Mold-Free Manufacturing of Ultra-Thin Composite Film with Flower-like Microstructures for Highly Sensitive Tactile Sensing

Abstract

1. Introduction

2. Materials and Methods

3. Results

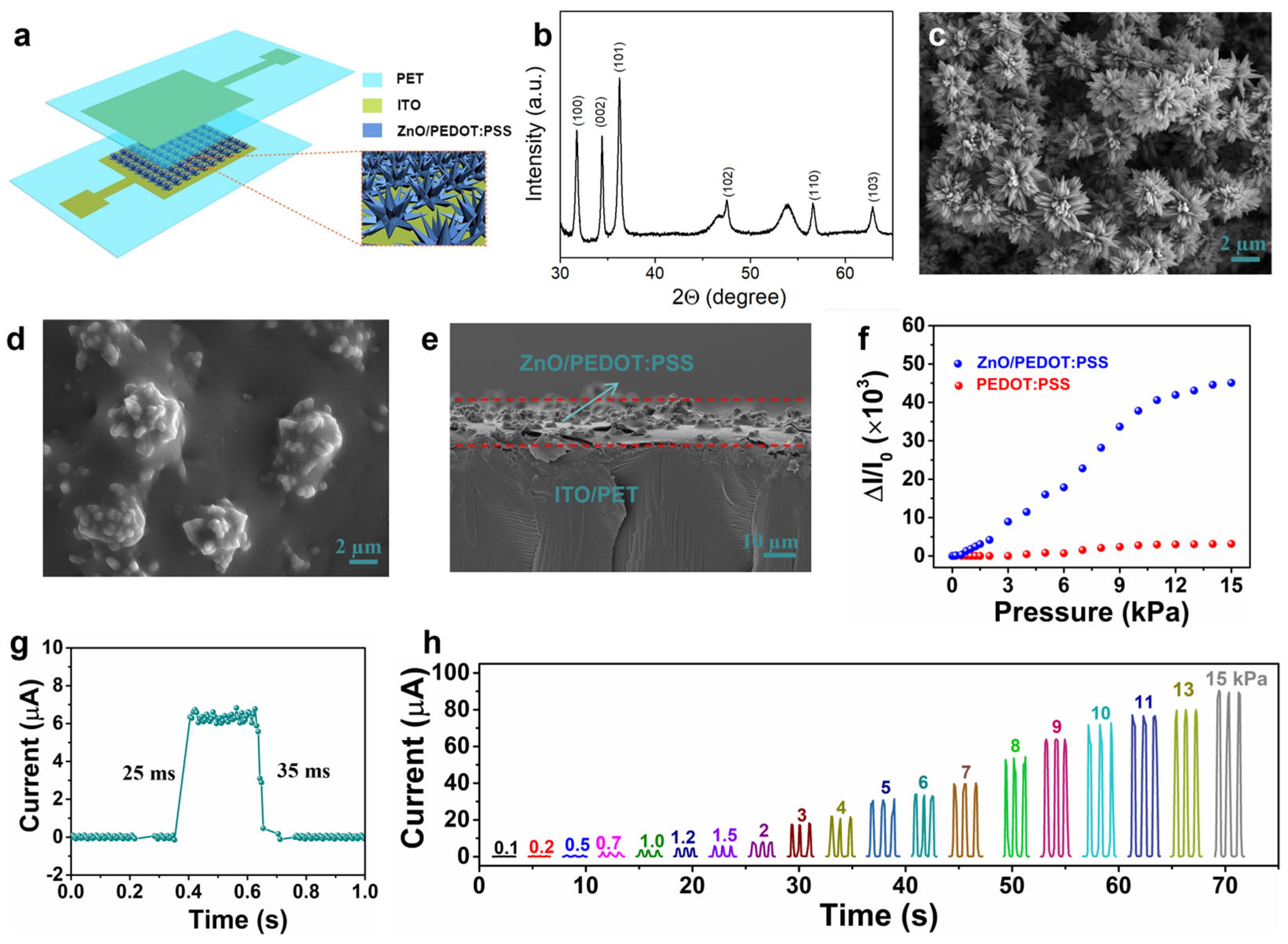

3.1. Fabrication of Tactile Sensors

3.2. Sensing Performance of the Ultra-Thin Tactile Sensors

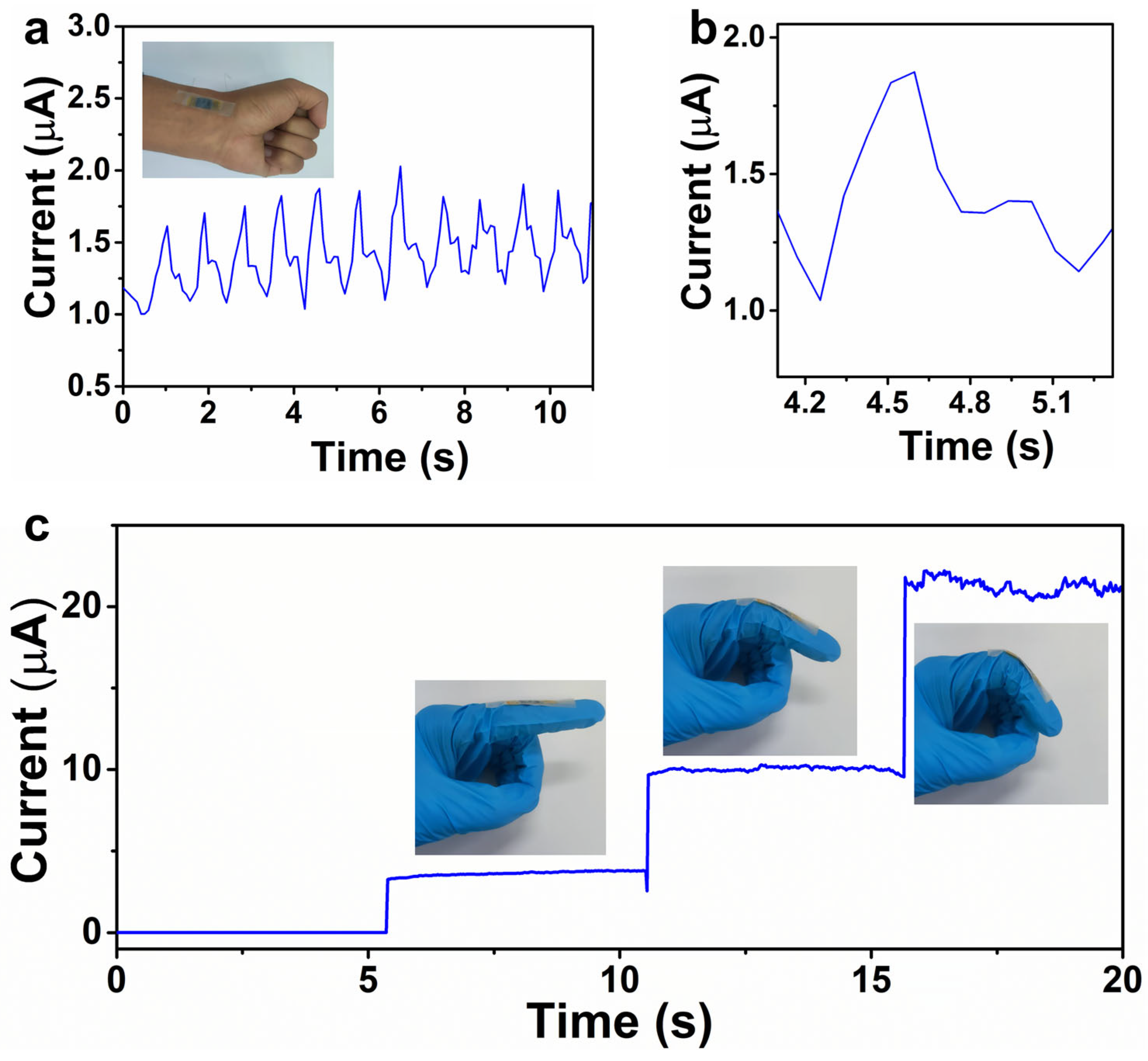

3.3. The Tactile Sensor for Real-Time Health Monitoring

3.4. Tactile Sensor Array for Spatial Pressure Mapping

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Li, Y.; Chen, X.; Zhang, S.; Yi, L.; Liu, P.; Gong, Y.; Liu, Z.; Wu, G.; Liu, F. 3D Integrated Physicochemical-Sensing Electronic Skin. Small 2025, 21, 2411435. [Google Scholar] [CrossRef] [PubMed]

- Gong, T.; Shao, H.-Q.; Sun, X.-R.; Guo, J.-X.; Hou, J.-R.; Ke, K.; Gong, L.; Cao, Y.; Cao, Y.-H.; Bao, R.-Y.; et al. Spatial hetero-structured composites with ultrawide linear range for positive-negative pressure sensing and e-skin of bionic fish. Nano Energy 2024, 120, 109173. [Google Scholar] [CrossRef]

- Liu, S.-Z.; Guo, W.-T.; Zhao, X.-H.; Tang, X.-G.; Sun, Q.-J. Self-powered sensing for health monitoring and robotics. Soft Sci. 2025, 5, 14. [Google Scholar] [CrossRef]

- Yin, Z.X.; Chen, H.; Yin, S.F.; Zhang, D.; Tang, X.G.; Roy, V.A.L.; Sun, Q.J. Recent Progress on Heterojunction-Based Memristors and Artificial Synapses for Low-Power Neural Morphological Computing. Small 2025, 21, 2412851. [Google Scholar] [CrossRef]

- Lai, Q.T.; Zhao, X.H.; Sun, Q.J.; Tang, Z.; Tang, X.G.; Roy, V.A.L. Emerging MXene-Based Flexible Tactile Sensors for Health Monitoring and Haptic Perception. Small 2023, 19, 2300283. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, D.; Cao, J. Development of a Skin-Like Tactile Sensor Array for Curved Surface. IEEE Sens. J. 2014, 14, 55–61. [Google Scholar] [CrossRef]

- Guo, W.-T.; Lei, Y.; Zhao, X.-H.; Li, R.; Lai, Q.-T.; Liu, S.-Z.; Chen, H.; Fan, J.-C.; Xu, Y.; Tang, X.-G.; et al. Printed-scalable microstructure BaTiO3/ecoflex nanocomposite for high-performance triboelectric nanogenerators and self-powered human-machine interaction. Nano Energy 2024, 131, 110324. [Google Scholar] [CrossRef]

- Zhao, X.H.; Lai, Q.T.; Guo, W.T.; Liang, Z.H.; Tang, Z.; Tang, X.G.; Roy, V.A.L.; Sun, Q.J. Skin-Inspired Highly Sensitive Tactile Sensors with Ultrahigh Resolution over a Broad Sensing Range. ACS Appl. Mater. Interfaces 2023, 15, 30486–30494. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, H.; Yue, W.; Gao, S.; Kan, H.; Zhang, C.; Zhang, C.; Pang, J.; Lou, Z.; Wang, L.; et al. Micro-Nano Processing of Active Layers in Flexible Tactile Sensors via Template Methods: A Review. Small 2021, 17, 2100804. [Google Scholar] [CrossRef]

- Sun, P.; Fang, Z.; Sima, W.; Niu, C.; Yuan, T.; Yang, M.; Liu, Q.; Tang, W. Microstructured Self-Healing Flexible Tactile Sensors Inspired by Bamboo Leaves. ACS Appl. Mater. Interfaces 2024, 16, 60699–60714. [Google Scholar] [CrossRef]

- Xiong, W.; Zhang, F.; Qu, S.; Yin, L.; Li, K.; Huang, Y. Marangoni-driven deterministic formation of softer, hollow microstructures for sensitivity-enhanced tactile system. Nat. Commun. 2024, 15, 5596. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wang, W.; Zhang, B.; Liu, W.; Zhang, H.; Zhang, D. High sensitivity SnSe2/MWCNTs flexible pressure sensors based on a lotus leaf biomimetic microstructure for electronic skin. J. Mater. Chem. C 2024, 12, 10669–10677. [Google Scholar] [CrossRef]

- Zhao, W.; Li, K.; Li, Z.; Wang, W.; Yu, X.; Zhang, T.; Yang, X. Flexible Pressure Sensor Arrays with High Sensitivity and High Density Based on Spinous Microstructures for Carved Patterns Recognition. Adv. Funct. Mater. 2025, 35, 2417238. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Liu, J.; Liu, X.; Zhang, C. 3D Printing of Anisotropic Piezoresistive Pressure Sensors for Directional Force Perception. Adv. Sci. 2024, 11, 2309607. [Google Scholar] [CrossRef]

- Liu, L.; Jia, X.; Yang, Q.; Huang, S.; Ke, L.; Yang, J.; Kitipornchai, S. Optimisation of properties of multidimensional hybrid polymer nanocomposites for flexible pressure sensors. Chem. Eng. J. 2024, 493, 152705. [Google Scholar] [CrossRef]

- Liu, X.; Tong, J.; Wang, J.; Lu, S.; Yang, D.; Li, H.; Liu, C.; Song, Y. BaTiO3/MXene/PVDF-TrFE composite films via an electrospinning method for flexible piezoelectric pressure sensors. J. Mater. Chem. C 2023, 11, 4614–4622. [Google Scholar] [CrossRef]

- Sun, Q.J.; Lai, Q.T.; Tang, Z.; Tang, X.G.; Zhao, X.H.; Roy, V.A.L. Advanced Functional Composite Materials toward E-Skin for Health Monitoring and Artificial Intelligence. Adv. Mater. Technol. 2023, 8, 2201088. [Google Scholar] [CrossRef]

- Zhuang, Y.; Li, R.; Jiao, M.; He, X.; Gu, X.; Huang, S. A flexible piezoresistive pressure sensor based on a perovskite MAPbBr3 nanocrystal-embedded polymer composite. J. Mater. Chem. C 2024, 12, 10494–10503. [Google Scholar] [CrossRef]

- Hu, X.; He, Q.; Ma, H.; Li, J.; Jiang, Y.; Wang, K. Flexible Eyelid Pressure and Motion Dual-Mode Sensor Using Electric Breakdown-Induced Piezoresistivity and Electrical Potential Sensing. ACS Appl. Mater. Interfaces 2025, 17, 8394–8402. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, R.; Lei, Y.; Cheng, C.; Wang, W.; Wang, T.; Yang, L.; Shu, D.; Jiao, L.; Yang, S.; et al. A lightweight, supercompressible and superelastic aramid nanofiber/nanocellulose-derived carbon aerogel with in-plane micro-wrinkle honeycomb structure for thermal insulation. J. Mater. Sci. Technol. 2025, 230, 139–150. [Google Scholar] [CrossRef]

- Naderizadeh, S.; Santagiuliana, G.; Restasari, A.; Tu, W.; Bilotti, E.; Busfield, J.J.C. Optimising polyurethane/CNTs piezoresistive pressure sensors by varying the modulus of the polymer matrix. Compos. Sci. Technol. 2024, 252, 110614. [Google Scholar] [CrossRef]

- Song, Y.; Liu, T.; Hu, A.; Wang, F.; Wang, H.; Wu, L.; Hu, R. A Haptic Glove with Flexible Piezoresistive Sensors Made by Graphene and Polyurethane Sponge for Object Recognition Based on Machine Learning Methods. ACS Appl. Electron. Mater. 2025, 7, 3448–3460. [Google Scholar] [CrossRef]

- Guo, X.; Ma, L.; Wu, W.; Li, S.; Lei, X.; Wu, X.; Yu, X.; Liu, F. Ultra-sensitive flexible piezoresistive pressure sensor prepared by laser-assisted copper template for health monitoring. Sens. Actuators A Phys. 2022, 334, 113325. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, X.; Zhang, Q.; Liang, J.; Zhang, H.; Zhang, T.; Xue, C. Fully sprayed MXene-based high-performance flexible piezoresistive sensor for image recognition. Nano Mater. Sci. 2024, 6, 77–85. [Google Scholar] [CrossRef]

- Tang, X.; Yang, J.; Luo, J.; Cheng, G.; Sun, B.; Zhou, Z.; Zhang, P.; Wei, D. A graphene flexible pressure sensor based on a fabric-like groove structure for high-resolution tactile imaging. Chem. Eng. J. 2024, 495, 153281. [Google Scholar] [CrossRef]

- Zhang, P.; Huang, L.; Li, Y.; Guo, C.; Zhang, Y. Biomimetic Wearable Flexible Pressure Sensor With Multilevel Microstructured Piezoresistive Layer. IEEE Sens. J. 2024, 24, 16744–16751. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, T.; Wang, Z.; Zhang, H.; Yan, Z.; Li, X.; Hong, W.; Zhang, A.; Qian, Z.; Zhang, X.; et al. Tactile corpuscle-inspired piezoresistive sensors based on (3-aminopropyl) triethoxysilane-enhanced CNPs/carboxylated MWCNTs/cellulosic fiber composites for textile electronics. J. Colloid Interface Sci. 2024, 660, 203–214. [Google Scholar] [CrossRef]

- Zhao, W.; Natsuki, J.; Trung, V.; Li, H.; Tan, J.; Yang, W.; Natsuki, T. AgNPs/CNTs modified nonwoven fabric for PET-based flexible interdigitated electrodes in pressure sensor applications. Chem. Eng. J. 2024, 499, 156252. [Google Scholar] [CrossRef]

- Lei, P.; Bao, Y.; Zhang, W.; Gao, L.; Zhu, X.; Xu, J.; Ma, J. Synergy of ZnO Nanowire Arrays and Electrospun Membrane Gradient Wrinkles in Piezoresistive Materials for Wide-Sensing Range and High-Sensitivity Flexible Pressure Sensor. Adv. Fiber Mater. 2024, 6, 414–429. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Zhang, H.; Li, B.; Zang, J.; Zhao, X.; Zhao, X.; Xue, C. A novel MXene-based high-performance flexible pressure sensor for detection of human motion. Smart Mater. Struct. 2023, 32, 065007. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, X.; Liu, Y.; Yang, C.; Liu, W.; Qi, M.; Zhang, D. PDMS Film-Based Flexible Pressure Sensor Array with Surface Protruding Structure for Human Motion Detection and Wrist Posture Recognition. ACS Appl. Mater. Interfaces 2024, 16, 2554–2563. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Huang, K.; Chen, G.; Tian, Y.; Jiang, N.; Zhao, C.; Liu, H. A dual-mode wearable sensor with coupled ion and pressure sensing. Soft Sci. 2024, 4, 8. [Google Scholar] [CrossRef]

- An, T.; Zhang, Y.; Wen, J.; Dong, Z.; Du, Q.; Liu, L.; Wang, Y.; Xing, G.; Zhao, X. Multi-Level Pyramidal Microstructure-Based Pressure Sensors with High Sensitivity and Wide Linear Range for Healthcare Monitoring. ACS Sens. 2024, 9, 726–735. [Google Scholar] [CrossRef] [PubMed]

| Materials | Sensitivity | Response Time | Durability [Cycles] | Ref. |

|---|---|---|---|---|

| polyurethane sponge/graphene | 1.7356 kPa−1 at 0–55 kPa | 147 ms | 2000 | [22] |

| CNTs | 1150.9 kPa−1 at 0–50 Pa | 43 ms | >2000 | [23] |

| MXene | 175 kPa−1 at 0–10 kPa | 0.43 s | 5000 | [24] |

| GNW | 2297.47 kPa−1 | 9 ms | 10,000 | [25] |

| MWNTs/PDMS | 1.619 kPa−1 | 80 ms | 1000 | [26] |

| (3-aminopropyl) triethoxysilane-enhanced CNPs/carboxylated MWCNTs/cellulosic fiber composites | 1.0005 kPa−1 | 40 ms | 500 | [27] |

| AgNPs/CNTs | 20 kPa−1 at 0–2 kPa | 48 ms | 6000 | [28] |

| MXene/ZnO | 236.5 kPa−1 | 100 ms | 10,000 | [29] |

| MXene/PDMS | 519 kPa−1 | 62.7 | 500 | [30] |

| ZnO/PEDOT:PSS | 4 × 103 kPa−1 within pressure range 0–10 N | 25 ms | 3000 | this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.-H.; Liu, L.-F.; He, Q.; Sun, Q.-J. Mold-Free Manufacturing of Ultra-Thin Composite Film with Flower-like Microstructures for Highly Sensitive Tactile Sensing. Materials 2025, 18, 2863. https://doi.org/10.3390/ma18122863

Zhao X-H, Liu L-F, He Q, Sun Q-J. Mold-Free Manufacturing of Ultra-Thin Composite Film with Flower-like Microstructures for Highly Sensitive Tactile Sensing. Materials. 2025; 18(12):2863. https://doi.org/10.3390/ma18122863

Chicago/Turabian StyleZhao, Xin-Hua, Ling-Feng Liu, Qinyu He, and Qi-Jun Sun. 2025. "Mold-Free Manufacturing of Ultra-Thin Composite Film with Flower-like Microstructures for Highly Sensitive Tactile Sensing" Materials 18, no. 12: 2863. https://doi.org/10.3390/ma18122863

APA StyleZhao, X.-H., Liu, L.-F., He, Q., & Sun, Q.-J. (2025). Mold-Free Manufacturing of Ultra-Thin Composite Film with Flower-like Microstructures for Highly Sensitive Tactile Sensing. Materials, 18(12), 2863. https://doi.org/10.3390/ma18122863