1. Introduction

Reclaimed powder refers to fine dust with a particle size of less than 0.075 mm collected by bag filters during the production of asphalt mixtures. According to statistics, approximately 50–70 kg of reclaimed powder is generated per ton of asphalt mixture produced, and the annual output of reclaimed powder nationwide reaches tens of millions of tons. Currently, the main disposal methods are open-air stacking and landfilling, which not only occupy a large amount of land but also incur high disposal costs, exerting significant negative impacts on the urban environment and economy. However, in reality, studies by Esquinas et al. [

1] and Valentin et al. [

2] have proven that reclaimed powder possesses considerable reuse value. Its application in civil engineering materials can yield remarkable engineering and environmental benefits.

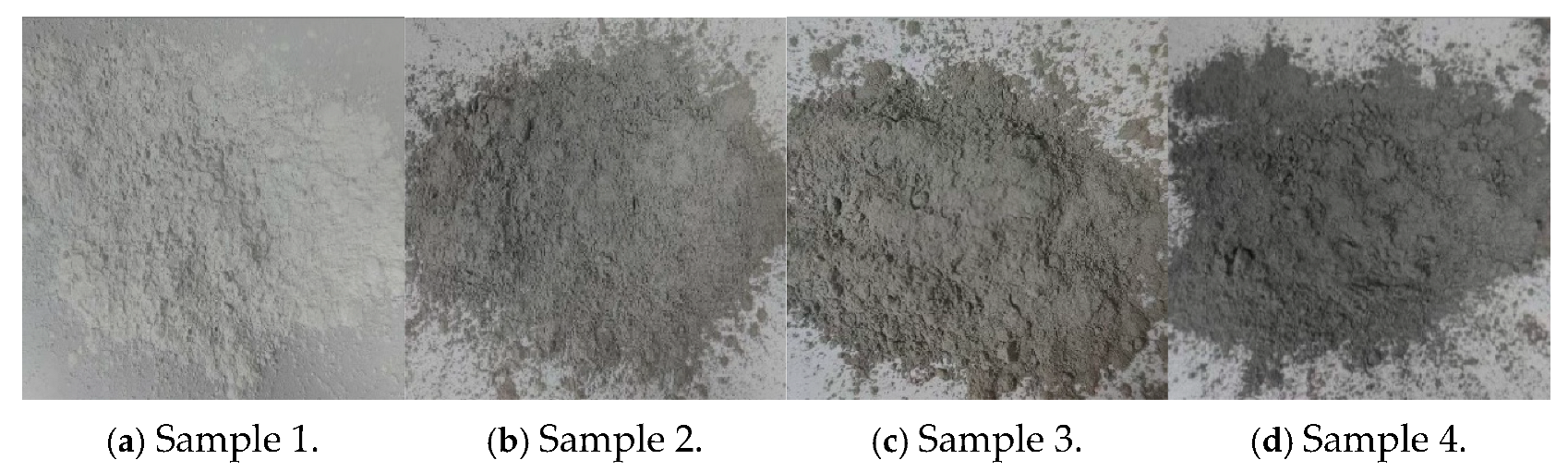

The main component of reclaimed powder is stone powder, which may be accompanied by a small amount of mud powder (related to the cleanliness of raw materials). The main mineral components of stone powder (CaCO

3, SiO

2) can undergo secondary reactions with Ca(OH)

2 (a hydration product of cement) in an alkaline environment to form calcium silicate hydrate (C-S-H) gel with cementitious properties [

3,

4,

5]. Meanwhile, its ultra-fine particle size can effectively fill the gaps in the aggregate skeleton, thereby improving the matrix strength and durability [

6,

7]. Studies by Umar, M et al. [

8], and Nair et al. [

9] have indicated that the use of stone powder as an admixture in cement-based materials is feasible, and both workability and mechanical properties can meet design indicators and application requirements. Research by Joyce et al. [

10], Sundaralingam et al. [

11], and Cohen et al. [

12] has shown that an appropriate amount of stone powder can improve the mechanical properties of cement concrete. Chitkeshwar et al. [

13] proposed that replacing 25% of river sand with stone powder can significantly enhance the compressive strength of concrete; some studies have directly replaced cement with stone powder in equal quantities. Jain et al. [

7] pointed out that the compressive strength of concrete with 20% of cement replaced by stone powder (by mass) is higher than that of plain concrete, and Alizada et al. [

14] also achieved positive results when applying stone powder to ultra-high-performance concrete. Additionally, studies by Nakayenga et al. [

15] and Pakkiyacha et al. [

16] have indicated that the application of stone powder in concrete can significantly reduce carbon emissions. Furthermore, stone powder has also been applied in other cement-based materials such as metakaolin-based geopolymers and cement-stabilized lateritic soil in existing research [

5,

17]. It can be seen from this that the application of reclaimed powder in cement-based materials is an important means for its large-scale resource utilization. As a commonly used cement-based material for high-grade highways in China, cement-stabilized macadam exhibits characteristics such as high strength, excellent integrity, good water stability, and frost resistance. The application of reclaimed powder in cement-stabilized macadam holds broad prospects and significant engineering value.

However, the practical application of reclaimed powder faces major challenges, mainly due to the small amount of mud powder it contains, which can degrade the performance of cement-based materials [

18,

19], leading to unstable performance of cement-based materials. Li et al. [

20] pointed out that the addition of mud powder has a negative impact on the workability of mortar and concrete; mud powder can wrap around cementitious material particles or aggregate interfaces, hindering the cement hydration process and the development of interface bonding strength and degrading the mechanical properties of cement mortar. Zhao et al. [

21] noted that mud powder itself has basically no cementitious activity, and its excessive presence can damage the aggregate skeleton and increase the risk of plastic deformation. It can be seen that the key to the resource utilization of reclaimed powder lies in revealing the influence law of mud powder on the performance of cement-based materials and controlling its negative impacts. However, existing studies often ignore the influence of mud powder characteristics on the performance of cement-based materials, mainly due to the lack of indicators effectively characterizing the mud powder content in reclaimed powder. In China’s engineering construction standards, such as Sand for Construction (GB/T 14684-2022) [

22] and Concrete for Railway Construction (TB/T 3275-2018) [

23], the methylene blue (MB) value is used to characterize the clay content in manufactured sand– and natural sand. Existing studies have confirmed [

4,

24,

25] that the MB value has a significant linear positive correlation with the mud powder content. The mud powder in reclaimed powder and that in manufactured sand (or natural sand) both originate from natural clay in sand and stone raw materials and are highly homologous. Therefore, it is practically feasible to evaluate the clay content of reclaimed powder using the MB value.

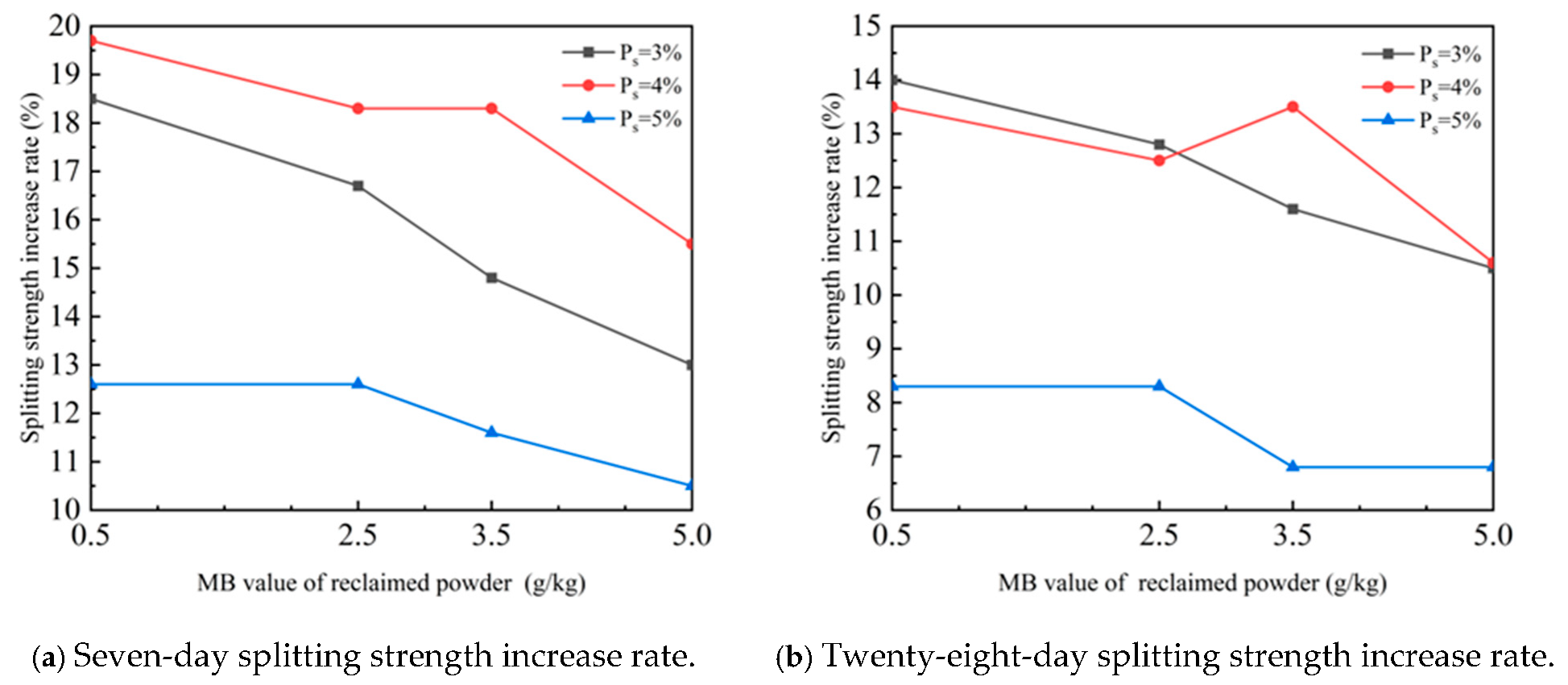

Therefore, this study investigates the influence laws of the MB value and content of reclaimed powder on the mechanical strength of cement-stabilized macadam, establishes fitting equations for the mechanical strength with respect to the reclaimed powder content, proposes the required MB value and recommended content of reclaimed powder, explores the influence amplitude of the MB value of reclaimed powder on mechanical strength under the optimal content, conducts an equivalence analysis between reclaimed powder and cement content, and puts forward the replaceable cement content. This study is conducive to improving the resource utilization rate of reclaimed powder and provides a reference basis for the application of reclaimed powder in cement-stabilized macadam.

4. Equivalence Analysis of Reclaimed Powder and Cement Content

The 7-day compressive strength and splitting strength are key indicators for determining whether cement-stabilized macadam meets the strength design requirements. Therefore, based on the principle of 7 days strength equivalence, the variation law of the influence of cement content on the mechanical properties of different types of cement-stabilized macadam is plotted in

Figure 10. In the figure, RP4-MB0.5 indicates the external addition of 4% reclaimed powder with an MB value of 0.5 g/kg, and the rest of the expressions follow the same rule.

(1) With the increase in cement content, the compressive strength and splitting strength of cement-stabilized macadam without reclaimed powder and with 4% reclaimed powder of various MB values all approximately show a linear increasing trend.

(2) Within the range of the reclaimed powder’s MB value of 0.5–5.0 g/kg, the 7 days compressive strength and 7 days splitting strength of cement-stabilized macadam with 4% reclaimed powder and 3% cement content are equivalent to those of cement-stabilized macadam without reclaimed powder with 3.8–4.0% and 3.4–3.6% cement content, respectively.

(3) Within the range of the reclaimed powder’s MB value of 0.5–5.0 g/kg, the 7 days compressive strength and 7 days splitting strength of cement-stabilized macadam with 4% reclaimed powder and 4% cement content are equivalent to those of cement-stabilized macadam without reclaimed powder with 4.8–5.0% and 4.4–4.5% cement content, respectively.

In summary, when the cement content is 3% or 4% and the reclaimed powder content is 4%, based on the principle of equivalent compressive strength and splitting strength, respectively, reclaimed powder can replace 0.8–1.0% or 0.4–0.6% of the cement content.

5. Comprehensive Benefit Analysis

5.1. Economic Benefits

When the reclaimed powder content is 4%, the cement dosage can be reduced by 0.4% to 0.6%, corresponding to a cement saving of 40 to 60 tons per 10,000 tons of cement-stabilized macadam. Based on the national market price of P.O 42.5 grade cement at CYN 358 per ton in December 2025, the direct economic benefits generated by cement saving are CNY 136,000, CNY 152,000, and CNY 168,000 per 10,000 cubic meters of C30, C40, and C50 concrete, respectively. For every 10,000 tons of cement-stabilized macadam, the direct economic benefit can reach CNY 14,000 to 21,000. Meanwhile, 400 tons of reclaimed powder can be absorbed per 10,000 tons of cement-stabilized macadam. Calculated at a landfill disposal cost of CNY 300 per ton, an additional disposal cost saving of CNY 152,000 can be achieved, further enhancing the economic feasibility of the technology application.

5.2. Social and Environmental Benefits

The production of 1 ton of cement consumes an average of approximately 200 kg of coal and 100 kWh of electricity, accompanied by 0.85 tons of CO2 emissions. By saving 40 to 60 tons of cement per 10,000 tons of cement-stabilized macadam, CO2 emissions can be reduced by 34.5 to 51.6 tons, lowering the carbon emission intensity of cement production. Furthermore, the combustion of coal during cement production releases toxic and harmful gases such as CO, SO2, and NOx, and the alternative application of reclaimed powder can indirectly reduce the emission of such pollutants. From the perspective of reclaimed powder disposal, its output is large but the resource utilization rate is relatively low. Except for a small amount used as filler in asphalt mixtures, most of it is disposed of through stacking or landfilling. During stacking disposal, particles with a particle size of ≤0.075 mm are prone to scattering under wind action, causing air pollution and threatening the health of surrounding populations. Landfill disposal not only occupies limited land resources but also may lead to groundwater pollution as reclaimed powder seeps into the ground after being washed by rainwater.

In summary, the resourceful application of reclaimed powder in cement-stabilized macadam can not only save cement consumption and reduce resource depletion and pollutant emissions during cement production but also realize the efficient disposal of reclaimed powder, solving the problems of severe environmental pollution and high disposal costs. It boasts significant environmental and social benefits.

6. Conclusions

This study investigated the influence laws of the MB value and content of reclaimed powder on the compressive strength and splitting strength of cement-stabilized macadam, established fitting equations for the compressive strength and splitting strength with respect to the reclaimed powder content; proposed the required MB value and recommended content of reclaimed powder; explored the influence law of the reclaimed powder’s MB value on mechanical strength under this content condition; and analyzed the equivalence between reclaimed powder and cement content based on the principle of consistent mechanical strength. The main conclusions are as follows:

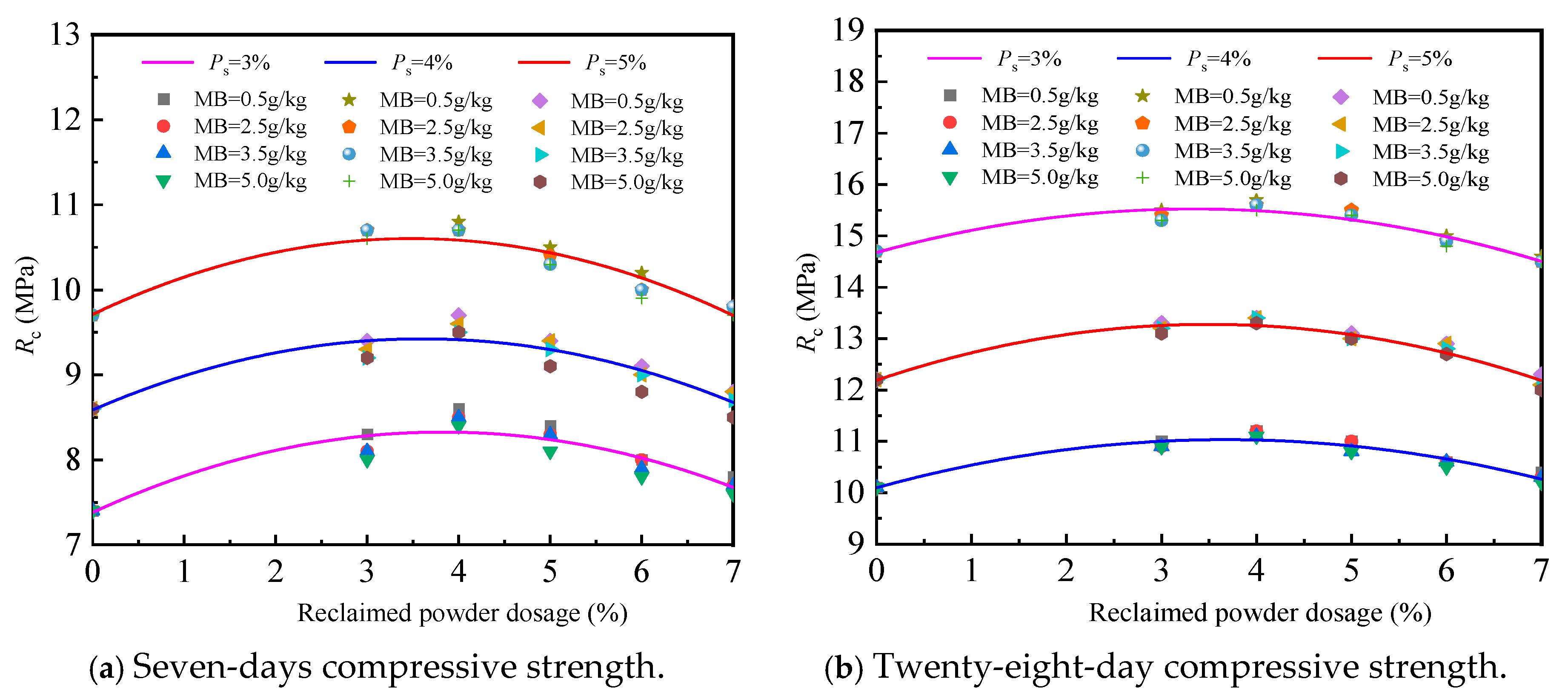

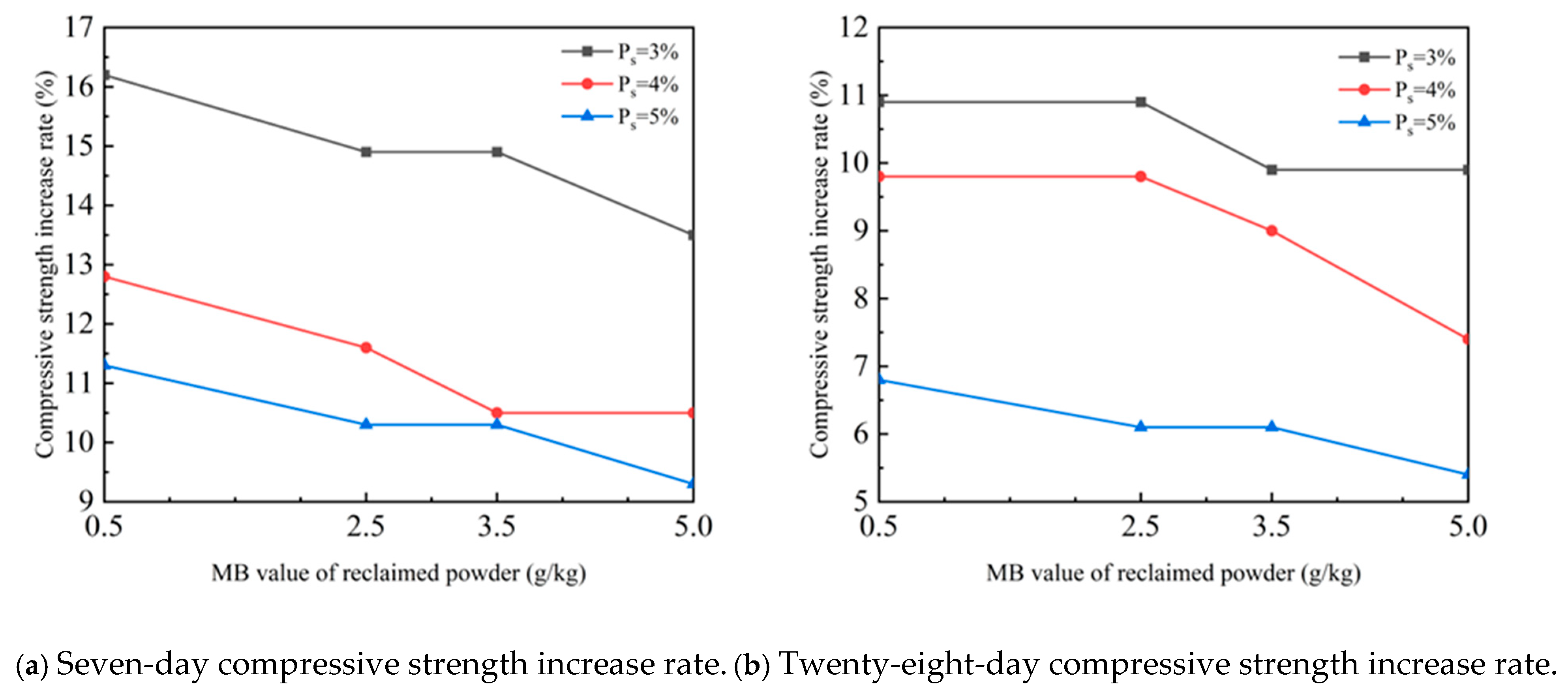

(1) Within the MB value range of the reclaimed powder adopted in the test (≤5.0 g/kg), the mechanical strength of cement-stabilized macadam decreases slightly with the increase in the reclaimed powder’s MB value, but the maximum reduction amplitude does not exceed 4.2%.

(2) When the reclaimed powder content is ≤7%, the mechanical strength of cement-stabilized macadam shows a trend of first increasing and then decreasing with the increase in the reclaimed powder content. The compressive strength and splitting strength reach their peak values when the reclaimed powder content is 3.0–4.0% and 5.0–5.5%, respectively.

(3) Compared with the case without reclaimed powder, the 7 days compressive strength and splitting strength of cement-stabilized macadam with 4% reclaimed powder can be increased by at least 9.3% and 10.5%, respectively, and the 28 days compressive strength and splitting strength can be increased by at least 5.4% and 6.8%, respectively. The addition of reclaimed powder can significantly improve the strength of cement-stabilized macadam and is more conducive to the formation of early strength.

(4) With higher cement content, the improvement effect of reclaimed powder on the mechanical strength of cement-stabilized macadam gradually becomes weaker. Considering mechanical strength and economic benefits comprehensively, when the cement content is 3–4%, adding 4% reclaimed powder can replace at least 0.4–0.5% of the cement content.