A Preliminary Study of the Effect of 3D Printing Orientation on Mechanical Properties and Fracture of Samples Made from AlSi10Mg

Abstract

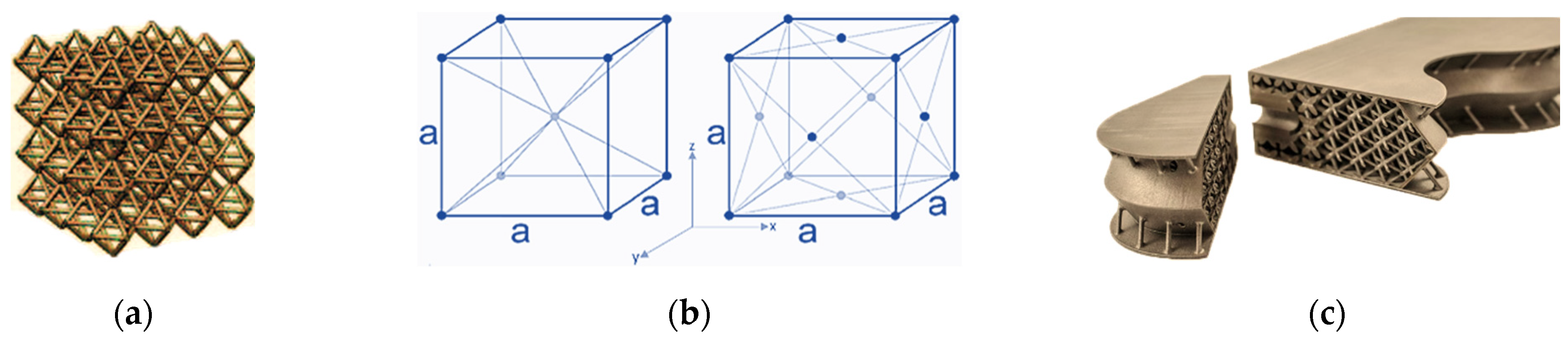

1. Introduction

2. State of the Art

3. Materials and Methods

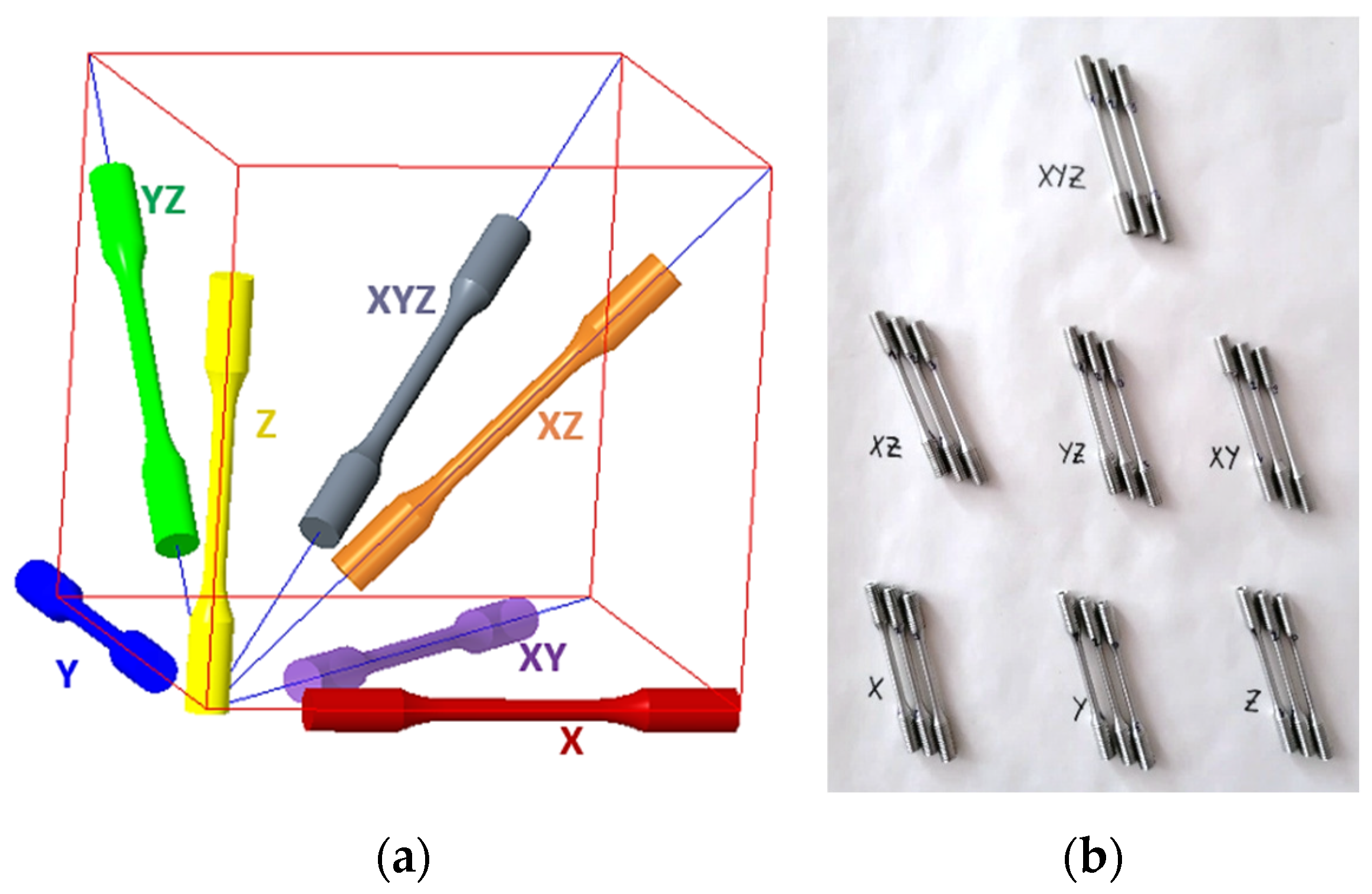

3.1. Samples Characteristics, Production and Testing

3.2. Production and Testing of Samples

3.3. Fractography, Microscopy and EBSD Analysis

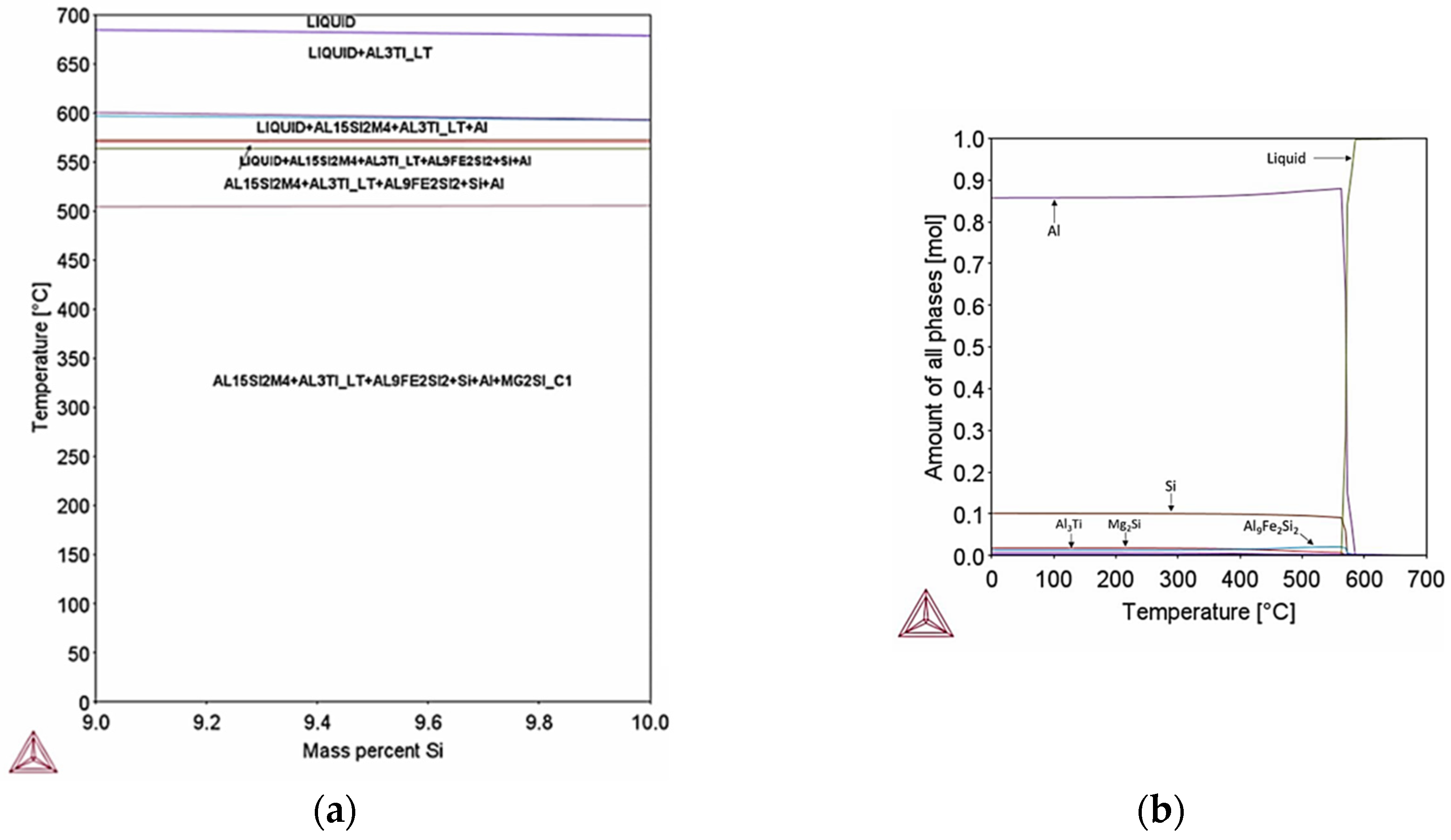

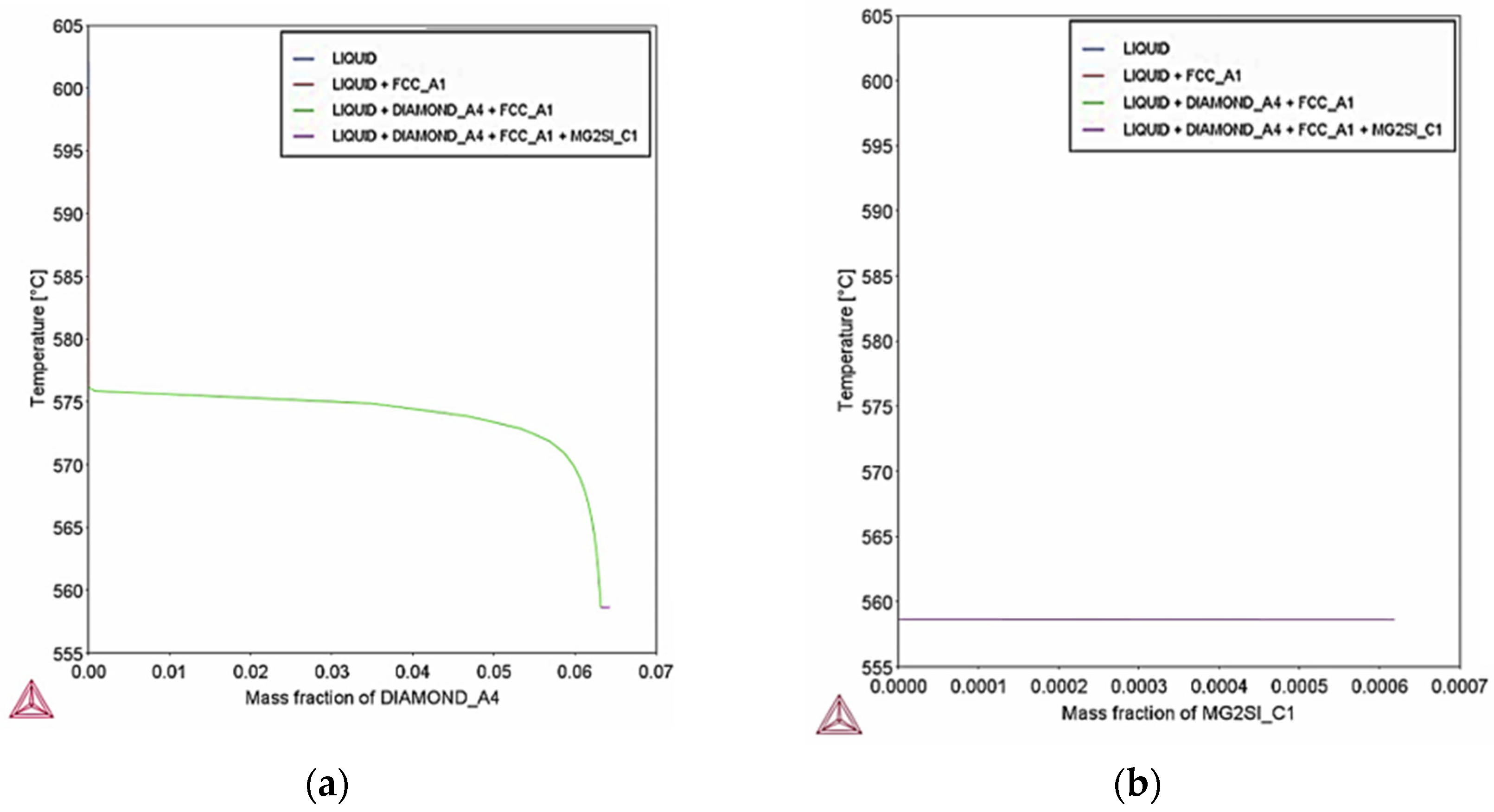

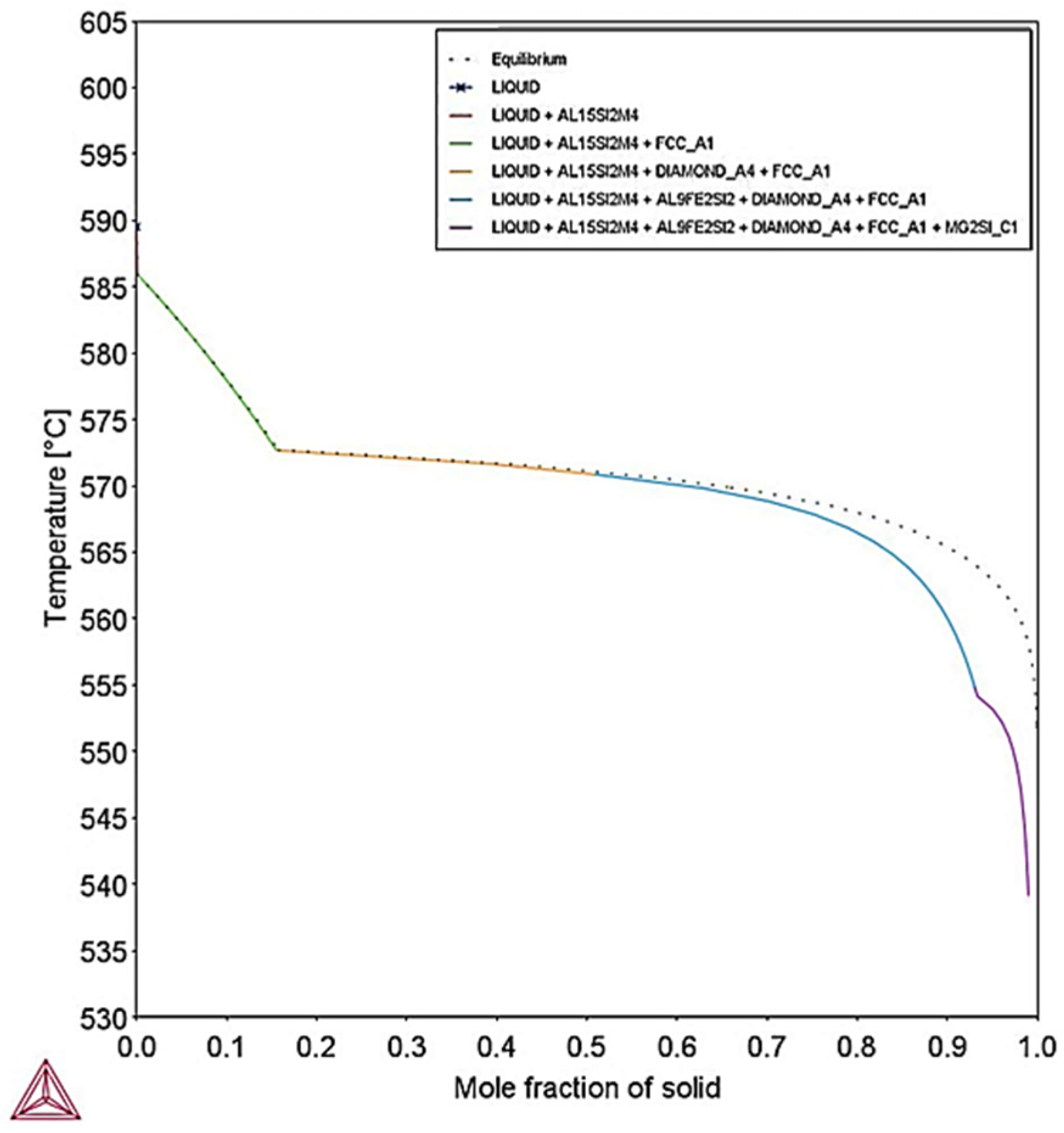

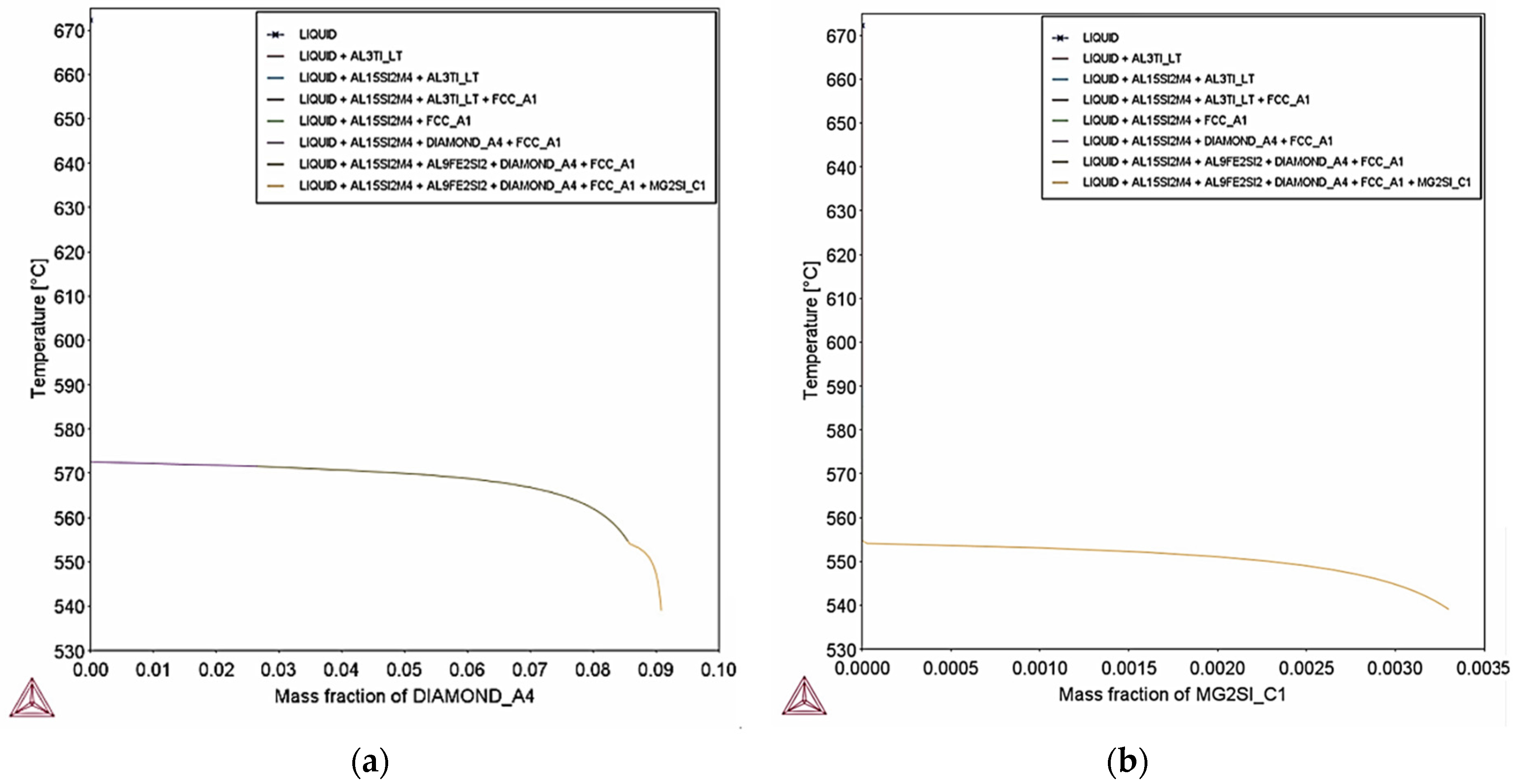

3.4. Thermodynamic Simulation

4. Results and Discussion

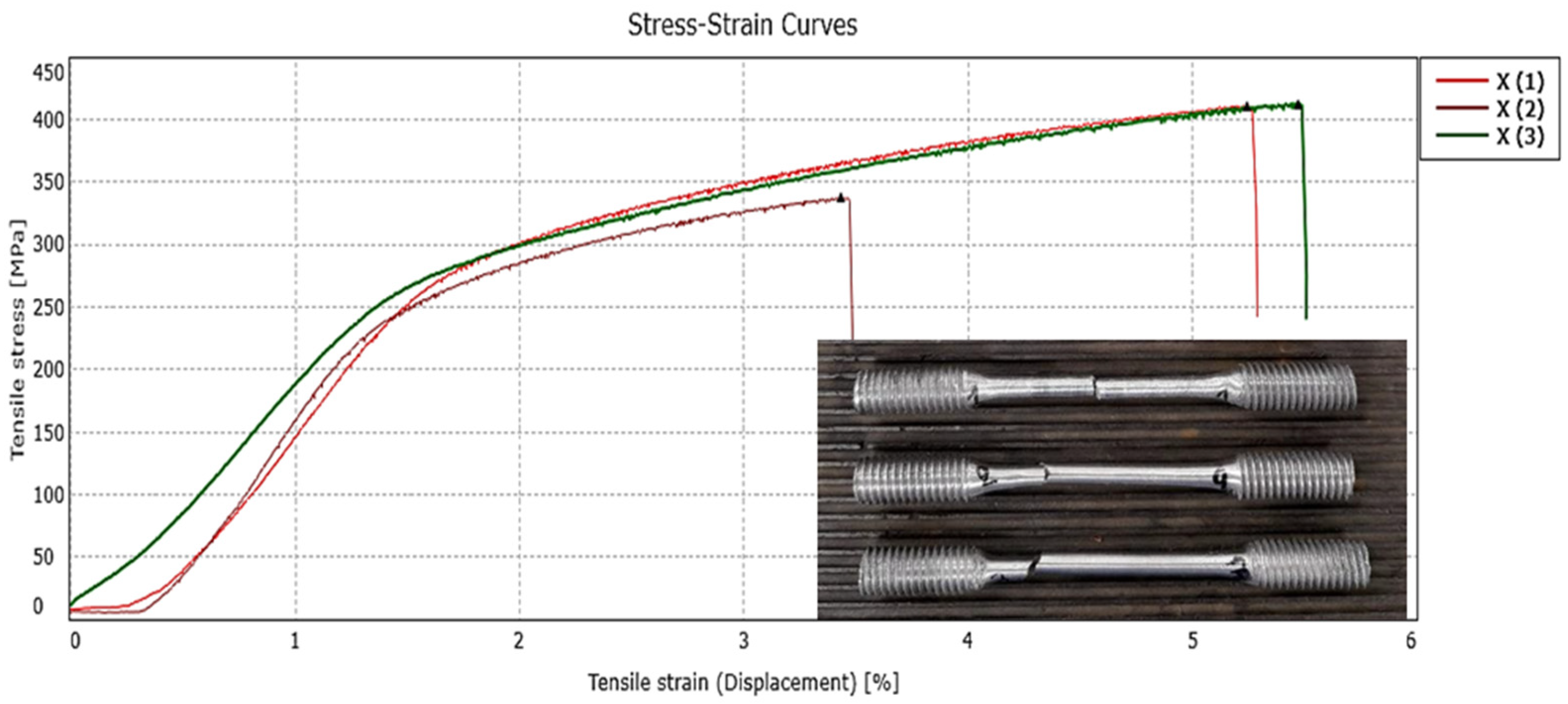

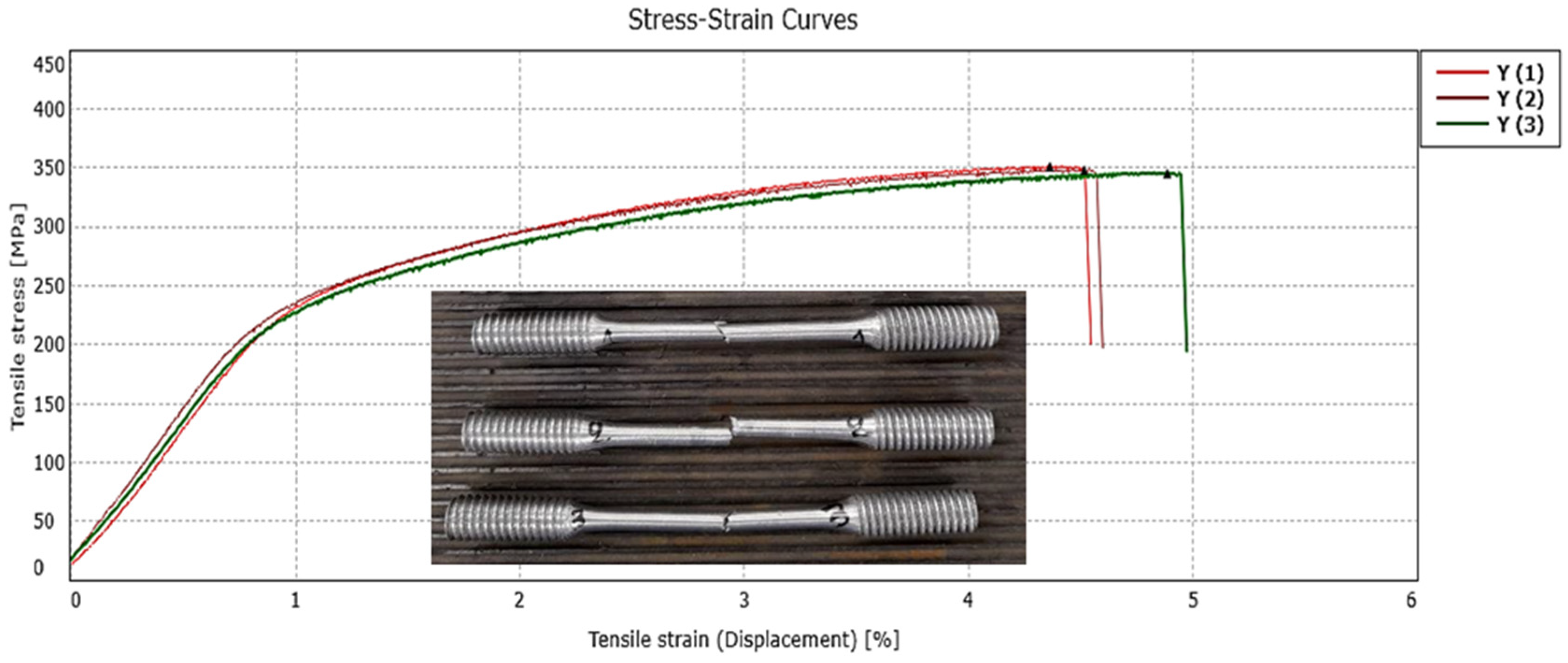

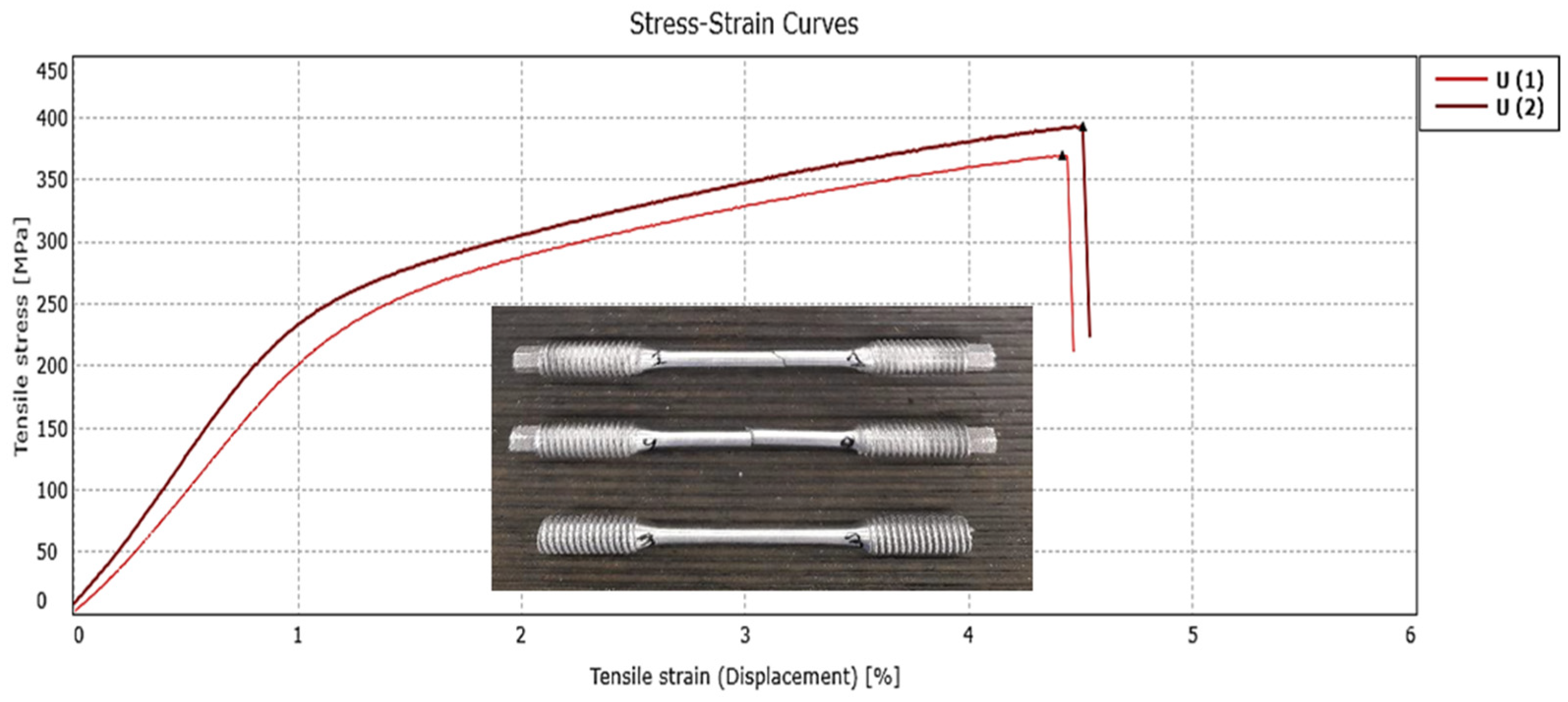

4.1. Tensile Properties—Experimental Testing

- Yield strength (Rp0.2): from 243 MPa for Y-samples up to 282 MPa for X-samples;

- Ultimate tensile strength (Rm): from 348 MPa for Y-samples up to 412 MPa for X-samples;

- Elongation (A35): 3% for X- and XY-samples up to—4.3% for Z-samples;

- Effective elastic modulus (Eef) from 21.8 for X-samples to 26 GPa for Y-samples.

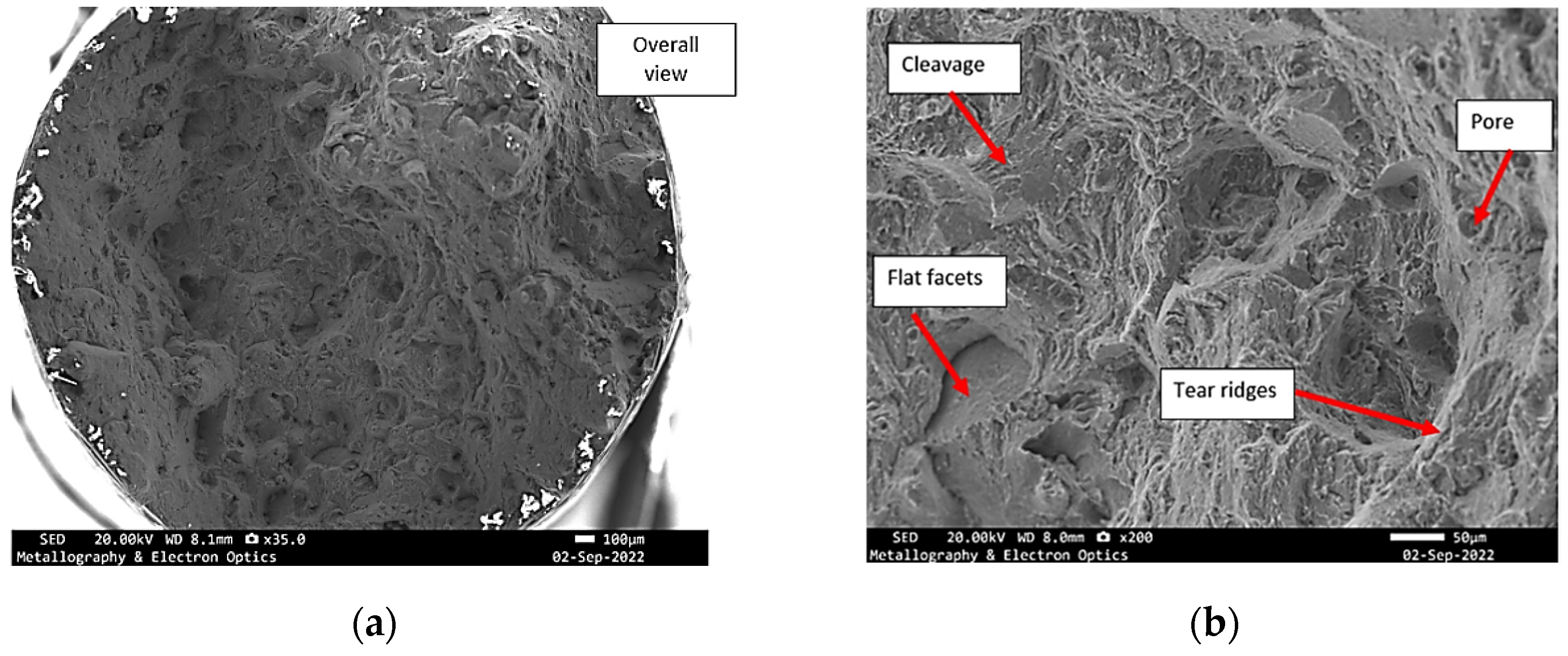

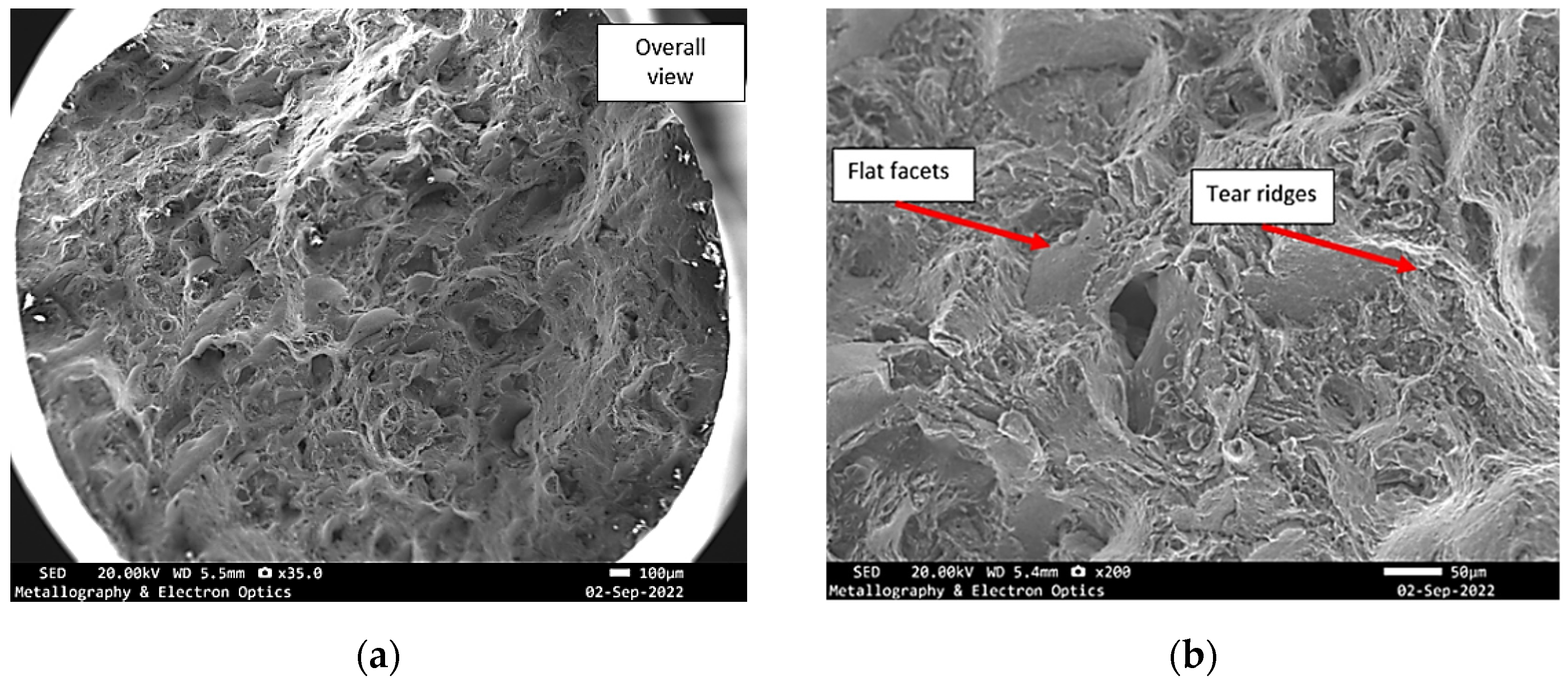

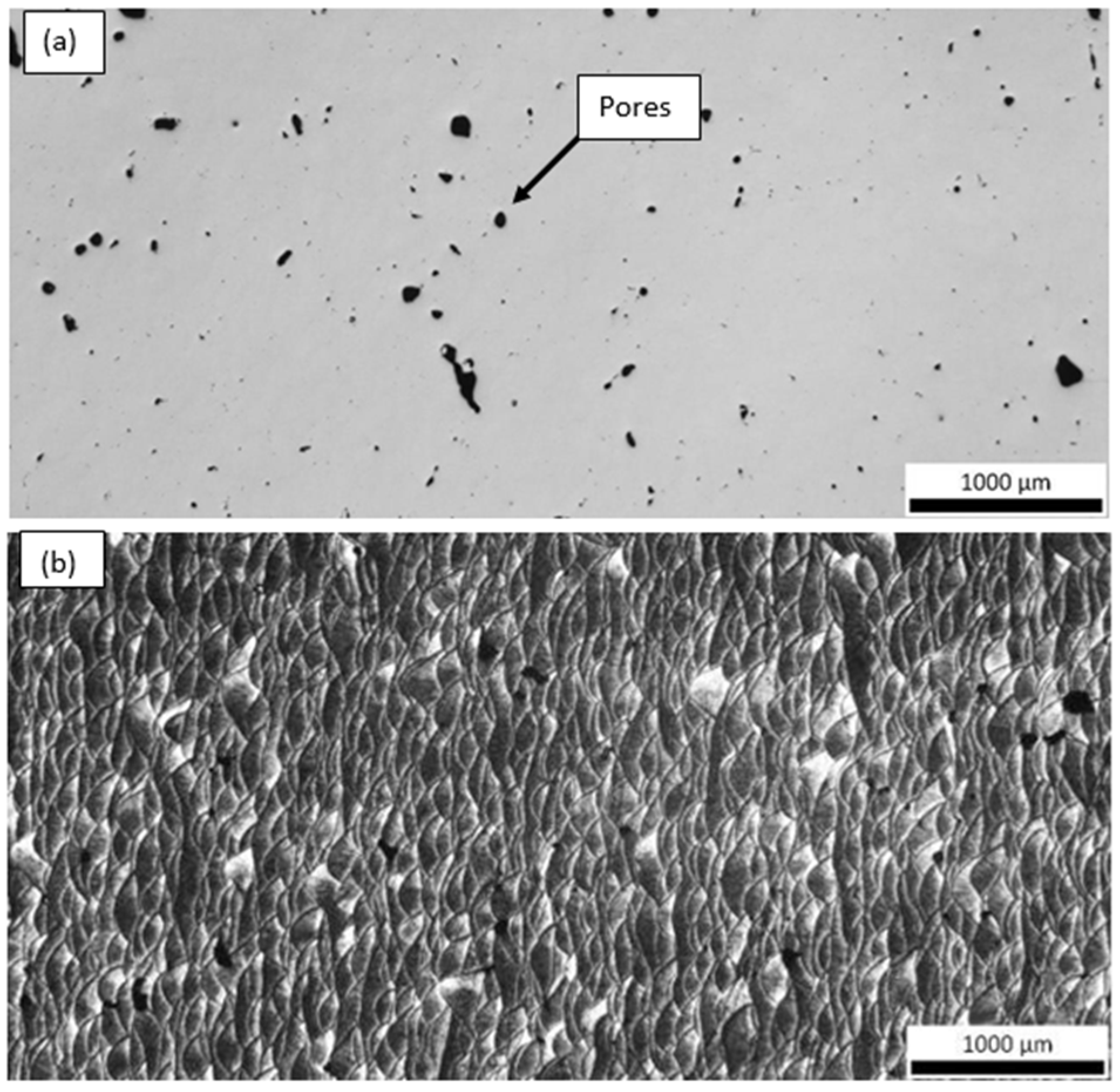

4.2. Stereo- and SEM Fractography

- A.

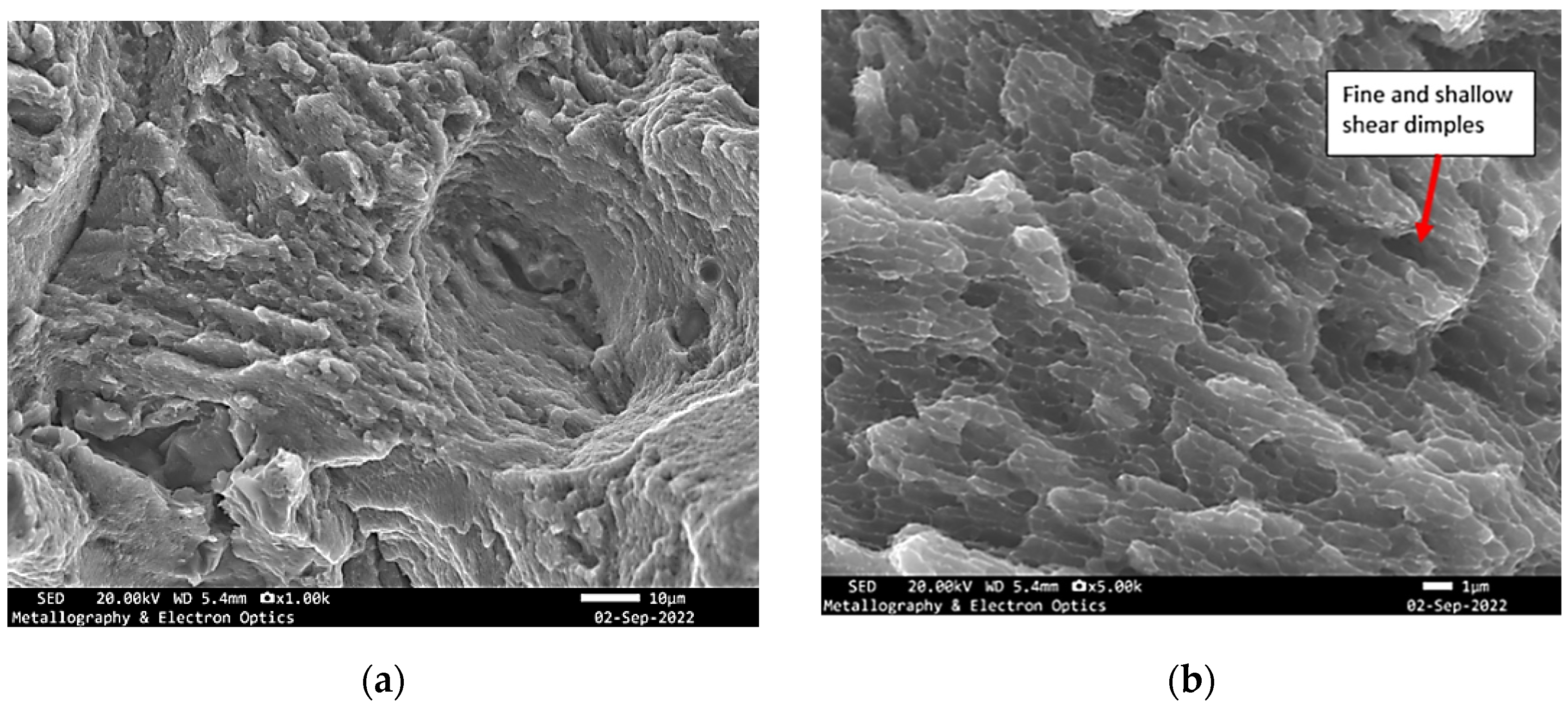

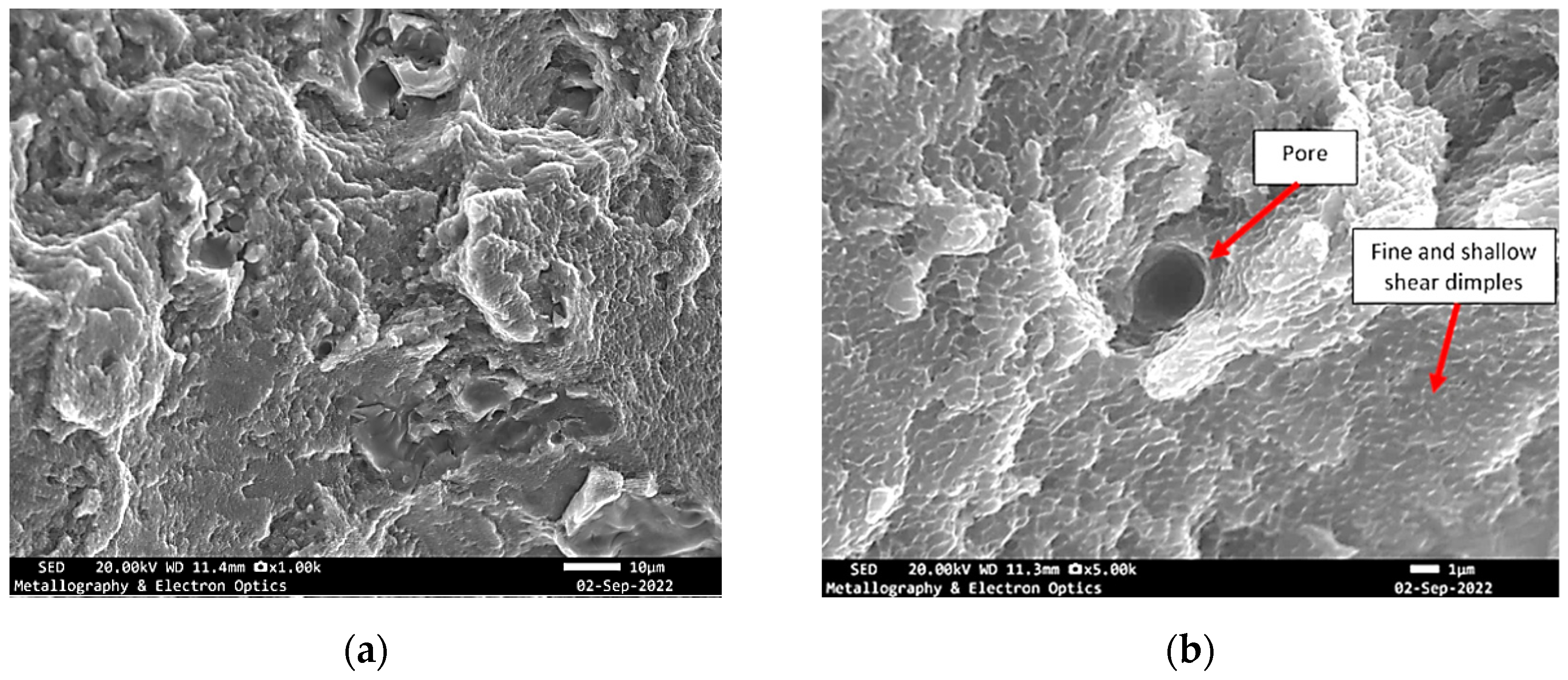

- Regions densely populated with fine and shallow dimples, typically formed due to micro-void nucleation and growth under tensile stress, suggesting localized ductile deformation.

- B.

- Tear ridges and interconnected cavities or pores, often aligned along the crack propagation direction, indicative of plastic deformation and the interaction between adjacent micro-voids.

- C.

- Flat facets with mirror-like appearance, commonly associated with quasi-cleavage fracture, reflecting areas of brittle failure possibly initiated at second-phase particles or microstructural inhomogeneities.

- D.

- Un-melted spherical particles of the feedstock material embedded or partially fused at the fracture interface, which may act as stress concentrators or crack initiation sites due to incomplete fusion during processing.

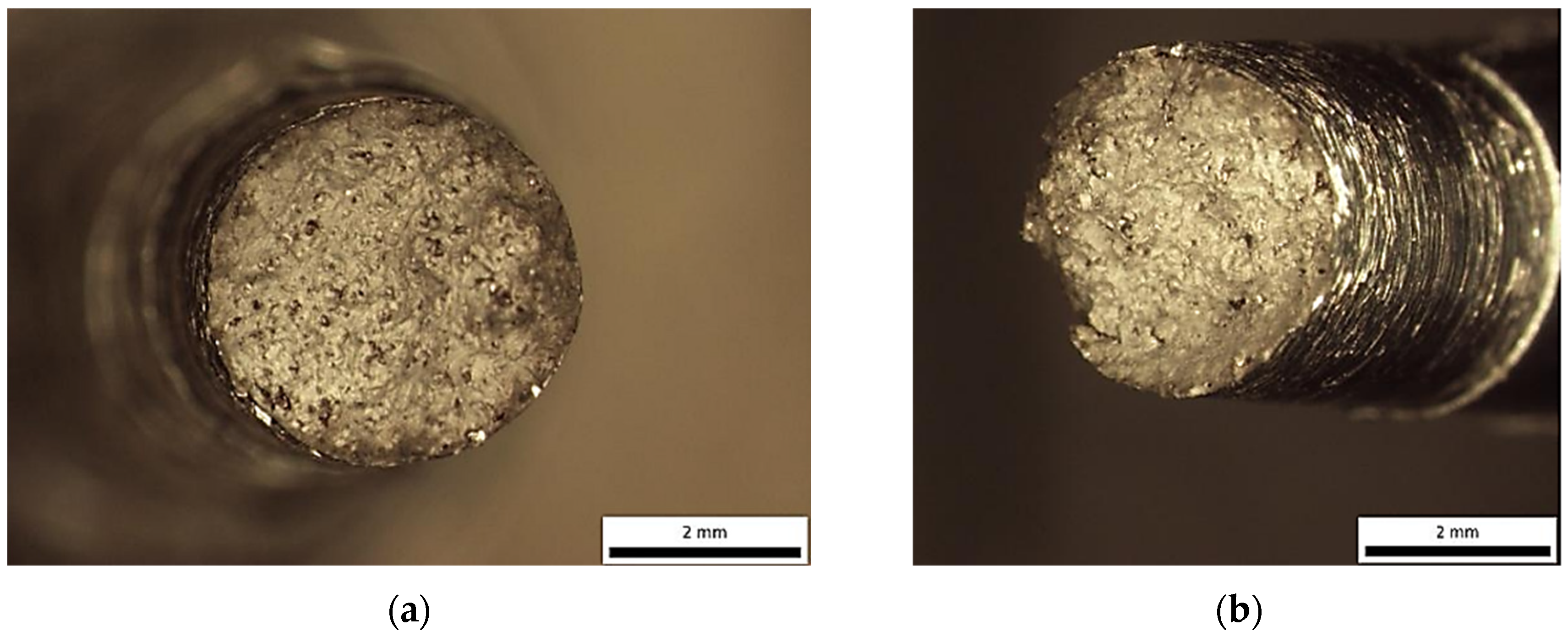

4.2.1. Sample Printed in X-Direction

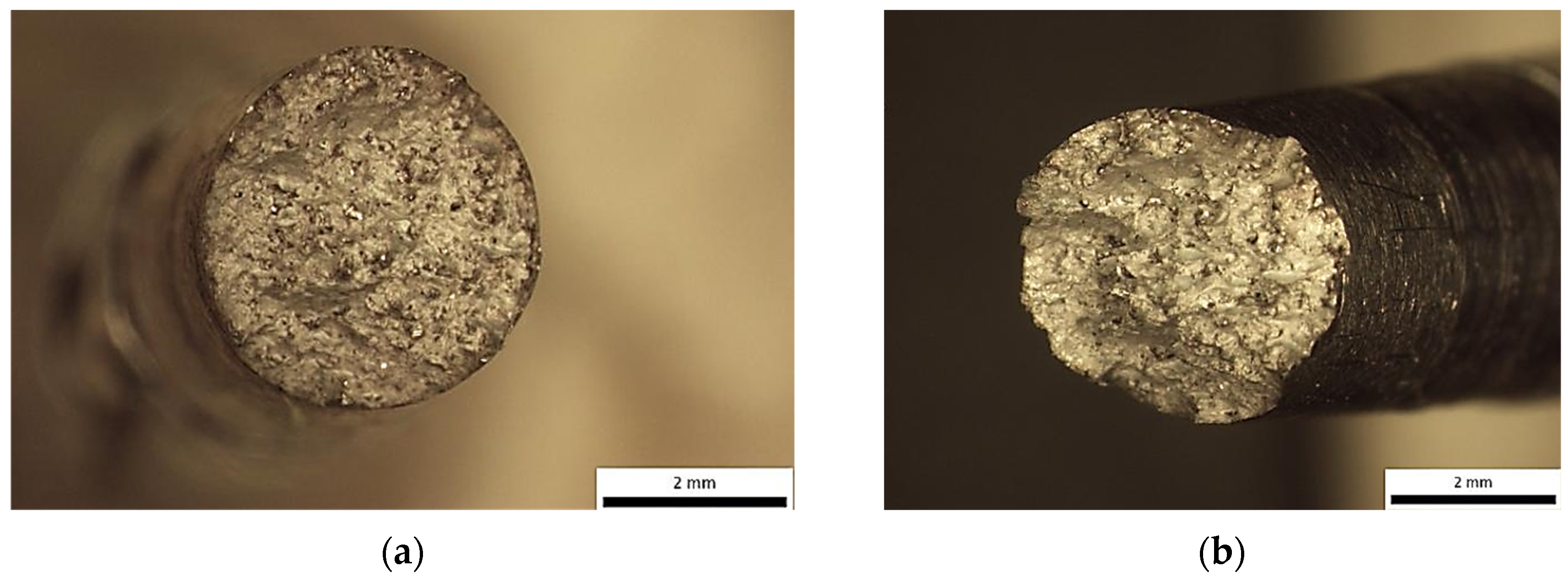

4.2.2. Sample Printed in Y-Direction

4.2.3. Sample Printed in Z-Direction

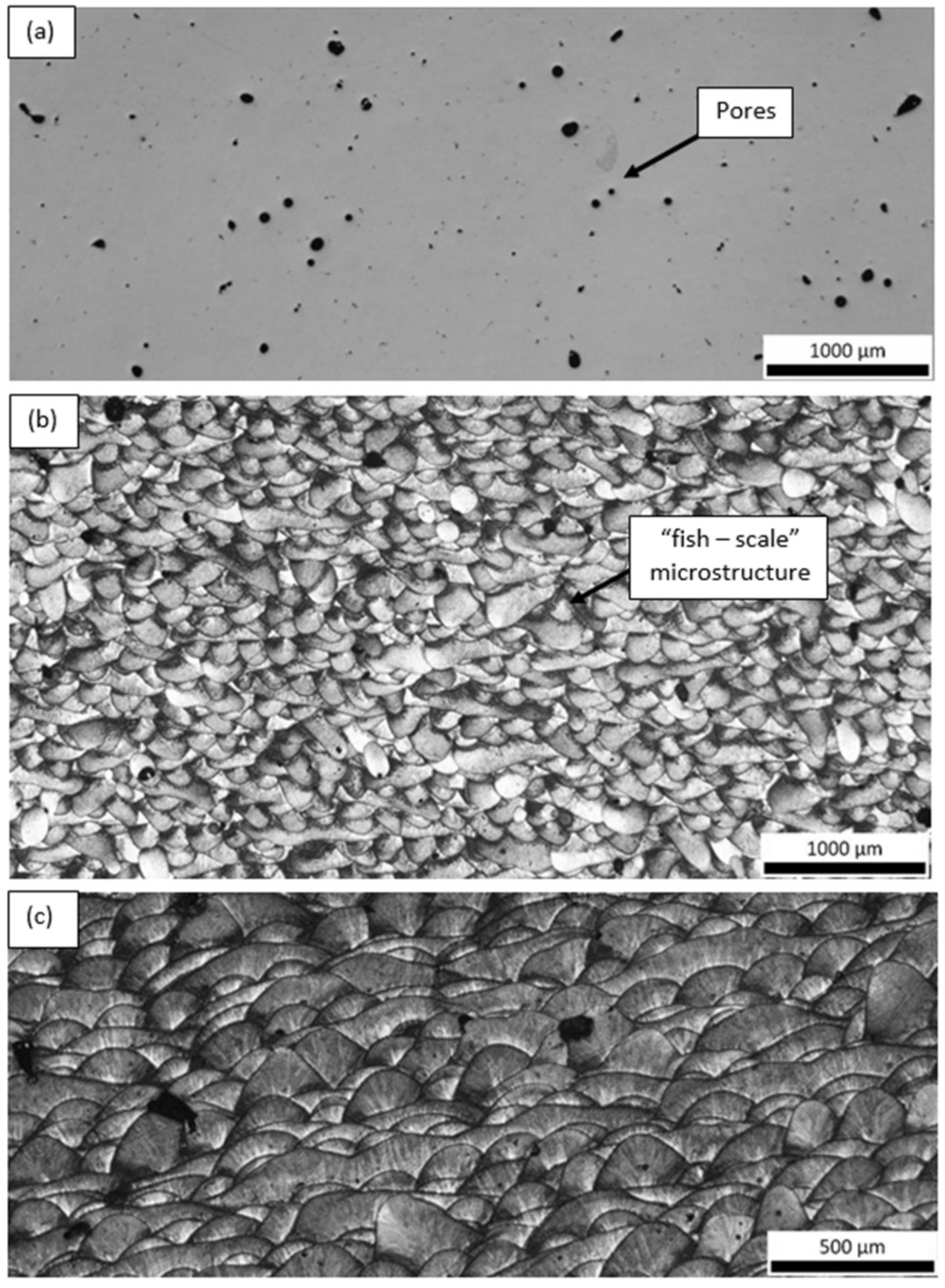

4.3. Optical, Electron Microscopy and Electron Backscatter Diffraction (EBSD) Textural Analysis

4.3.1. Microstructure (Grain Morphology)

- I.

- Laser-related parameters—laser power, spot size, pulse duration, pulse frequency;

- II.

- Scan-related parameters—scan speed, scan spacing, scan pattern;

- III.

- Powder-related parameters—particle size, particle shape and distribution, powder bed density, layer thickness, material properties; and

- IV.

- Temperature-related parameters—powder bed temperature, powder feeder temperature, temperature uniformity.

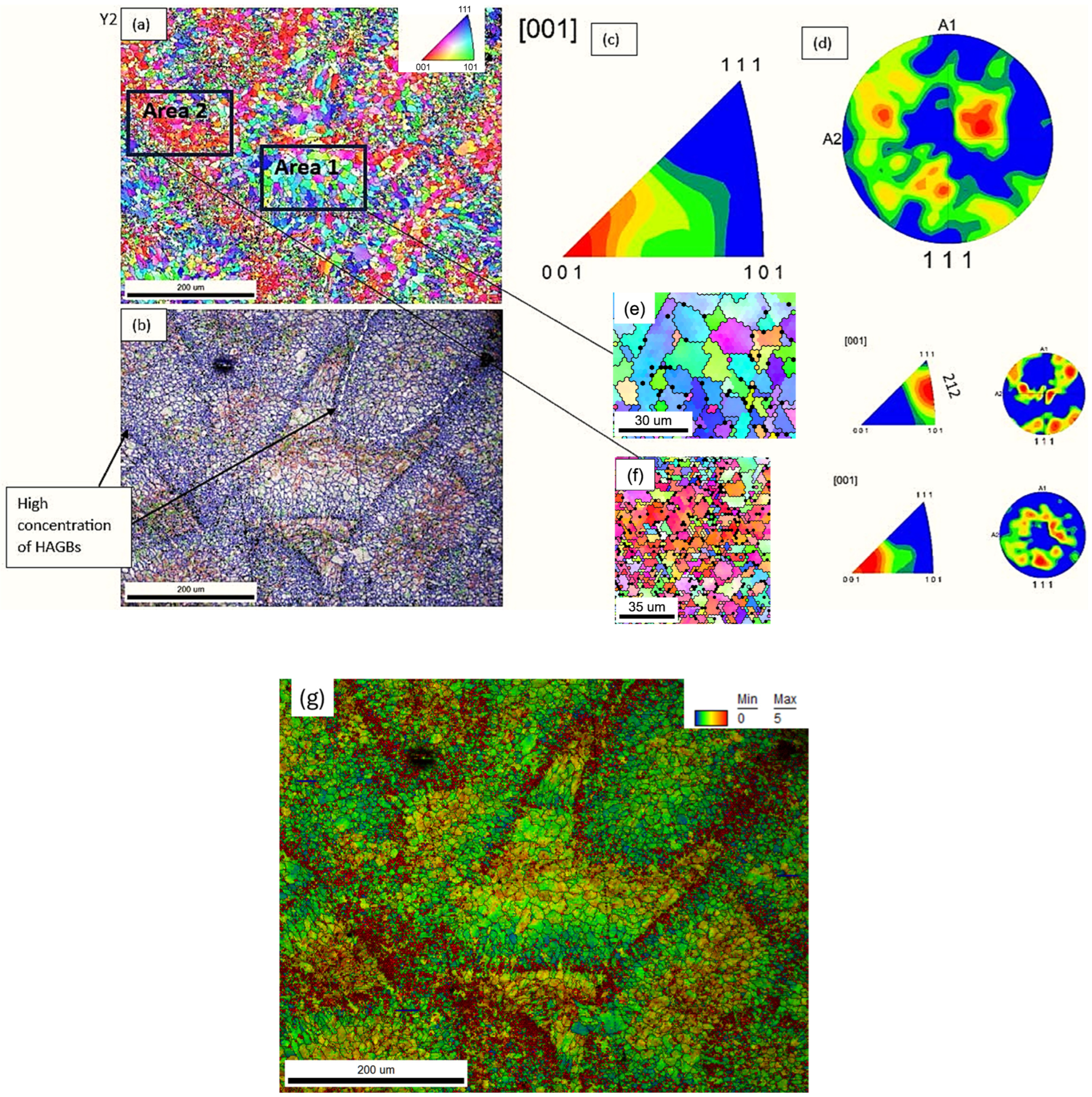

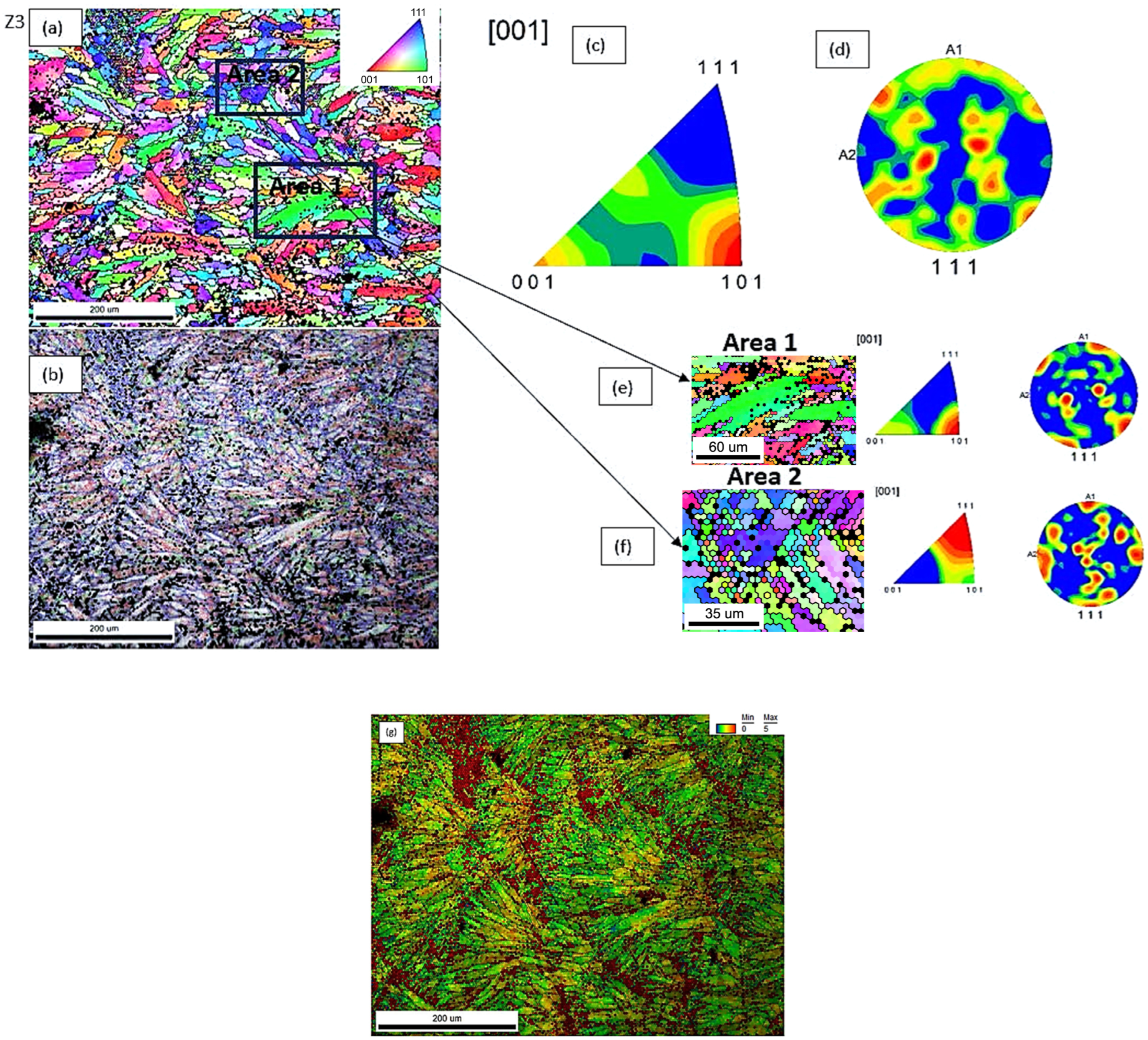

4.3.2. EBSD Analysis

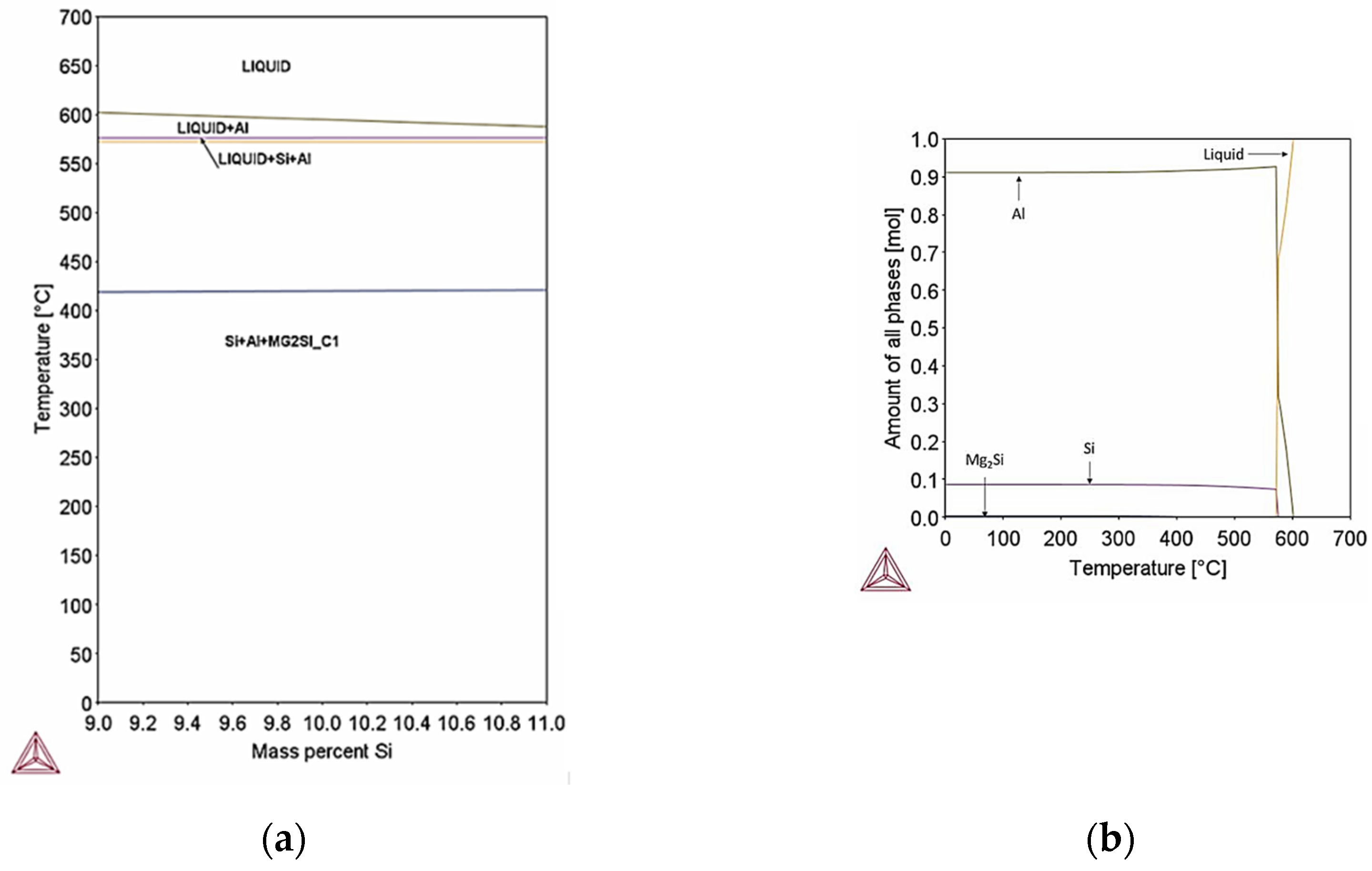

4.4. Thermodynamic and Scheil–Gulliver Simulation

5. Conclusions

- Yield strength (Rp0.2), ultimate strength (Rm), elongation (A35) elongation at break and Young’s modulus were evaluated.

- The Y-sample series showed the minimum tensile properties (yield 243 MPa and ultimate 348 MPa tensile strength), while the X-sample series showed the maximum ones (282 MPa and 412 MPa). The strength of the samples is highly dependent on the orientation of grains, their size and morphology. Individually evaluated, the Y(3) sample showed the minimum tensile properties (A35 = 4%, Rp0.2 = 239 MPa and Rm = 346 MPa), while Z(3) showed the maximum ones (A35 = 4%, Rp0.2 = 273 MPa and Rm = 420 MPa). Fractographic investigation on tensile fractures identified predominantly a low ductility failure mechanism, showing fine size shear (mostly), dimple formation, tear ridges, flat facets, pores and cavities as well as spheres of un-melted feed material.

- Sample Y(3) exhibited a strong, dual-component crystallographic texture, with two dominant orientation clusters along the <212> and <001> directions. The disparity in texture intensity between these regions is likely responsible for localized mechanical incompatibilities and strain heterogeneity, resulting in preferential crack paths and reduced mechanical strength. In contrast, sample Z(3) presented a more randomized orientation distribution, with less distinguishable texture zones, enabling better strain accommodation and more uniform plastic deformation, which correlates with its higher tensile and yield strength.

- Although sample Y(3) had finer grains (5–7 μm) compared to Z(3) (7–9 μm), it exhibited lower mechanical strength. This deviation from the Hall–Petch relationship is attributed to the dominant effect of strong crystallographic texture in Y(3), which counteracted the expected strengthening effect of grain refinement. This highlights the complex interplay between grain size and texture in LPBF-produced materials.

- Sample Y(3) contained a higher fraction of high-angle grain boundaries (HAGBs) (>70%) and lower low-angle grain boundary (LAGB) content (<20%), indicative of a more recrystallized but less accommodating microstructure. On the other hand, Z(3), with LAGBs >30%, supported smoother dislocation movement and enhanced grain compatibility, contributing to improved ductility and resistance to fracture.

- Despite Z(3) showing a higher overall KAM value (2.68 vs. 2.48 in Y(3)), its KAM gradient was lower (~0.5) compared to Y(3) (~0.8). This suggests a more homogeneous distribution of local misorientation in Z(3), implying less abrupt strain gradients and lower risk of strain localization, whereas Y(3) may exhibit more concentrated deformation bands prone to crack initiation.

- Both samples demonstrated mixed-mode fracture characteristics, with dimples, cavities, pores, and flat facets. Tear ridges were more prominent and vertically developed in certain regions, especially in areas with flat fracture planes and deeper topographical features (confirmed via 3D visualization). These regions likely indicate localized plastic instability and strain concentration.

- The direction <101> accompanied by the most isotropic microstructure of sample Z(3) as well as the lower KAM gradient affect between the different areas observed led to superior mechanical response in contrast to sample Y(3) although the latter exhibited finer mean grain size.

- The results show that precipitation of Si is expected both on minimum and maximum composition reaching up to 10%. In case of maximum composition, precipitation of other phases is observed at lower percentage (<5%) such as Al15Si2M4, (M:Fe, Mn) Al9Fe2Si2 and Mg2Si.

6. Suggestions for Further Research

- quantification of porosity, microstructure, texture and defects for a full set of different sample orientations to investigate whether there is any correlation with the observed mechanical behavior;

- expanding EBSD mapping to all orientations to justify anisotropy trends;

- providing a detailed view on each orientation summarizing grain size, texture intensity, porosity, yield/UTS, and elongation, including Hall–Petch together with an anisotropy factor for more physical interpretations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No | Sample ID | Diameter (mm) | Max. Load (kN) | Rp0.2 (MPa) * | Rm (MPa) | A35 (%) |

|---|---|---|---|---|---|---|

| 1 | X (1) | 3.64 | 4.3 | 285 | 411 | 3 |

| 2 | X (2) | 3.48 | Rejected due to early breakage | |||

| 3 | X (3) | 3.81 | 4.7 | 278 | 413 | 3 |

| AVERAGE VALUES | 282 | 412 | 3 | |||

| No | Sample ID | Diameter (mm) | Max. Load (kN) | Rp0.2 (MPa) * | Rm (MPa) | A35 (%) |

|---|---|---|---|---|---|---|

| 1 | Y (1) | 3.63 | 3.6 | 249 | 351 | 3 |

| 2 | Y (2) | 3.68 | 3.7 | 241 | 348 | 3 |

| 3 | Y (3) | 3.73 | 3.8 | 239 | 346 | 4 |

| AVERAGE VALUES | 243 | 348 | 3 | |||

| No | Sample ID | Diameter (mm) | Max. Load (kN) | Rp0.2 (MPa) * | Rm (MPa) | A35 (%) |

|---|---|---|---|---|---|---|

| 1 | Z (1) | 3.97 | 4.5 | 247 | 365 | 4 |

| 2 | Z (2) | 3.83 | 4.8 | 269 | 414 | 5 |

| 3 | Z (3) | 3.77 | 4.7 | 273 | 420 | 4 |

| AVERAGE VALUES | 263 | 400 | 4 | |||

| No | Sample ID | Diameter (mm) | Max. Load (kN) | Rp0.2 (MPa) * | Rm (MPa) | A35 (%) |

|---|---|---|---|---|---|---|

| 1 | B (1)–XZ | 3.81 | 4.5 | 274 | 398 | 4 |

| 2 | B (2)–XZ | 3.81 | 4.6 | 275 | 405 | 4 |

| 3 | B (3)–XZ | 3.80 | 4.7 | 276 | 418 | 4 |

| AVERAGE VALUES | 275 | 407 | 4 | |||

| No | Sample ID | Diameter (mm) | Max. Load (kN) | Rp0.2 (MPa) * | Rm (MPa) | A35 (%) |

|---|---|---|---|---|---|---|

| 1 | C (1)–YZ | 3.84 | 4.6 | 259 | 398 | 4 |

| 2 | C (2)–YZ | 3.83 | 4.4 | 267 | 382 | 4 |

| 3 | C (3)–YZ | 3.74 | Rejected due to early breakage | |||

| AVERAGE VALUES | 263 | 390 | 4 | |||

| No | Sample ID | Diameter (mm) | Max. Load (kN) | Rp0.2 (MPa) * | Rm (MPa) | A35 (%) |

|---|---|---|---|---|---|---|

| 1 | U (1)–XYZ | 3.85 | 4.3 | 251 | 369 | 4 |

| 2 | U (2)–XYZ | 3.73 | 4.3 | 258 | 393 | 4 |

| 3 | U (3)–XYZ | Not valid specimen (no proper thread manufacturing) | ||||

| AVERAGE VALUES | 255 | 381 | 4 | |||

References

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Hague, R. Shape complexity and process energy consumption in electron beam melting: A case of something for nothing in additive manufacturing? J. Ind. Ecol. 2016, 21, 98–106. [Google Scholar] [CrossRef]

- Panesar, A.; Ashcroft, I.; Brackett, D.; Wildman, R.; Hague, R. Design framework for multifunctional additive manufacturing: Coupled optimization strategy for structures with embedded functional systems. Addit. Manuf. 2017, 16, 98–106. [Google Scholar] [CrossRef]

- Maskery, I.; Hussey, A.; Panesar, A.; Aremu, A.; Tuck, C.; Ashcroft, I.; Hague, R. An investigation into reinforced and functionally graded lattice structures. J. Cell. Plast. 2016, 53, 151–165. [Google Scholar] [CrossRef]

- Panesar, A.; Brackett, D.; Ashcroft, I.; Wildman, R.; Hague, R. Hierarchical remeshing strategies with mesh mapping for topology optimisation. Int. J. Numer. Methods Eng. 2017, 111, 676–700. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Saleh, E.; Wildman, R.D.; Hague, R.J.M.; Tuck, C.J. Optimisation of substrate angles for multi-material and multi-functional inkjet printing. Sci. Rep. 2018, 8, 9030. [Google Scholar] [CrossRef] [PubMed]

- Bean, G.E.; McLouth, T.D.; Witkin, D.B.; Sitzman, S.D.; Adams, P.M.; Zaldivar, R.J. Build Orientation Effects on Texture and Mechanical Properties of Selective Laser Melting Inconel 718. J. Mater. Eng. Perform. 2019, 28, 1942–1949. [Google Scholar] [CrossRef]

- Monkova, K.; Papadopoulou, S.; Bouzouni, M.; Toulfatzis, A.; Pantazopoulos, G. The effect of 3D printing orientation on tensile behaviour and fracture mechanisms of Inconel 718. Eng. Fail. Anal. 2024, 166, 108920. [Google Scholar] [CrossRef]

- Monkova, K.; Zetkova, I.; Kučerová, L.; Zetek, M.; Monka, P.; Daňa, M. Study of 3D printing direction and effects of heat treatment on mechanical properties of MS1 maraging steel. Arch. Appl. Mech. 2019, 89, 791–804. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Yi, F.; Liu, H.; Zhou, Q.; Yan, Z.; Lin, J. Anisotropy in microstructure and mechanical properties of additively manufactured Ni-based GH4099 alloy. J. Mater. Res. Technol. 2023, 26, 6552–6564. [Google Scholar] [CrossRef]

- Singh, P.K.; Kumar, S.; Jain, P.K.; Dixit, U.S. Effect of Build Orientation on Metallurgical and Mechanical Properties of Additively Manufactured Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2024, 33, 3476–3493. [Google Scholar] [CrossRef]

- Barba, D.; Alabort, C.; Tang, Y.T.; Viscasillas, M.J.; Reed, R.C.; Alabort, E. On the size and orientation effect in additive manufactured Ti-6Al-4V. Mater. Des. 2020, 186, 108235. [Google Scholar] [CrossRef]

- Pal, R.; Kemerling, B.; Ryan, D.; Bollapragada, S.; Basak, A. Incorporating surface roughness into numerical modeling for predicting fatigue properties of L-PBF AlSi10Mg specimens. Eng. Fail. Anal. 2024, 161, 108250. [Google Scholar] [CrossRef]

- Lassance, D.; Fabrègue, D.; Delannay, F.; Pardoen, T. Micromechanics of room and high temperature fracture in 6xxx Al alloys. Prog. Mater. Sci. 2007, 52, 62–129. [Google Scholar] [CrossRef]

- Asgari, H.; Baxter, C.; Hosseinkhani, K.; Mohammadi, M. On microstructure and mechanical properties of additively manufactured AlSi10Mg_200C using recycled powder. Mater. Sci. Eng. A 2017, 707, 148–158. [Google Scholar] [CrossRef]

- Zavala-Arredondo, M.; Boone, N.; Willmott, J.; Childs, D.T.D.; Ivanov, P.; Groom, K.M.; Mumtaz, K. Laser diode area melting for high speed additive manufacturing of metallic components. Mater. Des. 2017, 117, 305–315. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Hartunian, P.; Eshraghi, M. Effect of Build Orientation on the Microstructure and Mechanical Properties of Selective Laser-Melted Ti-6Al-4V Alloy. J. Manuf. Mater. Process. 2018, 2, 69. [Google Scholar] [CrossRef]

- Data Sheet Aluminium AlSi10Mg, MT 3D Ltd. Available online: www.metaltechnics3d.com (accessed on 15 September 2023).

- DIN EN1706/EN AC-43000; Material Data Sheet. SLM Solutions Group AG: Lübeck, Germany, 2023; p. 12.

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature, CEN-CENELEC, Brussels. R&B Inc.: Daejeon, Republic of Korea, 2019.

- Available online: https://www.jeol.com/products/scientific/sem/SMILE_VIEW_MAP.php (accessed on 12 November 2025).

- Available online: https://www.edax.com.cn/-/media/ametekedax/files/ebsd/product_bulletins/team_ebsd_analysis_system_pb.pdf (accessed on 12 November 2025).

- Andersson, J.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc and DICTRA, Computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Sotiriou, M.; Aristeidakis, J.; Tzini, M.-I.; Papadioti, I.; Haidemenopoulos, G.; Aravas, N. Microstructural and Thermomechanical Simulation of the Additive Manufacturing Process in 316L Austenitic Stainless Steel. Mater. Proc. 2021, 3, 20. [Google Scholar]

- Andani, M.; Lakshmanan, A.; Sundararaghavan, V.; Allison, J.; Misra, A. Quantitative study of the effect of grain boundary parameters on the slip system level Hall- Petch slope for basal slip system in Mg-4Al. Acta Mater. 2020, 200, 148–161. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Georgakopoulos-Soares, I.; Cichocki, K.; Lisiecka-Graca, P.; Papazoglou, E.L. Compressive and energy absorption properties of titanium hybrid lattice structures for bioimplant applications fabricated via LPBF. Mater. Des. 2025, 254, 114045. [Google Scholar] [CrossRef]

- Arshad, A.; Cong, P.; Elmenshawy, A.A.E.; Blumbergs, I. Design optimization for the weight reduction of 2-cylinder reciprocating compressor crankshaft. Arch. Mech. Eng. 2021, 68, 449–471. [Google Scholar] [CrossRef]

- Adjamsky, S.; Dovgyy, B.; Kononenko, G.; Karmiris-Obratański, P.; Podolskyi, R. Peculiarities of the evolution of the microstructure and mechanical properties depending on the correction of the focal length in parts made by laser melting in a powder layer. Mater. Res. Proc. 2024, 46, 57–64. [Google Scholar] [CrossRef]

- Bazios, P.; Tserpes, K.; Pantelakis, S. Modelling and Experimental Validation of the Porosity Effect on the Behaviour of Nano-Crystalline Materials. Metals 2020, 10, 821. [Google Scholar] [CrossRef]

- Halama, R.; Markopoulos, A.; Šmach, J.; Govindaraj, B. Theory, application and implementation of modified Abdel-Karim-Ohno model for uniaxial and multiaxial fatigue loading. In Fatigue Damage in Metals—Numerical Based Approaches and Applications; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Monková, K.; Monka, P.; Vegnerová, P.; Čep, R.; Müllerová, J.; Bražina, D.; Duspara, M. Factor analysis of the abrasive waterjet factors affecting the surface roughness of titanium. Teh. Vjesn. Tech. Gaz. 2011, 18, 73–77. [Google Scholar]

- Stergioudi, F.; Prospathopoulos, A.; Farazas, A.; Tsirogiannis, E.C.; Michailidis, N. Mechanical Properties of AA2024 Aluminum/MWCNTs Nanocomposites Produced Using Different Powder Metallurgy Methods. Metals 2022, 12, 1315. [Google Scholar] [CrossRef]

- Grbović, A.; Kastratović, G.; Božić, Ž.; Božić, I.; Obradović, A.; Sedmak, A.; Sedmak, S. Experimental and numerical evaluation of fracture characteristics of composite material used in the aircraft engine cover manufacturing. Eng. Fail. Anal. 2022, 137, 106286. [Google Scholar] [CrossRef]

- Arshad, A.; Kovaļčuks, V. Computational Investigations for the Feasibility of Passive Flow Control Devices for Enhanced Aerodynamics of Small-Scale UAVs. Aerospace 2024, 11, 473. [Google Scholar] [CrossRef]

- ASTM F3318-18; Standard for Additive Manufacturing—Finished Part Properties—Specification for AlSi10Mg with Powder Bed Fusion—Laser Beam. ASTM International: West Conshohocken, PA, USA, 2018; p. 8. [CrossRef]

- Medrano, V.A.; Arrieta, E.; Merino, J.; Ruvalcaba, B.; Caballero, K.; Ramirez, B.; Diemann, J.; Murr, L.E.; Wicker, R.B.; Godfrey, D.; et al. A comprehensive and comparative study of microstructure and mechanical properties for post-process heat treatment of AlSi7Mg alloy components fabricated in different laser powder bed fusion systems. J. Mater. Res. Technol. 2023, 24, 6820–6842. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, S.; Zhu, H. Effect of scanning strategy on geometric accuracy of the circle structure fabricated by selective laser melting. J. Manuf. Process. 2021, 64, 907–915. [Google Scholar] [CrossRef]

- ASTM E111; Standard Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2010; p. 7. [CrossRef]

- E1875−08; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Sonic Resonance. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2021; p. 8. [CrossRef]

- Kiass, E.M.; Zarbane, K.; Beidouri, Z. Process parameters effect on porosity rate of AlSi10Mg parts additively manufactured by Selective Laser Melting: Challenges and research opportunities. Arch. Mater. Sci. Eng. 2023, 122, 22–33. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mech. Work. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Rakesh, C.S.; Priyanka, N.; Jayaganthan, R.; Vasa, N.J. Effect of build atmosphere on the mechanical properties of AlSi10Mg produced by selective laser melting. Mater. Today Proc. 2018, 5, 17231–17238. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of Selective Laser Melting Process Parameters on the Quality of Al Alloy Parts: Powder Characterization, Density, Surface Roughness, and Dimensional Accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef]

- Giovagnoli, M.; Silvi, G.; Merlin, M.; Di Giovanni, M.T. Optimisation of process parameters for an additively manufactured AlSi10Mg alloy: Limitations of the energy density-based approach on porosity and mechanical properties estimation. Mater. Sci. Eng. A 2021, 802, 140613. [Google Scholar] [CrossRef]

- Chen, J.; Hou, W.; Wang, X.; Chu, S.; Yang, Z. Microstructure, porosity and mechanical properties of selective laser melted AlSi10Mg. Chin. J. Aeronaut. 2020, 33, 2043–2054. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies Rapid Prototyping to Direct Digital Manufacturing; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Avateffazeli, M.; Haghshenas, M. Ultrasonic fatigue of laser beam powder bed fused metals: A state-of-the-art review. Eng. Fail. Anal. 2022, 134, 106015. [Google Scholar] [CrossRef]

- Takata Zhang, G.; Xu, L.R. Simplified criterion to predict the lower bounds of the anisotropic ultimate strengths of 3D printing metals. Eng. Fail. Anal. 2023, 149, 107240. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Montero Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.-P.; Humbeeck, J.V. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Roveda, I.; Serrano-Munoz, I.; Kromm, A.; Madia, M. Investigation of residual stresses and microstructure effects on the fatigue behaviour of a L-PBF AlSi10Mg alloy. Procedia Struct. Integr. 2022, 38, 564–571. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of Zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting. Scr. Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Romanova, V.; Dymnich, E.; Balokhonov, R.; Mohebbi, M.S.; Ploshikhin, V. Investigation of the inhomogeneous mechanical response at the grain scale for additive AlSi10Mg alloy. Procedia Struct. Integr. 2022, 35, 196–202. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zhang, H.; Yin, J.; Ke, L.; Zeng, X. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Lutovinov, M.; Halama, R.; Papuga, J.; Bartošák, M.; Kuželka, J.; Růžička, M. An Approximate Method for Calculating Elastic–Plastic Stress and Strain on Notched Specimens. Materials 2022, 15, 1432. [Google Scholar] [CrossRef]

- Vazdirvanidis, A.; Rikos, A.; Toulfatzis, A.I.; Pantazopoulos, G.A. Electron Backscatter Diffraction (EBSD) Analysis of Machinable Lead-Free Brass Alloys: Connecting Texture with Fracture. Metals 2022, 12, 569. [Google Scholar] [CrossRef]

- Uddagiri, M.; Shchyglo, O.; Steinbach, I.; Tegeler, M. Solidifcation of the Ni-based superalloy CMSX-4 simulated with full complexity in 3-dimensions. Prog. Addit. Manuf. 2024, 9, 1185–1196. [Google Scholar] [CrossRef]

- Shakil, S.; Hadadzadeh, A.; Amirkhiz, B.S.; Pirgazi, H.; Mohammadi, M.; Haghshenas, M. Additive manufactured versus cast AlSi10Mg alloy: Microstructure and micromechanics. Results Mater. 2021, 10, 100178. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Ultimate tensile strength (MPa) | 410 |

| Yield strength (MPa) | 240 |

| Young’s modulus (GPa) | 70 ± 5 |

| Elongation at break * (%) | 5 ± 2 |

| Element | Al | Mg | Si | Ni | Sn | Pb | Cu | Zn | Ti | Mn | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. (%) | bal. | 0.2–0.45 | 9–11 | <0.05 | <0.05 | <0.05 | <0.05 | <0.1 | <0.15 | <0.45 | <0.55 |

| Sample | Misorientation Angle Grain Boundaries (°) | Main Directions | IPF | PF | Grain Size (Mean Diameter, μm) | KAM | KAM Gradient | |

|---|---|---|---|---|---|---|---|---|

| Y(3) (all the scanned area) | 2–5° | 18.4 | <001> | 1.226 | 1.437 | 5.3 | 2.48951 | |

| 5–15° | 11.7 | |||||||

| 15–180° | 69.9 | |||||||

| Y(3) (Area 1) | 2–5° | 21.2 | <212> | 3.033 | 5.467 | 7.1 | 1.73955 | 0.8 |

| 5–15° | 8.4 | |||||||

| 15–180° | 70.4 | |||||||

| Y(3) (Area 2) | 2–5° | 18.4 | <001> | 2.583 | 3.179 | 5.1 | 2.50741 | |

| 5–15° | 11.7 | |||||||

| 15–180° | 69.9 | |||||||

| Z(3) (all the scanned area) | 2–5° | 37.0 | <101> <001> | 1.451 | 1.943 | 8.7 | 2.67953 | |

| 5–15° | 12.3 | |||||||

| 15–180° | 50.7 | |||||||

| Z(3) (Area 1) | 2–5° | 17.3 | <101> | 1.561 | 3.541 | 7.0 | 2.22937 | 0.5 |

| 5–15° | 7.4 | |||||||

| 15–180° | 75.3 | |||||||

| Z(3) (Area 2) | 2–5° | 39.9 | <111> | 4.617 | 7.528 | 9.3 | 2.73511 | |

| 5–15° | 13.5 | |||||||

| 15–180° | 46.6 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monkova, K.; Bouzouni, M.; Pantazopoulos, G.A.; Toulfatzis, A.I.; Papadopoulou, S. A Preliminary Study of the Effect of 3D Printing Orientation on Mechanical Properties and Fracture of Samples Made from AlSi10Mg. Materials 2025, 18, 5294. https://doi.org/10.3390/ma18235294

Monkova K, Bouzouni M, Pantazopoulos GA, Toulfatzis AI, Papadopoulou S. A Preliminary Study of the Effect of 3D Printing Orientation on Mechanical Properties and Fracture of Samples Made from AlSi10Mg. Materials. 2025; 18(23):5294. https://doi.org/10.3390/ma18235294

Chicago/Turabian StyleMonkova, Katarina, Marianthi Bouzouni, George A. Pantazopoulos, Anagnostis I. Toulfatzis, and Sofia Papadopoulou. 2025. "A Preliminary Study of the Effect of 3D Printing Orientation on Mechanical Properties and Fracture of Samples Made from AlSi10Mg" Materials 18, no. 23: 5294. https://doi.org/10.3390/ma18235294

APA StyleMonkova, K., Bouzouni, M., Pantazopoulos, G. A., Toulfatzis, A. I., & Papadopoulou, S. (2025). A Preliminary Study of the Effect of 3D Printing Orientation on Mechanical Properties and Fracture of Samples Made from AlSi10Mg. Materials, 18(23), 5294. https://doi.org/10.3390/ma18235294