Road Performance of Hot Central Plant Versus Hot In-Place Recycling Asphalt Mixtures: A Quantitative Comparison and Adaptability Analysis

Abstract

1. Introduction

2. Materials and Mixture Preparation

2.1. Aggregates and Asphalt

2.2. Reclaimed Asphalt Pavement (RAP)

2.3. Rejuvenator

2.4. Fibers

2.5. Mix Design

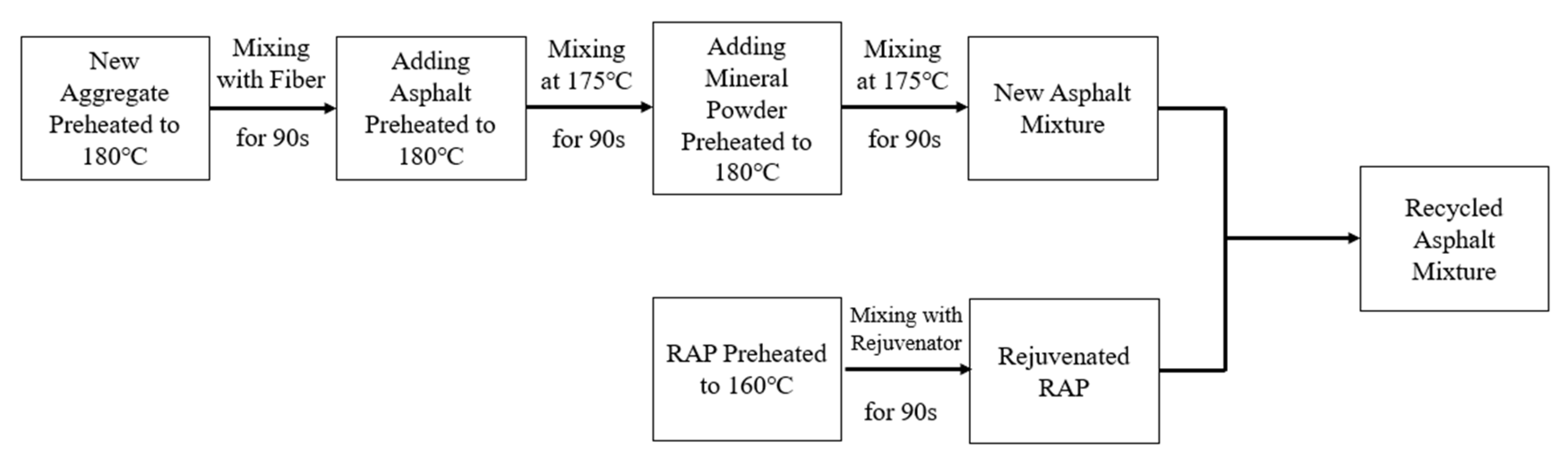

2.6. Preparation of Hot Recycled Asphalt Mixtures

- (1)

- Preparation of Hot Central Plant Recycling Asphalt Mixture

- (2)

- Preparation of Hot In-Place Recycling Asphalt Mixture

- (3)

- Determination of Rejuvenator Content

3. Test Methods

3.1. Wheel Tracking Test

3.2. Dynamic Creep Test

3.3. Low-Temperature Bending Beam Test

3.4. Semi-Circular Bend (SCB) Test

3.5. Freeze–Thaw Splitting Test

3.6. Hamburg Wheel-Tracking Test

4. Results and Analysis

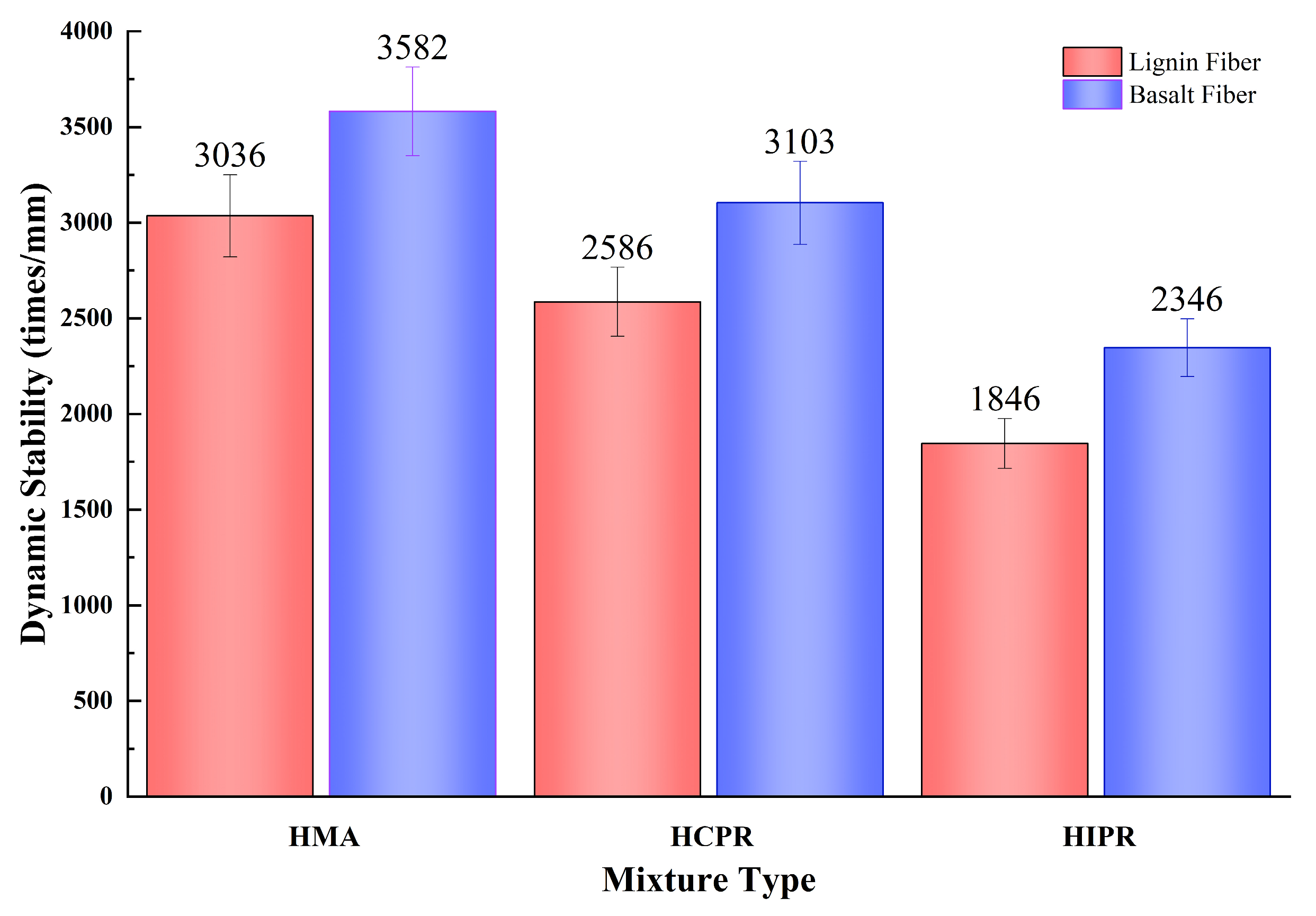

4.1. High-Temperature Stability Performance

- (1)

- Wheel Tracking Test Results

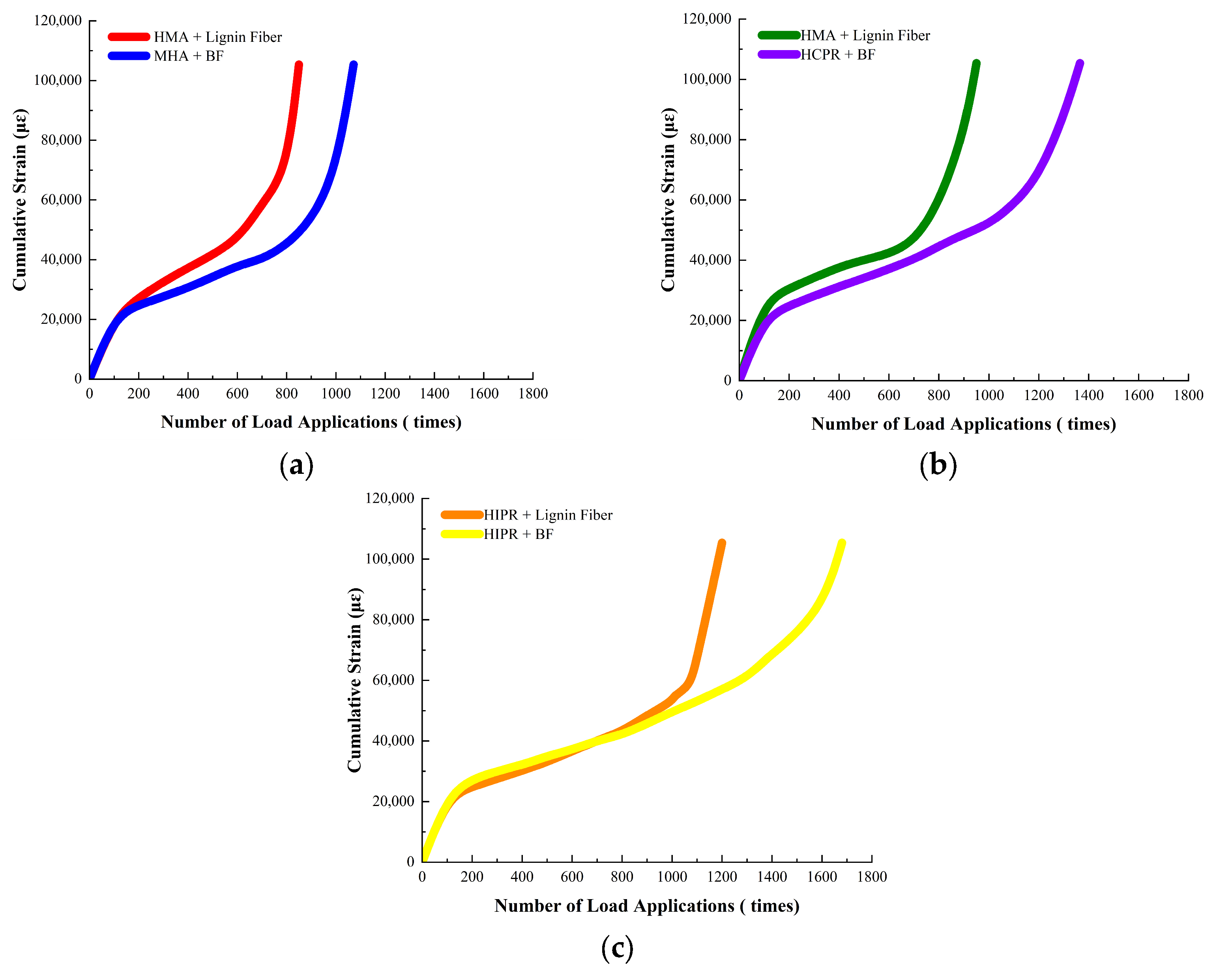

- (2)

- Dynamic Creep Test Results

4.2. Low-Temperature Crack Resistance

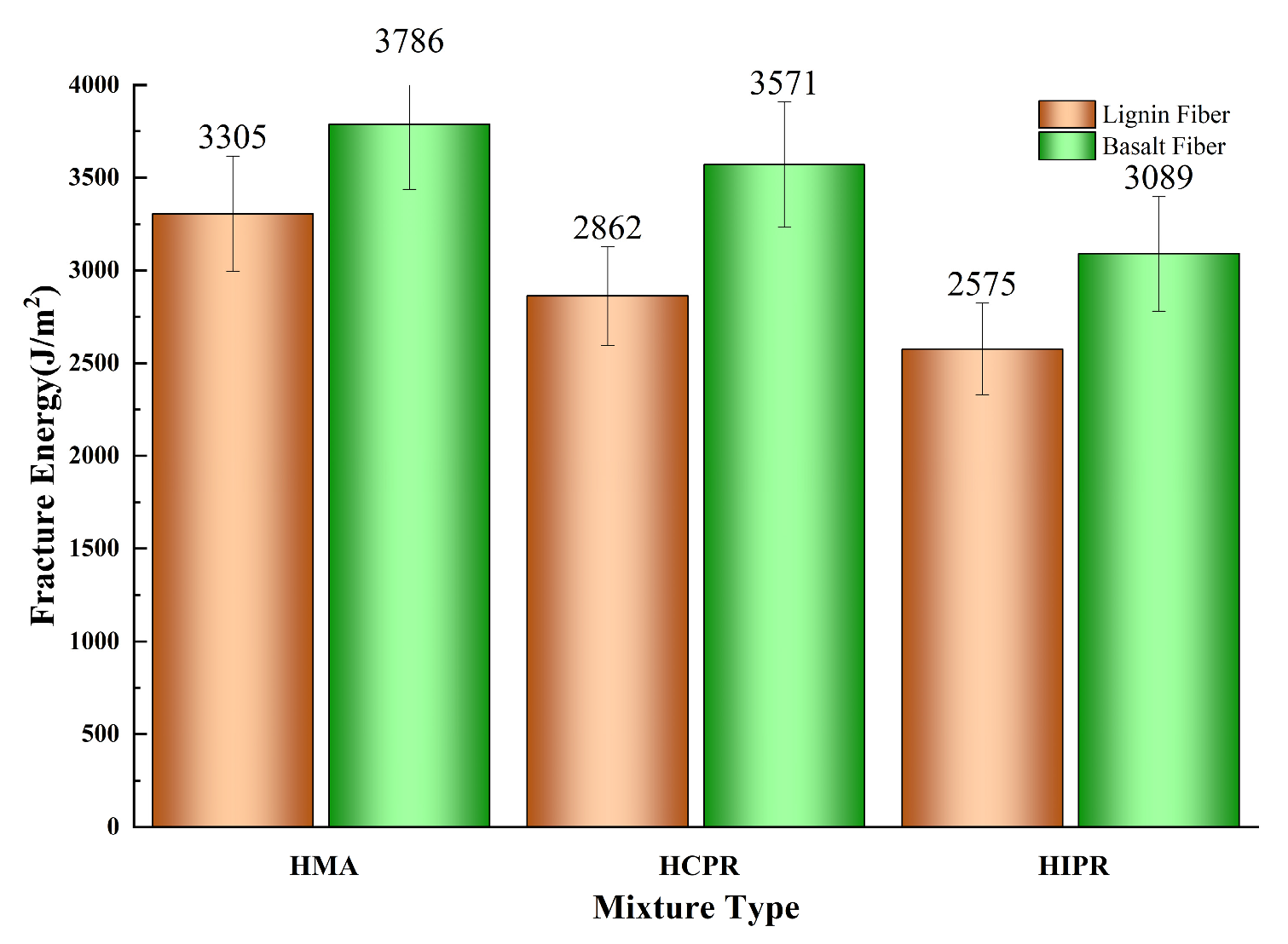

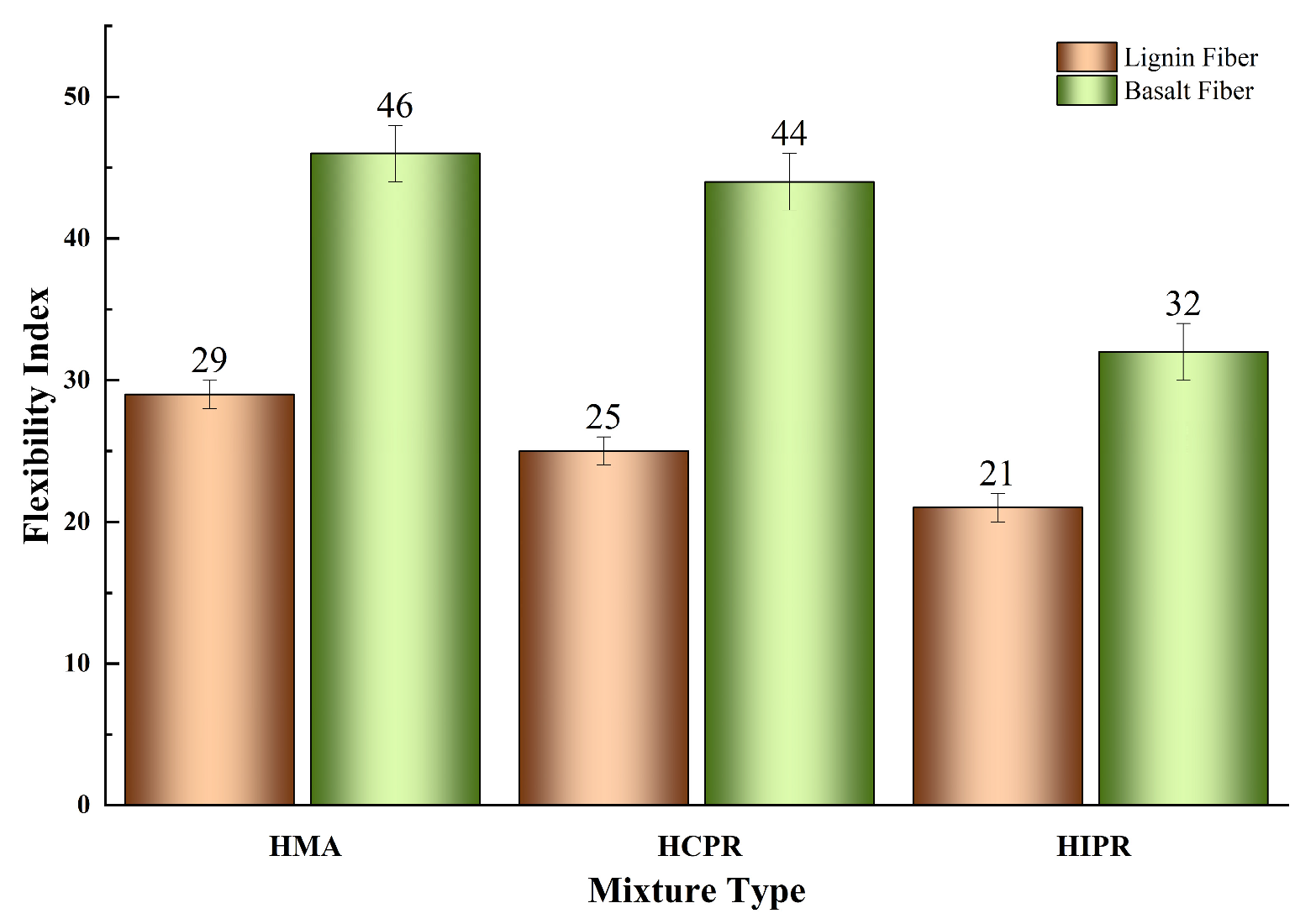

4.3. Intermediate-Temperature Crack Resistance

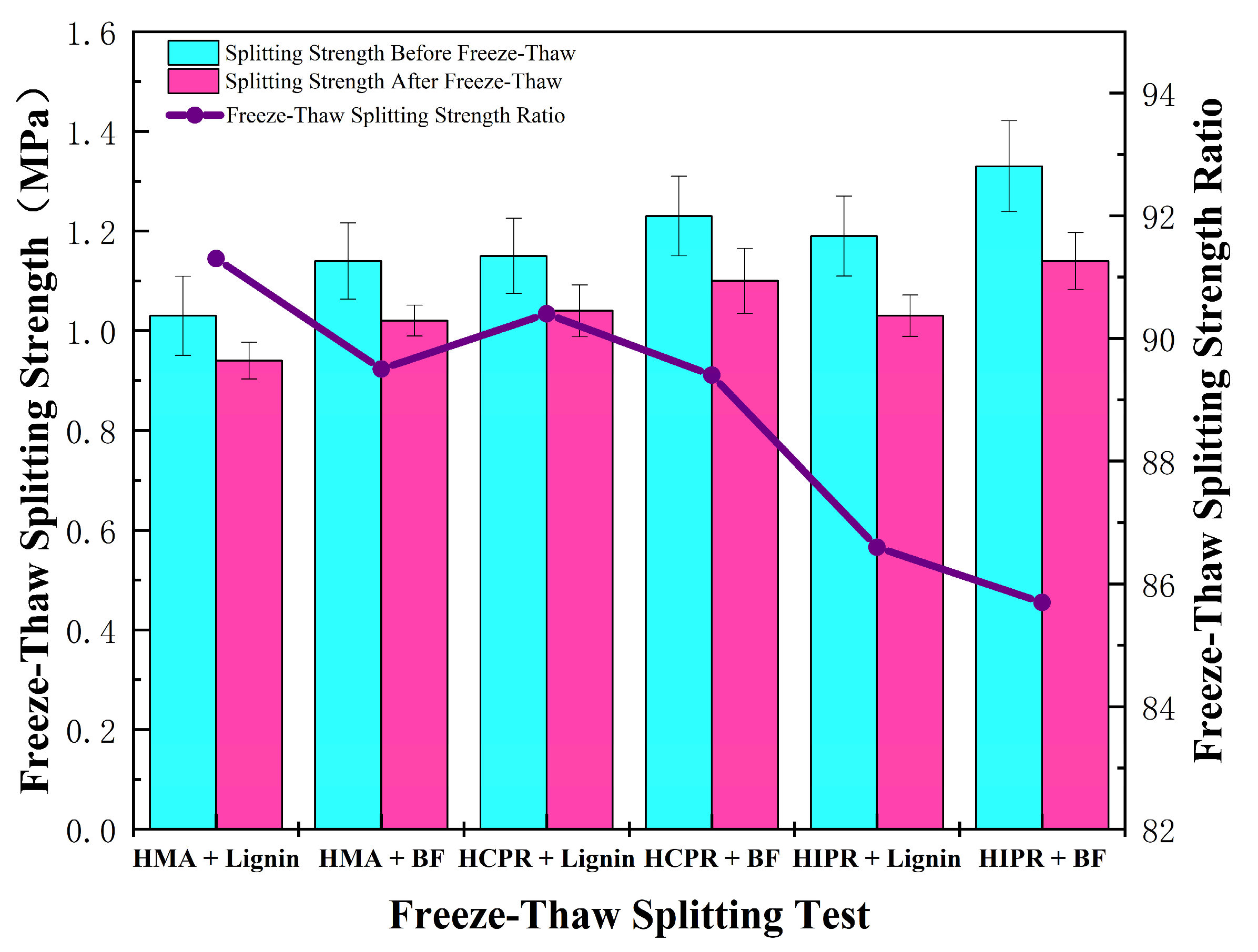

4.4. Moisture Susceptibility

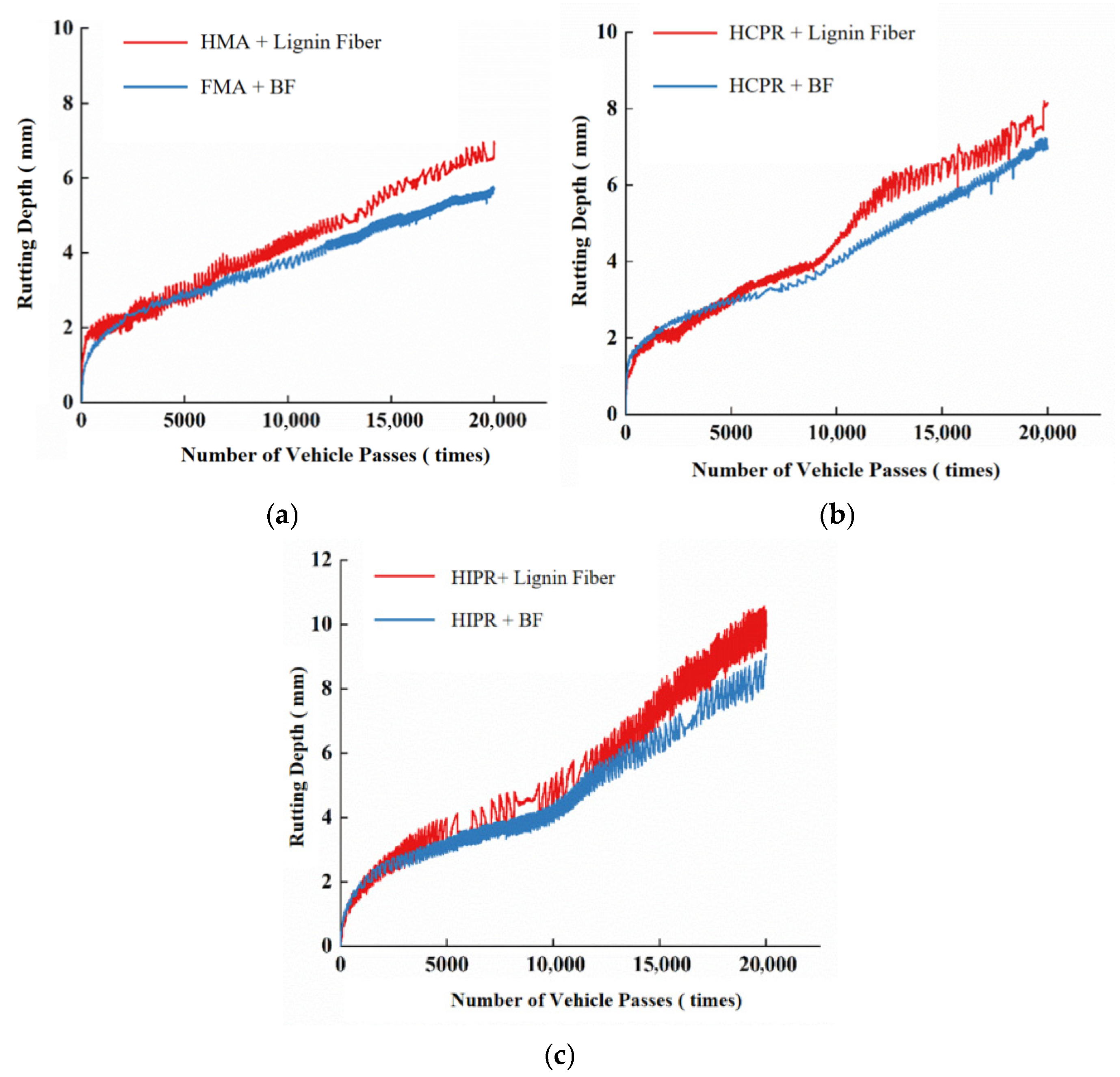

4.5. Performance Under Simulated Moisture–Thermal Conditions

4.6. Discussion

5. Conclusions

- (1)

- Hot recycled asphalt mixtures demonstrate a distinct “high-strength, low-toughness” characteristic compared to virgin HMA. Quantitatively, the high-temperature stability, as measured by dynamic stability, significantly increases, with the HIPR mixture (80% RAP) showing the most pronounced improvement of 80.7% over the virgin mix. Conversely, cracking resistance deteriorates markedly with higher RAP content. The HIPR mixture exhibits a 60.8% reduction in low-temperature flexural tensile strain and a 22.1% decrease in intermediate-temperature fracture energy compared to the virgin mix, representing substantially server deterioration than the HCPR mixture (30% RAP).

- (2)

- While the freeze–thaw splitting strength ratio of all recycled mixtures met the specification requirement (≥80%), their performance in the Hamburg wheel-tracking test revealed limitations. Both HCPR and HIPR mixtures exhibited clear stripping behavior under simulated hydrothermal conditions, with stripping inflection points recorded at 12,483 and 8637 load cycles, respectively. This indicates a potential vulnerability to moisture damage in real-world, rainy and hot environments that is not captured by conventional tests.

- (3)

- The incorporation of basalt fibers (BFs) effectively mitigates the performance deficiencies of recycled mixtures. The three-dimensional network formed by the fibers delivers comprehensive enhancements: it increases dynamic stability by 8.2–9.2%, boosts low-temperature flexural tensile strain by 20.0–27.1%, and raises the fracture energy by 20.0–24.7% compared to lignin fiber-reinforced counterparts. This synergistic improvement makes BF a superior modifier for tackling the performance trade-offs in recycling.

- (4)

- Based on performance balance and engineering applicability, hot central plant recycling mixture (RAP 30%) is recommended for surface courses of high-grade pavements in most regions of China. Meanwhile, hot in-place recycling mixture (RAP 80%), with its exceptional high-temperature rutting resistance, is recommended for applications in regions less sensitive to low-temperature cracking.

- (5)

- As an efficient reinforcing material, basalt fibers effectively compensate for the performance deficiencies of hot recycled mixtures. Their incorporation enables the application of hot central plant recycling mixtures to be extended to severely cold regions. The reliability of hot in-place recycling mixtures is also significantly enhanced, establishing them as viable rapid maintenance solutions under broader climatic and traffic conditions. This advancement strongly promotes the high-quality and sustainable development of asphalt pavement recycling technology.

Limitations and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, L.; Shen, J.; Wang, W. Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials 2024, 17, 2096. [Google Scholar] [CrossRef]

- Germin-Aizac, J.; Maitre, A.; Balducci, F.; Montlevier, S.; Marques, M.; Tribouiller, J.; Demeilliers, C.; Persoons, R. Bitumen Fumes and PAHs in Asphalt Road Paving: Emission Characteristics, Determinants of Exposure and Environmental Impact. Environ. Res. 2023, 228, 115824. [Google Scholar] [CrossRef] [PubMed]

- Xing, C.; Chang, Z.; Jiang, W.; Han, Z.; Li, M. Hot central-plant recycling technology: A systematic review on raw materials and performance-influencing factors. J. Traffic Transp. Eng.-Engl. Ed. 2025, 12, 1040–1063. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Liu-Li, P. Variability Investigation of Reclaimed Asphalt Pavement Materials. J. Mater. Civ. Eng. 2024, 36, 04023558. [Google Scholar] [CrossRef]

- Xue, Y.H.; Liu, C.C.; Shi, Q.J.; Ju, Z.; Fan, G.; Zhang, C.; Lv, S. Road performance and mechanism of Hot in-place recycling asphalt mixture modified by direct-to-plant SBS. Constr. Build. Mater. 2024, 416, 135122. [Google Scholar] [CrossRef]

- Zhu, Y.; Ma, T.; Xu, G.; Fan, J.; Zhang, Y.; Wu, M. Study of the Mixing between Asphalt and Rejuvenator in Hot In-Place Recycled Layer. J. Transp. Eng. Part B Pavements 2023, 149, 04023005. [Google Scholar] [CrossRef]

- Strouop-Gardiner, M. Recycling and Reclamation of Asphalt Pavements Using In-Place Methods: NCHRP Synthesis 421; Transportation Research Board (TRB): Washington, DC, USA, 2011. [Google Scholar]

- Liu, X.; Deng, L.; Zhang, H.; Yu, J. Quantitative study on carbon emissions of modified recycled asphalt mixture based on life cycle assessment method. Dev. Built Environ. 2024, 20, 100584. [Google Scholar] [CrossRef]

- Ankit, S.; Gondaimei-Ransinchung-Rongmei, N.; Praveen, K.; Rai, P. Mix design, development, production and policies of recycled hot mix asphalt: A review. J. Traffic Transp. Eng. 2022, 9, 765–794. [Google Scholar]

- Yu, H.; Zhang, X.; Chen, Q.; Lu, G.; Tan, Z. Carbon emission assessment in asphalt pavement maintenance: A Comparative Study of Five Methods. Case Stud. Constr. Mater. 2025, 22, e04668. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Yang, J.; Song, L.; Xu, J.; He, L.; Tao, W. Migration behavior of reclaimed asphalt pavement mastic during hot mixing. J. Clean. Prod. 2022, 376, 134123. [Google Scholar] [CrossRef]

- Yu, B.; Gu, X.; Wu, M.; Ni, F. Application of a high percentage of reclaimed asphalt pavement in an asphalt mixture: Blending process and performance investigation. Road Mater. Pavement Des. 2017, 18, 753–765. [Google Scholar] [CrossRef]

- Xia, X.; Zhao, Y.; Tang, D. The state-of-the-art review on the utilization of reclaimed asphalt pavement via hot in-place recycling technology. J. Clean. Prod. 2025, 492, 144887. [Google Scholar] [CrossRef]

- Song-Wei, M.; Yang-Wen, L.; Wu, H. Effect of specimen size on mode I fracture performance of hot mix asphalt at the low temperature. Theor. Appl. Fract. Mech. 2024, 130, 104309. [Google Scholar] [CrossRef]

- Zhan, Y.; Wu, H.; Song, W.; Chen, X.; Liao, H. A novel approach to investigate the crack resistance of recycled asphalt mixture based on energy evolution. Eng. Fract. Mech. 2024, 307, 110284. [Google Scholar] [CrossRef]

- Wu, X.; Kang, A.; Easa, S.; Lou, K.; Xiao, P.; Zheng, X. Performance evaluation of reinforced asphalt using six organic and inorganic fibers. J. Mater. Civ. Eng. 2023, 35, 04023111. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, W.; Zhao, J.; Lv, P.; Sun, L. Application of graphene–basalt fiber asphalt mixtures in pavement engineering in seasonally frozen regions. J. Mater. Civ. Eng. 2025, 37, 04025069. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Li, B.; Kang, A.; Wang, Y. Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber. Materials 2024, 17, 1762. [Google Scholar] [CrossRef] [PubMed]

- JTG F40-2004; Technical Specification for Construction of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China; China Communications Press: Beijing, China, 2004.

- Jin, L. Research on the Pavement Performance of Recycled Asphalt mixture Based on the Method of Classification Grading for Recycled Asphalt. Master’s Thesis, Yangzhou University, Yangzhou, China, 2015. [Google Scholar]

- JTG/T 5521-2019; Technical Specifications for Highway Asphalt Pavement Recycling. Ministry of Transport of the People’s Republic of China; China Communications Press: Beijing, China, 2019.

- T/CHTS 10016-2019; Technical Guide for Construction of Basalt Fiber Asphalt Pavement. China Highway and Transportation Society; Communications Press Co., Ltd.: Beijing, China, 2019.

- JTG E20-2011; Test Procedures for Bitumen and Bituminous Mixtures in Highway Engineering. Ministry of Transport of the People’s Republic of China; China Communications Press: Beijing, China, 2011.

- AASHTO TP 105; American Association of State Highway and Transportation Officials: Standard Method of Test for Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry (SCB). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- Yang, T.; Chen-Si, Y.; Pan-Yuan, Y.; Zhao, Y. Investigation of the accuracy of fracture energy in evaluating the low-temperature cracking performance of asphalt mixture. J. Mater. Civ. Eng. 2022, 34, 04022201. [Google Scholar] [CrossRef]

- AASHTOT324:2014; American Association of State Highway and Transportation Officials: Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- JTG 3410:2025; Standard Test Methods of Asphalt and Asphalt Mixture for Highway Engineering. Ministry of Transport of the People’s Republic of China; China Communications Press: Beijing, China, 2025.

- Xia, X.; Tang, D.; Wang, P.; Zhao, Y. Comparative analysis of aged-sbsma regeneration in hot in-place recycling: Individual and coupled effects of aromatic oil and sbs/sbr polymer modifiers. J. Mater. Civ. Eng. 2025, 37, 04025177. [Google Scholar] [CrossRef]

- Kong, L.; Xu, J.; Yang, H.; Wu, P.; Li, X.; Ma, D.; Wang, Z.; Ren, D.; Ai, C. Enhancing crack resistance in basalt fiber asphalt mixtures: A full-field time-domain investigation of stress distribution and pore structure optimization. Int. J. Pavement Eng. 2025, 26, 2460746. [Google Scholar] [CrossRef]

- Hassan, A.; Abdelsalam, M.; Gamal, A.; Eisa, M.S. Laboratory study on the asphalt mixture performance by nano-caco3 and basalt fiber. Case Stud. Constr. Mater. 2025, 23, e04923. [Google Scholar]

- Abu-Sao, M.; Kassem, E.; Muftah, A. Cracking performance evaluation of rap mixes. J. Transp. Eng. Part B Pavements 2023, 149, 04022072. [Google Scholar] [CrossRef]

- Jiu, X.; Wang, Y.; Wu, Z.; Xiao, P.; Kang, A. High-temperature performance evaluation of asphalt mixtures by adding short-chopped basalt fiber. Buildings 2023, 13, 370. [Google Scholar] [CrossRef]

- Li, L.; Cheng-cheng, Y.; Zhao-hui, L. Multiparameter sensitivity analysis of flexural–tensile property of basalt fiber–reinforced asphalt mixture. J. Highw. Transp. Res. Dev. (Engl. Ed.) 2021, 15, 14–21. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, L.; Zhang, Y.; Lv, Z.; Zhu, C. Quantitative analysis of effect and interaction of diatomite and basalt fiber on asphalt performance. J. Mater. Civ. Eng. 2019, 31, 04019306. [Google Scholar] [CrossRef]

| Technical Indicators | Results | Requirements in [19] |

|---|---|---|

| Penetration (25 °C)/0.1 mm | 39 | 50–80 |

| Softening point/°C | 69 | ≥60 |

| Ductility (5 °C)/cm | 7.8 | ≥30 |

| Rotary Viscosity (135 °C)/Pa·s | 2.33 | ≤3 |

| Passing Ratio/% | Sieve Size/mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | ||

| SMA-13 | Upper limit | 100 | 100 | 75 | 34 | 26 | 24 | 20 | 16 | 15 | 12 |

| Lower limit | 100 | 90 | 50 | 20 | 15 | 14 | 12 | 10 | 9 | 8 | |

| RAP aggregates | 100 | 92.1 | 61.2 | 31.0 | 25.4 | 21.3 | 16.9 | 13.3 | 11.0 | 8.1 | |

| Test Items | Test Results | Requirements in [22] |

|---|---|---|

| Density/g-cm-3 | 2.72 | 2.60–2.80 |

| Tensile strength/MPa | 3800 | ≥2000 |

| Elongation at break/% | 2.69 | ≥2.1 |

| Elasticity Modulus/GPa | 102 | ≥80 |

| Heat resistance, retention of breaking strength/% | 92 | ≥85 |

| Alkali resistance, retention of breaking strength/% | 87 | ≥75 |

| Test Items | Test Results | Requirements in [19] |

|---|---|---|

| Ash content/% | 19.3 | 18 ± 5 |

| pH value | 7.7 | 7.5 ± 1.0 |

| oil absorption | 6.2 | 5 times by the fiber mass |

| No. | Gradation Type | Fiber Type | Fiber Content/% | Optimum Oil/Stone Ratio/% |

|---|---|---|---|---|

| 1 | Hot mix Asphalt (HMA) | lignin fiber | 0.3 | 6.0 |

| 2 | basalt fiber | 0.3 | 5.8 | |

| 3 | Hot central plant recycling mixture (HCPR) | lignin fiber | 0.3 | 6.1 |

| 4 | basalt fiber | 0.3 | 5.9 | |

| 5 | Hot in-place recycling mixture (HIPR) | lignin fiber | 0.1 | 6.0 |

| 6 | basalt fiber | 0.3 | 6.0 |

| Pilot Project | Rejuvenator Content/% | SBS Asphalt | ||||

|---|---|---|---|---|---|---|

| 0 | 4 | 6 | 8 | 10 | ||

| penetration (25 °C)/0.1 mm | 39 | 60 | 68 | 74 | 78 | 71 |

| Softening point/°C | 69 | 65 | 63 | 61 | 56 | 64 |

| Ductility (5 °C)/cm | 7.8 | 22.4 | 28.6 | 31.4 | 34.6 | 48 |

| Type of Mix | Stage II Model | R2 | Creep Rate | Rheological Number Fn |

|---|---|---|---|---|

| HMA + lignin | y = 46x + 17,778 | 0.993 | 46 | 552 |

| MHA + BF | y = 32x + 16,984 | 0.992 | 32 | 748 |

| HCPR + lignin | y = 28x + 20,166 | 0.983 | 28 | 782 |

| HCPR + BF | y = 25x + 27,159.5 | 0.997 | 25 | 963 |

| HIPR + lignin | y = 22x + 21,747 | 0.983 | 22 | 980 |

| HIPR + BF | y = 17x + 28,341 | 0.992 | 17 | 1289 |

| Mix Type | Maximum Rutting Depth/mm | Creep Slope | Spalling Slope | Spalling Point/Time |

|---|---|---|---|---|

| HMA + lignin | 6.91 | 1.3 × 10−4 | / | / |

| MHA + BF | 5.71 | 8.7 × 10−5 | / | / |

| HCPR + lignin | 8.15 | 1.8 × 10−4 | 4.0 × 10−4 | 12,483 |

| HCPR + BF | 6.94 | 1.5 × 10−4 | 3.1 × 10−4 | 15,630 |

| HIPR + lignin | 10.03 | 2.6 × 10−4 | 5.8 × 10−4 | 8637 |

| HIPR + BF | 9.07 | 2.2 × 10−4 | 5.2 × 10−4 | 10,536 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Q.; Zhou, L.; Li, B. Road Performance of Hot Central Plant Versus Hot In-Place Recycling Asphalt Mixtures: A Quantitative Comparison and Adaptability Analysis. Materials 2025, 18, 5149. https://doi.org/10.3390/ma18225149

Shi Q, Zhou L, Li B. Road Performance of Hot Central Plant Versus Hot In-Place Recycling Asphalt Mixtures: A Quantitative Comparison and Adaptability Analysis. Materials. 2025; 18(22):5149. https://doi.org/10.3390/ma18225149

Chicago/Turabian StyleShi, Qinyu, Lixin Zhou, and Bo Li. 2025. "Road Performance of Hot Central Plant Versus Hot In-Place Recycling Asphalt Mixtures: A Quantitative Comparison and Adaptability Analysis" Materials 18, no. 22: 5149. https://doi.org/10.3390/ma18225149

APA StyleShi, Q., Zhou, L., & Li, B. (2025). Road Performance of Hot Central Plant Versus Hot In-Place Recycling Asphalt Mixtures: A Quantitative Comparison and Adaptability Analysis. Materials, 18(22), 5149. https://doi.org/10.3390/ma18225149