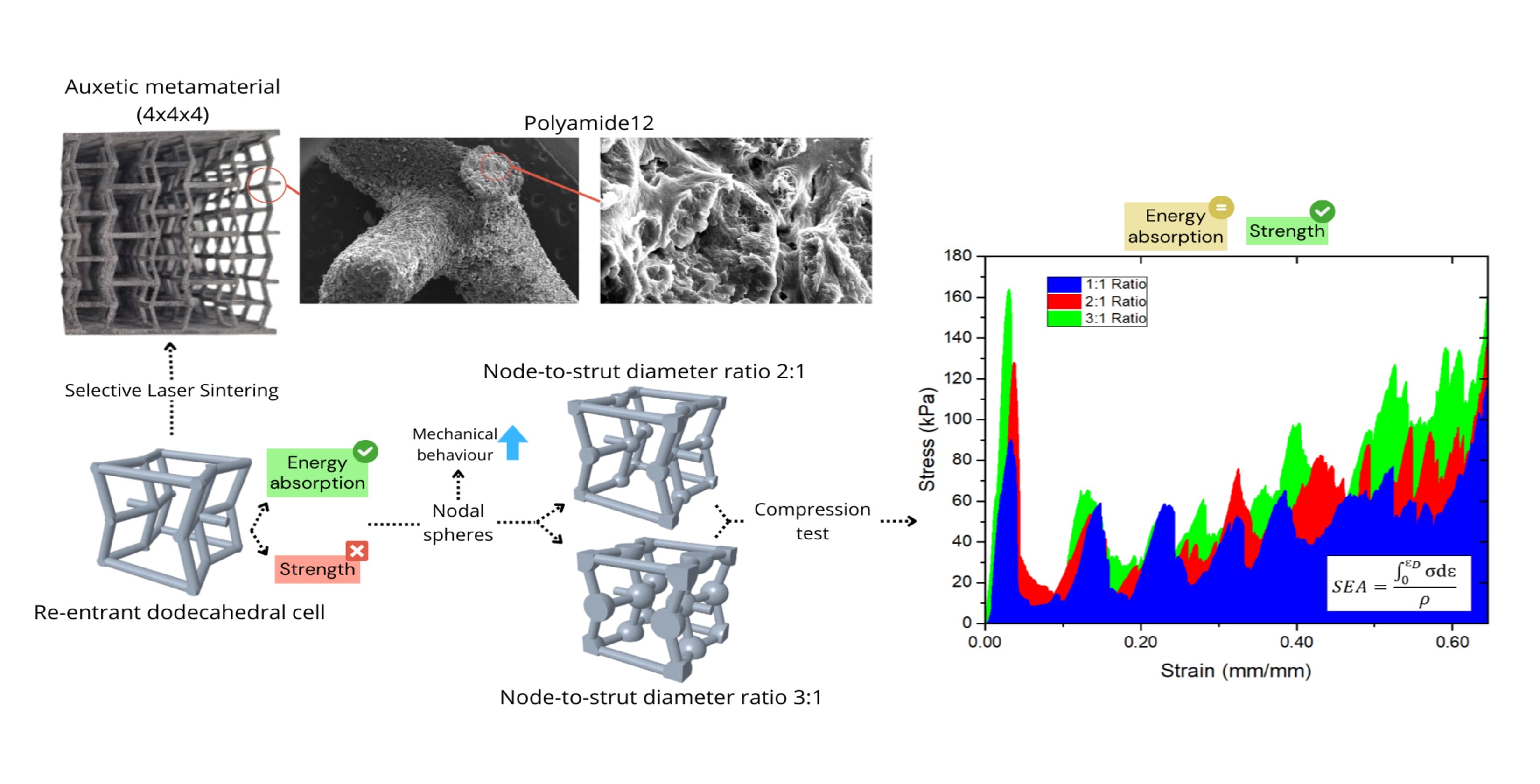

Influence of Nodal Spheres on the Mechanical Behaviour of Auxetic Materials Manufactured with PA12

Abstract

Share and Cite

Lamas, I.; Feijoo, I.; Gómez, S.; Pereira, A.; Pérez, J.A.; Pérez, M.C. Influence of Nodal Spheres on the Mechanical Behaviour of Auxetic Materials Manufactured with PA12. Materials 2025, 18, 5688. https://doi.org/10.3390/ma18245688

Lamas I, Feijoo I, Gómez S, Pereira A, Pérez JA, Pérez MC. Influence of Nodal Spheres on the Mechanical Behaviour of Auxetic Materials Manufactured with PA12. Materials. 2025; 18(24):5688. https://doi.org/10.3390/ma18245688

Chicago/Turabian StyleLamas, Ismael, Iria Feijoo, Silvia Gómez, Alejandro Pereira, José A. Pérez, and M. Consuelo Pérez. 2025. "Influence of Nodal Spheres on the Mechanical Behaviour of Auxetic Materials Manufactured with PA12" Materials 18, no. 24: 5688. https://doi.org/10.3390/ma18245688

APA StyleLamas, I., Feijoo, I., Gómez, S., Pereira, A., Pérez, J. A., & Pérez, M. C. (2025). Influence of Nodal Spheres on the Mechanical Behaviour of Auxetic Materials Manufactured with PA12. Materials, 18(24), 5688. https://doi.org/10.3390/ma18245688