrossRef]

- Min, J.; Wan, H.; Carlson, B.E.; Lin, J.; Sun, C. Application of laser ablation in adhesive bonding of metallic materials: A review. Opt. Laser Technol. 2020, 128, 106188. [Google Scholar] [CrossRef]

- Fu, Y.; Soldera, M.; Wang, W.; Voisiat, B.; Lasagni, A.F. Picosecond Laser Interference Patterning of Periodical Micro-Architectures on Metallic Molds for Hot Embossing. Materials 2019, 12, 3409. [Google Scholar] [CrossRef]

- Pan, Q.; Cao, Y.; Xue, W.; Zhu, D.; Liu, W. Picosecond Laser-Textured Stainless Steel Superhydrophobic Surface with an Antibacterial Adhesion Property. Langmuir 2019, 35, 11414–11421. [Google Scholar] [CrossRef]

| Copper | Brass | Molybdenum | Nickel | Stainless Steel | |

|---|---|---|---|---|---|

| C | 26.24% | 24.23% | 25.61% | 19.30% | 29.72% |

| O | 5.03% | 5.14% | 39.89% | 2.11% | 4.84% |

| Cu | 68.73% | 45.44% | |||

| Zn | 25.19% | ||||

| Mo | 27.11% | ||||

| N | 5.43% | ||||

| S | 1.95% | ||||

| Ni | 78.59% | 5.08% | |||

| Fe | 48.14% | ||||

| Cr | 12.22% |

| Untextured | 50 mm/s | 500 mm/s | 1500 mm/s | 2500 mm/s | ||

|---|---|---|---|---|---|---|

| Brass | Cu | 45.44 | 24.12 | 42.86 | 43.22 | 43.44 |

| Zn | 25.19 | 15.49 | 23.77 | 23.77 | 24.12 | |

| C | 24.23 | 39.72 | 25.19 | 25.27 | 25.70 | |

| O | 5.14 | 20.68 | 8.18 | 7.74 | 6.74 | |

| Copper | Cu | 68.73 | 46.62 | 70.53 | 71.97 | 77.19 |

| C | 26.24 | 34.43 | 24.18 | 24.10 | 18.84 | |

| O | 5.03 | 18.95 | 5.29 | 3.93 | 3.97 | |

| Mo | 27.11 | 26.94 | 25.63 | 30.15 | 28.04 | |

| N | 5.43 | 0.00 | 4.96 | 0.00 | 0.00 | |

| Molybdenum | S | 1.95 | 2.34 | 1.99 | 2.47 | 2.30 |

| C | 25.61 | 32.93 | 27.47 | 32.41 | 31.95 | |

| O | 39.89 | 37.79 | 39.95 | 34.96 | 37.70 | |

| Ni | 78.59 | 43.51 | 75.05 | 79.41 | 74.64 | |

| Nickel | C | 19.30 | 39.28 | 21.43 | 17.71 | 22.32 |

| O | 2.11 | 17.21 | 3.52 | 2.88 | 3.04 | |

| Stainless steel | Fe | 48.14 | 27.71 | 41.35 | 43.31 | 43.51 |

| Cr | 12.22 | 7.47 | 10.96 | 11.23 | 11.20 | |

| Ni | 5.08 | 2.80 | 4.24 | 4.49 | 4.39 | |

| C | 29.72 | 31.37 | 31.00 | 33.50 | 34.56 | |

| O | 4.84 | 30.66 | 12.45 | 7.48 | 6.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corsaro, C.; Neri, F.; Ossi, P.M.; Bonanno, D.; Pelleriti, P.; Fazio, E. Graining and Texturing of Metal Surfaces by Picosecond Laser Treatment. Materials 2025, 18, 1398. https://doi.org/10.3390/ma18071398

Corsaro C, Neri F, Ossi PM, Bonanno D, Pelleriti P, Fazio E. Graining and Texturing of Metal Surfaces by Picosecond Laser Treatment. Materials. 2025; 18(7):1398. https://doi.org/10.3390/ma18071398

Chicago/Turabian StyleCorsaro, Carmelo, Fortunato Neri, Paolo Maria Ossi, Domenico Bonanno, Priscilla Pelleriti, and Enza Fazio. 2025. "Graining and Texturing of Metal Surfaces by Picosecond Laser Treatment" Materials 18, no. 7: 1398. https://doi.org/10.3390/ma18071398

APA StyleCorsaro, C., Neri, F., Ossi, P. M., Bonanno, D., Pelleriti, P., & Fazio, E. (2025). Graining and Texturing of Metal Surfaces by Picosecond Laser Treatment. Materials, 18(7), 1398. https://doi.org/10.3390/ma18071398