Development of Acoustic Absorbent Materials Using Pine Needles

Abstract

1. Introduction

2. Materials and Methods

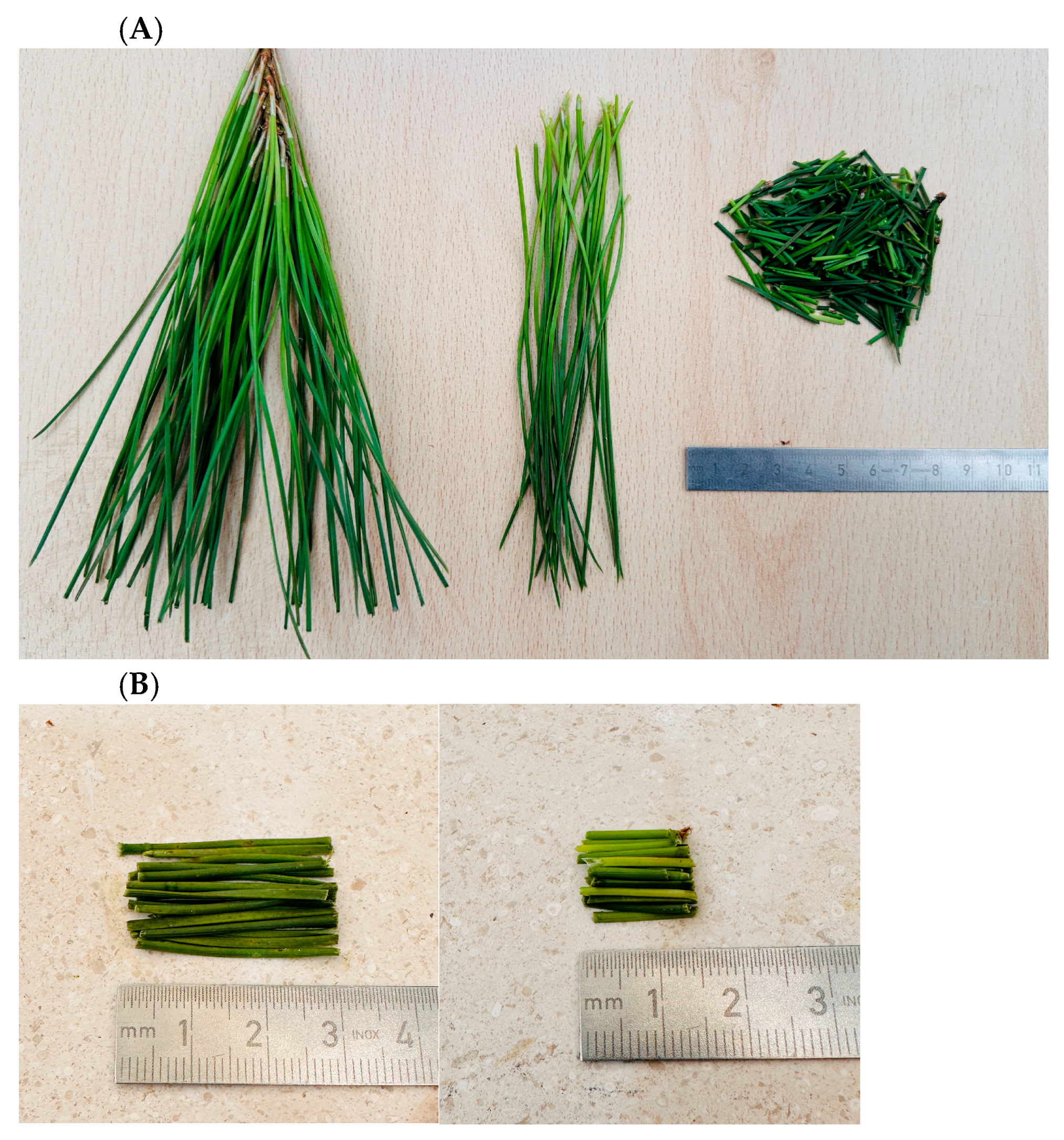

2.1. Materials

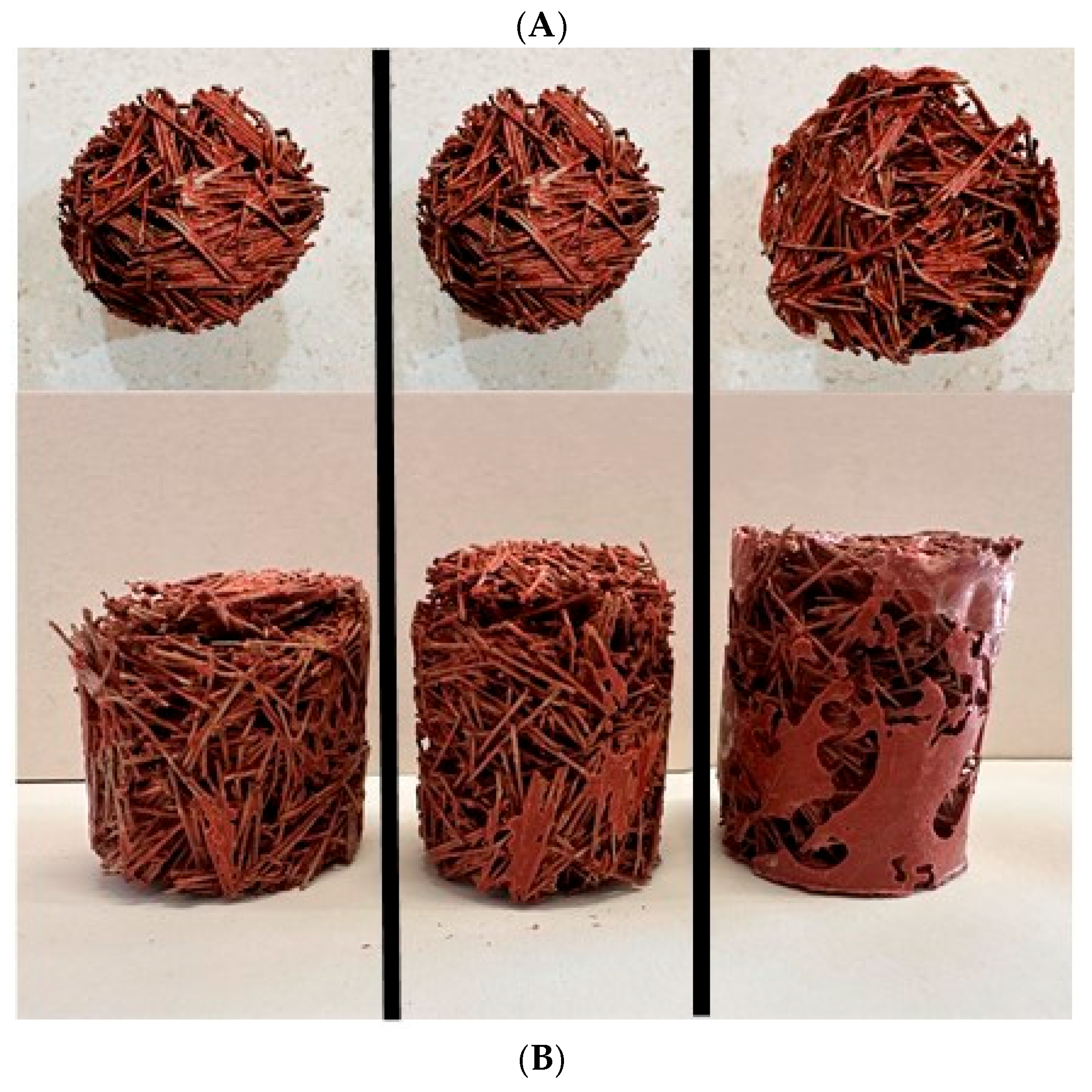

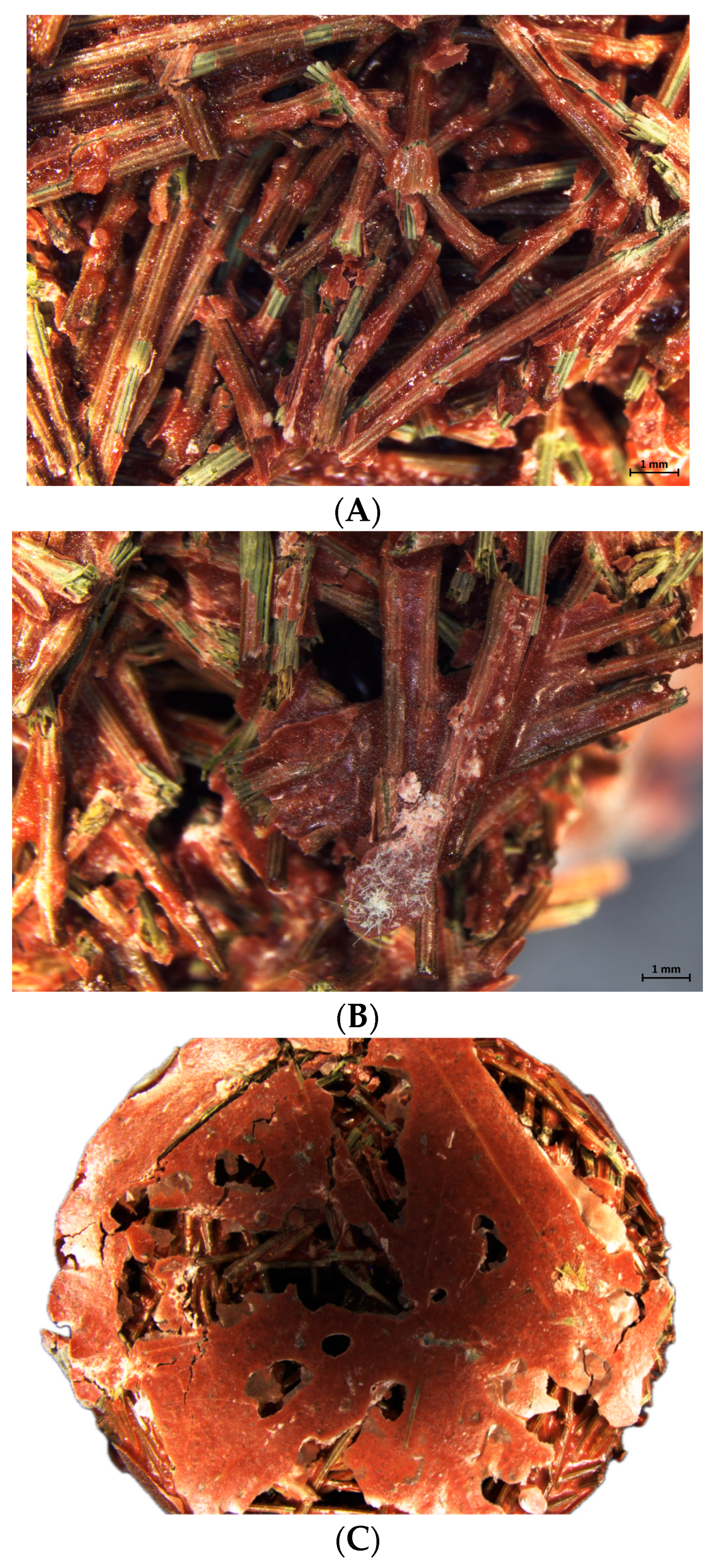

2.2. Preparation of Test Specimens

2.3. Test Methods

2.3.1. Sound Absorption Coefficient

2.3.2. Physical and Mechanical Properties

3. Results

3.1. Physical Properties

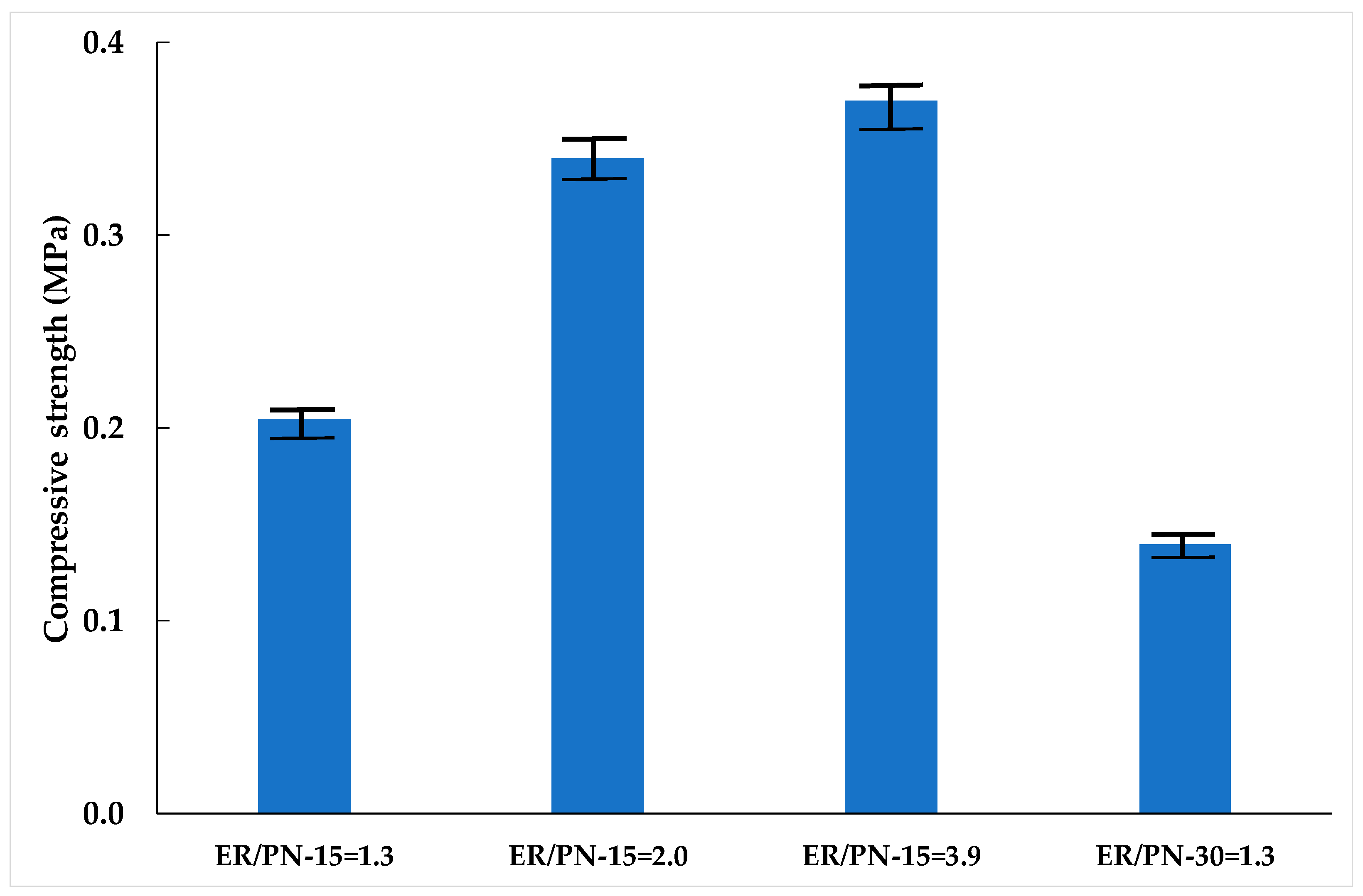

3.2. Compressive Strength

3.3. Acoustic Properties

4. Conclusions

- -

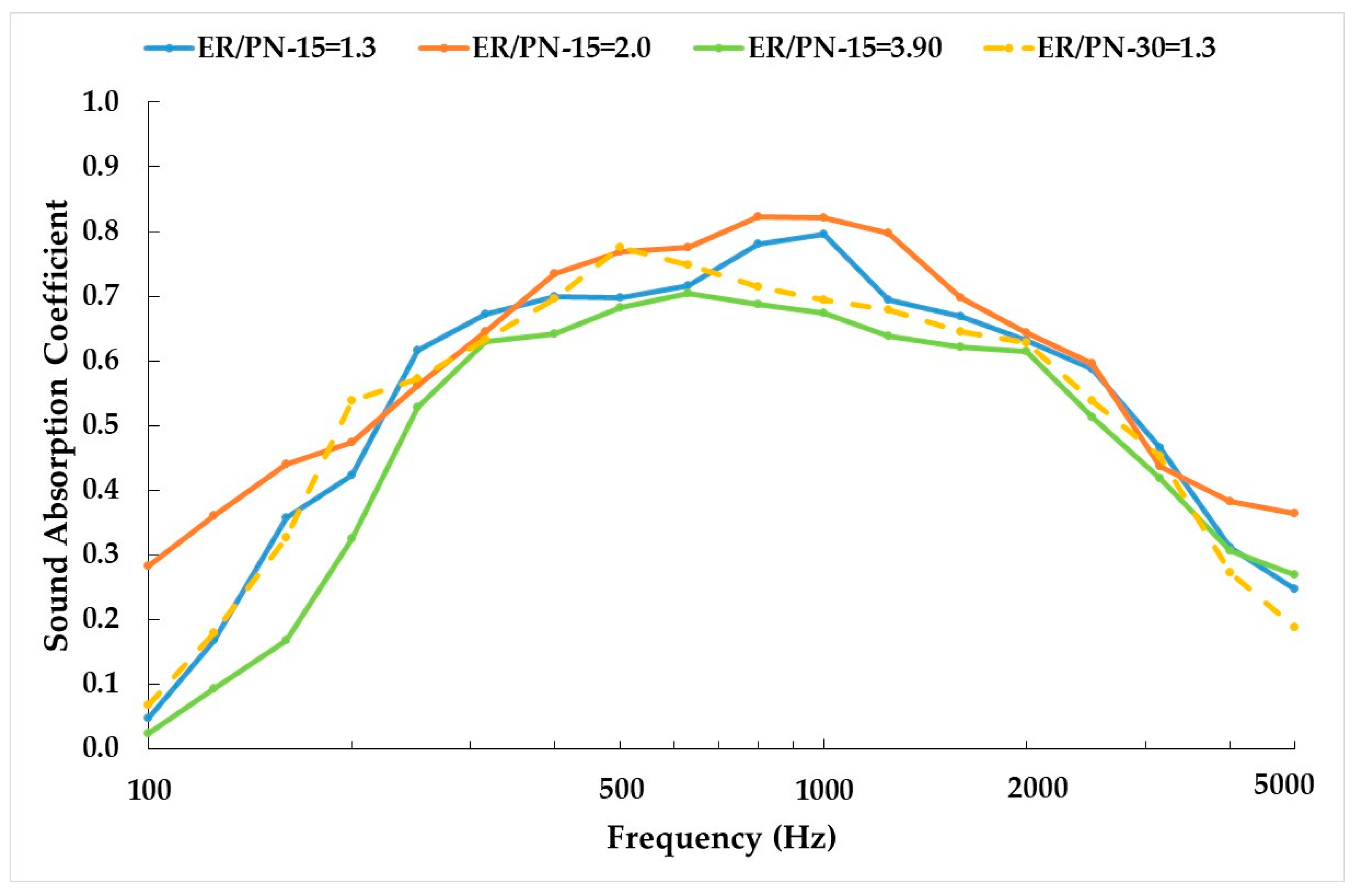

- Concerning the effect of the resin content, the porosity is found to be inversely proportional to the amount of resin, and as such the density is then directly proportional to the resin content. However, for large quantities of resin a clogging phenomenon occurs that produces a material with heterogeneous physical properties. Regarding the mechanical properties, it was determined that specimens with a greater amount of resin have a higher compression strength, but the clogging effect limits the increase in compressive strength for high ratios. An 80% higher compressive strength is reported for ER/PN-15-3.9 compared to ER/PN-15-1.3). While the sound absorption coefficient for the different ratios increases when the ratio ER/PN decreases. A 10% higher sound absorption coefficient is reported for ER/PN-15-1.3 when compared to ER/PN-15- = 3.9. The clogging effect on the other hand produces an absorbent section and a reflective section, which makes the decrease in the acoustic absorption coefficient not as high as one would expect.

- -

- Regarding the influence of the length of pine needle fragments, the porosity of the specimens is directly proportional to the length of the pine needle. Hence increasing the pine needles length increases the porosity in turn decreasing the density, which eventually has a negative effect on the compressive strength. However, the sound absorption coefficient does not change significantly. A 2% difference is found when comparing ER/PN-15-1.3 and ER/PN-30-1.3.

- -

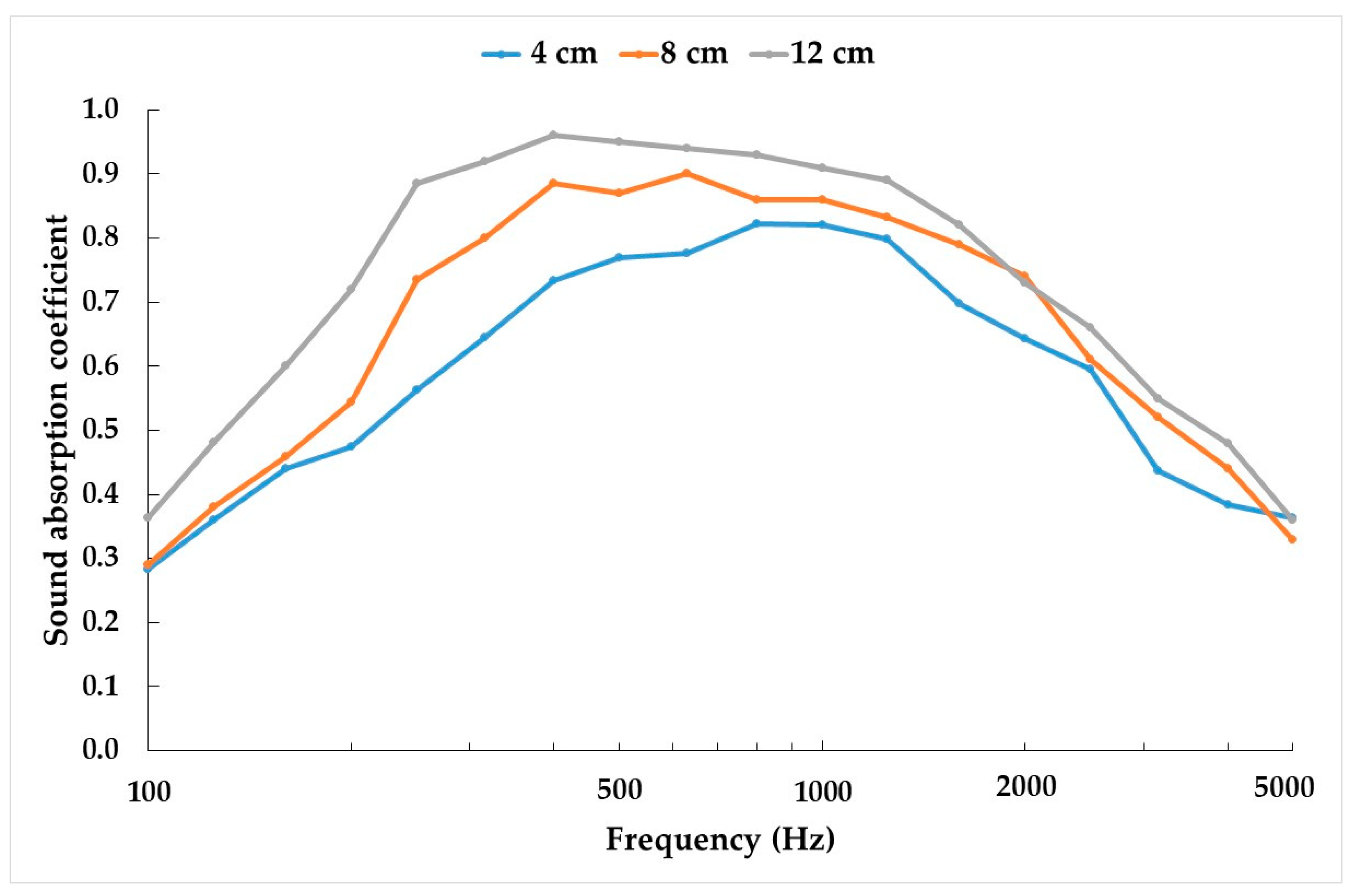

- With respect to the influence of thickness, the greater thickness of the specimens leads to improved sound absorption coefficients. For the same composition, i.e., uniform, ER/PN-15-2.0 provides an 18% greater sound absorption coefficient when extending the length from 4 to 12 cm. This is because sound waves travel a longer path and hence are more effectively absorbed by the material. The tests for the ER/PN-15-2.0 yield the best sound absorption coefficient for the longest of the specimens at 12 mm.

- -

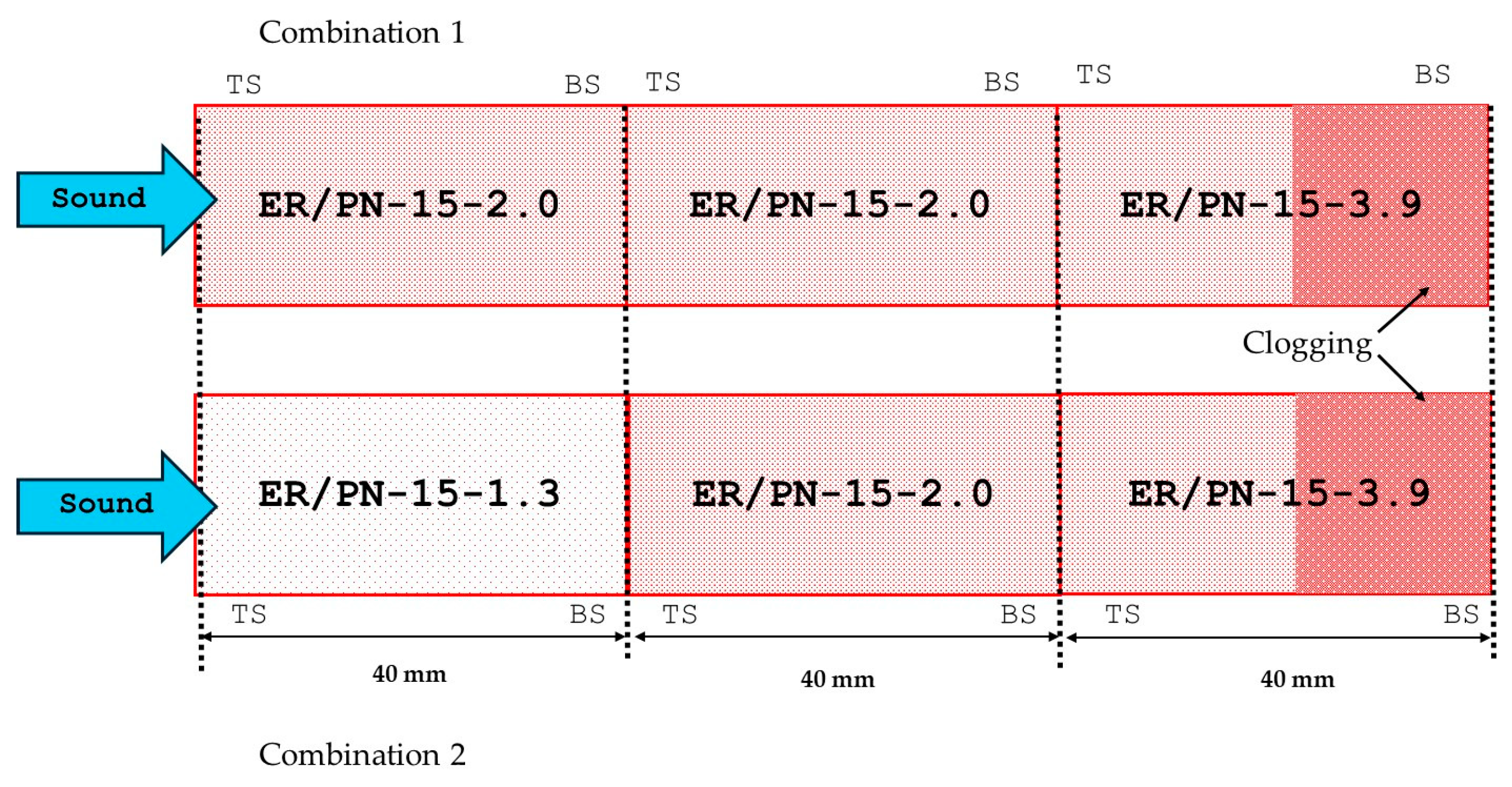

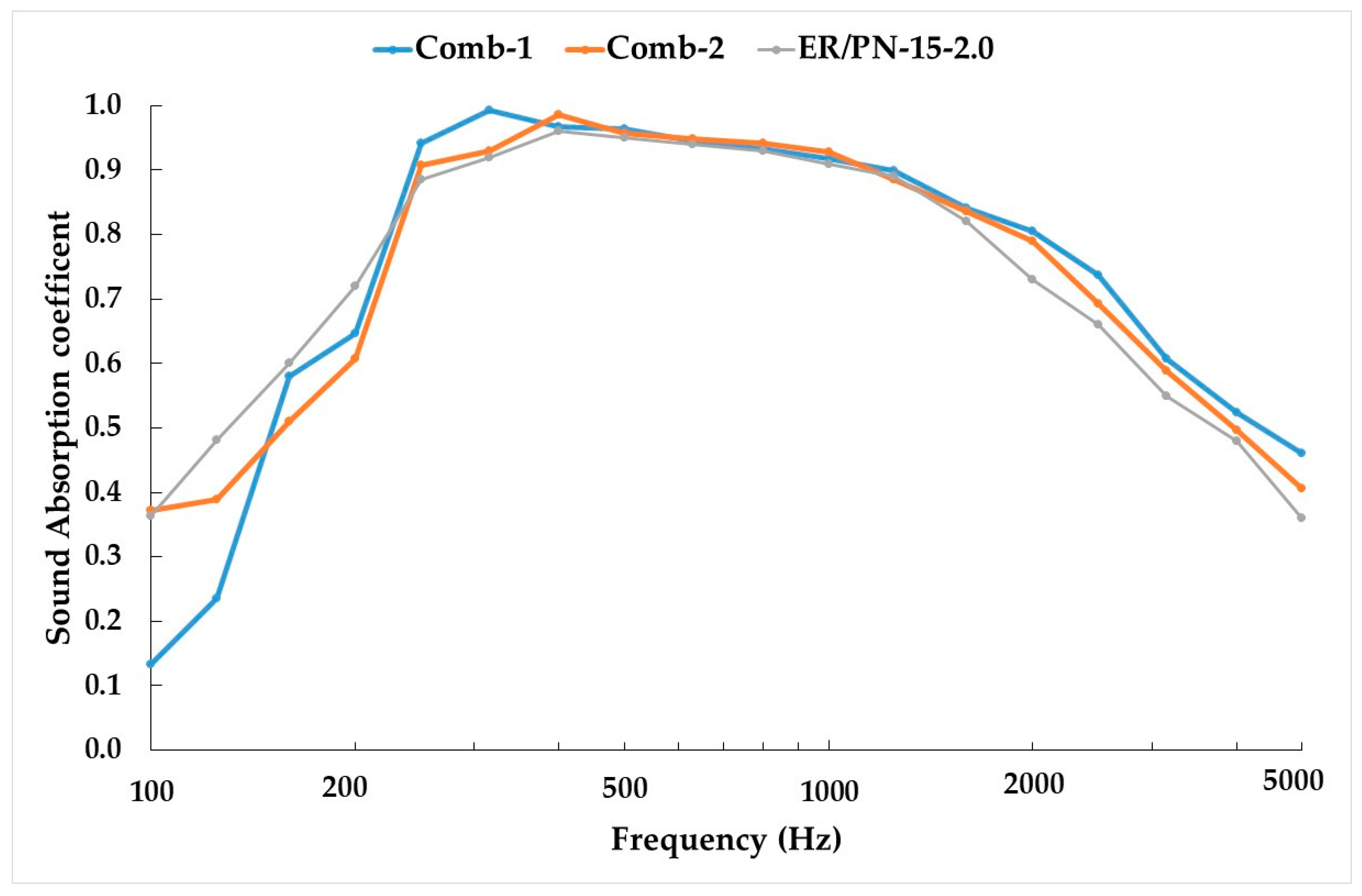

- Regarding the influence of combining different ratios, an increase in the sound absorption coefficient at medium and high frequencies was observed, which is attributed to the presence of clogging at the end of the high ER/PN ratio specimens. While at lower frequencies the specimen compressing different ER/PN ratios of 1.3/2.0/3.9 placed in series presents the best acoustic properties. A 6% and a 7% increase for NRC and DLα, respectively, are reported when compared to the uniform ER/PN-15-2.0 for 12 cm of thickness. Both combinations of ER/PN ratios can be classified as A3.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fires Ravage Forests in Himalayas, Threatening Health and Biodiversity. 2017. Third Pole. Available online: https://www.Thethirdpole.Net/En/Climate/Fires-Ravage-Forests-Himalayas-Threatening-Health-Biodiversity/ (accessed on 9 January 2022).

- Calef, M.P.; Schmidt, J.I.; Varvak, A.; Ziel, R. Predicting the Unpredictable: Predicting Landcover in Boreal Alaska and the Yukon Including Succession and Wildfire Potential. Forests 2023, 14, 1577. [Google Scholar] [CrossRef]

- Sengar, A.; Sharma, V.; Agrawal, R.; Dwivedi, A.; Dwivedi, P.; Joshi, K.; Dixit, G.; Sharma, P.K.; Barthwal, M. Prioritization of Barriers to Energy Generation Using Pine Needles to Mitigate Climate Change: Evidence from India. J. Clean. Prod. 2020, 275, 123840. [Google Scholar] [CrossRef]

- Singh, V.; Pant, N.; Sharma, R.K.; Padalia, D.; Rawat, P.S.; Goswami, R.; Singh, P.; Kumar, A.; Bhandari, P.; Tabish, A.; et al. Adsorption Studies of Pb(II) and Cd(II) Heavy Metal Ions from Aqueous Solutions Using a Magnetic Biochar Composite Material. Separations 2023, 10, 389. [Google Scholar] [CrossRef]

- Jeon, C.; Solis, K.L.; An, H.-R.; Hong, Y.; Igalavithana, A.D.; Ok, Y.S. Sustainable Removal of Hg(II) by Sulfur-Modified Pine-Needle Biochar. J. Hazard. Mater. 2020, 388, 122048. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Yang, M.; Qiang, M.; Li, X.; Morrell, J.J.; Yao, Y.; Su, Y. Preparation of Cellulose Nanoparticles from Foliage by Bio-Enzyme Methods. Materials 2021, 14, 4557. [Google Scholar] [CrossRef]

- Xiao, S.; Gao, R.; Lu, Y.; Li, J.; Sun, Q. Fabrication and Characterization of Nanofibrillated Cellulose and Its Aerogels from Natural Pine Needles. Carbohydr. Polym. 2015, 119, 202–209. [Google Scholar] [CrossRef]

- Thakur, V.K.; Singha, A.S.; Thakur, M.K. Fabrication and Physico-Chemical Properties of High-Performance Pine Needles/Green Polymer Composites. Int. J. Polym. Mater. 2013, 62, 226–230. [Google Scholar] [CrossRef]

- Long, W.; Wang, Y. Effect of Pine Needle Fibre Reinforcement on the Mechanical Properties of Concrete. Constr. Build. Mater. 2021, 278, 122333. [Google Scholar] [CrossRef]

- Popescu, D.I.; Frum, A.; Dobrea, C.M.; Cristea, R.; Gligor, F.G.; Vicas, L.G.; Ionete, R.E.; Sutan, N.A.; Georgescu, C. Comparative Antioxidant and Antimicrobial Activities of Several Conifer Needles and Bark Extracts. Pharmaceutics 2023, 16, 52. [Google Scholar] [CrossRef]

- Kadam, A.A.; Singh, S.; Gaikwad, K.K. Chitosan Based Antioxidant Films Incorporated with Pine Needles (Cedrus Deodara) Extract for Active Food Packaging Applications. Food Control 2021, 124, 107877. [Google Scholar] [CrossRef]

- Varma, A.K.; Mondal, P. Pyrolysis of Pine Needles: Effects of Process Parameters on Products Yield and Analysis of Products. J. Therm. Anal. Calorim. 2018, 131, 2057–2072. [Google Scholar] [CrossRef]

- Wawro, A.; Jakubowski, J.; Gieparda, W.; Pilarek, Z.; Łacka, A. Potential of Pine Needle Biomass for Bioethanol Production. Energies 2023, 16, 3949. [Google Scholar] [CrossRef]

- Seddeq, H.S. Factors Influencing Acoustic Performance of Sound Absorptive Materials. Aust. J. Basic. Appl. Sci. 2009, 3, 4610–4617. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic Characterization of Natural Fibers for Sound Absorption Applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Othmani, C.; Taktak, M.; Zein, A.; Hentati, T.; Elnady, T.; Fakhfakh, T.; Haddar, M. Experimental and Theoretical Investigation of the Acoustic Performance of Sugarcane Wastes Based Material. Appl. Acoust. 2016, 109, 90–96. [Google Scholar] [CrossRef]

- Lim, Z.Y.; Putra, A.; Nor, M.J.M.; Yaakob, M.Y. Sound Absorption Performance of Natural Kenaf Fibres. Appl. Acoust. 2018, 130, 107–114. [Google Scholar] [CrossRef]

- Arenas, J.P.; del Rey, R.; Alba, J.; Oltra, R. Sound-Absorption Properties of Materials Made of Esparto Grass Fibers. Sustainability 2020, 12, 5533. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G.; Di Gabriele, M. The Acoustic Characterization of Broom Fibers. J. Nat. Fibers 2017, 14, 858–863. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A Review of Sustainable Materials for Acoustic Applications. Build. Acoust. 2012, 19, 283–311. [Google Scholar] [CrossRef]

- Leiva, C.; Arenas, C.; Vilches, L.F.; Arroyo, F.; Luna-Galiano, Y. Assessing Durability Properties of Noise Barriers Made of Concrete Incorporating Bottom Ash as Aggregates. Eur. J. Environ. Civ. Eng. 2019, 23, 1485–1496. [Google Scholar] [CrossRef]

- Arenas, C.; Ríos, J.D.; Cifuentes, H.; Peceño, B.; Leiva, C. Experimental Study of a Noise Reducing Barrier Made of Fly Ash. Mater. Construcción 2021, 71, e239. [Google Scholar] [CrossRef]

- Rios, J.D.; Arenas, C.; Cifuentes, H.; Peceño, B.; Leiva, C. Porous Structure by X-Ray Computed Tomography and Sound Absorption in Pervious Concretes with Air Cooled Blast Furnace Slag as Coarse Aggregate. Acoust. Aust. 2019, 47, 271–276. [Google Scholar] [CrossRef]

- Li, J.; Zhuang, X.; Leiva, C.; Arenas, C.; Cornejo, A.; Querol, X.; Moreno, N.; Font, O.; Fernández Pereira, C. Utilization of Boiler Slag from Pulverized-Coal-Combustion Power Plants in China for Manufacturing Acoustic Materials. Energies 2020, 13, 5705. [Google Scholar] [CrossRef]

- Arenas, C.; Ríos, J.D.; Cifuentes, H.; Vilches, L.F.; Leiva, C. Sound Absorbing Porous Concretes Composed of Different Solid Wastes. Eur. J. Environ. Civ. Eng. 2022, 26, 3805–3817. [Google Scholar] [CrossRef]

- Arenas, C.; Vilches, L.F.; Leiva, C.; Alonso-Fariñas, B.; Rodríguez-Galán, M. Recycling Ceramic Industry Wastes in Sound Absorbing Materials. Mater. Construcción 2016, 66, e106. [Google Scholar] [CrossRef]

- Badida, M.; Moravec, M.; Pinosova, M.; Andrejiova, M.; Pástor, K.; Nováková, A.; Dzuro, T. Analysis and Research on the Use of Bulk Recycled Materials for Sound Insulation Applications. Sustainability 2022, 14, 11539. [Google Scholar] [CrossRef]

- Yun, B.Y.; Cho, H.M.; Kim, Y.U.; Lee, S.C.; Berardi, U.; Kim, S. Circular Reutilization of Coffee Waste for Sound Absorbing Panels: A Perspective on Material Recycling. Environ. Res. 2020, 184, 109281. [Google Scholar] [CrossRef] [PubMed]

- Eziefula, U.G.; Ezeh, J.C.; Eziefula, B.I. Properties of Seashell Aggregate Concrete: A Review. Constr. Build. Mater. 2018, 192, 287–300. [Google Scholar] [CrossRef]

- Ali, M.; Al-Suhaibani, Z.; Almuzaiqer, R.; Albahbooh, A.; Al-Salem, K.; Nuhait, A. New Composites Derived from the Natural Fiber Polymers of Discarded Date Palm Surface and Pineapple Leaf Fibers for Thermal Insulation and Sound Absorption. Polymers 2024, 16, 1002. [Google Scholar] [CrossRef]

- Shoaib, M.; Jamshaid, H.; Mishra, R.K.; Ali, M.; Chandan, V.; Kolar, V.; Nazari, S.; Tm, A.; Jirku, P.; Muller, M.; et al. Facile-Solution-Processed Silicon Nanofibers Formed on Recycled Cotton Nonwovens as Multifunctional Porous Sustainable Materials. Materials 2024, 17, 412. [Google Scholar] [CrossRef]

- Bojković, J.; Marašević, M.; Stojić, N.; Bulatović, V.; Radičević, B. Thermal and Sound Characterization of a New Biocomposite Material. Materials 2023, 16, 4209. [Google Scholar] [CrossRef] [PubMed]

- Puyana-Romero, V.; Jaramillo Cevallos, W.A.; Ciaburro, G. Simulation of Acoustic Properties of Plaster Matrix Composite MATERIAL Reinforced with Corn Stem Fibers. Fibers 2023, 11, 26. [Google Scholar] [CrossRef]

- Ferrandez-Villena, M.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, M.T. Acoustic and Thermal Properties of Particleboards Made from Mulberry Wood (Morus alba L.) Pruning Residues. Agronomy 2022, 12, 1803. [Google Scholar] [CrossRef]

- Cottone, R.; Shtrepi, L.; Serra, V.; Pagliolico, S.L. The Recycling and Reuse of Natural Materials: Sound Absorbing Box Patterns That Use Waste from Olive Tree Pruning. Acoustics 2023, 5, 177–192. [Google Scholar] [CrossRef]

- Shaid Sujon, M.A.; Islam, A.; Nadimpalli, V.K. Damping and Sound Absorption Properties of Polymer Matrix Composites: A Review. Polym. Test. 2021, 104, 107388. [Google Scholar] [CrossRef]

- EN 1504-4; Products and Systems for the Protection and Repair of Concrete Structures—Definitions, Requirements, Quality Control and Evaluation of Conformity—Part 4: Structural Bonding. European Committee for Standardization: Brussels, Belgium, 2004.

- Peceño, B.; Perez-Soriano, E.; Ríos, J.D.; Luna-Galiano, Y.; Cifuentes, H.; Leiva Fernández, C. Morphological Analysis of Porosity and Sound Absorption in Sustainable Materials from Rice Husk. Build. Acoust. 2022, 29, 387–399. [Google Scholar] [CrossRef]

- Li, B.; Zhao, H.; Zhou, J.; Yao, T.; Guo, F.; Hu, Y. Investigation on Sound Absorption Coefficients of Porous Asphalt Concrete under Different Clogging Conditions. Constr. Build. Mater. 2024, 428, 136081. [Google Scholar] [CrossRef]

- ISO 10534-2:2023; Acoustics—Determination of Acoustic Properties in Impedance Tubes—Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. International Organization for Standardization: Geneva, Switzerland, 2025.

- EN 1793-1:2017; Road Traffic Noise Reducing Devices—Test Method for Determining the Acoustic Performance—Part 1: Intrinsic Characteristics of Sound Absorption Under Diffuse Sound Field Conditions. European Committee for Standardization: Brussels, Belgium, 2017.

- ASTM C39/C39M-05e2; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2005.

- Maderuelo-Sanz, R.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M.; Romero-Casado, A.; Acedo-Fuentes, P.; López-Ramos, L. Mechanical, Thermal and Acoustical Evaluation of Biocomposites Made of Agricultural Waste for Ceiling Tiles. Appl. Acoust. 2022, 191, 108689. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Haghighat, M.; Samaei, S.E.; Amininasab, S.; Faridan, M.; Mehrzad, S.; Sheikhmozafari, M.J.; Taban, E. The Impact of Fiber Size on the Sound Absorption Behavior of Composites Made from Sugarcane Bagasse Wastes Fibers. J. Nat. Fibers 2023, 20, 2175760. [Google Scholar] [CrossRef]

- Vasina, M.; Straznicky, P.; Hrbacek, P.; Rusnakova, S.; Bosak, O.; Kubliha, M. Investigation of Physical Properties of Polymer Composites Filled with Sheep Wool. Polymers 2024, 16, 690. [Google Scholar] [CrossRef]

- Miturska-Barańska, I.; Rudawska, A.; Sobotova, L.; Badida, M.; Olewnik-Kruszkowska, E.; Müller, M.; Hromasová, M. Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers. Materials 2024, 17, 4452. [Google Scholar] [CrossRef]

- Wang, D.; Peng, L.; Zhu, G.; Fu, F.; Zhou, Y.; Song, B. Improving the Sound Absorption Capacity of Wood by Microwave Treatment. Bioresources 2014, 9, 7504–7518. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous Materials for Sound Absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Jang, E.-S. Sound Absorbing Properties of Selected Green Material—A Review. Forests 2023, 14, 1366. [Google Scholar] [CrossRef]

- Koruk, H.; Ozcan, A.C.; Genc, G.; Sanliturk, K.Y. Jute and Luffa Fiber-Reinforced Biocomposites: Effects of Sample Thickness and Fiber/Resin Ratio on Sound Absorption and Transmission Loss Performance. J. Nat. Fibers 2022, 19, 6239–6254. [Google Scholar] [CrossRef]

- Bhuvaneswari, V.; Devarajan, B.; Arulmurugan, B.; Mahendran, R.; Rajkumar, S.; Sharma, S.; Mausam, K.; Li, C.; Eldin, E.T. A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites. Polymers 2022, 14, 4727. [Google Scholar] [CrossRef]

- Iannace, G.; Bevilacqua, A.; Trematerra, A.; Amadasi, G. Sound Absorption of Hydroponically Grown Plants. Acoustics 2025, 7, 24. [Google Scholar] [CrossRef]

- Nor, M.J.M.; Ayub, M.d.; Zulkifli, R.; Amin, N.; Fouladi, M.H. Effect of Different Factors on the Acoustic Absorption of Coir Fiber. J. Appl. Sci. 2010, 10, 2887–2892. [Google Scholar] [CrossRef]

- Piana, E.A.; Bonfiglio, P.; Rychtarikova, M. Acoustic Properties of Absorbing Materials. Appl. Sci. 2022, 12, 4446. [Google Scholar] [CrossRef]

| Category | DLα (dB) |

|---|---|

| A0 | Undetermined |

| A1 | <4 |

| A2 | 4 to 7 |

| A3 | 8 to 11 |

| A4 | >11 |

| Composition | Open Porosity (%) | Bulk Density (kg/m3) |

|---|---|---|

| ER/PN-15 = 1.3 | 64 ± 4 | 645 ± 14 |

| ER/PN-15 = 2.0 | 46 ± 3 | 786 ± 22 |

| ER/PN-15 = 3.9 | 31 ± 3 | 883 ± 32 |

| ER/PN-30 = 1.3 | 75 ± 4 | 331 ± 11 |

| Composition | NRC | DLα (dB) |

|---|---|---|

| ER/PN-15 = 1.3 | 0.69 ± 0.03 | 4.7 ± 0.2 |

| ER/PN-15 = 2.0 | 0.71 ± 0.03 | 5.3 ± 0.2 |

| ER/PN-15 = 3.9 | 0.63 ± 0.03 | 3.9 ± 0.2 |

| ER/PN-30 = 1.3 | 0.67 ± 0.04 | 4.4 ± 0.3 |

| Thickness (cm) | NRC | DLα (dB) |

|---|---|---|

| 4 | 0.70 ± 0.03 | 5.3 ± 0.2 |

| 8 | 0.76 ± 0.03 | 6.2 ± 0.2 |

| 12 | 0.85 ± 0.04 | 7.8 ± 0.4 |

| Sample | NRC | DLα (dB) |

|---|---|---|

| 2.0-2.0-3.9 | 0.90 ± 0.03 | 8.0 ± 0.2 |

| 1.3-2.0-3.9 | 0.91 ± 0.03 | 8.3 ± 0.4 |

| Uniform ER/PN-15-2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Martinez, J.D.; Peceño, B.; Carrasco, C.J.; Orejón, D.; Luna-Galiano, Y.; Leiva, C. Development of Acoustic Absorbent Materials Using Pine Needles. Materials 2025, 18, 4978. https://doi.org/10.3390/ma18214978

Ruiz-Martinez JD, Peceño B, Carrasco CJ, Orejón D, Luna-Galiano Y, Leiva C. Development of Acoustic Absorbent Materials Using Pine Needles. Materials. 2025; 18(21):4978. https://doi.org/10.3390/ma18214978

Chicago/Turabian StyleRuiz-Martinez, Jaime D., Begona Peceño, Carlos J. Carrasco, Daniel Orejón, Yolanda Luna-Galiano, and Carlos Leiva. 2025. "Development of Acoustic Absorbent Materials Using Pine Needles" Materials 18, no. 21: 4978. https://doi.org/10.3390/ma18214978

APA StyleRuiz-Martinez, J. D., Peceño, B., Carrasco, C. J., Orejón, D., Luna-Galiano, Y., & Leiva, C. (2025). Development of Acoustic Absorbent Materials Using Pine Needles. Materials, 18(21), 4978. https://doi.org/10.3390/ma18214978