Artificial Neural Network Modeling of Ti-6Al-4V Alloys to Correlate Their Microstructure and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection and Input–Output Variables of the Model

2.2. Training Procedure of the ANN Model

3. Results and Discussion

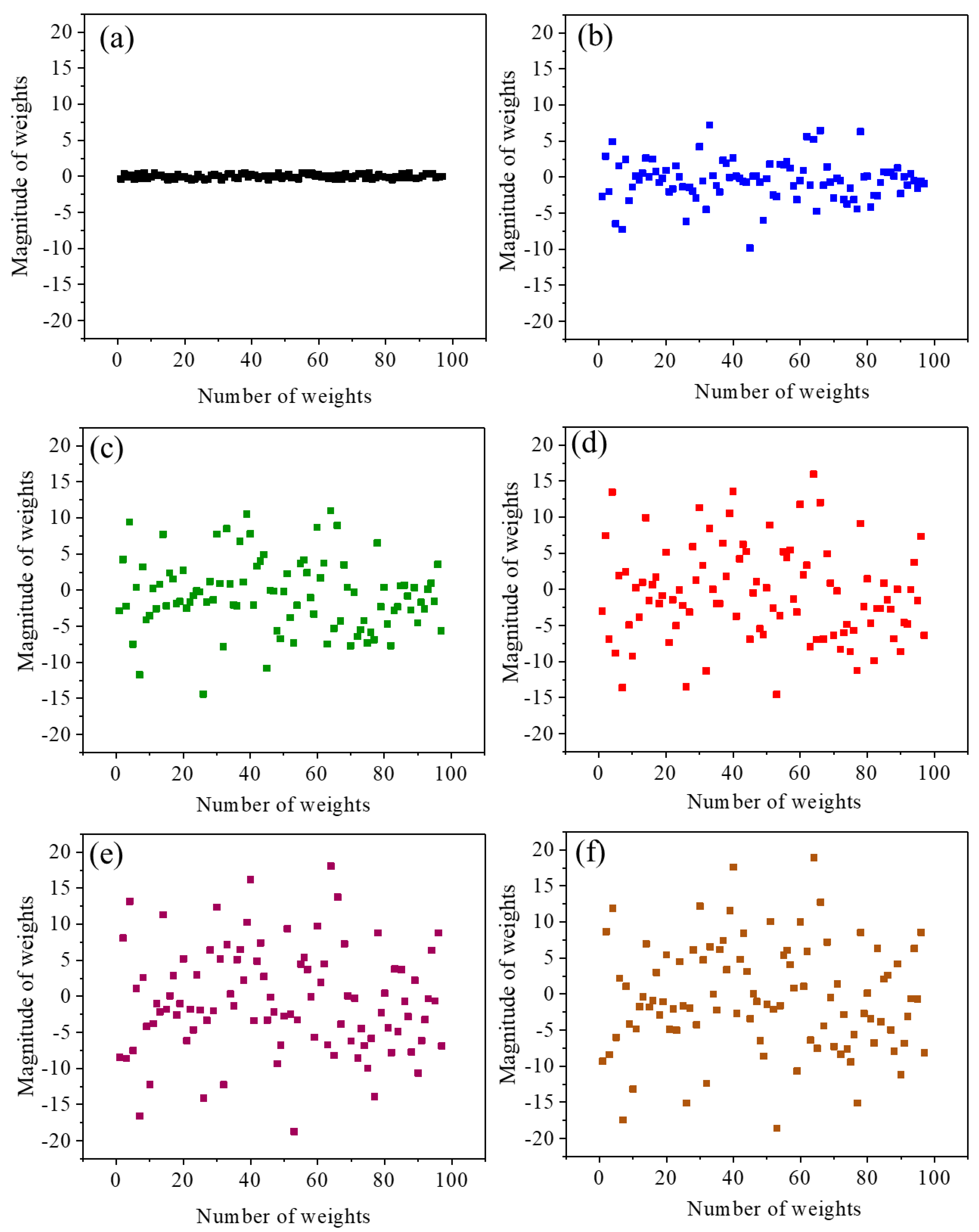

3.1. Validation of ANN Model and Weights Distribution

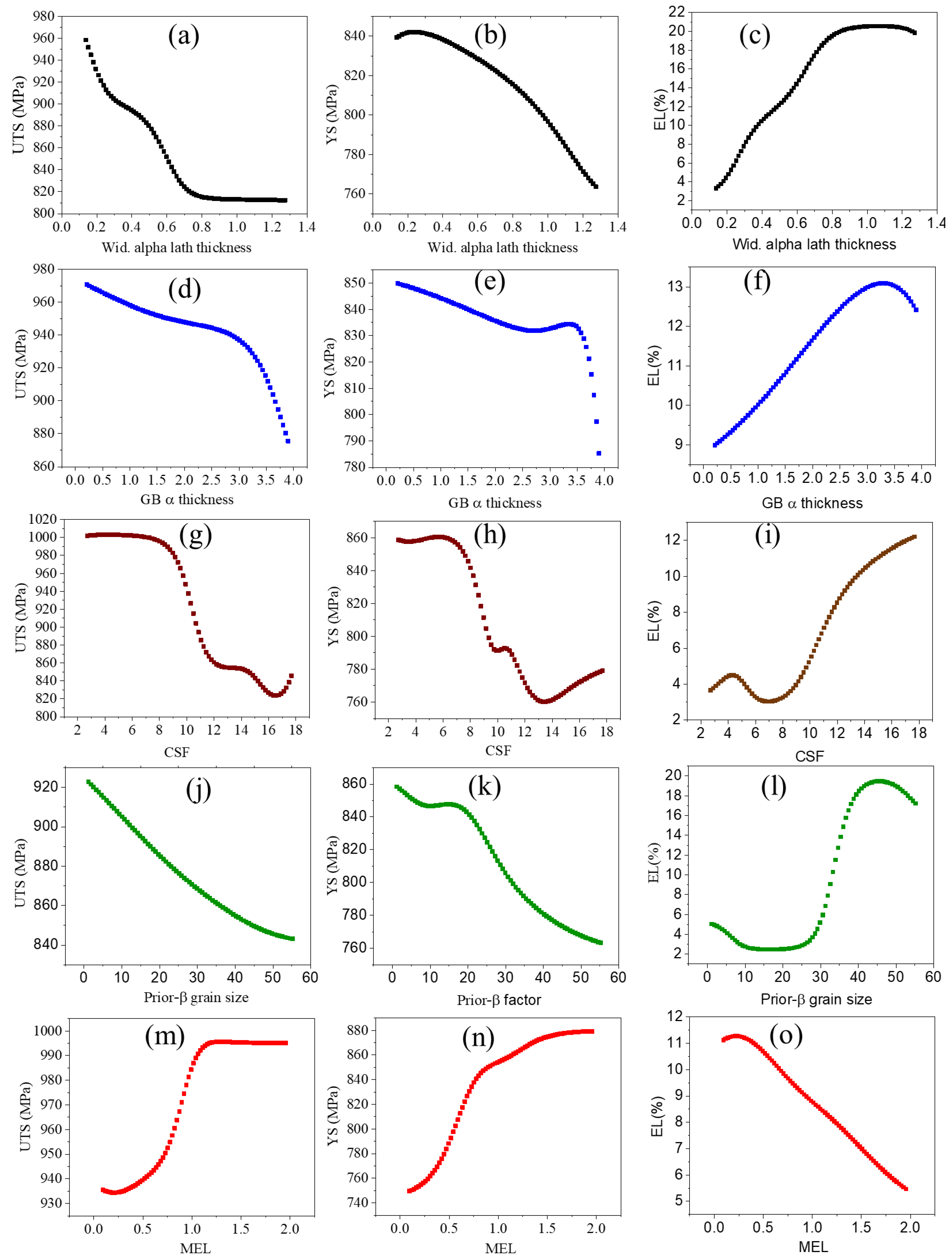

3.2. Prediction of the Relationship Between Process Parameters and Mechanical Properties

W = 0.1008M2 − 0.3547M + 0.53 (M > 0.7)

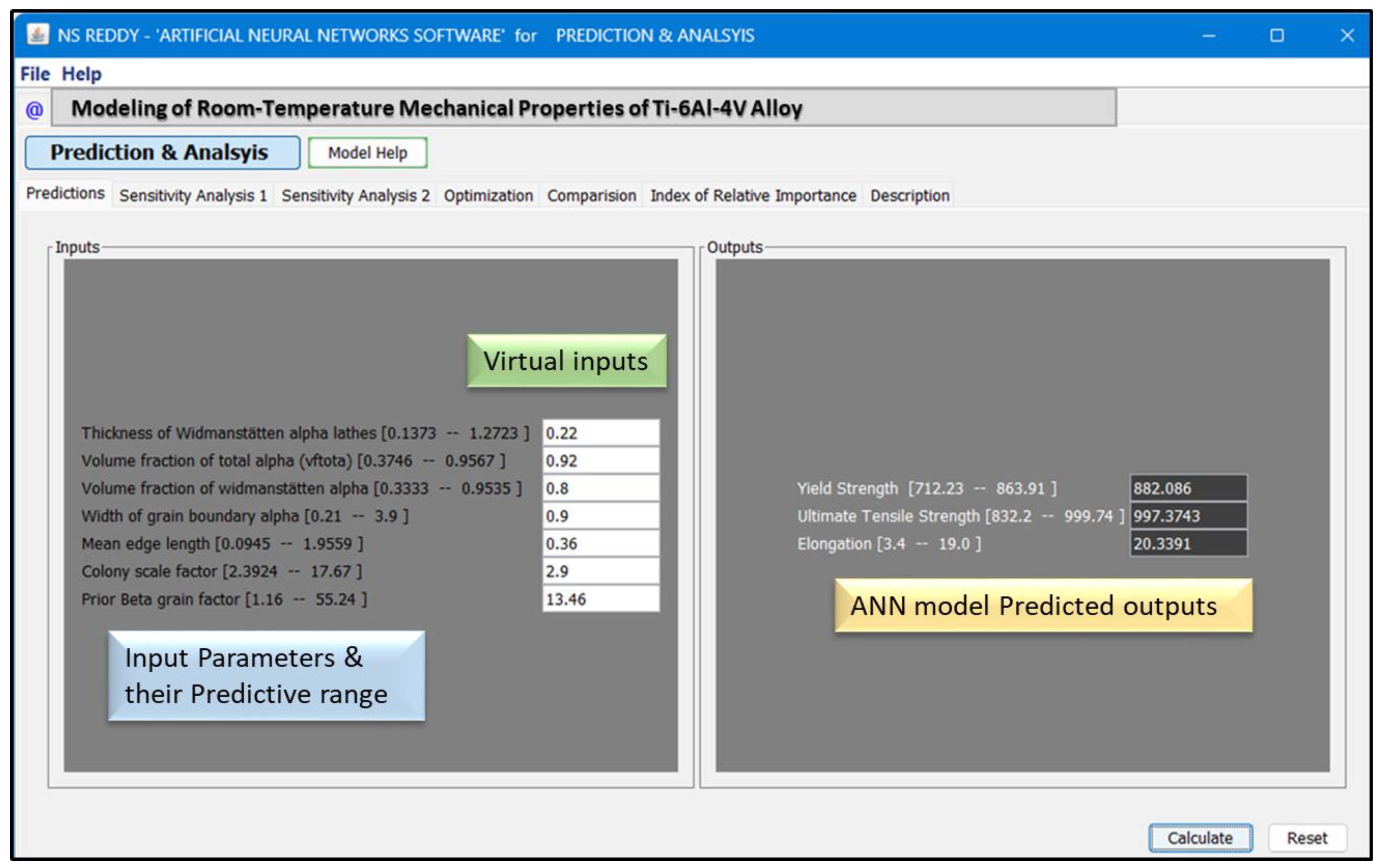

3.3. Graphical User Interface

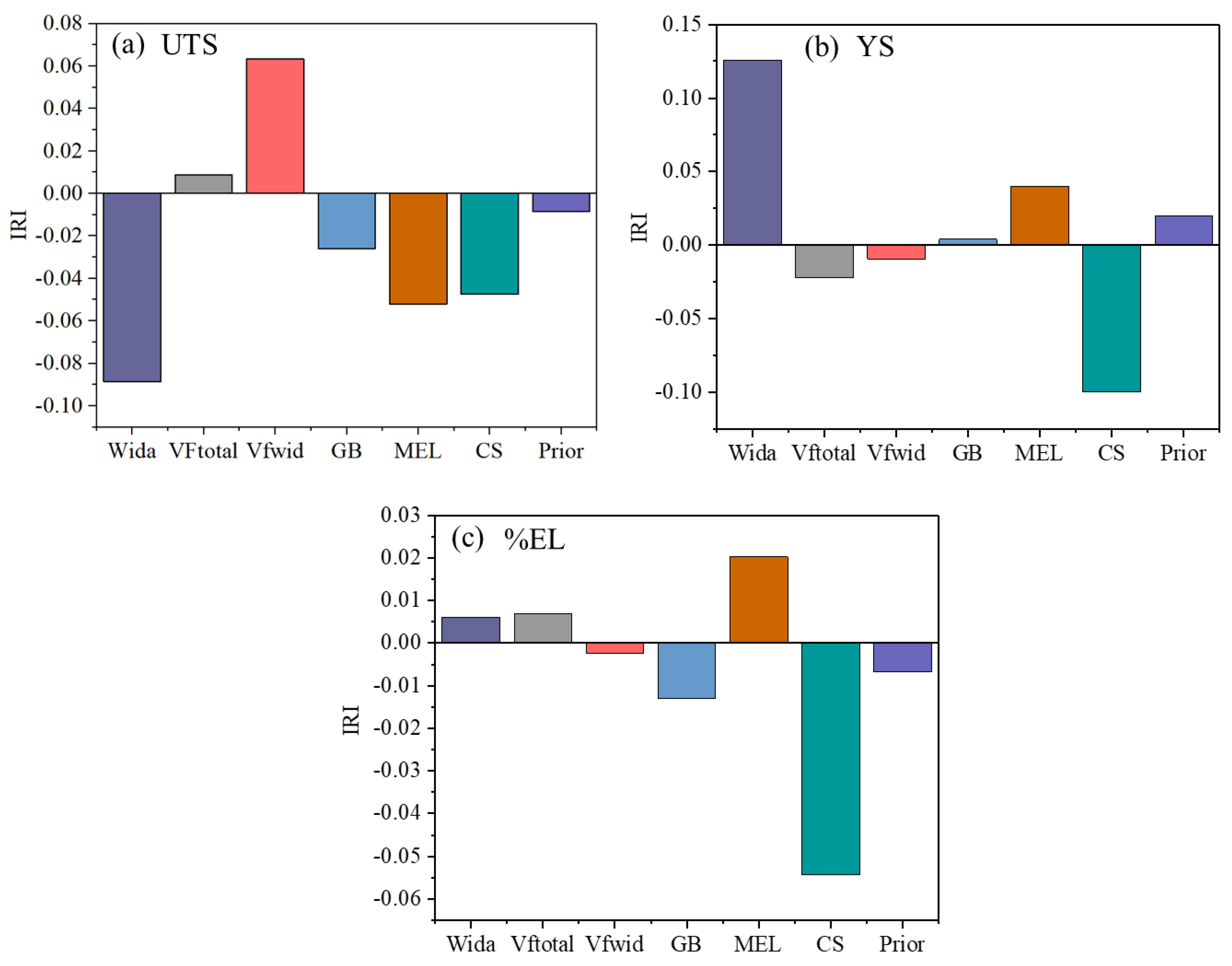

3.4. Index of the Relative Importance

4. Conclusions

- In this study, an ANN model was developed to study the influence of microstructural parameters on the mechanical properties of Ti-6Al-4V alloys. The developed model shows a high Adj. R2 value for the training and testing datasets for UTS, YS, and %EL. This shows that the model is highly accurate, with predictions of output values near the experimental values.

- The effects of microstructural parameters on the mechanical properties of Ti-6Al-4V alloys was explained with the help of 2D plots. The model’s predicted results show that the UTS of Ti-6Al-4V decreases with increases in prior β grain size, Widmanstatten α lath thickness, grain boundaries α thickness, colony scale factor, while UTS increases with mean edge length.

- The significance of each microstructural parameter on mechanical properties was described with the help of an index of relative importance. The Wida, Vfwid, MEL, and CSF are the parameters which most affect UTS.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, Z.; Feng, H. Study on selective laser melting and heat treatment of Ti-6Al-4V alloy. Results Phys. 2018, 10, 660–664. [Google Scholar] [CrossRef]

- Reda, R.; Nofal, A.; Hussein, A.-H. Effect of Single and Duplex Stage Heat Treatment on the Microstructure and Mechanical Properties of Cast Ti–6Al–4V Alloy. Metallogr. Microstruct. Anal. 2013, 2, 388–393. [Google Scholar] [CrossRef]

- Semiatin, S.; Knisley, S.; Fagin, P.; Barker, D.; Zhang, F. Microstructure evolution during alpha-beta heat treatment of Ti-6Al-4V. Metall. Mater. Trans. A 2003, 34, 2377–2386. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Al-Bermani, S.; Blackmore, M.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Artaza, T.; Suárez, A.; Veiga, F.; Braceras, I.; Tabernero, I.; Larrañaga, O.; Lamikiz, A. Wire arc additive manufacturing Ti6Al4V aeronautical parts using plasma arc welding: Analysis of heat-treatment processes in different atmospheres. J. Mater. Res. Technol. 2020, 9, 15454–15466. [Google Scholar] [CrossRef]

- Sui, S.; Chew, Y.; Hao, Z.; Weng, F.; Tan, C.; Du, Z.; Bi, G. Effect of cyclic heat treatment on microstructure and mechanical properties of laser aided additive manufacturing Ti–6Al–2Sn–4Zr–2Mo alloy. Adv. Powder Mater. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, H.; Jia, X.; Liang, X.; Lei, J. Heat treatment of titanium manufactured by selective laser melting: Microstructure and tensile properties. J. Mater. Res. Technol. 2022, 18, 245–254. [Google Scholar] [CrossRef]

- de Formanoir, C.; Martin, G.; Prima, F.; Allain, S.Y.P.; Dessolier, T.; Sun, F.; Vivès, S.; Hary, B.; Bréchet, Y.; Godet, S. Micromechanical behavior and thermal stability of a dual-phase α+α’ titanium alloy produced by additive manufacturing. Acta Mater. 2019, 162, 149–162. [Google Scholar] [CrossRef]

- Srinivasan, R.; Miracle, D.; Tamirisakandala, S. Direct rolling of as-cast Ti–6Al–4V modified with trace additions of boron. Mater. Sci. Eng. A 2008, 487, 541–551. [Google Scholar] [CrossRef]

- Maurya, A.K.; Yeom, J.-T.; Kang, S.W.; Park, C.H.; Hong, J.-K.; Reddy, N.S. Optimization of hybrid manufacturing process combining forging and wire-arc additive manufactured Ti-6Al-4V through hot deformation characterization. J. Alloys Compd. 2022, 894, 162453. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, K.; Ziaja, W.; Sieniawski, J. The effect of microstructure on the mechanical properties of two-phase titanium alloys. J. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Sahoo, S.; Joshi, A.; Balla, V.K.; Das, M.; Roy, S. Site-specific microstructure, porosity and mechanical properties of LENS™ processed Ti–6Al–4V alloy. Mater. Sci. Eng. A 2021, 820, 141494. [Google Scholar] [CrossRef]

- Hao, Y.-L.; Li, S.-J.; Yang, R. Biomedical titanium alloys and their additive manufacturing. Rare Met. 2016, 35, 661–671. [Google Scholar] [CrossRef]

- El-Hadad, S.; Nady, M.; Khalifa, W.; Shash, A. Influence of heat treatment conditions on the mechanical properties of Ti–6Al–4V alloy. Can. Metall. Q. 2018, 57, 186–193. [Google Scholar] [CrossRef]

- Reda, R.; Nofal, A.A.; Hussein, A.H.A. Effect of quenching temperature on the mechanical properties of cast Ti-6Al-4V alloy. J. Metall. Eng. (ME) 2013, 2, 48–54. [Google Scholar]

- Jovanović, M.T.; Tadić, S.; Zec, S.; Mišković, Z.; Bobić, I. The effect of annealing temperatures and cooling rates on microstructure and mechanical properties of investment cast Ti–6Al–4V alloy. Mater. Des. 2006, 27, 192–199. [Google Scholar] [CrossRef]

- Corona, A. Characterization of the Relationship Between the Microstructure and Tensile Strength of Annealed Ti-6Al-4V. Bachelor’s Thesis, California Polytechnic State University, Obispo, CA, USA, 2011. [Google Scholar]

- Lütjering, G.; Williams, J.C. (Eds.) Fundamental Aspects. In Titanium; Springer: Berlin/Heidelberg, Germany, 2007; pp. 15–52. [Google Scholar]

- Radhakrishnan, B.; Gorti, S.; Babu, S.S. Phase field simulations of autocatalytic formation of alpha lamellar colonies in Ti-6Al-4V. Metall. Mater. Trans. A 2016, 47, 6577–6592. [Google Scholar] [CrossRef]

- Stefansson, N.; Semiatin, S. Mechanisms of globularization of Ti-6Al-4V during static heat treatment. Metall. Mater. Trans. A 2003, 34, 691–698. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, J.; Yang, G.; Wang, Y.; Li, B.; An, D.; Zheng, J.; Wei, W. Microstructure evolution and fracture behavior of Ti–6Al–4V fabricated by WAAM-LDM additive manufacturing. J. Mater. Res. Technol. 2024, 28, 347–362. [Google Scholar] [CrossRef]

- Peng, X.-n.; Guo, H.-z.; Shi, Z.-f.; Qin, C.; Zhao, Z.-l. Microstructure characterization and mechanical properties of TC4-DT titanium alloy after thermomechanical treatment. Trans. Nonferrous Met. Soc. China 2014, 24, 682–689. [Google Scholar] [CrossRef]

- Hémery, S.; Villechaise, P.; Banerjee, D. Microplasticity at Room Temperature in α/β Titanium Alloys. Metall. Mater. Trans. A 2020, 51, 4931–4969. [Google Scholar] [CrossRef]

- Gil Mur, F.X.; Rodríguez, D.; Planell, J.A. Influence of tempering temperature and time on the α′-Ti-6Al-4V martensite. J. Alloys Compd. 1996, 234, 287–289. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.; Santos, T.G.; Oliveira, J. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Sabban, R.; Bahl, S.; Chatterjee, K.; Suwas, S. Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 2019, 162, 239–254. [Google Scholar] [CrossRef]

- Bermingham, M.; Nicastro, L.; Kent, D.; Chen, Y.; Dargusch, M. Optimising the mechanical properties of Ti-6Al-4V components produced by wire+ arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 2018, 753, 247–255. [Google Scholar] [CrossRef]

- Reddy, N.S.; Panigrahi, B.B.; Ho, C.M.; Kim, J.H.; Lee, C.S. Artificial neural network modeling on the relative importance of alloying elements and heat treatment temperature to the stability of α and β phase in titanium alloys. Comput. Mater. Sci. 2015, 107, 175–183. [Google Scholar] [CrossRef]

- Narayana, P.L.; Lee, S.W.; Park, C.H.; Yeom, J.-T.; Hong, J.-K.; Maurya, A.K.; Reddy, N.S. Modeling high-temperature mechanical properties of austenitic stainless steels by neural networks. Comput. Mater. Sci. 2020, 179, 109617. [Google Scholar] [CrossRef]

- Maurya, A.K.; Narayana, P.L.; Bhavani, A.G.; Jae-Keun, H.; Yeom, J.-T.; Reddy, N.S. Modeling the relationship between electrospinning process parameters and ferrofluid/polyvinyl alcohol magnetic nanofiber diameter by artificial neural networks. J. Electrost. 2020, 104, 103425. [Google Scholar] [CrossRef]

- Tiley, J.S. Modeling of Microstructure Property Relationships in Ti-6Al-4V. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2003. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Reddy, N.; Krishnaiah, J.; Hong, S.-G.; Lee, J.S. Modeling medium carbon steels by using artificial neural networks. Mater. Sci. Eng. A 2009, 508, 93–105. [Google Scholar] [CrossRef]

- Tao, X.; Yao, Z.; Zhang, S.; Li, Z.; Xu, Y. Correlation Between Heat-Treated Microstructure and Mechanical and Fretting Wear Behavior of Electron Beam Freeform-Fabricated Ti6Al4V Alloy. JOM 2019, 71, 2313–2320. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Gil, F.J.; Ginebra, M.P.; Manero, J.M.; Planell, J.A. Formation of α-Widmanstätten structure: Effects of grain size and cooling rate on the Widmanstätten morphologies and on the mechanical properties in Ti6Al4V alloy. J. Alloys Compd. 2001, 329, 142–152. [Google Scholar] [CrossRef]

- Lee, D.-G.; Lee, S.; Lee, C.S.; Hur, S. Effects of microstructural factors on quasi-static and dynamic deformation behaviors of Ti-6Al-4V alloys with widmanstätten structures. Metall. Mater. Trans. A 2003, 34, 2541. [Google Scholar] [CrossRef][Green Version]

- Tiley, J.; Searles, T.; Lee, E.; Kar, S.; Banerjee, R.; Russ, J.C.; Fraser, H.L. Quantification of microstructural features in α/β titanium alloys. Mater. Sci. Eng. A 2004, 372, 191–198. [Google Scholar] [CrossRef]

- Singh, A.K.; Ramachandra, C.; Tavafoghi, M.; Singh, V. Microstructure of β-solution-treated, quenched and aged α+β titanium alloy Ti-6Al-1.6Zr-3.30Mo-0.30Si. J. Alloys Compd. 1992, 179, 125–135. [Google Scholar] [CrossRef]

| Model | Learning Rate | Momentum Term | Iterations | Hidden Layers and Respective Neurons in Hidden Layer | RMSE | Etr |

|---|---|---|---|---|---|---|

| Model-1 (YS) | 0.5 | 0.6 | 13,254 | 2 9 9 | 0.00001 | 0.675 |

| Model-2 (UTS) | 0.6 | 0.7 | 17,346 | 2 6 6 | 0.00001 | 3.42 |

| Model-3 (%EL) | 0.7 | 0.5 | 15,561 | 2 6 6 | 0.00001 | 0.268 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maurya, A.K.; Narayana, P.L.; Yeom, J.-T.; Hong, J.-K.; Subba Reddy, N.G. Artificial Neural Network Modeling of Ti-6Al-4V Alloys to Correlate Their Microstructure and Mechanical Properties. Materials 2025, 18, 1099. https://doi.org/10.3390/ma18051099

Maurya AK, Narayana PL, Yeom J-T, Hong J-K, Subba Reddy NG. Artificial Neural Network Modeling of Ti-6Al-4V Alloys to Correlate Their Microstructure and Mechanical Properties. Materials. 2025; 18(5):1099. https://doi.org/10.3390/ma18051099

Chicago/Turabian StyleMaurya, Anoop Kumar, Pasupuleti Lakshmi Narayana, Jong-Taek Yeom, Jae-Keun Hong, and Nagireddy Gari Subba Reddy. 2025. "Artificial Neural Network Modeling of Ti-6Al-4V Alloys to Correlate Their Microstructure and Mechanical Properties" Materials 18, no. 5: 1099. https://doi.org/10.3390/ma18051099

APA StyleMaurya, A. K., Narayana, P. L., Yeom, J.-T., Hong, J.-K., & Subba Reddy, N. G. (2025). Artificial Neural Network Modeling of Ti-6Al-4V Alloys to Correlate Their Microstructure and Mechanical Properties. Materials, 18(5), 1099. https://doi.org/10.3390/ma18051099