Nano Carbon-Based Hybrid Strategies for Mitigating Silicon Anode Expansion in Lithium-Ion Batteries: A Comprehensive Review

Abstract

1. Introduction

2. Applications of Nano Carbons

2.1. MWCNT Strategies for Structurally Stable Si Anodes

2.2. SWCNT Strategies for Structurally Stable Silicon Anodes

2.3. Graphene Strategies for Structurally Stable Silicon Anodes

3. Applications of Other Carbon Materials

4. Commercialization Status and Production Technologies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Manthiram, A. An outlook on lithium ion battery technology. ACS Cent. Sci. 2017, 3, 1063–1069. [Google Scholar] [CrossRef] [PubMed]

- Baboukani, A.R.; Khakpour, I.; Adelowo, E.; Drozd, V.; Shang, W.; Wang, C. High-performance red phosphorus-sulfurized polyacrylonitrile. Electrochim. Acta 2020, 345, 136227. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.; Liu, L.; Zhao, J.; Zhang, W.; Bao, R.; Wang, L.; Yang, J.; Li, Y.; Jing, Z. Strategies, Perspectives, and Challenges of Improving the Initial Coulombic Efficiency and Tap Density of Sn-Based Anode Materials for Lithium-Ion Batteries. Chem. Eng. J. 2024, 495, 152444. [Google Scholar] [CrossRef]

- McDowell, M.T.; Lee, S.W.; Nix, W.D.; Cui, Y. 25th Anniversary Article: Understanding the Lithiation of Silicon and Other Alloying Anodes for Lithium-Ion Batteries. Adv. Mater. 2013, 25, 4966–4985. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Yan, S.; Ali, M.; Mahmood, F.; Zheng, Y.; Li, G.; Liu, J.; Song, X.; Wang, Y. Innovative Solutions for High-Performance Silicon Anodes in Lithium-Ion Batteries: Overcoming Challenges and Real-World Applications. Nano-Micro Lett. 2024, 16, 179. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Xu, W.; Li, Z.; Hu, Z.; Yang, J.; Qin, G.; Teng, W.; Zhang, T.; Zhang, W.; Sun, Z.; et al. Structural Design and Challenges of Micron-Scale Silicon-Based Lithium-Ion Batteries. Adv. Sci. 2025, 12, 2407540. [Google Scholar] [CrossRef]

- He, Z.; Zhang, C.; Zhu, Z.; Yu, Y.; Zheng, C.; Wei, F. Advances in Carbon Nanotubes and Carbon Coatings as Conductive Networks in Silicon-Based Anodes. Adv. Funct. Mater. 2024, 34, 2408285. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, N.; Cui, Y. Promises and challenges of nanomaterials for lithium-based rechargeable batteries. Nat. Energy 2016, 1, 16071. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Dou, Y.; Cheng, N.; Cui, D.; Du, Y.; Liu, P.; Al-Mamun, M.; Zhang, S.; Zhao, H. A Yolk–Shell Structured Silicon Anode with Superior Conductivity and High Tap Density for Full Lithium-Ion Batteries. Angew. Chem. Int. Ed. 2019, 58, 8824. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, J.; Dong, Z.; Zhan, Y.; Xi, J.; Xiao, J.; Huang, S.; Tian, F. Pd–Fe bimetallic nanoparticles anchored on N-doped carbon-modified graphene for efficient catalytic organic reactions. Carbon Let. 2023, 33, 77–87. [Google Scholar] [CrossRef]

- Dhason, M.V.A.; Bhattacharya, I.; Mansour, M.; Lazer, S.J.; Banik, T.; Soyoye, B. Conductive polymers in Si anodes for Lithium-ion batteries: Advancements, challenges and future aspects. Mater. Today Energy 2025, 51, 101897. [Google Scholar] [CrossRef]

- Mei, Y.; He, Y.; Zhu, H.; Ma, Z.; Pu, Y.; Chen, Z.; Li, P.; He, L.; Wang, W.; Tang, H. Recent Advances in the Structural Design of Silicon/Carbon Anodes for Lithium Ion Batteries: A Review. Coatings 2023, 13, 436. [Google Scholar] [CrossRef]

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Panachikkool, M.; Pandiyarajan, T. Graphene quantum dots as game-changers in solar cell technology: A review of synthetic processes and performance enhancement. Carbon Let. 2024, 34, 445–475. [Google Scholar] [CrossRef]

- Li, F.; Anjarsari, Y.; Wang, J.; Azzahiidah, R.; Jiang, J.; Zou, J.; Xiang, K.; Ma, H.; Arramel. Modulation of the lattice structure of 2D carbon-based materials for improving photo/electric properties. Carbon Let. 2023, 33, 1321–1331. [Google Scholar] [CrossRef]

- Hughes, K.J.; Lyer, K.A.; Bird, R.E.; Ivanov, J.; Banerjee, S.; Georges, G.; Zhou, Q.A. Review of Carbon Nanotube Research and Development: Materials and Emerging Applications. ACS Appl. Nano Mater. 2024, 7, 18695–18713. [Google Scholar] [CrossRef]

- Asghar, F.; Murtaza, B.; Shakoor, B.; Lqbal, N.; Shafique, M.; Murtaza, R.; Butler, I.S. Properties, assembly and characterization of carbon nanotubes: Their application in water purification, environmental pollution control and biomedicines—A comprehensive review. Carbon Let. 2023, 33, 275–306. [Google Scholar] [CrossRef]

- Lau, C.H.; Cervini, R.; Clarke, S.R.; Ginic-Markovic, M.; Matisons, J.G.; Hawkins, S.C.; Huynh, C.P.; Simon, G.P. The effect of functionalization on structure and electrical conductivity of multi-walled carbon nanotubes. J. Nanopart. Res. 2008, 10 (Suppl. 1), 77–88. [Google Scholar] [CrossRef]

- Osler, K.; Dheda, D.; Ngoy, J.; Wagner, N.; Daramola, M.O. Synthesis and evaluation of carbon nanotubes composite adsorbent for CO2 capture: A comparative study of CO2 adsorption capacity of single-walled and multi-walled carbon nanotubes. Int. J. Coal Sci. Technol. 2017, 4, 41–49. [Google Scholar] [CrossRef]

- Hasegawa, K.; Noda, S. Lithium ion batteries made of electrodes with 99 wt% active materials and 1 wt% carbon nanotubes without binder or metal foils. J. Power Sources 2016, 321, 155–162. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Liow, J.Y.H.; Sekulic, D.P. Minimum exergy requirements for the manufacturing of carbon nanotubes. In Proceedings of the 2010 IEEE International Symposium on Sustainable Systems and Technology, Arlington, VA, USA, 17–19 May 2010; pp. 1–5. [Google Scholar]

- Park, J.G.; Yun, N.G.; Park, Y.B.; Liang, R.; Lumata, L.; Brooks, J.S.; Zhang, C. Single-walled carbon nanotube buckypaper and mesophase pitch carbon/carbon composites. Carbon 2010, 48, 4276–4282. [Google Scholar] [CrossRef]

- Birch, M.E.; Ruda-Eberenz, T.A.; Chai, M.; Andrews, R.; Hatfield, R.L. Properties that influence the specific surface areas of carbon nanotubes and nanofibers. Ann. Occup. Hyg. 2013, 57, 1148–1166. [Google Scholar] [PubMed][Green Version]

- Isaacs, J.A.; Tanwani, A.; Healy, M.L.; Dahlben, L.J. Economic assessment of single-walled carbon nanotube processes. J. Nanopart. Res. 2010, 12, 551–562. [Google Scholar] [CrossRef]

- Jeong, S.; Yang, S.; Kim, B.G.; Lee, H.J.; Bae, J.J.; Kim, J.H.; Kim, J.M.; Lee, W.; Hwang, J.Y.; Choi, S.; et al. Highly conductive quasi-defect-free reduced graphene oxide for qualitative scalable production. Carbon 2023, 203, 221–229. [Google Scholar] [CrossRef]

- Mokhtar, M.; El Enein, S.A.; Hassaan, M.; Morsy, M.; Khalil, M. Thermally reduced graphene oxide: Synthesis, structural and electrical properties. Int. J. Nanopart. Nanotechnol. 2017, 3, 8. [Google Scholar]

- GrapheneRich. How Much Does Graphene for Battery Cost? 2024. Available online: https://graphenerich.com/how-much-does-graphene-for-battery-cost/ (accessed on 2 December 2025).

- Arvidsson, R.; Molander, S.; Sandén, B.A.; Håroz, M.K.L.; Hjelm, L.H.T.; Olstenberg, R.G.L. Prospective life cycle assessment of graphene production by ultrasonication and chemical reduction. Environ. Sci. Technol. 2014, 48, 4529–4536. [Google Scholar] [CrossRef] [PubMed]

- Su, P.; Zhang, H.; Yang, L.; Xing, C.; Pan, S.; Lu, W.; Zhang, S. Effects of conductive additives on the percolation networks and rheological properties of LiMn0.7Fe0.3PO4 suspensions for lithium slurry battery. Chem. Eng. J. 2022, 433, 133203. [Google Scholar] [CrossRef]

- Yan, Y.; Xia, H.; Qiu, Y.; Xu, Z.; Ni, Q.-Q. Fabrication of gradient vapor-grown carbon fiber-based polyurethane foam for shape-memory-driven microwave shielding. RSC Adv. 2019, 9, 9401–9409. [Google Scholar] [CrossRef]

- Santos, P.; Silva, A.P.; Reis, P.N.B. The effect of carbon nanofibers on the mechanical performance of epoxy-based composites: A review. Polymers 2024, 16, 2152. [Google Scholar] [CrossRef]

- Lau, J.; Dey, G.; Licht, S. Thermodynamic assessment of CO2 to carbon nanofiber transformation for carbon sequestration in a combined cycle gas or a coal power plant. Energy Convers. Manag. 2016, 122, 400–410. [Google Scholar] [CrossRef]

- Smolianova, I.; Hu, J.-L.; Zhao, X.-Y.; Dementiev, V.; Zhang, L.-Z. A high-capacity graphene/mesocarbon microbead composite anode for lithium-ion batteries. J. Zhejiang Univ. Sci. A 2020, 21, 392–400. [Google Scholar] [CrossRef]

- Linda, G.; Cuenca, R. Costs of Lithium-Ion Batteries for Vehicles; No. ANL/ESD-42; Argonne National Lab.: Lemont, IL, USA, 2000. [Google Scholar]

- Pamula, E.; Rouxhet, P.G. Bulk and surface chemical functionalities of type III PAN-based carbon fibres. Carbon 2003, 41, 1905–1915. [Google Scholar] [CrossRef]

- Nagapurkar, P.; Lara-Curzio, E. Technoeconomic and life cycle energy analysis of carbon fiber manufactured from coal via a novel solvent extraction process. Int. J. Coal Sci. Technol. 2025, 12, 27. [Google Scholar] [CrossRef]

- Kulkarni, S.; Huang, T.-Y.; Thapaliya, B.P.; Luo, H.; Dai, S.; Zhao, F. Prospective life cycle assessment of synthetic graphite manufactured via electrochemical graphitization. ACS Sustain. Chem. Eng. 2022, 10, 13607–13618. [Google Scholar] [CrossRef]

- Reynolds, C.D.; Hare, S.D.; Slater, P.R.; Simmons, M.J.; Kendrick, E. Rheology and structure of lithium-ion battery electrode slurries. Energy Technol. 2022, 10, 2200545. [Google Scholar] [CrossRef]

- Chen, Y.; Du, N.; Zhang, H.; Yang, D. Facile synthesis of uniform MWCNT@Si nanocomposites as high-performance anode materials for lithium-ion batteries. J. Alloys Compd. 2015, 622, 966–972. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, K.; Ji, P.; Chen, D.; Zeng, J.; Sun, Y.; Zhang, P.; Zhao, J. Silicon–multi-walled carbon nanotubes–carbon microspherical composite as high-performance anode for lithium-ion batteries. J. Mater. Sci. 2017, 52, 3630–3641. [Google Scholar] [CrossRef]

- Nyamaa, O.; Seo, D.-H.; Lee, J.-S.; Jeong, H.-M.; Huh, S.-C.; Yang, J.-H.; Dolgor, E.; Noh, J.-P. High electrochemical performance silicon thin-film free-standing electrodes based on buckypaper for flexible lithium-ion batteries. Materials 2021, 14, 2053. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, X.; Wei, C. Improving the electrochemical performance of lithium–silicon alloy anode using a conductive carbon nanotube network. Ionics 2020, 26, 1149–1158. [Google Scholar] [CrossRef]

- Xu, R.; Wei, R.; Hu, X.; Li, Y.; Wang, L.; Zhang, K.; Wang, Y.; Zhang, H.; Liang, F.; Yao, Y. A strategy and detailed explanations to the composites of Si–MWCNTs for lithium storage. Carbon 2021, 171, 265–275. [Google Scholar] [CrossRef]

- Liu, X.; Chen, W.; Xia, Y.; Li, Q. Improved electrochemical performance of silicon–carbon anodes by different conductive agents. J. Mater. Sci. 2022, 33, 21311–21320. [Google Scholar] [CrossRef]

- Choi, M.; Sung, J.; Yeo, G.; Chae, S.; Ko, M. A strategy of boosting the effect of carbon nanotubes in graphite-blended silicon anodes for lithium-ion batteries. J. Energy Storage 2023, 72, 108301. [Google Scholar] [CrossRef]

- Huang, S.; Fedorov, R.G.; Ein-Eli, Y. Silicon-coated multi-walled carbon nanotube (MWCNT) tissues as flexible free-standing anodes for advanced Li-ion batteries. J. Solid State Electrochem. 2024, 28, 2139–2149. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Liu, Y.; Huang, G.; Zhang, P.; Ma, X.; Gao, F.; Zhang, Z.; Wang, Y.; Wang, Y. Enhancing lithium-ion batteries with a 3D conductive network silicon–carbon nanotube composite anode. ACS Appl. Mater. Interfaces 2024, 16, 67791–67802. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Zhu, Y.; Williams, P.J.; Kabbani, M.; Brushett, F.R.; Rupp, J.L.M. Insights into Li+ storage mechanisms, kinet-ics, and reversibility of defect-engineered and functionalized multi-walled carbon nanotubes for enhanced energy storage. J. Mater. Chem. A 2024, 12, 4299–4311. [Google Scholar] [CrossRef]

- Ünal, L.; Maccio-Figgemeier, V.; Haneke, L.; Eshetu, G.G.; Kasnatscheew, J.; Winter, M.; Figgemeier, E. Prelithiated Carbon Nanotube–Embedded Silicon-Based Negative Electrodes for High-Energy Lithium-Ion Full Cells. Adv. Mater. Interfaces 2024, 11, 2400024. [Google Scholar] [CrossRef]

- Ji, H.; Han, Z.; Li, X.; Xu, X.; Yu, S.; Yuan, L.; Li, M.; Ji, R.; Tang, K. Synthesis of MWCNT–Si@Ag@CN composite with improved lithium storage performance from photovoltaic kerf loss Si waste. Ionics 2025, 31, 5465–5477. [Google Scholar] [CrossRef]

- Çakmakçı, N.; Shin, M.; Jung, H.; Lee, J.; Jeong, Y. One-step copper electroplating of carbon nanotube buckypaper using optimized electrolyte with additive chemicals. Carbon Let. 2023, 33, 1035. [Google Scholar] [CrossRef]

- Devarajan, J.; Arumugam, P. Nitrogen and phosphorous co-doped carbon nanotubes for high-performance supercapacitors. Carbon Let. 2023, 33, 1615–1627. [Google Scholar] [CrossRef]

- Tang, S.; Liang, A.; Liu, M.; Wang, W.; Zhang, F.; Luo, A. A glassy carbon electrode modified with a composite consisting of electrodeposited chitosan and carboxylated multi-walled carbon nanotubes for simultaneous voltammetric determination of dopamine, serotonin and melatonin. Carbon Let. 2023, 33, 2129–2139. [Google Scholar] [CrossRef]

- He, Z.; Xiao, Z.; Yue, H.; Jiang, Y.; Zhao, M.; Zhu, Y.; Yu, C.; Zhu, Z.; Lu, F.; Jiang, H.; et al. Single-Walled Carbon Nanotube Film as an Efficient Conductive Network for Si-Based Anodes. Adv. Funct. Mater. 2023, 33, 2300094. [Google Scholar] [CrossRef]

- Yap, J.W.; Wang, T.; Cho, H.; Kim, J.-H. Comparison of carbon-nanofiber and carbon-nanotube as conductive additives in Si anodes for high-energy lithium-ion batteries. Electrochim. Acta 2023, 446, 142108. [Google Scholar] [CrossRef]

- Lee, D.G.; Cho, J.Y.; Kim, J.H.; Ryoo, G.; Jo, A.; Lee, M.H.; Park, J.H.; Yoo, J.-K.; Lee, D.Y.; Choi, J.-H.; et al. Dispersant-Free Colloidal and Interfacial Engineering of Si-Nanocarbon Hybrid Anode Materials for High-Performance Li-Ion Batteries. Adv. Funct. Mater. 2024, 34, 2311353. [Google Scholar] [CrossRef]

- Park, G.; Moon, H.; Shin, S.; Lee, S.; Lee, Y.; Choi, N.-S.; Hong, S. Spatially Uniform Lithiation Enabled by Single-Walled Carbon Nanotubes. ACS Energy Lett. 2023, 8, 3154–3160. [Google Scholar] [CrossRef]

- Gueon, D.; Ren, H.; Sun, Z.; Mosevitzky Lis, B.; Nguyen, D.D.; Takeuchi, E.S.; Marschilok, A.C.; Takeuchi, K.J.; Reich-manis, E. Stress-Relieving Carboxylated Polythiophene/Single-Walled Carbon Nanotube Conductive Layer for Stable Sili-con Microparticle Anodes in Lithium-Ion Batteries. ACS Appl. Energy Mater. 2024, 7, 7220–7231. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Xu, Y.; Chen, L.; Xie, J.; Jiang, L.; Liang, Z.; Zang, G.; Zhang, Z. A 3D flexible conductive network skeleton by SWCNT-COOH and PVA-PAA enabling high performance for Si anode. Chem. Eng. J. 2024, 499, 156644. [Google Scholar] [CrossRef]

- Kang, W.; Zhang, Q.; Jia, Y.; Liu, X.; Jiang, N.; Zhao, Y.; Wu, C.; Guan, L. Enhancing the cycling stability of commercial silicon nanoparticles by carbon coating and thin layered single-walled carbon nanotube webbing. J. Power Sources 2024, 602, 234338. [Google Scholar] [CrossRef]

- Wang, H.; Chao, Y.; Li, J.; Qi, Q.; Lu, J.; Yan, P.; Nie, Y.; Wang, L.; Chen, J.; Cui, X. What Is the Real Origin of Single-Walled Carbon Nanotubes for the Performance Enhancement of Si-Based Anodes? J. Am. Chem. Soc. 2024, 146, 17041–17053. [Google Scholar] [CrossRef]

- He, Z.; Zhang, C.; Zhu, Y.; Wei, F. The acupuncture effect of carbon nanotubes induced by the volume expansion of silicon-based anodes. Energy Environ. Sci. 2024, 17, 3358–3364. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Kim, N.; Cha, H.; Kim, S.; Sung, J.; Cho, J. Unraveling the impact of CNT on electrode expansion in silicon-based lithium-ion batteries. Energy Storage Mater. 2025, 74, 103983. [Google Scholar] [CrossRef]

- Choi, M.S.; Jung, M.K.; Rana, H.H.; Park, H.S. Organic nanorods deposited onto the carbon nanotube networks for flexible zinc-ion batteries. Carbon Let. 2024, 34, 25–39. [Google Scholar] [CrossRef]

- Rublova, Y.; Meija, R.; Lazarenko, V.; Andzane, J.; Svirksts, J.; Erts, D. Modification of Single-Walled Carbon Nanotube Networks Anodes for Application in Aqueous Lithium-Ion Batteries. Batteries 2023, 9, 260. [Google Scholar] [CrossRef]

- Liu, B.; Li, X.; Li, S. Pavement performance analysis of carbon nanotube/SBS composite modified asphalt. Carbon Let. 2024, 34, 343–350. [Google Scholar] [CrossRef]

- Dressler, R.A.; Dahn, J.R. Optimization of Si-containing and SiO based Anodes with Single Walled Carbon Nanotubes for High Energy Density Applications. J. Electrochem. Soc. 2024, 171, 030520. [Google Scholar] [CrossRef]

- Zhang, D.; Yuan, T.; Zhang, H.; Shi, S.; Wang, X.; Ding, R.; He, Y. Research progress of carbon nanotubes as anode materials for lithium-ion batteries: A mini review. Carbon Let. 2024, 34, 2055–2079. [Google Scholar] [CrossRef]

- Idisi, D.O.; Aigbe, U.O.; Ahia, C.C.; Meyer, E.L. Graphene oxide: Fe2O3 nanocomposite: Synthesis, properties, and applications. Carbon Let. 2023, 33, 605–640. [Google Scholar] [CrossRef]

- Saaadaoui, J.R.M.; Djenizian, T. Synthesis and Structural Design of Graphene, Silicon and Silicon-Based Materials Including Incorporation of Graphene as Anode to Improve Electrochemical Performance in Lithium-Ion Batteries. Adv. Mater. Interface 2024, 11, 2301062. [Google Scholar]

- Toyoda, M.; Hou, S.; Huang, Z.H.; Inagaki, M. Exfoliated graphite: Room temperature exfoliation and their applications. Carbon Let. 2023, 33, 335–362. [Google Scholar] [CrossRef]

- Ni, C.; Xia, C.; Liu, W.; Xu, W.; Shan, Z.; Lei, X.; Qin, H.; Tao, Z. Effect of Graphene on the Performance of Silicon–Carbon Composite Anode Materials for Lithium-Ion Batteries. Materials 2024, 17, 754. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, C.R. Correlation between graphite morphology and interparticle space affecting rate performance in Li-ion battery anodes. Carbon Let. 2024, 34, 627–636. [Google Scholar] [CrossRef]

- Son, I.H.; Park, J.H.; Kwon, S.; Park, S.; Rümmeli, M.H.; Bachmatiuk, A.; Song, H.J.; Ku, J.; Choi, J.W.; Choi, J.-M.; et al. Silicon Carbide-Free Graphene Growth on Silicon for Lithium-Ion Battery with High Volumetric Energy Density. Nat. Commun. 2015, 6, 7393. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Yang, C.; Wu, S.; Wu, Z.; Wei, C.; Yang, M.; Lue, S. Preparation of ternary hierarchical silicon/reduced graphene oxide/carbon composites as anodes for lithium-ion batteries. J. Alloys Compd. 2019, 793, 433–445. [Google Scholar] [CrossRef]

- Huang, G.; Han, J.; Lu, Z.; Wei, D.; Kashani, H.; Watanabe, K.; Chen, M. Ultrastable Silicon Anode by Three-Dimensional Nanoarchitecture Design. ACS Nano 2020, 14, 4374–4382. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Wang, L.; Wang, D.; Huang, R.; Wang, C.; Chen, G.; Miao, C.; Peng, Y.; Li, A.; Miao, Y. Crucial Contact Interface of Si@Graphene Anodes for High-Performance Li-Ion Batteries. Appl. Surf. Sci. 2022, 603, 154383. [Google Scholar] [CrossRef]

- Lee, L.; To A Ran, W.; Lee, J.-H.; Hwang, S.M.; Kim, Y.-J. Self-Adaptive Anode Design with Graphene-Coated Si-Ox/Graphite for High-Energy Li-Ion Batteries. Chem. Eng. J. 2022, 442, 136166. [Google Scholar] [CrossRef]

- Shang, Z.; Liu, X.; Liu, J.; Liu, B.; Yu, Q.; Lai, Z.; Ding, N.; Zhong, S.; Li, X. Double core-shell structure stabilized porous Si@graphene@TiO2 microsphere anode with excellent cyclability and high coulombic efficiency. Electrochim. Acta 2022, 407, 139893. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, Y.; Song, J.; Zhang, Y.; Shi, Q.; Wang, J.; Tian, F.; Yuan, S.; Su, Z.; Zhou, C.; et al. Func-tionalization-assisted ball milling towards Si/graphene anodes in high performance Li-ion batteries. Carbon 2021, 181, 300–309. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Z.; Pan, S.; Wang, Y.; Chi, S.; Yi, X.; Han, J.; Kong, D.; Xiao, J.; Wei, W.; et al. Covalent Coating of Micro-Sized Silicon With Dynamically Bonded Graphene Layers Toward Stably Cycled Lithium Storage. Adv. Energy Mater. 2023, 13, 2300874. [Google Scholar] [CrossRef]

- Mery, A.; Chenavier, Y.; Marcucci, C.; Benayad, A.; Alper, J.P.; Dubois, L.; Haon, C.; Herlin Boime, N.; Sadki, S.; Duclairoir, F. Toward the Improvement of Silicon-Based Composite Electrodes via an In-Situ Si@C-Graphene Composite Syn-thesis for Li-Ion Battery Applications. Materials 2023, 16, 2451. [Google Scholar] [CrossRef]

- Liang, Y.-Z.; Hsu, T.-Y.; Su, Y.-S. Tailoring the Size of Reduced Graphene Oxide Sheets to Fabricate Silicon Composite Anodes for Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2024, 16, 29226–29234. [Google Scholar] [CrossRef]

- Jiao, M.; Song, Z.; Zhang, Y.; Ye, C. A three-dimensional printed Si/rGO anode for flexible Li-ion batteries. J. Mater. Chem. A 2024, 12, 25047–25055. [Google Scholar] [CrossRef]

- Kim, B.G.; Ryu, J.; Nam, K.-H.; Jeong, S.; Lee, H.J.; Kim, J.; Hong, D.G.; Kwon, O.S.; Yang, S.; Jeong, S.Y. One-Step Core-Shell Structuring of Silicon Graphene Composite Anode Materials by Aqueous Reduced Graphene Oxide: Toward Practical Use of High-Performance Lithium-Ion Battery. Energy Environ. Mater. 2025, e70086. [Google Scholar] [CrossRef]

- Cen, Y.; Qin, Q.; Tao, M.; Sisson, R.D.; Liang, J. The influence of Graphene quality on performance of a Si/Graphene nano-composite anode. Mater. Sci. Technol. 2019, 35, 725–730. [Google Scholar] [CrossRef]

- Cen, Y.; Sisson, R.D.; Qin, Q.; Liang, J. Current Progress of Si/Graphene Nanocomposites for Lithium-Ion Batteries. C 2018, 4, 18. [Google Scholar] [CrossRef]

- Kim, J.A.; Kim, D.K.; Shin, H.K.; Jeong, S.W.; Hong, Y.H.; Kang, B.J.; Ahn, W.; Sure, J.; Kim, H.K. Nanoperforated graphene hosts for stable lithium metal anodes. Carbon Let. 2024, 34, 2027–2033. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, Z.; Hu, X.; Liu, X.; Wang, H. Silicon in Hollow Carbon Nanospheres Assembled Microspheres Cross-linked with N-doped Carbon Fibers toward a Binder-Free, High-Performance, and Flexible Anode for Lithium-Ion Batteries. Adv. Funct. Mater. 2021, 31, 2101487. [Google Scholar] [CrossRef]

- Mu, Y.; Han, M.; Wu, B.; Wang, Y.; Li, Z.; Li, J.; Li, Z.; Wang, S.; Wan, J.; Zeng, L. Nitrogen, Oxygen-Codoped Vertical Graphene Arrays Coated 3D Flexible Carbon Nanofibers with High Silicon Content as an Ultrastable Anode for Superior Lithium Storage. Adv. Sci. 2022, 9, 2104685. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, Y.; Chang, A.-Y.; Liao, Y.; Zhang, S.; Wen, X.; Wang, S. Nanofiber-in-microfiber carbon/silicon composite anode with high silicon content for lithium-ion batteries. Carbon 2023, 203, 436–444. [Google Scholar] [CrossRef]

- Mashio, T.; Tomaru, T.; Shimanoe, H.; Ha, S.-J.; Jeon, Y.-P.; Nakabayashi, K.; Miyawaki, J.; Yoon, S.-H. Analysis of Spinnable Mesophase Pitch in Terms of Lyotropic Liquid Crystalline Solution. Carbon Lett. 2023, 33, 713–726. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, Y.-J.; Lee, H.-M.; Kim, B.-J. Preparation and Characterization of Pitch-Derived Activated Carbon Pellet for Butane Adsorption. Carbon Lett. 2024, 34, 691–701. [Google Scholar] [CrossRef]

- Abrego-Martinez, J.C.; Wang, Y.; Vanpeene, V.; Roué, L. From waste graphite fines to revalorized anode material for Li-ion batteries. Carbon 2023, 209, 118004. [Google Scholar] [CrossRef]

- Yi, S.; Su, M.; Yan, Z.; Zhang, Y.; Xiao, Y.; Zhang, X.; Wang, Z.; Ning, P.; Yang, D.; Du, N. Unlocking the influence of pitch-based and acetylene-based carbon coating on the electrochemical performance of SiO anodes: Bridging insights from half-cell to full-cell studies. Carbon 2024, 228, 119367. [Google Scholar] [CrossRef]

- Kim, K.N.; Kang, S.C.; Seo, S.W.; Seo, D.J.; Im, J.S.; Lee, S.H.; Seog, J.Y. Effects of macrostructure of carbon support in preparation of C/Six/C anode materials for lithium-ion batteries via silane decomposition. Carbon Lett. 2024, 34, 2305–2316. [Google Scholar] [CrossRef]

- Chen, C.Y.; Liang, A.H.; Huang, C.L.; Hsu, T.H.; Li, Y.Y. The pitch-based silicon-carbon composites fabricated by electrospraying technique as the anode material of lithium ion battery. J. Alloys Compd. 2020, 844, 156025. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, W.; Cao, Y.; Zhang, H.; Zhu, W. N-, P-co-doped hierarchically porous carbon fiber derived from bamboo pulp as efficient carbocatalyst for reduction of 4-nitrophenol. Carbon Let. 2024, 34, 2137–2148. [Google Scholar] [CrossRef]

- Panasonic Energy Co., Ltd. Panasonic Energy Partners with Sila for Procurement of Next-Generation Silicon Anode Material for EV Batteries. 2023. Available online: https://news.panasonic.com/global/press/en231212-3 (accessed on 2 December 2025).

- Amprius Technologies, Inc. Amprius Launches SiCore™ 450 Wh/kg High-Energy Cell with Near-Term Mass-Production Capability to Scale. 2025. Available online: https://ir.amprius.com/news-events/press-releases/detail/129/amprius-launches-sicore-450-whkg-high-energy-cell-with-near-term-mass-production-capability-to-scale (accessed on 2 December 2025).

- Group14 Technologies. Group14 Closes US$463M Series D Funding Round and Acquires 100% Ownership of BAM Factory in South Korea from SK, Inc. 2025. Available online: https://group14.technology/resources/press-releases/group14-closes-us463m-series-d-funding-round-and-acquires-100-ownership-of-bam-factory-in-south-korea-from-sk-inc/ (accessed on 2 December 2025).

- OneD Battery Sciences. News & Press: SINANODE® Platform Overview and Updates. 2024–2025. Available online: https://onedsinanode.com/media-room/news-and-press/ (accessed on 2 December 2025).

- BTR New Material Group Co., Ltd. Silicon-Based Anode (Anode Products). 2025. Available online: https://www.btrchina.com/en/NegativeProducts/index.aspx?lcid=76 (accessed on 2 December 2025).

- Nexeon. Nexeon Breaks Ground on First Silicon Anode Material Production Site, Securing Path to 2025 Delivery. 2024. Available online: https://www.nexeonglobal.com/media/groundbreaking-on-first-volume-production-site (accessed on 2 December 2025).

- Primc, G.; Mozetic, M. Surface Modification of Polymers by Plasma Treatment for Appropriate Adhesion of Coatings. Materials 2024, 17, 1494. [Google Scholar] [CrossRef]

- Nguyen, T.; Su, Y.S. A self-assembled carbon nanotube/silicon composite battery anode stabilized with chemically reduced graphene oxide sheets. Mater. Des. 2024, 240, 112861. [Google Scholar] [CrossRef]

- Malisz, K.; Zurek, B.S.; Sionkowska, A. Preparation and Characterization of Diamond-like Carbon Coatings for Biomedical Applications—A Review. Materials 2023, 16, 3420. [Google Scholar] [CrossRef]

- Church, R.B.; Gao, H.; Gallant, B.M.; Hart, A.J. Thick Architected Silicon Composite Battery Electrodes Using Honeycomb Patterned Carbon Nanotube Forests. J. Electrochem. Soc. 2023, 170, 090543. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhou, Z.; Chen, Q.; Tang, Y. Mo2C-Loaded Porous Carbon Nanosheets as a Multifunctional Separator Coating for High-Performance Lithium–Sulfur Batteries. Materials 2023, 16, 1635. [Google Scholar] [CrossRef]

- An, S.H.; Kim, K.Y.; Chung, C.W.; Lee, J.U. Development of cement nanocomposites reinforced by carbon nanotube dispersion using superplasticizers. Carbon Let. 2024, 34, 1481–1494. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, J.U.; Kim, S.H.; Hong, J.Y. Electrochemically exfoliated graphite as a highly efficient conductive additive for an anode in lithium-ion batteries. Battery Energy 2023, 2, 20230012. [Google Scholar] [CrossRef]

- Wood, D.L., III; Li, J.; Daniel, C. Prospects for Reducing the Processing Cost of Lithium Ion Batteries. J. Power Sources 2015, 275, 234–242. [Google Scholar] [CrossRef]

- Baade, P.; Wood, V. Ultra-High Throughput Manufacturing Method for Composite Solid-State Electrolytes. iScience 2021, 24, 102055. [Google Scholar] [CrossRef]

- Blomquist, N.; Phadatare, M.; Patil, R.; Zhang, R.; Leuschen, N.; Hummelgård, M. Large-Scale Compatible Roll-to-Roll Coating of Paper Electrodes and Their Compatibility as Lithium-Ion Battery Anodes. Nanomaterials 2025, 15, 113. [Google Scholar] [CrossRef]

- Baker, C.G.J.; McKenzie, K.A. Energy Consumption of Industrial Spray Dryers. Dry. Technol. 2005, 23, 365–386. [Google Scholar] [CrossRef]

- Chicinaș, H.-F. Water-Based Spray Drying of WC–Co Powders: A Sustainable Route to Environmentally Safer Granulation Without Compromising Performance. Powders 2025, 4, 25. [Google Scholar] [CrossRef]

- Lipton, J.; Weng, G.-M.; Röhr, J.A.; Wang, H.; Taylor, A.D. Layer-by-Layer Assembly of Two-Dimensional Materials: Meticulous Control on the Nanoscale. Matter 2020, 2, 1148–1165. [Google Scholar] [CrossRef]

- Seo, S.; Lee, S.; Park, Y.T. Note: Automatic Layer-by-Layer Spraying System for Functional Thin Film Coatings. Rev. Sci. Instrum. 2016, 87, 036110. [Google Scholar] [CrossRef]

- Rosenthal, T.; Weller, J.M.; Chan, C.K. Needleless Electrospinning for High-Throughput Production of Li7La3Zr2O12 Solid Electrolyte Nanofibers. Ind. Eng. Chem. Res. 2019, 58, 17399–17405. [Google Scholar] [CrossRef]

- Gilmore, T.S.; Gouma, P.-I. Scalable Electrospinning Using a Desktop, High-Throughput, Self-Contained System. Sci. Rep. 2024, 14, 25844. [Google Scholar] [CrossRef]

- Meshkova, A.S.; Elam, F.M.; Starostin, S.A.; van de Sanden, M.C.M.; de Vries, H.W. The Role of Carrier Gas Flow in Roll-to-Roll AP-PECVD Synthesized Silica Moisture Barrier Films. Surf. Coat. Technol. 2018, 339, 20–26. [Google Scholar] [CrossRef]

- Top, M.; Schönfeld, S.; Fahlteich, J.; Bunk, S.; Kühnel, T.; Straach, S.; De Hosson, J.T. Hollow-Cathode Activated PECVD for the High-Rate Deposition of Permeation Barrier Films. Surf. Coat. Technol. 2017, 314, 155–159. [Google Scholar] [CrossRef]

- Madocks, J.; Rewhinkle, J.; Barton, L. Packaging Barrier Films Deposited on PET by PECVD Using a New High-Density Plasma Source. Mater. Sci. Eng. B 2005, 119, 268–273. [Google Scholar] [CrossRef]

- Mottaghi, M.; Pearce, J.M. A Review of 3D Printing Batteries. Batteries 2024, 10, 110. [Google Scholar] [CrossRef]

| Materials | Electrical Conductivity (S/cm) | Specific Surface Area (m2/g) | Defect Content (ID/IG) | Cost ($/kg) | Precursor Cost ($/ton) | Slurry Viscosity at 1~2 wt%, 0.1 S−1 (η, mPa·s) | Number of Steps (in Battery Mfg.) | Overall Energy Consumption (kWh/kg) | Scalability (Tons/Year) | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|

| MWCNT | 10~500 | 10~300 | 0.7~1.2 | 50~300 | 600–1000 | 2000~5000 | 5~6 | 150–500 | 10,000–50,000 | [18,19,20,21] |

| SWCNT | 1000~10,000 | 800~1300 | 0.01~0.1 | 1500~2000 | 1400–3300 | >10,000 | 6~7 | 5000–20,000 | 100–200 | [21,22,23,24] |

| Graphene | 100~1500 | 300~1000 | 0.1 (CVD), 1.0–1.5 (rGO) | 50~500 | 1000–3000 | 3000~7000 | 6~7 | 50–200 (rGO) | 1000–5000 (rGO, GNP) | [25,26,27,28,29] |

| CNF | 5~100 | 20~300 | 0.9~1.3 | ~25 | 200–500 | 500~1500 | 5~6 | 100–300 | 300–1000 | [30,31,32] |

| Pitch-derived Carbon | 10~800 (MCMB), 2000~10,000 (CF) | 1~20 (MCMB), ~5 (CF) | 1.0~1.8 | 10~80 (MCMB), 20~100 (CF) | 700–1300 | <500 | 7~9 | 100–120 (MCMB), 15–100 (CF) | 100,000 | [33,34,35,36,37,38] |

| Key Features | Initial Capacity (mAh g−1) | ICE (%) | Electrode Loading (mg cm−2) | Cycling Stability (mAh g−1) | Retention Rate (%) | C-Rate Condition | Ref. |

|---|---|---|---|---|---|---|---|

| MWCNT@Si core–shell (magnesiothermic) | 1547/786 | 51 | N/R | 520 after 70 cycles | N/R | 0.4 A g−1 | [39] |

| Si–MWCNT–C microspheres | 1848/1228 | 66.4 | N/R | ~1050 after 60 cycles | N/R | 0.2 A g−1 | [40] |

| Si sputtered on MWCNT buckypaper | 930.6/107.8 | 12 | ~1.8 | 193 μAh after 100 cycles | 99.5 | 125 μA | [41] |

| Si/Ag/Porous-MWCNT (Si/Ag/PM) | 2163/1707 | 78.9 | ~1.0 | 706 after 300 cycles | 68.6 | 1.0 A g−1 | [42] |

| Si–MWCNTs@FPC + SC (freeze-dried) | 2300/1260 | 54.8 | 2.0 | 501 after 500 cycles | >99.5 | 1.0 A g−1 | [43] |

| SiO2/Si/PAN + rGO:MWCNT (1:1) | 3009/2889 | 96.0 | ~0.8 | 1513 after 100 cycles | N/R | 0.1 C | [44] |

| Graphite blended MWCNT-implanted Si composite (Gr-MSC) | 573/500 | 87.3 | ~4.5 | 492 after 50 cycles | 98.4 | 0.5 C | [45] |

| Si/MWCNT tissue (sputtered) | ≈1300/299 | 23 | ~2.0 | 39% after 100 cycles | 39 | 0.07 mA cm−2 | [46] |

| Si/MWCNT@C spray-dried microsphere | 1466/1026.2 | 70 | 1.0–1.2 | 536.6 after 300 cycles | 80.5 | 1 A g−1 | [47] |

| Defect-engineered MWCNTs | 1565.1/626.1 | 40 | 0.7–1.0 | 856 after 100 cycles; 88% after 500 cycles | 88.2 | 0.1, 0.5 A g−1 | [48] |

| Prelithiated MWCNT–Si/Gr with NCM 622 full cell | 200.6/174.9 | 87.2 | 16 | 129.3 after 100 cycles (NCM 622 full cell) | 73.9 | 0.5 C | [49] |

| MWCNT–Si@Ag@CN (recycled Si) | 2672.7/1273.5 | 58.0 | 1.0–1.2 | 1077.7 after 100 cycles (0.1 A g−1); 580.0 after 100 cycles (0.5 A g−1) | 97.8 (at 1 A g−1) | 0.1, 0.5, 1 A g−1 | [50] |

| Key Features | Initial Capacity (mAh g−1) | ICE (%) | Electrode Loading (mg cm−2) | Cycling Stability (mAh g−1) | Retention Rate (%) | C-Rate Condition | Ref. |

|---|---|---|---|---|---|---|---|

| Binder-free SWCNT vs. MWCNT (SiOx@C) | 1785/1455 | 81.5 | ~1.5–2.0 | 915.9 after 200 cycles; 658.8 after 500 cycles | N/R | 1.0 A g−1 | [54] |

| CNT/CNF additives replacing Super P | N/R | N/R | ~1.0 | ~60% capacity retention after 45 cycles | ~60 | 0.5 C | [55] |

| Fe–Si alloy/rGO + N–SWCNT (8 wt%) | 1416/1224 | 86.4 | 2.75, 12.8 (NCM 811 full cell) | 82.3% after 100 cycles; 65% in NCM 811 full cell after 200 cycles | 82.3/65 | 0.1 C (half-cell), 0.5 C (NCM 811 full cell) | [56] |

| SWCNT in SiO/graphite (contact integrity) | N/R | N/R | N/R | >90% after 90 cycles | >90 | 0.1–0.5 C | [57] |

| PPBT/SWCNT@Si MPs (capping layer) | ~2230/1895 | 85.0 | ~1.0 | 1894 after 300 cycles; ~150 in NCM 523 full cell with ~80% retention after 50 cycles | 92/~80 | 2.0 A g−1 (half-cell), 0.2 C (full cell) | [58] |

| SiMP/SWCNT–COOH@PVA–PAA (self-standing) | 2973/2868.5 | 96.5 | 1.5–2.0 | 1795.6 after 300 cycles; ~1000 after 1000 cycles | 96.5 | 0.2 C (100 cycles), 1 C (1000 cycles) | [59] |

| Dual-layer Si@C@SWCNT | 2337/2072 | 88.7 | ~2.0 | 1267.3 after 500 cycles | N/R | 1.0 A g−1 | [60] |

| Ultra-lean SWNT (1 wt%) in SiOx@C | 600/491.4 | 81.9 | N/R | 474 in NCM 811 full cell after 400 cycles | 493 Wh/kg with 81.7 | 0.5 A g−1 (in NCM 811 full cell) | [61] |

| Long vs. Short CNT (acupuncture effect) | SW-l: 1781/1386; SW-s: 1760/1360; MW-l: 1752/1352; MW-s: 1731/1314 | 75.8–77.9 | 1.6–1.8 | SW-l: 989; MW-l: 883; SW-s: 786; MW-s: 712 (after 200 cycles) | ~55–60 | 0.5 A g−1 | [62] |

| Ultra-low CNT in Si–graphite with SC-NCM pouch cell | ~1372.3/~1198 | 87.3 | 7.8 (anode), 22.0 (cathode) | 94.6% after 100 cycles | 94.6 | pouch full cell, ~0.5 C | [63] |

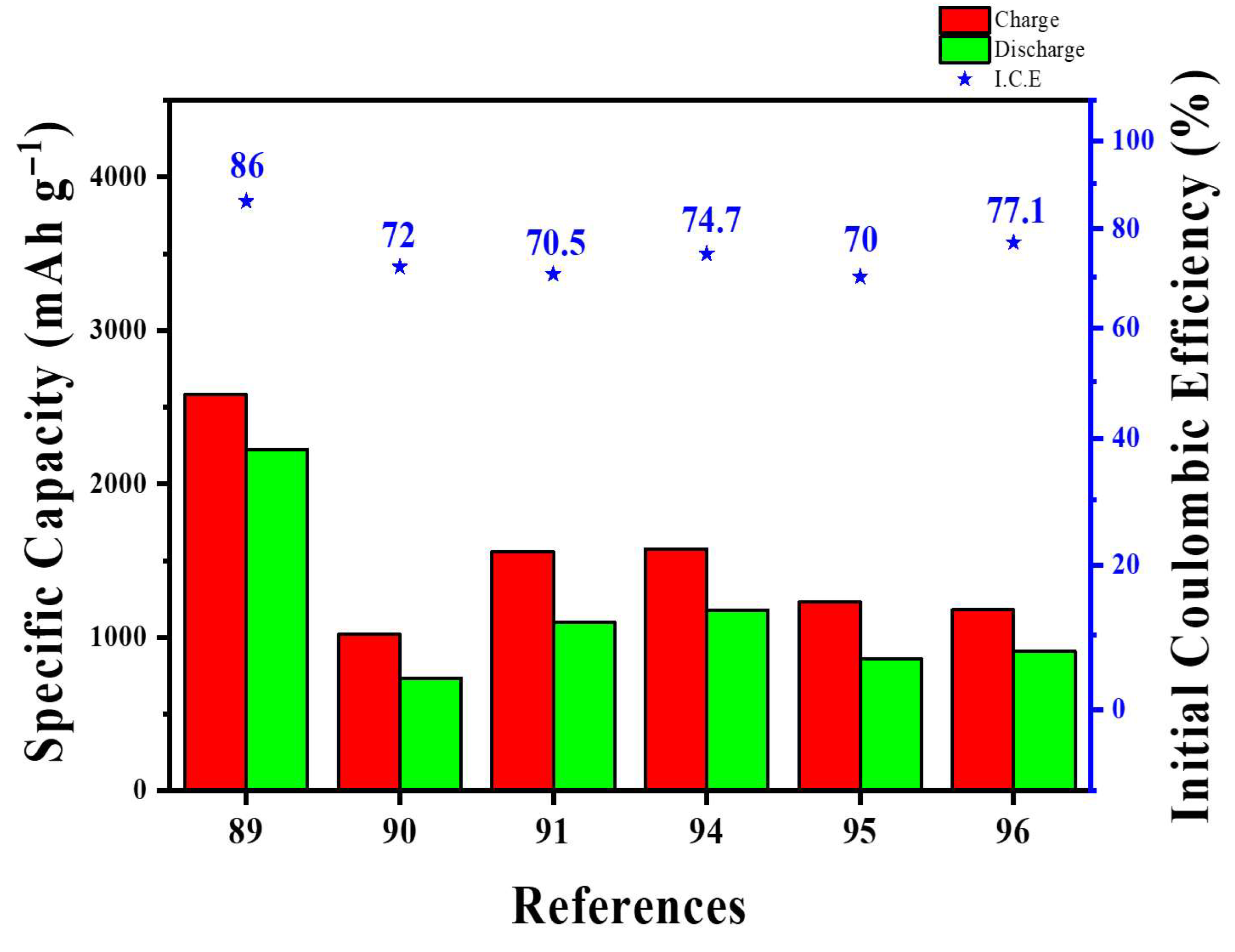

| Key Features | Initial Capacity (mAh g−1) | ICE (%) | Electrode Loading (mg cm−2) | Cycling Stability (mAh g−1) | Retention Rate (%) | C-Rate Condition | Ref. |

|---|---|---|---|---|---|---|---|

| Multilayer graphene on Si (CVD growth) | 2820/2340 | 83 | 0.3–2.5 | 700 Wh/L after 200 cycles (LiCoO2 full cell) | 72 in LiCoO2 full cell | 0.5 C in LiCoO2 Full cell | [74] |

| Si/rGO/C porous microspheres | 1005/615 | 61.2 | 1.5–1.8 | 602 after 500 cycles | 75 | 0.4 A g−1 | [75] |

| N-graphene@Si@silicate sandwich | 1871/1516 | 81.0 | 0.085–0.308 | 817 after 10,000 cycles | N/R | 5.0 C | [76] |

| Pressure-tuned Si@graphene | 2096.9/1902.6 | 90.7 | 1.3 | 1730 after 150 cycles | 82.6 | 300 mA g−1 | [77] |

| Graphene-coated SiOx/graphite | ~740/533 | 72.1 | 3.0–5.0 | 620 after 300 cycles | 69 | 0.5 C | [78] |

| Si@graphene@TiO2 core–shell | 2597.9/2094.5 | 80.6 | 1.0–1.2 | 1005.1 after 300 cycles | 68 | 2.0 A g−1 | [79] |

| Si@graphene (APTES ball-milled) | 2919.4/1952.8 | 66.9 | 0.1–0.3 | 1151.5 after 1000 cycles | N/R | 1.0 A g−1 | [80] |

| Si with graphitic graphene shell | 2660.1/2198 | 82.6 | 3.05 | 747 after 500 cycles | N/R | 1.0 C | [81] |

| Si@C–graphene hydrogel | up to 2200/~2200 | >99 | 0.8 | 2200 after 200 cycles | >99 | C/5 | [82] |

| Si@rGO(S) small-sheet shell | 2586/2405 | 93.0 | 1.0–1.1 | 2018 after 100 cycles; ~78% after 150 cycles | 78 | 0.1 C | [83] |

| 3D-printed Si/rGO grid | 1219.4/898.0 | 73.7 | 70 mg/mL | 930.6 after 350 cycles | 68.9 | C/2 | [84] |

| SiOx/C@QrGO core–shell | 2023/1596 | 78.9 | N/R | ~87% after 100 cycles; 76% after 500 cycles (NCM 622 full cell) | 87/ 76 in NCM 622 Full cell | 0.5 C (half-cell), 1 C(NCM 622 full cell) | [85] |

| Key Features | Initial Capacity (mAh g−1) | ICE (%) | Electrode Loading (mg cm−2) | Cycling Stability (mAh g−1) | Retention Rate (%) | C-Rate Condition | Ref. |

|---|---|---|---|---|---|---|---|

| Hollow C nanospheres + N-doped CNF (binder-free paper) | 2583/2224 | 86 | 1.0–1.8 | 1442 after 800 cycles; 450 after 200 cycles (in LiCoO2 full cell) | 86/ 50.5 in LiCoO2 full cell | 1.0 A g−1 (half-cell), 0.5 A g−1 (LiCoO2 full cell) | [89] |

| Nitrogen/oxygen co-doped vertical graphene grown on Si-coated CNF | 3233 | ~75 | 0.8–1.5 | 2390.5 after 100 cycles | 73.9 | 0.1 A/g | [90] |

| Nanofiber-in-microfiber C/Si composite (40 wt% Si) | 2458/1749 | 71.1 | 1.95 | 900 after 250 cycles | 51.5 | 50 mA/g | [91] |

| Upcycled waste graphite fines via spray-drying and pitch coating | 410/351 | 86.2 | 5.1 | 331 after 200 cycles | 95.1 | 0.11 C | [94] |

| Pitch vs. acetylene-CVD carbon on SiO | 2110/1576 (CVD); 2106/1534 (Pitch) | 74.7 (CVD); 72.9 (Pitch) | 2.5 | 732 (CVD); 437 (Pitch) after 50 cycles | 46.5 (CVD); 28.5 (Pitch) | 0.2 C (half-cell) | [95] |

| Pitch-derived porous C support to C/Six/C (Na, K, PC) | N/R | 78.8 (Na); 87.6 (K); 79.2 (PC) | 1.5–2.0 | N/R | 69.5 (Na); 67.4 (K); 48.3 (PC) after 50 cycles | 0.1 A g−1 | [96] |

| Process | Throughput | Yield | Energy Cost vs. Slurry | Refs. |

|---|---|---|---|---|

| Conventional slurry | 1–25 m/min | ≥98% | 1.0× | [112,113,114] |

| Spray drying | 20–50 kg/h | ≥95% | 1.2–3.0 kWh/kg | [115,116] |

| Electrostatic assembly | ~0.5–2 m/min | 90–95% | lower (ambient, ovenless/low heat) | [117,118] |

| 3D printing | 0.3–2.4 m/min | 70–90% | lower/medium (drying eliminated) | [119] |

| Electrospinning | 0.02–2.6 g/h | 80–90% | low–medium (low thermal load) | [120,121] |

| CVD/PECVD | 0.06–2 m/min | 90–99% | ≫1.0× (vacuum/plasma) | [122,123,124] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, W.; Jung, Y.; Hong, J.-Y.; Jeon, Y.-P.; Lee, J.U. Nano Carbon-Based Hybrid Strategies for Mitigating Silicon Anode Expansion in Lithium-Ion Batteries: A Comprehensive Review. Materials 2025, 18, 5532. https://doi.org/10.3390/ma18245532

Lee W, Jung Y, Hong J-Y, Jeon Y-P, Lee JU. Nano Carbon-Based Hybrid Strategies for Mitigating Silicon Anode Expansion in Lithium-Ion Batteries: A Comprehensive Review. Materials. 2025; 18(24):5532. https://doi.org/10.3390/ma18245532

Chicago/Turabian StyleLee, Wonhwa, Yunki Jung, Jin-Yong Hong, Young-Pyo Jeon, and Jea Uk Lee. 2025. "Nano Carbon-Based Hybrid Strategies for Mitigating Silicon Anode Expansion in Lithium-Ion Batteries: A Comprehensive Review" Materials 18, no. 24: 5532. https://doi.org/10.3390/ma18245532

APA StyleLee, W., Jung, Y., Hong, J.-Y., Jeon, Y.-P., & Lee, J. U. (2025). Nano Carbon-Based Hybrid Strategies for Mitigating Silicon Anode Expansion in Lithium-Ion Batteries: A Comprehensive Review. Materials, 18(24), 5532. https://doi.org/10.3390/ma18245532