Base Oils and Formulated Transmission Oils for Electrical Vehicles: Thermophysical and Tribological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Refractive Index of Oil Samples

2.3. Density, Viscosity, and Viscosity Index of Lubricant Oils

2.4. Contact Angle Analysis and Surface Tension

2.5. Tests of Friction and Wear Examination

3. Results

3.1. Refractive Index Results

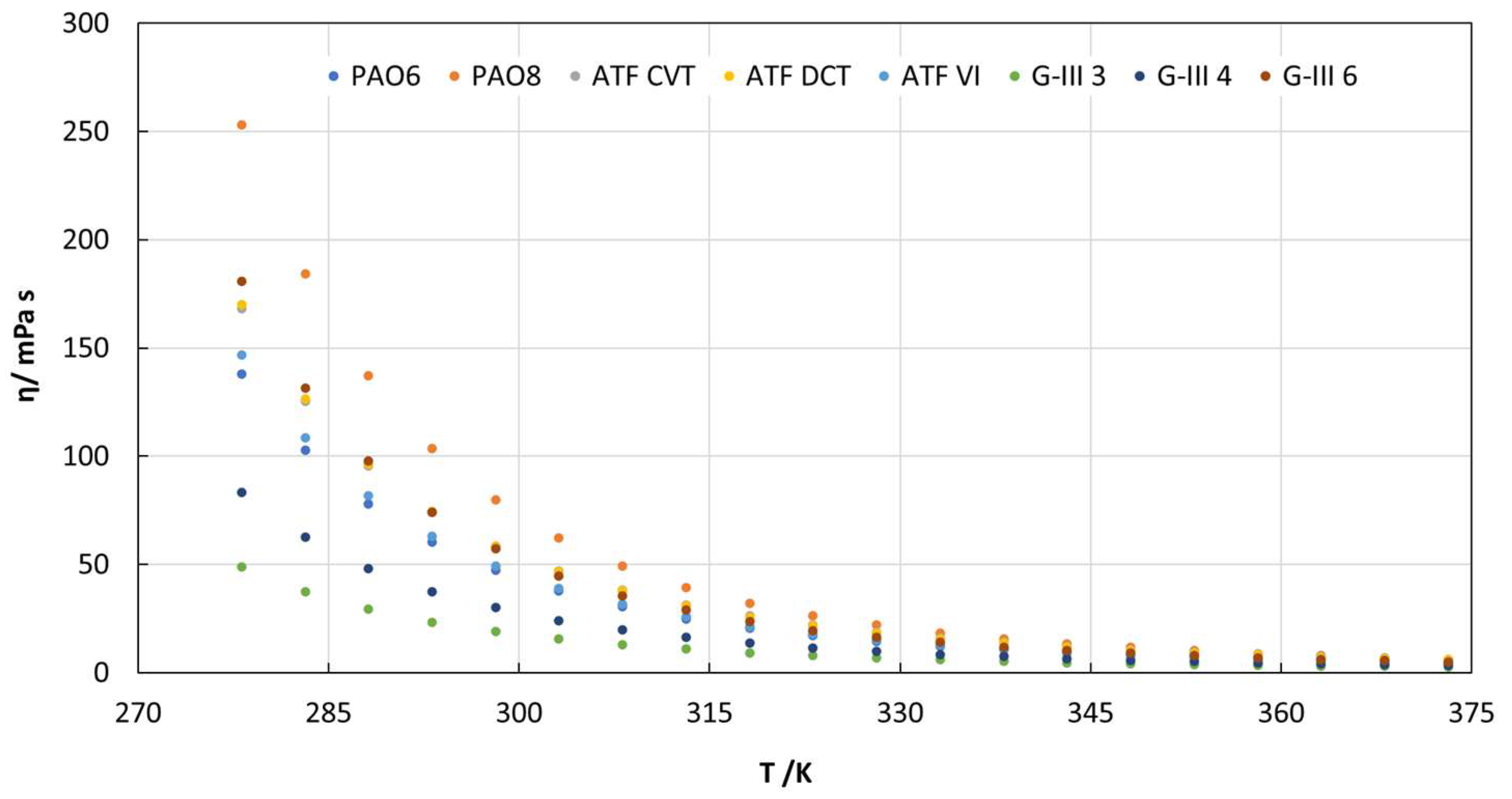

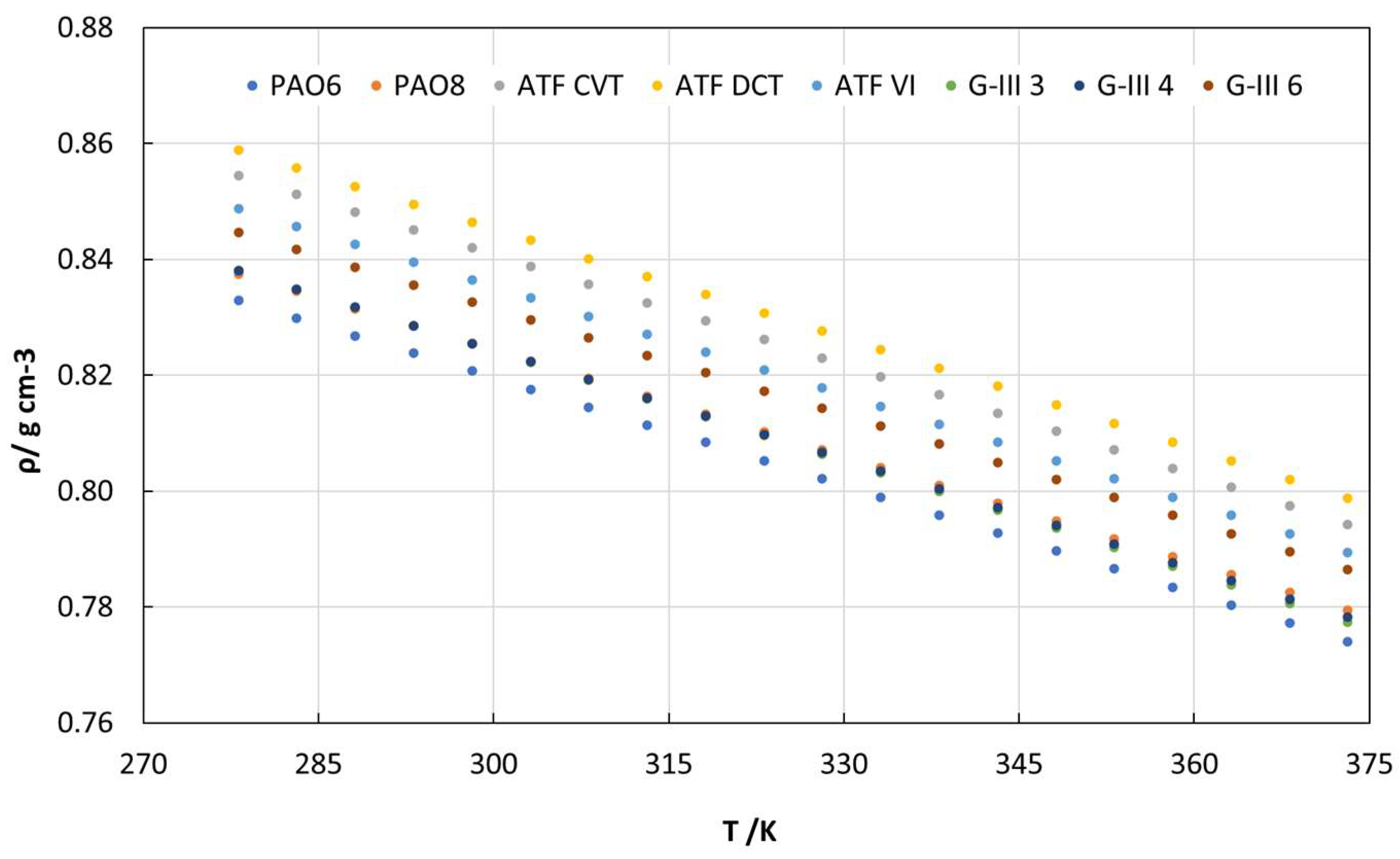

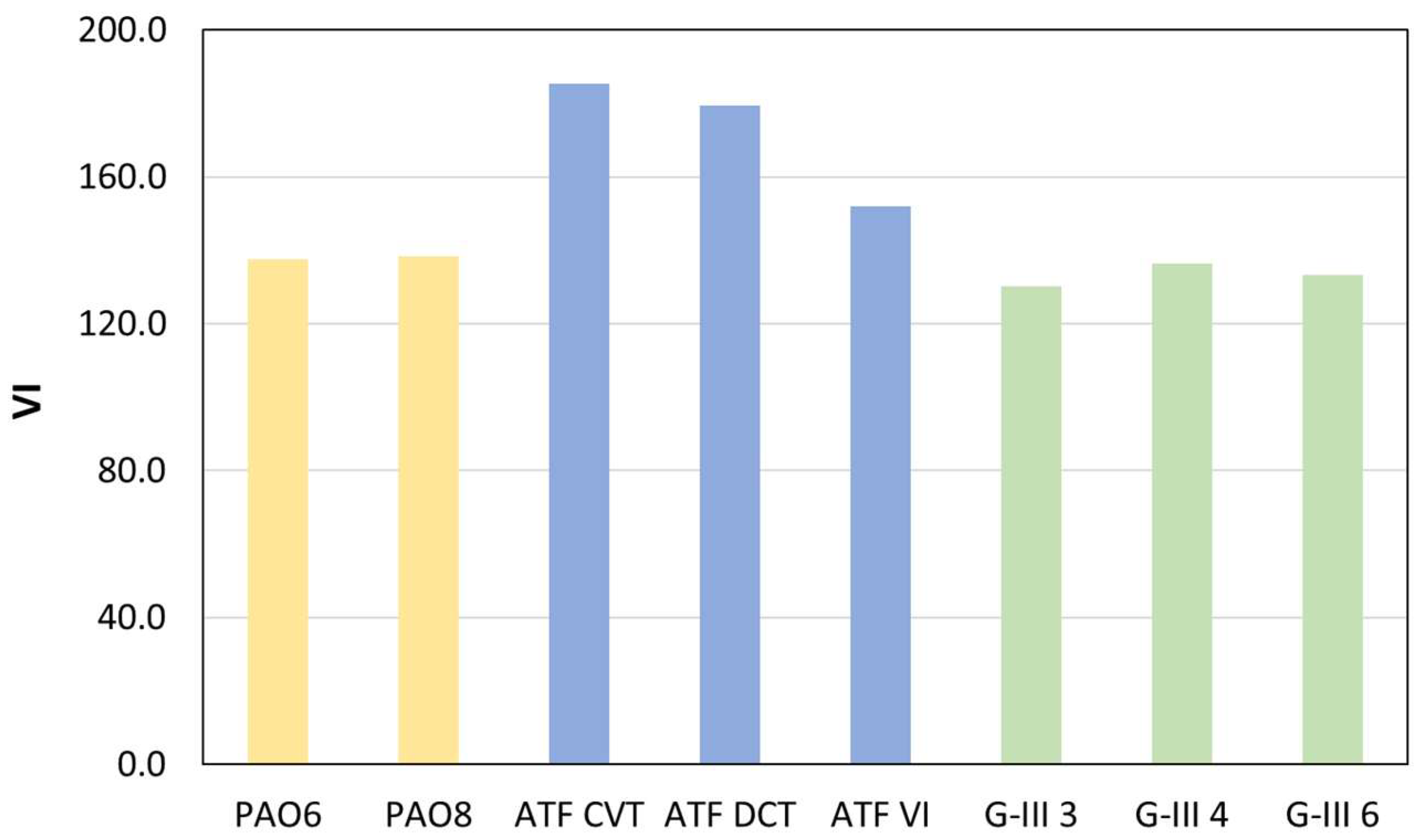

3.2. Density, Viscosity, and Viscosity Index Results

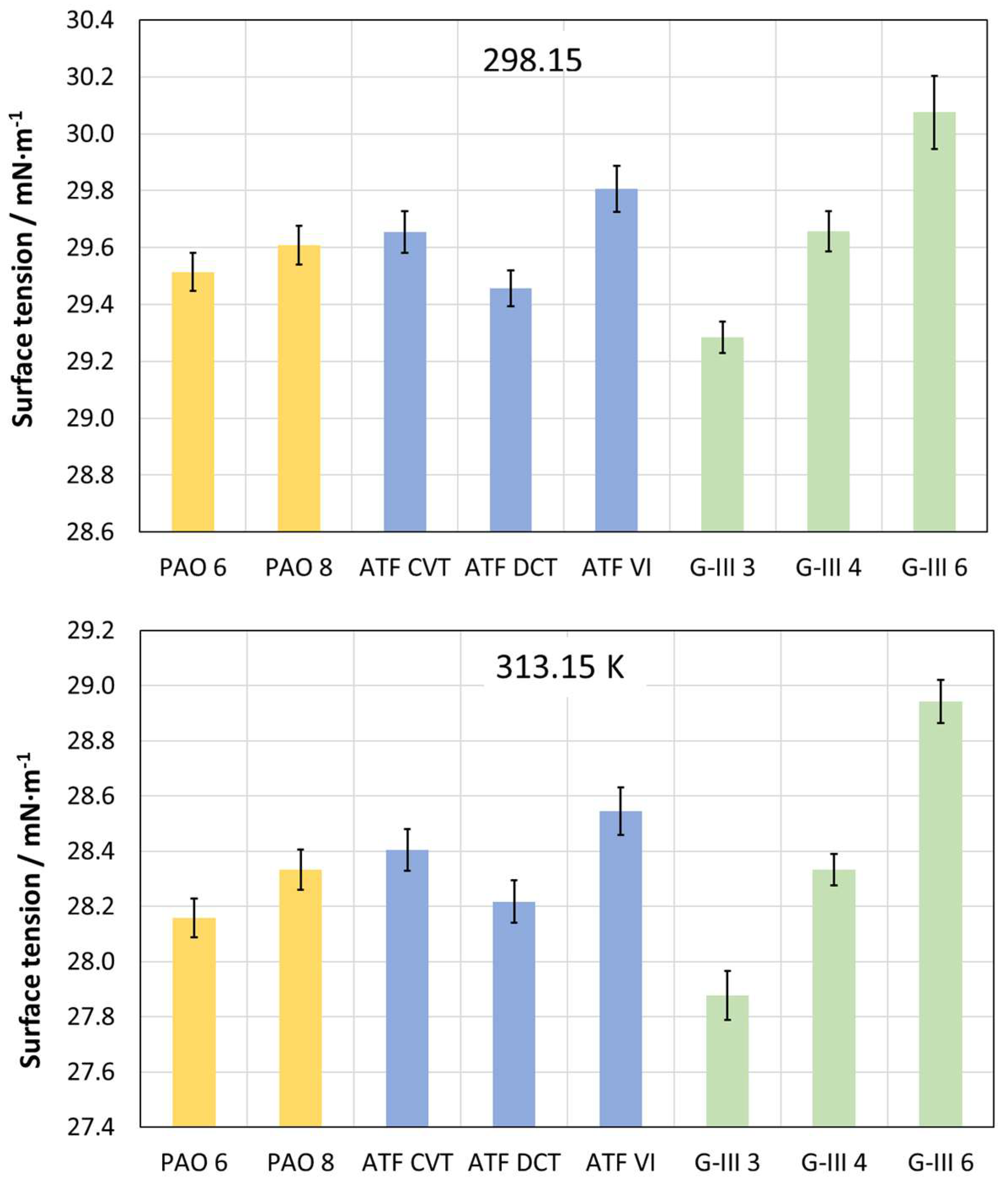

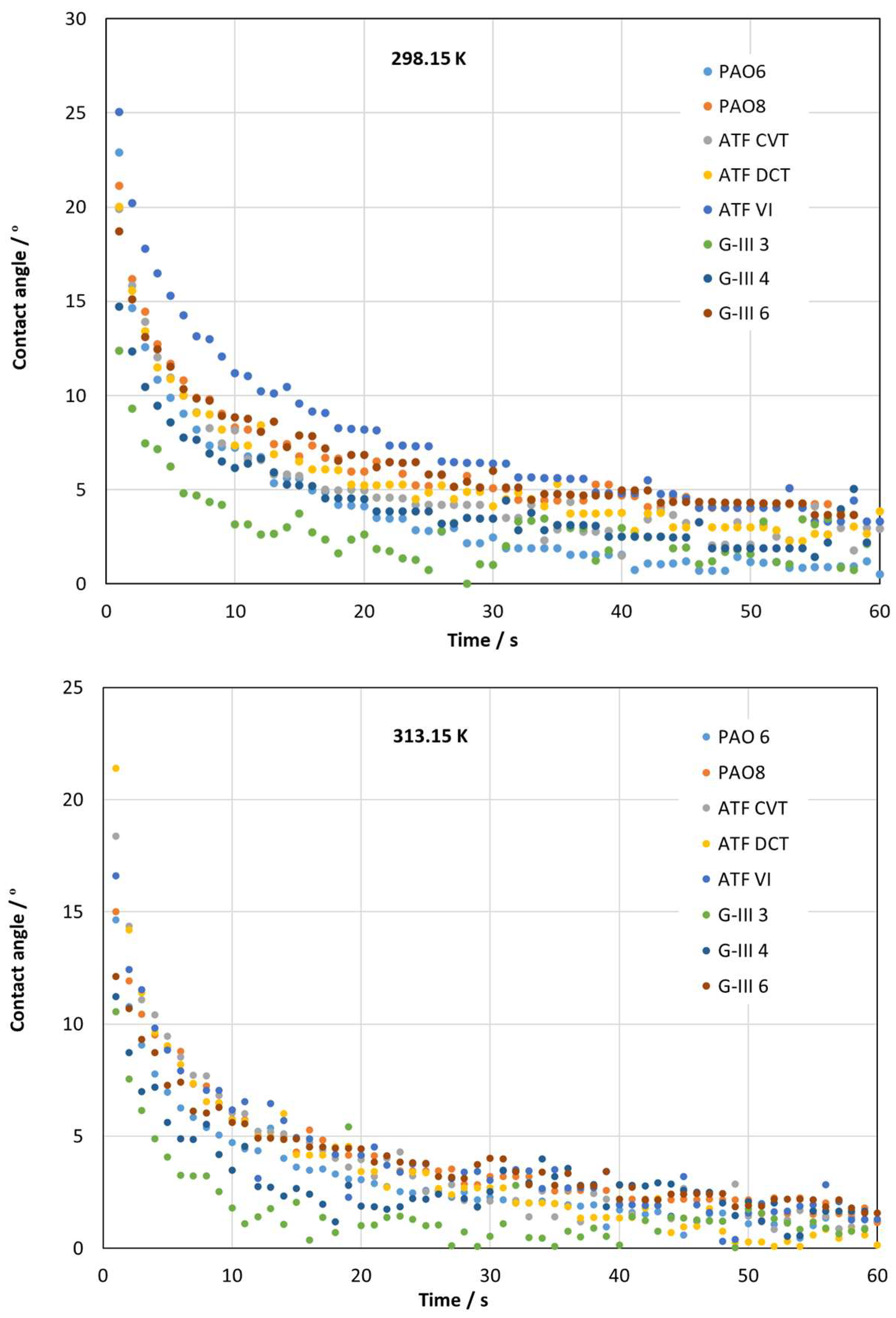

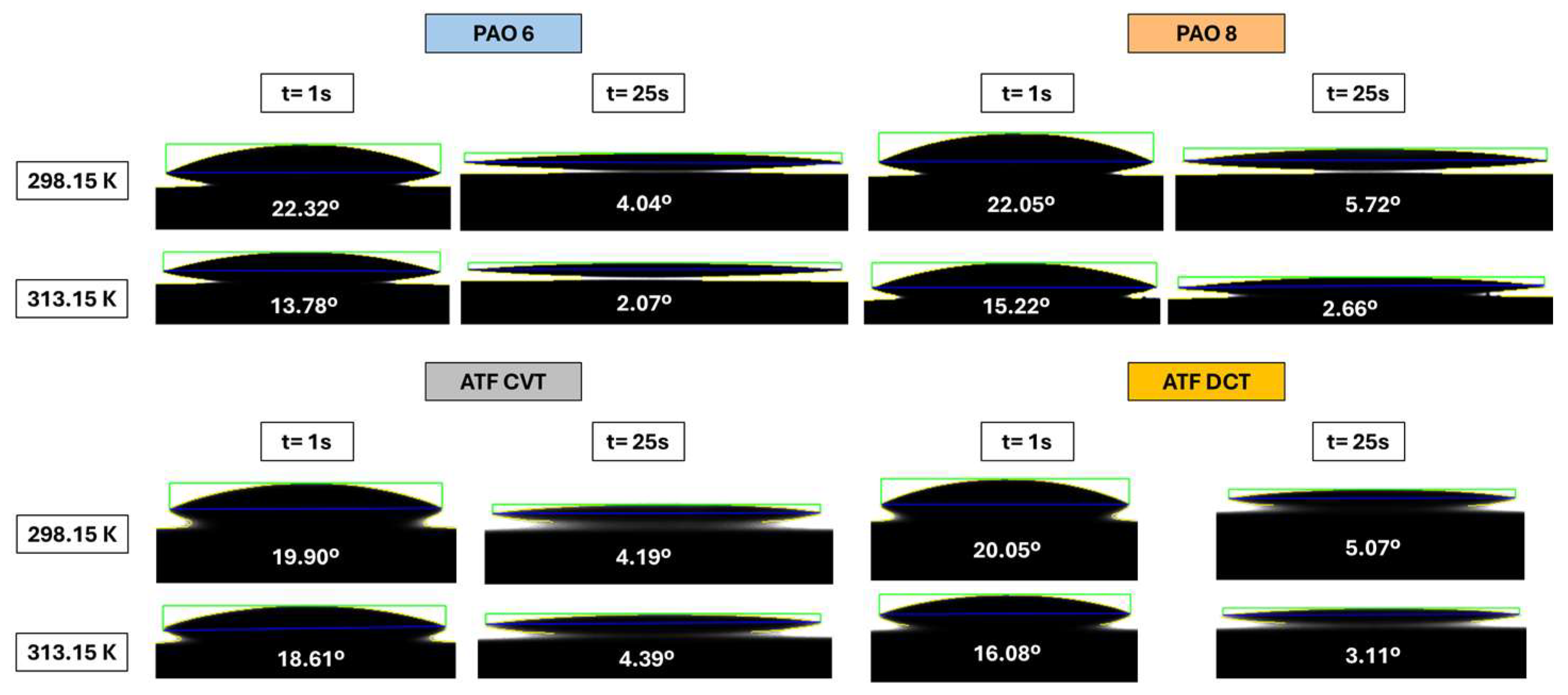

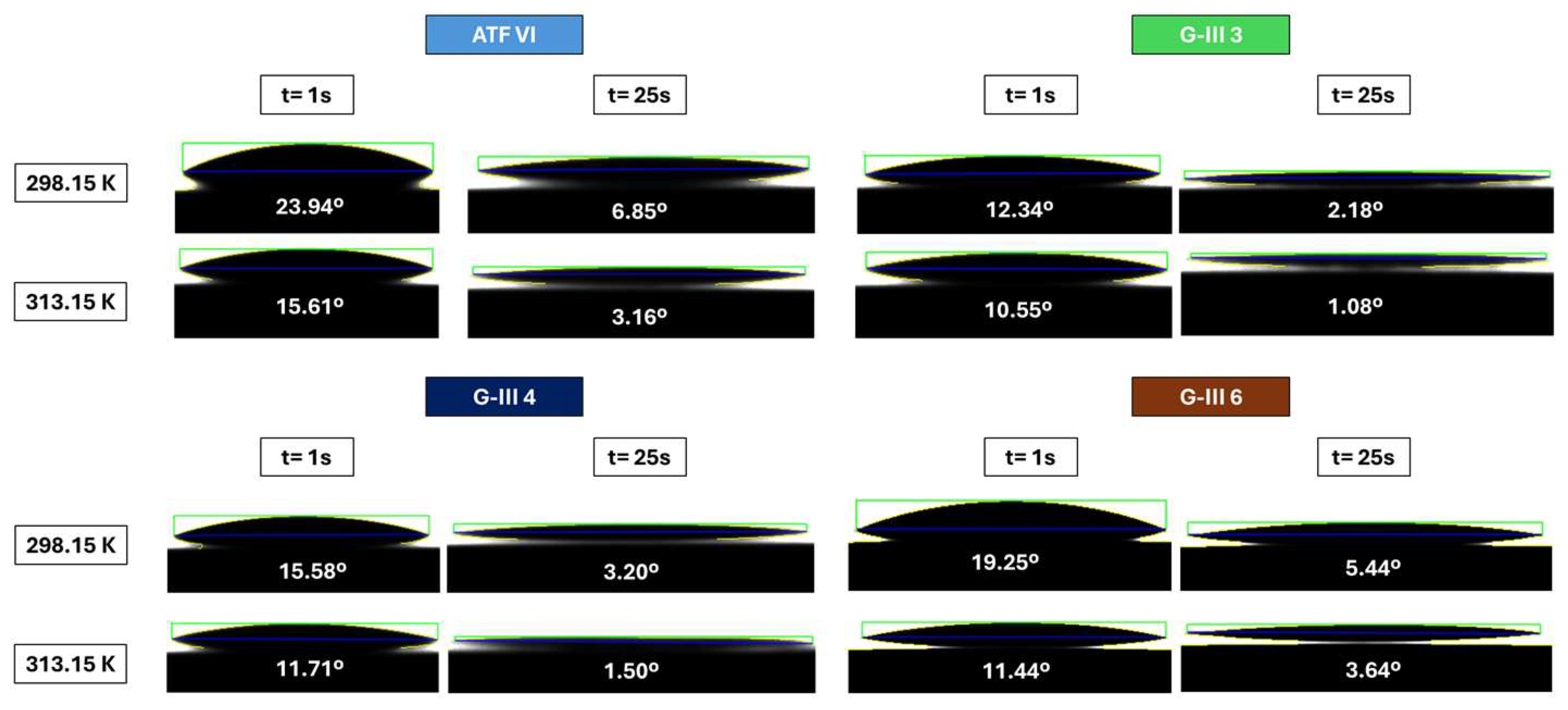

3.3. Contact Angle and Surface Tension and Results

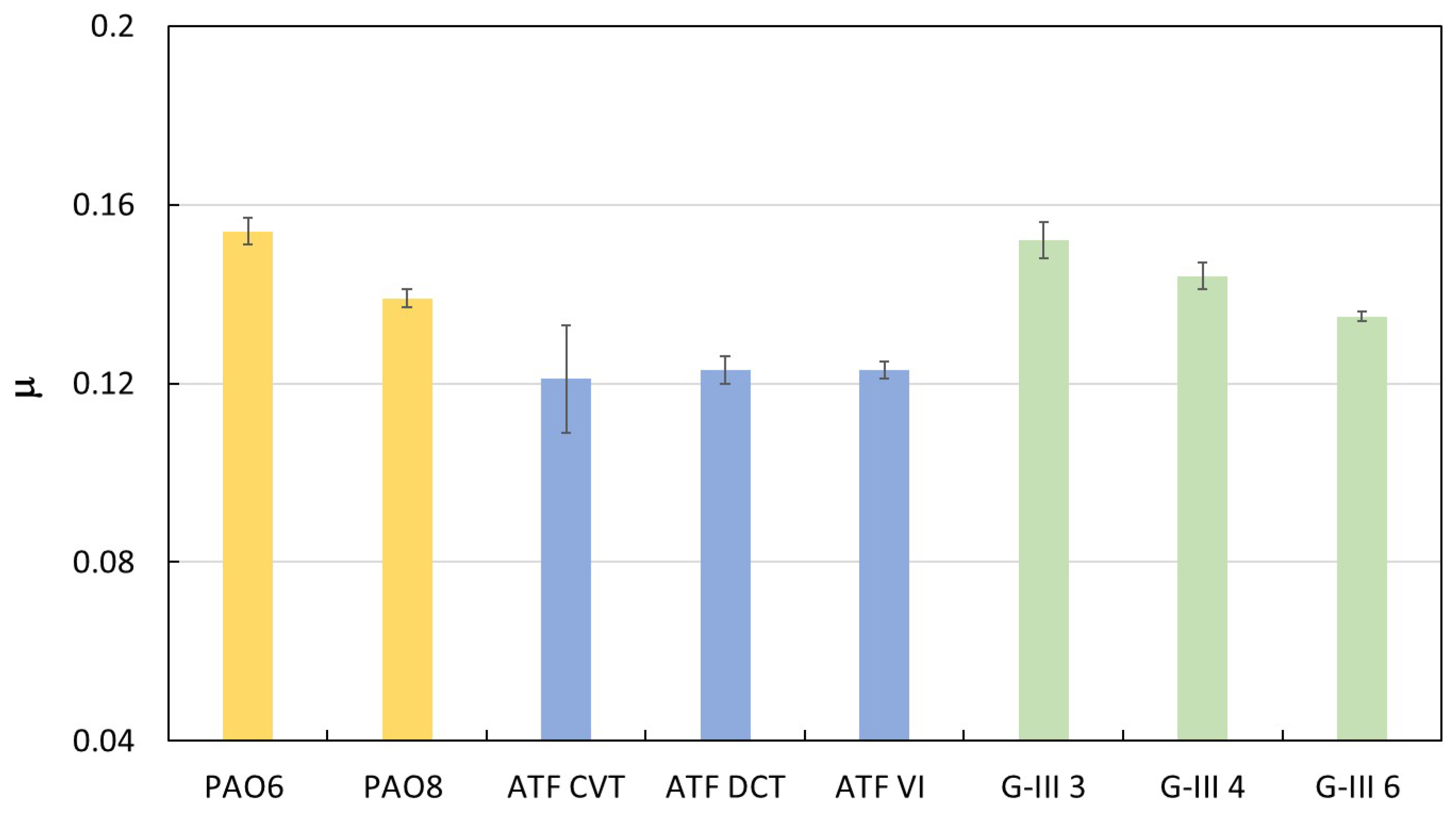

3.4. Friction and Wear Results

4. Conclusions

- -

- Refractive index values were higher for the formulated oils than for base oils. For G-III and PAO base oils, the refractive index increased as the viscosity rose.

- -

- The dynamic viscosities of the tested oils at 278.15 K ranged between 253 and 49 mPa s, for PAO8 and G-III 3, respectively. On the other hand, at 373.15 K, all the lubricants had similar viscosities (between 3 and 8 mPa s).

- -

- The densities of the formulated lubricants (ATF DCT, ATF CVT, and ATF VI) were the highest, whereas PAOs had the lowest densities (PAO6).

- -

- The surface tensions of PAOs and G-IIIs rose gradually with an increase in viscosity, the surface tension being greatest for G-III 6 and lowest for G-III 3.

- -

- As the temperature increased, the contact angle values decreased. Therefore, at the operational temperature of EV transmissions, contact angles will be low, indicating increased wettability and the formation of a tribofilm that could prevent surface contact.

- -

- As expected, the lowest friction coefficients were obtained with the formulated lubricants, due to the presence of the additive package. The highest friction coefficients were obtained for the low-viscosity PAOs and G-IIIs, PAO6 and G-III 3, respectively.

- -

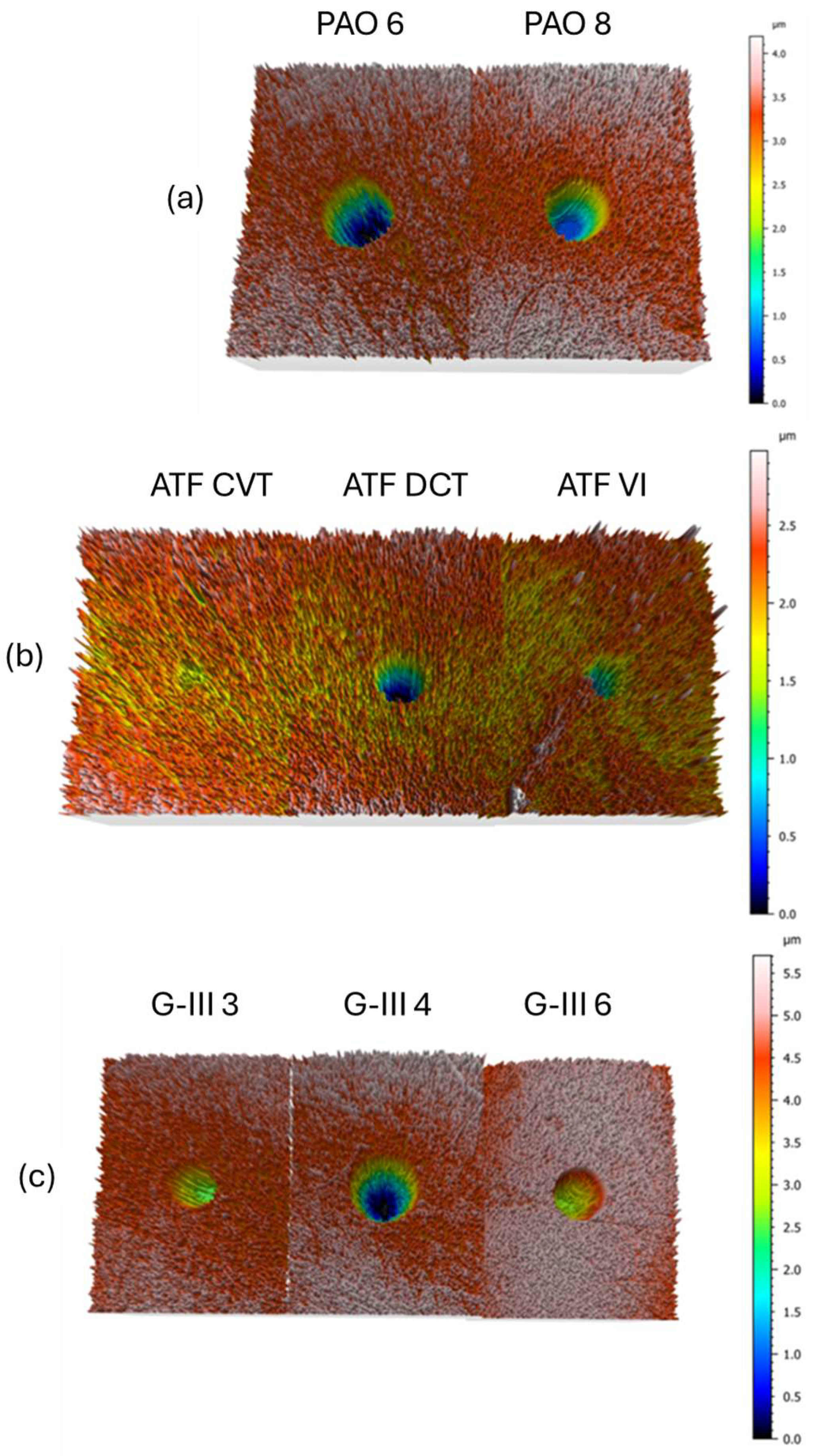

- The lowest wear generated in the pins was obtained for those lubricated with formulated oils. Regarding the base oils, the tested pins lubricated with PAOs presented greater wear than those lubricated with G-IIIs.

- -

- Based on the results, it should be interesting to study the tribological performance of these base oils with different nanoadditives to design potential EV lubricants and compare them with the tribological performance obtained by the formulated oils.

- -

- Before using these lubricants in EVs, more studies are needed, such as tribological tests with long times at high loads, to estimate their possible degradation with time.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García Tuero, A.; Sanjurjo, C.; Rivera, N.; Viesca, J.L.; González, R.; Hernández Battez, A. Electrical conductivity and tribological behavior of an automatic transmission fluid additised with a phosphonium-based ionic liquid. J. Mol. Liq. 2022, 367, 120581. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.; Erdemir, A. Electric Vehicle Tribology. In Elsevier Series on Tribology and Surface Engineering; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar]

- Choma, E.F.; Evans, J.S.; Hammitt, J.K.; Gómez-Ibáñez, J.A.; Spengler, J.D. Assessing the health impacts of electric vehicles through air pollution in the United States. Environ. Int. 2020, 144, 106015. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I. Tribology of electric vehicles: A review of critical components, current state and future improvement trends. Tribol. Int. 2019, 138, 473–486. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Erdemir, A.; Cao-Romero-Gallegos, J.A.; Alam, I.; Lee, S. Electrification effects on dry and lubricated sliding wear of bearing steel interfaces. Wear 2023, 516, 204592. [Google Scholar] [CrossRef]

- García Tuero, A.; Rivera, N.; Rodríguez, E.; Fernández-González, A.; Viesca, J.L.; Hernández Battez, A. Influence of Additives Concentration on the Electrical Properties and the Tribological Behaviour of Three Automatic Transmission Fluids. Lubricants 2022, 10, 276. [Google Scholar] [CrossRef]

- Rodríguez, E.; Rivera, N.; Fernández-González, A.; Pérez, T.; González, R.; Battez, A.H. Electrical compatibility of transmission fluids in electric vehicles. Tribol. Int. 2022, 171, 107544. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Narita, K.; Takekawa, D. Lubricants Technology Applied to Transmissions in Hybrid Electric Vehicles and Electric Vehicles; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Li, H.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Extreme pressure and antiwear additives for lubricant: Academic insights and perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 1–27. [Google Scholar] [CrossRef]

- Anand, O.N.; Kumar, V.; Singh, A.K.; Bisht, R.P.S. Anti-friction, anti-wear and load-carrying characteristics of environment friendly additive formulation. Lubr. Sci. 2007, 19, 159–167. [Google Scholar] [CrossRef]

- Blanco, D.; Bartolomé, M.; Ramajo, B.; Viesca, J.L.; González, R.; Hernández Battez, A. Wetting Properties of Seven Phosphonium Cation-Based Ionic Liquids. Ind. Eng. Chem. Res. 2016, 55, 9594–9602. [Google Scholar] [CrossRef]

- Edachery, V.; Shashank, R.; Kailas, S.V. Influence of surface texture directionality and roughness on wettability, sliding angle, contact angle hysteresis, and lubricant entrapment capability. Tribol. Int. 2021, 158, 106932. [Google Scholar] [CrossRef]

- Li, B.; Li, K. Droplet wettability and repellency on fluorinated lubricant-infused surfaces: A molecular dynamics study. Appl. Surf. Sci. 2022, 598, 153782. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Bai, P.; Jia, W.; Xu, Q.; Meng, Y.; Ma, L.; Tian, Y. Surface wettability effect on aqueous lubrication: Van der Waals and hydration force competition induced adhesive friction. J. Colloid Interface Sci. 2021, 599, 667–675. [Google Scholar] [CrossRef] [PubMed]

- Kotia, A.; Rajkhowa, P.; Rao, G.S.; Ghosh, S.K. Thermophysical and tribological properties of nanolubricants: A review. Heat Mass Transf. 2018, 54, 3493–3508. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Ahmed Ali, M.K.; Xianjun, H.; Essa, F.A.; Abdelkareem, M.A.A.; Elagouz, A.; Sharshir, S.W. Friction and Wear Reduction Mechanisms of the Reciprocating Contact Interfaces Using Nanolubricant Under Different Loads and Speeds. J. Tribol. 2018, 140, 051606. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A Review of Friction Performance of Lubricants with Nano Additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- Ali, Z.A.A.A.; Takhakh, A.M.; Al-Waily, M. A review of use of nanoparticle additives in lubricants to improve its tribological properties. Mater. Today Proc. 2022, 52, 1442–1450. [Google Scholar] [CrossRef]

- ISO 2909; Petroleum Products—Calculation of Viscosity Index from Kinematic Viscosity. ISO: Geneva, Switzerland, 2002.

- ASTM D2270; Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C. ASTM: West Conshohocken, PA, USA, 2016.

- Mariño, F.; López, E.R.; Arnosa, Á.; González Gómez, M.A.; Piñeiro, Y.; Rivas, J.; Alvarez-Lorenzo, C.; Fernández, J. ZnO nanoparticles coated with oleic acid as additives for a polyalphaolefin lubricant. J. Mol. Liq. 2022, 348, 118401. [Google Scholar] [CrossRef]

- Gaciño, F.M.; Regueira, T.; Lugo, L.; Comuñas, M.J.P.; Fernández, J. Influence of Molecular Structure on Densities and Viscosities of Several Ionic Liquids. J. Chem. Eng. Data 2011, 56, 4984–4999. [Google Scholar] [CrossRef]

- Weissberger, A.; Rossiter, B.W. Physical Methods of Chemistry: Electrochemical Methods; Wiley-Interscience: Hoboken, NJ, USA, 1971. [Google Scholar]

- Coelho de Sousa Marques, M.A.; Guimarey, M.J.G.; Domínguez-Arca, V.; Amigo, A.; Fernández, J. Heat capacity, density, surface tension, and contact angle for polyalphaolefins and ester lubricants. Thermochim. Acta 2021, 703, 178994. [Google Scholar] [CrossRef]

- Läuger, J.; Pondicherry, K. New Insights into the Use of a Rotational Rheometer as Tribometer. Annu. Trans. Nord. Rheol. Soc. 2017, 25, 333–340. [Google Scholar]

- Heyer, P.; Läuger, J. Correlation between friction and flow of lubricating greases in a new tribometer device. Lubr. Sci. 2009, 21, 253–268. [Google Scholar] [CrossRef]

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- ISO 21920-2:2021; Geometrical product specifications (GPS) — Surface texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- Bin Abdollah, M.F.; Amiruddin, H.; Alif Azmi, M.; Mat Tahir, N.A. Lubrication mechanisms of hexagonal boron nitride nano-additives water-based lubricant for steel–steel contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1038–1046. [Google Scholar] [CrossRef]

- Tetteh, J.; Kubelka, J.; Qin, L.; Piri, M. Effect of ethylene oxide groups on calcite wettability reversal by nonionic surfactants: An experimental and molecular dynamics simulation investigation. J. Colloid Interface Sci. 2024, 676, 408–416. [Google Scholar] [CrossRef] [PubMed]

- Mate, C.M. Tribology on the Small Scale: A Bottom Up Approach to Friction, Lubrication, and Wear; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Behera, B.C.; Chetan; Setti, D.; Ghosh, S.; Rao, P.V. Spreadability studies of metal working fluids on tool surface and its impact on minimum amount cooling and lubrication turning. J. Mater. Process. Technol. 2017, 244, 1–16. [Google Scholar] [CrossRef]

- Mariño, F.; Liñeira del Río, J.M.; Gonçalves, D.E.P.; Seabra, J.H.O.; López, E.R.; Fernández, J. Effect of the addition of coated SiO2 nanoparticles on the tribological behavior of a low-viscosity polyalphaolefin base oil. Wear 2023, 530–531, 205025. [Google Scholar] [CrossRef]

- Liñeira del Río, J.M.; Mariño, F.; López, E.R.; Gonçalves, D.E.P.; Seabra, J.H.O.; Fernández, J. Tribological enhancement of potential electric vehicle lubricants using coated TiO2 nanoparticles as additives. J. Mol. Liq. 2023, 371, 121097. [Google Scholar] [CrossRef]

- Liñeira del Río, J.M.; López, E.R.; Fernández, J. Tribological behavior of electric vehicle transmission oils using Al2O3 nanoadditives. J. Mol. Liq. 2024, 397, 124036. [Google Scholar] [CrossRef]

- Liñeira del Río, J.M.; Rial, R.; López, E.R.; Fernández, J. Tribological enhancement using Mn3O4-Graphene nanocomposites as additives for potential transmission fluids of electric vehicles. J. Mol. Liq. 2022, 366, 120271. [Google Scholar] [CrossRef]

| Lubricant Oil | Nature | Density at 313.15 K g cm−3 | Dynamic Viscosity at 313.15 K mPa s |

|---|---|---|---|

| PAO6 | Synthetic | 0.8114 | 24.853 |

| PAO8 | Synthetic | 0.8163 | 39.470 |

| ATF CVT | Mineral | 0.8325 | 31.411 |

| ATF DCT | Mineral | 0.8370 | 30.943 |

| ATF VI | Mineral | 0.8271 | 25.814 |

| G-III 3 | Mineral | 0.8159 | 10.889 |

| G-III 4 | Mineral | 0.8162 | 16.298 |

| G-III 6 | Mineral | 0.8234 | 28.850 |

| Tribology Cell T-PTD200 | ||

|---|---|---|

| Ball-on-Three-Pins Disposition | Peltier HPTD200 | |

| Pairs | Test Information | |

| 100Cr6 steel ball: 12.7 mm diameter and 0.15 µm Ra 100Cr6 pins: 6 mm diameter and a 0.3 µm Ra Specimens: Hardness: 58–65 HRC Young’s modulus: 190–210 GPa Poisson ratio: 0.29 | Sample: 1.1 mL Tribological force (FN): 9.4 N Maximum contact pressure: 1.1 GPa Distance: 340 m Speed: 213 rpm | 120 °C |

| Sensofar S Neox | |

|---|---|

| Specifications | Measured Parameters |

| Analysis mode: confocal Objective: 10× | Wear scar diameter (WSD) Wear track depth (WTD) Worn area (Area) Surface roughness (Ra):

|

| G-III 6 | G-III 4 | G-III 3 | ATF CVT | ATF VI | ATF DCT | PAO6 | PAO8 | |

|---|---|---|---|---|---|---|---|---|

| 298.15 K | 1.46223 | 1.46210 | 1.46122 | 1.46643 | 1.46564 | 1.46612 | 1.46012 | 1.46231 |

| 313.15 K | 1.45668 | 1.45642 | 1.45546 | 1.46084 | 1.46145 | 1.46045 | 1.45761 | 1.45814 |

| 298.15 K | 313.15 K | |||

|---|---|---|---|---|

| γ/mN m−1 | σ/mN m−1 | γ/mN m−1 | σ/mN m−1 | |

| PAO6 | 29.51 | 0.07 | 28.16 | 0.07 |

| PAO8 | 29.61 | 0.07 | 28.33 | 0.07 |

| ATF CVT | 29.65 | 0.07 | 28.40 | 0.08 |

| ATF DCT | 29.46 | 0.06 | 28.22 | 0.08 |

| ATF VI | 29.81 | 0.08 | 28.55 | 0.09 |

| G-III 3 | 29.29 | 0.06 | 27.88 | 0.09 |

| G-III 4 | 29.66 | 0.07 | 28.33 | 0.06 |

| G-III 6 | 30.07 | 0.12 | 28.94 | 0.08 |

| 298.15 K | 313.15 K | |||

|---|---|---|---|---|

| θ/° | σ | θ/° | σ | |

| PAO6 | 7.1 | 0.4 | 4.7 | 1.0 |

| PAO8 | 9.2 | 1.7 | 6.0 | 0.2 |

| ATF CVT | 9.7 | 2.8 | 6.8 | 0.9 |

| ATF DCT | 8.1 | 0.8 | 6.0 | 0.5 |

| ATF VI | 12.0 | 2.3 | 5.7 | 0.6 |

| G-III 3 | 3.8 | 0.8 | 3.0 | 1.0 |

| G-III 4 | 5.9 | 0.3 | 3.9 | 0.7 |

| G-III 6 | 8.7 | 0.5 | 5.9 | 0.8 |

| PAO6 | PAO8 | ATF CVT | ATF DCT | ATF VI | G-III 3 | G-III 4 | G-III 6 | |

|---|---|---|---|---|---|---|---|---|

| 298.15 K | −65.35 | −79.52 | −66.40 | −86.90 | −32.67 | −54.72 | −35.50 | −88.96 |

| 313.15 K | −35.85 | −36.07 | −35.42 | −35.19 | −31.05 | −73.72 | −33.91 | −35.88 |

| Lubricant | µ | σ | WSD/μm | σ/μm | WTD/μm | σ/μm | Area/μm2 | σ/μm2 |

|---|---|---|---|---|---|---|---|---|

| PAO6 [35] | 0.154 | 0.003 | 435 | 10 | 2.60 | 0.19 | 806 | 65 |

| PAO8 [36] | 0.139 | 0.002 | 392 | 14 | 2.35 | 0.17 | 605 | 52 |

| ATFCVT | 0.121 | 0.012 | 236 | 11 | 0.55 | 0.08 | 66 | 10 |

| ATFDCT | 0.123 | 0.003 | 331 | 36 | 1.38 | 0.21 | 294 | 54 |

| ATFVI [37] | 0.123 | 0.002 | 289 | 16 | 0.82 | 0.09 | 163 | 27 |

| G-III 3 | 0.152 | 0.004 | 347 | 31 | 1.53 | 0.33 | 358 | 94 |

| G-III 4 | 0.144 | 0.003 | 381 | 46 | 2.05 | 0.41 | 589 | 62 |

| G-III 6 [38] | 0.135 | 0.001 | 366 | 18 | 2.11 | 0.19 | 607 | 44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liñeira del Río, J.M.; Alba, A.; Gómez Martínez, M.; Amigo, A.; Fernández, J. Base Oils and Formulated Transmission Oils for Electrical Vehicles: Thermophysical and Tribological Properties. Materials 2025, 18, 1207. https://doi.org/10.3390/ma18061207

Liñeira del Río JM, Alba A, Gómez Martínez M, Amigo A, Fernández J. Base Oils and Formulated Transmission Oils for Electrical Vehicles: Thermophysical and Tribological Properties. Materials. 2025; 18(6):1207. https://doi.org/10.3390/ma18061207

Chicago/Turabian StyleLiñeira del Río, José M., Alonso Alba, Martín Gómez Martínez, Alfredo Amigo, and Josefa Fernández. 2025. "Base Oils and Formulated Transmission Oils for Electrical Vehicles: Thermophysical and Tribological Properties" Materials 18, no. 6: 1207. https://doi.org/10.3390/ma18061207

APA StyleLiñeira del Río, J. M., Alba, A., Gómez Martínez, M., Amigo, A., & Fernández, J. (2025). Base Oils and Formulated Transmission Oils for Electrical Vehicles: Thermophysical and Tribological Properties. Materials, 18(6), 1207. https://doi.org/10.3390/ma18061207