Investigation of the Structural, Mechanical and Operational Properties of an Alloy AlSi18Cu3CrMn

Abstract

1. Introduction

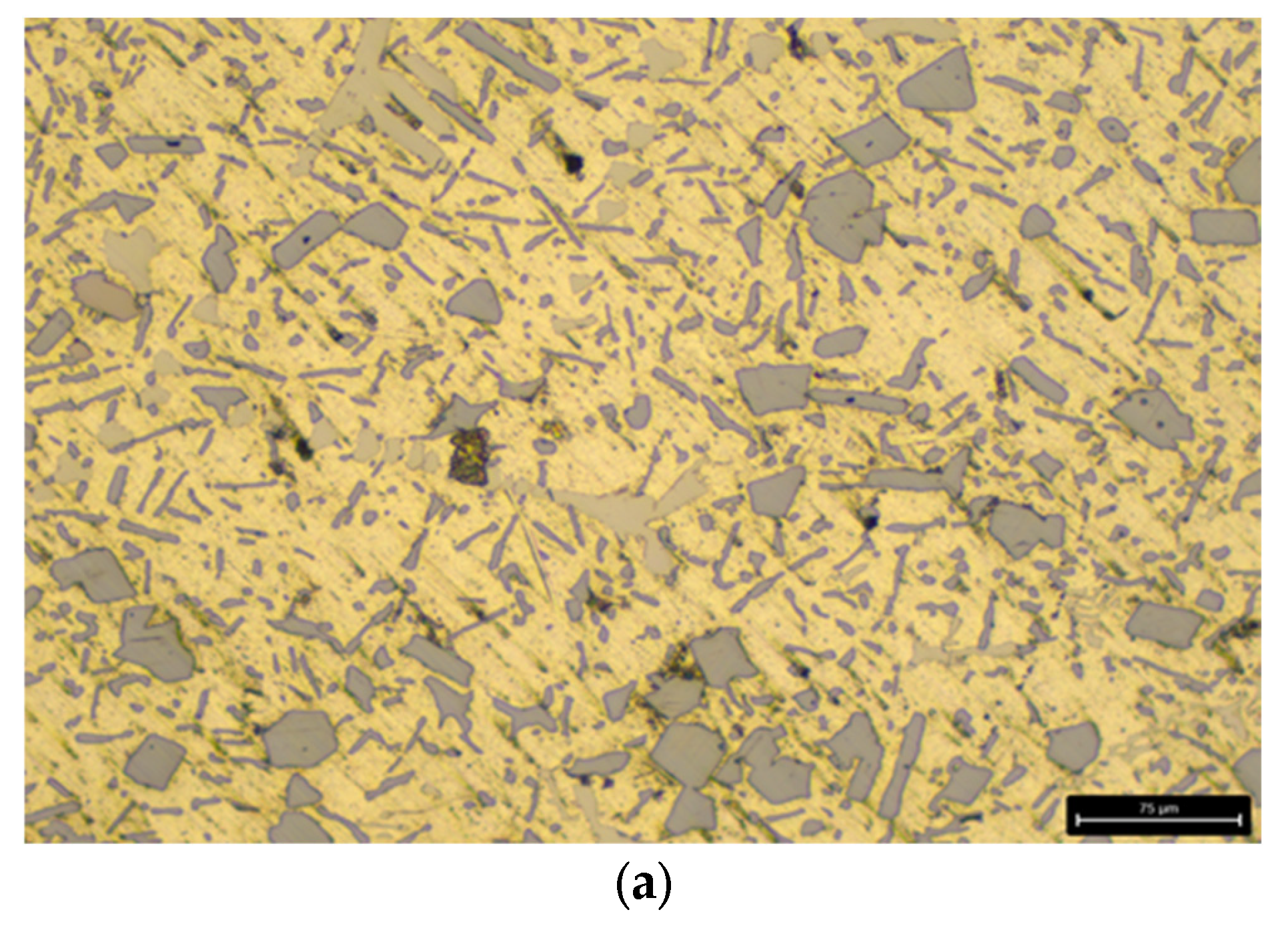

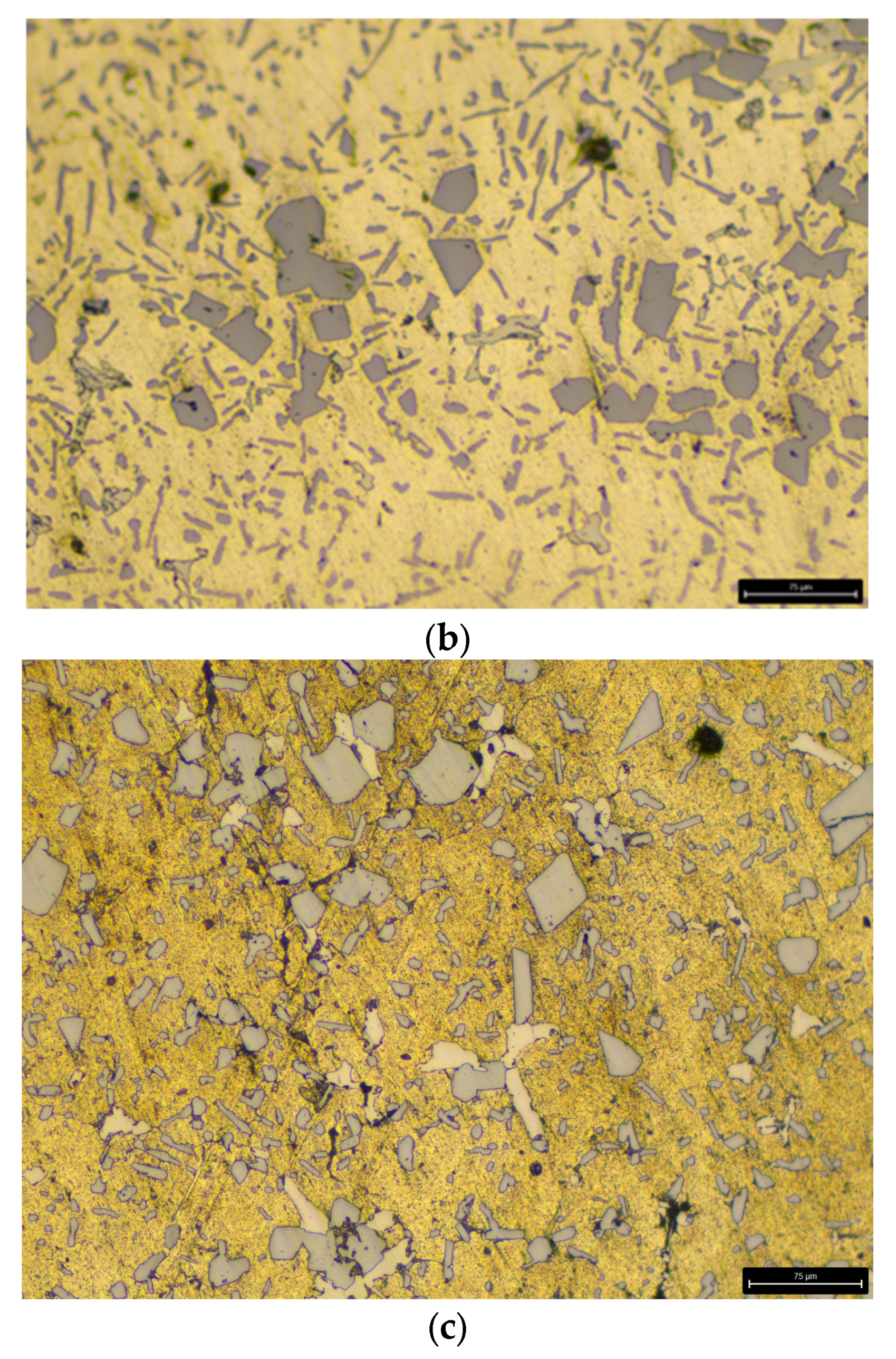

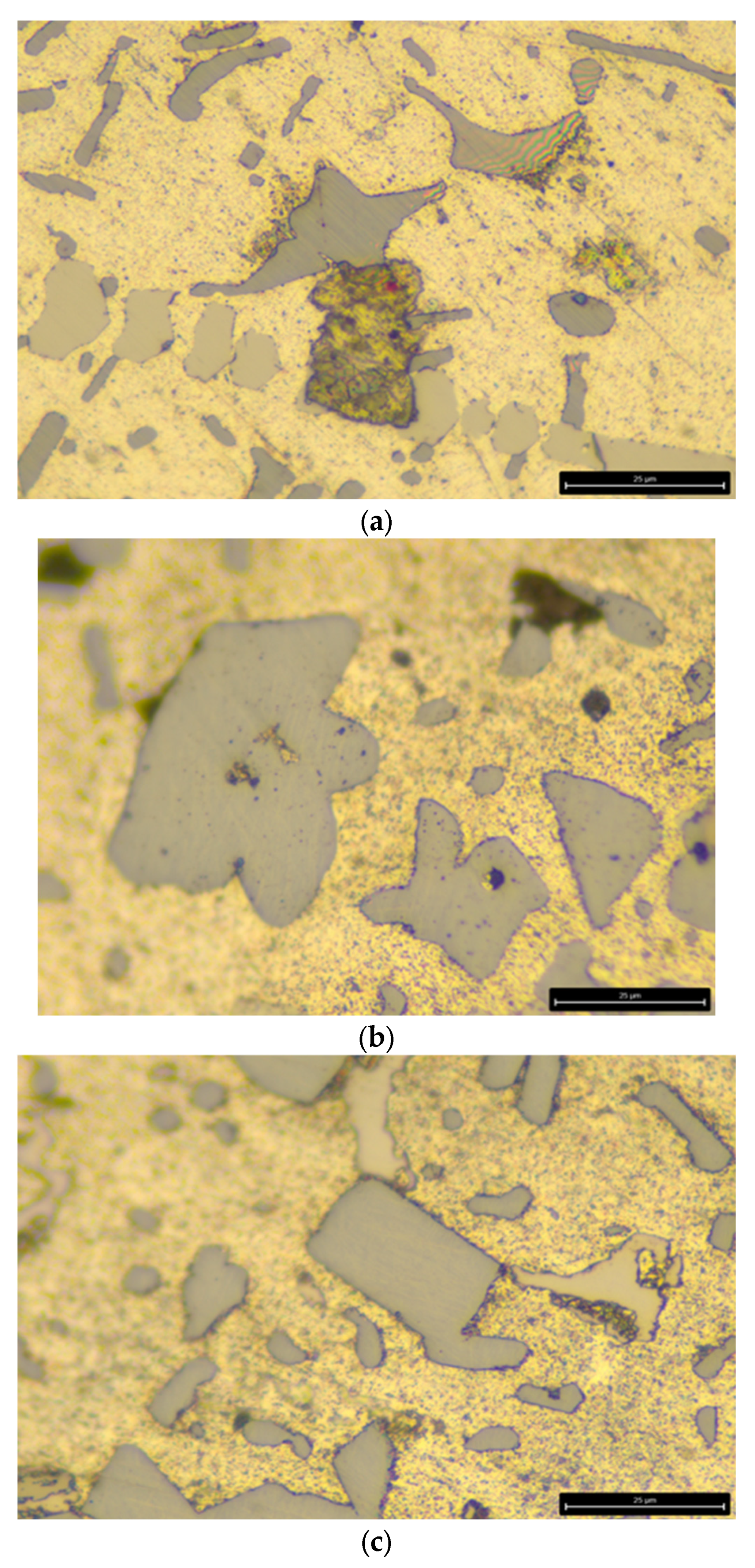

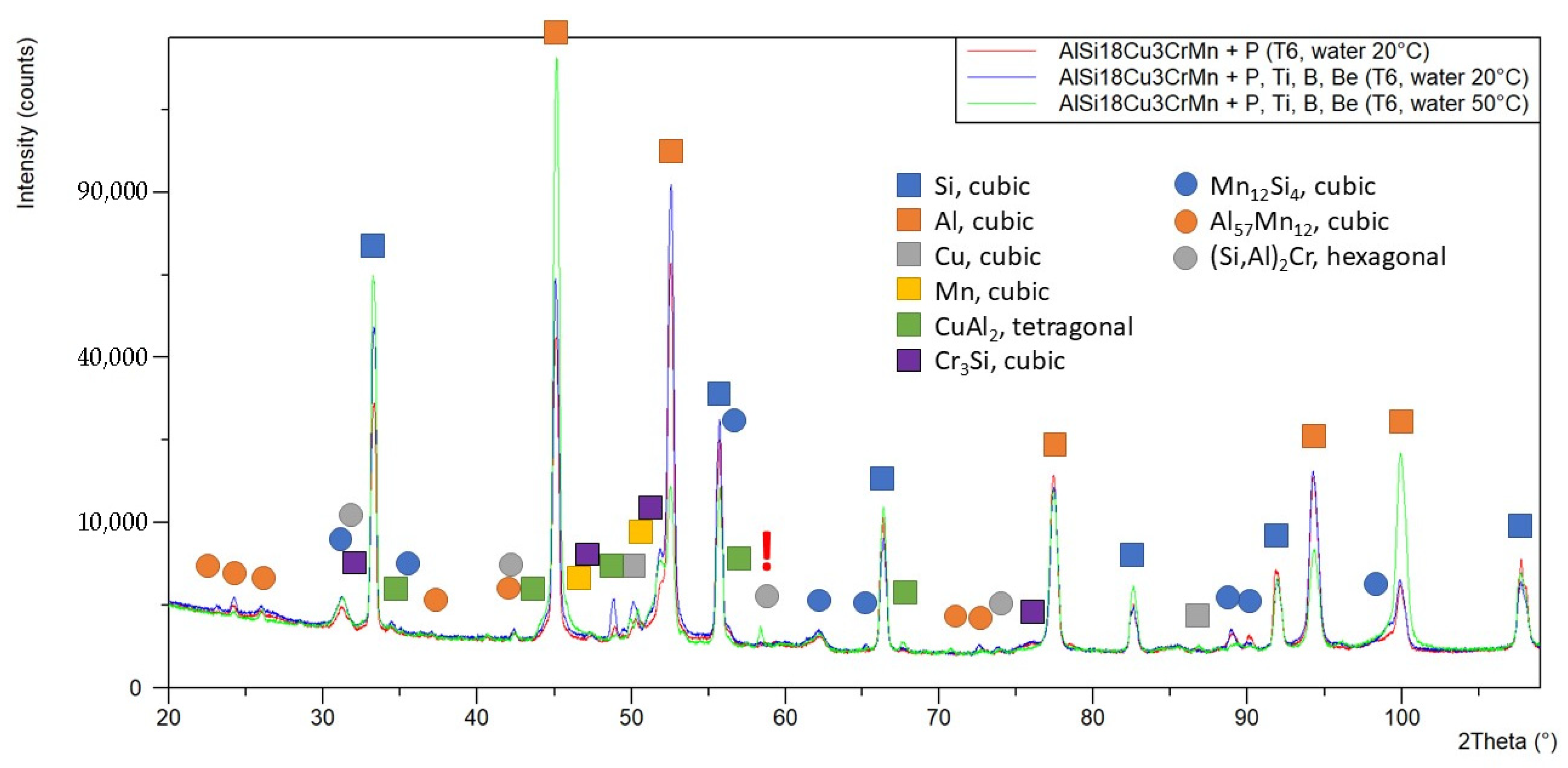

2. Materials and Methods

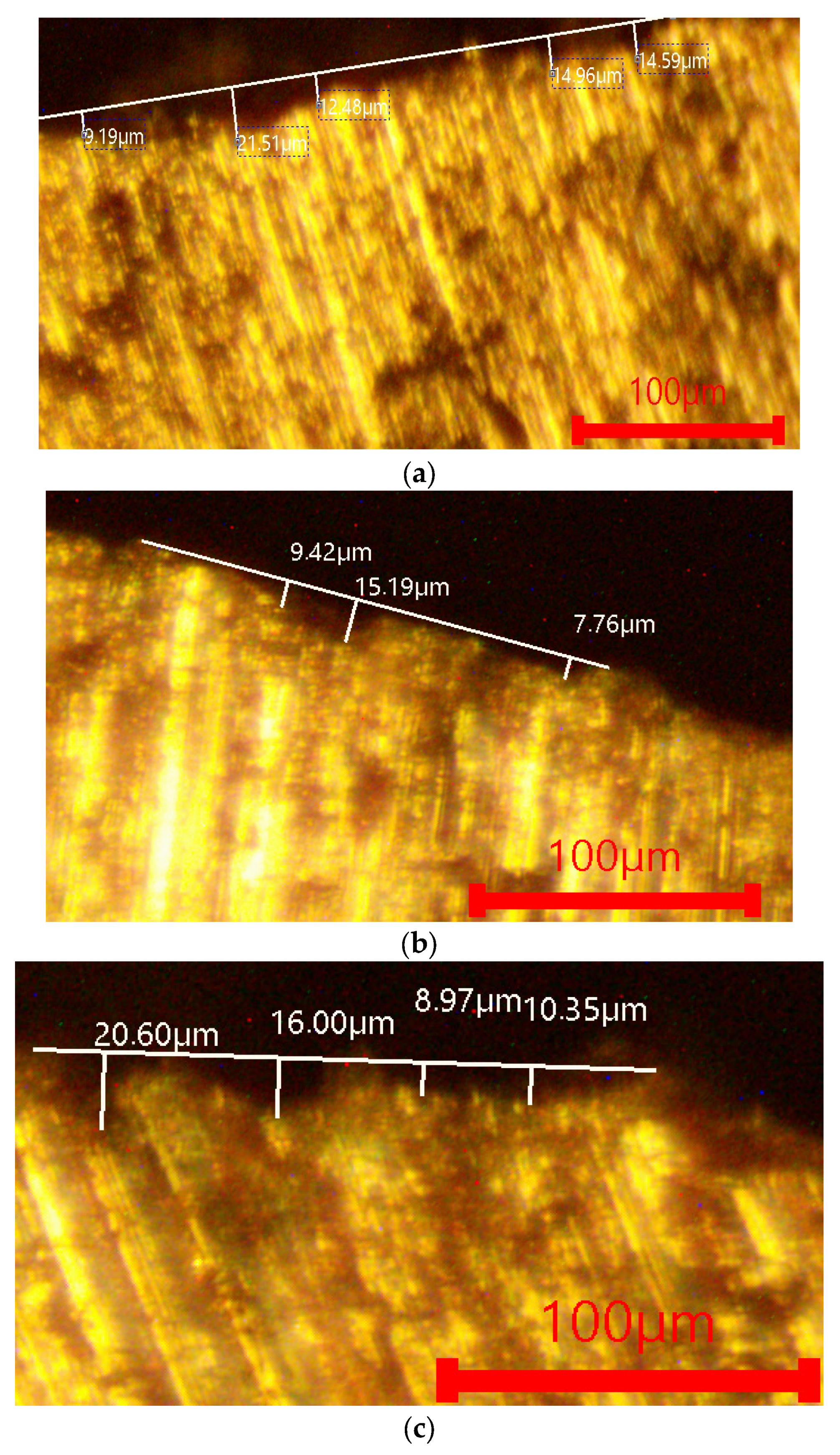

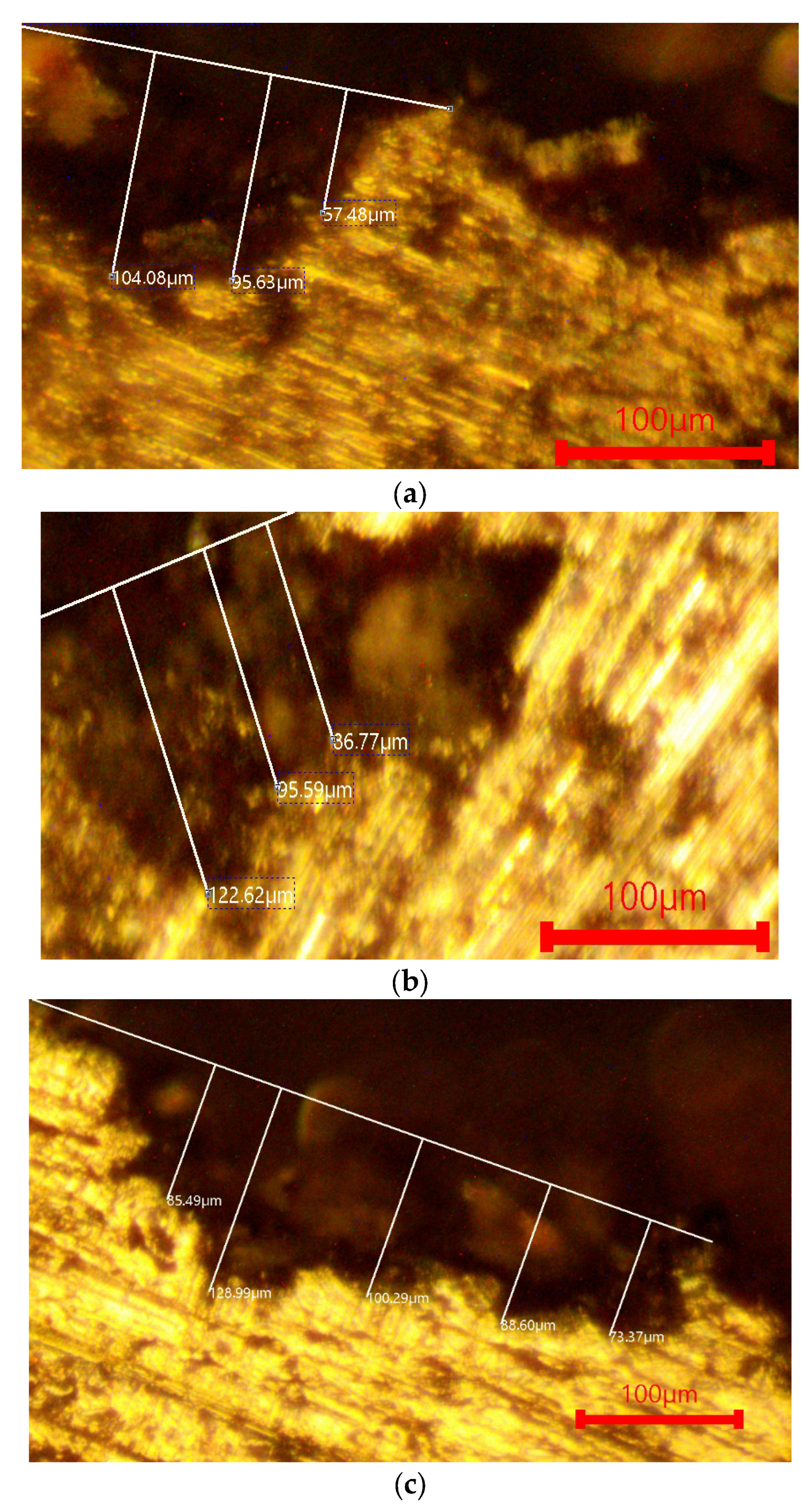

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tashev, A.; Dimitrov, E. LPG effect on performance parameters of diesel engine operated on dual-fuel mode. AIP Conf. Proc. 2022, 2449, 050010. [Google Scholar] [CrossRef]

- Dimitrov, E.; Tashev, A. CNG effect on performance parameters of diesel engine operated on dual-fuel mode. AIP Conf. Proc. 2022, 2449, 050009. [Google Scholar] [CrossRef]

- Kandeva, M.; Dochev, B.; Dimova, D.; Zagorski, M.; Kasabov, P. Investigation of the wear resistance of tribological systems composed of aluminium-silicon alloys: Part 1. J. Balk. Tribol. Assoc. 2024, 30, 59–66. [Google Scholar]

- Kandeva, M.; Dochev, B.; Dimova, D.; Zagorski, M.; Kasabov, P. Investigation of the wear resistance of tribological systems composed of aluminium-silicon alloys: Part 2. J. Balk. Tribol. Assoc. 2024, 30, 208–217. [Google Scholar]

- Mahle GmbH. Piston materials. In Pistons and Engine Testing; ATZ/MTZ-Fachbuch; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2012. [Google Scholar] [CrossRef]

- Miladinović, S.; Stojanović, B.; Gajević, S.; Vencl, A. Hypereutectic Aluminum Alloys and Composites: A Review. Silicon 2023, 15, 2507–2527. [Google Scholar] [CrossRef]

- Joseph, O.O.; Olubambi, P.A.; Joseph, O.O.; Edun, B.M.; Okeniyi, J.O.; Abioye, O.P. Effects of Alloying on Aluminium-Silicon Alloys—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012116. [Google Scholar] [CrossRef]

- Efzan, M.N.E.; Kong, H.J.; Kok, C.K. Review: Effect of Alloying Element on Al-Si Alloys. Adv. Mater. Res. 2013, 845, 355–359. [Google Scholar] [CrossRef]

- Abalymov, V.R.; Zhereb, V.P.; Kleimenov, Y.A.; Antonov, M.M. Effect of Heat Treatment on the Structure and Mechanical Properties of Eutectic Silumin Alloyed with Magnesium. Met. Sci. Heat Treat. 2021, 63, 291–296. [Google Scholar] [CrossRef]

- Elsharkawi, E.A.; Ibrahim, M.F.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Understanding the Effect of Be Addition on the Microstructure and Tensile Properties of Al–Si–Mg Cast Alloys. Int. J. Met. 2022, 16, 1777–1795. [Google Scholar] [CrossRef]

- Liu, X.; Wang, C.; Zhang, S.; Song, J.; Zhou, X.; Zha, M.; Wang, H. Fe-Bearing Phase Formation, Microstructure Evolution, and Mechanical Properties of Al-Mg-Si-Fe Alloy Fabricated by the Twin-Roll Casting Process. J. Alloys Compd. 2021, 886, 161202. [Google Scholar] [CrossRef]

- Furui, M.; Kitamura, T.; Ishikawa, T.; Ikeno, S.; Saikawa, S.; Sakai, N. Evaluation of Age Hardening Behavior Using Composite Rule and Microstructure Observation in Al-Si-Mg Alloy Castings. Mater. Trans. 2011, 52, 1163–1167. [Google Scholar] [CrossRef]

- Stanić, D.; Brodarac, Z.Z.; Li, L. Influence of Copper Addition in AlSi7MgCu Alloy on Microstructure Development and Tensile Strength Improvement. Metals 2020, 10, 1623. [Google Scholar] [CrossRef]

- Wang, E.R.; Hui, X.D.; Wang, S.S.; Zhao, Y.F.; Chen, G.L. Improved Mechanical Properties in Cast Al-Si Alloys by Combined Alloying of Fe and Cu. Mater. Sci. Eng. A 2010, 527, 7878–7884. [Google Scholar] [CrossRef]

- Jeong, C. High Temperature Mechanical Properties of AlSiMg-(Cu) Alloys for Automotive Cylinder Heads. Mater. Trans. 2013, 54, 588–594. [Google Scholar] [CrossRef]

- Bogdanoff, T.; Lattanzi, L.; Merlin, M.; Ghassemali, E.; Jarfors, A.E.W.; Seifeddine, S. The Complex Interaction between Microstructural Features and Crack Evolution during Cyclic Testing in Heat-Treated Al–Si–Mg–Cu Cast Alloys. Mater. Sci. Eng. A 2021, 825, 141930. [Google Scholar] [CrossRef]

- Lumley, R.N.; Gunasegaram, D.R.; Gershenzon, M.; O’Donnell, R.G. Effect of Alloying Elements on Heat Treatment Response of Aluminium High Pressure Die Castings. Int. Heat Treat. Surf. Eng. 2010, 4, 25–32. [Google Scholar] [CrossRef]

- Pratheesh, K.; Ravi, M.; Kanjirathinkal, A.; Joseph, M.A. Effects of Sr and Pressure on Microstructure, Mechanical and Wear Properties of near Eutectic Al–Si Piston Alloys. Int. J. Cast Met. Res. 2015, 28, 301–309. [Google Scholar] [CrossRef]

- Demirtaş, H.; Karakulak, E.; Babu, N.H. Understanding the Effect of Ni Content on Microstructure and Mechanical Properties of A384 HPDC Alloy. J. Alloys Compd. 2022, 896, 163111. [Google Scholar] [CrossRef]

- Lattanzi, L.; Giovanni, M.T.; Giovagnoli, M.; Fortini, A.; Merlin, M.; Casari, D.; Di Sabatino, M.; Cerri, E.; Garagnani, G.L. Room Temperature Mechanical Properties of A356 Alloy with Ni Additions from 0.5 Wt to 2 Wt%. Metals 2018, 8, 224. [Google Scholar] [CrossRef]

- Fedak, M.; Rimar, M.; Corny, I.; Kuna, S. Experimental Study of Correlation of Mechanical Properties of Al-Si Casts Produced by Pressure Die Casting with Si/Fe/Mn Content and Their Mutual Mass Relations. Adv. Mater. Sci. Eng. 2013, 2013, 585514. [Google Scholar] [CrossRef]

- Ozyurek, D.; Yıldırım, M.; Yavuzer, B.; Simsek, I.; Tuncay, T. The Effect of Ni Addition on Microstructure and Mechanical Properties of Cast A356 Alloy Modified with Sr. Met. Mater. 2021, 59, 391–399. [Google Scholar] [CrossRef]

- Mbuya, T.O.; Odera, B.O.; Ng’ang’a, S.P. Influence of Iron on Castability and Properties of Aluminium Silicon Alloys: Literature Review. Int. J. Cast Met. Res. 2003, 16, 451–465. [Google Scholar] [CrossRef]

- Totten, G.E.; Tiryakioglu, M.; Kessler, O. (Eds.) Encyclopedia of Aluminum and Its Alloys; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Szymczak, T.; Gumienny, G.; Klimek, L.; Goły, M.; Szymszal, J.; Pacyniak, T. Characteristics of Al-Si Alloys with High Melting Point Elements for High Pressure Die Casting. Materials 2020, 13, 4861. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, J.; Damoah, L.; Robertson, D.G. Removal of Iron from Aluminum: A Review. Miner. Process. Extr. Metall. Rev. 2012, 33, 99–157. [Google Scholar] [CrossRef]

- Hwang, J.Y.; Doty, H.W.; Kaufman, M.J. The Effects of Mn Additions on the Microstructure and Mechanical Properties of Al-Si-Cu Casting Alloys. Mater. Sci. Eng. A 2008, 488, 496–504. [Google Scholar] [CrossRef]

- Taylor, J.A. Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Švecová, I.; Tillová, E.; Kuchariková, L.; Knap, V. Possibilities of Predicting Undesirable Iron Intermetallic Phases in Secondary Al-Alloys. Transp. Res. Procedia 2021, 55, 797–804. [Google Scholar] [CrossRef]

- Dunn, R. Aluminum Melting Problems and Their Influence on Furnace Selection. Die Cast. Eng. B 1965, 9, 8–30. [Google Scholar]

- Kumar, L.; Cheol, J.; Hui, J.; Kwang, S.S. Effects of Cr and Ti Addition on Mechanical Properties and Thermal Conductivity of Al–7Si–3Mg Die-casting Alloys. Met. Mater. Int. 2022, 29, 204–214. [Google Scholar] [CrossRef]

- Ling, H.; Shi, H.; Du, X.; Zan, J.; Liu, J. Effect of Chromium Content on Microstructure and Properties of Casting Al-7Si-0.35Mg-0.02Sr Alloy. Mater. Werkst. 2022, 53, 1229–1241. [Google Scholar] [CrossRef]

- Liang, Y.; Cui, C.; Geng, H.; Liu, L.; Zhang, S.; Jin, R. Synergistic Effects of Cr and Sr Addition on the Mechanical and Corrosion Properties of A356.2 Alloy. Mater. Charact. 2022, 191, 112152. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Wu, Y.; Wei, Z.; Liu, X. Supportive Strengthening Role of Cr-Rich Phase on Al-Si Multicomponent Piston Alloy at Elevated Temperature. Mater. Sci. Eng. A 2011, 528, 4427–4430. [Google Scholar] [CrossRef]

- Wang, X.; Ma, P.; Meng, Z.; Zhang, S.; Liu, X.; Wang, C.; Wang, H. Effect of Trace Cr Alloying on Centerline Segregations in Sub-Rapid Solidified Al–Mg–Si (AA6061) Alloys Fabricated by Twin-Roll Casting. Mater. Sci. Eng. A 2021, 825, 141896. [Google Scholar] [CrossRef]

- Kaufman, J.G.; Rooy, E.L. Aluminum Alloy Castings: Properties, Processes, and Applications, 1st ed.; ASM International: Almere, The Netherlands, 2004. [Google Scholar]

- Lumley, R.N. (Ed.) Fundamentals of Aluminium Metallurgy: Production, Processing and Applications; Woodhead Publishing: Sawston, UK, 2011. [Google Scholar]

- Polmear, I.; StJohn, D.; Nie, J.-F.; Qian, M. Light Alloys: Metallurgy of the Light Metals, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Ganesh, M.R.S.; Reghunath, N.; Levin, M.J.; Prasad, A.; Doondi, S.; Shankar, K.V. Strontium in Al–Si–Mg Alloy: A Review. Met. Mater. Int. 2022, 28, 1–40. [Google Scholar] [CrossRef]

- Nafisi, S.; Ghomashchi, R. Effects of Modification during Conventional and Semi-Solid Metal Processing of A356 Al-Si Alloy. Mater. Sci. Eng. A 2006, 415, 273–285. [Google Scholar] [CrossRef]

- Vincze, F.; Tokár, M.; Fegyverneki, G.; Gyarmati, G. Examination of the Eutectic Modifying Effect of Sr on an Al-Si-Mg-Cu Alloy Using Various Technological Parameters. Arch. Foundry Eng. 2020, 2020, 79–84. [Google Scholar] [CrossRef]

- Sigworth, G.K. The Modification of Al-Si Casting Alloys: Important Practical and Theoretical Aspects. Int. J. Met. 2008, 2, 19–40. [Google Scholar] [CrossRef]

- Flores, A.V.; Lopez, J.C.; Escobedo, J.C.B.; Castillejos, A.H.E.; Acosta, F.A.G. Effects of S and Sb Additions on the Microstructure and Mechanical Properties of the Al-Si 319 Alloy. Can. Metall. Q. 1994, 33, 133–138. [Google Scholar] [CrossRef]

- Medlen, D.; Bolibruchova, D. Effect of Sb-Modification on the Microstructure and Mechanical Properties of Secondary Alloy 319. Arch. Metall. Mater. 2016, 61, 553–558. [Google Scholar] [CrossRef][Green Version]

- Birol, Y. Effect of silicon content in grain refining hypoeutectic Al–Si foundry alloys with boron and titanium additions. Mater. Sci. Technol. 2012, 28, 385–389. [Google Scholar] [CrossRef]

- Qi, M.; Kanga, Y.; Qiu, Q.; Tang, W.; Li, J.; Li, B. Microstructures, mechanical properties, and corrosion behavior of novel high-thermal-conductivity hypoeutectic Al-Si alloys prepared by rheological high pressure die-casting and high pressure die-casting. J. Alloys Compd. 2018, 749, 487–502. [Google Scholar] [CrossRef]

- Sigworth, G.K. Modification of Aluminum-Silicon Alloys. In ASM Handbook Casting; ASM International: Materials Park, OH, USA, 2008; pp. 240–254. [Google Scholar] [CrossRef]

- Shlyaptseva, A.D.; Petrov, I.A.; Ryakhovsky, A.P.; Medvedeva, E.V.; Tcherdyntsev, V.V. Complex Structure Modification and Improvement of Properties of Aluminium Casting Alloys with Various Silicon Content. Metals 2021, 11, 1946. [Google Scholar] [CrossRef]

- Hanna, M.D.; Lu, S.Z.; Hellawell, A.A. Modification in the aluminum silicon system. Metall. Trans. 1984, 15, 459–469. [Google Scholar] [CrossRef]

- Jiang, Q.C.; Xu, C.L.; Lu, M.; Wang, H.Y. Effect of new Al–P–Ti–TiC–Y modifier on primary silicon in hypereutectic Al–Si alloys. Mater. Lett. 2005, 59, 624–628. [Google Scholar] [CrossRef]

- Tenekedjiev, N.; Gruzleski, J.E. Hypereutectic Aluminium-Silicon Casting Alloys—A Review. Cast Met. 2016, 3, 96–105. [Google Scholar] [CrossRef]

- McDonald, S.D.; Nogita, K.; Dahle, A.K. Eutectic nucleation in Al–Si alloys. Acta Mater. 2004, 524, 4273–4280. [Google Scholar] [CrossRef]

- Dwivedi, D.K. Adhesive wear behaviour of cast aluminium–silicon alloys: Overview. Mater. Des. 2010, 31, 2517–2531. [Google Scholar] [CrossRef]

- Mueller, M.G.; Fornabaio, M.; Žagar, G.; Mortensen, A. Microscopic strength of silicon particles in an aluminium–silicon alloy. Acta Mater. 2016, 105, 165–175. [Google Scholar] [CrossRef]

- Elmadagli, M.; Perry, T.; Alpas, A.T. A parametric study of the relationship between microstructure and wear resistance of Al–Si alloys. Wear 2007, 262, 79–92. [Google Scholar] [CrossRef]

- Ganchenkova, M.; Nieminen, R.M. Chapter Eleven—Mechanical Properties of Silicon Microstructures. In Handbook of Silicon Based MEMS Materials and Technologies, Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2010; pp. 179–219. [Google Scholar] [CrossRef]

- Zhang, D.L.; Zheng, L.H.; StJohn, D.H. Effect of a short solution treatment time on microstructure and mechanical properties of modified Al–7wt.%Si–0.3wt.%Mg alloy. J. Light Met. 2002, 2, 27–36. [Google Scholar] [CrossRef]

- Lian, J.; Baudelet, B. A modified Hall-Petch relationship for nanocrystalline materials. Nanostructured Mater. 1993, 2, 415–419. [Google Scholar] [CrossRef]

- Timelli, G.; Bonollo, F. The influence of Cr content on the microstructure and mechanical properties of AlSi9Cu3(Fe) die-casting alloys. Mater. Sci. Eng. A 2010, 528, 273–282. [Google Scholar] [CrossRef]

- Jiandon, P.; Talangkun, S. Microstructural Modification Hardness and Surface Roughness of Hypereutectic Al-Si Alloys by a Combination of Bismuth and Phosphorus. Crystals 2022, 12, 1026. [Google Scholar] [CrossRef]

- Dang, B.; Jian, Z.-Y.; Xu, J.-F.; Chang, F.-E.; Zhu, M. Effect of phosphorus and heat treatment on microstructure of Al-25%Si alloy. Res. Dev. 2017, 14, 10–15. [Google Scholar] [CrossRef]

- Hong, X.; Chen, D.; Xu, Y.; Zhu, H.; Zhang, J.; Liu, Y.; Peng, Y.; Hou, L. Effect of Different Phosphorus Modifiers on Microstructure and Properties for Al-Si Alloy. IOP Conf. Ser. Earth Environ. Sci. 2021, 692, 032053. [Google Scholar] [CrossRef]

- Gursoy, O.; Timelli, G. Lanthanides: A focused review of eutectic modification in hypoeutectic Al–Si alloys. J. Mater. Res. Technol. 2020, 9, 8652–8666. [Google Scholar] [CrossRef]

- Wang, Y.; Xiong, Y. Effects of beryllium in Al–Si–Mg–Ti cast alloy. Mater. Sci. Eng. A 2020, 280, 124–127. [Google Scholar] [CrossRef]

- Averkin, A.I.; Korchunov, B.N.; Nikanorov, S.P.; Osipov, V.N. The effect of strontium on the mechanical properties of aluminum–silicon alloy. Tech. Phys. Lett. 2016, 42, 201–203. [Google Scholar] [CrossRef]

- Mahanty, S.; Gouthama. Surface modification of Al–Si alloy by excimer laser pulse processing. Mater. Chem. Phys. 2016, 173, 192–199. [Google Scholar] [CrossRef]

- Xu, C.L.; Yang, Y.F.; Wang, H.Y.; Jiang, Q.C. Effects of modification and heat-treatment on the abrasive wear behavior of hypereutectic Al–Si alloys. J. Mater. Sci. 2007, 42, 6331–6338. [Google Scholar] [CrossRef]

- Zykova, A.; Kazantsev, L.; Popova, N.; Vorozhtsov, A.; Kurzina, I. Influence of Modifying Mixtures on Si Crystal Formation in Al-7%Si Alloy. Metals 2018, 8, 98. [Google Scholar] [CrossRef]

- Jasim, T.A. Review on the Mechanisms of Modification Al-Si alloys. J. Univ. Babylon Eng. Sci. 2019, 27, 338–343. [Google Scholar] [CrossRef]

- Rana, R.S.; Purohit, R.; Das, S. Reviews on the Influences of Alloying elements on the Microstructure and Mechanical Properties of Aluminum Alloys and Aluminum Alloy Composites. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- McDonald, S.D.; Nogita, K.; Dahle, A.K. Eutectic grain size and strontium concentration in hypoeutectic aluminium–silicon alloys. J. Alloys Compd. 2006, 422, 184–191. [Google Scholar] [CrossRef]

- Chandra, P.V.; Rao, S.; Devib, A.S.; Basava Kumarc, K.G. Influence of Melt Treatments on Dry Sliding Wear Behavior of Hypereutectic Al-15Si-4Cu Cast Alloys. Jordan J. Mech. Ind. Eng. 2012, 6, 55–61. [Google Scholar]

- Abdollahi, A.; Gruzleski, J.E. An evaluation of calcium as a eutectic modifier in A357 alloy. Int. J. Cast Met. Res. 1998, 11, 145–155. [Google Scholar] [CrossRef]

- Nogita, K.; Dahle, A.K. Eutectic solidification in hypoeutectic Al–Si alloys: Electron backscatter diffraction analysis. Mater. Charact. 2001, 46, 305–310. [Google Scholar] [CrossRef]

- Hegde, S.; Prabhu, K.N. Modification of eutectic silicon in Al–Si alloys. J. Mater. Sci. 2008, 43, 3009–3027. [Google Scholar] [CrossRef]

- Nogita, K.; McDonald, S.D.; Tsujimoto, K.; Yasuda, K.; Dahle, A.K. Aluminium phosphide as a eutectic grain nucleus in hypoeutectic Al-Si alloys. Microscopy 2004, 53, 361–369. [Google Scholar] [CrossRef]

- Barrirero, J. Eutectic Modification of Al-Si Casting Alloys. Ph.D. Thesis, Linkopings Universitet, Linköping, Sweden, 2019; p. 27764720. [Google Scholar] [CrossRef]

- Li, C.; Liu, F.; Yin, J.; Yu, F.; Zheng, D.; Qiao, H.; He, Y.; Le, Q. Effect of P modification on the banded structure and mechanical properties in direct-chill casting Al-16.5Si-3Cu-0.6Mg-0.1Zr alloys. J. Alloys Compd. 2024, 1002, 175167. [Google Scholar] [CrossRef]

- Jeon, J.H.; Shin, J.H.; Bae, D.H. Si phase modification on the elevated temperature mechanical properties of Al-Si hypereutectic alloys. Mater. Sci. Eng. A 2019, 748, 367–370. [Google Scholar] [CrossRef]

- Dochev, B.; Panov, I.V.; Dimova, D. Investigation of the influence of heat treatment on the structure and properties of aluminum-silicon alloy AlSi18Cu3CrMn. AIP Conf. Proc. 2021, 2449, 060020. [Google Scholar] [CrossRef]

- Kamarska, K. Study of the corrosion behavior of aluminum-silicon alloy AlSi18Cu3CrMn in acidic media. AIP Conf. Proc. 2021, 2449, 060018. [Google Scholar] [CrossRef]

- Dochev, B.; Dimova, D.; Zagorski, M.; Kasabov, P.; Chuchulska, B. Investigation of the influence of the manufacturing process on the structure of hypereutectic aluminium-silicon alloys. In Proceedings of the 15th International Scientific and Practical Conference, Rezekne, Latvia, 27–28 June 2024; Engineering Sciences and Production Technologies. Volume 3, pp. 53–57. [Google Scholar] [CrossRef]

- Dimova, D.; Nikolov, V.; Chuchulska, B.; Tsonev, V.; Geshanova, N. A Study of the Microstructure of Non-Standardised Alternative Piston Aluminium–Silicon Alloys Subjected to Various Modifications: The Influence of Modification Treatments on the Microstructure and Properties of These Alloys. Eng. Proc. 2025, 100, 46. [Google Scholar] [CrossRef]

- Dochev, B. Izsledvane vliyanieto na razlichni kontsentratsii fosfor varhu strukturata i mekhanichnite svoistva na legirani s Cu aluminii-silitsievi splavi [Study of the Influence of Different Phosphorus Concentrations on the Structure and Mechanical Properties of Cu-Alloyed Al–Si Alloys]. In Proceedings of the Natsionalen Mladezhki Forum “Nauka, Tehnologii, Inovatsii, Biznes”, Plovdiv, Bulgaria, 25–26 November 2021; pp. 104–108, ISSN 2367-8569. [Google Scholar]

- Dochev, B.; Dimova, D.; Trojan, K.; Čapek, J.; Kamarska, K.; Chuchulska, B. Investigation of the Influence of Alloying Elements Ni, Cr, Co and Mo on the Crystallization Process, Phase Composition and Corrosion Resistance of AlSi25Cu4Cr and AlSi25Cu5Cr Alloys. Materials 2025, 18, 907. [Google Scholar] [CrossRef]

- BDS EN ISO 6892-1:2020; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2020.

- BDS EN ISO 6892-2:2018; Metallic Materials—Tensile Testing—Part 2: Method of Test at Elevated Temperature. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2018.

- Dochev, B.; Panov, I.; Tsonev, V.; Dimova, D. Study of the Behavior of Aluminum–Silicon Alloys Interfused with Cu and Mg at High Temperatures. J. Balk. Tribol. Assoc. 2021, 27, 1077–1083, ISSN 1310-4772. [Google Scholar]

- Dochev, B.; Panov, I.; Tsonev, V.; Dimova, D. High-Temperature Tests of Piston Hypereutectic Aluminum–Silicon Alloy AlSi18Cu3CrMn. AIP Conf. Proc. 2022, 2462, 060005. [Google Scholar] [CrossRef]

- Kamarska, K.; Dochev, B.; Dimova, D. Investigation of the Corrosion and Electrochemical Behaviour of AlSi18Cu5Mg Alloy Modified with Be in Acidic Media. Oxid. Commun. 2022, 45, 529–537. [Google Scholar]

- Kamarska, K.; Dimova, D.; Dochev, B.; Koleva, Y.; Popova, T. Effect of Ni, Co, and Mo Alloying on the Corrosion Behaviour of Hypereutectic Al–Si Alloys in Acidic Media. AIP Conf. Proc. 2024, 2924, 060006. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 18.50 | 0.25 | 3.12 | 0.76 | 0.01 | 1.0 | 0.01 | 0.13 | 0.002 | rest |

| Phase | Alloy | ||

|---|---|---|---|

| № 1 | № 2 | № 3 | |

| Si, cubic | ✔ | ✔ | ✔ |

| Al, cubic | ✔ | ✔ | ✔ |

| Cu, cubic | ✔ | ✔ | ✔ |

| Mn, cubic | ✔ | ✔ | ✔ |

| CuAl2, tetragonal | ✔ | ✔ | ✔ |

| Cr3Si, cubic | ✔ | ✔ | ✔ |

| Mn12Si4, cubic | ✔ | ✔ | ✔ |

| Al57Mn12, cubic | ✔ | ✔ | ✔ |

| (Si,Al)2Cr, hexagonal | ✔ | ||

| № | Alloy | Rm/MPa | Rm/MPa 200 °C | Rm/Mpa 250 °C | Rm/Mpa 300 °C | HB2.5/62.5/30 | µHV50/10 |

|---|---|---|---|---|---|---|---|

| 1 | AlSi18Cu3CrMn + P (T6, water 20 °C) | 230 | 181 | 159 | 120 | 116 | 140.7 |

| 2 | AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 20 °C) | 165 | 205 | 179 | 136 | 133 | 139 |

| 3 | AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 50 °C) | 175 | - | - | - | 133 | 104.5 |

| Denotement | Mass Before Wear, g | Mass After Wear, g | Mass Loss, mg | ||

|---|---|---|---|---|---|

| AlSi18Cu3CrMn + P (T6, water 20 °C) | 1.6515 | 1.6511 | 0.4 | 5.5 | |

| Counterbody | 26.7808 | 26.7757 | 5.1 | ||

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 20 °C) | 1.6376 | 1.6373 | 0.3 | 3.3 | |

| Counterbody | 30.9147 | 30.9117 | 3.0 | ||

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 50 °C) | 1.6991 | 1.6987 | 0.4 | 1.3 | |

| Counterbody | 30.9117 | 30.9108 | 0.9 | ||

| Denotement | Wear, mg | Wear Intensity, mg/(m·N) | Wear Resistance, (m·N)/mg | Wear-induced Mass Loss (mg) | |||

|---|---|---|---|---|---|---|---|

| Mass loss, mg | Wear Rate, mg/(m·N) | Wear Resistance, (m·N)/mg | |||||

| AlSi18Cu3CrMn + P (T6, water 20 °C) | 0.6 | 4.9 × 10−4 | 2.0 × 103 | 5.5 | 45.8 × 10−4 | 0.22 × 103 | |

| counterbody | 5.0 | 40.1 × 10−4 | 0.25 × 103 | ||||

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 20 °C) | 0.3 | 2.5 × 10−4 | 4.0 × 103 | 3.3 | 27.0 × 10−4 | 0.37 × 103 | |

| counterbody | 3.0 | 24.5 × 10−4 | 0.4 × 103 | ||||

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 50 °C) | 0.4 | 3.3 × 10−4 | 3.0 × 103 | 1.3 | 10.6 × 10−4 | 0.94 × 103 | |

| counterbody | 0.9 | 7.4 × 10−4 | 1.4 × 103 | ||||

| Alloy | 72 h CR, g/(m2·h) | 240 h CR, g/(m2·h) | 360 h CR, g/(m2·h) |

|---|---|---|---|

| AlSi18Cu3CrMn + P (T6, water 20 °C) | 0 | 0 | 0.00015 |

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 20 °C) | 0.0014 | 0.00015 | 0.00015 |

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 50 °C) | 0 | 0.00015 | 0.00014 |

| Alloy | 72 h CR, g/(m2·h) | 240 h CR, g/(m2·h) | 360 h CR, g/(m2·h) |

|---|---|---|---|

| AlSi18Cu3CrMn + P (T6, water 20 °C) | 0.0132 | 0.0126 | 0.0126 |

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 20 °C) | 0.0128 | 0.0123 | 0.0124 |

| AlSi18Cu3CrMn + P, Ti, B, Be (T6, water 50 °C) | 0.0133 | 0.0126 | 0.0136 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimova, D.; Dochev, B.; Trojan, K.; Kamarska, K.; Sofronov, Y.; Zagorski, M.; Tsonev, V.; Nikolov, A. Investigation of the Structural, Mechanical and Operational Properties of an Alloy AlSi18Cu3CrMn. Materials 2025, 18, 5434. https://doi.org/10.3390/ma18235434

Dimova D, Dochev B, Trojan K, Kamarska K, Sofronov Y, Zagorski M, Tsonev V, Nikolov A. Investigation of the Structural, Mechanical and Operational Properties of an Alloy AlSi18Cu3CrMn. Materials. 2025; 18(23):5434. https://doi.org/10.3390/ma18235434

Chicago/Turabian StyleDimova, Desislava, Boyan Dochev, Karel Trojan, Kalina Kamarska, Yavor Sofronov, Mihail Zagorski, Veselin Tsonev, and Antonio Nikolov. 2025. "Investigation of the Structural, Mechanical and Operational Properties of an Alloy AlSi18Cu3CrMn" Materials 18, no. 23: 5434. https://doi.org/10.3390/ma18235434

APA StyleDimova, D., Dochev, B., Trojan, K., Kamarska, K., Sofronov, Y., Zagorski, M., Tsonev, V., & Nikolov, A. (2025). Investigation of the Structural, Mechanical and Operational Properties of an Alloy AlSi18Cu3CrMn. Materials, 18(23), 5434. https://doi.org/10.3390/ma18235434