Creep Failure Behavior in the Weak Areas of 12Cr1MoV Main Steam Pipe Elbow Utilized in Thermal Power Plants

Abstract

1. Introduction

2. Methods

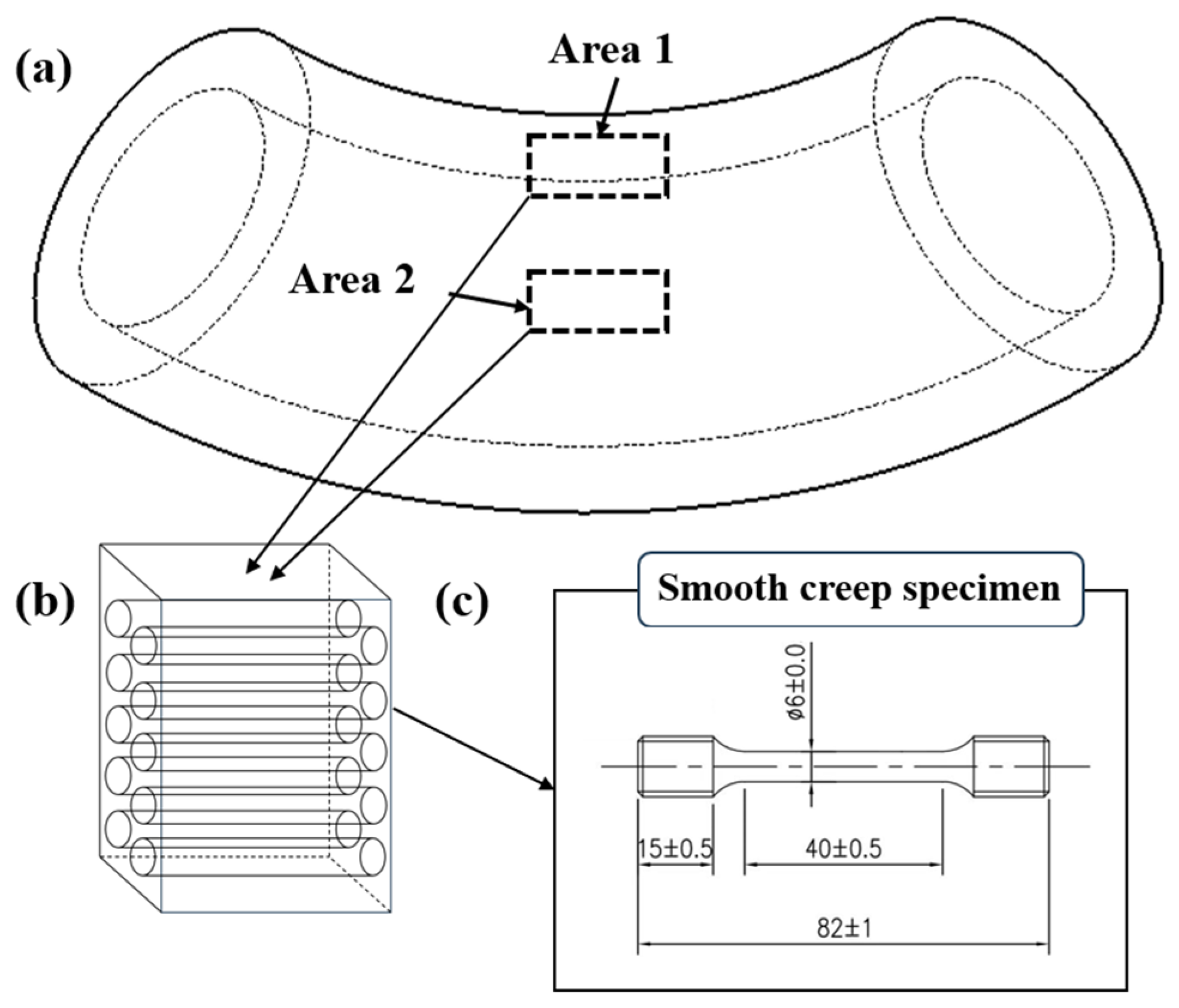

2.1. Materials and Creep Testing Methods

2.2. Microstructural Characterization

3. Results and Discussions

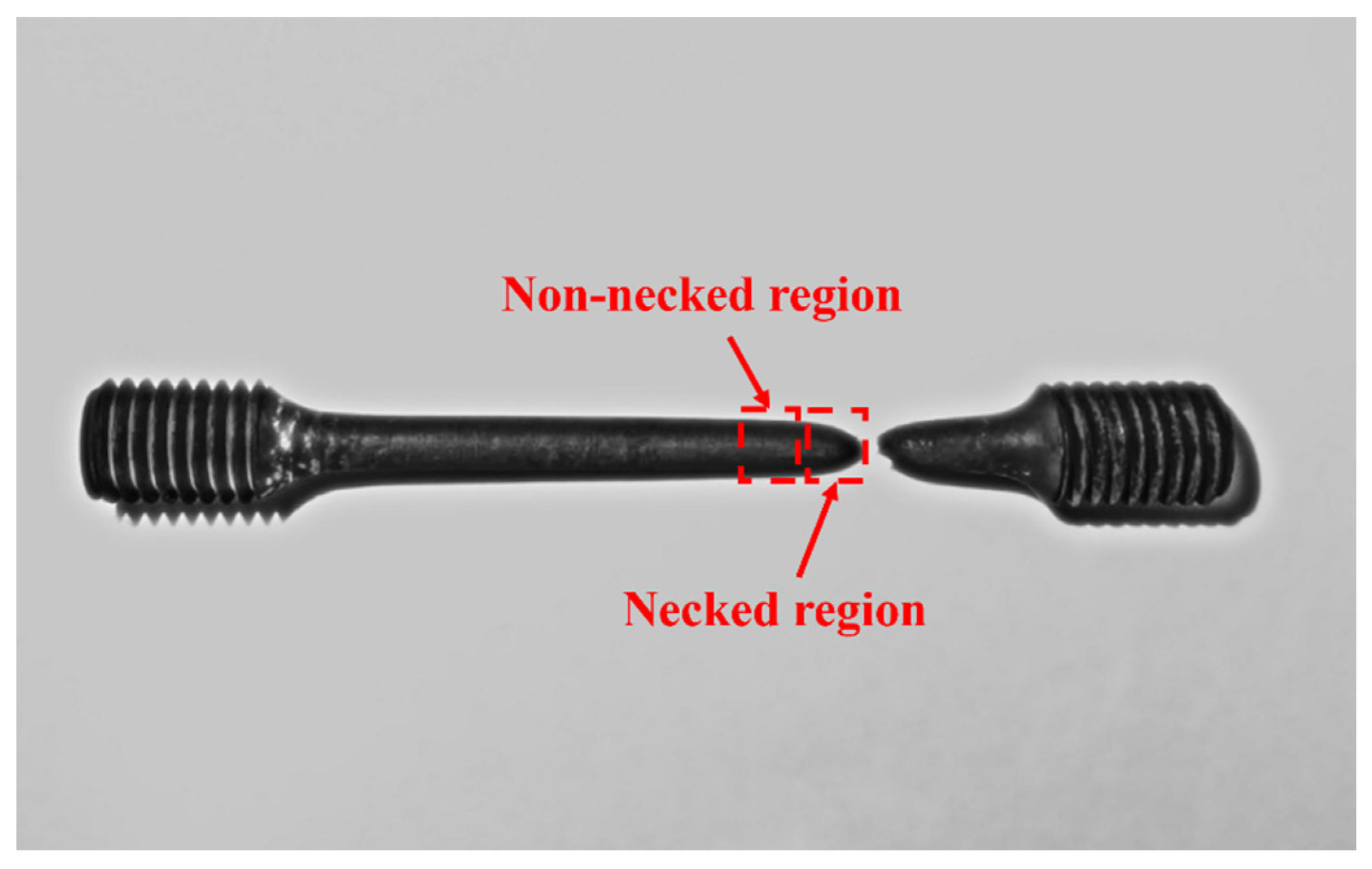

3.1. Creep Test Results

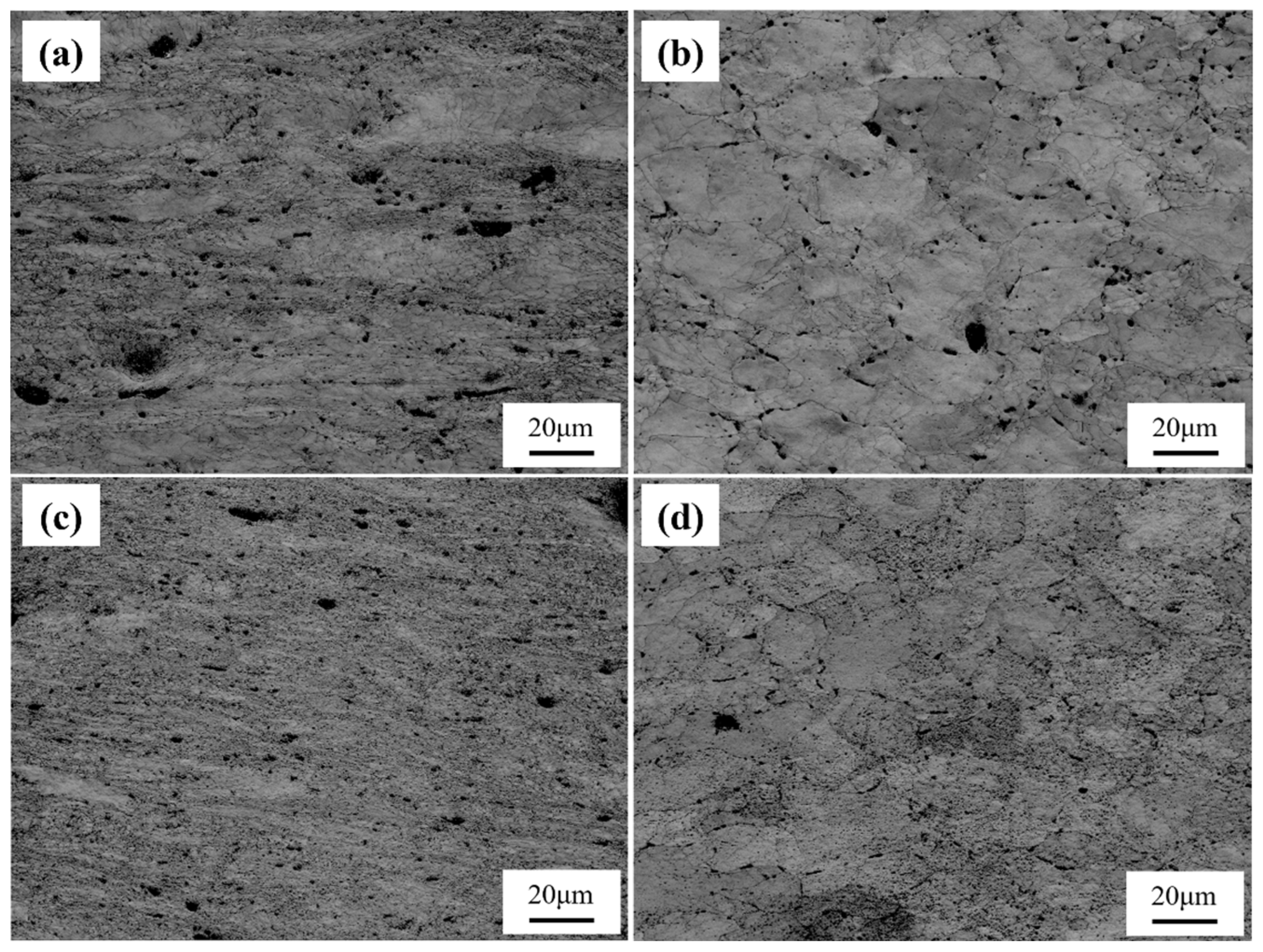

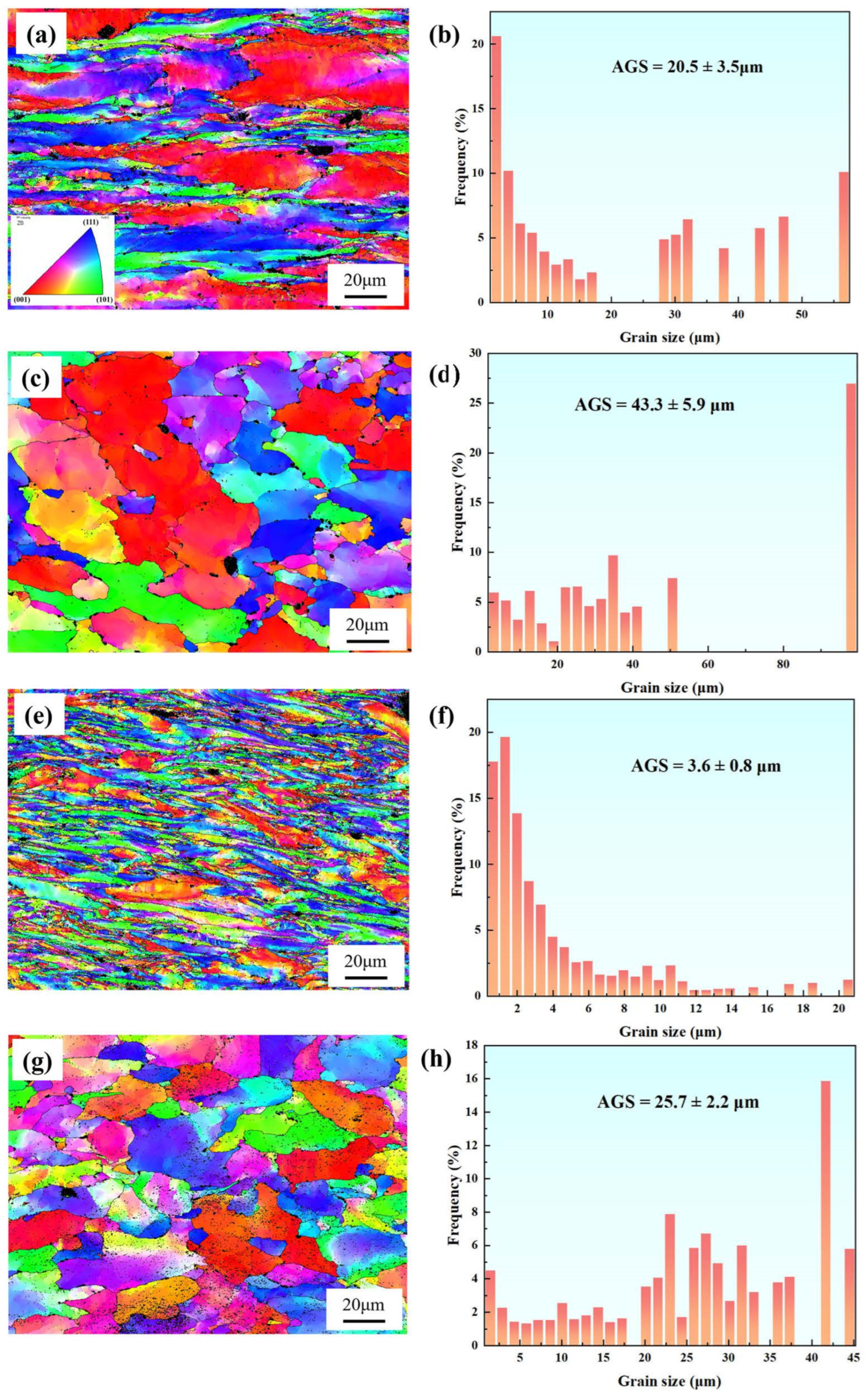

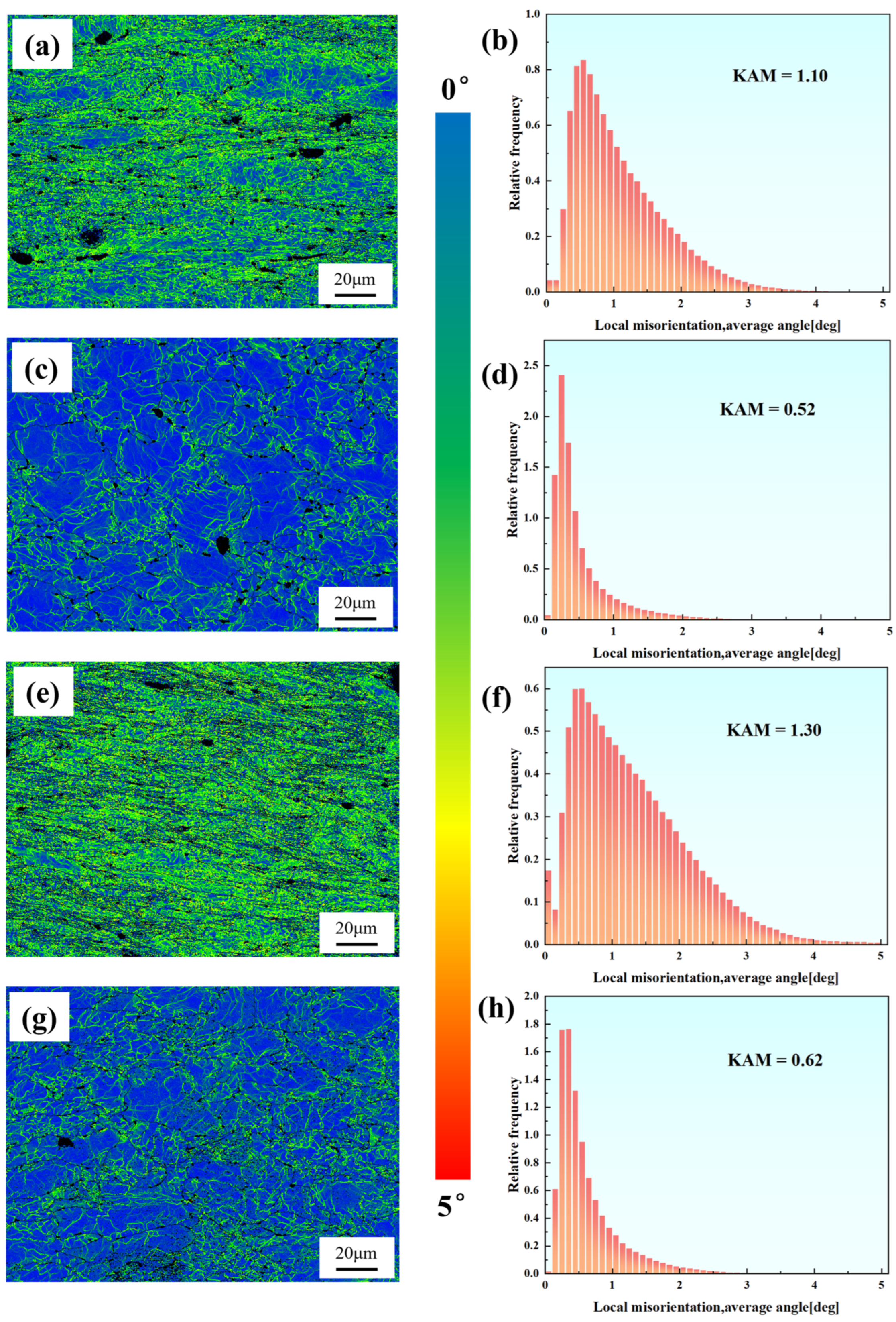

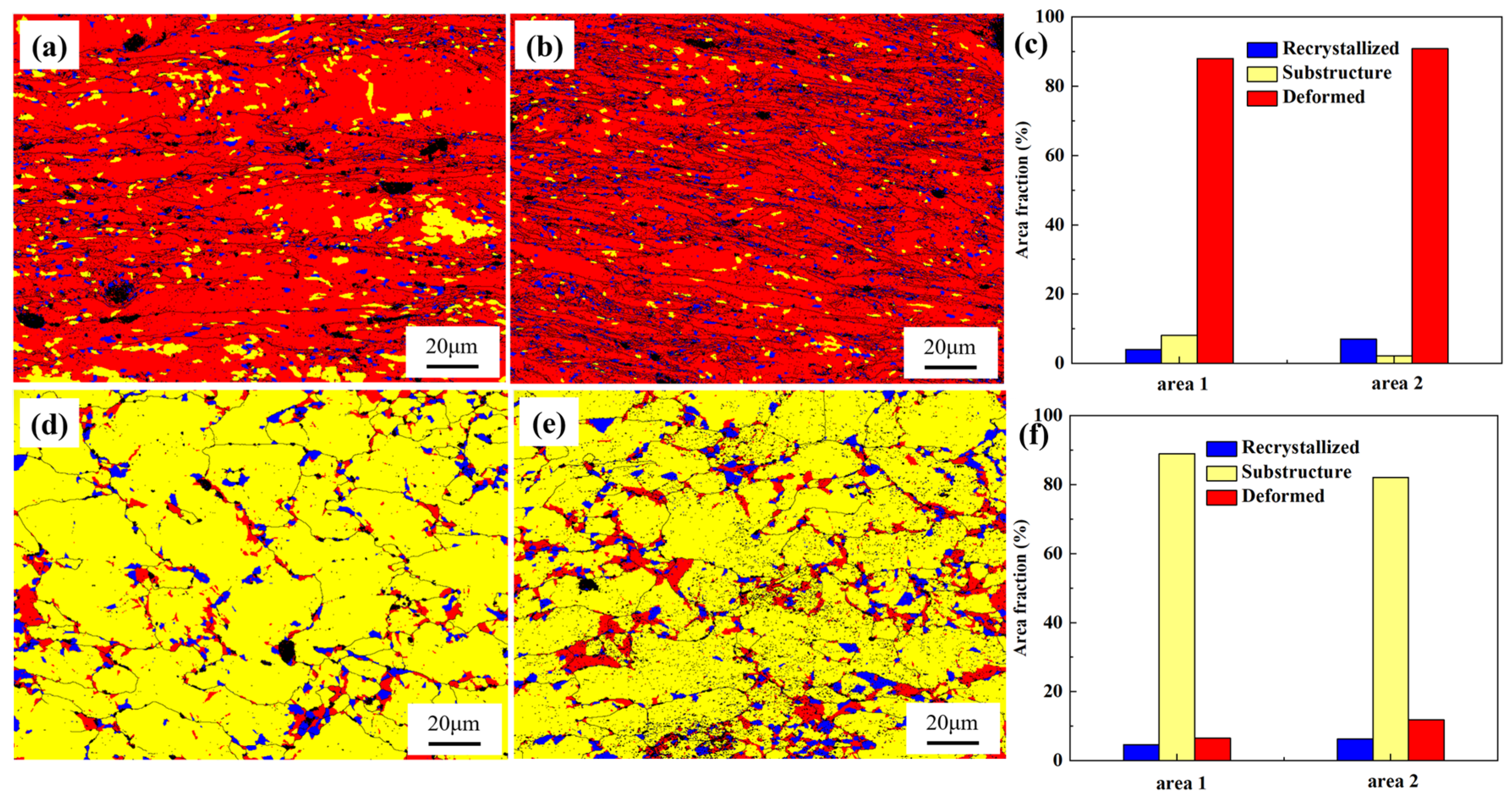

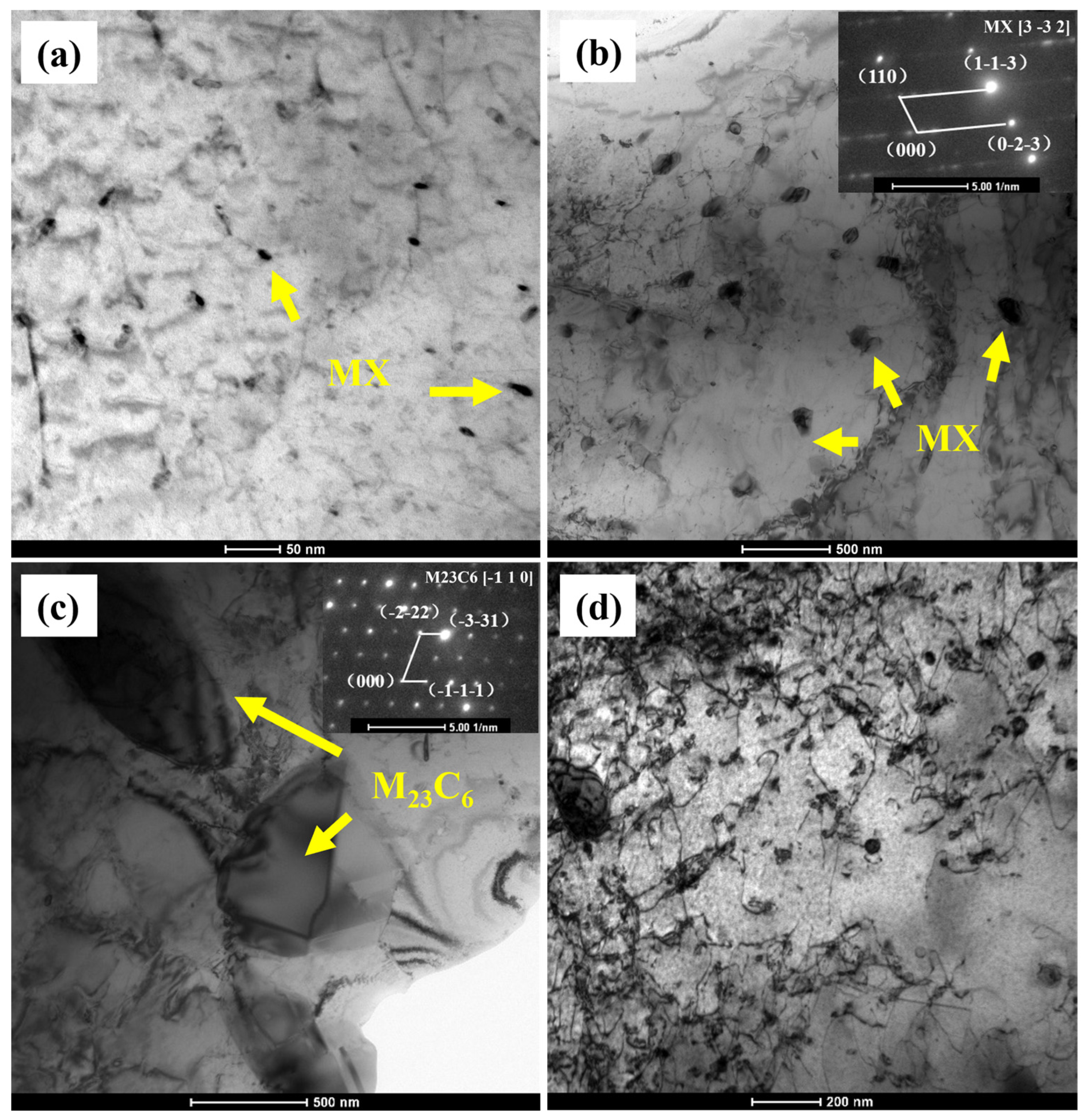

3.2. Microstructure of Samples Before and After Creep Testing

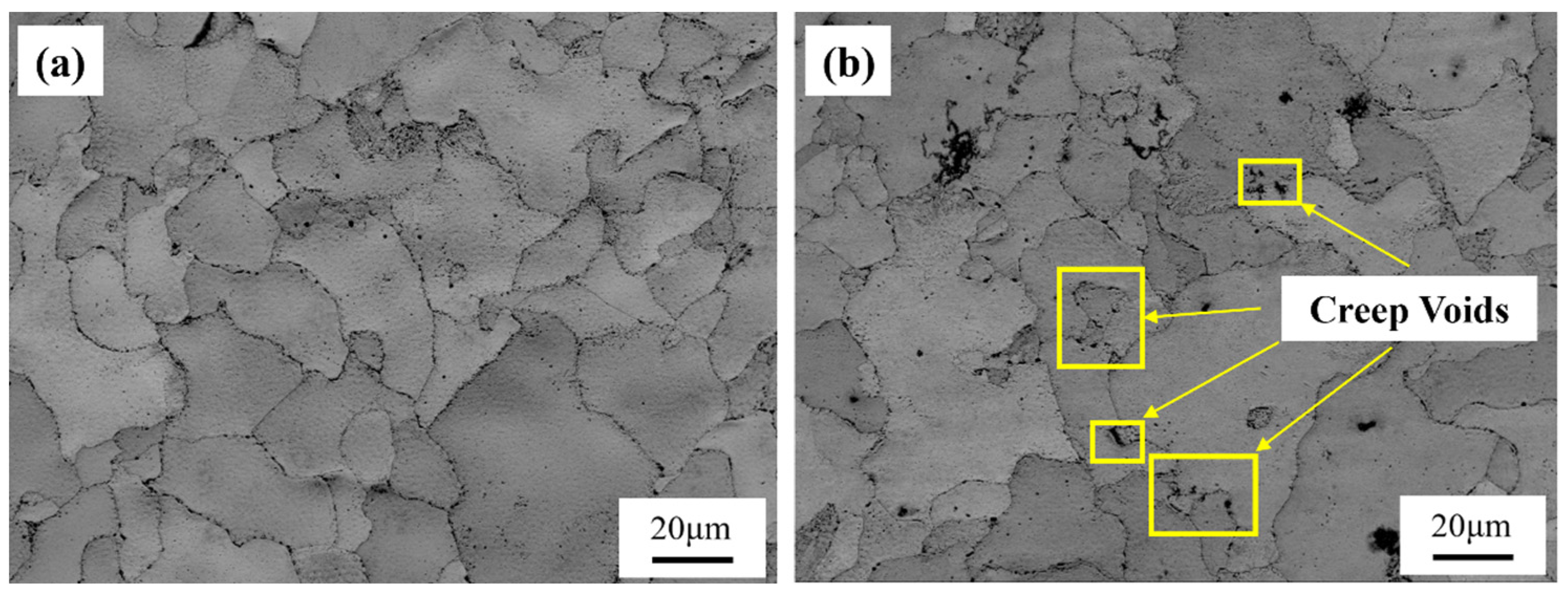

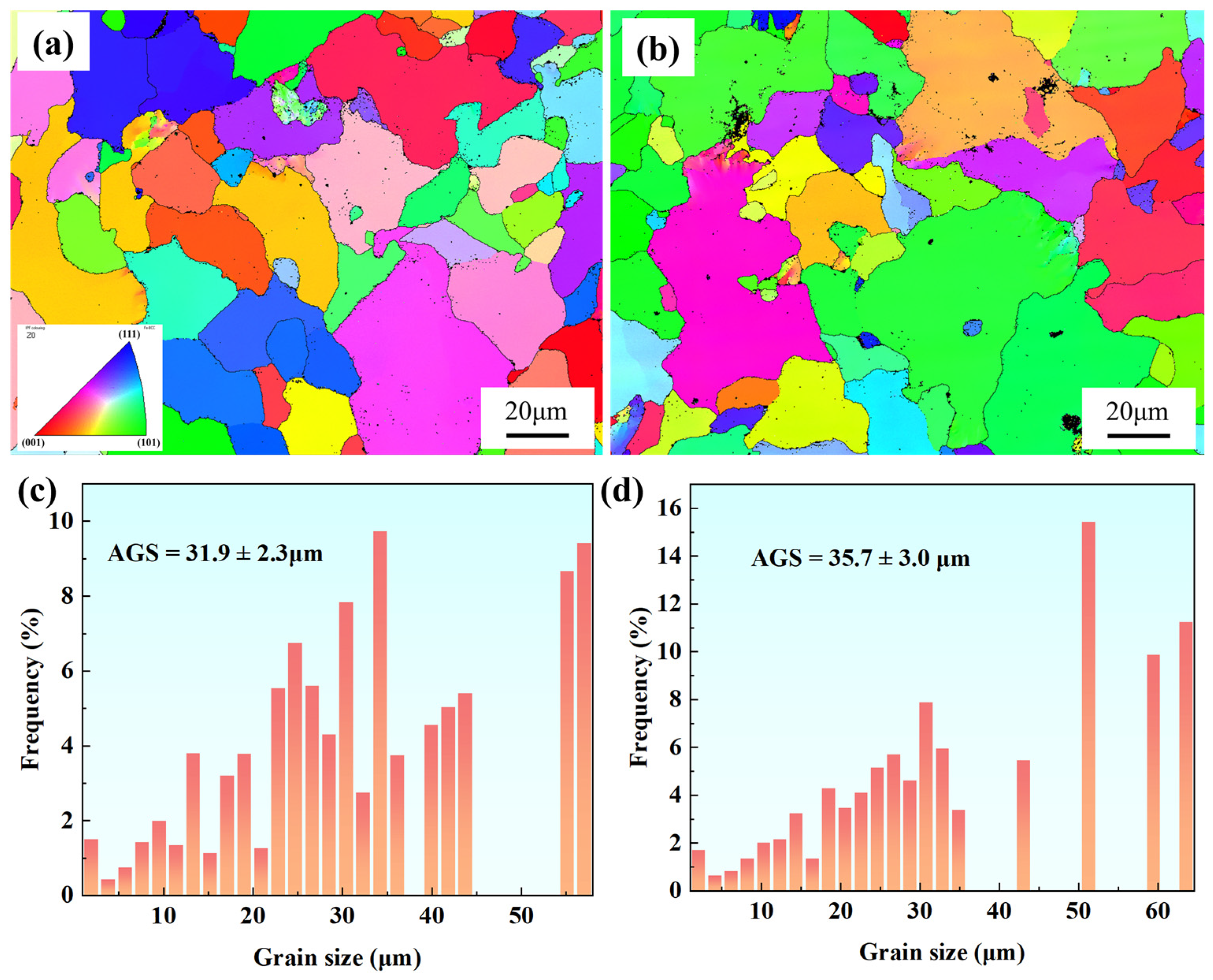

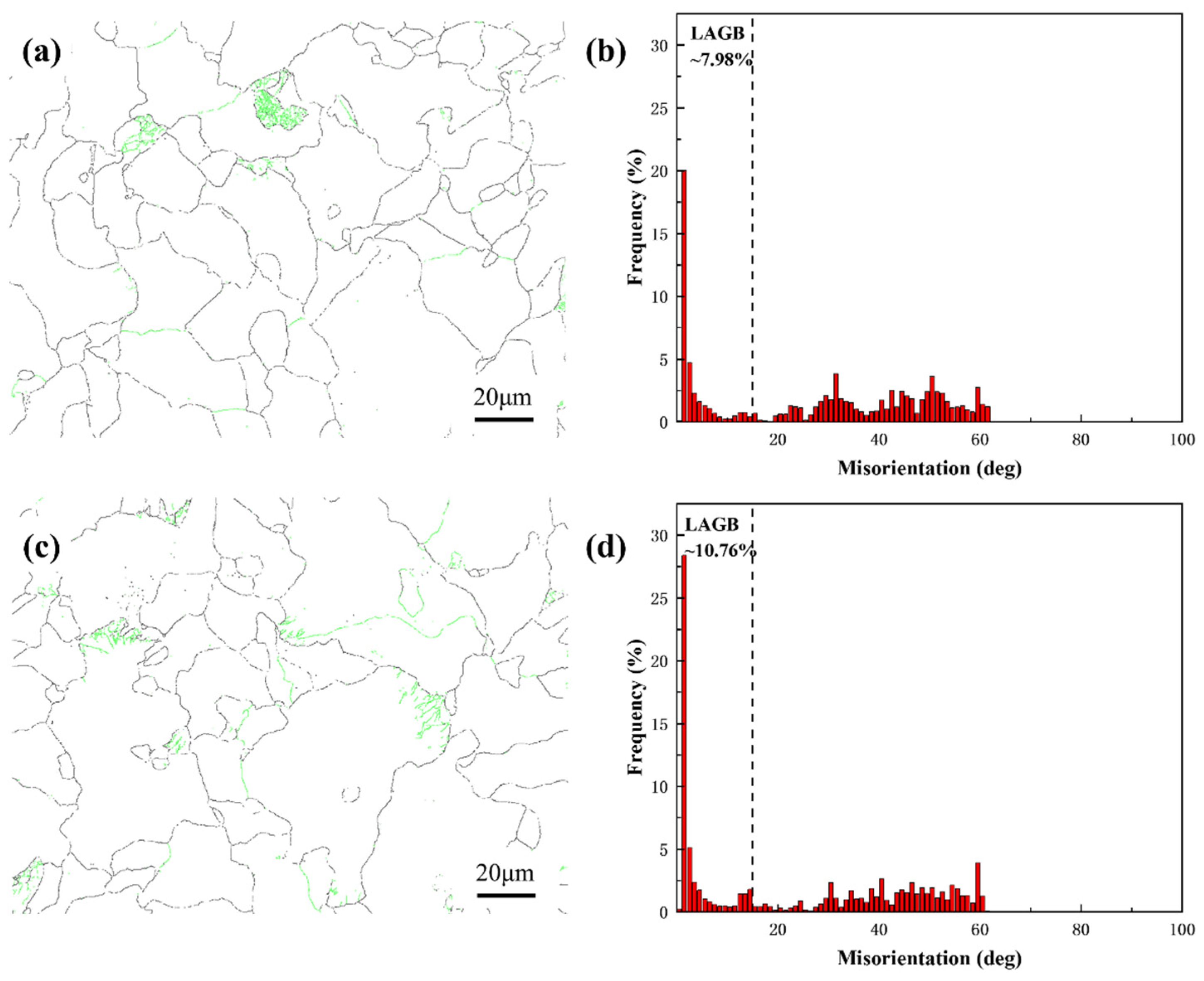

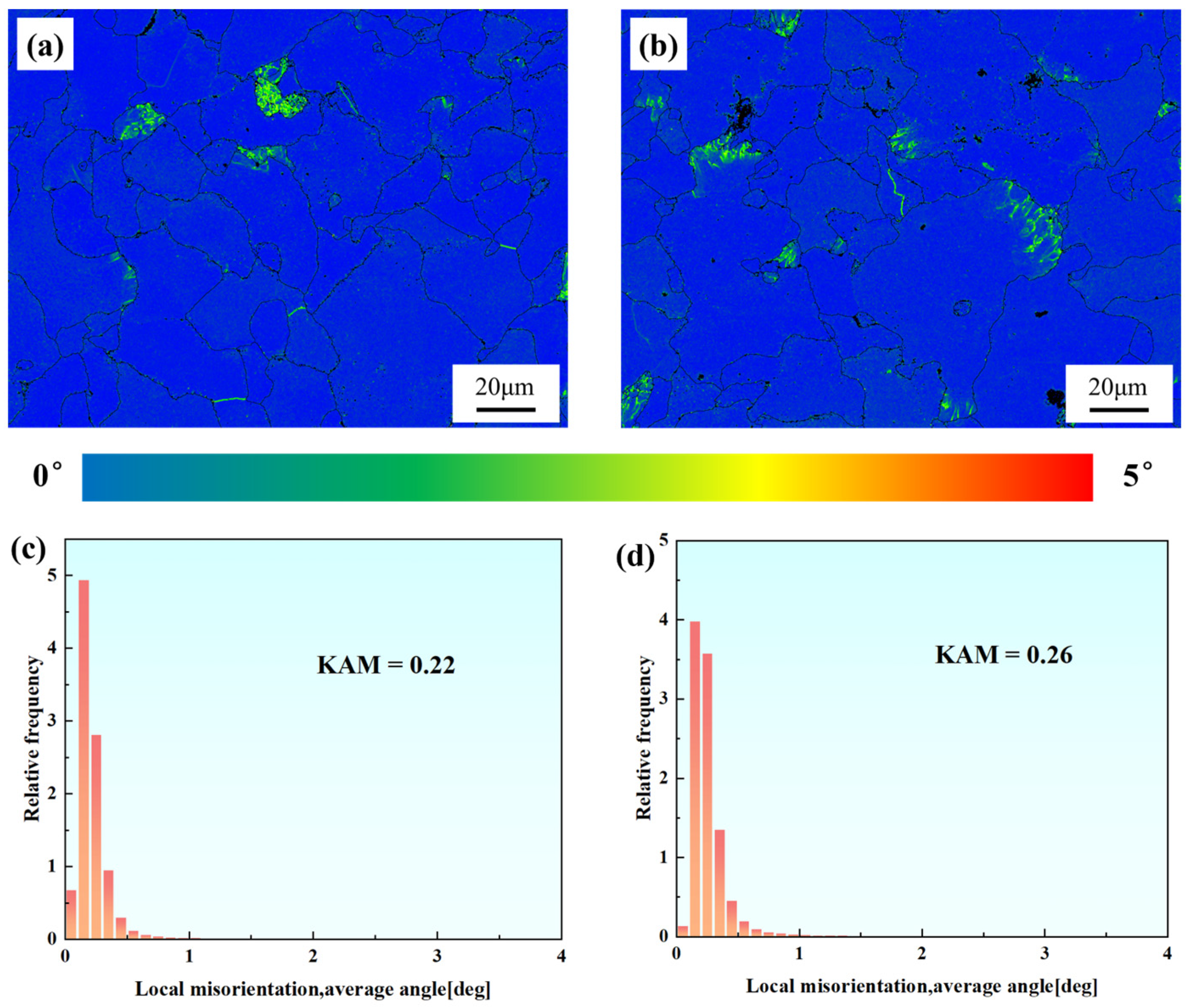

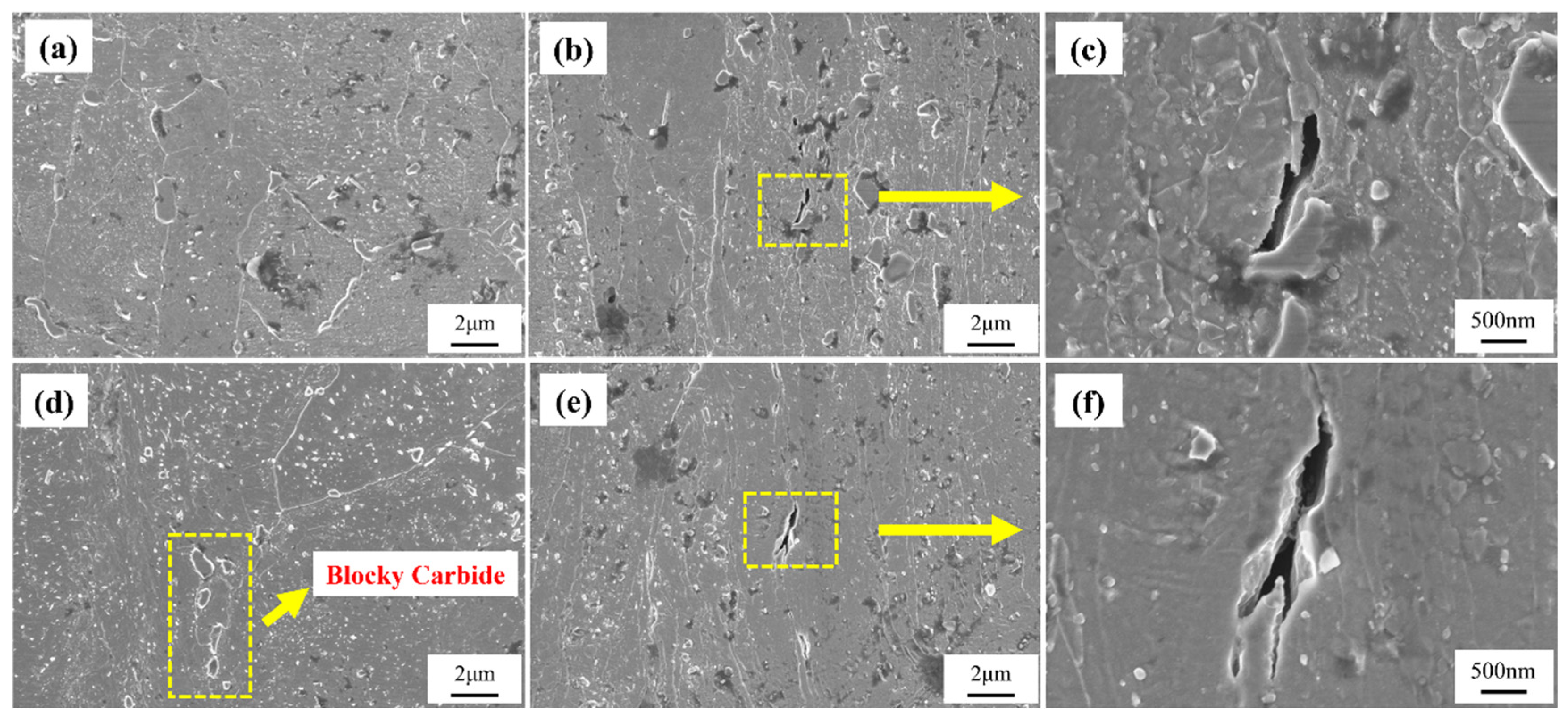

3.2.1. Microstructure of Samples Before Creep Testing

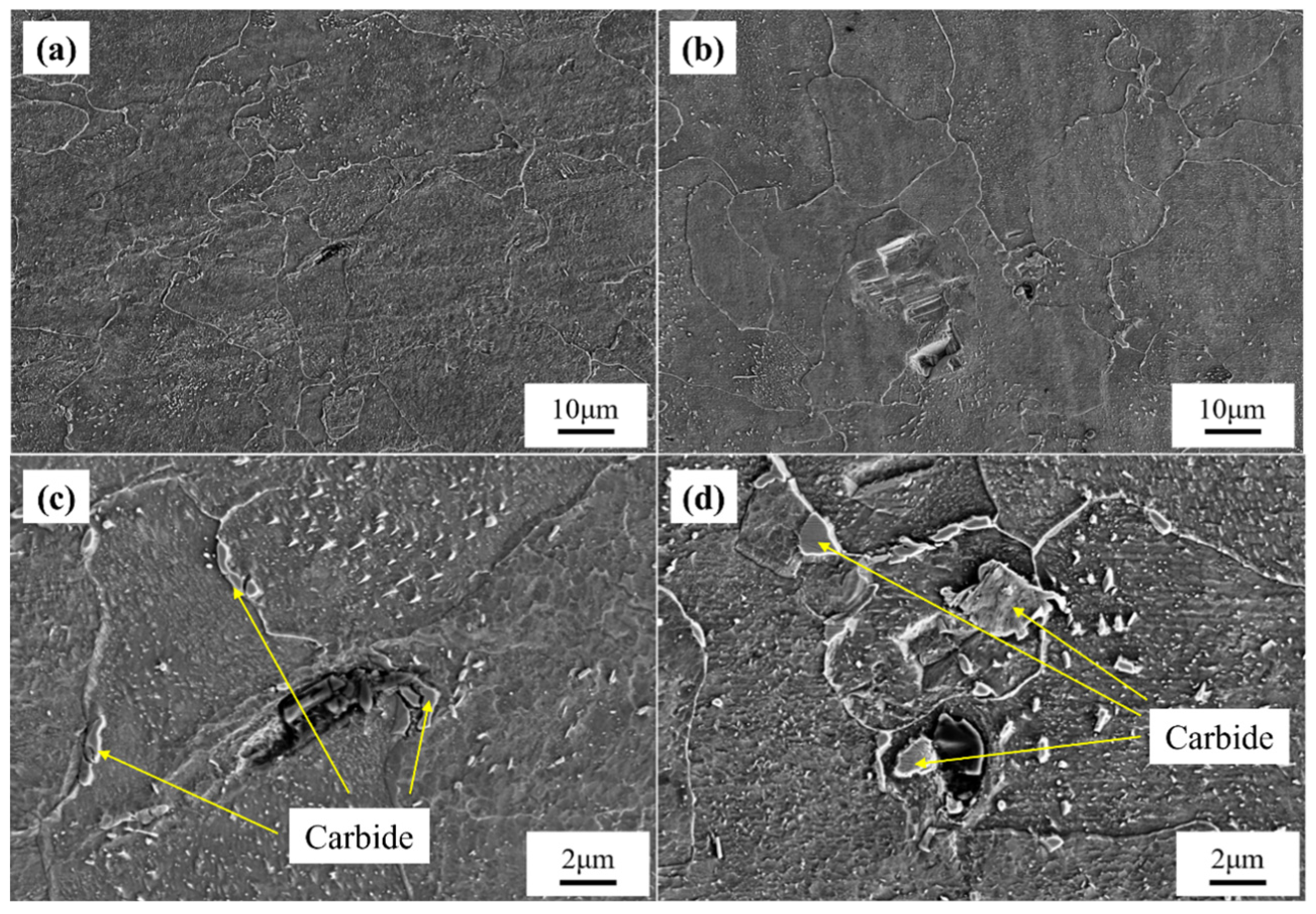

3.2.2. Microstructure of the Samples After Creep Testing

3.3. Key Factors Influencing the Creep Performance of Different Regions of the Elbow

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Z.; Abd El-Aty, A.; Zhang, R.; Cheng, C.; Guo, X.; Tao, J. Finite Element Modeling and Experimental Investigation on Manufacturing TA18 Alloy Pipes via Hot Free Bending Forming Technology: Forming Characteristics and Process Optimization. J. Mater. Res. Technol. 2024, 29, 5225–5240. [Google Scholar] [CrossRef]

- Malinowski, L.; Rup, K. Measurement of the Fluid Flow Rate with Use of an Elbow with Oval Cross Section. Flow Meas. Instrum. 2008, 19, 358–363. [Google Scholar] [CrossRef]

- Dong, J.; Bao, X.; Zheng, X. Comparison of Two Methods of Finite Element Modeling for Elbows with Unequal Wall Thickness. Phys. Procedia 2012, 33, 498–504. [Google Scholar] [CrossRef]

- Ye, S.C.; Zhang, H.J.; Guo, Y.J.; Xiao, K.R.; Jiang, Y.M.; Li, H.Y. Stress Analysis of Unequal-wall-thickness P92 Elbow. Chem. Eng. Equip. 2023, 174–176. (In Chinese) [Google Scholar]

- An, J.P. Stress Analysis of Non-circular Section Elbow under Internal Pressure. Electr. Power Constr. 2001, 22, 24–27. (In Chinese) [Google Scholar]

- Li, H.Y.; Guo, Y.J.; Qiao, L.J. Stress Analysis of Non-circular Section Pipe Components under Pressure Load. Chem. Process Mach. 2021, 48, 224–228. (In Chinese) [Google Scholar]

- Wang, J.; Zhang, R.; Shi, Y.; Song, Z. Failure Analysis on 12cr1mov Steel Tube of High Temperature Reheater for 600 Mw Subcritical Boiler. IOP Conf. Ser. Mater. Sci. Eng. 2019, 612, 022061. [Google Scholar] [CrossRef]

- He, J.; Yang, K.; Wang, G.; Li, W.; Bao, J.; Chen, J. Study on Tensile Creep Behavior of 12Cr1MoV Alloy Steel under High-Temperature Alkali Metal Salt Environment for Solar Thermal Power Generation. Int. J. Photoenergy 2020, 2020, 7095872. [Google Scholar] [CrossRef]

- Pan, J.; Xu, B.; Zhu, X.; Yu, X.; Tan, L. Structural Changes of 12Cr1MoVG Steel during High-Temperature Creep. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1040, 012013. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y. Influence of 12Cr1MoV Material on Tissue Properties at High Temperature and Long Operating Time. Processes 2022, 10, 192. [Google Scholar] [CrossRef]

- Tang, P.; Huang, S.; Tian, W.; Ling, Z.; Jin, N.; Li, F. Residual Life Evaluation of 12Cr1MoVG Steel for Main Steam Pipeline. IOP Conf. Ser. Earth Environ. Sci. 2021, 675, 012193. [Google Scholar] [CrossRef]

- Komai, N.; Tokiyoshi, T.; Igari, T.; Ohyama, H.; Masuyama, F.; Kimura, K. Experimental Observation of Creep Damage Evolution in Seam-Welded Elbows of Mod. 9Cr-1Mo Steel. Mater. High Temp. 2016, 33, 617–625. [Google Scholar] [CrossRef]

- Zakavi, S.J.; Aghaei, Y. The Ratcheting Behavior of Carbon Steel Piping Elbows under Cyclic Bending Moment and Temperature. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 436. [Google Scholar] [CrossRef]

- Ab Razak, N.; Davies, C.M.; Nikbin, K.M. Testing and Assessment of Cracking in P91 Steels under Creep-Fatigue Loading Conditions. Eng. Fail. Anal. 2018, 84, 320–330. [Google Scholar] [CrossRef]

- Vivas, J.; Capdevila, C.; Altstadt, E.; Houska, M.; Sabirov, I.; San-Martín, D. Microstructural Degradation and Creep Fracture Behavior of Conventionally and Thermomechanically Treated 9% Chromium Heat Resistant Steel. Met. Mater. Int. 2019, 25, 343–352. [Google Scholar] [CrossRef]

- Bronkhorst, C.A.; Hansen, B.L.; Cerreta, E.K.; Bingert, J.F. Modeling the Microstructural Evolution of Metallic Polycrystalline Materials under Localization Conditions. J. Mech. Phys. Solids 2007, 55, 2351–2383. [Google Scholar] [CrossRef]

- Mahesh, S.; Matthew, M.D. Modeling the Effect of Grain Boundary Sliding on Creep Lifetime: Application to Two Austenitic Stainless Steels. Procedia Eng. 2013, 55, 747–750. [Google Scholar] [CrossRef]

- Petkov, M.P.; Elmukashfi, E.; Tarleton, E.; Cocks, A.C.F. Evaluation of Local Stress State Due to Grain-Boundary Sliding during Creep within a Crystal Plasticity Finite Element Multi-Scale Framework. Int. J. Mech. Sci. 2021, 211, 106715. [Google Scholar] [CrossRef]

- Li, J.; Zhang, P.; He, T.; Cheng, L.; Wang, L.; Li, H. Effect of Carbides on High-Temperature Aging Embrittlement in 12%Cr Martensitic Heat-Resistant Steel. J. Mater. Res. Technol. 2019, 8, 5833–5846. [Google Scholar] [CrossRef]

- Cao, T.; Cheng, C.; Ye, F.; Xv, H.; Zhao, J. Relationship between Carbon Segregation and the Carbide Precipitation along Grain Boundary Based on the Structural Plant Model. J. Mater. Sci. 2020, 55, 7883–7893. [Google Scholar] [CrossRef]

- Hamdi, H.; Abedi, H.R. Thermal Stability of Ni-Based Superalloys Fabricated through Additive Manufacturing: A Review. J. Mater. Res. Technol. 2024, 30, 4424–4476. [Google Scholar] [CrossRef]

- Liu, L.R.; Jin, T.; Zhao, N.R.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Formation of Carbides and Their Effects on Stress Rupture of a Ni-Base Single Crystal Superalloy. Mater. Sci. Eng. A 2003, 361, 191–197. [Google Scholar] [CrossRef]

- Wu, S.; Dai, S.B.; Heilmaier, M.; Peng, H.Z.; Zhang, G.H.; Huang, S.; Zhang, X.J.; Tian, Y.; Zhu, Y.M.; Huang, A.J. The Effect of Carbides on the Creep Performance of Hastelloy X Fabricated by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2023, 875, 145116. [Google Scholar] [CrossRef]

- Ou, M.; Ma, Y.; Hou, K.; Wang, M.; Ma, G.; Liu, K. Effect of Grain Boundary Precipitates on the Stress Rupture Properties of K4750 Alloy after Long-Term Aging at 750 °C for 8000 h. J. Mater. Sci. Technol. 2021, 92, 11–20. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, C.; Wu, Y.; Zhou, L. Effect of Phosphorus Segregation on Carbides and Creep Damage of Ni–Fe-Based GH984G Alloy. J. Mater. Res. Technol. 2022, 19, 2018–2030. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Sun, L.X.; Tao, N.R. Raising Thermal Stability of Nanograins in a CuCrZr Alloy by Precipitates on Grain Boundaries. J. Alloys Compd. 2021, 867, 159016. [Google Scholar] [CrossRef]

- Rodenburg, C.; Rainforth, W.M. A Quantitative Analysis of the Influence of Carbides Size Distributions on Wear Behaviour of High-Speed Steel in Dry Rolling/Sliding Contact. Acta Mater. 2007, 55, 2443–2454. [Google Scholar] [CrossRef]

- Gaude-Fugarolas, D.; De Carlan, Y. Modelling Precipitate Distribution in Reduced-Activation Steels. J. Nucl. Mater. 2008, 374, 109–115. [Google Scholar] [CrossRef]

- Phaniraj, M.P.; Prasad, M.J.N.V.; Chokshi, A.H. Grain-Size Distribution Effects in Plastic Flow and Failure. Mater. Sci. Eng. A 2007, 463, 231–237. [Google Scholar] [CrossRef]

- Fedorov, A.A.; Gutkin, M.Y.; Ovid’ko, I.A. Triple Junction Diffusion and Plastic Flow in Fine-Grained Materials. Scr. Mater. 2002, 47, 51–55. [Google Scholar] [CrossRef]

- Chiang, P.J.; Wu, J.Y.; Yu, H.Y.; Kao, C.R. Creep Behaviors Along Characteristic Crystal Orientations of Sn and Sn-1.8Ag by Using Nanoindentation. JOM 2019, 71, 2998–3011. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Xiang, S.S.; Pharr, G.M. Effects of Crystal Orientation on the Indentation Creep of β-Tin. J. Mater. Res. 2021, 36, 2434–2443. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, J.; Li, R.; Kou, H.; Chen, Z.; Wang, Q.; Zhang, H.; Wang, J.; Gao, Q.; Li, J. Orientation Dependent Behavior of Tensile-Creep Deformation of Hot Rolled Ti65 Titanium Alloy Sheet. J. Mater. Sci. Technol. 2021, 75, 265–275. [Google Scholar] [CrossRef]

| Specimen Labeling | Test Temperature/°C | Test Stress/MPa | Creep Rupture Time/h | Steady-State Creep Rate/s−1 | Steady-State Creep Time/h |

|---|---|---|---|---|---|

| 1 | 540 | 150 | 661 | 3.27 × 10−5 | 533.3 |

| 140 | 2434 | 7.18 × 10−6 | 1945.5 | ||

| 130 | Unfractured (4917) | 5.53 × 10−7 | Unfractured | ||

| 2 | 150 | 104 | 2.05 × 10−4 | 83.0 | |

| 140 | 253 | 7.96 × 10−5 | 202.2 | ||

| 130 | 782 | 2.42 × 10−5 | 630.2 |

| Sample | 1#-150 | 2#-150 | 1#-140 | 2#-140 | 2#-130 |

|---|---|---|---|---|---|

| Shear Lip Length (µm) | 343.2 | 354.5 | 354.1 | 401.7 | 285.5 |

| Total Fracture Surface Length (µm) | 2038.3 | 1799.5 | 2385.5 | 1815.6 | 1906.0 |

| Proportion of Shear Lip Length (%) | 16.84% | 19.70% | 14.84% | 22.12% | 14.98% |

| Fibrous Zone Area (mm2) | 1.58 | 1.16 | 2.23 | 1.08 | 1.56 |

| Total Fracture Surface Area (mm2) | 3.00 | 2.53 | 3.68 | 2.75 | 2.92 |

| Proportion of Fibrous Zone Area (%) | 52.67% | 45.85% | 60.60% | 39.27% | 53.42% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Shi, R.; Wu, J.; Yang, C.; Liu, H. Creep Failure Behavior in the Weak Areas of 12Cr1MoV Main Steam Pipe Elbow Utilized in Thermal Power Plants. Materials 2025, 18, 812. https://doi.org/10.3390/ma18040812

Wang S, Shi R, Wu J, Yang C, Liu H. Creep Failure Behavior in the Weak Areas of 12Cr1MoV Main Steam Pipe Elbow Utilized in Thermal Power Plants. Materials. 2025; 18(4):812. https://doi.org/10.3390/ma18040812

Chicago/Turabian StyleWang, Shutao, Renqiang Shi, Jian Wu, Chao Yang, and Huan Liu. 2025. "Creep Failure Behavior in the Weak Areas of 12Cr1MoV Main Steam Pipe Elbow Utilized in Thermal Power Plants" Materials 18, no. 4: 812. https://doi.org/10.3390/ma18040812

APA StyleWang, S., Shi, R., Wu, J., Yang, C., & Liu, H. (2025). Creep Failure Behavior in the Weak Areas of 12Cr1MoV Main Steam Pipe Elbow Utilized in Thermal Power Plants. Materials, 18(4), 812. https://doi.org/10.3390/ma18040812