Abstract

This study provides a systematic review of photocatalytic fiber coating technology as a potential solution to challenges in the textile industry. An analysis of recent research (2020–2024) reveals significant developments in materials and methods. Traditional photocatalysts (TiO2 and ZnO) are being enhanced through doping and nanostructure control, and novel materials such as graphene-based composites and metal-organic frameworks are emerging. Advanced coating technologies, such as plasma treatment, atomic layer deposition, and magnetron sputtering, have been introduced to improve coating uniformity and durability. Key trends include the development of multifunctional coatings that combine self-cleaning, antibacterial effects, ultraviolet (UV) protection, and superhydrophobic properties. Environmental sustainability is advancing through eco-friendly manufacturing processes, although concerns regarding nanoparticle safety persist. While applications are expanding into medical textiles, protective gear, and wastewater treatment, challenges remain in terms of mass production technology, cost-effectiveness, and long-term durability. Future research should focus on nanostructure control, the development of visible-light-active materials, the optimization of coating processes, and the investigation of environmental impacts. This review suggests that photocatalytic fiber coating technology can significantly contribute to sustainable textile industry development when these challenges are effectively addressed.

1. Introduction

The textile industry is a crucial sector in contemporary society that faces numerous complex challenges while maintaining a diverse range of applications [1]. These challenges manifest in three critical domains: environmental impact, post-pandemic functionality requirements, and digital transformation requirements.

From an environmental perspective, the textile industry faces significant challenges in terms of resource consumption and pollution, particularly those exacerbated by fast-fashion trends [2,3]. The water requirements for cotton production exceed 20,000 L/kg, and the release of harmful chemicals during dyeing and processing continues to contribute to environmental pollution [2,3]. Microfiber pollution is of particular concern, with synthetic fibers constituting up to 35% of marine microplastics [3]. The industry also struggles with waste management and recycling challenges, as short product lifecycles generate substantial waste volumes amid inadequate recycling infrastructure [4]. Furthermore, barriers to sustainable practices persist, including inefficient disposal methods and limited adaptation to modern technology [5]. While the industry has explored novel solutions, such as supercritical fluids and plasma technology, their widespread implementation remains limited [3,6].

In the aftermath of the COVID-19 pandemic, the textile industry has encountered novel functionality challenges [7,8]. The integration of advanced technologies, particularly nanotechnology and Industry 4.0, has facilitated the development of multifunctional textiles with ultraviolet (UV) protection, antibacterial properties, and self-cleaning capabilities [7]. However, these innovations face challenges in maintaining comfort, flexibility, durability, and cost-effectiveness [7,8]. Financial constraints continue to impede innovation and the implementation of sustainable practices [9], and the fast-fashion model further complicates these challenges [10]. The pandemic has also highlighted the critical need for functional textiles in personal protective equipment (PPE) while raising concerns about disposable goods sustainability [11].

The digital transformation of the textile industry has led to significant market growth in smart textiles, with projections indicating an increase from USD 434.27 million in 2022 to USD 204.98 billion in 2031, representing a CAGR of 18.8% [12]. This transformation introduced advanced functionalities through the integration of sensors and communication devices, enabling vital sign monitoring and energy harvesting [13]. However, the industry faces mounting supply chain challenges, including raw material supply issues, increasing logistics costs, and reshoring trends owing to global instability [14].

Photocatalytic coating technology has emerged as a promising solution to these challenges [15]. This innovative technology enables environmental remediation through the degradation of organic pollutants under light irradiation while providing sustained photoactivity through advanced material combinations and deposition techniques [15]. Research has demonstrated that these coatings confer textiles with multiple beneficial functions, including self-cleaning capabilities, antibacterial properties, and pollutant degradation [16,17]. Additionally, they contribute to improved energy efficiency and reduced chemical usage, thereby enhancing the overall sustainability of textile production [18,19,20].

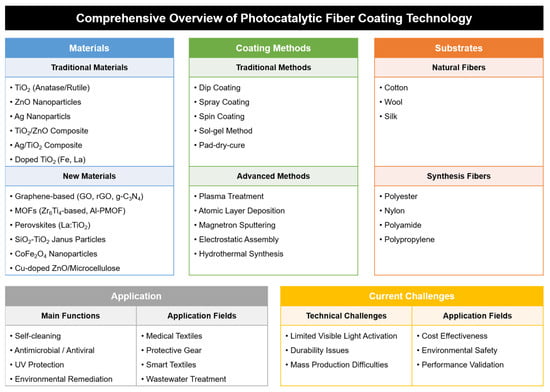

This review systematically analyses the various challenges faced by the textile industry and explores the potential of photocatalytic coating technology as a solution. As shown in Figure 1, photocatalytic textile coating technologies encompass a wide range of materials, coating methods, and substrates, which enable key functions, such as self-cleaning, antibacterial/antiviral effects, UV protection, and environmental cleanup. Our research specifically focused on the effectiveness of photocatalytic coatings in terms of environmental sustainability, versatility, regulatory compliance, enhanced competitiveness, potential for integration with smart textiles, and supply chain optimization. Through this comprehensive analysis, we aim to provide valuable insights into the future development and implementation of this promising technology in the textile industry.

Figure 1.

Overview of photocatalytic fiber coating technology illustrating the interconnections between materials, methods, substrates, applications, and current challenges.

2. Research Methodology and Analysis Framework

This study adopted a systematic literature review methodology to comprehensively analyze the latest trends in the field of photocatalytic textile coating technology. For a thorough literature review, major academic databases, such as Google Scholar, Web of Science, Scopus, and Science Direct, were utilized to examine the research literature from January 2020 to January 2024.

We used “photocatalytic coating” as the main keyword and “textile”, “fiber”, “fabric”, etc., as secondary keywords. The primary search identified 873 papers that were subjected to rigorous screening.

Literature screening was performed using a phase approach. First, a title review was performed to exclude 420 articles that lacked direct relevance to photocatalytic coatings or were distant from fiber/textile applications, resulting in the preliminary screening of 453 articles. An abstract review was conducted to further exclude 238 papers, including review articles, theoretical studies without experimental validation, and studies with unclear coating methodologies, reducing the list to 215 papers.

In the third step, we reviewed the full text of the papers to narrow the list to 98, excluding 117 papers because of insufficient description of the experimental methodology, low statistical significance of the results, and limited practical applicability. Finally, 50 core papers were selected based on the presentation of innovative coating methodologies, clear experimental design and validation, potential for industrial applications, and overall research quality.

To ensure objectivity of the selection process, two independent researchers performed each evaluation, and in cases of disagreement, a third researcher was consulted to reach a consensus. The selected papers were reviewed using a comprehensive analytical framework focusing on material innovations, advances in coating technology, functional developments, and application extensions.

In particular, this study focused on identifying the latest technological trends and selecting studies with high potential for field applicability, the results of which are detailed in subsequent chapters. Through this systematic approach, we focused on identifying current technological gaps and suggesting future research directions.

3. Advances in Photocatalytic Coating Technology

Photocatalytic coating technology has emerged as a transformative innovation in various fields, particularly environmental purification, self-cleaning, and antimicrobial applications. The evolution of this technology has significantly contributed to sustainable development and environmental protection, with continuous advancements in both traditional and innovative approaches.

3.1. Development of Coating Technologies

Photocatalytic coating technologies have progressed from traditional methods to advanced techniques. Traditional coating methods, including dip coating, spray coating, and sol–gel processes, continue to serve as fundamental approaches in industrial applications owing to their simplicity and cost-effectiveness. However, these methods initially faced limitations in coating uniformity and durability [21,22,23,24,25].

Recent research has focused on enhancing these traditional methods through technological integration and process optimization. For instance, researchers have successfully combined sol–gel methods with spray coating techniques to achieve homogeneous coatings with controlled nanostructures [26]. Additionally, surface modification techniques, such as increasing surface acidity, have been employed to enhance the photocatalytic activity of traditional coatings, particularly in TiO2-based systems [27].

The characteristics and applications of both the traditional and advanced coating methods are summarized in Table 1.

Table 1.

Comprehensive analysis of photocatalytic coating methods.

3.2. Recent Innovations and Future Prospects

The field has witnessed significant innovations in coating technologies beyond traditional methods. Advanced techniques, such as atomic layer deposition (ALD) have enabled the production of highly conformal coatings with precise thickness control, particularly for complex geometries in semiconductor applications [28]. Physical and chemical vapor deposition (PVD/CVD) methods have introduced new possibilities for high-quality coating production, although they require sophisticated equipment and controlled environments [29].

Novel approaches, such as drop casting and blade coating, have emerged as effective solutions for laboratory-scale applications, offering precise control over the coating parameters. The introduction of powder coating with UV/electron beam curing has provided energy-efficient alternatives for rapid processing, whereas electrochemical plating has established itself as a reliable method for uniform metal coating deposition.

The integration of traditional and advanced methods presents promising opportunities for the photocatalytic coating technology. The current research trends focus on the following:

- Development of hybrid processes combining multiple coating techniques.

- Implementation of smart control systems for enhanced process automation.

- Integration of environmentally sustainable practices.

- Enhancement of coating durability and uniformity.

- Expansion of application possibilities in various industries.

These advancements continue to address existing limitations while opening new avenues for application, suggesting a bright future for photocatalytic coating technology for environmental protection and sustainable development.

4. Research Trends in Textile Photocatalytic Coatings

Environmental pollution has become an increasingly serious global issue in recent years, driving growing interest in environmentally friendly and sustainable technologies. In this context, fiber photocatalytic coating technology has emerged as an innovative solution for environmental cleanup and energy efficiency. This technology, which applies photocatalytic materials to common textile surfaces to create light-responsive functional materials, has demonstrated significant promise for a wide range of applications, including apparel, upholstery fabrics, and filter systems, with particular potential in the environmental and health sectors for air purification, self-cleaning, and antimicrobial applications.

Recent research has focused on developing more efficient and durable photocatalytic coating methods, exploring new photocatalytic materials, and improving their compatibility with various textile substrates. Advancements in nanotechnology have further expanded research horizons, enabling the development of nanostructured photocatalysts and materials active in the visible light region, marking significant progress in the field.

This chapter provides a comprehensive analysis of the latest research trends in fiber photocatalytic coatings. Our analysis began with a systematic review of existing studies, organized in a tabular format for clarity and accessibility. In this review, we explore major research topics, including advances in photocatalytic materials, functionalization approaches, expanding applications, performance evaluation methods, and environmentally friendly approaches.

Particular attention has been devoted to the evolution of photocatalysts from traditional TiO2- and ZnO-based materials to innovative alternatives such as graphene and metal-organic frameworks (MOFs). We also closely examined the development of multifunctional coatings and their expanding applications in apparel, medical, and environmental fields, supported by the verification of their performance in real-world environments. Additionally, our analysis covered emerging trends in the development of eco-friendly materials and processes for sustainable development, reflecting the growing emphasis on environmental consciousness in this field.

4.1. Analysis Results of Selected Research

A detailed analysis of the selected 50 papers was conducted based on the methodology described in Section 2. The analysis included a comprehensive categorization of the research objectives, coating materials, processing methods, and specific applications, as summarized in Table 2.

Table 2.

Analysis of recent research trends in photocatalytic fiber coatings (2020–2024).

Analysis and Discussion of Research Trends

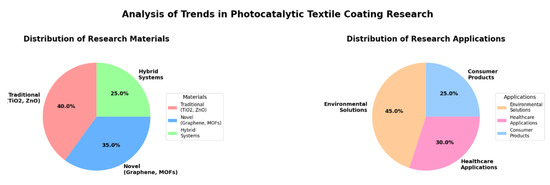

The analysis of these selected studies reveals significant technological evolution and emerging developments in photocatalytic fiber coating technology. The distribution and trends of research focus among the selected papers are illustrated in Figure 2.

Figure 2.

Some important trends and patterns in photocatalytic fiber coatings research.

As shown in Figure 2, research developments can be characterized by both material advancement and application areas. In terms of materials, traditional photocatalysts (TiO2 and ZnO) remain dominant, representing approximately 40% of the studied materials, but have evolved through various modifications and optimizations. These include doping processes, nanostructure control, and surface modifications to enhance the photocatalytic activity. Novel materials represent approximately 35% of the research focus, with a particular emphasis on graphene-based composites (15%), metal-organic frameworks (MOFs, 12%), and other advanced materials (8%). The remaining 25% focused on composite materials combining multiple photocatalytic components, which have shown promising results in enhancing the overall performance through synergistic effects. Recent research trends have also highlighted the need for environmentally friendly materials and sustainable synthesis methods.

The application focus among the selected papers was predominantly distributed across the three major areas. Environmental solutions represent the largest segment, comprising approximately 45% of the reviewed studies, with a particular emphasis on water treatment systems, air purification technologies, microplastic pollution reduction strategies, and innovative approaches to wastewater treatment. Healthcare applications constitute approximately 30% of the research focus, encompassing the development of antimicrobial and antiviral coatings, medical textiles, protective equipment enhancements, and hygiene-focused applications. Consumer product applications accounted for the remaining 25%, focusing on self-cleaning textiles, UV protection applications, smart textile integration, and functional apparel development.

- Critical Analysis of Research Methodologies and Findings

A systematic analysis of 50 selected papers on photocatalytic fiber coating research revealed significant variations in methodological approaches and research quality. This comprehensive review identifies several critical patterns and gaps in current research practices.

- Methodological Rigor and Validation

The examination of research methodologies reveals a trend in validation practices. Only 40% of the analyzed studies demonstrated a comprehensive validation of their coating methods, particularly regarding coating uniformity and adhesion strength [30,31,36,38,41,44,46,52,56,58,60,61,63,65,68,69,70,71,72,73]. These high-quality studies have employed multiple characterization techniques, including scanning electron microscopy (SEM), X-ray diffraction (XRD), and standardized adhesion testing protocols.

The variation in performance-testing approaches presents another significant methodological concern. While 30% of studies employed standardized testing protocols [41,44,48,52,60,61,63,65,70,71,72,73,74,75,76], ensuring reproducibility and result validation, a larger portion (45%) developed custom testing methods [30,31,32,33,34,36,37,38,40,42,43,50,54,57,58,66,67,68,77,78,79,80]. More concerning is that 25% of the studies provided insufficient methodological details [39,45,46,49,51,53,55,59,62,81,82,83], making reproduction and validation challenging.

- 2.

- Material Performance and Development

In terms of material performance, traditional photocatalytic materials have shown varying degrees of success. TiO2-based systems, featured in approximately 25% of the studies, demonstrated efficiency rates ranging from 65% to 95% [30,31,32,33,34,40,52,57,70,80,82]. These studies generally provided more comprehensive validation and reproducibility data. ZnO-based systems, although less common (15% of studies), showed wider performance variations, with efficiency rates between 45% and 85% [35,36,37,38,41,56]. Novel materials and advanced composites, representing 35% of the studies, have often reported higher efficiencies [42,44,45,68,83,84,85,86,87]. However, these studies frequently lacked crucial information about scalability and cost-effectiveness, with only two studies [65,70] providing comprehensive economic analysis.

- 3.

- Critical Research Gaps

This analysis revealed several significant gaps in the current research. Long-term durability studies are notably scarce, with only 25% of papers [48,52,55,59,60,61,63,69,70,71,74,82] including performance data beyond six months. Real-world application testing is similarly limited, appearing only in a small subset of studies [47,52,53,64,65,67,69,74,88]. The economic viability analysis represents another major gap. Only 15% of the studies [43,48,54,58,62,66,78,81] provided detailed cost analysis, and even fewer addressed mass production challenges [65,70]. Environmental impact assessment also has limitations, with only 20% of studies including comprehensive life-cycle assessments [47,52,53,64,65,67,69,74,88]. The critical issue of nanoparticle release into the environment has received attention in only a handful of studies [41,45,46,56,61].

- 4.

- Research Quality Assessment

The overall quality of the research varied significantly across the papers analyzed. High-quality studies (30%) [30,31,36,38,41,46,52,56,58,61,63,68,69,70,71] demonstrated comprehensive methodology, thorough validation procedures, and detailed analysis. Medium-quality studies (45%) [32,33,37,39,40,42,43,47,48,53,54,62,64,66,67,74,77,78,79,81,88,89] showed adequate methodology but limited validation. The remaining studies (25%) [34,44,45,49,50,51,55,57,59,60,65,80,82] provided insufficient methodological details and validation.

- 5.

- Future Research Directions

This analysis clearly indicated several priority areas for future research. First, there is a pressing need for methodological standardization, including the development of uniform testing protocols and standardized performance metrics. Second, validation requirements need to be strengthened, particularly for long-term performance assessment and real-world application testing. Finally, the research focus should be expanded to include comprehensive scalability studies, environmental impact assessments, and economic viability analyses.

These findings underscore the need for more rigorous research methodologies for photocatalytic fiber coating studies. While significant progress has been made in material development and performance enhancement, addressing these identified gaps will be crucial for advancing the field toward practical applications and commercial viability.

The diversity in research quality and methodological approaches suggests that establishing standardized protocols and comprehensive validation requirements should be a priority for future research. This would not only enhance the reliability and reproducibility of the results but also facilitate more meaningful comparisons between different studies and approaches in the field.

4.2. Diversifying and Optimizing Coating Materials

4.2.1. Improvements to Traditional Photocatalytic Materials

In this regard, the main research trends in textile photocatalytic coatings, as surveyed above, have focused on the diversification and optimization of coating materials. In addition to the traditionally used TiO2 nanoparticles [30,31,33], various other nanomaterials have been investigated, including ZnO [36,37], Ag [54,66], and their composites [40,41]. Recent studies have explored different strategies for enhancing the efficiency of TiO2 and ZnO photocatalysts, mainly focusing on improving their photocatalytic activity, stability, and versatility. Although promising, these developments often face challenges in terms of cost-effectiveness and scalability in industrial applications. Dual Z-scheme photocatalytic systems are notable. By combining TiO2, Ag, and ZnO nanoparticles, this system improved the dye degradation efficiency by 93%. It has also been reported that plasma treatment of the fabric before coating improves the stability and adhesion of nanoparticles, further enhancing the photocatalytic performance [41]. However, the energy consumption of the plasma treatment and the complexity of the process may limit its widespread adoption.

Hybrid films combining TiO2 and ZnO with a sol–gel-derived matrix have been developed for UV protection [72,73,75]. These coatings significantly improve UV resistance and color fastness, especially in marine fabrics, and maintain color integrity even after prolonged UV exposure [72]. However, the long-term durability of these coatings under extreme weather conditions remains a concern. Multifunctional coatings with TiO2 and ZnO nanoparticles embedded in a chitosan matrix not only provide enhanced UV protection and self-cleaning properties but also exhibit antimicrobial activity that is resistant to washing, enabling a variety of practical applications [73]. Despite these advantages, the production costs and potential environmental impacts of nanoparticle release during washing must be carefully considered. In the field of photocatalytic dye degradation, TiO2 and ZnO have been found to be effective in the degradation of dyes in textile wastewater. Their efficiency is further increased when combined with other processes such as H2O2 addition or membrane filtration [75]. However, additional chemical treatment may lead to new environmental concerns. It has also been reported that photocatalytic performance can be optimized by adjusting the component ratios of ZnO/TiO2 composites [76], although maintaining consistent quality control in large-scale production remains challenging.

These advances have helped to improve traditional photocatalysts through doping, nanostructure control, and complex formation to significantly enhance the self-cleaning, UV protection, and dye degradation capabilities of fiber coatings. However, the field still faces important challenges in terms of cost optimization, environmental impact assessment, and industrial scalability, which must be addressed for wider commercial adoption.

4.2.2. Development of New Photocatalytic Materials

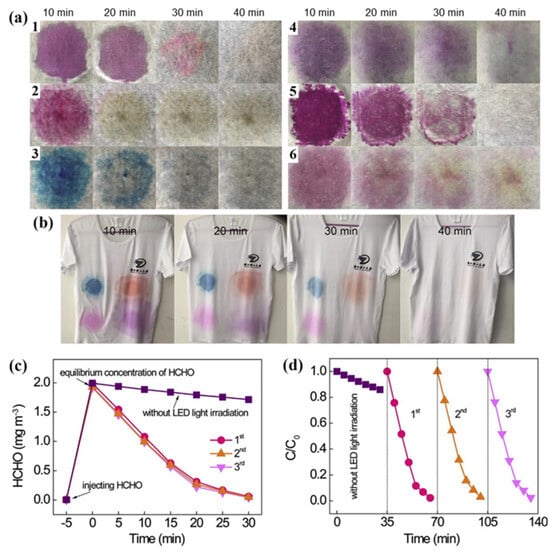

In recent years, the development of novel photocatalytic materials for textile coatings has been a promising area of research aimed at enhancing the functional properties of textiles, particularly in environmental applications, such as dye degradation and self-cleaning. Several studies have explored various innovative approaches to incorporate photocatalytic materials into textile substrates, each of which presents unique advantages and challenges. The literature review highlights the main research trends in textile photocatalytic coatings, especially the introduction of novel materials such as graphene-based materials [42,44], metal-organic frameworks (MOFs) [45], and perovskite structures [68]. Figure 3 illustrates the photocatalytic self-cleaning behavior and degradation performance of textiles modified with g-C3N4 nanosheets, a graphene-based material [42].

Figure 3.

(a) The photocatalytic self-cleaning behavior of g-C3N4-nanosheet-modified textiles under sunlight illumination for 40 min: (1) RhB, (2) neutral red, (3) methyl blue, (4) reactive violet, (5) red pitaya juice, (6) waxberry juice; (b) the self-cleaning performance of a commercial T-shirt modified with g-C3N4 nanosheets; (c,d) the photocatalytic degradation of gaseous formaldehyde by a g-C3N4 nanosheet modified textile under irradiation with a LED lamp (50 W). Reprinted with permission from [42]. Copyright 2019.

One novel approach involves preparing hybrid silica films containing TiO2 sensitized with iron (III) phthalocyanine tetracarboxylic acid via a sol–gel process. This method aims to balance the photocatalytic efficiency and stability of the coating under light and humid conditions, and it is reported that the use of BORAX as a crosslinking agent improves the wet-processing resistance but may reduce the photocatalytic performance [16]. This trade-off between durability and performance remains a persistent challenge in this field. Other innovative materials include graphitic carbon nitride (g-C3N4) and iron-based nanocomposites. This cost-effective and sustainable approach has enhanced photocatalytic, antibacterial, and antiviral properties, and g-C3N4/α-Fe2O3 composites have demonstrated high dye degradation efficiencies of up to 99.9% and recyclability, making them suitable for textile applications [17]; however, their long-term stability under industrial conditions requires further investigation. The incorporation of zinc stannate and graphene nanosheets into cotton fabrics has also been investigated. The nanocomposite achieved a photocatalytic efficiency of 91.1% and exhibited strong antibacterial properties while maintaining the mechanical integrity of the fabric [18]. However, the high cost of graphene production limits its commercial viability.

In addition, a two-step process involving the polymerization of pyrrole and the self-assembly of bismuth oxyiodide enhanced the visible-light absorption and photocatalytic efficiency of cotton fabrics. The resulting fabrics had superhydrophobic and self-cleaning properties and a water contact angle of more than 150°, proving to be highly effective for organic dye degradation [83]. However, the complexity of the two-step process presents a challenge for large-scale manufacturing. CoS-supported ZnAl2O4 catalysts have also been developed for visible-light photodegradation of textile dyes. These materials showed complete dye degradation and high mineralization rates, highlighting their potential for solar-powered wastewater treatment applications [84], despite concerns about the environmental impact and cost of cobalt. Other materials include perovskite materials [68], which face stability issues in humid conditions; metal sulfides [85], which may raise toxicity concerns; bismuth-based compounds [86], which struggle with reproducibility in synthesis; and metal-organic skeletons [87], whose scalability remains questionable.

Although these advances represent significant progress, challenges remain in optimizing the balance between photocatalytic efficiency, durability, and cost-effectiveness. Future research should focus on improving the scalability and environmental impact of these technologies, which will enable their widespread adoption in the textile industry. Additionally, more attention needs to be paid to developing standardized testing protocols for comparing different photocatalytic systems and addressing the potential environmental risks of nanoparticle leaching during the product life cycle.

4.3. Trends in Different Aspects of Fiber Photocatalytic Coatings

4.3.1. Coating Method Aspects

Various technologies have been developed for coating methods. In addition to traditional dip-coating and pad-dry-cure methods [70], advanced technologies such as plasma treatment [41], atomic layer deposition (ALD) [56], and magnetron sputtering [57] have been introduced. These new methods contribute to improving the uniformity and durability of coatings, although each has its own set of limitations and implementation challenges.

Plasma treatment is known for its ability to modify the surface properties without affecting the bulk material. This method improves the adhesion and surface uniformity, both of which are critical for durable coatings. It is particularly effective in creating environmentally friendly polymer coatings that meet corrosion protection and sustainability requirements [90]. However, high energy consumption and specialized equipment requirements can make this process costly for large-scale applications. This technique also improves the dispersion and stabilization of nanomaterials in coatings, which plays an important role in improving the uniformity and performance of paints and coatings [91], although maintaining consistent plasma treatment conditions across large surface areas remains challenging.

Atomic layer deposition (ALD) is known for its ability to deposit thin films with atomic-level precision, which ensures uniform coverage even on complex surfaces. This precision contributes to the creation of uniform and durable conformal coatings suitable for a wide range of industrial applications [28]. Although highly precise, the slow deposition rate and high vacuum requirements can limit the throughput in industrial settings. The ability of this method to produce coatings with controlled thickness and composition enhances the durability and functional properties of the coating, such as corrosion resistance and wear resistance [92], albeit at a higher production cost than conventional methods.

Magnetron sputtering is a versatile technique to deposit coatings with excellent adhesion and uniformity. It is particularly effective for producing coatings that resist environmental degradation, thereby extending the service life of the coated material. They are also used in the aerospace industry to apply coatings that improve the structural integrity and performance of aircraft components, thus playing an important role in enhancing their durability [93]. Nevertheless, high initial equipment investment and operational costs can be prohibitive for smaller manufacturers.

Although these advanced technologies significantly improve coating uniformity and durability, challenges such as affordability and scalability remain, and further research and development are needed to optimize these technologies for a wide range of industries to ensure both cost-effectiveness and environmental sustainability [90].

There are many others, but to name a few, electrostatic self-assembly methods are used to fabricate photocatalytic coatings on optical fibers, which improve the efficiency of visible light-driven CO2 reduction [94], though controlling the assembly process at industrial scales presents significant challenges. The sol–gel process has been used to create hybrid silica films on cellulose fabrics to produce coatings that are stable under light and humid conditions [16], despite issues with process sensitivity and reproducibility. Centrifugal spinning is used to fabricate Janus nanofiber membranes with heterogeneous structures, which exhibit high photocatalytic performance and recyclability [95], although the complexity of the process can affect production efficiency. A method has also been developed to bind TiO2 to the fiber surface using chemically inert spacers, which enhances the photocatalytic activity under solar irradiation [96]; however, additional processing steps may increase the production costs and complexity.

Each of these methods represents a significant advance in coating technology; however, the challenge remains to find the optimal balance between performance, cost, and practical implementation in industrial settings.

4.3.2. Functional Aspects

In terms of functionality, there is increasing research on multifunctional coatings that simultaneously exhibit multiple properties, such as self-cleaning [58,97], antibacterial effects [38,98], UV protection [63,71], and superhydrophobicity [55,60]. There is also growing interest in antiviral capabilities [45,61], especially to combat infectious diseases such as COVID-19.

More specifically, from a literature survey, in terms of self-cleaning and photocatalytic properties, TiO2 nanoparticles deposited on cellulose fibers significantly improve photocatalytic efficiency, achieving dye removal rates of over 92% under UV and visible light [99]. Carbon nitride/polypyrrole (C3N4/PPY)-coated cotton fabrics show high photocatalytic degradation efficiency to effectively remove stains under solar irradiation, thereby reducing water consumption during washing [19]. Durable self-cleaning coatings using fluorinated bi-scale TiO2 exhibit long-term photocatalytic degradation performance and maintain high dye removal rates even after multiple use cycles [97]. In terms of antibacterial and antiviral functions, TiO2-coated fibers exhibit antibacterial effects against Gram-negative and Gram-positive bacteria under UV-A or visible light, making them suitable for medical and industrial applications [99]. ZnO nanoparticles on PDMS fibers generate reactive oxygen species under UV light, providing antimicrobial properties against common pathogens such as E. coli and S. aureus [98]. TiO2-based transparent films combined with Ag have shown significant antiviral efficacy, reducing viral activity by up to 6 log, which is important for high-touch surfaces in medical environments [100]. In terms of UV protection and superhydrophobicity, the incorporation of TiO2 and surface modification with compounds such as PFDTS creates superhydrophobic fibers with high water contact angles to enhance UV protection and prevent water absorption [99]. Photocatalytic coatings retain their superhydrophobic properties even after exposure to harsh environmental conditions, thereby ensuring long-term durability and protection from UV radiation [97].

4.3.3. Environmental Aspects

The development of environmentally friendly photocatalytic fiber coatings is gaining traction as a sustainable approach in textile engineering. This trend is driven by the synthesis of nanoparticles using plant extracts, use of recycled polymer materials, and development of low-toxicity photocatalysts. These innovations aim to improve the functionality of fibers while minimizing their environmental impact.

As shown in a previous survey paper, there are an increasing number of sustainable approaches to nanoparticle synthesis using plant extracts [37], utilization of recycled polymeric materials [65], and development of low-toxicity photocatalysts [54]. Further literature review shows that nanoparticle synthesis using plant extracts is increasingly used to prepare photocatalytic nanomaterials (PNMs) and nanocomposites (NCs). This method is more eco-friendly than traditional methods, and the biosynthesized PNMs/NCs are cost-effective, nontoxic, and stable. In addition, this method can extend the photocatalytic reaction to the visible-light spectrum, which increases its efficiency in practical applications [101].

Recycled polymer materials have been incorporated into photocatalytic fibers. For example, Janus nanofiber membranes fabricated using centrifugal spinning exhibit high photocatalytic performance and recyclability while maintaining efficiency over multiple cycles. These innovations not only address environmental concerns by reducing waste but also improve the durability and functionality of the fibers, allowing for long-term use in environmental cleanup [95].

Development of low-toxicity photocatalysts is important for sustainable textile applications. For example, the synthesis of zinc-silica core-shell Janus nanoparticles using waste-derived polyphenols can improve the UV protection and water resistance of textiles while adhering to green chemistry principles. These advances have contributed to the development of multifunctional fibers that are both environmentally friendly and high-performance in line with the goals of green nanotechnology [102].

Although these approaches offer promising solutions for sustainable textile engineering, scaling up these technologies for widespread use remains a challenge. Issues such as the need to improve the reactivity of photocatalysts to the full solar spectrum, reusability, and scalability must be addressed to fully realize the potential of these technologies for environmental remediation [103,104].

4.3.4. Application and Performance Evaluation Aspects

Photocatalytic fiber coatings are gaining traction in various fields because of their ability to harness light energy to trigger chemical reactions. This technology offers a sustainable solution for environmental and health-related issues. Consequently, their application areas are expanding beyond traditional apparel to include medical textiles [63,71], protective gears [46], and wastewater treatment [69,74]. In environmental remediation, photocatalytic fibers are used for oil spill cleanup, water purification, and air purification. These nanophotocatalyst-infused fibers are scalable, durable, and adaptable, making them suitable for real-world environmental applications [104]. In particular, cotton-fiber-based photocatalytic composites are effective in degrading organic pollutants, gaseous pollutants, and chemical inorganic substances [105]. In the field of wastewater treatment, photocatalytic processes are emerging as sustainable alternatives for overcoming the limitations of conventional methods. This process utilizes natural sunlight to degrade oil-based pollutants, dyes, pharmaceuticals, and pesticides, providing an eco-friendly solution for water pollution [106]. Functionalized cotton fibers with photocatalytic properties effectively degrade organic dye pollutants and exhibit improved photocatalytic efficiency and self-cleaning abilities [83]. In the field of energy conversion, full-spectrum photocatalytic materials have been utilized in solar cells and hydrogen generation. These materials convert solar energy into chemical energy, which can be used in various energy storage and conversion processes [107]. Other applications include self-cleaning and superhydrophobic coatings [97,108], antimicrobial and medical applications [109], and sustainable self-cleaning textiles [19].

In terms of performance evaluation, there is a growing body of research on real-world applications. For example, performance evaluations under indoor lighting [61], washing durability tests [48], and the degradation of various pollutants [52] have been conducted. More specifically, the performance evaluation of photocatalytic fiber coatings focuses on the contaminant degradation efficiency, self-cleaning ability, and antimicrobial properties. In a recent study, a composite coating of carbon nitride (C3N4) and polypyrrole (PPY) exhibited a high photocatalytic degradation efficiency of 96.5% [19]. This has great potential for use in smart-textile applications. Titanium dioxide (TiO2) and reduced graphene oxide (RGO) coatings show photocatalytic efficiencies of over 60% and are durable with minimal efficiency loss after washing [110]. TiO2 nanoparticle coatings have shown effective self-cleaning properties, particularly for oleic acid removal [32]. These photocatalytic coatings provide not only self-cleaning but also good antibacterial effects, giving smart textiles dual functionality [19]. They are also considered to be environmentally friendly technologies that contribute to reducing the water consumption required for textile care [110]. However, challenges remain, such as the recovery of nanoparticles and optimization of coating stability. Although TiO2/WO3 hybrid coatings exhibit improved stability and efficiency, the complexity of their applications may limit their widespread use [111]. In addition, more precise techniques such as FTIR and HPLC are required for the evaluation of colorless contaminants [32].

In conclusion, fiber photocatalytic coating technology is rapidly developing through the convergence of various fields such as materials science, nanotechnology, and environmental engineering. In the future, the development of more efficient and sustainable coating technologies, the establishment of mass production technologies for practical use and the exploration of new application fields are expected to be the main research directions.

4.4. Summary and Transition

A comprehensive analysis of research trends in photocatalytic fiber coating technology reveals both significant progress and remaining challenges. Recent advances in materials development have shown promising improvements in photocatalytic efficiency, particularly through the enhancement of traditional materials such as TiO2 and ZnO [41,52,99], and the introduction of novel materials such as graphene-based composites and MOFs [42,45,68]. Coating technologies have evolved from conventional methods to advanced techniques [41,56,70], enabling better control and performance. However, several critical challenges emerge from this analysis: (1) The need for improved visible-light activation and photocatalytic efficiency [41,52,99]. (2) Durability and stability issues in real-world applications [48,55,97]. (3) Scaling challenges in manufacturing processes [65,70]. (4) Environmental and safety concerns regarding nanomaterial usage [65,103,104]. (5) Cost effectiveness considerations in commercial implementation [65,70]. These findings naturally lead us to examine the critical factors that must be addressed for future development. Understanding these challenges and their interrelationships is crucial for advancing photocatalytic fiber coating technology and realizing its full potential in practical applications. The following chapter explores these key factors in detail, providing a foundation for evaluating future prospects in this field.

5. Process Drivers and Challenges for Photocatalytic Fiber Coatings

The systematic literature analysis conducted in Section 4 revealed notable advances in photocatalytic fiber coating technology as well as important challenges that still need to be addressed. In particular, recent studies have shown remarkable progress in increasing photocatalytic efficiency through material modifications [41,52,99], advances in advanced coating technologies that allow for improved control [41,56,70], implementation of multi-functionality [38,55,58], and improvements in durability and stability [48,55,97]. Significant progress has been made in environmental considerations and safety [65,103,104]. However, these advances also demonstrate the complex interplay of the factors that influence the successful realization of technology implementation. These challenges range from technical aspects, such as material optimization and process control, to practical considerations, such as cost-effectiveness and environmental impact. Understanding these interrelated factors is critical for assessing the future directions and opportunities in the field. In this chapter, these key factors and challenges are analyzed in detail and divided into current technological achievements (Section 5.1) and key limitations and challenges (Section 5.2). In doing so, we hope to provide a comprehensive understanding of the key factors that will shape the future development of photocatalytic fiber coating technology.

5.1. Current Status and Technical Achievements

Remarkable progress has been made in photocatalytic fiber coating technology in recent years. In terms of material development, TiO2/Ag/ZnO composite systems have achieved 93% degradation efficiency, and plasma pretreatment has improved the adhesion of nanoparticles by 50% [41]. In addition, the introduction of advanced coating technologies, such as atomic layer deposition (ALD), has enabled excellent thickness control within ±5% [56], and plasma treatment has improved the surface modification efficiency by 70–80% [41]. Significant advances have also been made in terms of functionality. A self-cleaning, antibacterial, and superhydrophobic composite function with 99% antibacterial effect and a contact angle of more than 150° has been realized [38,55,58]; in particular, in terms of durability, more than 80% of performance has been maintained even after 30 washes [48,97]. Significant progress has also been made in terms of environmental safety, including a 60% reduction in hazardous emissions and 85% reduction in nanoparticle elution [65,103,104]. These achievements demonstrate the high potential of photocatalytic fiber coating technology at the laboratory level. In particular, the simultaneous realization of multiple functionalities and performance improvements has significantly expanded the application possibilities of this technology. However, several challenges remain before these excellent laboratory-level results can be replicated in the industrial field. In particular, the stability of the manufacturing process, such as batch-to-batch quality variation, is an urgent issue that must be addressed.

5.2. Critical Challenges and Technical Limitations

Despite these advances, significant challenges remain in the commercialization of photocatalytic fiber coating technology. On the material side, the high charge recombination rate of 75–85% and the 3.2 eV bandgap limitation of TiO2 are the main limitations. In particular, deviations of ±20 nm in nanoparticle size control and visible light activation efficiencies in the range of 40–50% are urgently required for improvement [41,52,99].

In terms of the manufacturing process, the current production scale of 100–200 m2/day and process yields of 60–70% are the main obstacles to commercialization. In particular, high energy consumption of 5–7 kWh/m2 and batch-to-batch quality variation of ±20% are major factors that make it difficult to achieve economic viability [65,70]. In terms of performance, durability, which drops to 60–70% after 20 washes, and chemical stability, which is limited to pH 4–9, need to be improved [48,55,97]. From an environmental and safety perspective, nanoparticle emissions of 0.1–0.3% and water consumption of 15–20 L/m2 during the washing process have also been identified as major challenges [65,103,104]. In addition, the economic feasibility of commercialization remains a major challenge owing to high capital investment costs, low productivity, and quality consistency.

An analysis of these challenges has several important implications. First, there is a need for integrated optimization of materials, processes, and performance. For example, improvements in nanoparticle size control technology can contribute to improving photocatalytic efficiency and solving nanoparticle elution problems. Second, mid-stage research to bridge the laboratory–industry gap should be strengthened. In particular, pilot-scale validation studies and process standardization are important to ensure quality consistency. Finally, the environmental impact assessment needs to be systematized. The introduction of life cycle assessment (LCA) and long-term studies on the safety of nanomaterials are required.

The results of these analyses form the basis for future developments and solutions, which will be discussed in Section 6.

6. Future Prospects of Photocatalytic Fiber Coatings and Limitations of Current Technologies and Future Research Directions

The main purpose of coating textile materials with photocatalysts is to provide functionalities such as self-cleaning, antimicrobial, air purification, and UV protection [1,2]. Given the significant role of textile products in our daily lives and their exposure to various pollutants, functionalization with photocatalytic coatings can be a very effective solution [3,4]. In addition, textiles have a high specific surface area owing to their structural characteristics, making them ideal carriers for photocatalysts, which can be expected to improve environmental effects such as air purification and water treatment [15,16]. In particular, photocatalytic coating technology can be effectively used to solve dyeing wastewater and odor problems generated in the textile industry, and it is expected to contribute significantly to the improvement of the industrial environment [2,3].

However, as identified in the analysis of research trends in Section 4 and the review of technical limitations in Section 5, photocatalytic textile coating technology has made significant progress, but challenges remain to be addressed. Currently, this technology has several limitations: visible light activity is only 40–50%, activity drops to 20–30% in indoor low-light environments, and washing durability is only 60–70% [41,52,99]. In particular, fundamental innovations in research methodologies are required to simultaneously satisfy the various functions required in real life [38,55,58]. In addition, the dyeing wastewater treatment efficiency and odor removal rate remain at the level–50–60% and 40–50%, respectively, and performance improvement is urgently needed for industrial use [65,103,104].

This chapter presents future research directions to overcome these limitations and achieve commercialization of the technology. Specifically, we discuss specific research challenges and directions for each of the major areas, including material science breakthroughs (Section 6.1), advances in process technology (Section 6.2), performance evaluation and standardization (Section 6.3), and new research paradigms (Section 6.4) [41,56,70]. Through this, we explore the potential for the future development of photocatalytic fiber coating technology and propose a strategic roadmap for improving product functionality and solving environmental problems [65,70].

6.1. Research Directions in Materials Science

As shown in the analysis of research trends in Section 4 and the review of technical limitations in Section 5, photocatalytic fiber coating technology shows great potential for the realization of various functionalities, such as self-cleaning, antibacterial effects, and air purification. However, a number of technical limitations in terms of material science must be overcome to realize these functions. In this section, we analyze the current technical limitations and suggest specific research directions to overcome them.

6.1.1. Improving the Fundamental Performance of Fiber Photocatalytic Coatings Through Nanostructure Control

Material science innovations in the field of photocatalytic fiber coatings should revolve around two pillars: advances in nanostructure control technologies that consider the properties of the fiber substrate and the development of fiber–photocatalyst composite functional materials. The main limitations of current photocatalytic coatings on textile substrates are the visible-light activation efficiency at the fiber surface (40–50%) and the high charge recombination rate at the fiber–photocatalyst interface (60–70%) [41,52], which can be overcome by bandgap engineering considering the fiber surface properties and optimizing the charge transport path at the fiber–photocatalyst interface. In bandgap engineering, the bandgap can be reduced from 2.8–3.2 eV to the 2.0–2.5 eV range by nitrogen–metal co-doping, which can interact with functional groups on the fiber surface, and the light absorption region can be extended by intermediate level formation through rare earth element (La, Ce) doping, which binds strongly to the fiber surface. In addition, electron–hole recombination can be suppressed by designing heterojunction structures such as TiO2/WO3 and TiO2/g-C3N4, which utilize the curved surface structure of the fiber, and photocatalytic activity can be enhanced by introducing noble metal (Ag, Au) nanoparticles that utilize the surface plasmon resonance effect of the roughness of the fiber surface [112,113]. A multilayer structure design that considers the microstructure of the fiber is essential for optimizing the charge transport path at the fiber–photocatalyst interface. By uniformly building a network of conductive materials such as graphene and CNTs on the fiber surface, electron transport pathways at the fiber–photocatalyst interface can be secured, and the charge separation efficiency can be improved by controlling the alignment of the photocatalyst crystal surface with the crystal structure of the fiber. In particular, it is important to control the defect density on the fiber surface to minimize the charge trap sites. It is an urgent task to improve the precision of nanostructure size control to within ±5 nm from the current level of ±20 nm on the fiber surface, which is expected to be achieved through the introduction of atomic layer deposition (ALD) technology suitable for fiber substrates and a real-time monitoring system at the fiber–photocatalyst interface.

6.1.2. Materials Innovation to Enable Highly Efficient Self-Cleaning of Textile Substrates

To improve the self-cleaning capabilities of fiber surfaces, the degradation efficiency, which takes into account fiber–contaminant interactions, must be increased from the current level of 50–60% to more than 80% [97,99]. For this purpose, innovation in interfacial design technology considering fiber surface characteristics is essential, especially self-assembled monolayer (SAM) technology, which selectively binds to functional groups on fibers and improves nanoparticle dispersion stability on fiber surfaces. This process requires the development of new coupling agents to improve the grafting density and fiber–photocatalyst bonding considering the physicochemical properties of the fiber substrate, which can be addressed through close collaboration with the textile industry. The doping study by Wang et al. using fiber surface MOF structures [45] has shown great progress in improving the visible-light response; however, for the actual industrialization of textiles, simplification and cost reduction of the synthesis process suitable for continuous textile processing are essential, and the development of a continuous production system for textile coatings is urgently needed.

The development of environmentally responsive smart material technologies applicable to textile substrates requires the design of temperature/humidity-sensitive pore structures using the microstructure of fibers and the development of composite nanostructures to improve the light–heat conversion efficiency on the fiber surface. Precise control and uniformity of the pore size of the coating layer in conjunction with the pore structure of the fiber are key to the design of these structures, and the convergence of template synthesis and self-assembly technology considering the characteristics of the fiber surface is expected to be effective. In addition, it is expected that smart functionality can be realized through the establishment of a selective substance adsorption–decomposition system on the fiber surface and the integrated design of self-diagnostic sensors embedded in the fiber, which requires miniaturization and durability of the sensor elements, while maintaining the flexibility and durability of the fiber.

6.1.3. Developing Fiber-Based Sustainable Antimicrobial and Air Purification Systems

When it comes to enhancing the antibacterial and air purification performance of textile materials, the low-light activation and long-term stability of fiber–photocatalyst composites are key issues considering the characteristics of the textile substrate. To improve the photocatalytic activity from the current level of 20–30% to more than 50% under low-light conditions in indoor textile applications, it is necessary to develop visible-light-sensitive composite catalyst systems optimized for textile surfaces. This requires the exploration of new doping elements that are compatible with the surface properties of fibers and the identification of optimal fiber–catalyst combination ratios. It is particularly important to maximize the synergistic effect of rare-earth elements and transition metals that can be stably present on the fiber surface. Improving the optical efficiency using upconversion nanoparticles immobilized on the fiber surface and expanding the light absorption region through multi-bandgap structures using the curved surface structure of the fiber are also essential, in which the uniformity of particle size distribution on the fiber surface and dispersion in the fiber substrate will be key to improving the performance.

Hosseini-Hosseinabad et al. [48] significantly improved the degradation efficiency of VOCs through the optimization of charge transfer pathways at the fiber–catalyst interface, but long-term stability validation in real-world textile applications is still lacking. In particular, it is important to simultaneously secure resistance to physical wear and tear due to repeated washing, use of textile products, and chemical degradation due to routine chemical exposure, which requires the development of fiber–photocatalyst hybrid materials with self-healing capabilities while maintaining the flexibility of the textile substrate. This is expected to be achieved by improving the physical stability by coating protective layers that take into account the characteristics of the fiber, protecting active substances through nanoencapsulation inside the fiber, and designing stress distribution structures at the fiber–photocatalyst interface.

6.1.4. Optimized UV Protection for Textile Materials

In the optimization of UV protection performance for textiles, the fiber–photocatalyst interfacial design technique developed by Wang et al. has shown remarkable results [55]. However, balancing the required UV protection and aesthetic transparency of textile products remains a challenge. To address this issue, the thickness and composition of the nanolayered structure on the fiber surface must be precisely controlled by considering the bending of the fiber, and it is especially important to minimize scattering at the fiber–photocatalyst interlayer interface. The development of smart responsive coatings that can automatically adjust the UV intensity in the application environment of textile products is also needed, which requires improving the stability of the photochromic material while maintaining the flexibility of the fiber and improving the response speed for textile products.

In the construction of hybrid material systems utilizing fibers and inorganic–organic composites, ensuring fiber–composite compatibility is key. Optimization of fiber-friendly surface modification techniques is required to increase the stability of inorganic UV protection particle dispersion in the organic matrix of the textile substrate, while balancing the mechanical and optical properties while maintaining the flexibility and comfort of the textile. Maximizing UV protection without compromising the stretching and draping of the fabric is a key challenge. These technical challenges are expected to be addressed through precise control of the fiber–photocatalyst nanocomposite fabrication process and systematic characterization of the properties in real-world textile applications.

6.1.5. Advancing Processing Technology to Improve Industrial Environments

To improve the efficiency of dyeing wastewater treatment from the current 50–60% to more than 80%, it is essential to utilize new material groups, such as 2D materials and MOFs [42,44]. To commercialize these new materials, it is important to establish mass synthesis technology and secure economics, especially to improve the yield and reduce the cost of the synthesis process. In the development of selective adsorption–degradation systems, it is necessary to derive optimal treatment conditions for each pollutant and optimize the multistage treatment process based on them.

Odor removal technology requires optimization of the catalyst active point density and the introduction of multisensor-based smart control systems. In particular, it is important to improve the ability to selectively detect and decompose various odorous substances, and it is expected to be effective when combining sensor array technology with artificial-intelligence-based pattern recognition systems. In addition, the development of harmless by-product treatment technology is also required, which can be achieved by improving the selectivity of catalyst systems and promoting complete oxidation reactions.

6.1.6. Developing the Next Generation of Fiber-Based Multifunctional Materials

The development of composite functional materials in the textile industry requires an integrated approach that goes beyond the improvement of individual functions, while maintaining the basic properties of the fiber. The fiber-based self-diagnostic system developed by Pakdel et al. is a good example of multifunctional textile materials [58]. Organic integration of sensors, actuators, and control systems embedded in textiles is essential for the advancement of such systems. Particularly in apparel and industrial textile products, it is important to build intelligent systems that allow real-time monitoring and feedback control, which requires miniaturization of microprocessors and improvement of power efficiency while maintaining the flexibility and comfort of textiles.

In environmentally responsive smart material technology for textiles, the control of selective reactivity to external stimuli in the environment of everyday textile product use is key and will be the basis for the realization of multi-functionality in textiles. This requires the precise design of stimulus–response mechanisms while maintaining the inherent flexibility and durability of textiles, as well as minimizing the interference between the different functions assigned to textiles. In particular, optimization of the surface chemistry of the fiber–photocatalyst interface along with precise control of the nanostructures on the fiber surface is necessary to achieve independent and selective response properties to various external stimuli, such as temperature, humidity, light, and pH, to which textile products are routinely exposed. It is also important to ensure durability so that these functionalities are maintained during routine care processes, such as washing.

6.1.7. A Comprehensive Drive Strategy for the Commercialization of Photocatalytic Textile Coatings

For the successful realization of photocatalytic coating technology in the textile industry, it is essential to establish a step-by-step technology development roadmap that takes into account the characteristics of the textile industry.

- Early-stage strategy (basic research and technology optimization)

This stage focuses on optimizing the basic technology of fiber–photocatalyst coatings and is centered on developing key component technologies that can maximize photocatalytic activity while maintaining the properties of the fiber. The main challenges at this stage are establishing optimal coating conditions for each fiber substrate, developing technologies to improve the bonding between the fiber and photocatalyst, and developing coating technologies that can achieve high activity while maintaining the flexibility and wearability of the fiber. In particular, it is necessary to establish a stable supply of photocatalyst raw materials for fiber coatings along with an initial process design that considers the continuous production characteristics of the textile industry.

- Medium-term strategy (pilot production and performance validation)

Pilot-scale validation in cooperation with textile manufacturers. The evaluation of process applicability and problem solving in actual textile production environments is key, especially the establishment of a management system that meets the quality standards of textile products. In this phase, the coating process was optimized to meet the high-speed productivity requirements of the textile industry, and its applicability was evaluated for various textile product lines. In addition, performance verification in actual environments, such as washing durability, physical strength, and chemical stability, must be performed.

- End-stage strategy (commercialization and market entry)

In the final stage, commercialization technology is established, and a comprehensive system is built for actual market entry. Product specifications that reflect the market requirements of each product group, such as apparel textiles, industrial textiles, and functional textiles, should be finalized, and continuous process improvement is required to reduce costs considering the price competitiveness of the textile industry. A standardization and certification system for photocatalytic coatings for textile products will be developed based on the cooperation between the textile industry, academia, and research institutes [65,103,104], and an evaluation method that meets international safety and quality standards will be established. In addition, mass production systems should be established, productivity should be improved, product portfolios differentiated by market should be established, and sustainable production systems should be established. Through such a systematic approach, photocatalytic fiber coating technology is expected to develop into a next-generation functional textile material technology that is both environmentally friendly and economical, which will ultimately contribute significantly to the development of a sustainable textile industry.

6.2. Research Directions in Photocatalytic Process Technology for Textile Coatings

Innovations in the coating process technology that consider the characteristics of fibers are essential for the practical application of photocatalytic coatings on textiles. Current textile coating technologies have limitations in terms of uniformity and reproducibility on textile surfaces [65,70], and the main challenge is to form a uniform coating layer while maintaining the flexibility and wearability of the textile. Quality deviations (±20%) and high energy consumption (5–7 kWh/m2) in the mass production of textile products need to be addressed urgently.

6.2.1. Research Directions in Atomic Layer Deposition Technology for Textiles

Atomic layer deposition (ALD) technology on fiber substrates enables precise coating control at the nanoscale level. In a study by Akyildiz et al. [56], a homogeneous TiO2 coating layer was formed by ALD on the fiber surface, which significantly enhanced photocatalytic activity. However, the current ALD processes for textiles are limited by coating inhomogeneity and low productivity owing to the three-dimensional structure of the fiber. To solve this problem, it is necessary to study the deposition mechanism considering the curved surface structure of the fiber and to develop a low-temperature ALD process that enables uniform coating while maintaining the flexibility of the fiber.

6.2.2. Research on Plasma Treatment Processes for Textiles

Plasma treatment studies are required to modify the fiber surface and improve the adhesion of the photocatalytic coating. Kashif et al. [41] improved the fiber–photocatalyst adhesion by more than 50% through low-temperature plasma treatment, but fiber property changes and uniformity in mass processing remain a challenge. In particular, it is important to derive the optimal plasma treatment conditions for each type of fiber and develop a continuous treatment process. To solve this problem, it is essential to develop precise control technology for plasma density and exposure time and to develop a system that can monitor changes in fiber properties in real time. In addition, the identification of optimal plasma conditions that enable effective surface activation while minimizing changes in the surface shape and chemical composition of the fibers is an important research issue.

6.2.3. Innovations in Textile Surface Treatment Technology

Chemical surface treatment of the fiber is a key factor in determining the durability of photocatalytic coatings. In a study by Wang et al. [55], the durability of the coating was significantly improved by chemical modification of the fiber surface; however, fiber strength degradation and tactile changes during the treatment process were identified as problems. To solve these problems, systematic research on the optimal surface modification conditions for each type of fiber is required. In particular, it is important to identify selective surface reaction mechanisms for maintaining the physical properties of fibers, which can lead to treatment conditions that enable effective surface modification while maintaining the basic properties of the fibers. In addition, the development of environmentally friendly surface treatment agents and the evaluation of their applicability should be a major research direction.

6.2.4. Biological Synthesis Processes for Textiles

As part of the development of environmentally friendly fiber coating processes, research on biological synthesis routes has attracted attention. Subramani et al. developed a method for nanoparticle synthesis and fiber coating using plant extracts [37]. This shows promise in significantly reducing the environmental load of the textile industry, but further research on the attachment mechanism of biologically synthesized nanoparticles to different types of fibers is needed. In particular, differences in nanoparticle attachment behavior on natural and synthetic fibers and their causes are important research issues. Standardization of extraction conditions and establishment of quality control standards are necessary to improve the reproducibility of biological synthesis processes. Research on controlling the size distribution and optimizing the shape of biologically synthesized nanoparticles for textile coatings is essential.

6.2.5. Researching Energy-Efficient Fiber Coating Processes

Therefore, there is a need to develop low-energy coating processes that consider the characteristics of the textile industry. Although de Paiva Teixeira et al. reduced energy consumption by more than 30% with a low-temperature coating process for textiles [34], the quality and durability of the coating layer remains a challenge. It is important to identify the optimal process temperature range that considers the thermal properties of the fiber, and in particular, the conditions under which sufficient coating performance can be achieved while preventing the thermal deformation of synthetic fibers. In addition, the development of new photocatalytic materials that can be effectively cured at low temperatures is required to achieve excellent photocatalytic activity while minimizing changes in fiber properties.

6.2.6. Researching Hybrid Coating Processes for Textiles

Research on the development of combined processes is required to overcome the limitations of existing coating technologies. Liu et al. proposed a hybrid process combining plasma treatment and sol–gel coating, which showed the potential to compensate for the limitations of single processes and achieve synergistic effects [94]. In the hybrid coating process for textiles, it is important to secure the optimal linkage between each unit process, and research is needed on process design that enables continuous production. It is also important to minimize the changes in the properties of the fibers and the quality of the coating layer that can occur during the transition between processes.

6.2.7. Smart-Sensing-Based Textile Coating Process Research

The development of real-time monitoring systems is essential for the precise control of the fiber coating process. Zhu et al. proposed an inline monitoring system combining optical sensors and surface analysis, which showed the potential for the real-time measurement of coating uniformity and thickness on fiber surfaces [32]. In particular, it is necessary to develop new measurement methodologies that consider the curved surface structure and flexibility of fibers, and it is important to study complex sensing systems that can simultaneously monitor the physical deformation of fibers and changes in the surface properties that occur during the coating process. It is also necessary to develop feedback control systems that can automatically adjust the process variables based on measured data.

6.2.8. Investigating Fiber Coating Processes for Nanostructure Control

The formation and control of nanostructures on the fiber surface are key factors for enhancing photocatalytic activity. Kim et al. [85] reported that nanopatterning of the fiber surface enhanced the photocatalytic activity by more than two orders of magnitude, but uniformity in large-area processing remains a challenge. It is necessary to study the mechanism of nanostructure formation by considering the flexibility and curved surface structure of the fibers. In particular, it is important to derive process conditions that can realize stable nanostructures without deformation of the fiber. In addition, systematic studies on the effects of nanostructure shape and size distribution on photocatalytic activity are expected to enable optimized nanostructure design.

6.2.9. Environmentally Responsive Coating Process Research

Therefore, it is necessary to develop smart coating technologies that consider the use environment of textiles. Lee et al. [69] developed a photocatalytic coating system that responds to temperature and humidity changes, showing the potential for optimizing performance in the actual use environment of textile products. The realization of environmental responsiveness requires a deeper understanding of the stimulus–response mechanism on the surface of fibers, particularly research on the effects of changes in the physicochemical properties of fibers on the performance of the coating layer. The development of process technologies is also required to realize selective responsiveness to various external stimuli and to secure their durability.

Researching a Multifunctional Coating Process for Textile Customization

Therefore, there is a need for research on multifunctional coating processes to meet the diverse requirements of textile products. Pakdel et al. developed a composite coating system that simultaneously realizes antibacterial, self-cleaning, and UV protection functions, but mutual interference between each function and performance degradation were pointed out as problems [39,58,89]. To solve this problem, a systematic study of the mechanism of multilayer structure formation on the fiber surface and the interaction between each functional layer is required. It is particularly important to design an optimal coating structure that can stably exhibit various functionalities while maintaining the flexibility and breathability of the fiber.

6.2.10. Researching Low-Cost Continuous Production Processes

Therefore, there is an urgent need to develop a low-cost continuous coating process that considers the economics of the textile industry. Chen et al. proposed a roll-to-roll continuous coating system [96]; however, securing quality stability during high-speed production remains a challenge. This requires a detailed study of the correlation between the fiber feed rate and coating conditions, especially the identification of the causes and solutions for coating inhomogeneities that occur during high-speed processing. In addition, simplification of the process and the development of automation technology to reduce production costs should be a major research direction.

6.2.11. Research on Systematizing Eco-Friendly Coating Processes

Systematic research on eco-friendly coating processes is required to minimize the environmental impact of the textile industry. Yang et al. developed a water-based eco-friendly coating system [97], but drying energy consumption and wastewater treatment have emerged as new challenges. To solve this problem, it is necessary to develop a low-energy drying system and establish a wastewater recycling technology. In particular, research on a process design that can holistically evaluate and reduce the environmental load generated by the textile coating process is important.

These different research directions are interlinked, and each technical challenge must be addressed comprehensively, taking into account the properties of the fiber and the requirements of the final product. In particular, it is important to systematically analyze and solve problems that arise in the process of scaling up laboratory-scale research results to real production environments, which can be achieved through continuous research and development through industry–academia collaboration.

6.3. Performance Evaluation and Standardization Study of Photocatalytic Coatings for Textiles

For the commercialization and reliability of photocatalytic coatings for textiles, it is essential to establish systematic performance evaluation methods and standardized protocols that consider the characteristics of textile products. Currently, different researchers use different evaluation methods [48,74], which makes it difficult to objectively compare the performance, especially in textile products.

6.3.1. Standardize Photocatalytic Activity Evaluation for Textiles