Effect of Microencapsulated Temperature Rise Inhibitor on the Temperature Rise of Medium-Sized Concrete

Abstract

1. Introduction

2. Experimental Program

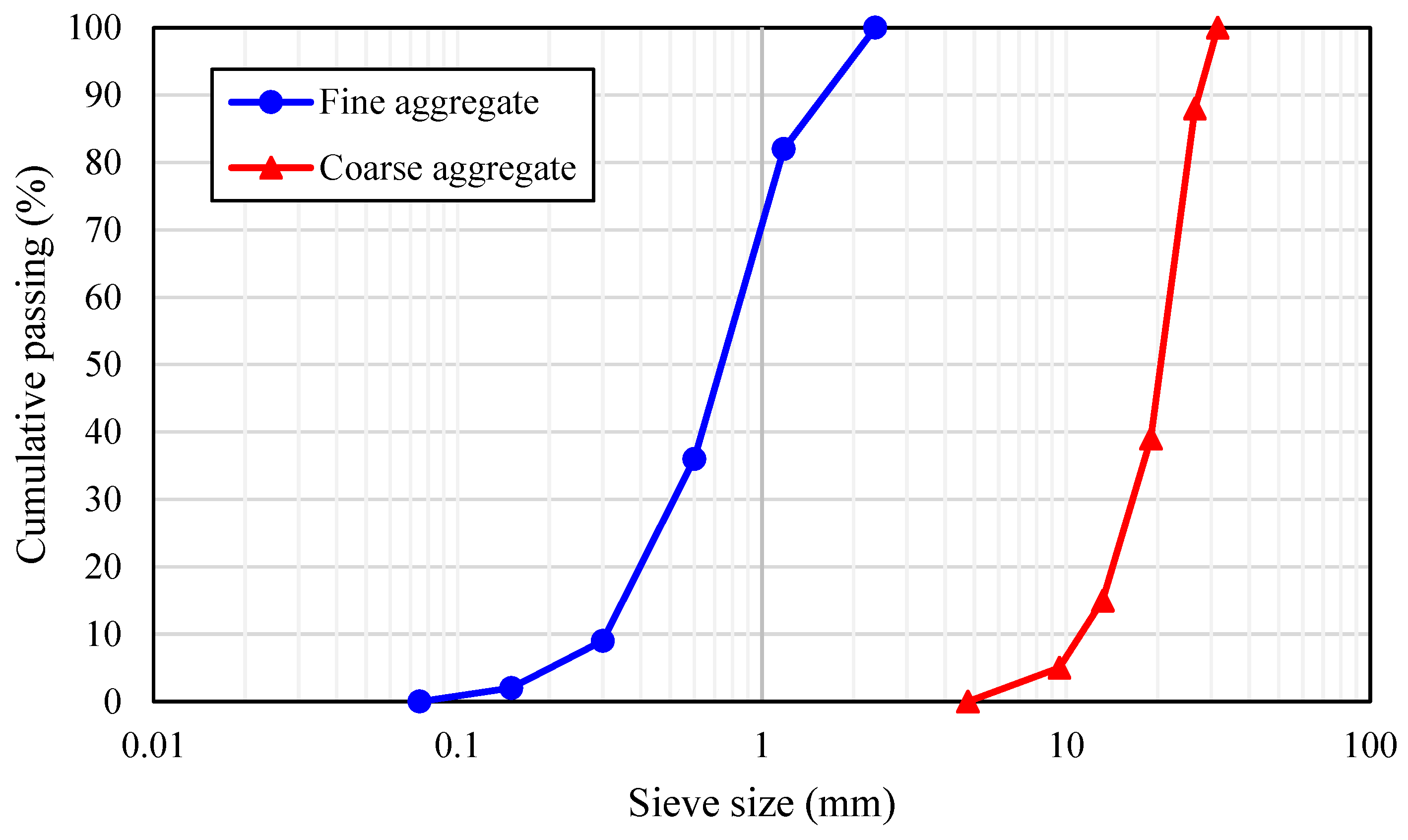

2.1. Materials and Mix Design

2.2. Mechanical Properties Test

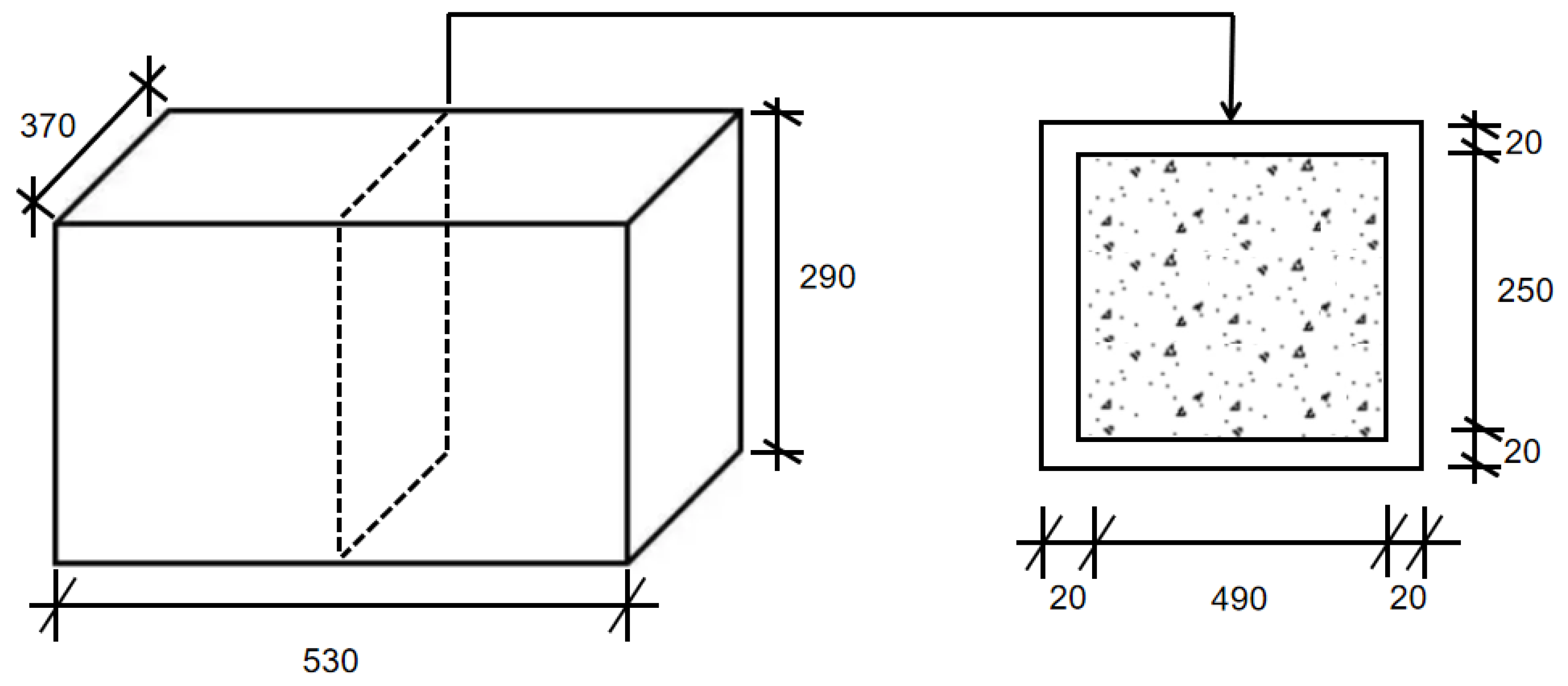

2.3. Temperature Rise Test

2.4. Microscopic Test

2.5. Quality Assurance

3. Test Results and Discussion

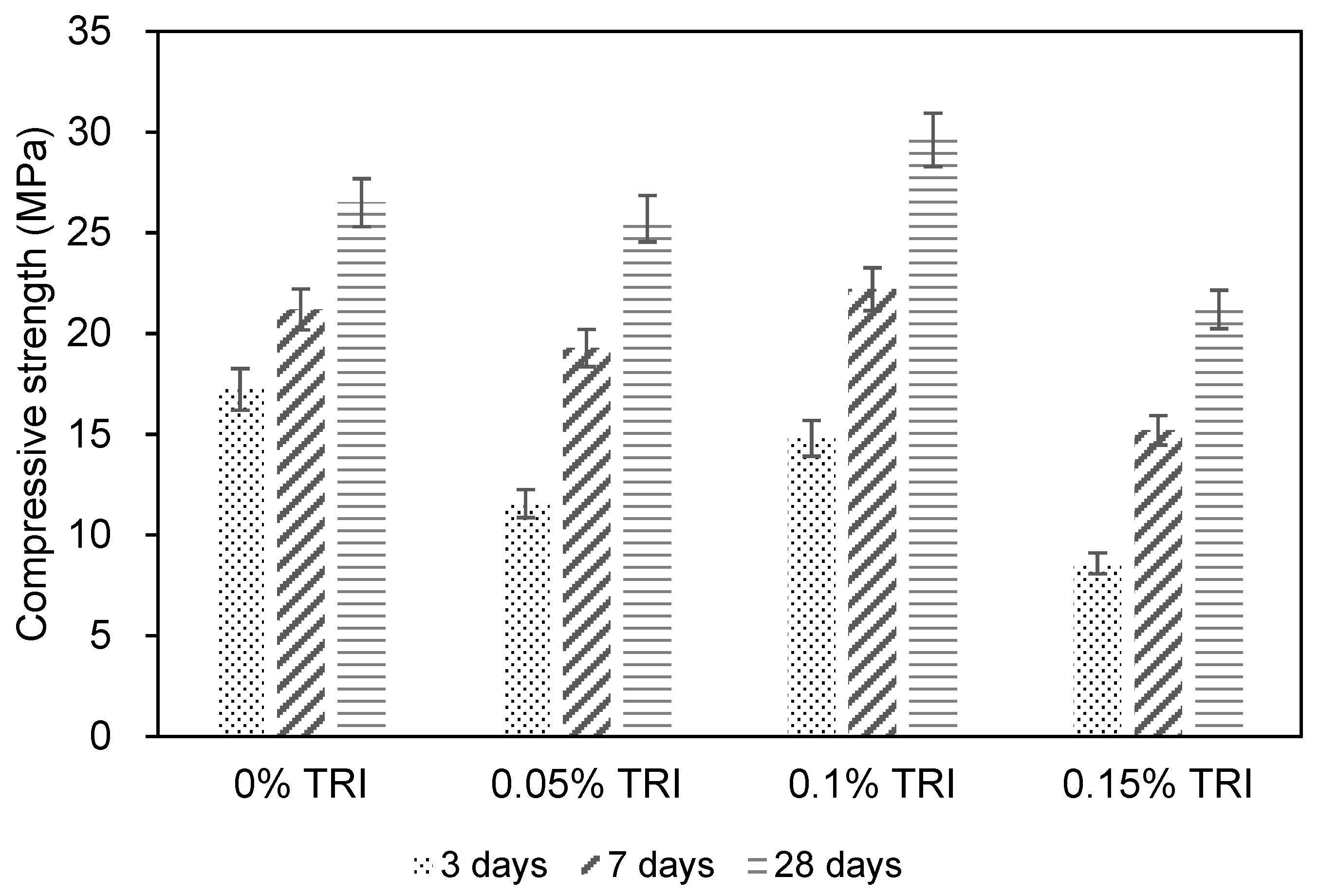

3.1. Compressive Strength

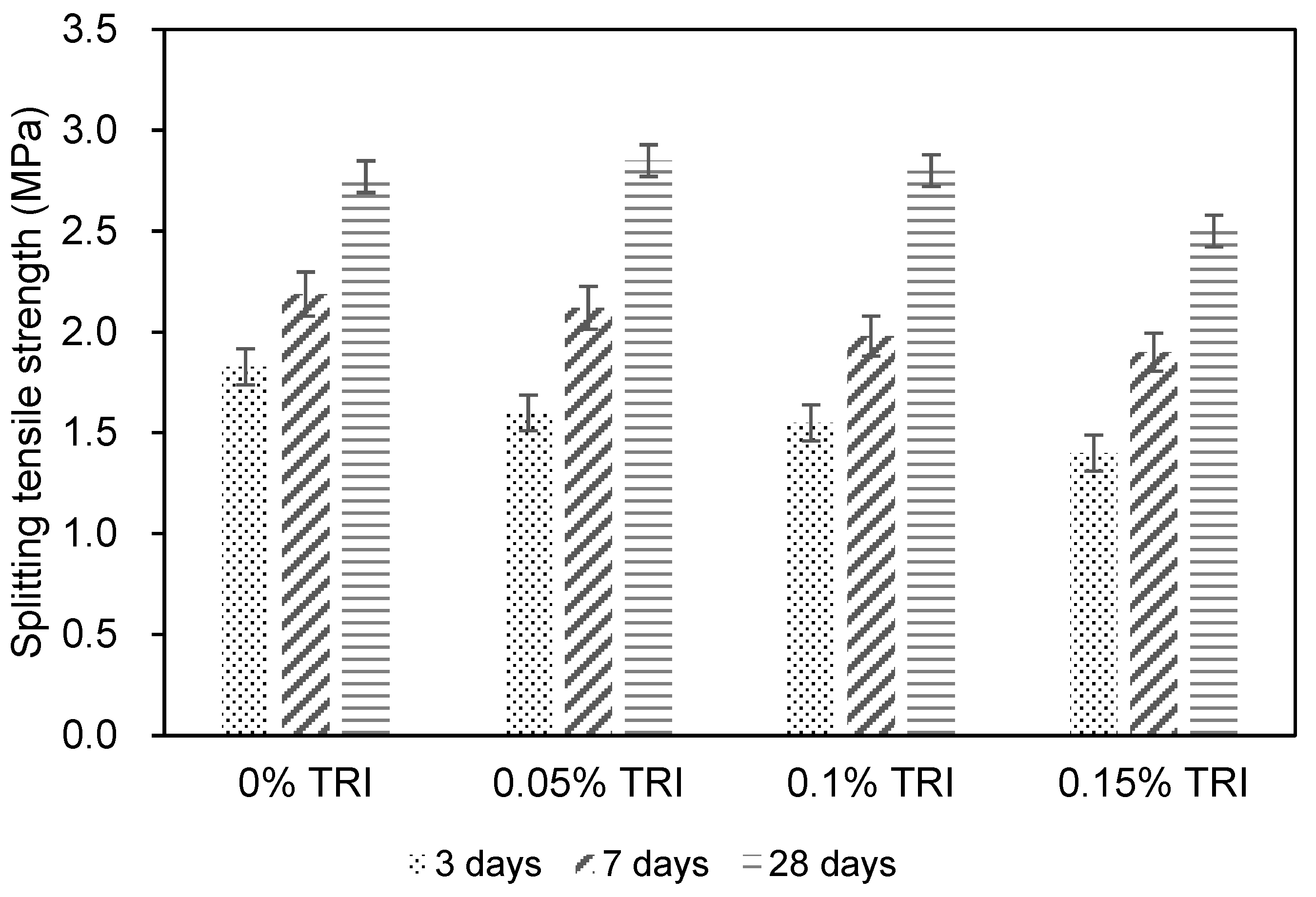

3.2. Splitting Tensile Strength

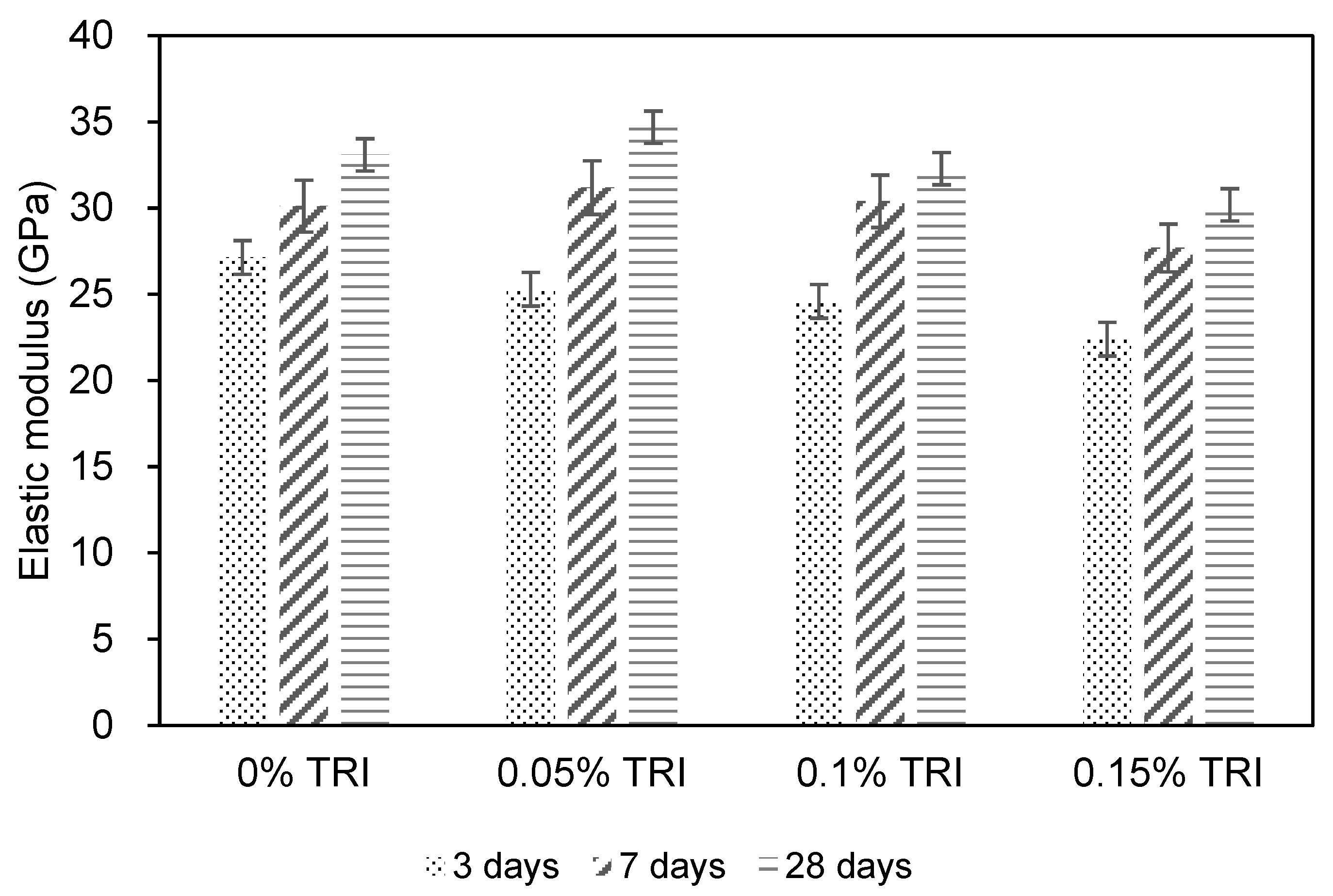

3.3. Elastic Modulus

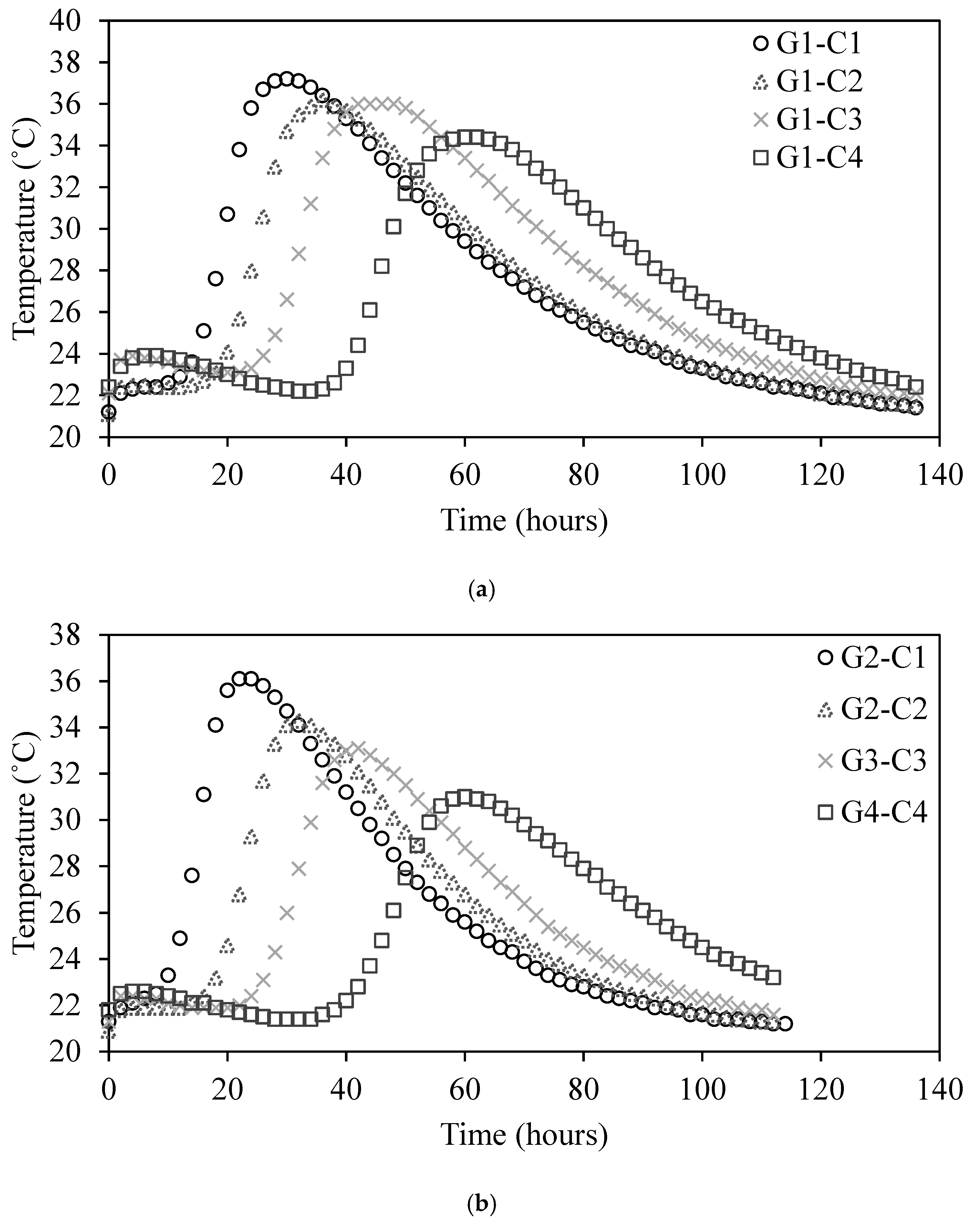

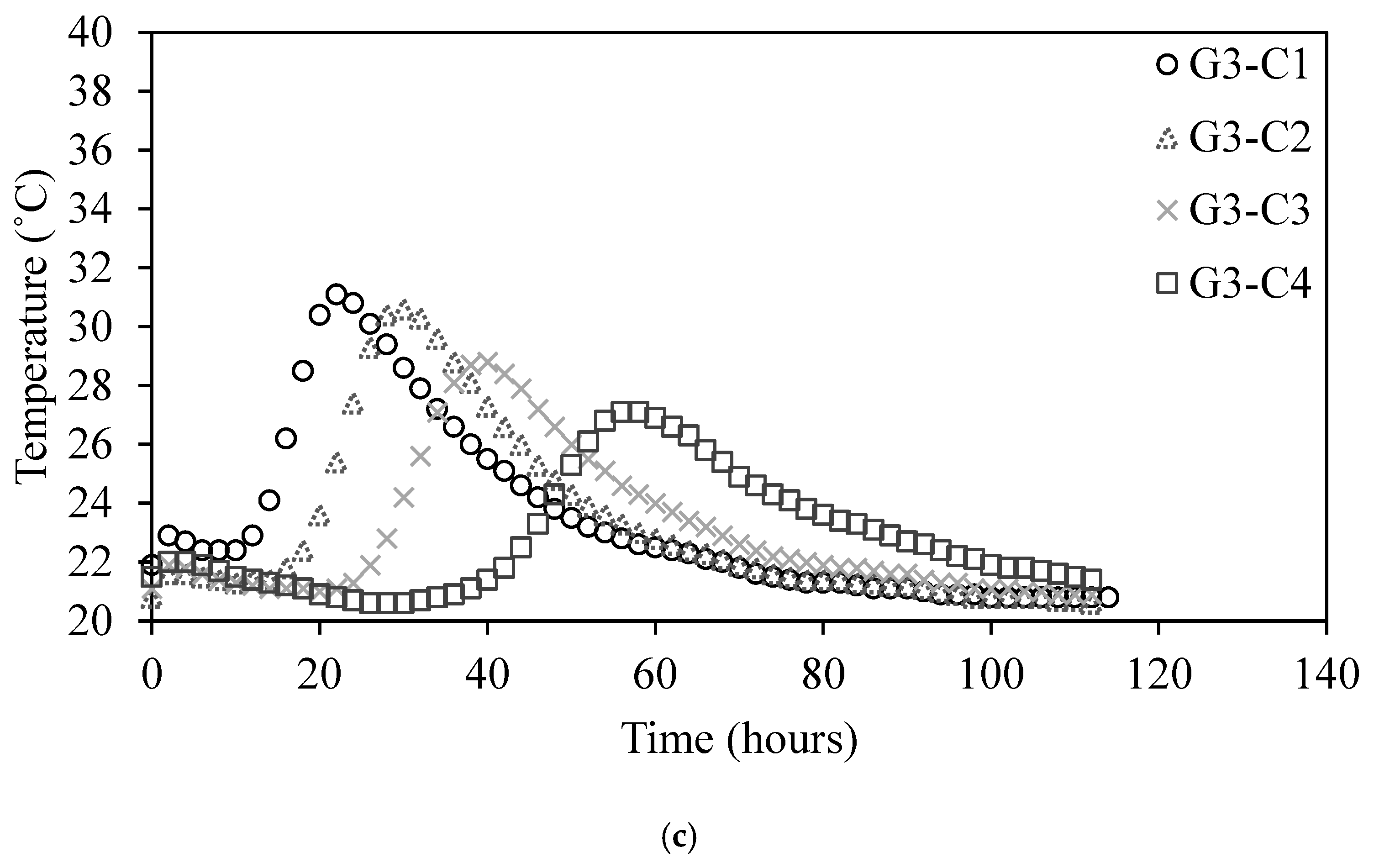

3.4. Effect of TRIs on Temperature Rise

3.5. Effect of Size on Temperature Rise

3.6. Microscopic Analysis

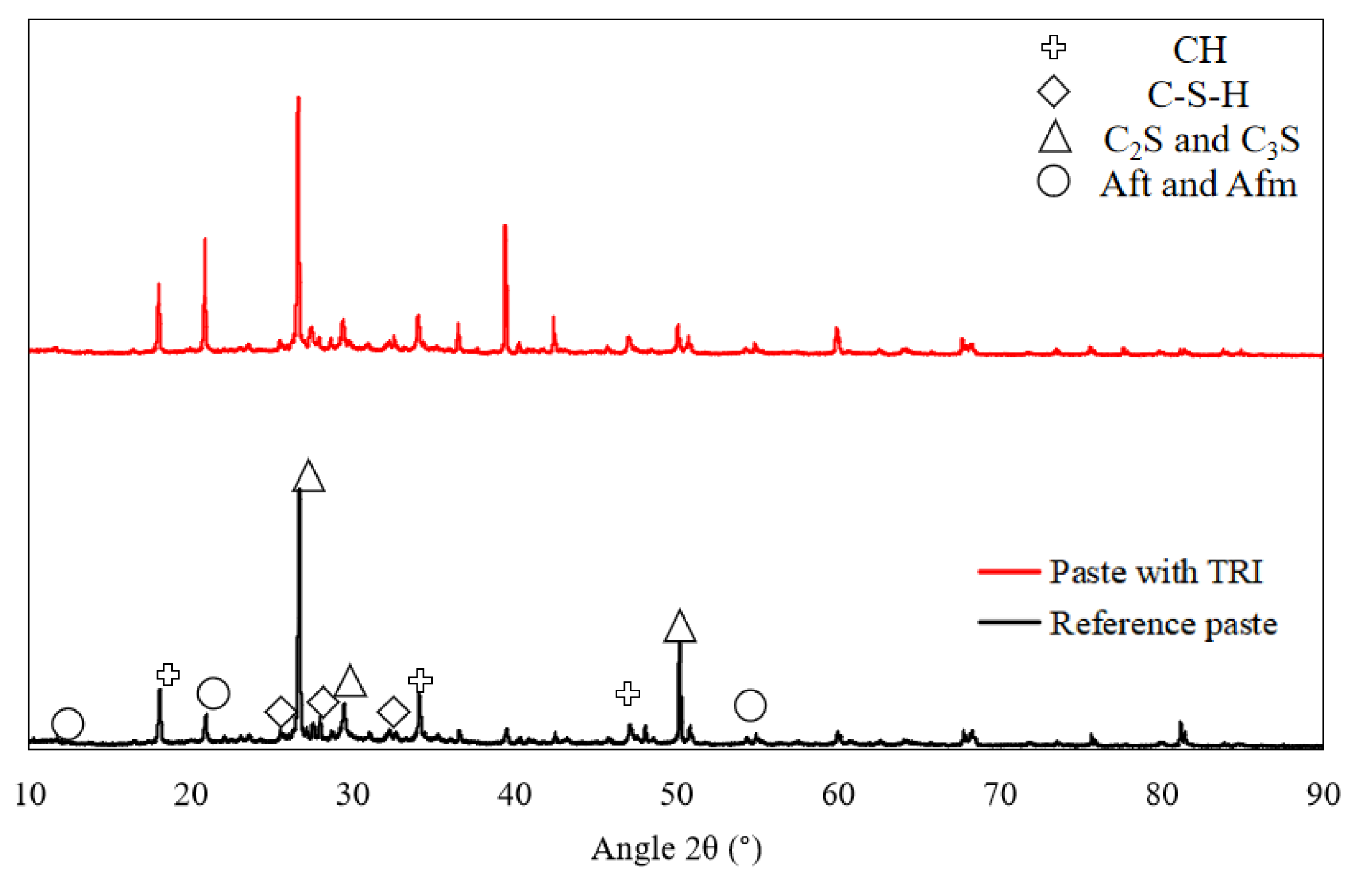

4. Conclusions

- (1)

- Microstructural analysis via XRD and SEM revealed that the hydration suppression effect of TRIs follows a controlled-release mechanism. The encapsulated TRIs gradually dissolve over time, forming a temporary hydration barrier on cement particles, thereby slowing CH crystallization and altering C-S-H gel development. This mechanism results in reduced early age heat accumulation, effectively mitigating thermal stress-induced cracking.

- (2)

- Mechanical performance tests indicated that TRI incorporation slightly reduces early age compressive and tensile strength due to delayed hydration. However, strength recovery was observed over time, with TRI-modified concrete achieving comparable long-term mechanical properties to the reference mix. Notably, a TRI dosage of 0.1% provided the optimal balance, significantly reducing hydration temperature while maintaining acceptable strength development. In contrast, higher dosages (0.15%) excessively suppressed hydration, leading to prolonged setting time and potential strength limitations.

- (3)

- From an engineering perspective, these findings highlight the potential of TRIs as a practical strategy for controlling hydration temperature in medium-sized concrete structures, particularly in applications where external cooling measures are limited. A 0.1% TRI dosage was found to be the optimal balance between hydration heat suppression and mechanical integrity, reducing peak temperature rise while maintaining adequate early age strength. Using more than 0.1% TRI can lead to prolonged setting times and reduced strength, whereas less than 0.1% TRI may be insufficient in controlling hydration heat effectively. The controlled-release mechanism of TRIs ensures gradual hydration suppression, which minimizes thermal stress differentials and enhances long-term durability.

- (4)

- While its current production cost is higher than traditional retarders, its ability to mitigate thermal stress and improve long-term durability may offset the initial cost. Further research should focus on cost-effective encapsulation methods to enhance the competitiveness of TRIs in commercial concrete applications. Future studies should also incorporate field trials on real construction site conditions to better understand the performance of TRIs under practical conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, M.; Ninić, J.; Zhang, Q. BIM, machine learning and computer vision techniques in underground construction: Current status and future perspectives. Tunn. Undergr. Space Technol. 2021, 108, 103677. [Google Scholar] [CrossRef]

- Malik, M.; Bhattacharyya, S.; Barai, S. Thermal and mechanical properties of concrete and its constituents at elevated temperatures: A review. Constr. Build. Mater. 2021, 270, 121398. [Google Scholar] [CrossRef]

- Alhamad, A.; Yehia, S.; Lublóy, É.; Elchalakani, M. Performance of different concrete types exposed to elevated temperatures: A review. Materials 2022, 15, 5032. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Zhang, Y.; Liu, Z.; Si, R.; Wu, J. A review on early-age cracking of concrete: Causes and control. Case Stud. Constr. Mater. 2024, 21, e03848. [Google Scholar] [CrossRef]

- Shen, L.; Monte, F.; Di Luzio, G.; Cusatis, G.; Li, W.; Felicetti, R.; Lombardi, F.; Lualdi, M.; Cao, M.; Ren, Q. On the moisture migration of concrete subject to high temperature with different heating rates. Cem. Concr. Res. 2021, 146, 106492. [Google Scholar] [CrossRef]

- Chen, C.; Chen, S. Study on Temperature Control and Cracking Risk of Mass Concrete Sidewalls with a Cooling-Pipe System. Buildings 2024, 14, 872. [Google Scholar] [CrossRef]

- Lu, S.; Liu, J.; Peng, C.; Zhang, J.; Sun, H. Multi-objective optimization of mix proportions for mass concrete with enhanced resistance to cracking and reduced temperature rise. Case Stud. Constr. Mater. 2024, 20, e02810. [Google Scholar] [CrossRef]

- Zhang, Y.; Kim, T.; Castel, A.; Xu, T. Thermal cracking in high volume of fly ash and GGBFS concrete. Int. J. Concr. Struct. Mater. 2023, 17, 65. [Google Scholar] [CrossRef]

- Springenschmid, R. Prevention of Thermal Cracking in Concrete at Early Ages; CRC Press: London, UK, 2004. [Google Scholar]

- De Maio, U.; Gaetano, D.; Greco, F.; Luciano, R.; Pranno, A. Degradation analysis of dynamic properties for plain concrete structures under mixed-mode fracture conditions via an improved cohesive crack approach. Fract. Struct. Integr. 2024, 18, 422–439. [Google Scholar] [CrossRef]

- Wang, Y.; Miao, Y.; Li, Y.; Wang, F.; Mu, S.; Wang, L.; Gao, S.; Lu, Z.; Liu, Z.; Jiang, J. Investigation of the damage self-healing and chloride-water coupled transport inhibition mechanism of microencapsulated concrete. Constr. Build. Mater. 2024, 435, 136838. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, G.; Liu, Y.; Wang, Z.; Yang, N.; Wang, Y.; Mou, R.; Qiao, Y.; Wang, J.; Wu, Z. Environmental impact and thermal cracking resistance of low heat cement (LHC) and moderate heat cement (MHC) concrete at early ages. J. Build. Eng. 2020, 32, 101668. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xu, Z.; Yuan, W.; Xu, Y.; Yao, Z.; Liu, Z.; Si, R. Early-Age Cracking of Fly Ash and GGBFS Concrete Due to Shrinkage, Creep, and Thermal Effects: A Review. Materials 2024, 17, 2288. [Google Scholar] [CrossRef]

- Tasri, A.; Susilawati, A. Effect of cooling water temperature and space between cooling pipes of post-cooling system on temperature and thermal stress in mass concrete. J. Build. Eng. 2019, 24, 100731. [Google Scholar] [CrossRef]

- Raghav, M.; Park, T.; Yang, H.; Lee, S.; Karthick, S.; Lee, H. Review of the effects of supplementary cementitious materials and chemical additives on the physical, mechanical and durability properties of hydraulic concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef]

- Yan, Y.; Scrivener, K.; Yu, C.; Ouzia, A.; Liu, J. Effect of a novel starch-based temperature rise inhibitor on cement hydration and microstructure development: The second peak study. Cem. Concr. Res. 2021, 141, 106325. [Google Scholar] [CrossRef]

- Wang, L.; Ju, S.; Chu, H.; Liu, Z.; Yang, Z.; Wang, F.; Jiang, J. Hydration process and microstructure evolution of low exothermic concrete produced with urea. Constr. Build. Mater. 2020, 248, 118640. [Google Scholar] [CrossRef]

- Song, H.; Yum, W.; Sim, S.; Jeon, D.; Yoon, S.; Oh, J. Proposed specific heat capacity model for a concrete wall containing phase change material (PCM) under field experiment conditions. Constr. Build. Mater. 2022, 336, 127381. [Google Scholar] [CrossRef]

- Mello, L.; dos Anjos, M.; de Sá, M.; de Souza, N.; de Farias, E. Effect of high temperatures on self-compacting concrete with high levels of sugarcane bagasse ash and metakaolin. Constr. Build. Mater. 2020, 248, 118715. [Google Scholar] [CrossRef]

- Jia, F.; Yao, Y.; Wang, J. Influence and mechanism research of hydration heat inhibitor on low-heat portland cement. Front. Mater. 2021, 8, 697380. [Google Scholar] [CrossRef]

- Pang, X.; Sun, L.; Sun, F.; Zhang, G.; Guo, S.; Bu, Y. Cement hydration kinetics study in the temperature range from 15 C to 95 C. Cem. Concr. Res. 2021, 148, 106552. [Google Scholar] [CrossRef]

- Linderoth, O.; Wadsö, L.; Jansen, D. Long-term cement hydration studies with isothermal calorimetry. Cem. Concr. Res. 2021, 141, 106344. [Google Scholar] [CrossRef]

- De Matos, P.; Neto, J.; Jansen, D.; Angeles, G.; Kirchheim, A.; Campos, C. In-situ laboratory X-ray diffraction applied to assess cement hydration. Cem. Concr. Res. 2022, 162, 106988. [Google Scholar] [CrossRef]

- T/CECS10270-2023; Hydration-Inhibiting and Anti-Cracking Water-Repellent Admixtures for Concrete. China Association for Engineering Construction Standardization: Suzhou, China, 2023.

- GB175-2023; Common Portland Cement. China Standard Press: Beijing, China, 2023.

- GB/T1596-2017; Fly Ash Used for Cement and Concrete. China Standard Press: Beijing, China, 2017.

- GB/T14684-2022; Sand for Construction. China Building Materials Federation: Beijing, China, 2022.

- GB/T14685-2022; Pebble and Crushed Stone for Construction. China Building Materials Federation: Beijing, China, 2022.

- Jia, F.; Yao, Y.; Li, C. Preparation and Mechanism Research of Hydration-heat-inhibiting Materials with Microcapsule Sustained-releasing Technology. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2021, 36, 697–705. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- Zhang, Z.; Scherer, G.; Bauer, A. Morphology of cementitious material during early hydration. Cem. Concr. Res. 2018, 107, 85–100. [Google Scholar] [CrossRef]

- Esteves, L. On the hydration of water-entrained cement–silica systems: Combined SEM, XRD and thermal analysis in cement pastes. Thermochim. Acta 2011, 518, 27–35. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Martínez, M.; Cabeza, L.; Fernández, A. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): A review. Renew. Sustain. Energy Rev. 2016, 53, 1059–1075. [Google Scholar] [CrossRef]

- Makul, N.; Sua-iam, G. Effect of granular urea on the properties of self-consolidating concrete incorporating untreated rice husk ash: Flowability, compressive strength and temperature rise. Constr. Build. Mater. 2018, 162, 489–502. [Google Scholar] [CrossRef]

- Wang, L.; Shen, X.; Yang, M.; Zhang, Y.; Liu, Z.; Jiang, J. Design and synthesis of sustained-release microcapsules and their impact on the regulation of cement hydration. Constr. Build. Mater. 2025, 459, 139686. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, R.; Liu, J.; Tang, J.; Scrivener, K. Effect of a liquid-type temperature rise inhibitor on cement hydration. Cem. Concr. Res. 2021, 140, 106286. [Google Scholar] [CrossRef]

- Safiuddin, M.; Kaish, A.; Woon, C.; Raman, S. Early-age cracking in concrete: Causes, consequences, remedial measures, and recommendations. Appl. Sci. 2018, 8, 1730. [Google Scholar] [CrossRef]

- de Oliveira, A.; Oliveira, A.; Vieira, J.; Junior, A.; Cascudo, O. Study of the development of hydration of ternary cement pastes using X-ray computed microtomography, XRD-Rietveld method, TG/DTG, DSC, calorimetry and FTIR techniques. J. Build. Eng. 2023, 64, 105616. [Google Scholar] [CrossRef]

| Chemical Oxides | SiO2 | CaO | Al2O3 | SO3 | Fe2O3 | K2O | MgO | Na2O | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| OPC | 20.31 | 65.5 | 4.8 | 2.1 | 4.99 | 0.4 | 1.3 | 0.15 | 0.39 |

| FA | 46.59 | 4.98 | 38.52 | 0.66 | 3.93 | 0.66 | 0.96 | 0.2 | 1.69 |

| Sample ID | Cement | Fly Ash | Fine Aggregate | Coarse Aggregate | WRA | AEA | Water | TRI |

|---|---|---|---|---|---|---|---|---|

| C1 | 280 | 150 | 675 | 1148 | 5.16 | 2.15 | 140 | 0 |

| C2 | 280 | 150 | 675 | 1148 | 5.16 | 2.15 | 140 | 0.05% |

| C3 | 280 | 150 | 675 | 1148 | 5.16 | 2.15 | 140 | 0.1% |

| C4 | 280 | 150 | 675 | 1148 | 5.16 | 2.15 | 140 | 0.15% |

| Group ID | Length | Width | Height |

|---|---|---|---|

| G1 | 530 | 370 | 290 |

| G2 | 450 | 295 | 260 |

| G3 | 340 | 220 | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, J.; Chen, J.; Yan, Z.; Liu, X.; Zhang, H. Effect of Microencapsulated Temperature Rise Inhibitor on the Temperature Rise of Medium-Sized Concrete. Materials 2025, 18, 1230. https://doi.org/10.3390/ma18061230

Zhang Y, Zhang J, Chen J, Yan Z, Liu X, Zhang H. Effect of Microencapsulated Temperature Rise Inhibitor on the Temperature Rise of Medium-Sized Concrete. Materials. 2025; 18(6):1230. https://doi.org/10.3390/ma18061230

Chicago/Turabian StyleZhang, Yingda, Junru Zhang, Jun Chen, Zhijian Yan, Xinyue Liu, and Haojie Zhang. 2025. "Effect of Microencapsulated Temperature Rise Inhibitor on the Temperature Rise of Medium-Sized Concrete" Materials 18, no. 6: 1230. https://doi.org/10.3390/ma18061230

APA StyleZhang, Y., Zhang, J., Chen, J., Yan, Z., Liu, X., & Zhang, H. (2025). Effect of Microencapsulated Temperature Rise Inhibitor on the Temperature Rise of Medium-Sized Concrete. Materials, 18(6), 1230. https://doi.org/10.3390/ma18061230