The Effect of Different Thermomechanical Treatments on the Metastable Phase in a Cu-Ni-Be Alloy

Abstract

1. Introduction

2. Materials and Methods

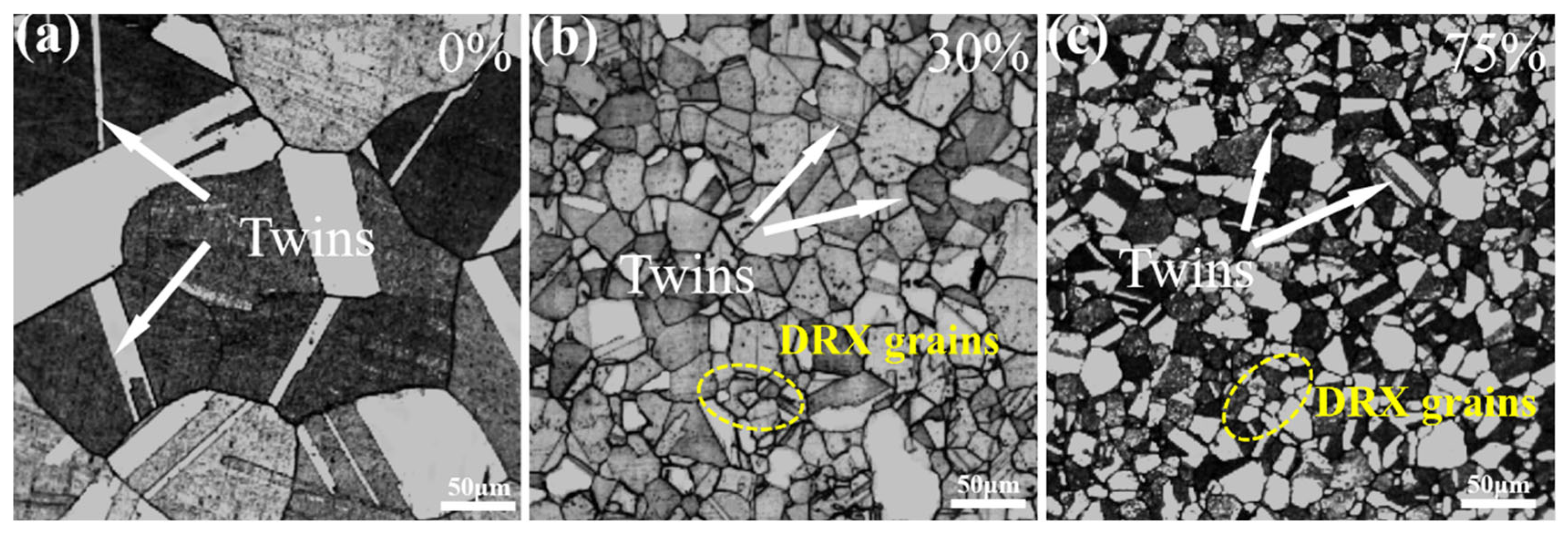

3. The Effect of Different Amounts of Thermal Deformation on Structure and Properties

4. Analysis and Discussion

5. Conclusions

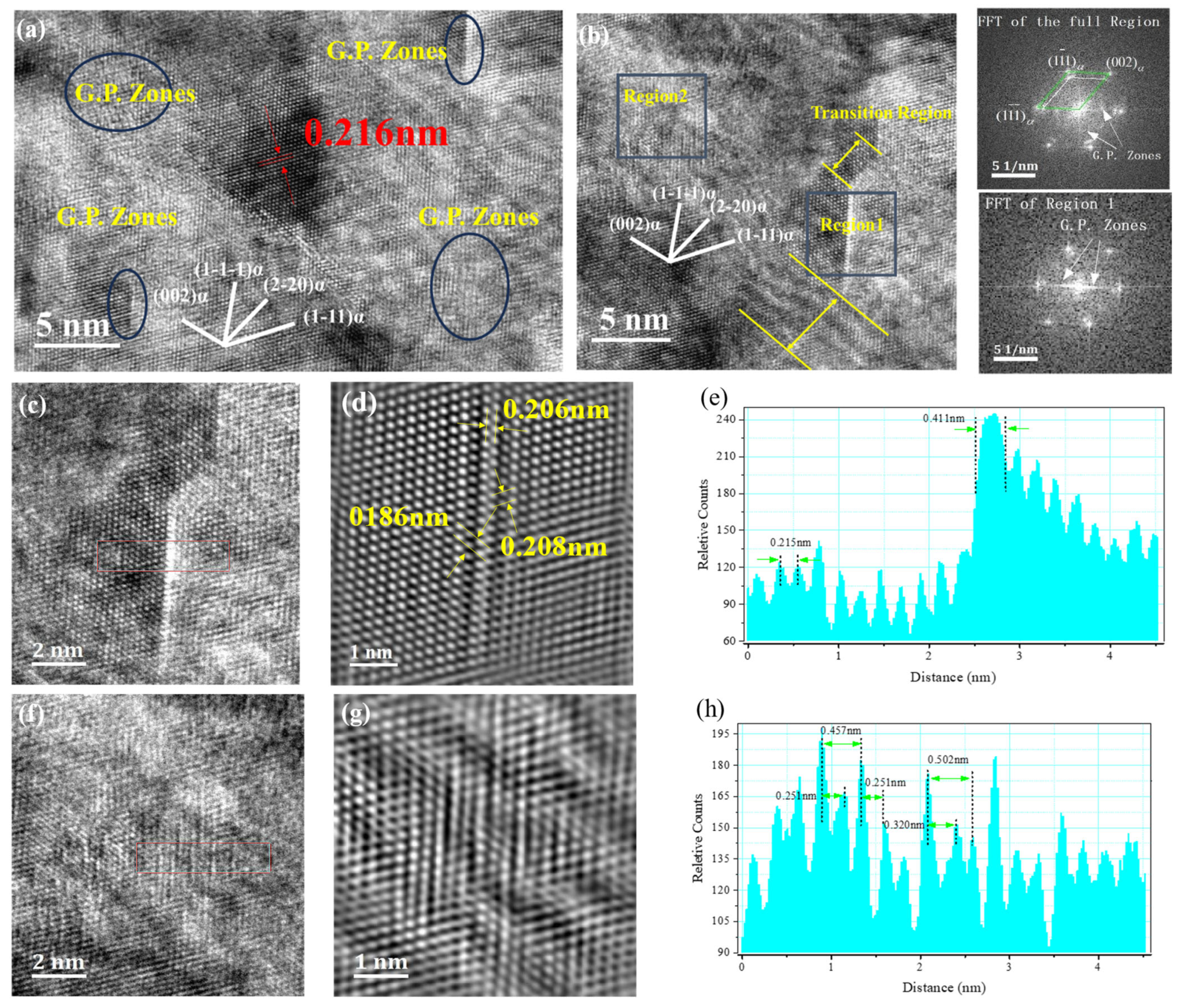

- The fourth orientation relationship between precipitates and the matrix arose from the thermomechanical treatment process, leading to multiple orientation relationships that maximized macroscopic hardness.

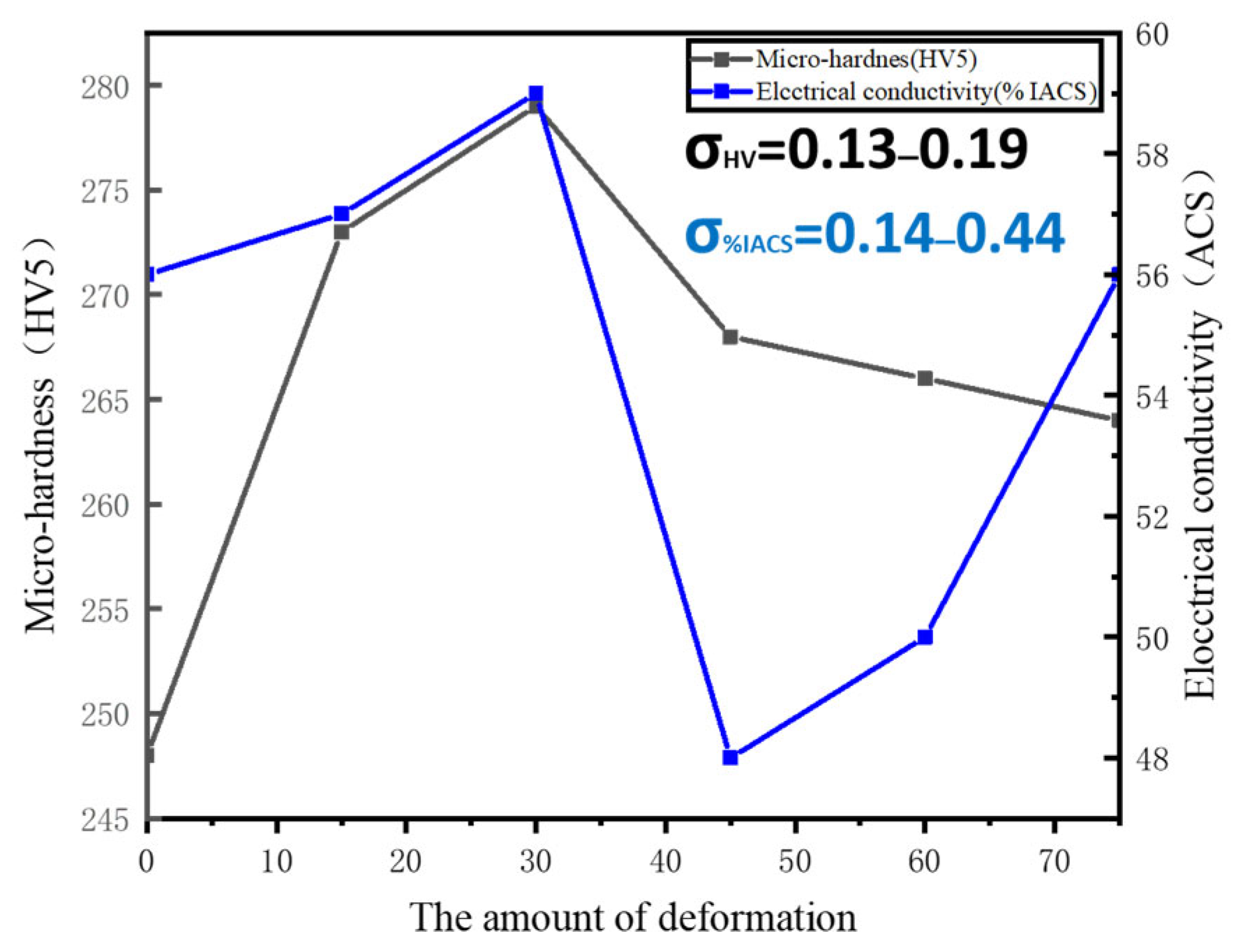

- At 45% deformation, the full development of GP zones in the alloy reduced electrical conductivity. When deformation reached 75%, the presence of γ′ phases with coherent interfaces with the matrix enhanced electrical conductivity while reducing hardness.

- In this alloy, the second phase grew along dislocation lines, and increased deformation accelerated the coarsening process of γ″ phases.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guha, A. Development of a High-Strength High-Conductivity Cu--Ni--Be Alloy. In High Conductivity Copper and Aluminum Alloys; Springer: Berlin/Heidelberg, Germany, 1984; pp. 133–145. [Google Scholar]

- Xie, G.L.; Wang, Q.S.; Guo, Q.M.; Liu, D.M.; Xie, W.B.; Mi, X.J.; Xiong, B.Q. Precipitation process and mechanical properties of an elastic Cu-Ni-Mn Alloy. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2015; Volume 817. [Google Scholar]

- Ota, S.; Muramatsu, N.; Sengoku, K.; Watanabe, C.; Monzen, R. Mechanical and electrical properties and microstructure in Cu-Ni-Bc alloys. J. Soc. Mater. Sci. 2007, 54, 531–536. [Google Scholar] [CrossRef]

- Monzen, R.; Okawara, S.; Watanabe, C. Stress-assisted nucleation and growth of γ ″and γ′ precipitates in a Cu–1.2 wt% Be–0.1 wt% Co alloy aged at 320° C. Philos. Mag. 2012, 92, 1826–1843. [Google Scholar] [CrossRef]

- Wei, R.; Lou, H.; Ren, H.; Yu, L.; Hong, J. Effect of cold deformation on aging precipitation characteristics of Cu-Ni-low Be alloys. J. Met. Heat Treat. 1993, 14, 5. [Google Scholar]

- Monzen, R.; Watanabe, C.; Seo, T.; Sakai, T. Effect of applied stress on precipitation of Guinier–Preston zones in a Cu–0.9 wt.% Be single crystal. Philos. Mag. Lett. 2005, 85, 603–612. [Google Scholar] [CrossRef]

- Fang, S.; Chen, L.; Zhou, Q.; Zhou, S. Effects of Aging Process on the Microstructure and Properties of Cu-Ni-Be Alloy. Spec. Cast. Nonferrous Alloys 2023, 41, 867–871. [Google Scholar]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Some aspects of the precipitation of metastable intermetallic phases in INCONEL 718. Metall. Trans. A 1992, 23, 2015–2028. [Google Scholar] [CrossRef]

- Zhu, Z.; Cai, Y.; Sui, Y.; Song, K.; Zhou, Y.; Zou, J. Precipitation characteristics of the metastable γ ″phase in a Cu-Ni-Be alloy. Materials 2018, 11, 1394. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Wang, J.; Meng, Y.; Hong, Z.; Zhao, H.; Dong, X. Double-peak age strengthening phenomenon and mechanism of Cu–Be–Ni–Co alloys. Mater. Des. 2024, 238, 112666. [Google Scholar] [CrossRef]

- Lou, H.; Shen, G.; Wei, R.; Ren, H. TEM study on aging precipitation of Cu-Ni-Be high conductivity wear-resistant alloys. J. Electron Microsc. 1993, 12, 5. [Google Scholar]

- Phillips, V.A.; Tanner, L.E. High resolution electron microscope observations on GP zones in an aged Cu-1.97 wt.% Be crystal. Acta Metall. 1973, 21, 441–448. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, F.; Yang, H.; Liu, J.; Ma, J.; Fang, Y. Progress in research on nanoprecipitates in high-strength conductive copper alloys: A review. J. Zhejiang Univ.-Sci. A 2023, 24, 206–225. [Google Scholar] [CrossRef]

- Peng, L.J.; Xiong, B.Q.; Xie, G.L.; Wang, Q.S.; Hong, S.B. Precipitation process and its effects on properties of aging Cu–Ni–Be alloy. Rare Met. 2013, 32, 332–337. [Google Scholar] [CrossRef]

| Element | Cu | Ni | Be | Impurty |

|---|---|---|---|---|

| (wt.%) | Bal. | 2.16 | 0.272 | ≤ 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Yuan, Q.; Jia, J.; Wang, T.; Shen, Y.; Zhu, Z. The Effect of Different Thermomechanical Treatments on the Metastable Phase in a Cu-Ni-Be Alloy. Materials 2025, 18, 839. https://doi.org/10.3390/ma18040839

Xu J, Yuan Q, Jia J, Wang T, Shen Y, Zhu Z. The Effect of Different Thermomechanical Treatments on the Metastable Phase in a Cu-Ni-Be Alloy. Materials. 2025; 18(4):839. https://doi.org/10.3390/ma18040839

Chicago/Turabian StyleXu, Jinwen, Qinde Yuan, Junbo Jia, Tianhong Wang, Yubo Shen, and Zhiyuan Zhu. 2025. "The Effect of Different Thermomechanical Treatments on the Metastable Phase in a Cu-Ni-Be Alloy" Materials 18, no. 4: 839. https://doi.org/10.3390/ma18040839

APA StyleXu, J., Yuan, Q., Jia, J., Wang, T., Shen, Y., & Zhu, Z. (2025). The Effect of Different Thermomechanical Treatments on the Metastable Phase in a Cu-Ni-Be Alloy. Materials, 18(4), 839. https://doi.org/10.3390/ma18040839