Finding Optimal Thermo-Mechanical Processing for a TNTZ-O Beta-Titanium Alloy

Abstract

1. Introduction

2. Materials and Methods

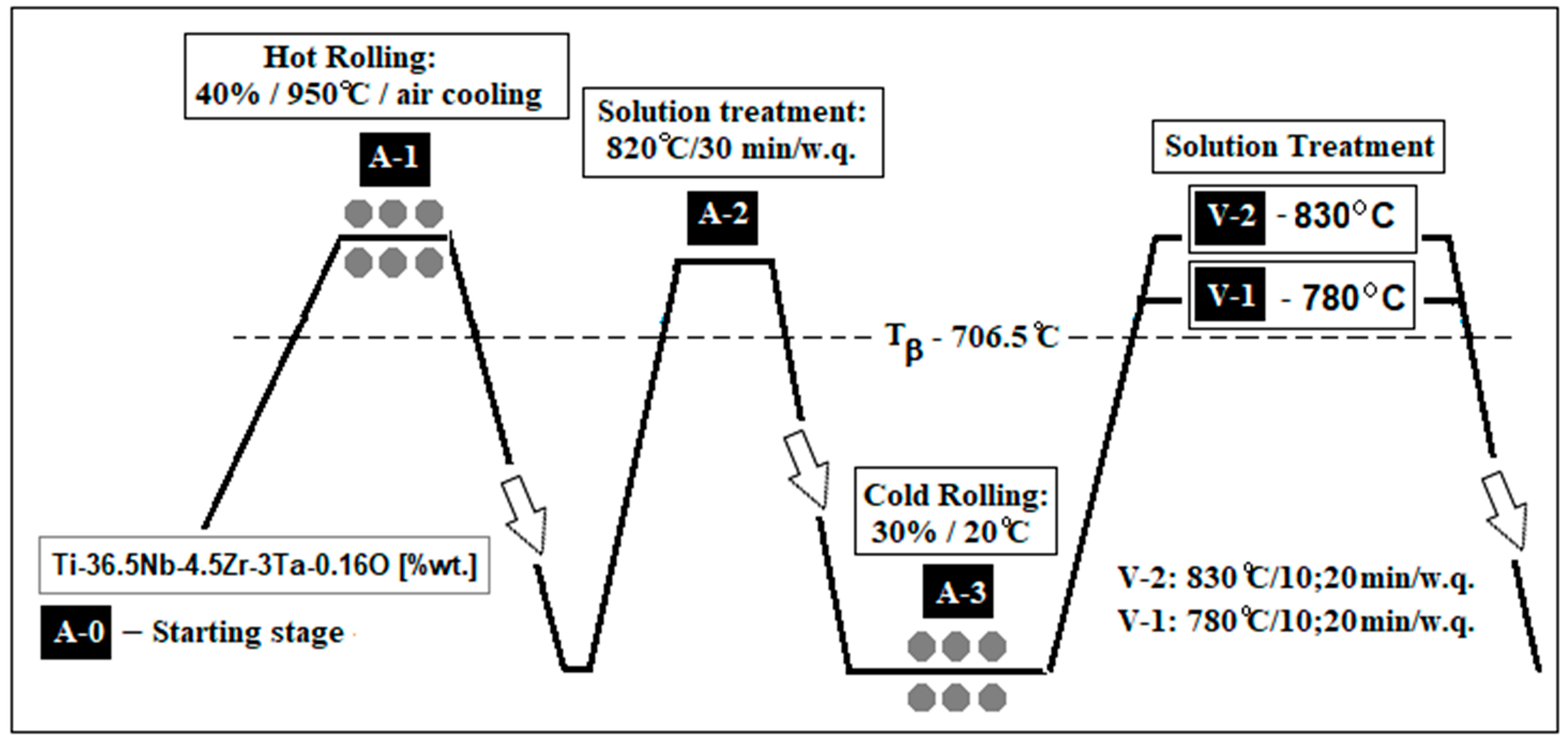

2.1. Alloy Synthesis and Thermo-Mechanical Processing

- Preliminary stages (A):

- A-0: Starting Stage: as-cast sample;

- A-1: Hot Rolling (40% reduction at 950 °C, air cooled-a.c.);

- A-2: Solution Treatment (820 °C, 30 min, water quench-w.q.);

- A-3: Cold Rolling (30% reduction at room temperature).

- Solution Treatments (V):

- V-1: Near β-transus (780 °C); V-1-1 for 10 min.; V-1-2 for 20 min.

- V-2: Above β-transus (830 °C); V-2-1 for 10 min.; V-2-2 for 20 min.

- Holding times: 10 and 20 min, followed by water quenching.

2.2. Microstructural and Mechanical Characterization

3. Results

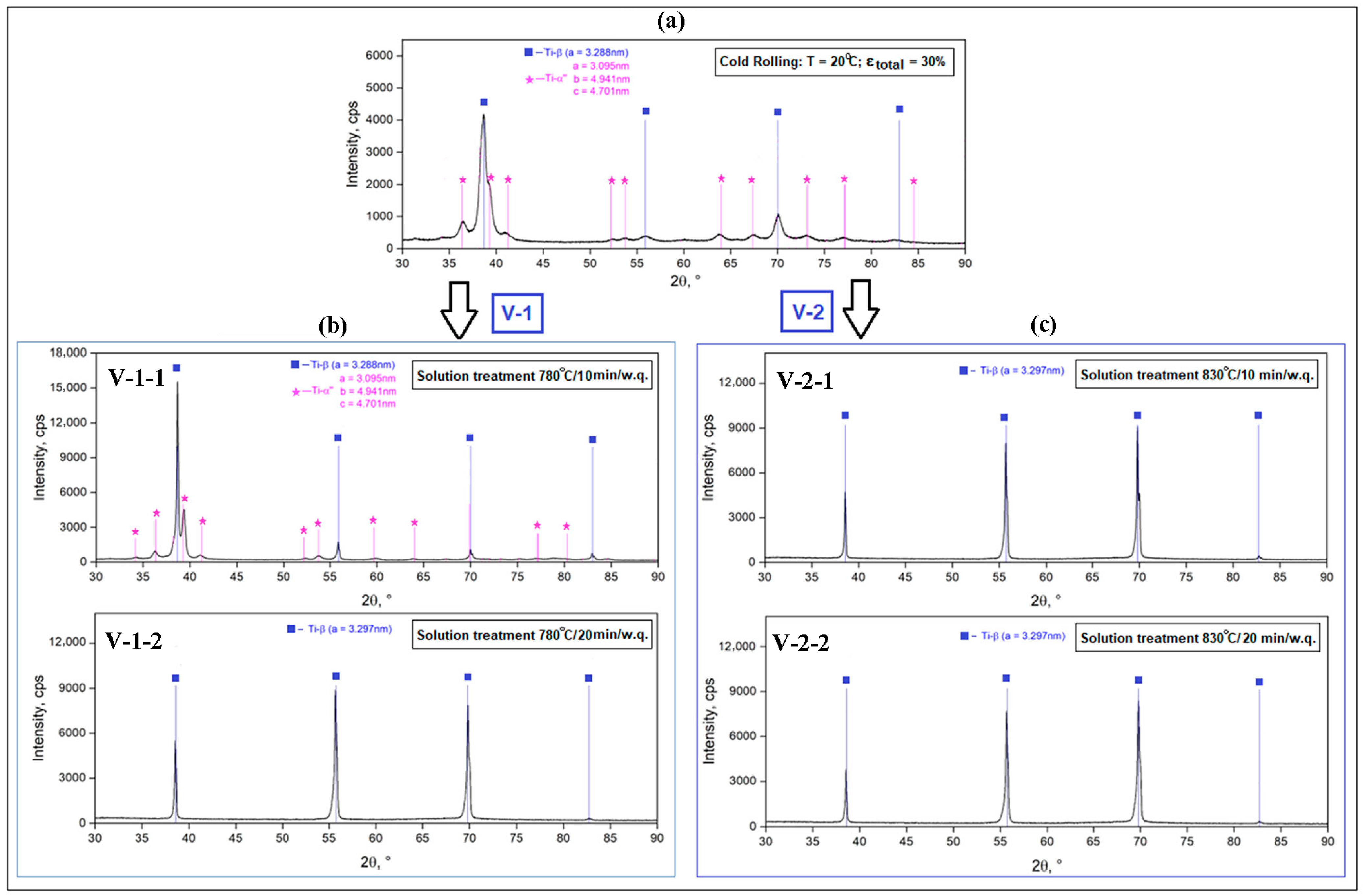

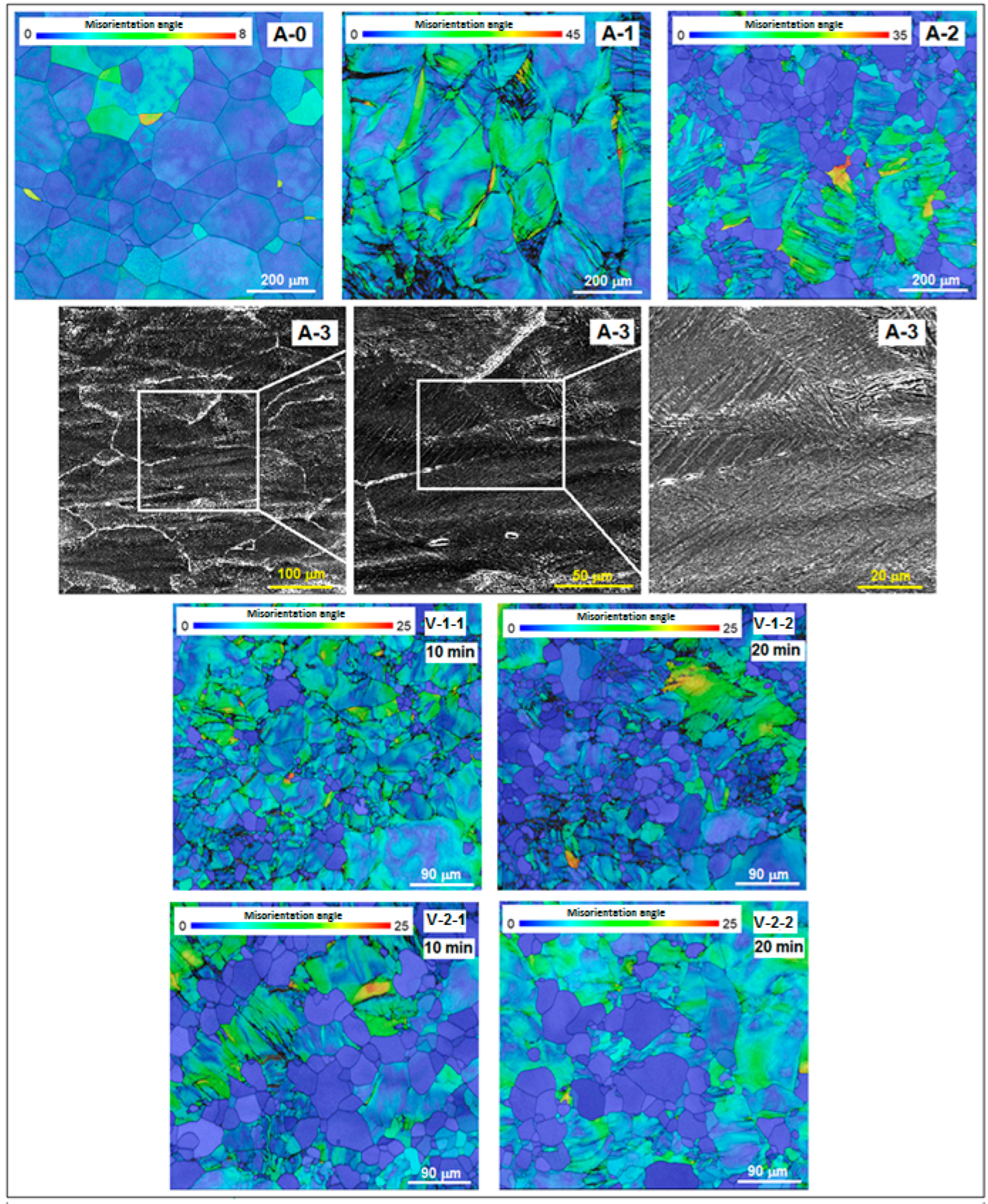

3.1. Microstructural Characterization of the Studied Alloy

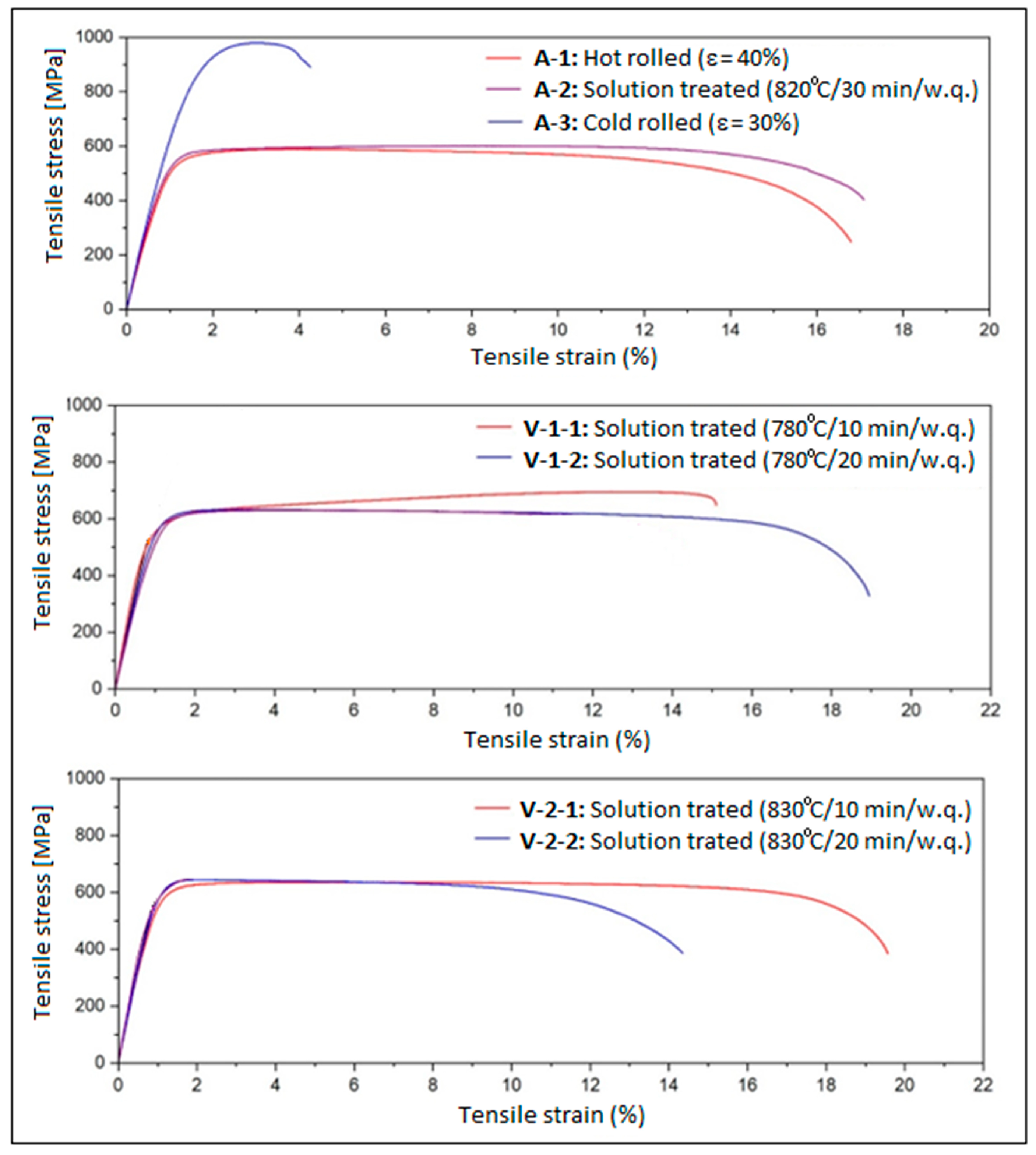

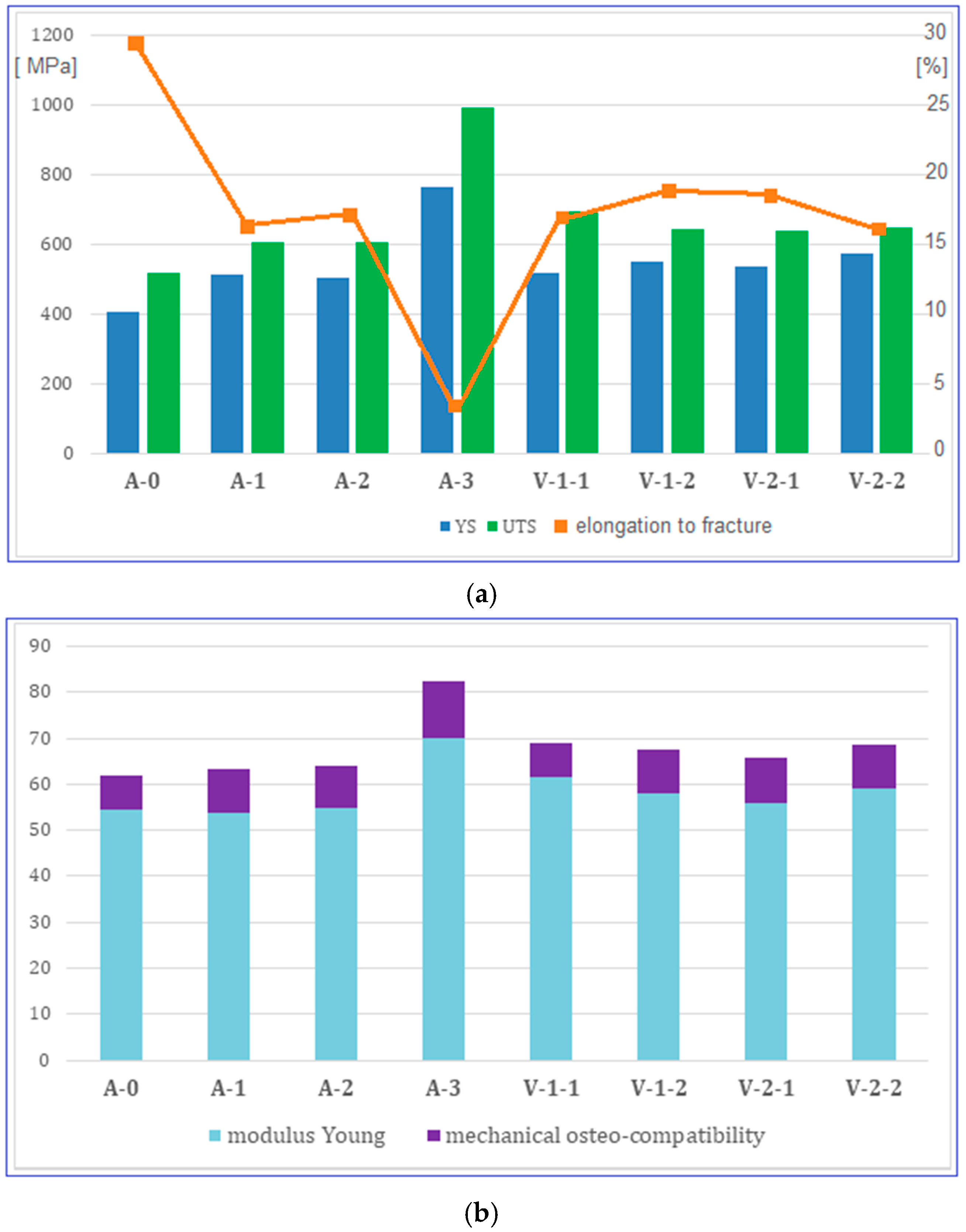

3.2. Analysis of the Alloy Mechanical Property Evolution

- (a)

- Ti-6Al-4V (wt.%): UTS = 1100 MPa; E = 120 GPa [48];

- (b)

- Ti-35.3Nb-7.1Zr-5.1Ta (wt.%): UTS = 500 MPa; E = 63 GPa [10];

- (c)

- Ti-41.1Nb-7.1Zr (wt.%): UTS = 500 MPa; E = 65 GPa [18];

- (d)

- Ti-30Nb-12Zr-5Ta-2Sn-1.25Fe (wt.%): UTS = 705 MPa; E = 55 GPa; εf = 11% [64];

- (e)

- Ti-15Mo-5Zr-3Al (wt.%): UTS = 820 MPa; E = 78 GPa; εf = 11% [48];

- (f)

- Ti-25Nb-17Ta-1Fe-0.25O (wt.%): UTS = 851 MPa; E = 60 GPa [19];

- (g)

- Ti-36.5Nb-4.5Zr-3Ta-0.16O (wt.%): UTS = 640 MPa; E = 56 GPa; present work.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kacsó, A.-B.; Peter, I. A Review of Past Research and Some Future Perspectives Regarding Titanium Alloys in Biomedical Applications. J. Funct. Biomater. 2025, 16, 144. [Google Scholar] [CrossRef] [PubMed]

- Bashir, T.T.; Zuhailawati, H.; Lockman, Z.; Al-Ashraf Abdullah, S.; Yusof, F.; Abdel-Hady Gepreel, M.; Nambu, S. Effect of alloying and surface modification on mechanical properties and cellular behaviour of Ti–Mo–Fe alloys in orthopaedic application. Mater. Chem. Phys. 2025, 345, 131292. [Google Scholar] [CrossRef]

- Srivastav, C.K.; Prasad, N.K.; Khan, D. Nanocrystalline Ti-Nb-Ta-Fe0.35-Co0.35 High-Entropy Alloy as a Possible Hard Tissue Implant. J. Mater. Eng. Perform 2024, 34, 18140–18156. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A. Biomedical Applications of Titanium Alloys: A Comprehensive Review. Materials 2024, 17, 114. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. A Review—Metastable β Titanium Alloy for Biomedical Applications. J. Eng. Appl. Sci. 2023, 70, 25. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Cui, Y.-W.; Zhang, L.-C. Recent Development in Beta Titanium Alloys for Biomedical Applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Anene, F.A.; Jaafar, C.N.A.; Zainol, I.; Hanim, M.A.A.; Suraya, M.T. Biomedical materials: A review of titanium-based alloys. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 3792–3805. [Google Scholar] [CrossRef]

- Florea, A.; Stancel, C.D.; Butu, M.; Buzatu, M.; Serban, N.; Ursu, V. Improvement of Mechanical Properties for some Ti-Mo-Fe Alloys by Heat Treatment. UPB Sci. Bull. Ser. B 2024, 86, 325–336. [Google Scholar]

- Lee, T.; Lee, S.; Kim, I.S.; Moon, Y.H.; Kim, H.S.; Park, C.H. Breaking the limit of Young’s modulus in low-cost Ti–Nb–Zr alloy for biomedical implant applications. J. Alloys Comp. 2020, 828, 154401. [Google Scholar] [CrossRef]

- Bahl, S.; Suwas, S.; Chatterjee, K. Comprehensive review on alloy design, processing, and performance of_Titanium alloys as biomedical materials. Int. Mater. Rev. 2020, 66, 114–139. [Google Scholar]

- Xiang, C.; Li, P.; Jia, D.; Zou, C.; Wang, W.Y.; Li, J. Unveiling the mechanisms of solid-solution strengthening in Ti alloys with dual-phase structures: An in-depth first-principles investigation. Met. Corros. 2025, 60, 3096–3112. [Google Scholar] [CrossRef]

- Eroshenko, A.Y.; Legostaeva, E.V.; Uvarkin, P.V.; Tolmachev, A.I.; Khimich, M.A.; Kuznetsov, V.P.; Stepanov, S.I.; Vorontsov, I.A.; Mukanov, G.Z.; Sharkeev, Y.P. Evolution of microstructure and mechanical properties of Ti-Nb-Zr and Ti-Nb-Zr-Ta-Sn alloys in severe plastic deformation. Mater. Lett. 2024, 382, 137805. [Google Scholar] [CrossRef]

- Kolli, R.; Devaraj, A. A review of metastable beta titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Intravaia, J.T.; Graham, T.; Kim, H.S.; Nanda, H.S.; Kumbar, S.G.; Nukavarapu, S.P. Smart orthopedic biomaterials and implants. Curr. Opin. Biomed. Eng. 2023, 25, 100439. [Google Scholar] [CrossRef]

- Walunj, G.; Desai, J.; Bohara, S.; Contieri, R.; Kothapalli, C.; Ivanov, E.; Borkar, T. Light Weight-Low Modulus Biocompatible Titanium Alloys Processed via Spark Plasma Sintering. J. Alloys Metall. Syst. 2023, 3, 100018. [Google Scholar] [CrossRef]

- Marković, G.; Manojlović, V.; Ružić, J.; Sokić, M. Predicting Low-Modulus Biocompatible Titanium Alloys Using Machine Learning. Materials 2023, 16, 6355. [Google Scholar] [CrossRef] [PubMed]

- Marković, G.; Ružić, J.; Sokić, M.; Milojkov, D.; Manojlović, V.D. Prediction of elastic modulus, yield strength, and tensile strength in biocompatible titanium alloys. J. Min. Metall. Sect. B Metall. 2024, 60, 273–282. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on Titanium and Titanium Based Alloys as Biomaterials for Orthopaedic Applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Spataru, M.C.; Butnaru, M.; Sandu, A.V.; Vulpe, V.; Vlad, M.D.; Baltatu, M.S.; Geanta, V.; Voiculescu, I.; Vizureanu, P.; Solcan, C. In-depth assessment of new Ti-based biocompatible materials. Mater. Chem. Phys. 2021, 258, 123959. [Google Scholar] [CrossRef]

- Ishiguro, Y.; Tsukada, Y.; Koyama, T. Phase-field study of the spinodal decomposition rate of β phase in oxygen added Ti–Nb alloys. Comput. Mater. Sci. 2020, 174, 109471. [Google Scholar] [CrossRef]

- Slokar, L.; Štrkalj, A.; Glavaš, Z. Synthesis of Ti-Zr alloy by powder metallurgy. Eng. Rev. 2019, 39, 115–123. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Molotnikov, A.; Lapovok, R.; Zeller, R.; Berner, S.; Habersetzer, P.; Torre, F.D. Microstructure and mechanical properties of Ti–15Zr alloy used as dental implant material. J. Mech. Behav. Biomed. Mater. 2016, 62, 384–398. [Google Scholar] [CrossRef] [PubMed]

- Grandin, H.M.; Berner, S.; Dard, M. A review of Titanium Zirconium (TiZr) alloys for use in endosseous dental implants. Materials 2012, 5, 1348–1360. [Google Scholar] [CrossRef]

- Pang, E.L.; Pickering, E.J.; Baik, S.I.; Seidman, D.N.; Jones, N.G. The effect of zirconium on the omega phase in Ti-24Nb-[0–8]Zr (at.%) alloys. Acta Mater. 2018, 153, 62–70. [Google Scholar] [CrossRef]

- Han, C.-B.; Lee, D.-G. Effect of Oxygen on Static Recrystallization Behaviors of Biomedical Ti-Nb-Zr Alloys. Metals 2024, 14, 333. [Google Scholar] [CrossRef]

- Kozlík, J.; Preisler, D.; Stráský, J.; Veselý, J.; Veverková, A.; Chráska, T.; Janeček, M. Phase transformations in a heterogeneous Ti-xNb-7Zr-0.8O alloy prepared by a field-assisted sintering technique. Mater. Des. 2021, 198, 109308. [Google Scholar] [CrossRef]

- Niinomi, M.; Liu, Y.; Nakai, M.; Liu, H.; Li, H. Biomedical titanium alloys with Young’s moduli close to that of cortical bone. Regen. Biomater. 2016, 3, 173–185. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Tasaki, W.; Makioka, Y.; Miyazaki, S.; Kim, H.Y. Enhancement of {110} <001> Texture by Controlling α-phase and Achievement of Low Young’s Modulus and High Strength in Metastable β-type Ti–Zr-Based Alloys. Adv. Eng. Mater 2024, 26, 2401402. [Google Scholar] [CrossRef]

- Hermes, W.P.; Haskel, T.; Plaine, A.H.; Barbieri, R. Torsional Fatigue of Ti15Mo Titanium Alloy. Mater. Res.–Ibero-Am. J. Mater. 2025, 28, e20240358. [Google Scholar] [CrossRef]

- Acharya, S.; Panicker, A.G.; Laxmi, D.V.; Suwas, S.; Chatterjee, K. Study of the influence of Zr on the mechanical properties and functional response of Ti-Nb-Ta-Zr-O alloy for orthopedic applications. Mater. Des. 2019, 164, 107555. [Google Scholar] [CrossRef]

- Yokota, K.; Bahador, A.; Shitara, K.; Umeda, J.; Kondoh, K. Mechanisms of tensile strengthening and oxygen solid solution in single β-phase Ti-35 at%Ta + O alloys. Mater. Sci. Eng. A 2021, 802, 140677. [Google Scholar] [CrossRef]

- Stráský, J.; Janeček, M.; Harcuba, P.; Preisler, D.; Landa, M. 4.2-biocompatible beta-Ti alloys with enhanced strength due to increased oxygen content. In Titanium in Medical and Dental Applications; Froes, F.H., Qian, M., Eds.; Woodhead Publishing: Cambridgeshire, UK, 2018; pp. 371–392. [Google Scholar] [CrossRef]

- Preisler, D. Oxygen-Strengthened Biomedical Beta Titanium Alloys. Master’s Thesis, Charles University, Prague, Czech Republic, 2018. Available online: https://hdl.handle.net/20.500.11956/98671 (accessed on 22 September 2025).

- Silva, M.R.D.; Gargarella, P.; Plaine, A.H.; Pauly, S.; Bolfarini, C. Influence of oxygen and plastic deformation on the microstructure and the hardness of a Ti–Nb–Ta–Zr–O Gum Metal. Mater. Sci. Eng. A 2021, 828, 142122. [Google Scholar] [CrossRef]

- Ji, X.; Gutierrez-Urrutia, I.; Emura, S.; Tsuchiya, K. Deformation mechanisms and effect of oxygen addition on mechanical properties of Ti-7.5Mo alloy with α” martensite. MATEC Web Conf. 2020, 321, 11059. [Google Scholar] [CrossRef]

- Wu, H.; Zhou, J. The quantitative understanding on the influence of α″ phase on mechanical behavior of Ti-Nb-Ta-Zr-O alloy. J. Alloys Comp. 2018, 768, 914–923. [Google Scholar] [CrossRef]

- Wei, L.S.; Kim, H.Y.; Miyazaki, S. Effects of oxygen concentration and phase stability on nano-domain structure and thermal expansion behavior of Ti–Nb–Zr–Ta–O alloys. Acta Mater. 2015, 100, 313. [Google Scholar] [CrossRef]

- Strasky, J.; Harcuba, P.; Vaclavova, K.; Horvath, K.; Landa, M.; Srba, O.; Janecek, M. Increasing strength of a biomedical Ti-Nb-Ta-Zr alloy by alloying with Fe, Si and O. J. Mech. Behav. Biomed. Mat. 2017, 71, 329–336. [Google Scholar] [CrossRef]

- Hussein, A.H.; Gepreel, M.A.H.; Gouda, M.K.; Hefnawy, A.M.; Kandil, S.H. Biocompatibility of new Ti–Nb–Ta base alloys. Mater. Sci. Eng. C 2016, 61, 574–578. [Google Scholar] [CrossRef]

- Nakai, M.; Niinomi, M.; Akahori, T.; Tsutsumi, H.; Ogawa, M. Effect of Oxygen Content on Microstructure and Mechanical Properties of Biomedical Ti-29Nb-13Ta-4.6Zr Alloy under Solutionized and Aged Conditions. Mater. Trans. 2009, 50, 2716–2720. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hendrickson, M.; Nandwana, P.; Alam, T.; Choudhuri, D.; Banerjee, R. Influence of oxygen on omega phase stability in the Ti-29Nb-13Ta-4.6Zr alloy. Scr. Mater. 2016, 123, 144–148. [Google Scholar] [CrossRef]

- Sun, S.Y.; Deng, C. Accurate calculation of (α+β)/β phase transition of titanium alloys based on binary phase diagrams. Titan. Ind. Prog. 2011, 28, 21–25. [Google Scholar]

- Bania, P.J. Beta titanium alloys and their role in the titanium industry. JOM 1994, 46, 16–19. [Google Scholar] [CrossRef]

- Cullity, B.D. Stock, Elements of X-Ray Diffraction, 3rd ed.; Pearson: London, UK, 2001. [Google Scholar]

- Santhosh, R.; Geetha, M.; Nageswara Rao, M. Recent developments in heat treatment of Beta titanium alloys for aerospace applications. Trans. Indian Inst. Met. 2016, 70, 1681–1688. [Google Scholar] [CrossRef]

- Nomura, Y.; Okada, M.; Manaka, T.; Tsuchiya, T.; Iwasaki, M.; Matsuda, K.; Ishimoto, T. Effect of Partial Substitution of Zr for Ti Solvent on Young’s Modulus, Strength, and Biocompatibility in Beta Ti Alloy. Materials 2024, 17, 2548. [Google Scholar] [CrossRef] [PubMed]

- An, Z.; Yang, T.; Shi, C.; Mao, S.; Wang, L.; Li, A.; Li, W.; Xue, X.; Sun, M.; Bai, Y.; et al. Negative enthalpy alloys and local chemical ordering: A concept and route leading to synergy of strength and ductility. Natl. Sci. Rev. 2024, 11, nwae026. [Google Scholar] [CrossRef] [PubMed]

- An, Z.; Li, A.; Mao, S.; Yang, T.; Zhu, L.; Wang, R.; Wu, Z.; Zhang, B.; Shao, R.; Jiang, C.; et al. Negative mixing enthalpy solid solutions deliver high strength and ductility. Nature 2024, 625, 697–702. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, M.; Han, X.; Ding, Z.; Wang, H.; Liaw, P.K.; Wang, Y.; Lu, Y. Negative mixing enthalpy route guides strong and ductile soft magnetic high-entropy alloys with high saturation magnetization. Mater. Today 2025, 88, 45–54. [Google Scholar] [CrossRef]

- Hua, Z.; Zhang, D.; Guo, L.; Lin, S.; Zhang, X.; Li, Y.; Wen, C. Negative mixing enthalpy medium-entropy Ti–Zr–Nb–Al alloys with ultrahigh elastic admissible strain, strength-elongation product, and biocompatibility for bone implant applications. Acta Biomater. 2025, 197, 476–494. [Google Scholar] [CrossRef]

- Miedema, A.R.; Niessen, A.K. The enthalpy of solution for solid binary alloys of two 4d-transition metals. Calphad 1983, 7, 27–36. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Qian, M.; Shi, Z.; Song, T.; Huang, L.; Zou, J. A novel quaternary equiatomic Ti-Zr-Nb-Ta medium entropy alloy (MEA). Intermetallics 2018, 101, 39–43. [Google Scholar] [CrossRef]

- Zhang, B.; Tang, Y.; Li, S.; Ye, Y.; Zhu, L.; Zhang, Z.; Liu, X.; Wang, Z.; Bai, S. Effect of Ti on the Structure and Mechanical Properties of TixZr2.5-xTa Alloys. Entropy 2021, 23, 1632. [Google Scholar] [CrossRef]

- Liang, S. Review of the Design of Titanium Alloys with Low Elastic Modulus as Implant Materials (Review). Adv. Eng. Mater. 2020, 22, 2000555. [Google Scholar] [CrossRef]

- Chandran, M.; Subramanian, P.R.; Gigliotti, M.F. First principles calculation of mixing enthalpy of β-Ti with transition elements. J. Alloys Compd. 2013, 550, 501–508. [Google Scholar] [CrossRef]

- Skripnyak, N.V.; Ponomareva, A.V.; Belov, M.P.; Syutkin, E.A.; Khvan, A.V.; Dinsdale, A.T.; Abrikosov, I.A. Mixing enthalpies of alloys with dynamical instability: Bcc Ti-V system. Acta Mater. 2020, 188, 145–154. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, Y.; Yang, Z.; Liang, X.; Lei, Z.; Huang, H.; Wang, H.; Liu, X.; An, K.; Wu, W.; et al. Formation, structure and properties of biocompatible TiZrHfNbTa high-entropy alloys. Mater. Res. Lett. 2019, 7, 225–231. [Google Scholar] [CrossRef]

- Zhang, L.; Xiang, Y.; Han, J.; Srolovitz, D.J. The effect of randomness on the strength of high-entropy alloys. Acta Mater. 2019, 166, 424–434. [Google Scholar] [CrossRef]

- He, Q.; Yang, Y. On lattice distortion in high entropy alloys. Front. Mater. 2018, 5, 42. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Dan, A.; Serban, N.; Cojocaru, E.M.; Zărnescu-Ivan, N.; Gălbinasu, B.M. Effect of Cold-Rolling Deformation on the Microstructural and Mechanical Properties of a Biocompatible Ti-Nb-Zr-Ta-Sn-Fe Alloy. Materials 2024, 17, 2312. [Google Scholar] [CrossRef] [PubMed]

| Sample | Processing Details | Average Grain Dimension of β Phase (µm) | Reduction of Granulation (%) |

|---|---|---|---|

| A-0 | As-cast | 204.3 ± 2.4 | Reference value |

| A-1 | Hot Rolling: 950 °C/ε = 40%/a.c. | 316.4 ± 3.2 | - |

| A-2 | Solution Treatment: 820 °C/30 min/w.q. | 76.7 ± 1.2 | 62.45% |

| A-3 | Cold Rolling: 20 °C/ε = 30%/a.c. | - | - |

| V-1-1 | Solution Treatment: 780 °C/10 min/w.q. | 52.9 ± 0.8 | 74.11% |

| V-1-2 | Solution Treatment: 780 °C/20 min/w.q. | 63.8 ± 0.9 | 68.77% |

| V-2-1 | Solution Treatment: 830 °C/10 min/w.q. | 82.7 ± 1.8 | 59.52% |

| V-2-2 | Solution Treatment: 830 °C/20 min/w.q. | 86.2 ± 1.6 | 57.80% |

| Sample | UTS (MPa) | YS (MPa) | E (GPa) | ε (%) | YS/E | |

|---|---|---|---|---|---|---|

| A-0 | Test 1 | 537.16 | 412.54 | 55.17 | 35.48 | |

| Test 2 | 495.40 | 398.94 | 53.51 | 22.46 | ||

| Average | 516.28 ± 20.88 | 405.74 ± 6.80 | 54.34 ± 0.83 | 28.97 ± 6.51 | 7.46 | |

| A-1 | Test 1 | 588.09 | 498.31 | 53.30 | 16.79 | |

| Test 2 | 622.26 | 524.50 | 54.23 | 14.61 | ||

| Average | 605.18 ± 17.09 | 511.41 ± 13.10 | 53.77 ± 0.47 | 15.70 ± 1.09 | 9.51 | |

| A-2 | Test 1 | 600.51 | 499.86 | 56.39 | 17.08 | |

| Test 2 | 611.19 | 504.13 | 53.62 | 16.99 | ||

| Average | 605.85 ± 5.34 | 502.00 ± 2.13 | 55.01 ± 1.39 | 17.04 ± 0.04 | 9.13 | |

| A-3 | Test 1 | 978.65 | 731.13 | 69.81 | 4.25 | |

| Test 2 | 1009.20 | 796.57 | 70.35 | 3.03 | ||

| Average | 993.93 ± 15.28 | 763.85 ± 32.72 | 70.08 ± 0.27 | 3.64 ± 0.61 | 12.41 | |

| V-1-1 | Test 1 | 694.72 | 517.46 | 59.21 | 15.10 | |

| Test 2 | 697.27 | 521.56 | 63.84 | 18.32 | ||

| Average | 696.00 ± 1.27 | 519.51 ± 2.05 | 61.53 ± 2.32 | 16.71 ± 1.61 | 7.41 | |

| V-1-2 | Test 1 | 632.02 | 541.97 | 57.41 | 18.94 | |

| Test 2 | 657.34 | 561.17 | 58.65 | 18.04 | ||

| Average | 644.68 ± 12.66 | 551.57 ± 9.60 | 58.03 ± 0.62 | 18.49 ± 0.45 | 9.51 | |

| V-2-1 | Test 1 | 636.34 | 541.11 | 57.94 | 19.57 | |

| Test 2 | 644.16 | 533.48 | 54.21 | 16.62 | ||

| Average | 640.25 ± 3.91 | 537.30 ± 3.82 | 56.08 ± 1.87 | 18.10 ± 1.48 | 9.58 | |

| V-2-2 | Test 1 | 645.34 | 577.52 | 61.52 | 14.35 | |

| Test 2 | 651.63 | 567.34 | 56.69 | 17.98 | ||

| Average | 648.49 ± 3.14 | 572.43 ± 5.09 | 59.11 ± 2.42 | 16.17 ± 1.82 | 9.68 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cojocaru, V.D.; Nocivin, A.; Raducanu, D.; Cojocaru, C.I.; Irimescu, R.E.; Galbinasu, M.B. Finding Optimal Thermo-Mechanical Processing for a TNTZ-O Beta-Titanium Alloy. Materials 2025, 18, 5281. https://doi.org/10.3390/ma18235281

Cojocaru VD, Nocivin A, Raducanu D, Cojocaru CI, Irimescu RE, Galbinasu MB. Finding Optimal Thermo-Mechanical Processing for a TNTZ-O Beta-Titanium Alloy. Materials. 2025; 18(23):5281. https://doi.org/10.3390/ma18235281

Chicago/Turabian StyleCojocaru, Vasile Danut, Anna Nocivin, Doina Raducanu, Claudia Ioana Cojocaru, Raluca Elena Irimescu, and Mihai Bogdan Galbinasu. 2025. "Finding Optimal Thermo-Mechanical Processing for a TNTZ-O Beta-Titanium Alloy" Materials 18, no. 23: 5281. https://doi.org/10.3390/ma18235281

APA StyleCojocaru, V. D., Nocivin, A., Raducanu, D., Cojocaru, C. I., Irimescu, R. E., & Galbinasu, M. B. (2025). Finding Optimal Thermo-Mechanical Processing for a TNTZ-O Beta-Titanium Alloy. Materials, 18(23), 5281. https://doi.org/10.3390/ma18235281