The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.3. Characterization of Samples

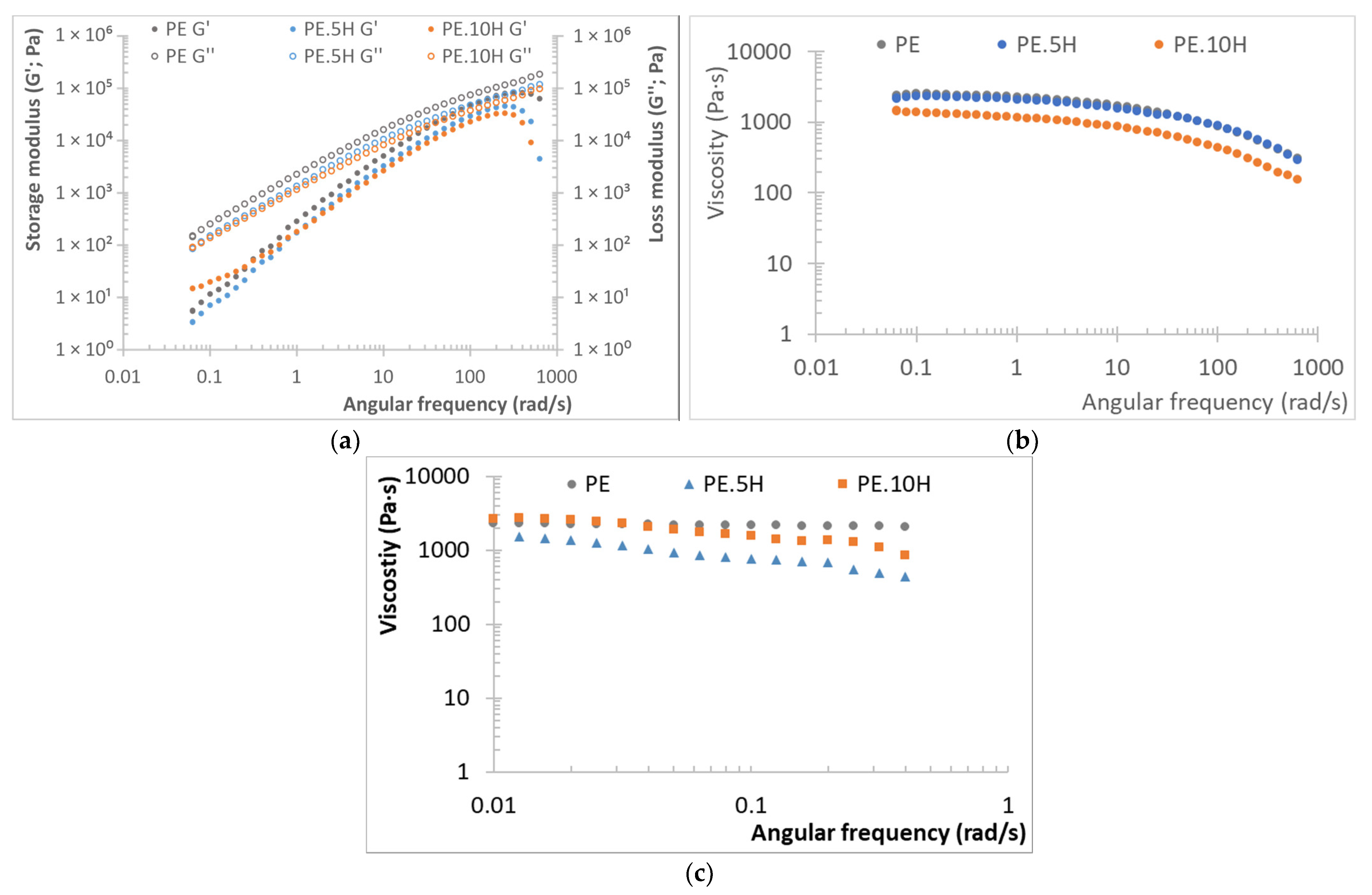

2.3.1. Rheology Assessment—Flow Behavior of Composites

2.3.2. Tensile Testing and UV-Weathering

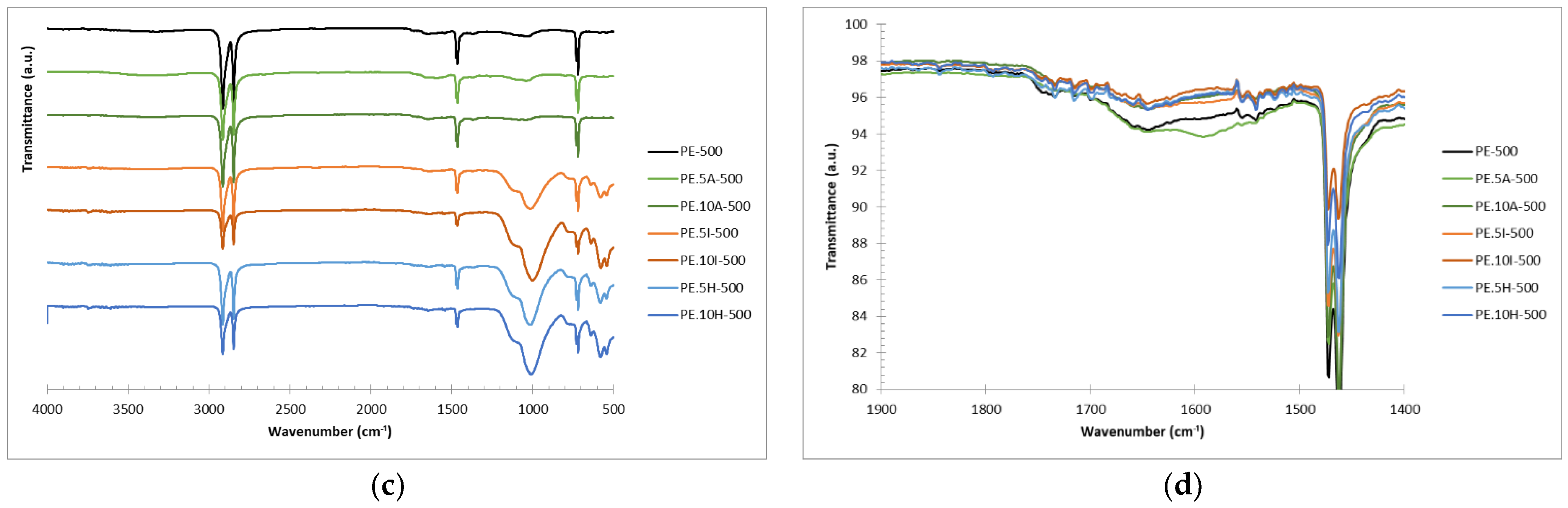

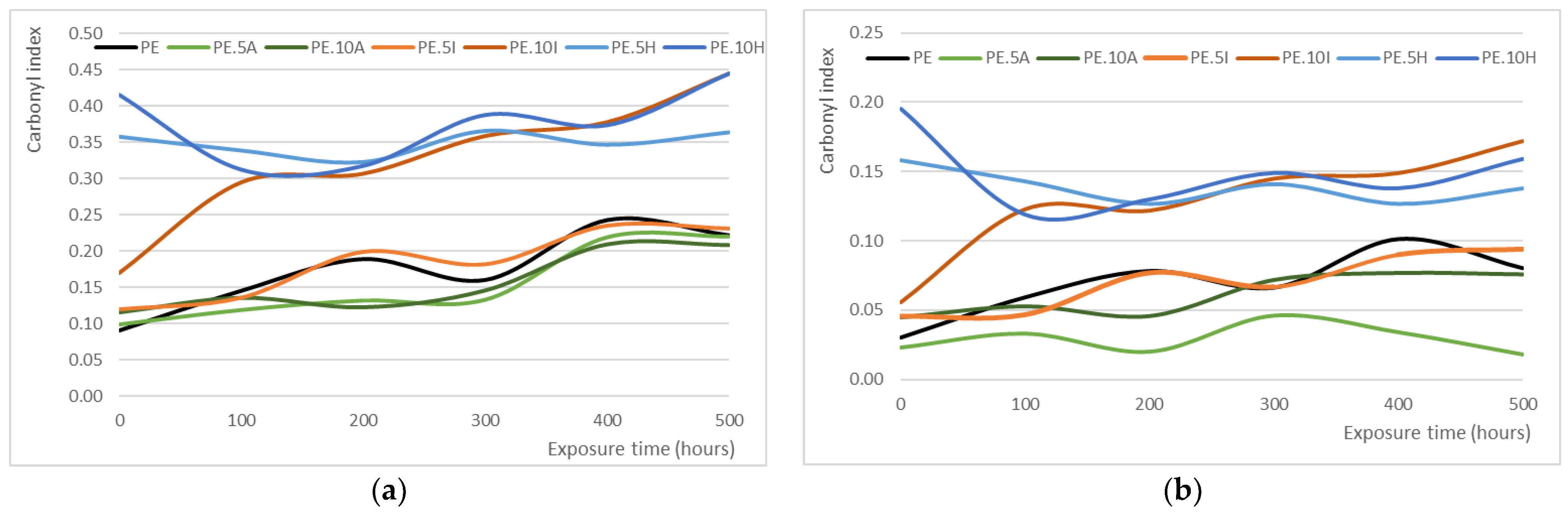

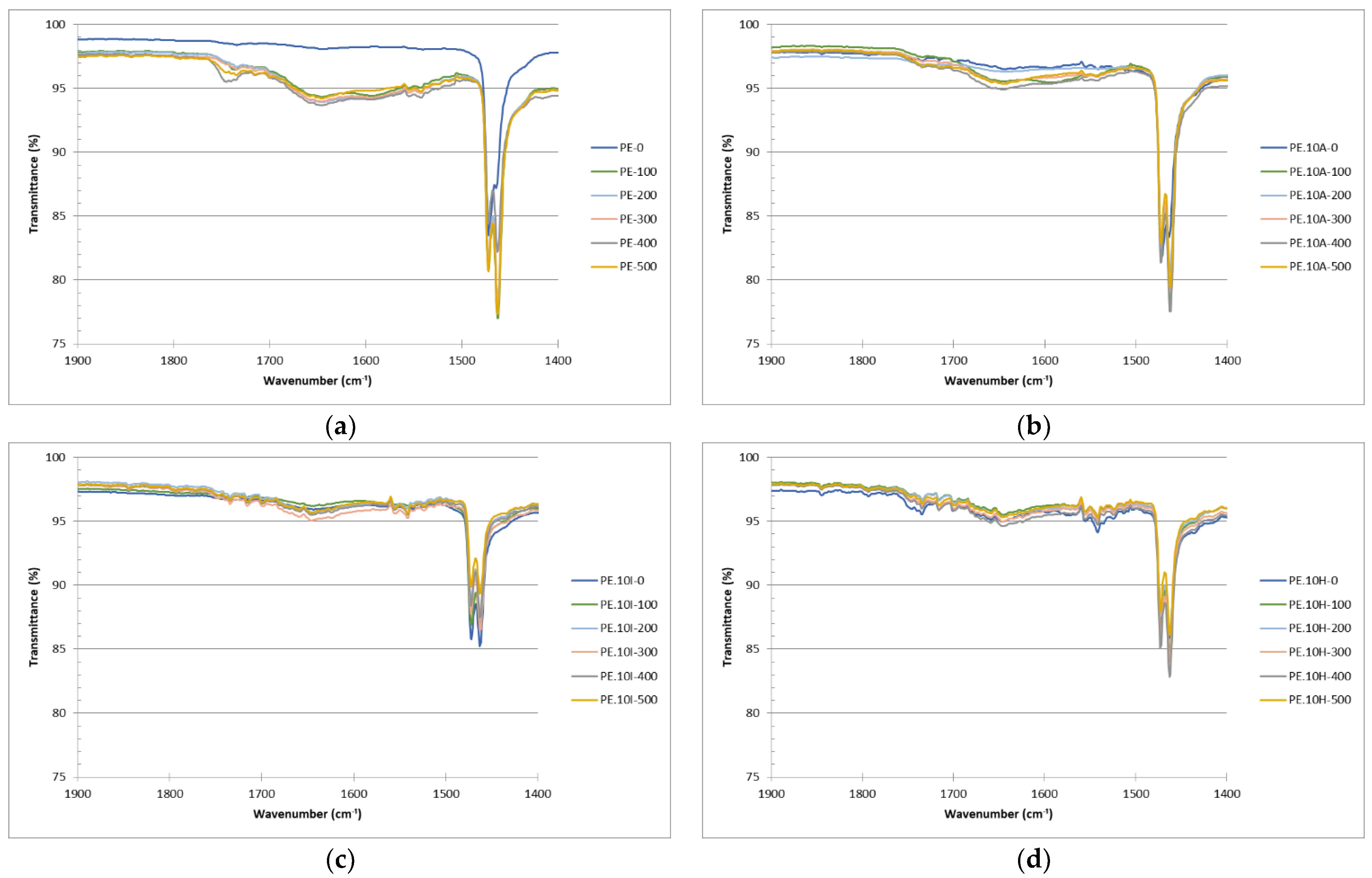

2.3.3. Carbonyl Index Determination by Fourier Infrared Spectroscopy

3. Results and Discussion

3.1. Cycle Time Analysis

3.2. Rheology Assessment of Rotomolded Composites

3.3. Tensile Properties

3.4. Carbonyl Index: Samples Surface Oxidation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational Molding of Linear Low-Density Polyethylene Composites Filled with Wheat Bran. Polymers 2020, 12, 1004. [Google Scholar] [CrossRef]

- Ghanem, Z.; Šourkova, H.J.; Sezemský, J.; Špatenka, P. The Effect of Plasma Treatment of Polyethylene Powder and Glass Fibers on Selected Properties of Their Composites Prepared via Rotational Molding. Polymers 2022, 14, 2592. [Google Scholar] [CrossRef] [PubMed]

- Kelly-Walley, J.; Martin, P.; Ortega, Z.; Pick, L.; McCourt, M. Recent Advancements towards Sustainability in Rotomoulding. Materials 2024, 17, 2607. [Google Scholar] [CrossRef] [PubMed]

- Ghanem, Z.; Sasidharan, S.P.; Jenikova, Z.; Špatenka, P. Rotational Molding of Plasma Treated Polyethylene/Short Glass Fiber Composites. Int. J. Eng. Manag. Sci. 2019, 4, 102–108. [Google Scholar] [CrossRef]

- Ortega, Z.; McCourt, M.; Romero, F.; Suárez, L.; Cunningham, E. Recent Developments in Inorganic Composites in Rotational Molding. Polymers 2022, 14, 5260. [Google Scholar] [CrossRef]

- Guan, C.F.; Peng, W.; Qin, L.; Zhang, Y.C.; Yang, W.M. A Numerical Investigation on Temperature Field in the Oven of a Rotational Molding Machine. Key Eng. Mater. 2013, 561, 336–340. [Google Scholar] [CrossRef]

- Gupta, N.; Ramkumar, P.; Sangani, V. An Approach toward Augmenting Materials, Additives, Processability and Parameterization in Rotational Molding: A Review. Mater. Manuf. Process. 2020, 35, 1539–1556. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Rotational Molding of Polymer Composites Reinforced with Natural Fibers. Plast. Eng. 2015, 71, 28–31. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Rotational Molding of Self-Hybrid Composites Based on Linear Low-Density Polyethylene and Maple Fibers. Polym. Compos. 2018, 39, 4094–4103. [Google Scholar] [CrossRef]

- Gupta, N.; Ramkumar, P. Effect of Industrially Processed Glass Fibre Dust on Mechanical, Thermal and Morphological Properties Mixed with LLDPE for Rotational Molding Process. Sadhana—Acad. Proc. Eng. Sci. 2021, 46, 241. [Google Scholar] [CrossRef]

- Kelly-Walley, J.; Ortega, Z.; McCourt, M.; Millar, B.; Suárez, L.; Martin, P. Mechanical Performance of Rotationally Molded Multilayer MLDPE/Banana-Fiber Composites. Materials 2023, 16, 6749. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A. Rotational Molding of Biodegradable Composites Obtained with PLA Reinforced by the Wooden Backbone of Opuntia Ficus Indica Cladodes. J. Appl. Polym. Sci. 2015, 132, 42447. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pérez-Fonseca, A.A.; González-García, Y.; Ramírez-Arreola, D.E.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Polylactic Acid-Agave Fiber Biocomposites Produced by Rotational Molding: A Comparative Study with Compression Molding. Adv. Polym. Technol. 2018, 37, 2528–2540. [Google Scholar] [CrossRef]

- Aniśko, J.; Barczewski, M.; Mietliński, P.; Piasecki, A.; Szulc, J. Valorization of Disposable Polylactide (PLA) Cups by Rotational Molding Technology: The Influence of Pre-Processing Grinding and Thermal Treatment. Polym. Test. 2022, 107, 107481. [Google Scholar] [CrossRef]

- Cestari, S.P.; Martin, P.; Hanna, P.; Kearns, M.; Mendes, L.C. Rotational-Moulded Building Blocks for the Circular Economy. Mater. Sci. Forum 2021, 1042, 17–22. [Google Scholar] [CrossRef]

- Shaker, R.; Rodrigue, D. Rotomolding of Thermoplastic Elastomers Based on Low-Density Polyethylene and Recycled Natural Rubber. Appl. Sci. 2019, 9, 5430. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Morphological, Thermal and Mechanical Properties of Recycled HDPE Foams via Rotational Molding. J. Cell. Plast. 2022, 58, 305–323. [Google Scholar] [CrossRef]

- Pick, L.; Hanna, P.R.; Gorman, L. Assessment of Processibility and Properties of Raw Post-Consumer Waste Polyethylene in the Rotational Moulding Process. J. Polym. Eng. 2022, 42, 374–383. [Google Scholar] [CrossRef]

- Díaz, S.; Ortega, Z.; McCourt, M.; Kearns, M.P.; Benítez, A.N. Recycling of Polymeric Fraction of Cable Waste by Rotational Moulding. Waste Manag. 2018, 76, 199–206. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Effect of Particle Size, Fiber Content, and Surface Treatment on the Mechanical Properties of Maple-Reinforced LLDPE Produced by Rotational Molding. Polym. Polym. Compos. 2021, 29, 343–353. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Kuzmin, A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. J. Compos. Sci. 2021, 5, 44. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.D.; Benítez, A.N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and Abaca Fiber-Reinforced Plastic Composites Obtained by Rotational Molding Process. Mater. Manuf. Process. 2013, 28, 879–883. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of Fiber Content and Surface Treatment on the Mechanical Properties of Natural Fiber Composites Produced by Rotomolding. Compos. Interfaces 2017, 24, 35–53. [Google Scholar] [CrossRef]

- Ortega, Z.; Suárez, L.; Kelly-Walley, J.; McCourt, M. Mechanical Properties of Rotomolded Parts with Abaca Fiber: Effect of Manufacturing with 1, 2 or 3 Layers. Compos. Theory Pract. 2023, 3, 158–166. [Google Scholar] [CrossRef]

- Suárez, L.; Ortega, Z.; Romero, F.; Paz, R.; Marrero, M.D. Influence of Giant Reed Fibers on Mechanical, Thermal, and Disintegration Behavior of Rotomolded PLA and PE Composites. J. Polym. Environ. 2022, 30, 4848–4862. [Google Scholar] [CrossRef]

- León, L.D.V.E.; Escocio, V.A.; Visconte, L.L.Y.; Junior, J.C.J.; Pacheco, E.B.A.V. Rotomolding and Polyethylene Composites with Rotomolded Lignocellulosic Materials: A Review. J. Reinf. Plast. Compos. 2020, 39, 459–472. [Google Scholar] [CrossRef]

- Romero, F.; Suárez, L.; Díaz, S.; Ortega, Z. Rotomolded Polypropylene—Ignimbrite Composites: Giving a Second Life to Mineral Dust Wastes. Polym. Compos. 2025, 46, 6594–6608. [Google Scholar] [CrossRef]

- Barczewski, M.; Hejna, A.; Aniśko, J.; Andrzejewski, J.; Piasecki, A.; Mysiukiewicz, O.; Bąk, M.; Gapiński, B.; Ortega, Z. Rotational Molding of Polylactide (PLA) Composites Filled with Copper Slag as a Waste Filler from Metallurgical Industry. Polym. Test. 2022, 106, 107449. [Google Scholar] [CrossRef]

- Gupta, N.; Ramkumar, P. Rheological and Thermal Investigation of Industrially Processed Glass Fiber Blended with Linear Low-Density Polyethylene for Rotational Molding Process. Trans. Indian Inst. Met. 2021, 74, 2003–2011. [Google Scholar] [CrossRef]

- Ortega, Z.; Douglas, P.; Hanna, P.R.; Kelly-Walley, J.; McCourt, M. Influence of Mold Pressurization on Cycle Time in Rotational Molding Composites with Welded Ignimbrite as Loading. Compos. Commun. 2024, 45, 101797. [Google Scholar] [CrossRef]

- Aniśko, J.; Bartczak, D.; Barczewski, M. Limitations of Short Basalt Fibers Use as an Effective Reinforcement of Polyethylene Composites in Rotational Molding Technology. Adv. Sci. Technol. Res. J. 2023, 17, 110–123. [Google Scholar] [CrossRef]

- Głogowska, K.; Pączkowski, P.; Samujło, B. Study on the Properties and Structure of Rotationally Moulded Linear Low-Density Polyethylene Filled with Quartz Flour. Materials 2022, 15, 2154. [Google Scholar] [CrossRef]

- Ghanbarpour, B.; Moslemi, A. Evaluation of Mechanical, Optical, and Antibacterial Properties of Metal—Oxide Dispersed HDPE Nanocomposites Processed by Rotational Molding. Polym. Compos. 2022, 43, 3983–3991. [Google Scholar] [CrossRef]

- Qin, L.; Ding, Y.M.; Jiao, Z.W.; Liu, Y.X.; Yang, W.M. The Research on the Heating Time of Rotational Molding. Key Eng. Mater. 2013, 561, 285–290. [Google Scholar] [CrossRef]

- Luciano, G.; Vignolo, M.; Brunengo, E.; Utzeri, R.; Stagnaro, P. Study of Microwave-Active Composite Materials to Improve the Polyethylene Rotomolding Process. Polymers 2023, 15, 1061. [Google Scholar] [CrossRef] [PubMed]

- McCourt, M.; Kearns, M.P.; Martin, P.; Butterfield, J. A Comparison between Conventional and Robotic Rotational Moulding Machines. In Proceedings of the IMC34—34th International Manufacturing Conference, Sligo, Ireland, 30–31 August 2021. [Google Scholar]

- Malnati, P. New Era for Rotomolding? Innovative Technology and Equipment Offer Superior Process Control and Produce Better Parts with Higher Repeatability and Reproducibility. Plast. Eng. 2019, 75, 10–13. [Google Scholar]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A Review on the Degradability of Polymeric Composites Based on Natural Fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Moraczewski, K.; Stepczyńska, M.; Malinowski, R.; Karasiewicz, T.; Jagodziński, B.; Rytlewski, P. The Effect of Accelerated Aging on Polylactide Containing Plant Extracts. Polymers 2019, 11, 575. [Google Scholar] [CrossRef]

- Dopico-García, M.S.; Castro-López, M.M.; López-Vilariño, J.M.; González-Rodríguez, M.V.; Valentão, P.; Andrade, P.B.; García-Garabal, S.; Abad, M.J. Natural Extracts as Potential Source of Antioxidants to Stabilize Polyolefins. J. Appl. Polym. Sci. 2011, 119, 3553–3559. [Google Scholar] [CrossRef]

- Ahmad, H.; Rostami-Tapeh-Esmaeil, E.; Rodrigue, D. The Effect of Chemical Crosslinking on the Properties of Rotomolded High Density Polyethylene. J. Appl. Polym. Sci. 2024, 141, e54744. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Jorda-Vilaplana, A.; Balart, R.; Torres-Giner, S. A Comparative Study on the Effect of Different Reactive Compatibilizers on Injection-Molded Pieces of Bio-Based High-Density Polyethylene/Polylactide Blends. J. Appl. Polym. Sci. 2019, 136, 47396. [Google Scholar] [CrossRef]

- Weizman, O.; Uziel, A.; Mead, J.; Dodiuk, H.; Ophir, A.; Kenig, S. Quantitative Analysis of UV Protective Additives in Polyethylene Films by Solvent Extraction Coupled with UV Spectrophotometry. Polym. Adv. Technol. 2022, 33, 3411–3417. [Google Scholar] [CrossRef]

- López-Martínez, E.D.; Martínez-Colunga, J.G.; Ramírez-Vargas, E.; Sanchez-Valdes, S.; Ramos-de Valle, L.F.; Benavides-Cantu, R.; Rodríguez-Gonzalez, J.A.; Mata-Padilla, J.M.; Cruz-Delgado, V.J.; Borjas-Ramos, J.J.; et al. Influence of Carbon Structures on the Properties and Photodegradation of LDPE/LLDPE Films. Polym. Adv. Technol. 2022, 33, 1727–1741. [Google Scholar] [CrossRef]

- Ahmad, H.; Rodrigue, D. Development of Lightweight and Thermally Insulative Crosslinked Polypropylene via Rotomolding. Polym. Eng. Sci. 2025, 65, 3059–3072. [Google Scholar] [CrossRef]

- Liu, C.; Mei, C.; Xu, B.; Chen, W.; Yong, C.; Wang, K.; Wu, Q. Light Stabilizers Added to the Shell of Co-Extruded Wood/High-Density Polyethylene Composites to Improve Mechanical and Anti-UV Ageing Properties. R. Soc. Open Sci. 2018, 5, 180074. [Google Scholar] [CrossRef] [PubMed]

- Barczewski, M.; Aniśko-Michalak, J.; Skórczewska, K.; Maniak, M.; Kosmela, P.; Żukowska, W.; Przybylska-Balcerek, A.; Szwajkowska-Michałek, L.; Stuper-Szablewska, K.; Waliszewska, B.; et al. Correlation between Rotational Molding Process Temperature and Degradation Changes of Polyethylene and Composites Containing Coffee Spent Grains Used as an Active Filler. Sustain. Mater. Technol. 2025, 46, e01652. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O. Comparative Analysis of the Coffee and Cocoa Industry By-Products on the Performance of Polyethylene-Based Composites. Waste Biomass Valorization 2023, 14, 2691–2706. [Google Scholar] [CrossRef]

- Aniśko, J.; Barczewski, M. Uniaxial Rotational Molding of Bio-Based Low-Density Polyethylene Filled with Black Tea Waste. Materials 2023, 16, 3641. [Google Scholar] [CrossRef]

- Barczewski, M.; Aniśko, J.; Suárez, L.; Skórczewska, K.; Rackov, M.; Ortega, Z.; Hejna, A. Using the Potential of Canadian Goldenrod (Solidago Canadensis) as a Functional Filler with Antioxidant Activity of Low-Density Polyethylene Composites as an Example of Sustainable Development of an Invasive Plant. Ind. Crops Prod. 2024, 222, 119509. [Google Scholar] [CrossRef]

- Suárez, L.; Ortega, Z.; Barczewski, M.; Cunningham, E. Use of Giant Reed (Arundo donax L.) for Polymer Composites Obtaining: A Mapping Review. Cellulose 2023, 30, 4793–4812. [Google Scholar] [CrossRef]

- Díaz, S.; Romero, F.; Suárez, L.; Tcharkhtchi, A.; Ortega, Z. A Preliminary Study on the Use of Microalgae Biomass as a Polyolefin Stabilizer. Iran. Polym. J. (Engl. Ed.) 2025. [Google Scholar] [CrossRef]

- Mahzan, S.; Fitri, M.; Zaleha, M. UV Radiation Effect towards Mechanical Properties of Natural Fibre Reinforced Composite Material: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 165, 012021. [Google Scholar] [CrossRef]

- Nasri, K.; Toubal, L.; Loranger, É.; Koffi, D. Influence of UV Irradiation on Mechanical Properties and Drop-Weight Impact Performance of Polypropylene Biocomposites Reinforced with Short Flax and Pine Fibers. Compos. Part C Open Access 2022, 9, 100296. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, R.; Cao, J. Characterization of Surface Chemistry and Crystallization Behavior of Polypropylene Composites Reinforced with Wood Flour, Cellulose, and Lignin during Accelerated Weathering. Appl. Surf. Sci. 2015, 332, 253–259. [Google Scholar] [CrossRef]

- Charoensri, K.; Shin, Y.J.; Park, H.J. Innovative HDPE Composites Enriched with UV Stabilizer and Diatomaceous Earth/Zinc Oxide for Enhanced Seafood Packaging and Antimicrobial Properties. Polymers 2023, 15, 4577. [Google Scholar] [CrossRef] [PubMed]

- Christmann, J.; Gardette, J.-L.; Pichon, G.; Bouchut, B.; Therias, S. Photostabilization of Polyethylene by a Hindered Amine Light Stabilizer in Blooming Conditions and Impact of MDO Processing. Polym. Degrad. Stab. 2021, 191, 109683. [Google Scholar] [CrossRef]

- Takacs, K.; Tatraaljai, D.; Pregi, E.; Huszthy, P.; Pukanszky, B. Synthesis and Evaluation of a Novel Natural-Based Phosphine Antioxidant for the Thermal Stabilization of Polyethylene. J. Therm. Anal. Calorim. 2022, 147, 12513–12522. [Google Scholar] [CrossRef]

- Lee, S.J.; Lee, Y.J.; Lee, J.Y.; Yun, Y.S.; Kwon, T.K.; Jung, I. Development of Biocompatible Mesoporous Silica Materials for Enhanced UV Protection. Bull. Korean Chem. Soc. 2025, 46, 138–144. [Google Scholar] [CrossRef]

- Nizamov, R.; Poskela, A.; Kaschuk, J.; Henn, K.A.; Grande, R.; Granroth, S.; Nyberg, M.; Esmaeilzadeh, M.; Vapaavuori, J.; Österberg, M.; et al. Sustainable Nanocellulose UV Filters for Photovoltaic Applications: Comparison of Red Onion (Allium cepa) Extract, Iron Ions, and Colloidal Lignin. ACS Appl. Opt. Mater. 2025, 3, 664–675. [Google Scholar] [CrossRef]

- Suárez, L.; Barczewski, M.; Kosmela, P.; Marrero, M.D.; Ortega, Z. Giant Reed (Arundo donax L.) Fiber Extraction and Characterization for Its Use in Polymer Composites. J. Nat. Fibers 2023, 20, 2131687. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Accelerated Weathering of Unbleached and Bleached Kraft Wood Fibre Reinforced Polypropylene Composites. Polym. Degrad. Stab. 2008, 93, 1939–1946. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on Durability of Sustainable Biobased Composites: A Review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef] [PubMed]

- Almond, J.; Sugumaar, P.; Wenzel, M.N.; Hill, G.; Wallis, C. Determination of the Carbonyl Index of Polyethylene and Polypropylene Using Specified Area under Band Methodology with ATR-FTIR Spectroscopy. e-Polymers 2020, 20, 369–381. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A.; Forleo, S. Rotational Molding of Bio-Polymers. AIP Conf. Proc. 2014, 1593, 333–337. [Google Scholar] [CrossRef]

- Bellehumeur, C.T.; Bisaria, M.K.; Vlachopoulos, J. An Experimental Study and Model Assessment of Polymer Sintering. Polym. Eng. Sci. 1996, 36, 2198–2207. [Google Scholar] [CrossRef]

- Ortega, Z.; Suárez, L.; Kelly-Walley, J.; Hanna, P.R.; McCourt, M.; Millar, B. Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites. J. Compos. Sci. 2024, 8, 17. [Google Scholar] [CrossRef]

- Yoon, S.W.; Lee, S.; Choi, I.S.; Do, Y.; Park, S. Electrical and Mechanical Properties of Polyethylene/MWCNT Composites Produced by Polymerization Using Cp2ZrCl2 Supported on MWCNTs. Macromol. Res. 2015, 23, 713–718. [Google Scholar] [CrossRef]

- Pandey, A.K.; Singh, K.; Kar, K.K. Thermo-Mechanical Properties of Graphite-Reinforced High-Density Polyethylene Composites and Its Structure–Property Corelationship. J. Compos. Mater. 2017, 51, 1769–1782. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Andrzejewski, J.; Piasecki, A.; Strzemięcka, B.; Adamek, G. The Inhibiting Effect of Basalt Powder on Crystallization Behavior and the Structure-Property Relationship of α-Nucleated Polypropylene Composites. Polym. Test. 2021, 103, 107372. [Google Scholar] [CrossRef]

- Jabarin, S.A.; Lofgren, E.A. Photooxidative Effects on Properties and Structure of High—Density Polyethylene. J. Appl. Polym. Sci. 1994, 53, 411–423. [Google Scholar] [CrossRef]

- Hsueh, H.-C.; Kim, J.H.; Orski, S.; Fairbrother, A.; Jacobs, D.; Perry, L.; Hunston, D.; White, C.; Sung, L. Micro and Macroscopic Mechanical Behaviors of High-Density Polyethylene under UV Irradiation and Temperature. Polym. Degrad. Stab. 2020, 174, 109098. [Google Scholar] [CrossRef]

- Hiss, R.; Hobeika, S.; Lynn, C.; Strobl, G. Network Stretching, Slip Processes, and Fragmentation of Crystallites during Uniaxial Drawing of Polyethylene and Related Copolymers. A Comparative Study. Macromolecules 1999, 32, 4390–4403. [Google Scholar] [CrossRef]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Degradation Profile of Polyethylene after Artificial Accelerated Weathering. Polym. Degrad. Stab. 2003, 79, 385–397. [Google Scholar] [CrossRef]

- Suárez, L.; Hanna, P.R.; Ortega, Z.; Barczewski, M.; Kosmela, P.; Millar, B.; Cunningham, E. Influence of Giant Reed (Arundo donax L.) Culms Processing Procedure on Physicochemical, Rheological, and Thermomechanical Properties of Polyethylene Composites. J. Nat. Fibers 2024, 21, 2296909. [Google Scholar] [CrossRef]

- Russo, P.; Acierno, D.; Marinucci, L.; Greco, A.; Frigione, M. Influence of Natural and Accelerated Weathering on Performances of Photoselective Greenhouse Films. J. Appl. Polym. Sci. 2013, 127, 2213–2219. [Google Scholar] [CrossRef]

- Celina, M.C.; Linde, E.; Martinez, E. Carbonyl Identification and Quantification Uncertainties for Oxidative Polymer Degradation. Polym. Degrad. Stab. 2021, 188, 109550. [Google Scholar] [CrossRef]

- Patwary, F.; Mittal, V. Degradable Polyethylene Nanocomposites with Silica, Silicate and Thermally Reduced Graphene Using Oxo-Degradable Pro-Oxidant. Heliyon 2015, 1, e00050. [Google Scholar] [CrossRef]

- de Morais, F.L.D.; Medeiros, F.d.S.; Silva, G.G.; Rabello, M.S.; de Sousa, A.R. Photodegradation of UHMWPE Filled with Iron Ore Fine. Mater. Res. 2017, 20, 356–364. [Google Scholar] [CrossRef]

- Van Nguyen, K.; Nguyen, T.T.; Nguyen, D.T.; Pham, H.T.T. Effect of CaCO3 Filler on the Degradation of High Density Polyethylene (HDPE) Film Containing Prooxidants. Vietnam. J. Sci. Technol. 2018, 56, 79. [Google Scholar] [CrossRef]

- Redhwi, H.H.; Siddiqui, M.N.; Andrady, A.L.; Syed, H. Durability of LDPE Nanocomposites with Clay, Silica, and Zinc Oxide II. Weatherability of the Nanocomposites. Polym. Compos. 2013, 34, 1878–1883. [Google Scholar] [CrossRef]

| Short Name | PE | Ignimbrite | Giant Reed |

|---|---|---|---|

| PE | 100 | - | - |

| PE.5A | 95 | - | 5 |

| PE.10A | 90 | - | 10 |

| PE.5I | 95 | 5 | - |

| PE.10I | 90 | 10 | - |

| PE.5H | 95 | 2.5 | 2.5 |

| PE.10H | 90 | 5 | 5 |

| Cycle | Oven Time | Cooling Time | Total Cycle Time | |||

|---|---|---|---|---|---|---|

| (min) | Variation (%) | (min) | Variation (%) | (min) | Variation (%) | |

| PE | 10.7 | -- | 27.6 | -- | 38.3 | -- |

| PE.5A | 11.6 | 8.4 | 27.5 | −0.4 | 39.1 | 2.1 |

| PE.10A | 12.8 | 19.6 | 27.9 | 1.1 | 40.7 | 6.3 |

| PE.5I | 10.5 | −1.9 | 27.0 | −2.2 | 37.5 | −2.1 |

| PE.10I | 9.7 | −9.3 | 26.5 | −4.0 | 36.2 | −5.5 |

| PE.5H | 11.1 | 3.7 | 27.7 | 0.4 | 38.8 | 1.3 |

| PE.10H | 12.0 | 12.1 | 27.3 | −1.1 | 39.3 | 2.6 |

| Samples Series | Modulus | Tensile Strength | Elongation at Break |

|---|---|---|---|

| PE | 0.536 | 0.150 | 0.997 |

| PE.5A | 0.279 | 0.138 | 0.089 |

| PE.10A | 0.081 | 0.907 | 0.215 |

| PE.5I | 0.596 | 0.098 | 0.001 |

| PE.10I | 0.161 | 0.968 | 0.006 |

| PE.5H | 0.077 | 0.036 | 0.135 |

| PE.10H | 0.061 | 0.046 | 0.559 |

| Material | Exposure Time (h) | CI (Area) | CI (Heights) |

|---|---|---|---|

| PE | 0 | 0.090 ± 0.010 | 0.030 ± 0.001 |

| 100 | 0.145 ± 0.036 | 0.059 ± 0.013 | |

| 200 | 0.189 ± 0.040 | 0.078 ± 0.021 | |

| 300 | 0.160 ± 0.016 | 0.066 ± 0.014 | |

| 400 | 0.243 ± 0.029 | 0.101 ± 0.011 | |

| 500 | 0.222 ± 0.006 | 0.080 ± 0.015 | |

| PE.5A | 0 | 0.099 ± 0.023 | 0.039 ± 0.006 |

| 100 | 0.119 ± 0.033 | 0.042 ± 0.009 | |

| 200 | 0.132 ± 0.020 | 0.051 ± 0.008 | |

| 300 | 0.133 ± 0.046 | 0.053 ± 0.014 | |

| 400 | 0.219 ± 0.034 | 0.088 ± 0.012 | |

| 500 | 0.220 ± 0.018 | 0.086 ± 0.003 | |

| PE.10A | 0 | 0.116 ± 0.000 | 0.045 ± 0.000 |

| 100 | 0.136 ± 0.008 | 0.053 ± 0.005 | |

| 200 | 0.123 ± 0.019 | 0.046 ± 0.011 | |

| 300 | 0.146 ± 0.011 | 0.072 ± 0.013 | |

| 400 | 0.209 ± 0.040 | 0.077 ± 0.010 | |

| 500 | 0.208 ± 0.004 | 0.076 ± 0.000 | |

| PE.5I | 0 | 0.120 ± 0.003 | 0.046 ± 0.001 |

| 100 | 0.136 ± 0.007 | 0.047 ± 0.002 | |

| 200 | 0.199 ± 0.015 | 0.077 ± 0.005 | |

| 300 | 0.182 ± 0.016 | 0.067 ± 0.006 | |

| 400 | 0.235 ± 0.001 | 0.090 ± 0.000 | |

| 500 | 0.231 ± 0.001 | 0.094 ± 0.001 | |

| PE.10I | 0 | 0.170 ± 0.013 | 0.056 ± 0.005 |

| 100 | 0.295 ± 0.029 | 0.123 ± 0.008 | |

| 200 | 0.307 ± 0.021 | 0.122 ± 0.005 | |

| 300 | 0.359 ± 0.031 | 0.145 ± 0.003 | |

| 400 | 0.378 ± 0.025 | 0.149 ± 0.003 | |

| 500 | 0.445 ± 0.003 | 0.172 ± 0.007 | |

| PE.5H | 0 | 0.358 ± 0.013 | 0.158 ± 0.010 |

| 100 | 0.339 ± 0.016 | 0.143 ± 0.001 | |

| 200 | 0.323 ± 0.013 | 0.127 ± 0.006 | |

| 300 | 0.366 ± 0.022 | 0.141 ± 0.016 | |

| 400 | 0.347 ± 0.001 | 0.127 ± 0.005 | |

| 500 | 0.364 ± 0.018 | 0.138 ± 0.013 | |

| PE.10H | 0 | 0.416 ± 0.050 | 0.195 ± 0.027 |

| 100 | 0.313 ± 0.010 | 0.119 ± 0.006 | |

| 200 | 0.318 ± 0.002 | 0.130 ± 0.005 | |

| 300 | 0.388 ± 0.013 | 0.149 ± 0.011 | |

| 400 | 0.374 ± 0.012 | 0.138 ± 0.002 | |

| 500 | 0.445 ± 0.023 | 0.159 ± 0.009 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero, F.; Kelly-Walley, J.; McCourt, M.; Suárez, L.; Ortega, Z. The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination. Materials 2025, 18, 4723. https://doi.org/10.3390/ma18204723

Romero F, Kelly-Walley J, McCourt M, Suárez L, Ortega Z. The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination. Materials. 2025; 18(20):4723. https://doi.org/10.3390/ma18204723

Chicago/Turabian StyleRomero, Francisco, Jake Kelly-Walley, Mark McCourt, Luis Suárez, and Zaida Ortega. 2025. "The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination" Materials 18, no. 20: 4723. https://doi.org/10.3390/ma18204723

APA StyleRomero, F., Kelly-Walley, J., McCourt, M., Suárez, L., & Ortega, Z. (2025). The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination. Materials, 18(20), 4723. https://doi.org/10.3390/ma18204723