Adhesion of Polypropylene, Steel, and Basalt Fibres to a Geopolymer Matrix with Water Treatment Sludge Addition

Abstract

1. Introduction

2. Materials and Methods

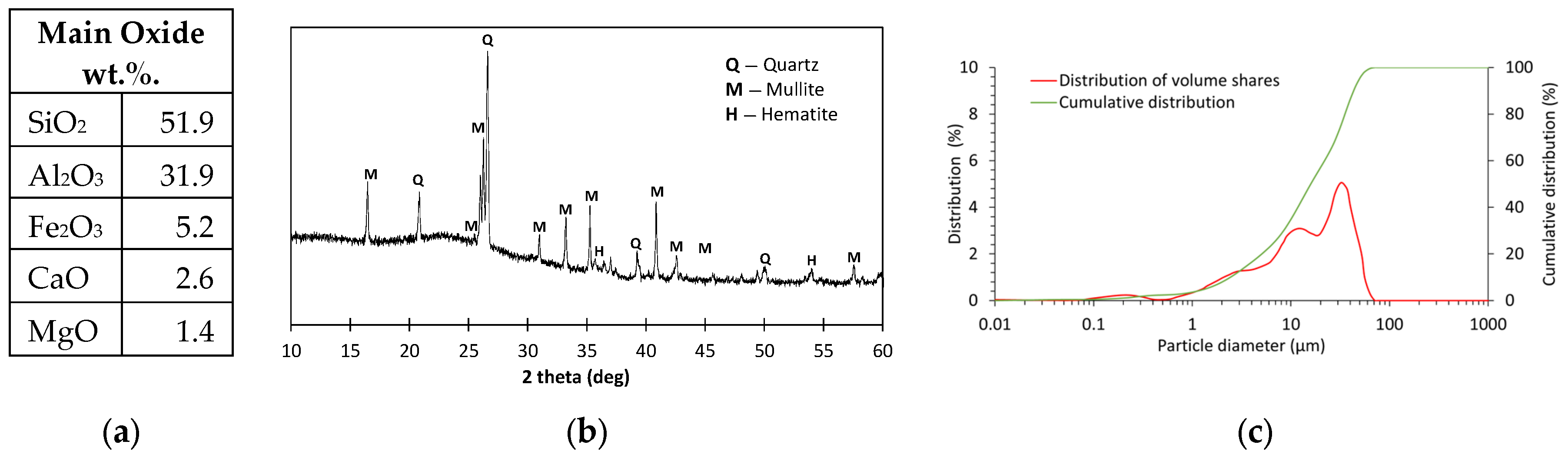

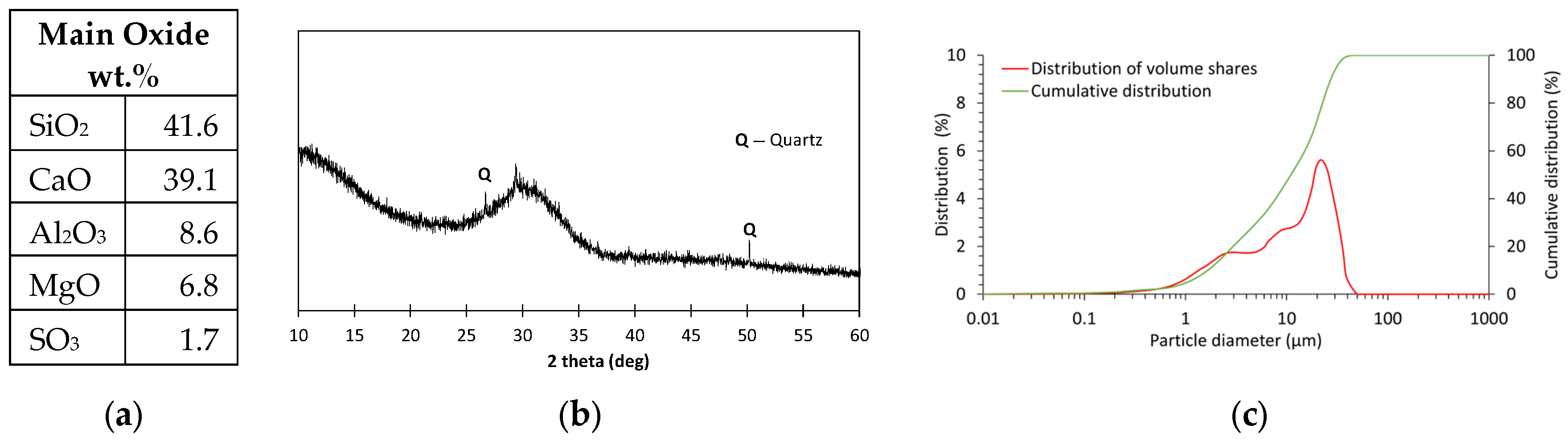

2.1. Fly Ash and Slag

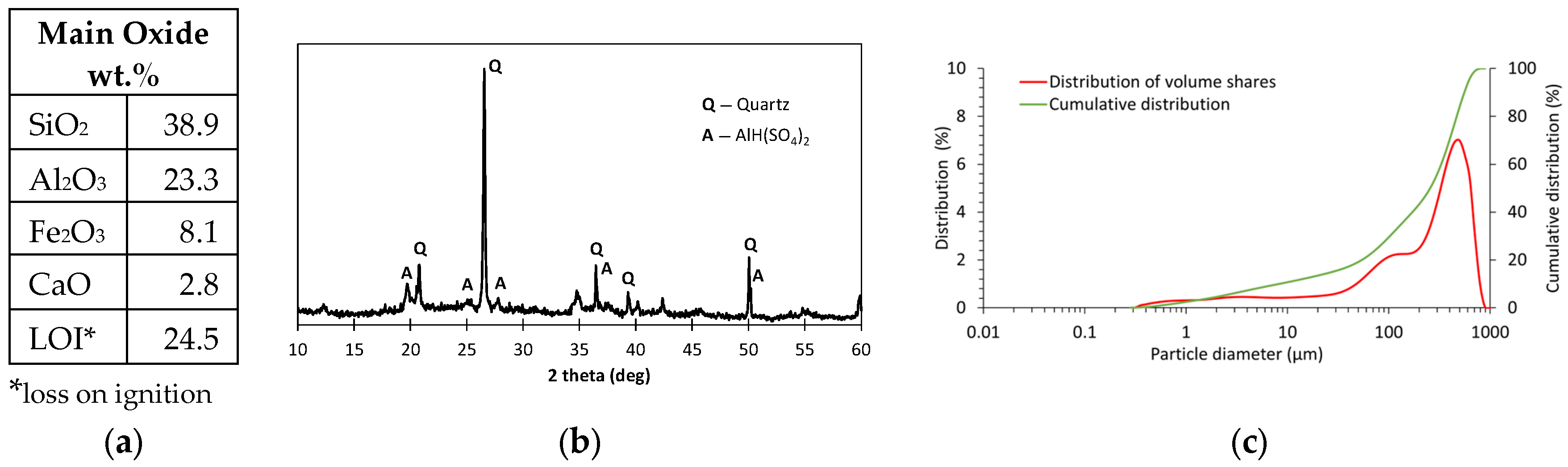

2.2. Water Treatment Sludge

2.3. Alkaline Activator

2.4. Steel, PP and Basalt Fibres

2.5. Compositions and Samples of Geopolymer Mortars

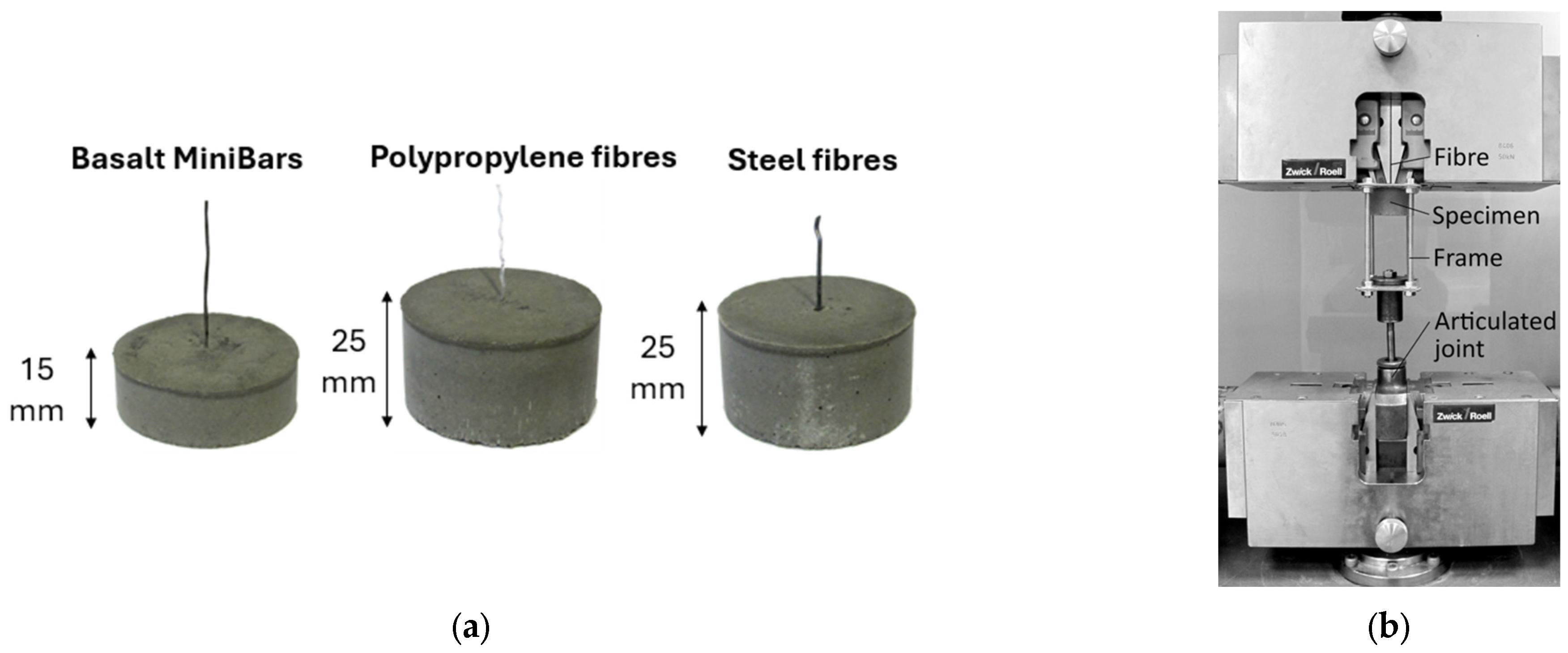

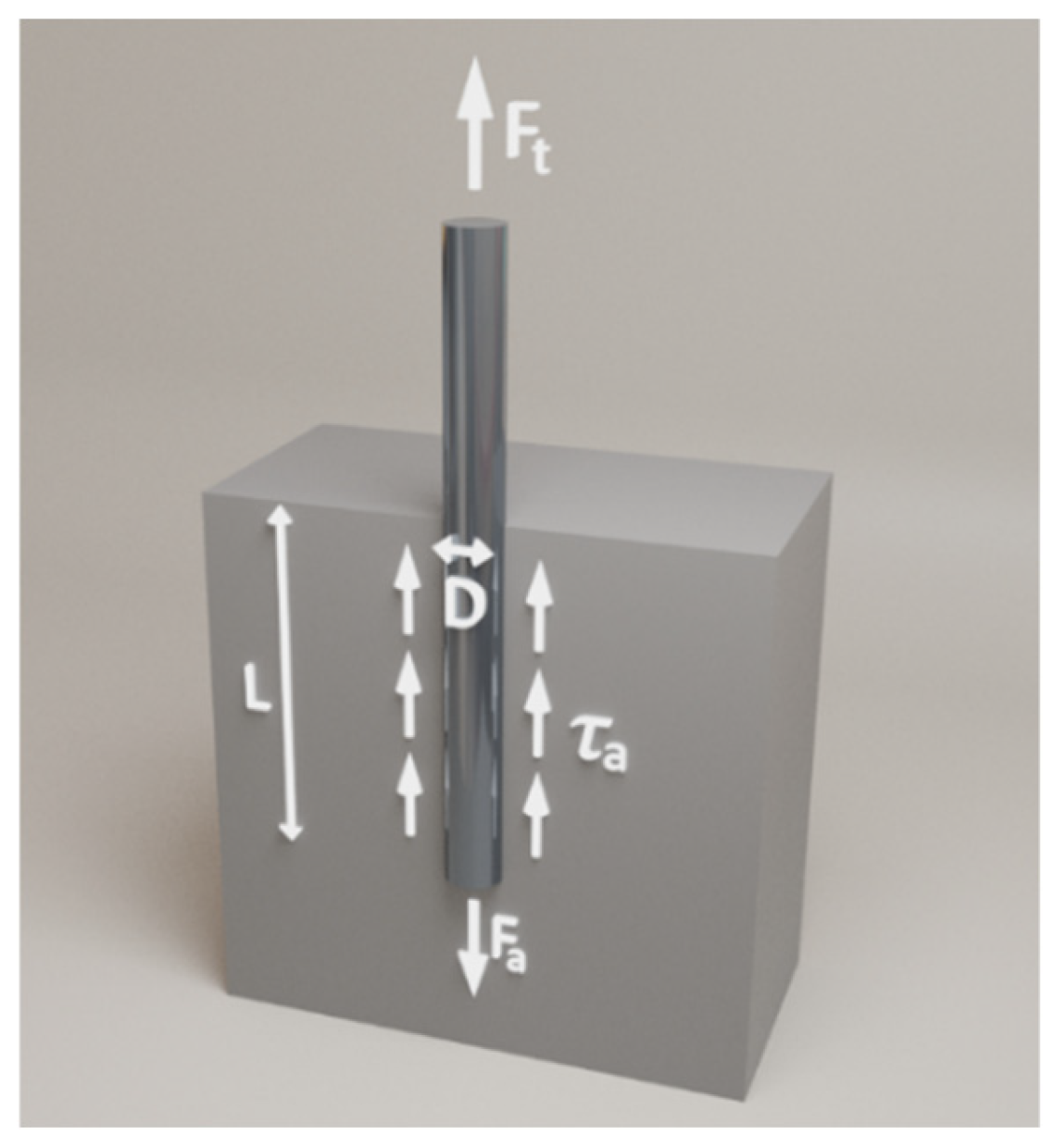

2.6. Pull-Out Test

- Fmax—maximum force [kN]

- S—fibre/matrix contact area [m2]

- Wpull-out—fibre pulling work based on the relationship:

- F—force [kN]

- δmax—maximum elongation—directly from the graph

- A—fibre cross-sectional area;

- Pf—fibre perimeter

- ft—fibre tensile strength

- τa—tangential stress (adhesion)

- D—Fiber diameter

3. Results and Discussion

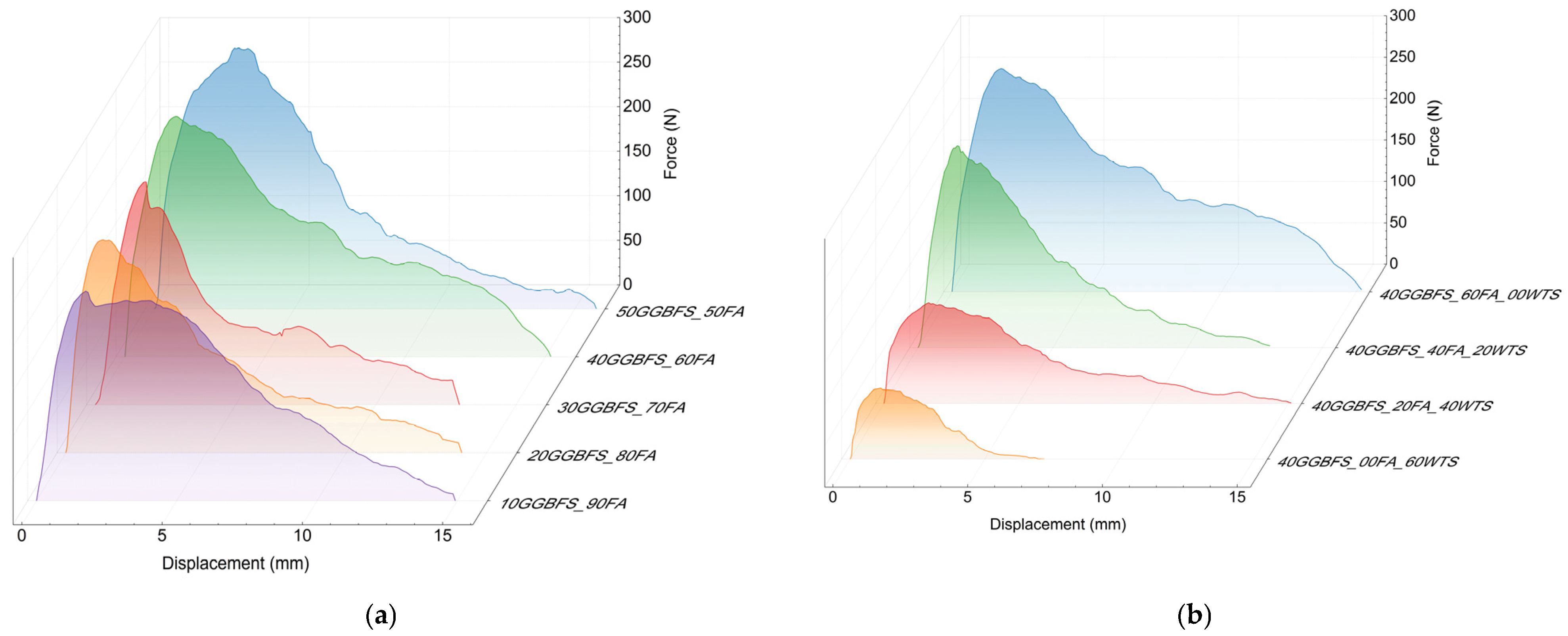

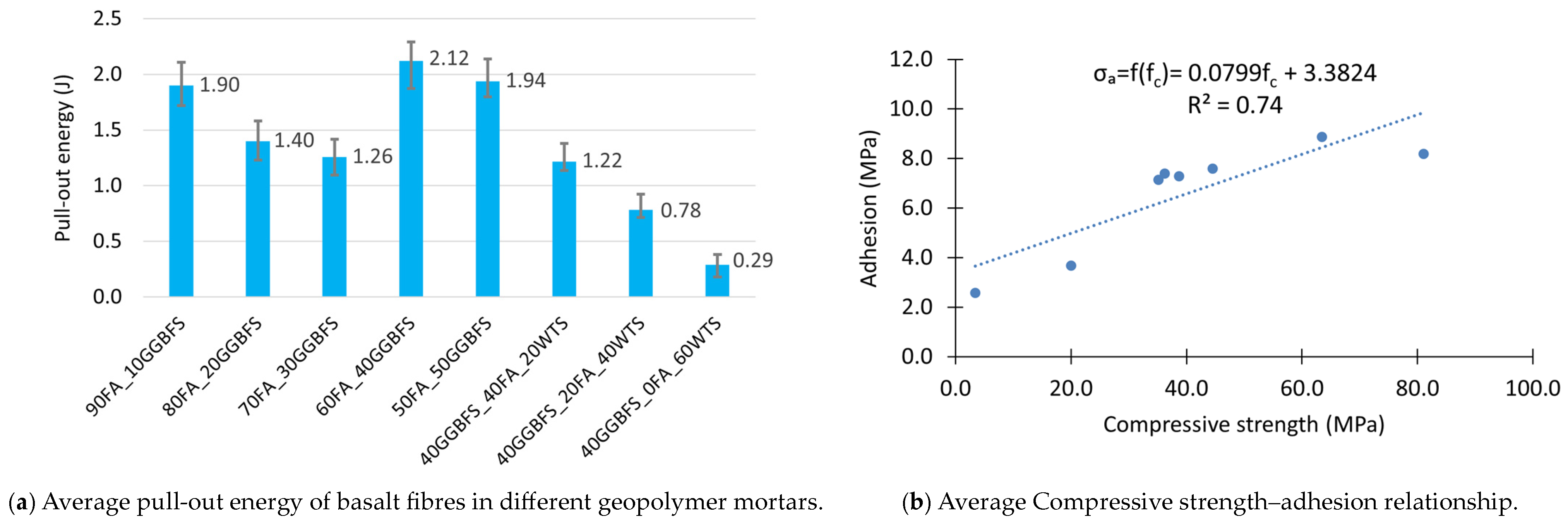

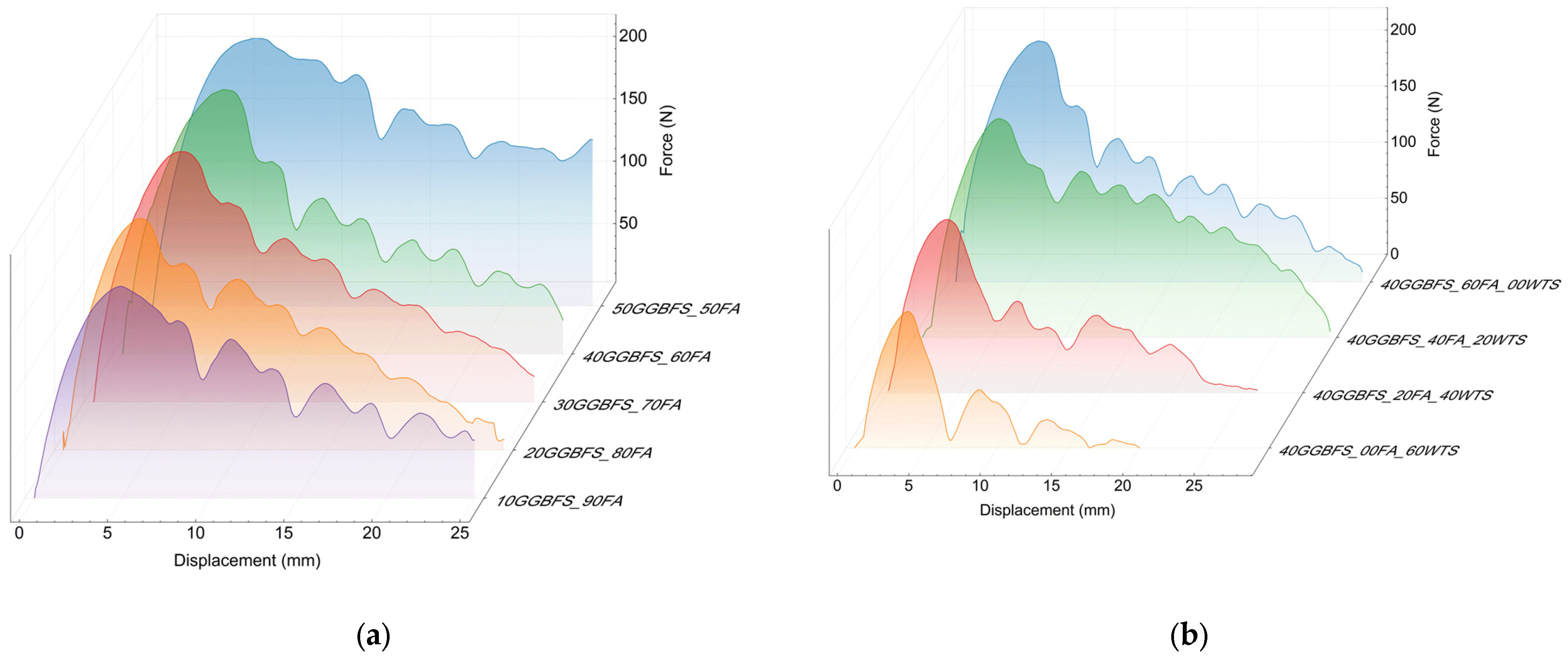

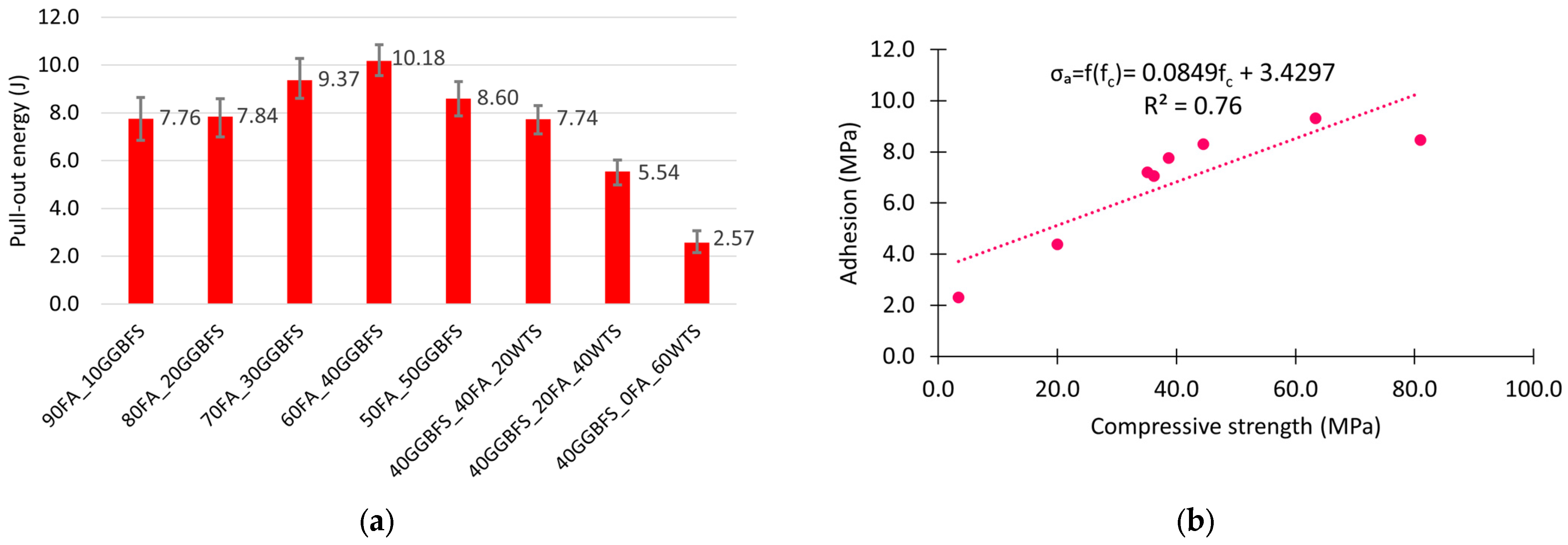

3.1. Basalt Fibres

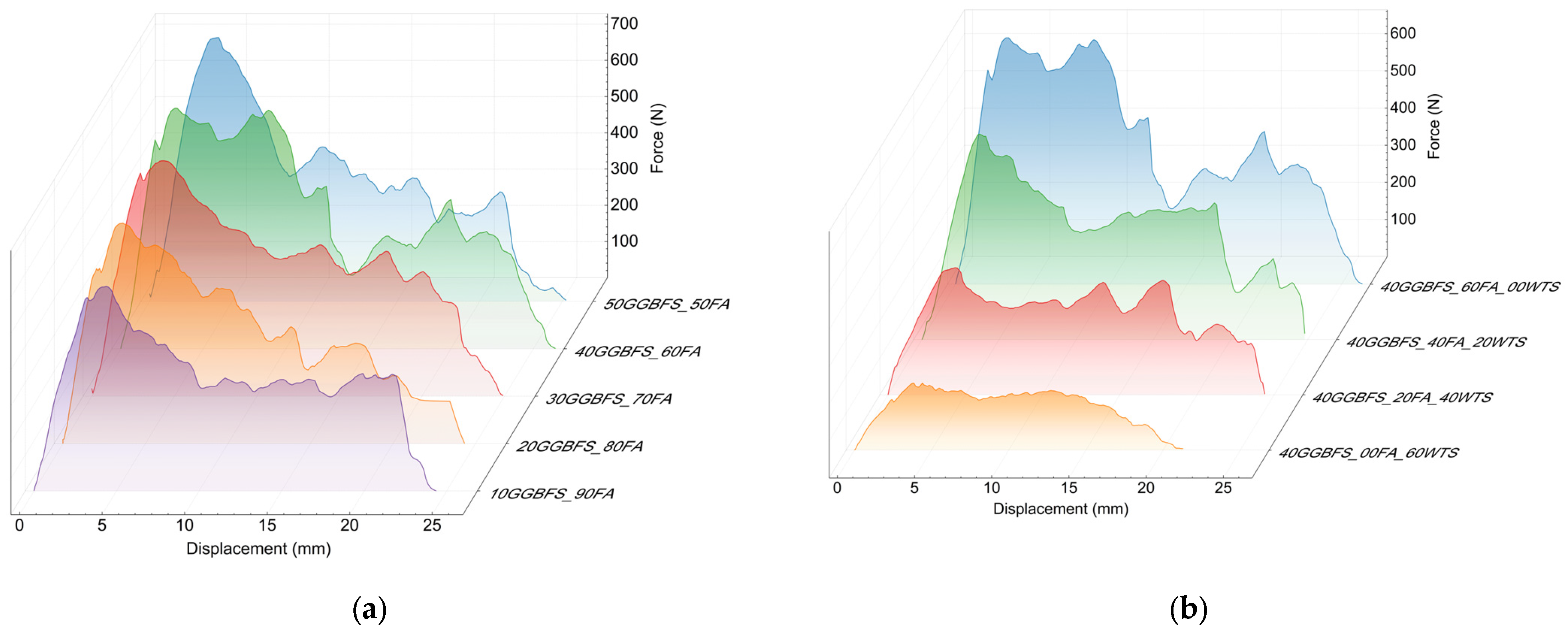

3.2. Steel Fibres

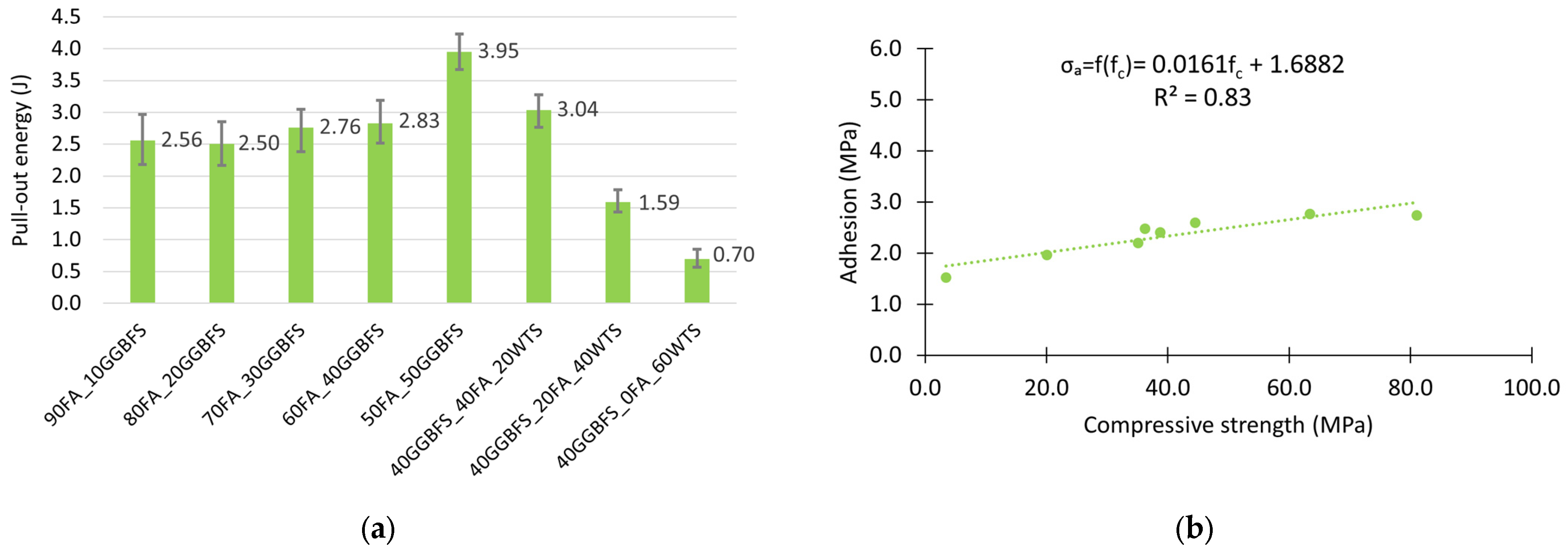

3.3. Polypropylene Fibres

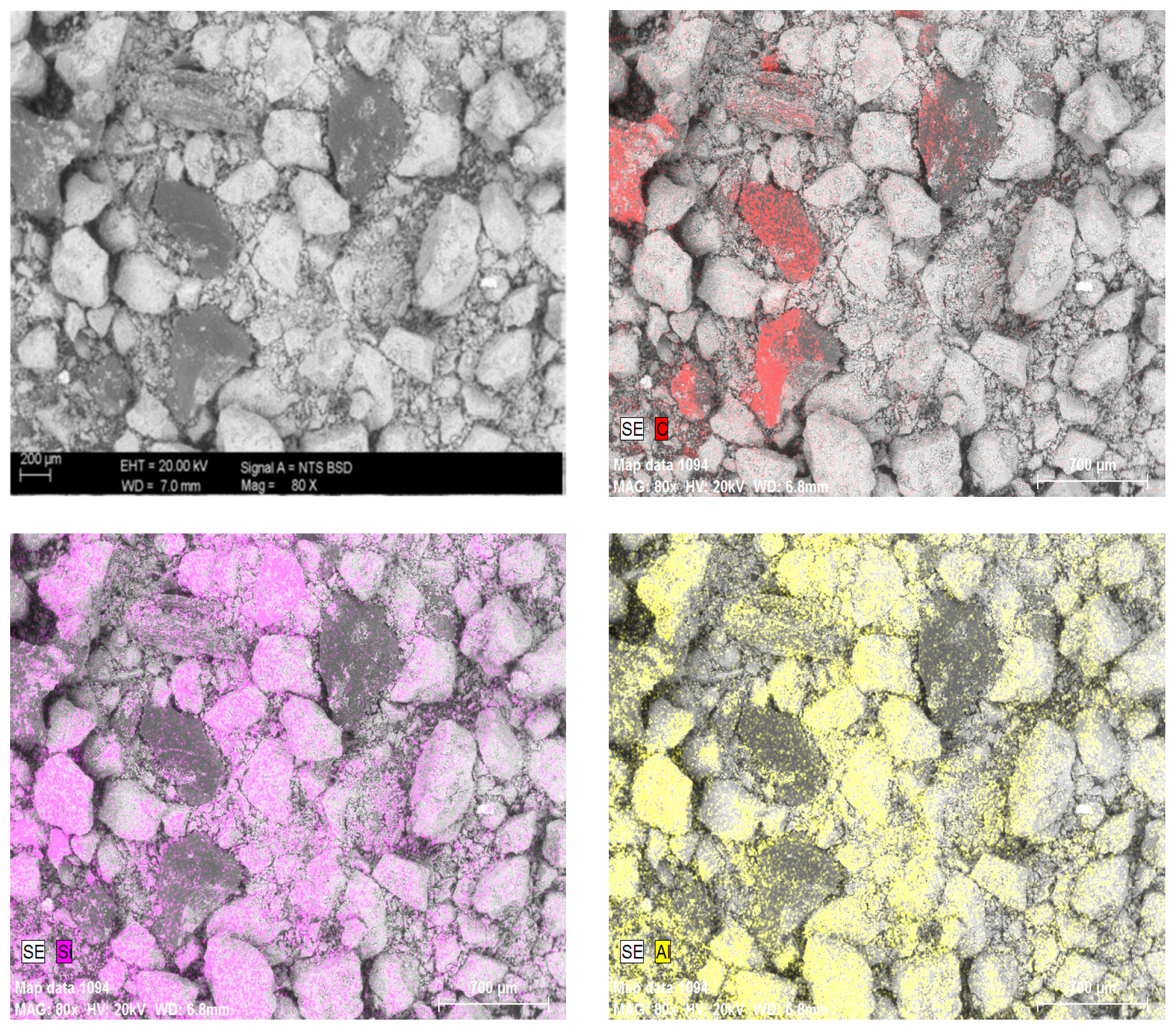

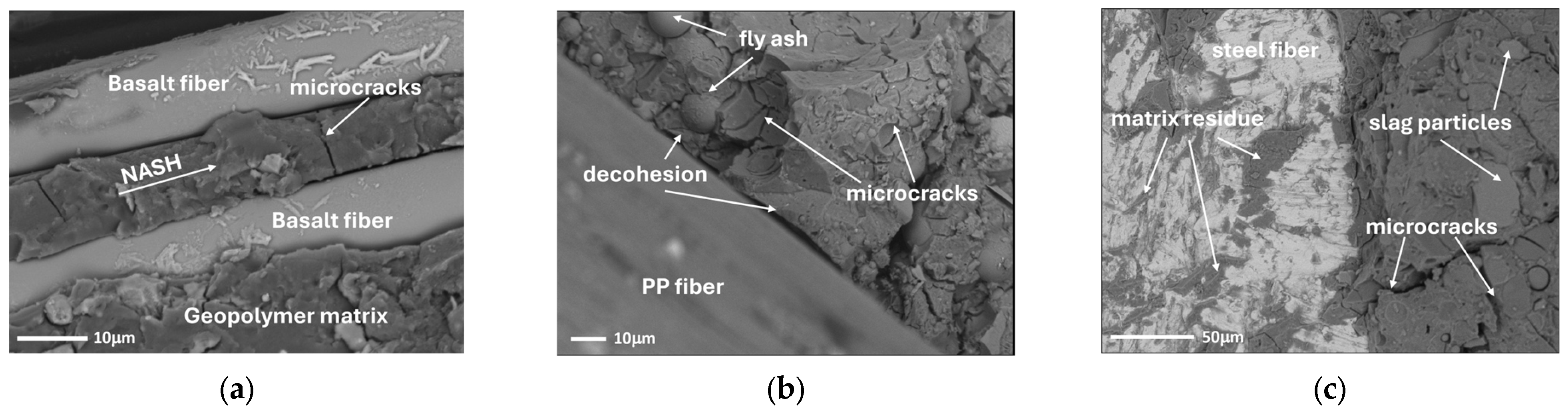

3.4. SEM Observation

4. Summary and Conclusions

- The presence of WTS as a precursor in the geopolymer binder of mortars significantly reduces their mechanical properties. An increase of this waste material content by 10% causes a decrease in flexural strength of approximately 1 MPa, whereas compressive strength is reduced by more than 12 MPa.

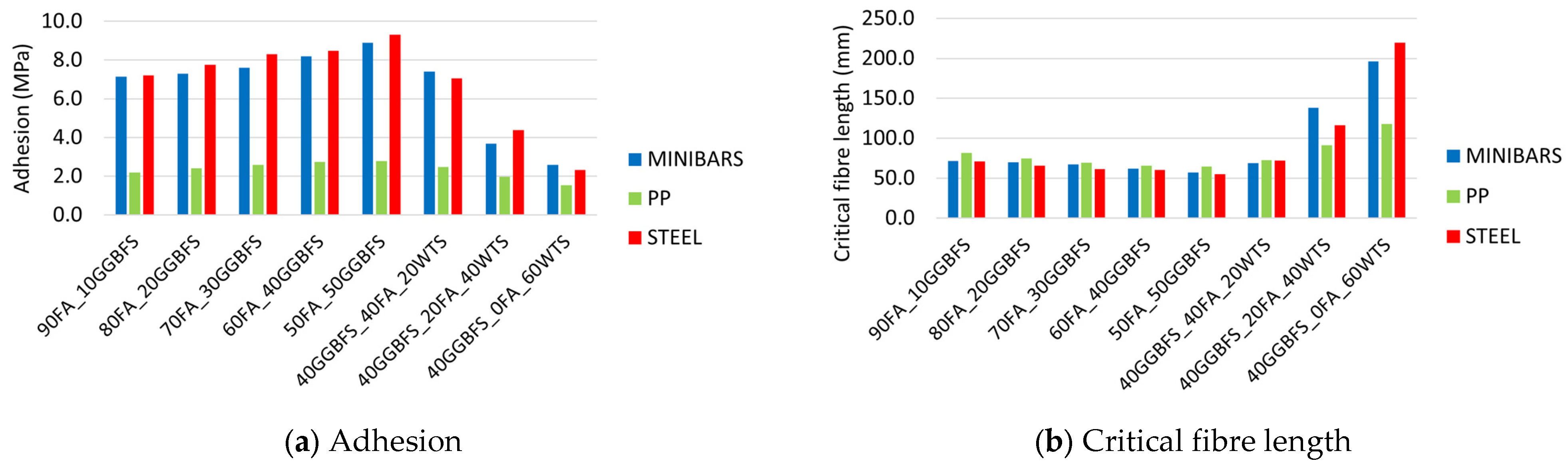

- Within the investigated range (10–50%), increasing the GGBFS content in the geopolymer binder increases fibre–matrix adhesion regardless of fibre type. This effect is more pronounced for steel and basalt fibres, where σa increases on average by approximately 0.5 MPa per 10% rise in GGBFS content, whereas for PP fibres, the increase is only about 0.15 MPa.

- Steel fibres exhibited the greatest sensitivity of adhesion to changes in matrix mechanical properties. Linear regression analysis within the compressive strength range up to 80 MPa showed that an increase of 1 MPa in compressive strength corresponds to an average adhesion increase of 85 kPa. By contrast, PP fibres showed the smallest changes, where the average adhesion increase observed was only 16 kPa.

- The presence of WTS reduces the adhesion of all types of fibres to the geopolymer matrix. The effect is strongest for steel and basalt fibres, where a 10% increase in WTS content in the matrix causes a reduction in adhesion of more than 1 MPa in both cases. For PP fibres, the decrease is approximately 0.2 MPa.

- Steel and basalt fibres exhibit the highest adhesion to the geopolymer matrix free of water treatment sludge, with values around 8–9 MPa. PP fibres show substantially lower adhesion, approximately one-third of that of steel and basalt, at below 3 MPa.

- Too-short fibres used to reinforce brittle mineral composites can increase flexural strength but typically provide low toughness. Conversely, overly long fibres tend to tangle, which can reduce flexural strength while often enhancing composite ductility. The results obtained allow for the determination of the optimum length for the studied fibres in geopolymer matrices. The critical length for basalt, steel, and PP fibres in matrices without WTS is approximately 50–70 mm. These values indicate that commercially produced fibres with lengths close to the reported range can be effectively used to manufacture reinforced mortars and concretes based on geopolymer matrices.

- SEM microscopic observations showed the presence of unreacted precursor particles, microcracks in the geopolymer matrix. In addition, particularly good adhesion of steel fibres is confirmed by the presence of matrix traces on the fibre surface and the integrity of the matrix–fibre contact zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fahim Huseien, G.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Abdulameer Hussein, A. Geopolymer Mortars as Sustainable Repair Material: A Comprehensive Review. Renew. Sustain. Energy Rev. 2017, 80, 54–74. [Google Scholar] [CrossRef]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; DeFord, H.D.; Townsend, T.G. A Review of Waste Products Utilized as Supplements to Portland Cement in Concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Narayanan, A.; Shanmugasundaram, P. Evaluation of Heat Resisting Behaviour of Basalt Fibre Reinforced FG Tiles. Constr. Build. Mater. 2018, 170, 679–689. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Yang, J.; Davoodabadi, M.; Li, L.; Du, Y.; Yang, B.; Hempel, S.; Mechtcherine, V. Electrochemical Oxidation of Recycled Carbon Fibers for an Improved Interaction toward Alkali-Activated Composites. J. Clean. Prod. 2022, 368, 133093. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Wang, X.; Tu, S.; Song, Y.; Shi, T.; Wang, L.; Zhou, H. A Comprehensive Benefit Evaluation of Recycled Carbon Fiber Reinforced Cement Mortar Based on Combined Weighting. Constr. Build. Mater. 2025, 489, 142196. [Google Scholar] [CrossRef]

- Zhu, J.F.; Xia, Y.N.; Ju, L.Y.; Yang, H.; Wang, Z.Q.; Jin, J.Y.; Zou, Y.C.; Liao, Y.C. Physico-Mechanical Performance and Micro–Mechanism Analysis on Urban Sludge Modified with a Low Carbon Binder. Acta Geotech. 2025, 20, 5585–5601. [Google Scholar] [CrossRef]

- Dai, T.; Fang, C.; Liu, T.; Zheng, S.; Lei, G.; Jiang, G. Waste Glass Powder as a High Temperature Stabilizer in Blended Oil Well Cement Pastes: Hydration, Microstructure and Mechanical Properties. Constr. Build. Mater. 2024, 439, 137359. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R.; Ozbakkaloglu, T.; Uddin Ahmed Shaikh, F.; Belarbi, R. Fly Ash and Ground Granulated Blast Furnace Slag-Based Alkali-Activated Concrete: Mechanical, Transport and Microstructural Properties. Constr. Build. Mater. 2020, 257, 119548. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Li, W.; Shi, G.; Lu, P. Effect of Slag on the Mechanical Properties and Bond Strength of Fly Ash-Based Engineered Geopolymer Composites. Compos. B Eng. 2019, 164, 747–757. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical Properties of Alkali Activated GGBS and Fly Ash Geopolymeric Recycled Concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Chinnaraju, K. Durability of Ambient Cured Alumina Silicate Concrete Based on Slag/Fly Ash Blends against Sulfate Environment. Constr. Build. Mater. 2019, 204, 70–83. [Google Scholar] [CrossRef]

- Ramamohana, B.; Gopinathan, P.; Chandrasekhar, I. Engineering Properties of GGBS & Fly Ash Synthesized Geopolymer Concrete at Different Environmental Conditions by Comparing with Conventional Concrete. Int. J. Recent Technol. Eng. 2019, 7, 399–406. [Google Scholar]

- Hager, I.; Sitarz, M.; Mróz, K. Fly-Ash Based Geopolymer Mortar for High-Temperature Application—Effect of Slag Addition. J. Clean. Prod. 2021, 316, 128168. [Google Scholar] [CrossRef]

- Yasaswini, K.; Venkateshwara Rao, A. Behaviour of Geopolymer Concrete at Elevated Temperature. Mater. Today Proc. 2020, 33, 239–244. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of Initial CaO/Al2O3 and SiO2/Al2O3 Ratios on the Properties of Slag/Fly Ash-Based Geopolymer Stabilized Clay: Synergistic Effects and Stabilization Mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Fu, K.; Xue, Y.; Qiu, D.; Wang, P.; Lu, H. Multi-Channel Fusion Prediction of TBM Tunneling Thrust Based on Multimodal Decomposition and Reconstruction. Tunn. Undergr. Space Technol. 2026, 167, 107061. [Google Scholar] [CrossRef]

- Fu, H.; Tian, J.; Chin, C.L.; Liu, H.; Yuan, J.; Tang, S.; Mai, R.; Wu, X. Axial Compression Behavior of GFRP-Steel Composite Tube Confined Seawater Sea-Sand Concrete Intermediate Long Columns. Eng. Struct. 2025, 333, 120157. [Google Scholar] [CrossRef]

- Sitarz, M.; Hager, I.; Choińska, M. Evolution of Mechanical Properties with Time of Fly-ash-based Geopolymer Mortars under the Effect of Granulated Ground Blast Furnace Slag Addition. Energies 2020, 13, 1135. [Google Scholar] [CrossRef]

- Bernal, S.A.; Bejarano, J.; Garzón, C.; Mejía de Gutiérrez, R.; Delvasto, S.; Rodríguez, E.D. Performance of Refractory Aluminosilicate Particle/Fiber-Reinforced Geopolymer Composites. Compos. B Eng. 2012, 43, 1919–1928. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Behaviour of Ambient Cured Steel Fibre Reinforced Geopolymer Concrete Columns Under Axial and Flexural Loads. Structures 2018, 15, 184–195. [Google Scholar] [CrossRef]

- Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z.; Islam, A.; Santhi, H.; Sharmin, A. Engineering Properties and Fracture Behaviour of High Volume Palm Oil Fuel Ash Based Fibre Reinforced Geopolymer Concrete. Constr. Build. Mater. 2016, 111, 286–297. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Ghazali, N.B.; Yusoff, S.; Bashar, I.I. Influence of Steel Fibers on the Mechanical Properties and Impact Resistance of Lightweight Geopolymer Concrete. Constr. Build. Mater. 2017, 152, 964–977. [Google Scholar] [CrossRef]

- Chen, R.; Ahmari, S.; Zhang, L. Utilization of Sweet Sorghum Fiber to Reinforce Fly Ash-Based Geopolymer. J. Mater. Sci. 2014, 49, 2548–2558. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Hao, Y.; Hao, H.; Shaikh, F.U.A.; Liu, K. Mechanical Properties of Ambient Cured High-Strength Plain and Hybrid Fiber Reinforced Geopolymer Composites from Triaxial Compressive Tests. Constr. Build. Mater. 2018, 185, 338–353. [Google Scholar] [CrossRef]

- Asrani, N.P.; Murali, G.; Parthiban, K.; Surya, K.; Prakash, A.; Rathika, K.; Chandru, U. A Feasibility of Enhancing the Impact Resistance of Hybrid Fibrous Geopolymer Composites: Experiments and Modelling. Constr. Build. Mater. 2019, 203, 56–68. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.B. Tensile Properties of a Novel Fibre Reinforced Geopolymer Composite with Enhanced Strain Hardening Characteristics. Compos. Struct. 2017, 168, 402–427. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Muthukannan, M. Development of High Performance Sustainable Optimized Fiber Reinforced Geopolymer Concrete and Prediction of Compressive Strength. J. Clean. Prod. 2021, 282, 124543. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Li, J.; Liu, Z.; Xu, S.; Liu, K.; Su, Y.; Fang, J.; Chen, G. Projectile Impact Resistance of Fibre-Reinforced Geopolymer-Based Ultra-High Performance Concrete (G-UHPC). Constr. Build. Mater. 2021, 290, 123189. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. Fiber-Reinforced One-Part Alkali-Activated Slag/Ceramic Binders. Ceram. Int. 2018, 44, 8963–8976. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.B. Steel Fibre Reinforced Geopolymer Concrete (SFRGC) with Improved Microstructure and Enhanced Fibre-Matrix Interfacial Properties. Constr. Build. Mater. 2017, 139, 286–307. [Google Scholar] [CrossRef]

- Al-mashhadani, M.M.; Canpolat, O.; Aygörmez, Y.; Uysal, M.; Erdem, S. Mechanical and Microstructural Characterization of Fiber Reinforced Fly Ash Based Geopolymer Composites. Constr. Build. Mater. 2018, 167, 505–513. [Google Scholar] [CrossRef]

- Nedeljković, M.; Luković, M.; van Breugel, K.; Hordijk, D.; Ye, G. Development and Application of an Environmentally Friendly Ductile Alkali-Activated Composite. J. Clean. Prod. 2018, 180, 524–538. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A State-of-the-Art Review on Fibre-Reinforced Geopolymer Composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Koenig, A.; Wuestemann, A.; Gatti, F.; Rossi, L.; Fuchs, F.; Fessel, D.; Dathe, F.; Dehn, F.; Minelli, F. Flexural Behaviour of Steel and Macro-PP Fibre Reinforced Concretes Based on Alkali-Activated Binders. Constr. Build. Mater. 2019, 211, 583–593. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. The Effect of Fiber Properties on High Performance Alkali-Activated Slag/Silica Fume Mortars. Compos. B Eng. 2013, 45, 63–69. [Google Scholar] [CrossRef]

- Bhutta, A.; Farooq, M.; Banthia, N. Matrix Hybridization Using Waste Fuel Ash and Slag in Alkali-Activated Composites and Its Influence on Maturity of Fiber-Matrix Bond. J. Clean. Prod. 2018, 177, 857–867. [Google Scholar] [CrossRef]

- Silva, F.J.; Thaumaturgo, C. Fibre Reinforcement and Fracture Response in Geopolymeric Mortars. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 167–172. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Cornelis Metselaar, H.S.; Jumaat, M.Z. Mechanisms of Interfacial Bond in Steel and Polypropylene Fiber Reinforced Geopolymer Composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. High Ductile Behavior of a Polyethylene Fiber-Reinforced One-Part Geopolymer Composite: A Micromechanics-Based Investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Nguyen, H.; Carvelli, V.; Adesanya, E.; Kinnunen, P.; Illikainen, M. High Performance Cementitious Composite from Alkali-Activated Ladle Slag Reinforced with Polypropylene Fibers. Cem. Concr. Compos. 2018, 90, 150–160. [Google Scholar] [CrossRef]

- Mohseni, E. Assessment of Na2SiO3 to NaOH Ratio Impact on the Performance of Polypropylene Fiber-Reinforced Geopolymer Composites. Constr. Build. Mater. 2018, 186, 904–911. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.A.; Bignozzi, M.C.; van Riessen, A. The Effect of Organic and Inorganic Fibres on the Mechanical and Thermal Properties of Aluminate Activated Geopolymers. Compos. B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- De Carvalho Gomes, S.; Zhou, J.L.; Li, W.; Long, G. Progress in Manufacture and Properties of Construction Materials Incorporating Water Treatment Sludge: A Review. Resour. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Nimwinya, E.; Arjharn, W.; Horpibulsuk, S.; Phoo-ngernkham, T.; Poowancum, A. A Sustainable Calcined Water Treatment Sludge and Rice Husk Ash Geopolymer. J. Clean. Prod. 2016, 119, 128–134. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Fernandes, L.F.R.; Camarini, G. Water Treatment Sludge and Rice Husk Ash to Sustainable Geopolymer Production. J. Clean. Prod. 2017, 149, 146–155. [Google Scholar] [CrossRef]

- Salimi, M.; Payan, M.; Hosseinpour, I.; Arabani, M.; Zanganeh Ranjbar, P. Geopolymer Stabilization of Construction and Demolition Waste Using Water Treatment Sludge and Silica Fume for Pavement Applications. J. Mater. Res. Technol. 2025, 37, 1834–1849. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Chanprasert, P.; Sukmak, P.; Arulrajah, A. Compressive Strength Development in Fly Ash Geopolymer Masonry Units Manufactured from Water Treatment Sludge. Constr. Build. Mater. 2015, 82, 20–30. [Google Scholar] [CrossRef]

- PN-EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. PKN: Warsaw, Poland, 2016.

- Nasir, M.; Mahmood, A.H.; Bahraq, A.A. History, Recent Progress, and Future Challenges of Alkali-Activated Binders—An Overview. Constr. Build. Mater. 2024, 426, 136141. [Google Scholar] [CrossRef]

- Bijalwan, A.; Mishra, A.K.; Sonowal, B. Strength, Durability, and Toxicity Characteristics of Water Treatment Sludge Based Geopolymers for Subgrade Application. Constr. Build. Mater. 2024, 447, 138162. [Google Scholar] [CrossRef]

- Bourzik, O.; Akkouri, N.; Baba, K.; Haddaji, Y.; Nounah, A.; Assafi, M.; Bazzar, K. Study of the Effects of Drinking Water Treatment Sludge on the Properties of Class F Fly Ash-Based Geopolymer. Environ. Sci. Pollut. Res. 2022, 29, 87668–87679. [Google Scholar] [CrossRef]

| Characteristic | Woellner Geosil 34417 |

|---|---|

| Na2O content (wt.%) | 16.74 |

| SiO2 content (wt.%) | 27.5 |

| Density (g/cm3) | 1.552 |

| Viscosity (mPa·s) | 470 |

| Weight ratio (WR = wt.% SiO2/wt.% Na2O) | 1.64 |

| Molar ratio (MR = mol SiO2/molNa2O) | 1.70 |

| Fibres | Anchorage Length [mm] | Diameter [mm] | Perimeter [mm] | Fibre–Matrix Contact Surface [mm2] | Tensile Strength [MPa] | Shape |

|---|---|---|---|---|---|---|

| MiniBars | 15 | 0.7 | 2.2 | 33.0 | 1456 |  |

| PP | 25 | 1.0 | 3.1 | 77.5 | 360 |  |

| Steel | 25 | 1.0 | 3.1 | 77.5 | 1020 |  |

| Component [g] | 10GGBFS/90FA | 30GGBFS/70FA | 40GGBFS/60FA | 50GGBFS/50FA | 40GGBFS/40FA/ 20WTS | 40GGBFS/20FA/ 40WTS | 40GGBFS/0FA/ 60WTS |

|---|---|---|---|---|---|---|---|

| Alkaline solution | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Water | 120 | 120 | 120 | 120 | 0 | 0 | 0 |

| FA | 720 | 560 | 480 | 400 | 320 | 160 | 0 |

| GGBFS | 80 | 240 | 320 | 400 | 320 | 320 | 320 |

| WTS (dry material) | 0 | 0 | 0 | 0 | 160 | 320 | 480 |

| Sand 0/2 mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Geopolymer Mix | Maximum Force Fmax | Adhesion σa (MPa) | Critical Fibre Length Lc (mm) | |

|---|---|---|---|---|

| (N) | Coefficient of Variation V (%) | |||

| 90FA_10GGBFS | 235.7 | 4.8 | 7.1 | 71.3 |

| 80FA_20GGBFS | 241.6 | 4.0 | 7.3 | 69.8 |

| 70FA_30GGBFS | 250.8 | 3.9 | 7.6 | 67.0 |

| 60FA_40GGBFS | 270.7 | 4.9 | 8.2 | 62.1 |

| 50FA_50GGBFS | 293.3 | 5.3 | 8.9 | 57.3 |

| 40GGBFS_40FA_20WTS | 244.3 | 4.4 | 7.4 | 68.8 |

| 40GGBFS_20FA_40WTS | 121.8 | 4.6 | 3.7 | 138.0 |

| 40GGBFS_0FA_60WTS | 85.6 | 6.6 | 2.6 | 196.3 |

| Geopolymer Mix | Maximum Force Fmax | Adhesion σa (MPa) | Critical Fibre Length Lc (mm) | |

|---|---|---|---|---|

| (N) | Coefficient of Variation V (%) | |||

| 90FA_10GGBFS | 565.5 | 5.8 | 7.2 | 70.8 |

| 80FA_20GGBFS | 609.5 | 6.3 | 7.8 | 65.7 |

| 70FA_30GGBFS | 651.7 | 5.6 | 8.3 | 61.4 |

| 60FA_40GGBFS | 664.9 | 5.2 | 8.5 | 60.2 |

| 50FA_50GGBFS | 730.7 | 4.8 | 9.3 | 54.8 |

| 40GGBFS_40FA_20WTS | 554.4 | 6.0 | 7.1 | 72.2 |

| 40GGBFS_20FA_40WTS | 343.8 | 6.3 | 4.4 | 116.4 |

| 40GGBFS_0FA_60WTS | 182.0 | 6.1 | 2.3 | 219.9 |

| Geopolymer Mix | Maximum Force Fmax | Adhesion σa (MPa) | Critical Fibre Length Lc (mm) | |

|---|---|---|---|---|

| (N) | Coefficient of Variation V (%) | |||

| 90FA_10GGBFS | 173.1 | 5.5 | 2.2 | 81.7 |

| 80FA_20GGBFS | 189.0 | 5.7 | 2.4 | 74.8 |

| 70FA_30GGBFS | 204.0 | 6.1 | 2.6 | 69.3 |

| 60FA_40GGBFS | 215.2 | 7.4 | 2.7 | 65.7 |

| 50FA_50GGBFS | 217.9 | 5.8 | 2.8 | 64.9 |

| 40GGBFS_40FA_20WTS | 195.2 | 8.1 | 2.5 | 72.4 |

| 40GGBFS_20FA_40WTS | 154.7 | 8.0 | 2.0 | 91.4 |

| 40GGBFS_0FA_60WTS | 119.8 | 8.3 | 1.5 | 118.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sitarz, M.; Zdeb, T.; Tracz, T.; Łach, M. Adhesion of Polypropylene, Steel, and Basalt Fibres to a Geopolymer Matrix with Water Treatment Sludge Addition. Materials 2025, 18, 4727. https://doi.org/10.3390/ma18204727

Sitarz M, Zdeb T, Tracz T, Łach M. Adhesion of Polypropylene, Steel, and Basalt Fibres to a Geopolymer Matrix with Water Treatment Sludge Addition. Materials. 2025; 18(20):4727. https://doi.org/10.3390/ma18204727

Chicago/Turabian StyleSitarz, Mateusz, Tomasz Zdeb, Tomasz Tracz, and Michał Łach. 2025. "Adhesion of Polypropylene, Steel, and Basalt Fibres to a Geopolymer Matrix with Water Treatment Sludge Addition" Materials 18, no. 20: 4727. https://doi.org/10.3390/ma18204727

APA StyleSitarz, M., Zdeb, T., Tracz, T., & Łach, M. (2025). Adhesion of Polypropylene, Steel, and Basalt Fibres to a Geopolymer Matrix with Water Treatment Sludge Addition. Materials, 18(20), 4727. https://doi.org/10.3390/ma18204727