Cementitious Composites Reinforced with Magnetically Oriented Steel Microfibers: Mechanical Properties, Deformability and Fracture Propagation

Abstract

1. Introduction

2. Materials and Methods

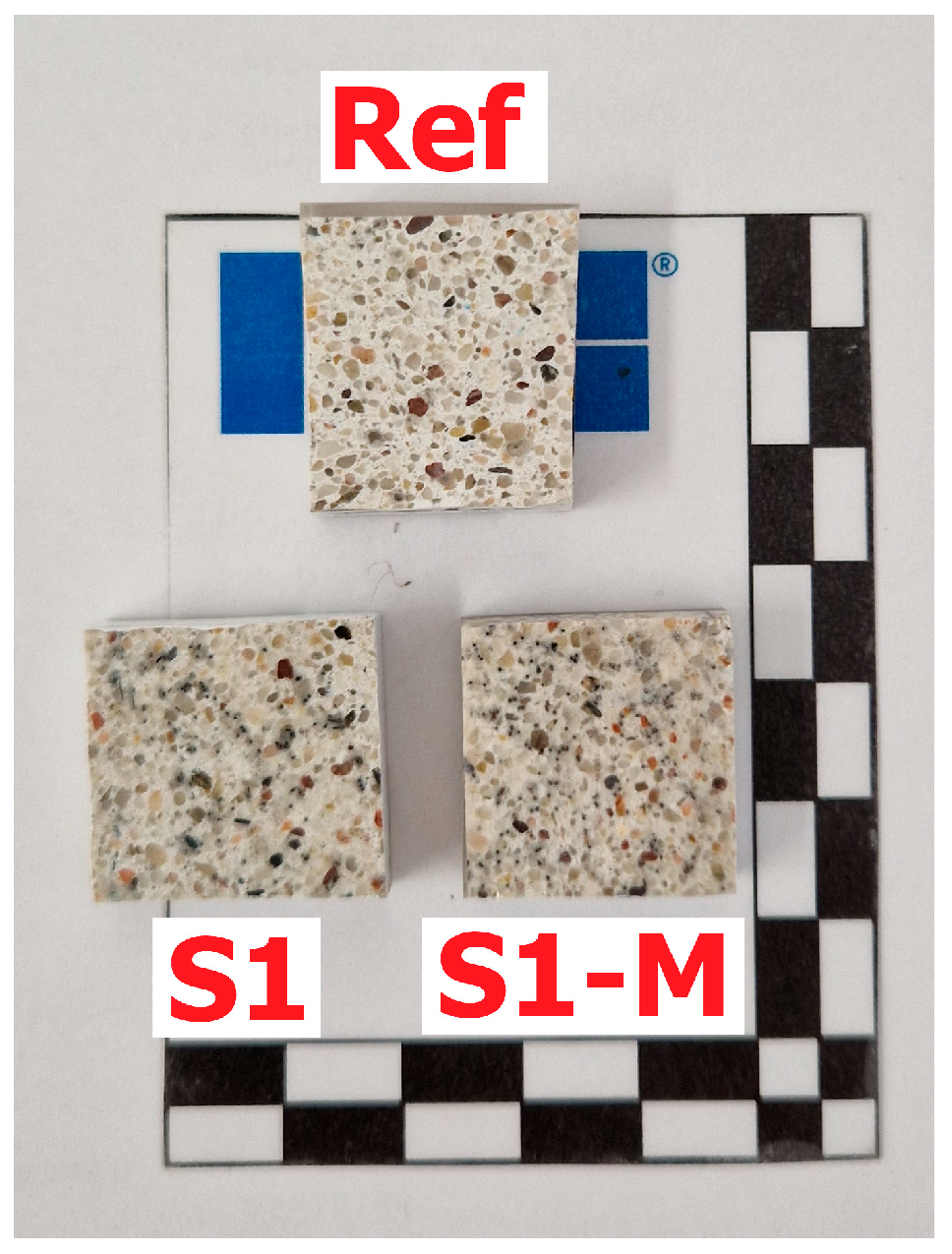

2.1. Materials and Specimen Preparation

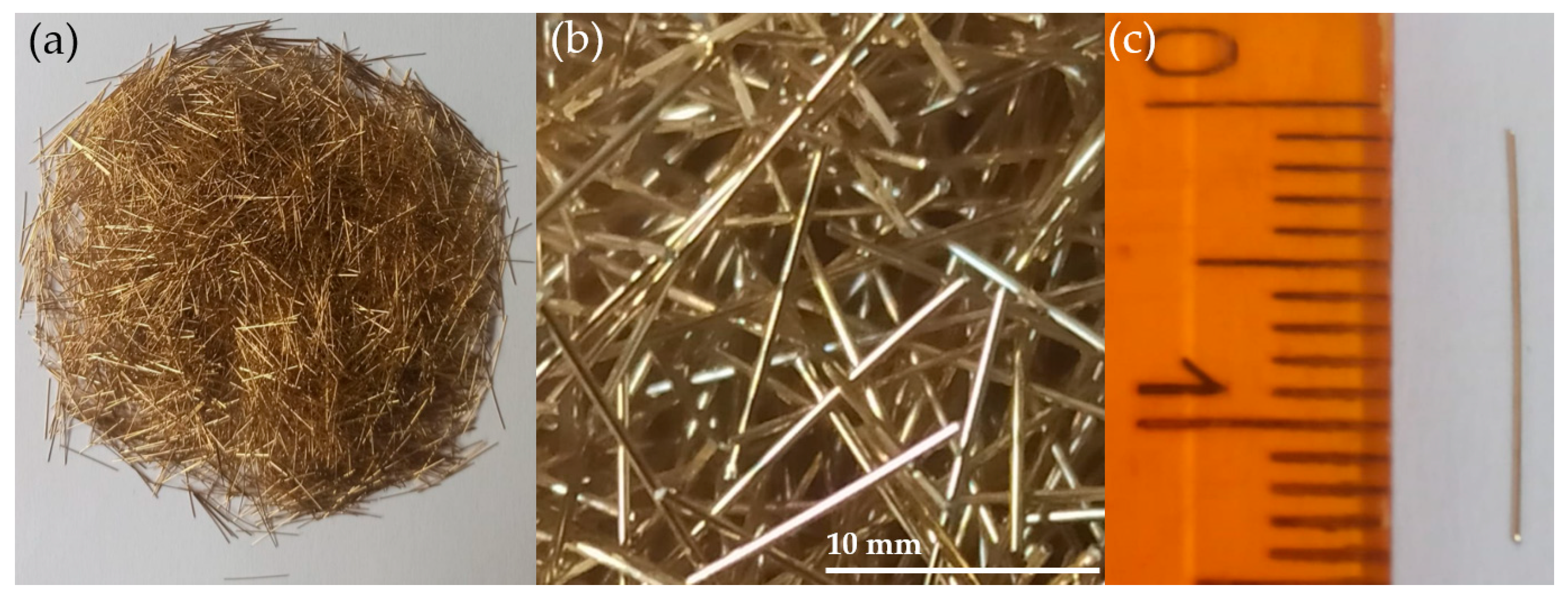

2.1.1. Components

2.1.2. Mix Preparation

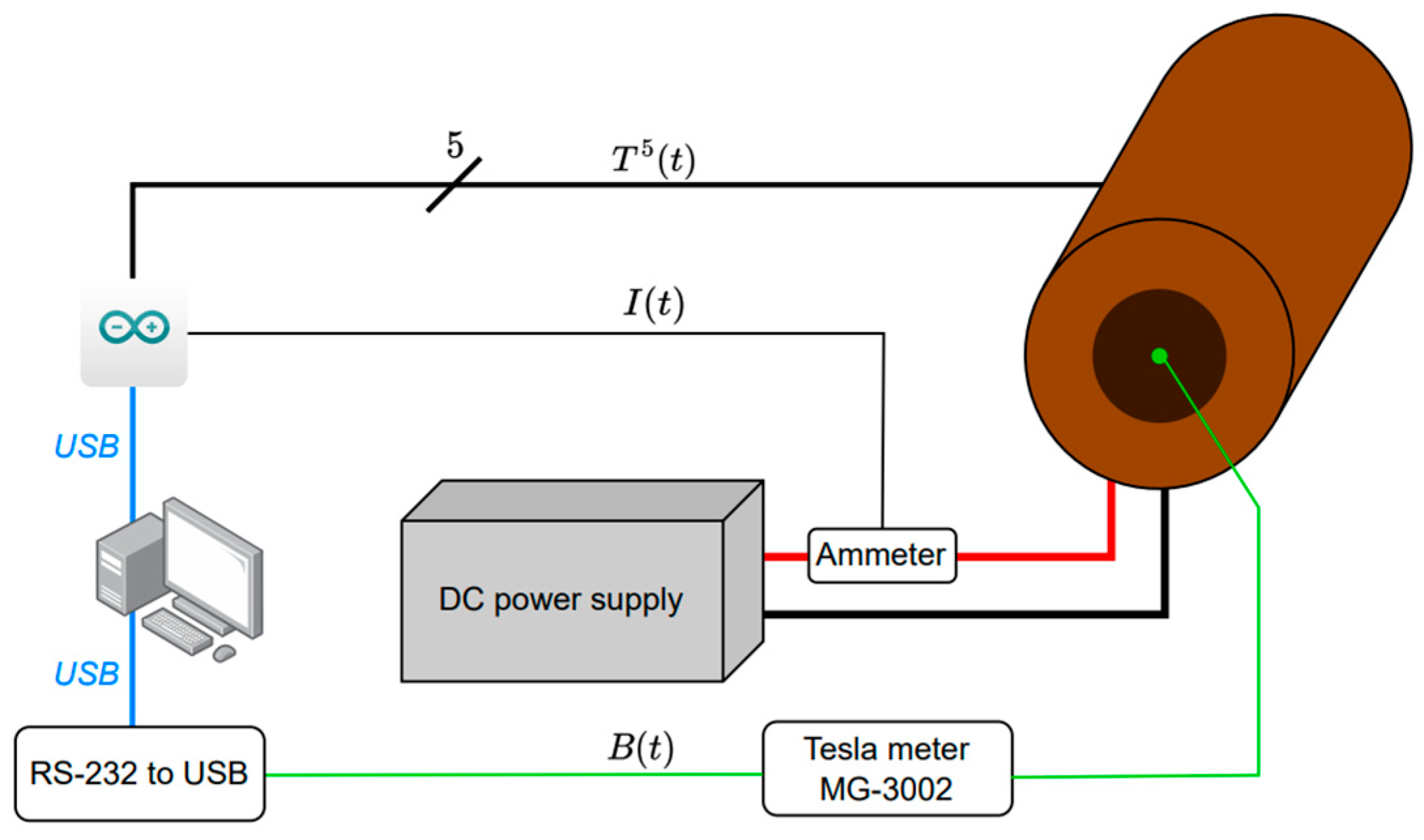

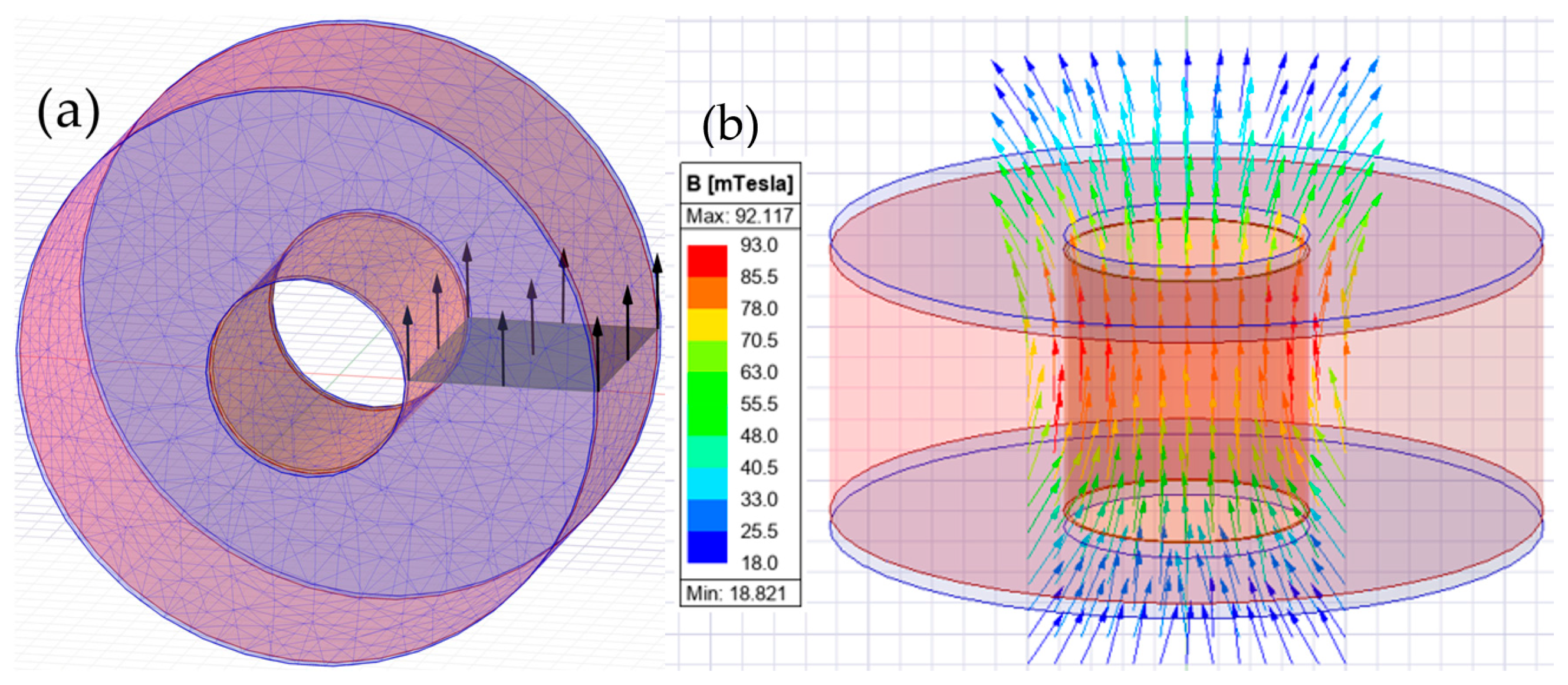

2.1.3. Electromagnet and Magnetic Field: Setup, Modeling and Verification

2.2. Experimental Methodology

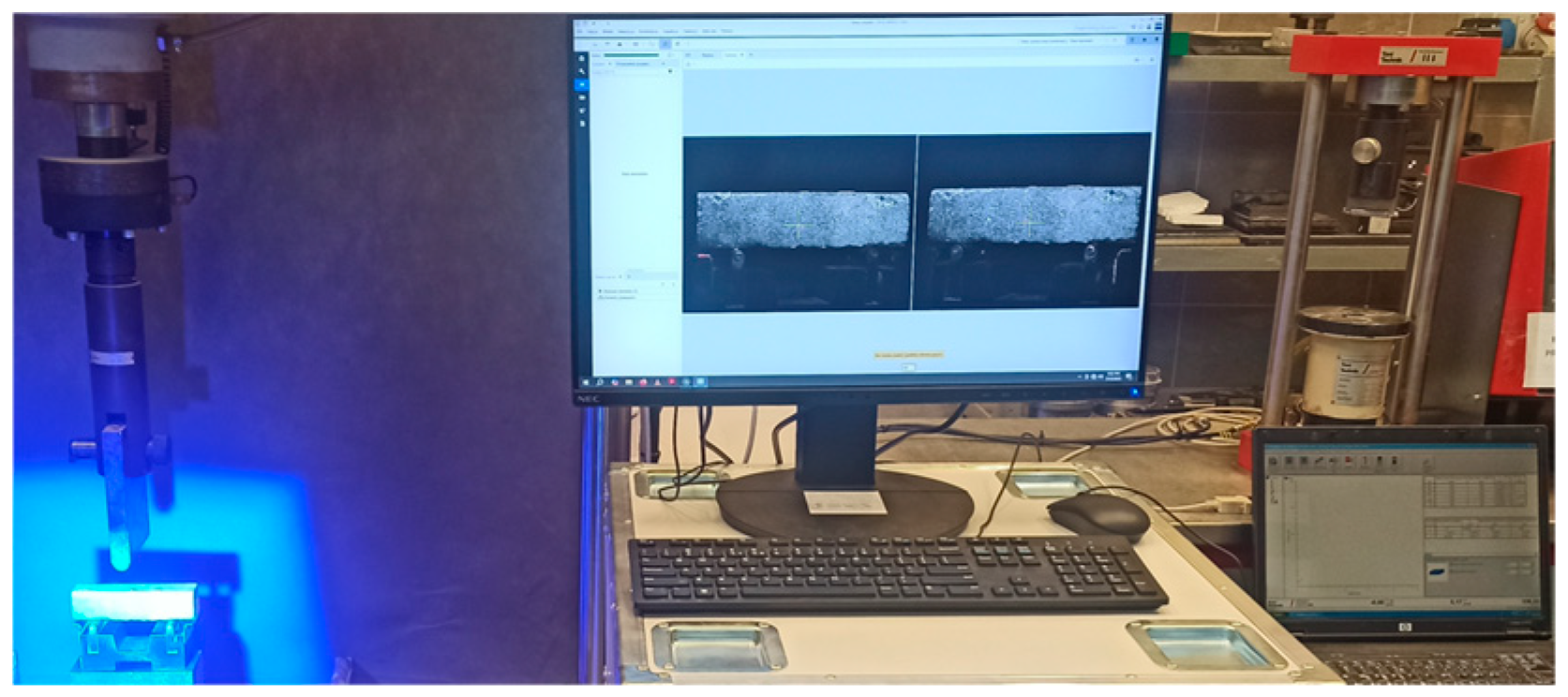

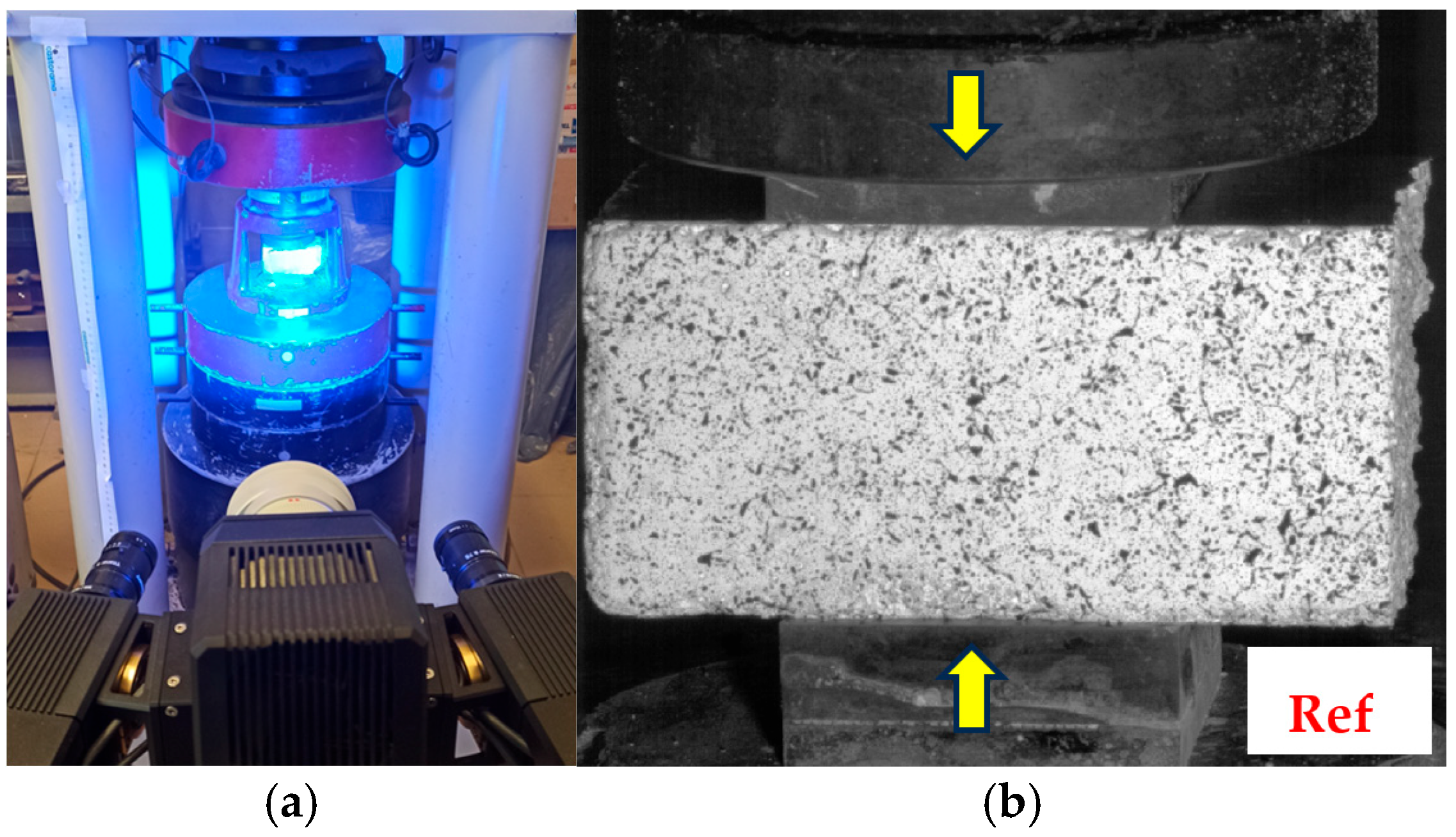

2.2.1. Digital Image Correlation (DIC) Settings

2.2.2. Mechanical Properties

Flexural Performance Test

Compression Test

2.2.3. Microstructure

3. Results and Discussion

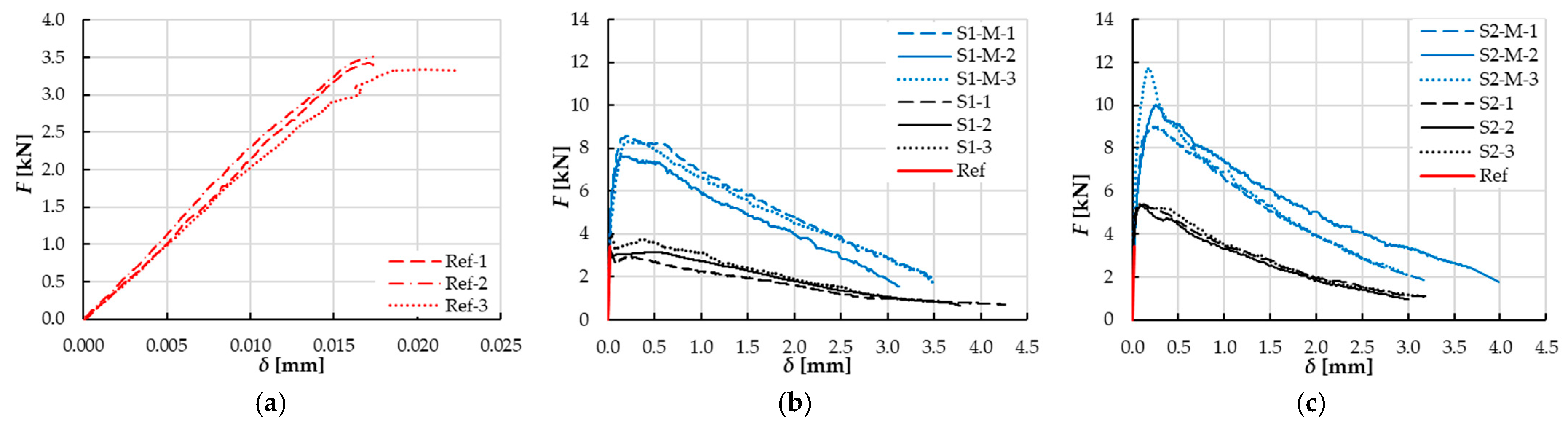

3.1. Force–Deflection Curves

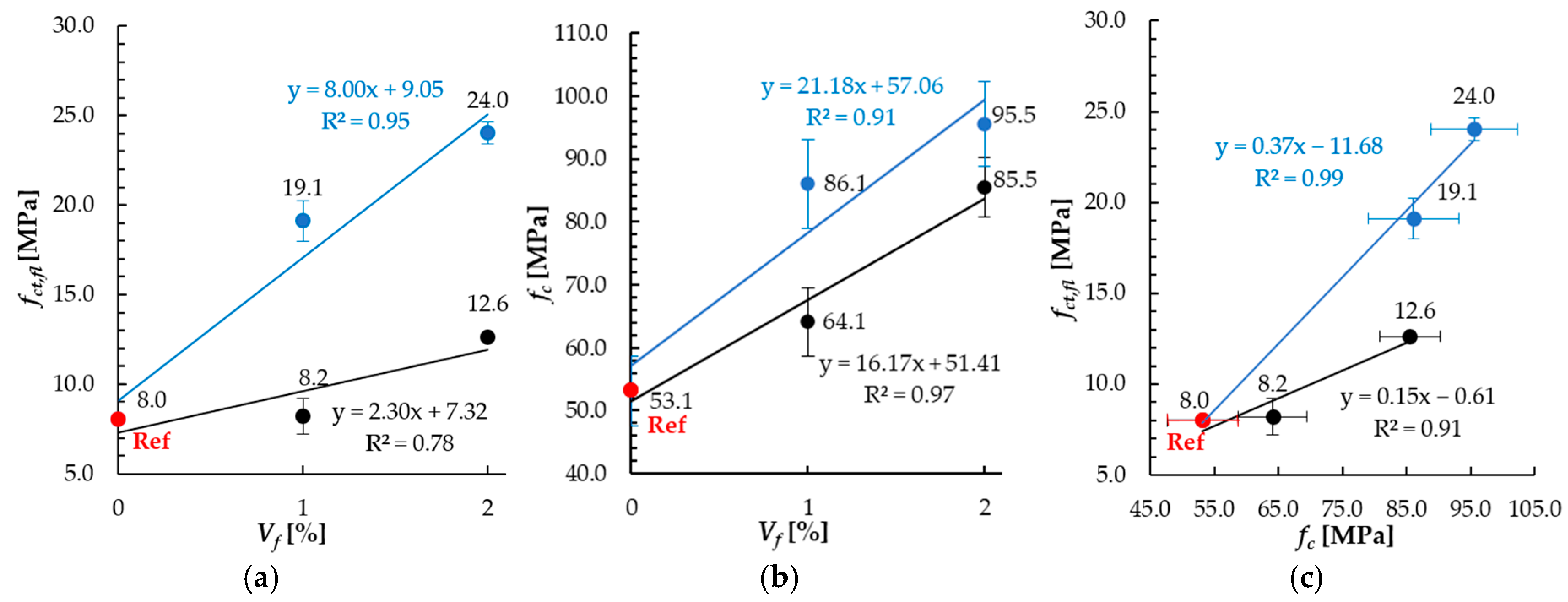

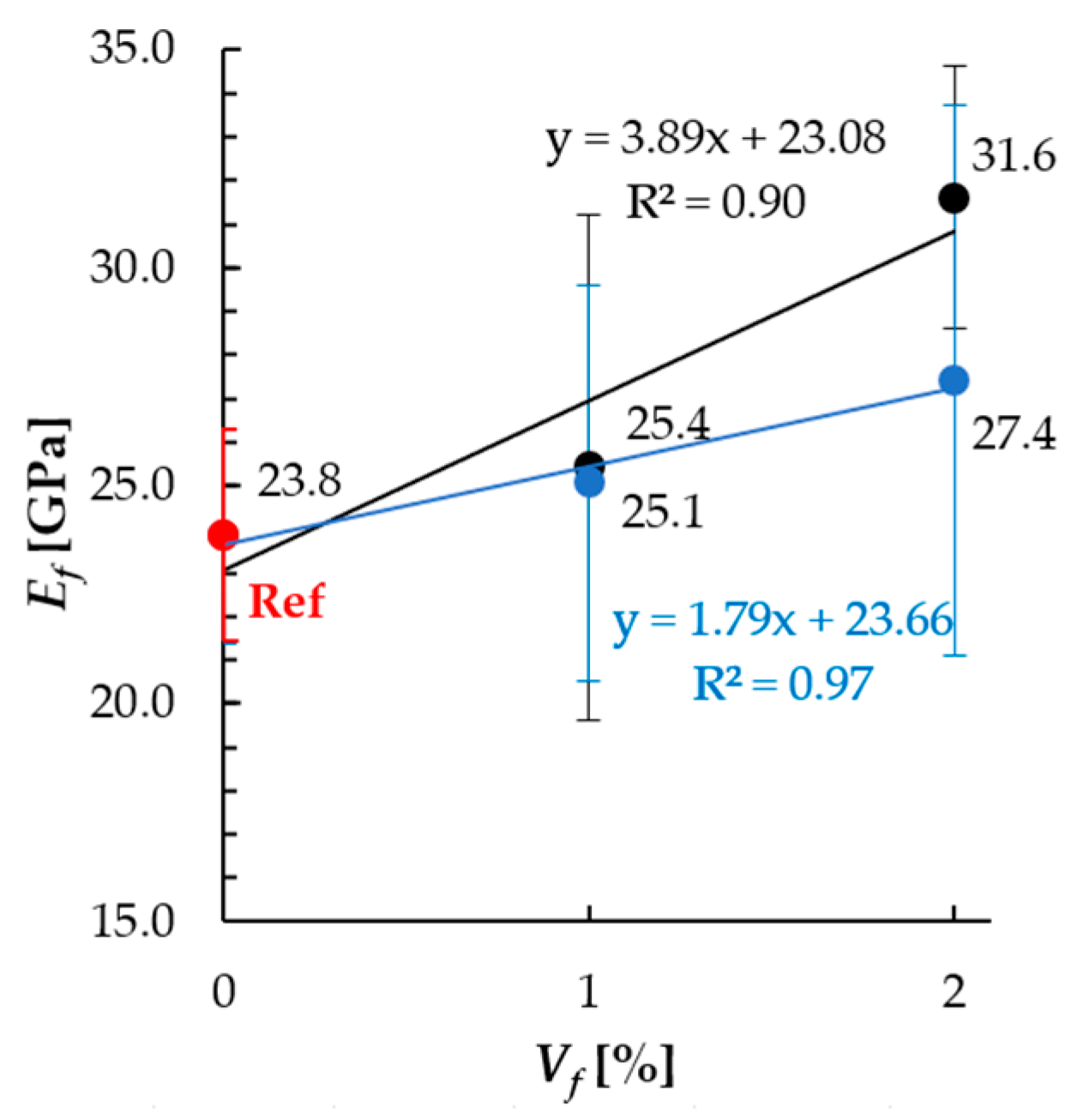

3.2. Mechanical Properties

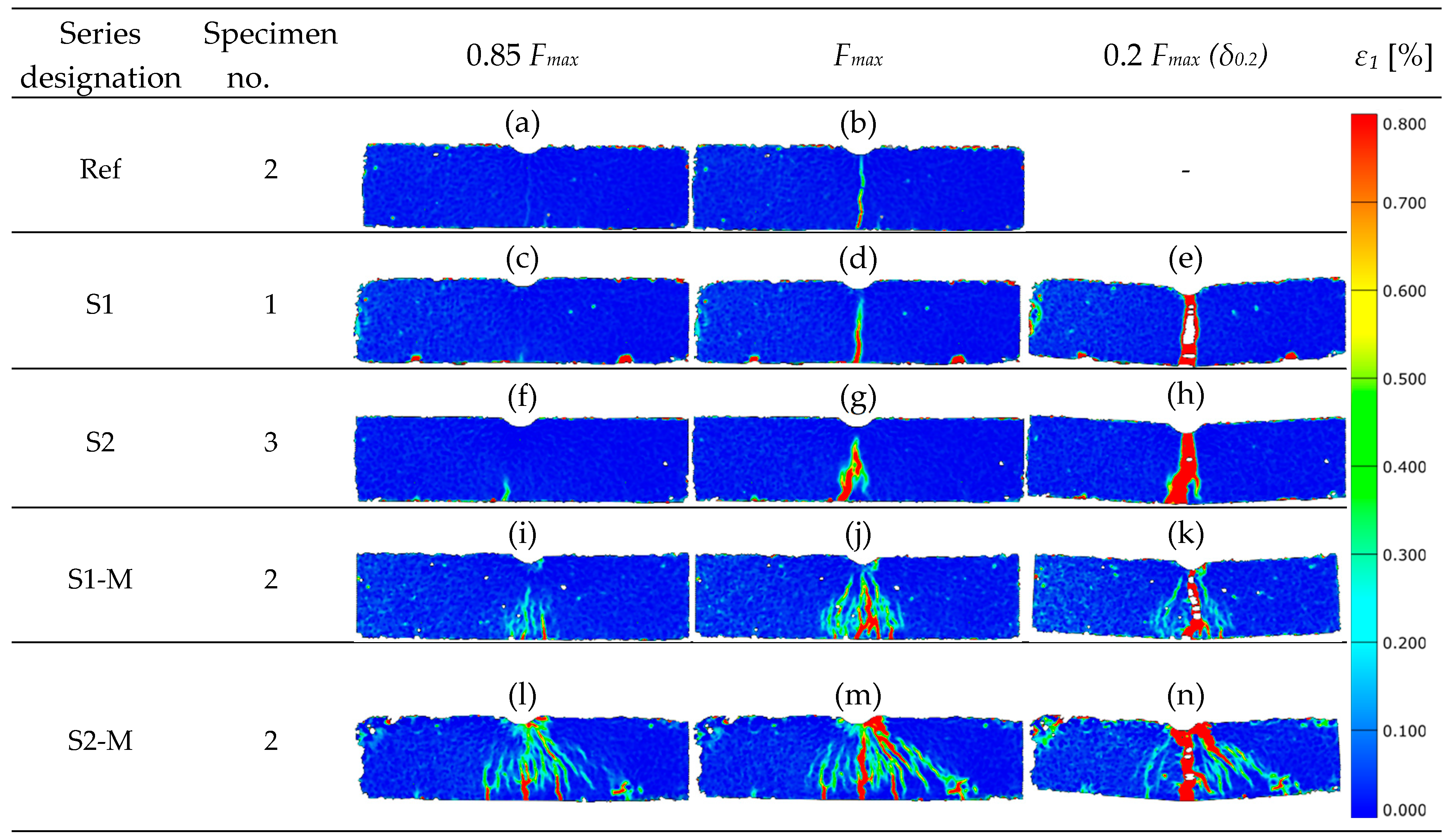

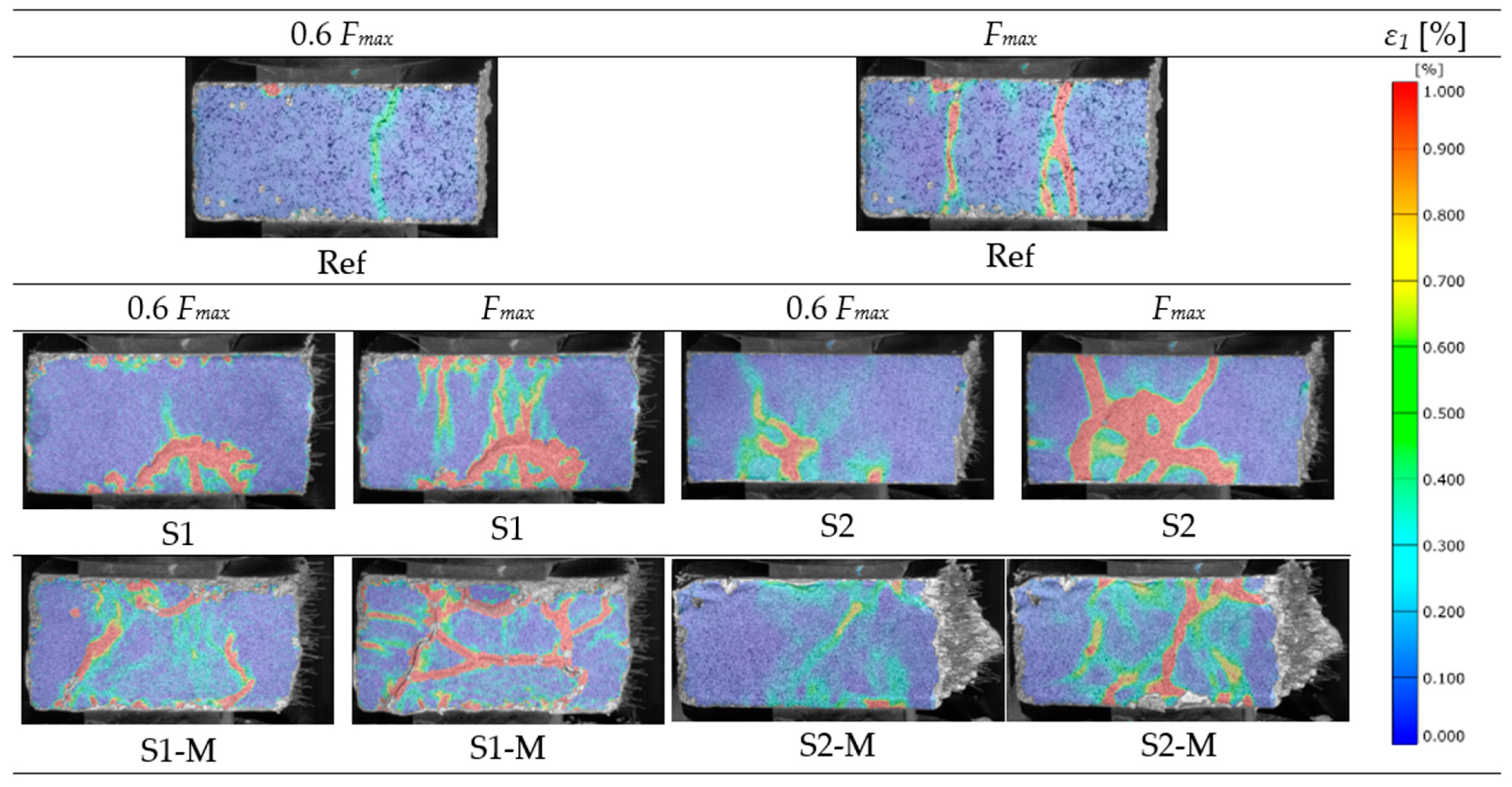

3.3. DIC Analysis of Strain Localization in Bending (3PB) and Compression

3.4. Microstructural Observations

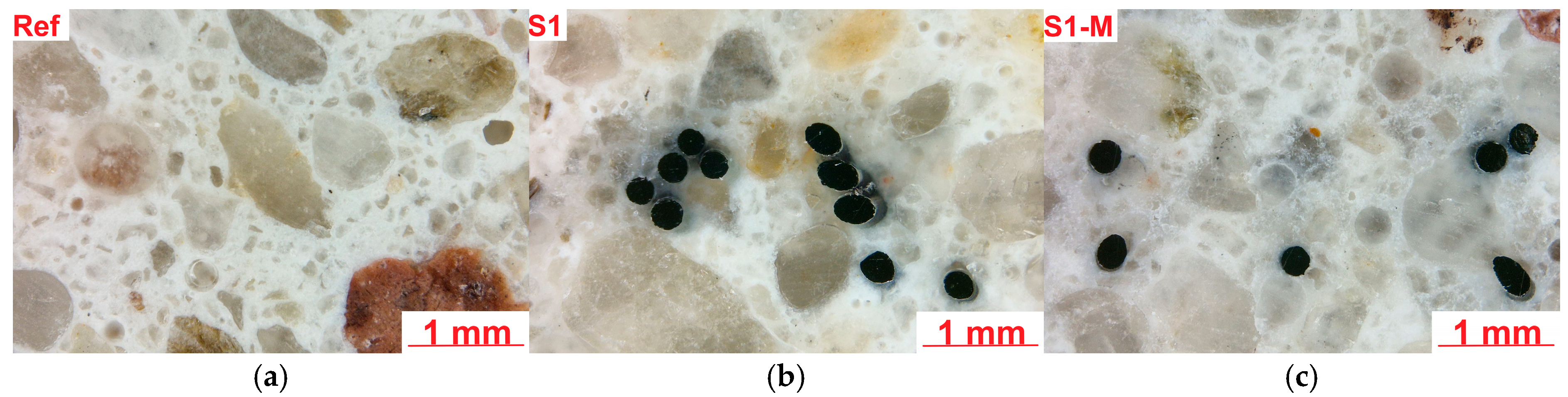

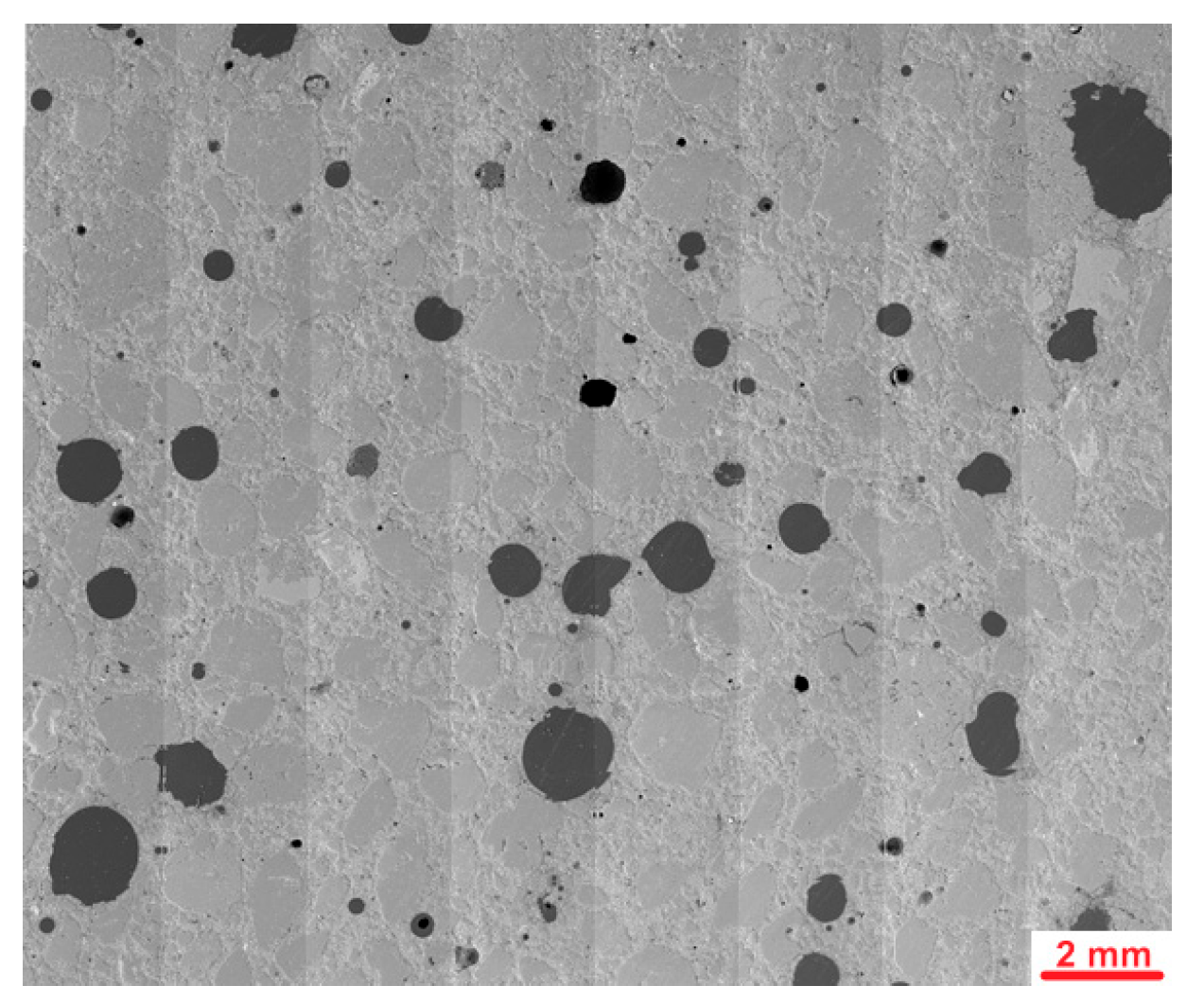

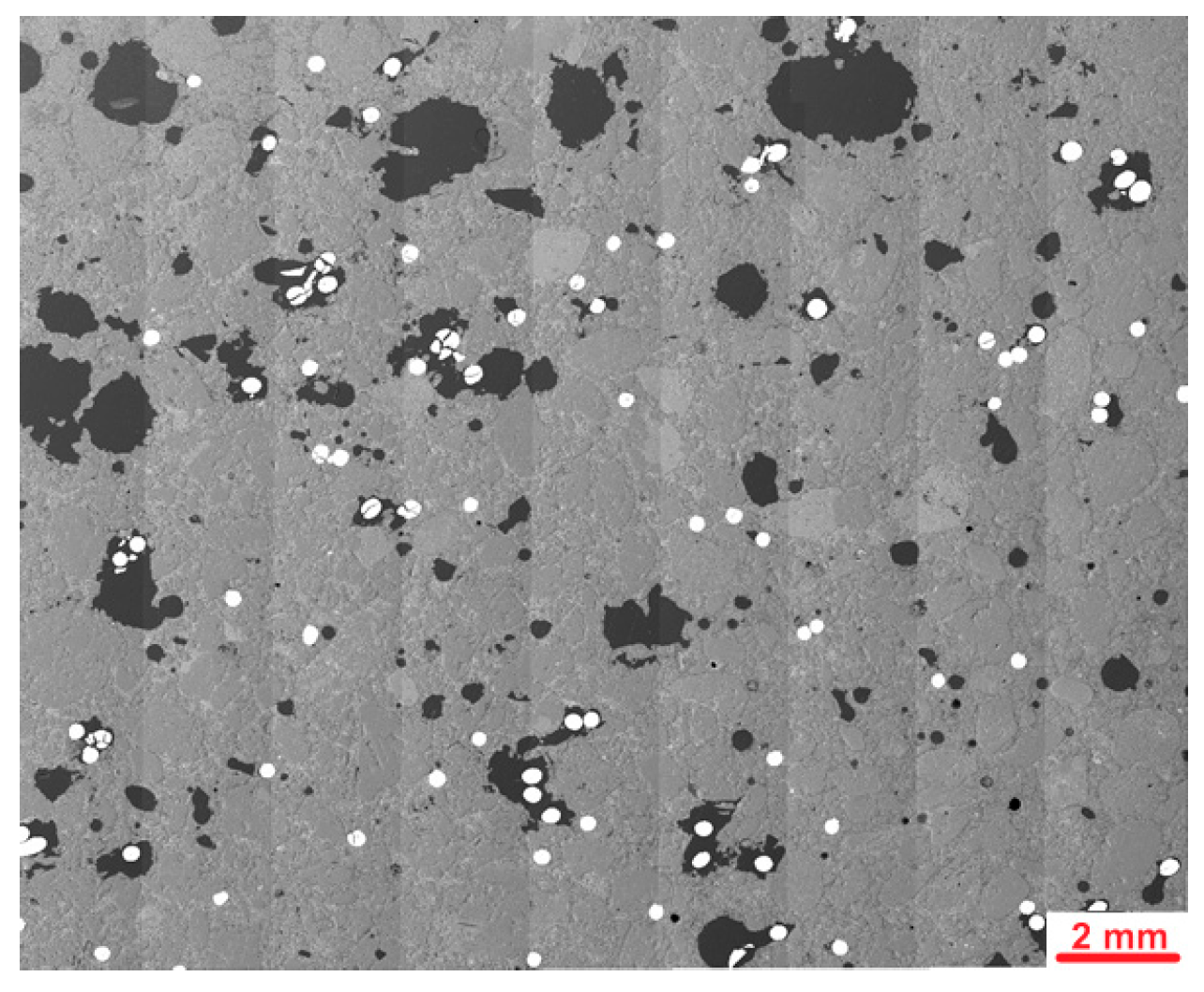

3.4.1. Optical Microscopy Observations

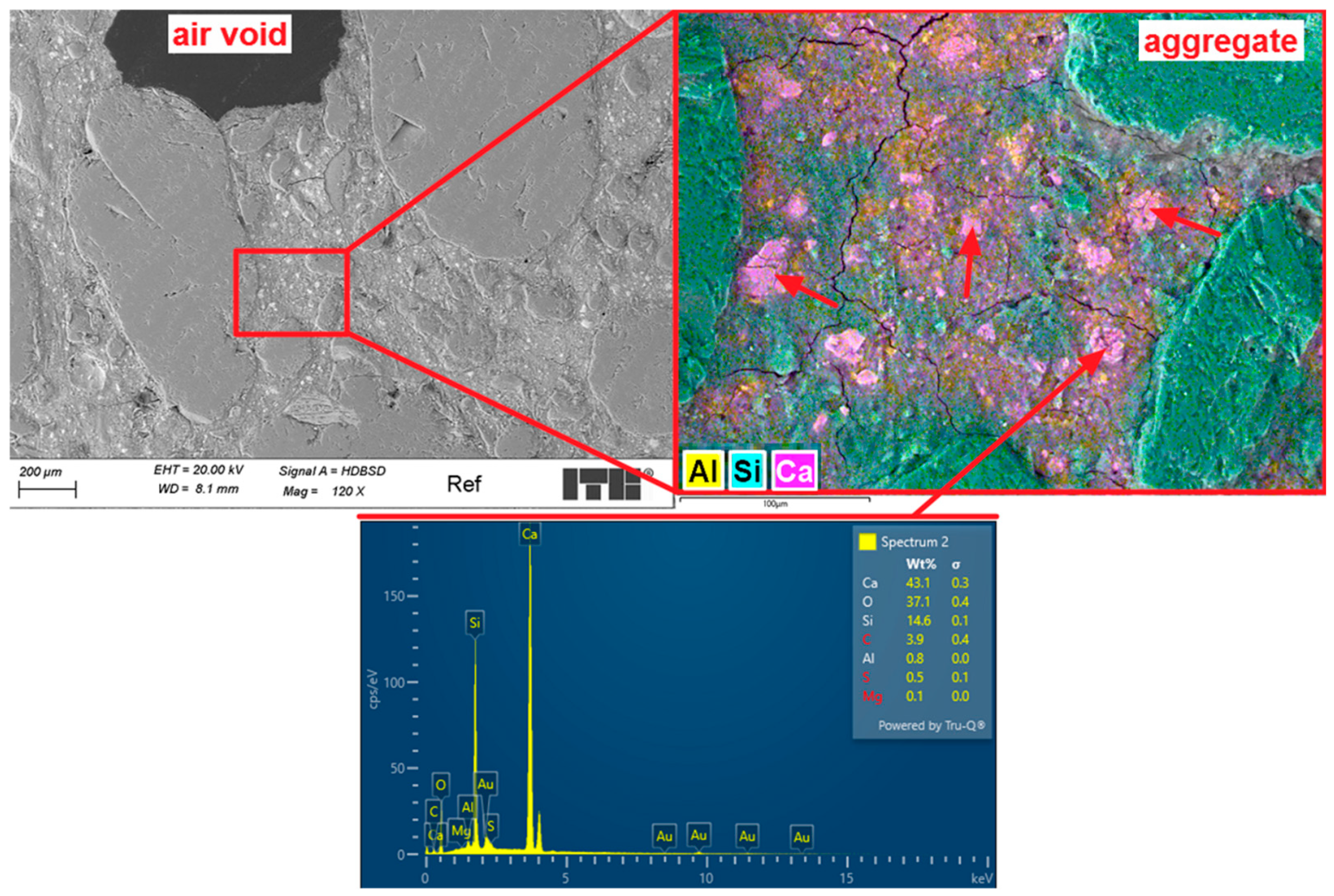

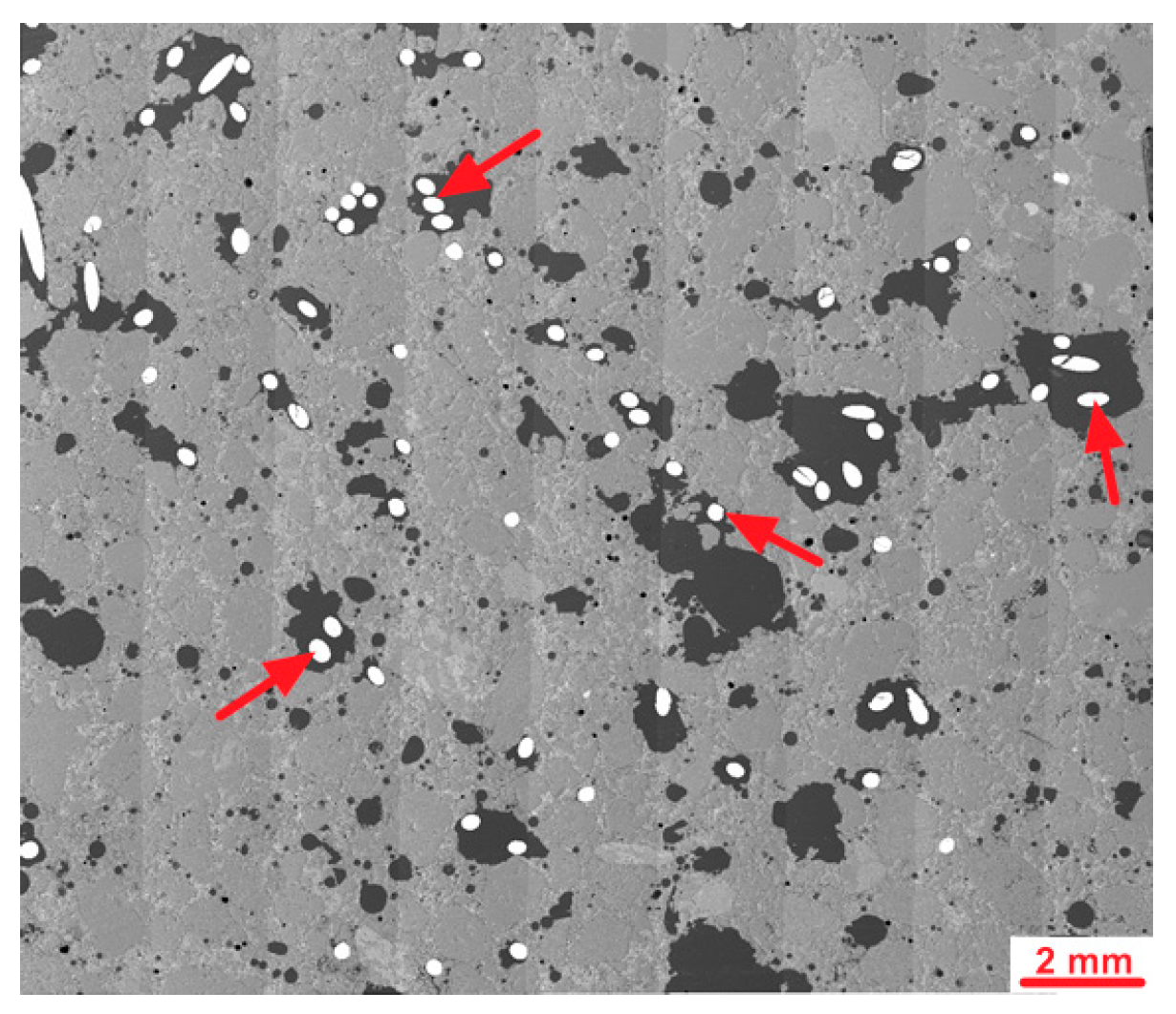

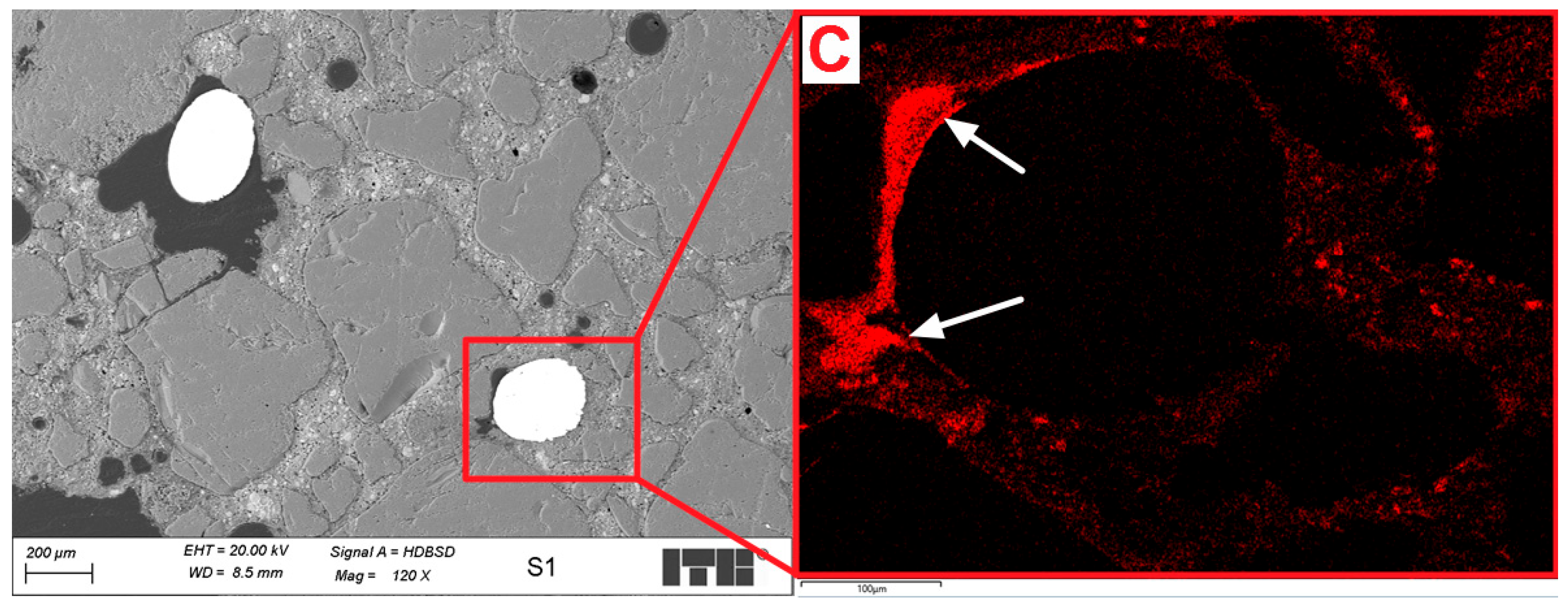

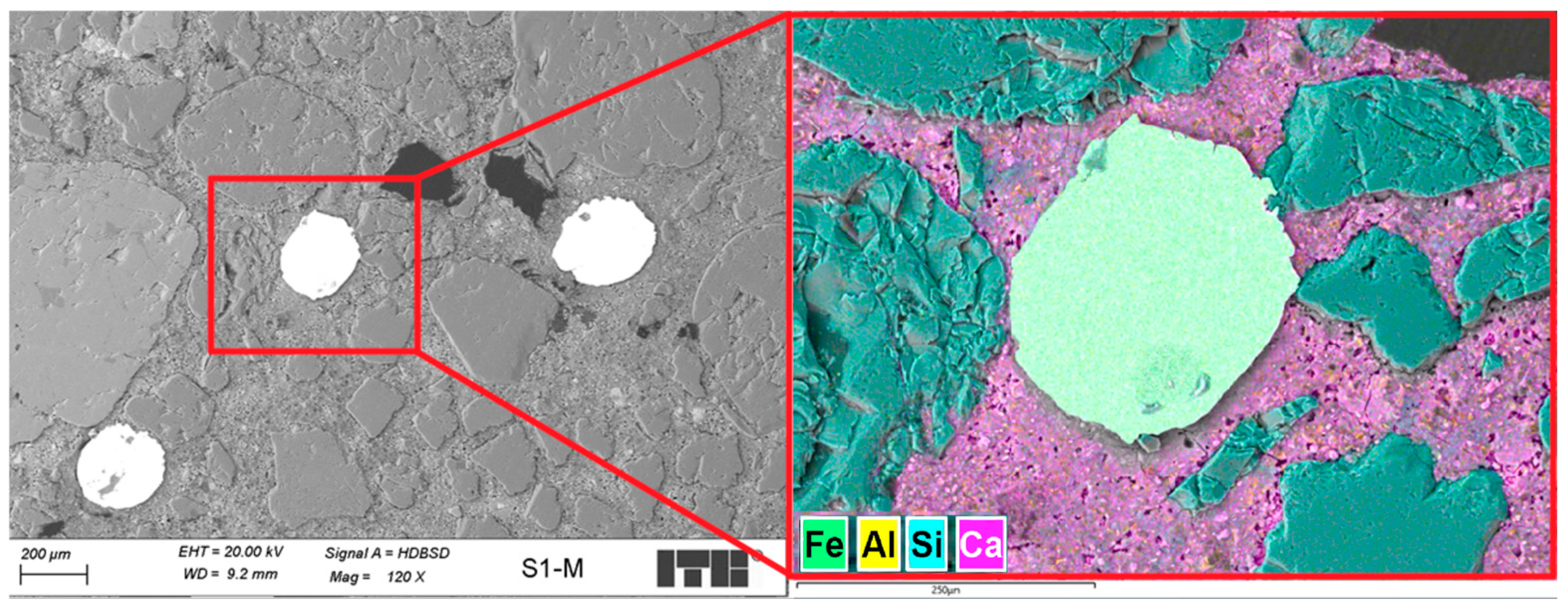

3.4.2. Scanning Electron Microscopy

4. Conclusions

- Maximum force (Fmax) values for the specimens with magnetically oriented fibers were higher by 133% (for Vf = 1%) and by 90% (Vf = 2%) than the values obtained for the specimens with random fiber arrangement, while fracture work Wf values increased by 132% and 106%, respectively.

- All the analyzed mechanical properties increased with the fiber content growth. For 1% vol. dosage, increase in flexural strength by about 3% and 139% was noted in comparison to reference, non-reinforced specimens for randomly and magnetically oriented fibers, respectively. For 2% vol. dosage, it was 58% and 200%.

- For 1% vol. dosage, the increase in compressive strength by 21% and 62% was noted for specimens with random and magnetic orientation of fibers, respectively. For 2% vol. fiber dosage, it was 61% and 80%.

- Higher values of strength were noted for specimens prepared with the use of magnetic field. Increase in the flexural strength was equal to 133% and 90% for 1% and 2% fiber dosage, respectively, when comparing specimens with magnetically oriented fibers (S-M) to those with random arrangement (S). In the case of compressive strength, it was about 34% and 12%.

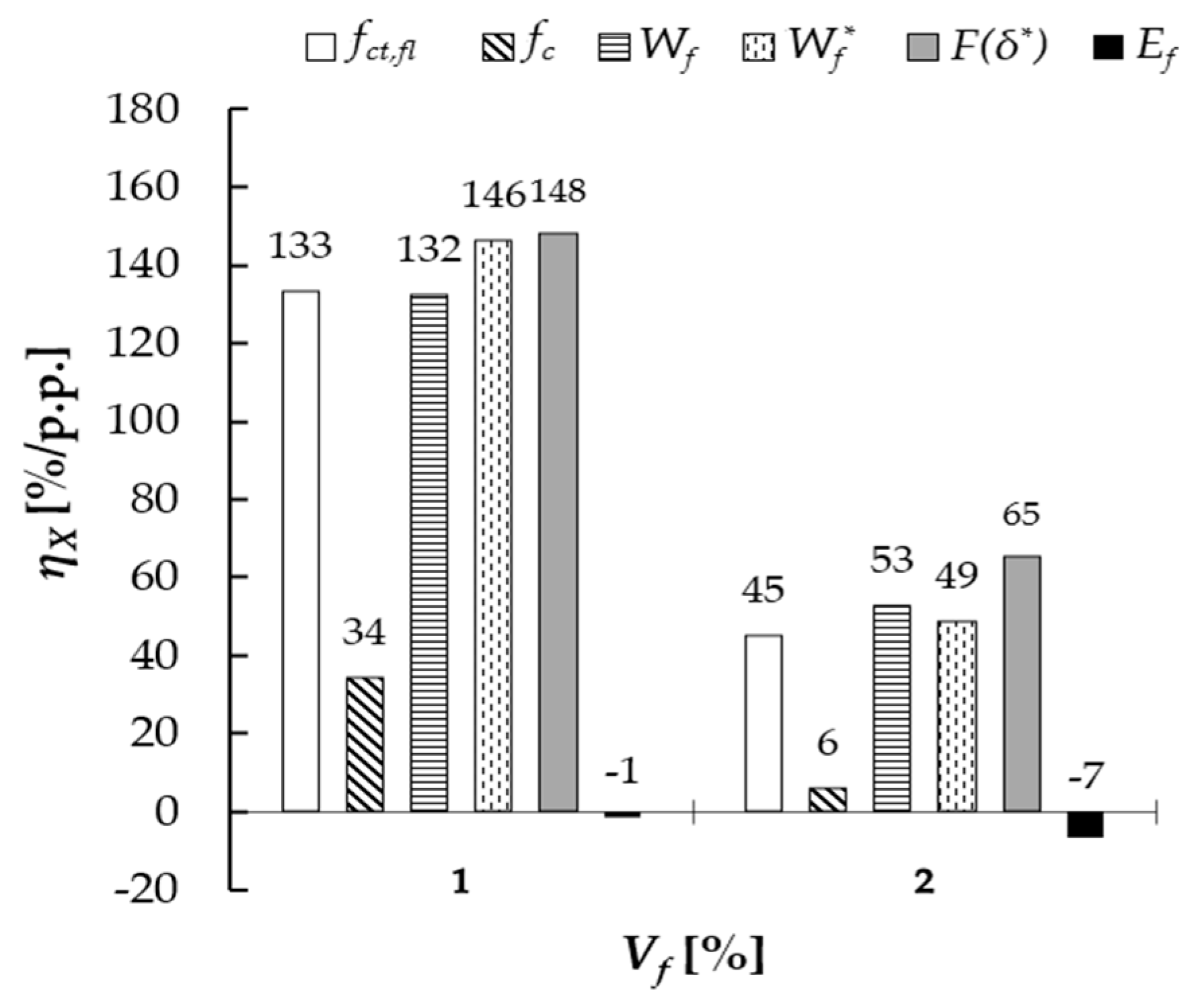

- Based on the efficiency factor (ηX) values (Figure 10), the positive influence of fibers’ magnetic orientation was confirmed. The highest influence was demonstrated for the residual force value F(δ*), fracture work (Wf*) and flexural tensile strength (fct, fl); moderate for compressive strength (fc) and marginal for the effective elastic modulus (Ef). The magnetic orientation beneficial effect was higher for Vf = 1% than for Vf = 2%.

- The use of magnetic field for the orientation of fibers changed the strain fields, as confirmed in the analysis of the ε1 principal tensile strain map created with the DIC method use in the flexural performance test. Multiple, skew bands were registered for the S-M type specimens instead of thin, singular bands noted for other beams. Singular (one or two) bands, parallel to the loading direction, dominated in the case of the reference specimens (without fibers) submitted to compression tests, while a net of wide-spread, skew (in reference to loading direction) bands was noted for specimens with magnetically oriented fibers.

- The proposed numerical model of the electromagnet performance was validated. The mean absolute percentage error (MAPE) was equal to 3.46%. A broader scope of investigation into the influence of different values of magnetic field induction and exposure time on fiber orientation in composites will be the subject of future research.

- Microstructural investigations have shown that the addition of steel fibers increases the air content in cement mortar, increasing the number of macropores, which is unfavorable. However, the magnetic field, apart from helping to orderly distribute steel fibers, seems to help release some of the excessive air entrapped in the cement composited during sample preparation. Microstructural analysis has shown that the magnetic field used during molding helps to fully cover the fibers with the cement matrix, which is beneficial for this type of cement composite and results in an increase in mechanical properties. It might also have an influence on decreasing the amount of fiber aggregates, although no statistics were carried out in this aspect, so it needs further investigations. Apart from the above, microstructural analysis has shown that the addition of steel fibers to cement composites reduces the number of microcracks, which are probably caused by a reduction in the shrinkage of the composite. The nature of the observations carried out was qualitative rather than quantitative. An in-depth quantitative analysis will be carried out as part of further research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Furtak, K. Contemporary challenges of science and technology-selected reflections. Cem. Wapno Beton 2021, 25, 413–430. [Google Scholar] [CrossRef]

- Czarnecki, L.; Gemert, D. Innovation in Construction Materials Engineering versus Sustainable Development. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 765–771. [Google Scholar] [CrossRef]

- Bywalski, C.; Kaźmierowski, M.; Kamiński, M.; Drzazga, M. Material Analysis of Steel Fibre Reinforced High-Strength Concrete in Terms of Flexural Behaviour. Experimental and Numerical Investigation. Materials 2020, 13, 1631. [Google Scholar] [CrossRef]

- Isa, M.; Pilakoutas, K.; Guadagnini, M.; Angelakopoulos, H. Mechanical performance of affordable and eco-efficient ultra-high performance concrete (UHPC) containing recycled tyre steel fibres. Constr. Build. Mater. 2020, 255, 119272. [Google Scholar] [CrossRef]

- Sanjeev, J.; Nitesh, K.S. Study on the effect of steel and glass fibers on fresh and hardened properties of vibrated concrete and self-compacting concrete. Mater. Today Proc. 2020, 27, 1559–1568. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M.; Wachowski, M. Mechanical and Material Properties of Mortar Reinforced with Glass Fiber: An Experimental Study. Materials 2021, 14, 698. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Hofer, L.; Toska, K.; De Domenico, D.; Pellegrino, C. Confinement of reinforced concrete columns with glass fiber reinforced cementitious matrix jackets. Eng. Struct. 2020, 218, 110847. [Google Scholar] [CrossRef]

- Khan, Z.I.; Arsad, A.; Mohamad, Z.; Habib, U.; Zaini, M.A.A. Comparative study on the enhancement of thermo-mechanical properties of carbon fiber and glass fiber reinforced epoxy composites. Mater. Today Proc. 2020, 39, 956–958. [Google Scholar] [CrossRef]

- Kossakowski, P.; Dygas, J. Natural carbon fibres—An overview. J. Mater. Sci. 2023, 6, 1–11. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Yarar, G.; Benli, A.; Kaplan, G.; Gencel, O.; Sutcu, M.; Kozłowski, M.; Kadela, M. Basalt fiber reinforced foam concrete with marble waste and calcium aluminate cement. Struct. Concr. 2023, 24, 1152–1178. [Google Scholar] [CrossRef]

- Wydra, M.; Dolny, P.; Sadowski, G.; Fangrat, J. Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres. Materials 2021, 14, 1334. [Google Scholar] [CrossRef]

- Bencardino, F.; Mazzuca, P.; do Carmo, R.; Costa, H.; Curto, R. Cement-Based Mortars with Waste Paper Sludge-Derived Cellulose Fibers for Building Applications. Fibers 2024, 12, 13. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yoon, Y.-S.; Banthia, N. Flexural Response of Steel-Fiber-Reinforced Concrete Beams: Effects of Strength, Fiber Content, and Strain-Rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Olivito, R.S.; Zuccarello, F.A. An Experimental Study on the Tensile Strength of Steel Fiber Reinforced Concrete. Compos. Part B Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Kadela, M.; Małek, M.; Jackowski, M.; Kunikowski, M.; Klimek, A.; Dudek, D.; Rośkowicz, M. Recycling of Tire-Derived Fiber: The Contribution of Steel Cord on the Properties of Lightweight Concrete Based on Perlite Aggregate. Materials 2023, 16, 2124. [Google Scholar] [CrossRef]

- Kaźmierowski, M.; Jaskulski, R.; Drzazga, M.; Nalepka, M.; Kordasz, M. Effects of the Addition of Short Straight Steel Fibers on the Strength and Strains of High-Strength Concrete during Compression. Sci. Rep. 2024, 14, 6989. [Google Scholar] [CrossRef]

- Abdallah, S.; Rees, D.W.A. Analysis of Pull-Out Behaviour of Straight and Hooked End Steel Fibres. Engineering 2019, 11, 332–341. [Google Scholar] [CrossRef]

- Lee, C.; Kim, H. Orientation Factor and Number of Fibers at Failure Plane in Ring-Type Steel Fiber Reinforced Concrete. Cem. Concr. Res. 2010, 40, 810–819. [Google Scholar] [CrossRef]

- Mu, R.; Li, H.; Qing, L.; Lin, J.; Zhao, Q. Aligning Steel Fibers in Cement Mortar Using Electro-Magnetic Field. Constr. Build. Mater. 2017, 131, 309–316. [Google Scholar] [CrossRef]

- Ghailan, D.B.; Al-Ghalib, A.A. Magnetic Alignment of Steel Fibres in Self-Compacting Concrete. Aust. J. Struct. Eng. 2020, 21, 333–341. [Google Scholar] [CrossRef]

- Soroushian, P.; Cha-Don, L. Distribution and Orientation of Fibers Reinforced Conrete. ACI Mater. J. 1999, 87, 433–439. [Google Scholar] [CrossRef]

- Miler, A.I.; Bjorklund, F.R. Method of Reinforcing Concrete with Fibres. U.S. Patent 4,062,913, 13 December 1977. [Google Scholar]

- Svedberg, B. Method and Device for Magnetic Alignment of Fibres. U.S. Patent 6,740,282 B1, 25 May 2004. [Google Scholar]

- Qing, L.; Yu, K.; Mu, R.; Forth, J.P. Uniaxial Tensile Behavior of Aligned Steel Fibre Reinforced Cementitious Composites. Mater. Struct. 2019, 52, 70. [Google Scholar] [CrossRef]

- da Silva Brito, I.; Alan Strauss Rambo, D.; Martini, S.; Pícolo Salvador, R.; Fabrízio de Menezes Freitas, M. Flexural Behavior of HPFRCC: Enhancing Post-Crack Strength and Toughness by Magnetic Alignment of the Reinforcement. Constr. Build. Mater. 2021, 269, 121265. [Google Scholar] [CrossRef]

- Cao, G.; Qing, L.; Mu, R.; Wang, L.; Yang, Z.; Zhang, J. Characterization of Toughness Enhancement of Aligned Steel Fibers in Cement-Based Composites Based on DDM Method and Meso-Scale Simulation. Constr. Build. Mater. 2022, 347, 128517. [Google Scholar] [CrossRef]

- Michels, J.; Gams, M. Preliminary Study on the Influence of Fibre Orientation in Fibre Reinforced Mortars. Građevinar 2016, 68, 645–655. [Google Scholar] [CrossRef]

- Wijffels, M.J.H.; Wolfs, R.J.M.; Suiker, A.S.J.; Salet, T.A.M. Magnetic Orientation of Steel Fibres in Self-Compacting Concrete Beams: Effect on Failure Behaviour. Cem. Concr. Compos. 2017, 80, 342–355. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of Fibre Orientation on the Tensile Behaviour of Ultra-High Performance Fibre Reinforced Cementitious Composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Abavisani, I.; Rezaifar, O.; Kheyroddin, A. Alternating Magnetic Field Effect on Fine-Aggregate Steel Chip-Reinforced Concrete Properties. J. Mater. Civ. Eng. 2018, 30, 04018087. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Morón, C.; Dorado, M.G.; Morón, A. Inductive Method for the Orientation of Steel Fibers in Recycled Mortars. Constr. Build. Mater. 2019, 222, 243–253. [Google Scholar] [CrossRef]

- Hajforoush, M.; Kheyroddin, A.; Rezaifar, O.; Kioumarsi, M. The Effects of Uniform Magnetic Field on the Mechanical and Microstructural Properties of Concrete Incorporating Steel Fibers. Sci. Iran 2021, 28, 2557–2567. [Google Scholar] [CrossRef]

- Javahershenas, F.; Gilani, M.S.; Hajforoush, M. Effect of Magnetic Field Exposure Time on Mechanical and Microstructure Properties of Steel Fiber-Reinforced Concrete (SFRC). J. Build. Eng. 2021, 35, 101975. [Google Scholar] [CrossRef]

- Mu, R.; Dong, R.; Liu, H.; Chen, H.; Cheng, Q.; Fan, C. Preparation of Aligned Steel-Fiber-Reinforced Concrete Using a Magnetic Field Created by the Assembly of Magnetic Pieces. Crystals 2021, 11, 837. [Google Scholar] [CrossRef]

- Ahmad, I.; Qing, L.; Khan, S.; Cao, G.; Ijaz, N.; Mu, R. Experimental Investigations on Fracture Parameters of Random and Aligned Steel Fiber Reinforced Cementitious Composites. Constr. Build. Mater. 2021, 284, 122680. [Google Scholar] [CrossRef]

- Khan, S.; Qing, L.; Ahmad, I.; Mu, R.; Bi, M. Investigation on Fracture Behavior of Cementitious Composites Reinforced with Aligned Hooked-End Steel Fibers. Materials 2022, 15, 542. [Google Scholar] [CrossRef]

- Carrera, K.; Künzel, K.; Konrád, P.; Sovják, R.; Papež, V.; Mára, M.; Fornůsek, J.; Kheml, P. Concrete Lintels Reinforced with Steel Fibres Oriented by a Magnetic Field. Acta Polytech. 2022, 62, 531–537. [Google Scholar] [CrossRef]

- Al Rifai, M.M.; Sikora, K.S.; Hadi, M.N.S. Magnetic Alignment of Micro Steel Fibers Embedded in Self-Compacting Concrete. Constr. Build. Mater. 2024, 412, 134796. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Y.; Mu, R.; Chen, J.; Zhang, G.; Wang, X.; Qing, L.; Liu, Y. Improving Reinforcement Efficiency of Aligned Steel Fibre on Cement-Based Composites by Hybridizing Polypropylene Fibre. J. Build. Eng. 2024, 93, 109783. [Google Scholar] [CrossRef]

- Cheol Lee, S.; Hwan Oh, J.; Yeol Cho, J. Fiber Orientation Factor on Rectangular Cross-Section in Concrete Members. Int. J. Eng. Technol. 2015, 7, 470–473. [Google Scholar] [CrossRef]

- Varzavand, S. Flexural and Tensile Characteristics of Steel and Polypropylene Fiber Hybrid Reinforced Concrete Composite. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 1993. [Google Scholar] [CrossRef]

- Villar, V.P.; Medina, N.F. Alignment of Hooked-End Fibres in Matrices with Similar Rheological Behaviour to Cementitious Composites through Homogeneous Magnetic Fields. Constr. Build. Mater. 2018, 163, 256–266. [Google Scholar] [CrossRef]

- EN 206-1; Concrete-Part 1: Specification, Performance, Production and Conformity. CEN: Brussels, Belgium, 2002.

- EN 196-6:2010; Methods of Testing Cement—Part 6: Determination of Fineness. CEN: Brussels, Belgium, 2010.

- EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. CEN: Brussels, Belgium, 2016.

- EN 1015-3:1999; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). CEN: Brussels, Belgium, 1999.

- Nováková, K.; Carrera, K.; Konrád, P.; Künzel, K.; Papež, V.; Sovják, R. Simulations of the Behaviour of Steel Ferromagnetic Fibres Commonly Used in Concrete in a Magnetic Field. Materials 2022, 15, 128. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Zhao, H.; Long, G.; Yang, K.; Chen, M.; Wu, Z. The Mechanical Characteristics of High-Strength Self-Compacting Concrete with Toughening Materials Based on Digital Image Correlation Technology. Materials 2023, 16, 1695. [Google Scholar] [CrossRef] [PubMed]

- EN 14651:2005+A1:2008; Test Method for Metallic Fibre Concrete-Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). CEN: Brussels, Belgium, 2008.

- Klun, M.; Bosiljkov, V.; Bokan-Bosiljkov, V. The Relation between Concrete, Mortar and Paste Scale Early Age Properties. Materials 2021, 14, 1569. [Google Scholar] [CrossRef]

- Chyliński, F. Microstructural Assessment of Pozzolanic Activity of Ilmenite Mud Waste Compared to Fly Ash in Cement Composites. Materials 2024, 17, 2483. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. A Review on the Assessment and Prediction of the Orientation and Distribution of Fibres for Concrete. Compos. Part B Eng. 2018, 151, 274–290. [Google Scholar] [CrossRef]

- Zakrzewski, M.; Gancarz, M.; Tvrdá, K.; Laskowska-Bury, J.; Domski, J. Comparative Analysis of Waste, Steel, and Polypropylene Microfibers as an Additive for Cement Mortar. Materials 2023, 16, 1625. [Google Scholar] [CrossRef]

- ASTM C1609/C1609M-05; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2005.

| Author | Year | Matrix | Fiber (typ, l/d) | Vf [%] | B [mT] | tB [s] | Property | Effect | |

|---|---|---|---|---|---|---|---|---|---|

| Michels and Gams | [28] | 2016 | M | H, 30/0.6 | 0.39–0.52 | 30 | 10 | fct, fl | ~35 |

| Wijffels et al. | [29] | 2017 | SCC | H, 50–60/0.8–1 | 0.5 | 20 | 30 | fct, fl, Gf | ~15–336 |

| Abrishambaf et al. | [30] | 2017 | M | I, 9 i 12/0.175 | 1.5–3 | - | - | fUTu | ~82–91 |

| Mu et al. | [20] | 2017 | M | I, 30/0.5 | 0.8–2 | 0.15 | 40 | fct, sp, fct, fl, T150 | ~87–196 |

| Abavisani et al. | [31] | 2018 | SCC | JSC, 15/- | 0.9 | 500 | - | fc | ~17 |

| Ferrandez et al. | [32] | 2019 | M * | I, 22/0.5 | 0.5–1 | 500 | - | fc, fct, fl | ~10 |

| Qing et al. | [25] | 2019 | M | I, 30/0.5 | 0.8–2 | 0.15 | 40 | fUTu, Gf | ~26–57 |

| Al-Ghalib and Ghailan | [21] | 2020 | SCC | H, 50/0.5 H, 32/0.4 I, 13/0.017 | 0.35–1.05 | 7.5 | 30 | fct, fl | ~40 |

| Hajforoush et al. | [33] | 2021 | C | H, 50/0.8 | 1–1.5 | 500 | 120 | fc, fct, sp | ~7–18 |

| Javahershenas et al. | [34] | 2021 | C | H, 50/0.8 | 0.4–1 | 500 | 60–180 | fc, fct, fl | ~8–27 |

| Da Silva Brito et al. | [26] | 2021 | M * | I, 12.5/0.5 | 1–5 | 9.5 | 40 | fct, fl, fc, Wf | ~22–115 |

| Mu et al. | [35] | 2021 | M | H, I, 30/0.5 | 0.8–1.6 | 100 | 60 | fct, fl | ~54–95 |

| Ahmad et al. | [36] | 2021 | C | I, 8/0.2 | 0.8–2 | 0.15 | 40 | Gf, KI,C | 36–108 |

| Cao et al. | [27] | 2022 | C | I, 30/0.5 | 0.8–2 | - | - | Gf, KI,C | ~30–170 |

| Khan et al. | [37] | 2022 | M | H, 25/0.5 | 0.8–2 | 0.15 | 40 | fct, fl, fR, Gf | ~51–86 |

| Carrera et al. | [38] | 2022 | C | I, 13/0.15 | 1.5 | 100 | 10 | fc, fct, fl | 9–179 |

| Al Rifai et al. | [39] | 2024 | SCC | I, 8/0.2 | 0.7–1.05 | 10 | 60 | fc, fct, sp, fct, fl | ~1–29 |

| Chen et al. | [40] | 2024 | M | H, 35/0.5 | 0.5–1.5 | 8 | 50 | fct, fl, Wf | ~19–46 |

| Series | Cement | Sand | Water | Steel Fibers (Vf) | Superplasticizer |

|---|---|---|---|---|---|

| Ref * | 450 | 1350 | 225 | 0.0 | 0.0 |

| S1 | 69.2 (1% vol.) | 2.2 | |||

| S2 | 138.4 (2% vol.) | 3.0 | |||

| S1-M | 69.2 (1% vol.) | 2.2 | |||

| S2-M | 138.4 (2% vol.) | 3.0 |

| Sample ID | fct, fl | Ef | δu | Wf | Wf* | F(δ*) |

|---|---|---|---|---|---|---|

| MPa | GPa | mm | kPa | kPa | kN | |

| Ref-1 | 8.0 | 22.4 | 0.017 | 0.123 | - | - |

| Ref-2 | 8.2 | 26.7 | 0.017 | 0.130 | - | - |

| Ref-3 | 7.8 | 22.4 | 0.022 | 0.180 | - | - |

| 8.0 | 23.8 | 0.019 | 0.144 | - | - | |

| s | 0.2 | 2.5 | 0.003 | 0.031 | - | - |

| CV | 2.7% | 10.3% | 15.1% | 21.4% | - | - |

| S1-1 | 7.9 | 23.4 | 4.26 | 26.7 | 22.6 | 0.98 |

| S1-2 | 7.4 | 20.9 | 3.78 | 28.6 | 25.9 | 1.05 |

| S1-3 | 9.3 | 32.0 | 3.97 | 30.8 | 28.5 | 1.04 |

| 8.2 | 25.4 | 4.01 | 28.7 | 25.7 | 1.02 | |

| s | 1.0 | 5.8 | 0.24 | 2.0 | 2.9 | 0.04 |

| CV | 12.1% | 22.8% | 6.0% | 7.1% | 11.5% | 4.0% |

| S2-1 | 12.6 | 33.4 | 3.19 | 34.9 | 34.1 | 1.14 |

| S2-2 | 12.5 | 28.1 | 2.86 | 31.6 | 32.1 | 0.95 |

| S2-3 | 12.8 | 33.4 | 3.19 | 35.6 | 34.8 | 1.16 |

| 12.6 | 31.6 | 3.08 | 34.0 | 33.7 | 1.08 | |

| s | 0.1 | 3.0 | 0.19 | 2.2 | 1.4 | 0.11 |

| CV | 1.0% | 9.6% | 6.3% | 6.4% | 4.1% | 10.6% |

| S1-M-1 | 20.1 | 30.0 | 3.52 | 72.4 | 67.5 | 2.91 |

| S1-M-2 | 17.9 | 24.1 | 3.12 | 58.2 | 57.4 | 1.87 |

| S1-M-3 | 19.4 | 21.1 | 3.50 | 69.5 | 64.9 | 2.84 |

| 19.1 | 25.1 | 3.38 | 66.7 | 63.3 | 2.54 | |

| s | 1.1 | 4.5 | 0.23 | 7.5 | 5.2 | 0.58 |

| CV | 5.9% | 18.1% | 6.7% | 11.2% | 8.3% | 22.9% |

| S2-M-1 | 21.1 | 22.3 | 4.28 | 63.3 | 61.7 | 2.08 |

| S2-M-2 | 23.5 | 25.5 | 3.99 | 82.0 | 71.9 | 3.34 |

| S2-M-3 | 27.5 | 34.5 | 2.85 | 64.6 | 65.9 | 2.08 |

| 24.0 | 27.4 | 3.71 | 70.0 | 66.5 | 2.50 | |

| s | 3.2 | 6.3 | 0.76 | 10.4 | 5.1 | 0.73 |

| CV | 13.5% | 23.1% | 20.4% | 14.9% | 7.7% | 29.1% |

| Ref | S1 | S2 | S1-M | S2-M | |

|---|---|---|---|---|---|

| 53.9 | 55.7 | 84.5 | 78.9 | 93.5 | |

| 54.6 | 62.1 | 77.9 | 89.1 | 94.5 | |

| 59.7 | 66.3 | 87.4 | 96.8 | 106.4 | |

| 44.6 | 67.5 | 90.5 | 82.7 | 87.8 | |

| 52.9 | 68.9 | 87.2 | 82.8 | 95.4 | |

| 53.1 | 64.1 | 85.5 | 86.1 | 95.5 | |

| s | 5.4 | 5.3 | 4.8 | 7.0 | 6.8 |

| CV | 10.3% | 8.3% | 5.6% | 8.2% | 7.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaźmierowski, M.; Kadela, M.; Kordasz, M.; Chyliński, F.; Jaskulski, R.; Drzazga, M.; Wydra, M.; Marchwicki, K.; Cińcio, A. Cementitious Composites Reinforced with Magnetically Oriented Steel Microfibers: Mechanical Properties, Deformability and Fracture Propagation. Materials 2025, 18, 4739. https://doi.org/10.3390/ma18204739

Kaźmierowski M, Kadela M, Kordasz M, Chyliński F, Jaskulski R, Drzazga M, Wydra M, Marchwicki K, Cińcio A. Cementitious Composites Reinforced with Magnetically Oriented Steel Microfibers: Mechanical Properties, Deformability and Fracture Propagation. Materials. 2025; 18(20):4739. https://doi.org/10.3390/ma18204739

Chicago/Turabian StyleKaźmierowski, Maciej, Marta Kadela, Michał Kordasz, Filip Chyliński, Roman Jaskulski, Michał Drzazga, Małgorzata Wydra, Kacper Marchwicki, and Andrzej Cińcio. 2025. "Cementitious Composites Reinforced with Magnetically Oriented Steel Microfibers: Mechanical Properties, Deformability and Fracture Propagation" Materials 18, no. 20: 4739. https://doi.org/10.3390/ma18204739

APA StyleKaźmierowski, M., Kadela, M., Kordasz, M., Chyliński, F., Jaskulski, R., Drzazga, M., Wydra, M., Marchwicki, K., & Cińcio, A. (2025). Cementitious Composites Reinforced with Magnetically Oriented Steel Microfibers: Mechanical Properties, Deformability and Fracture Propagation. Materials, 18(20), 4739. https://doi.org/10.3390/ma18204739