Synergistic Effects of High-Modulus Additives on SBS-Modified Asphalt: Microstructural, Rheological Enhancement, and Dosage-Dependent Performance Optimization

Abstract

1. Introduction

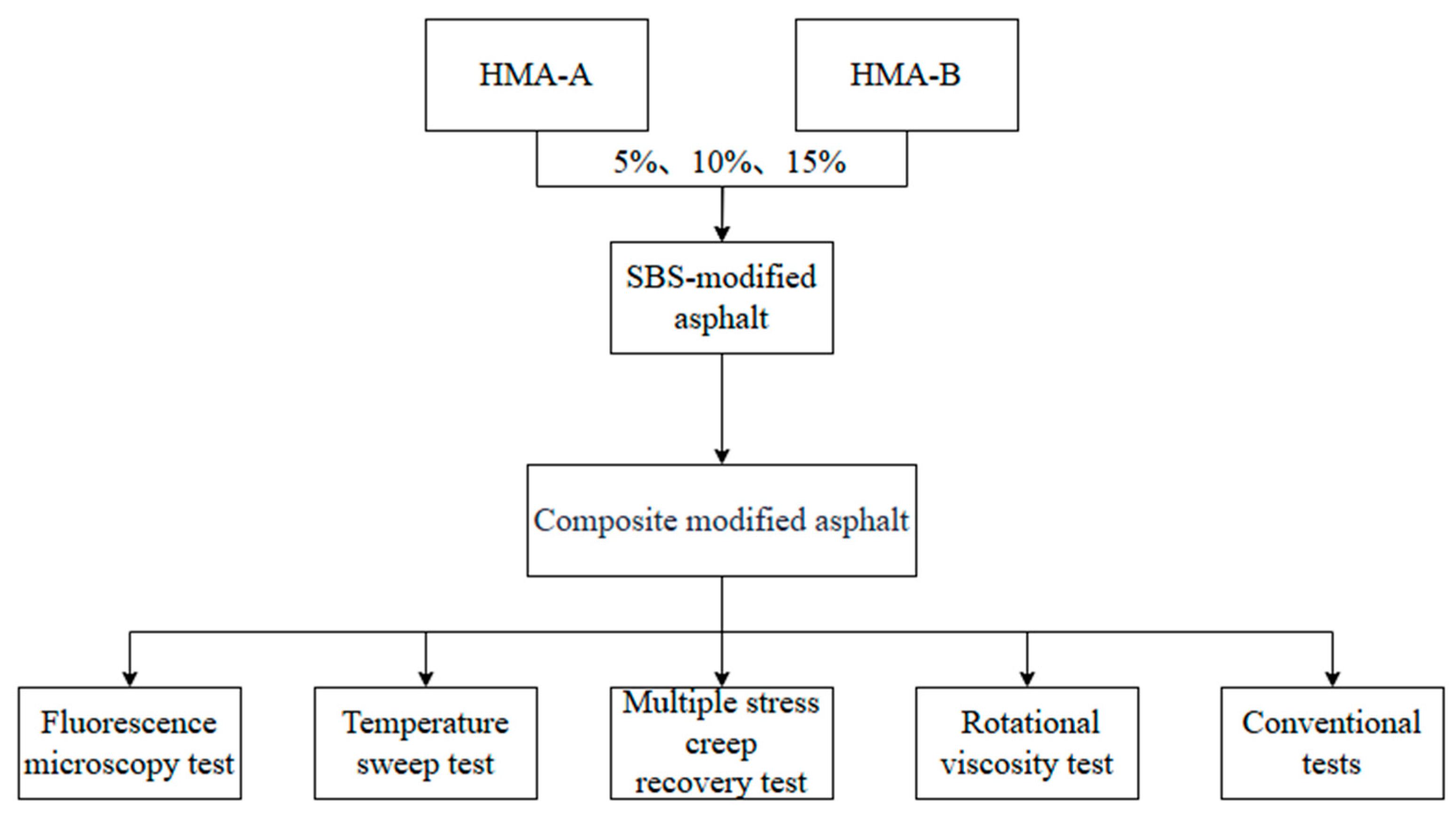

2. Materials and Methods

2.1. Material

2.2. Test Methods

2.2.1. Fluorescence Microscopy Test

2.2.2. Temperature Sweep (TS) Test

2.2.3. Multiple Stress Creep Recovery (MSCR) Test

2.2.4. Rotational Viscosity (RV) Test

2.2.5. Conventional Tests

3. Results

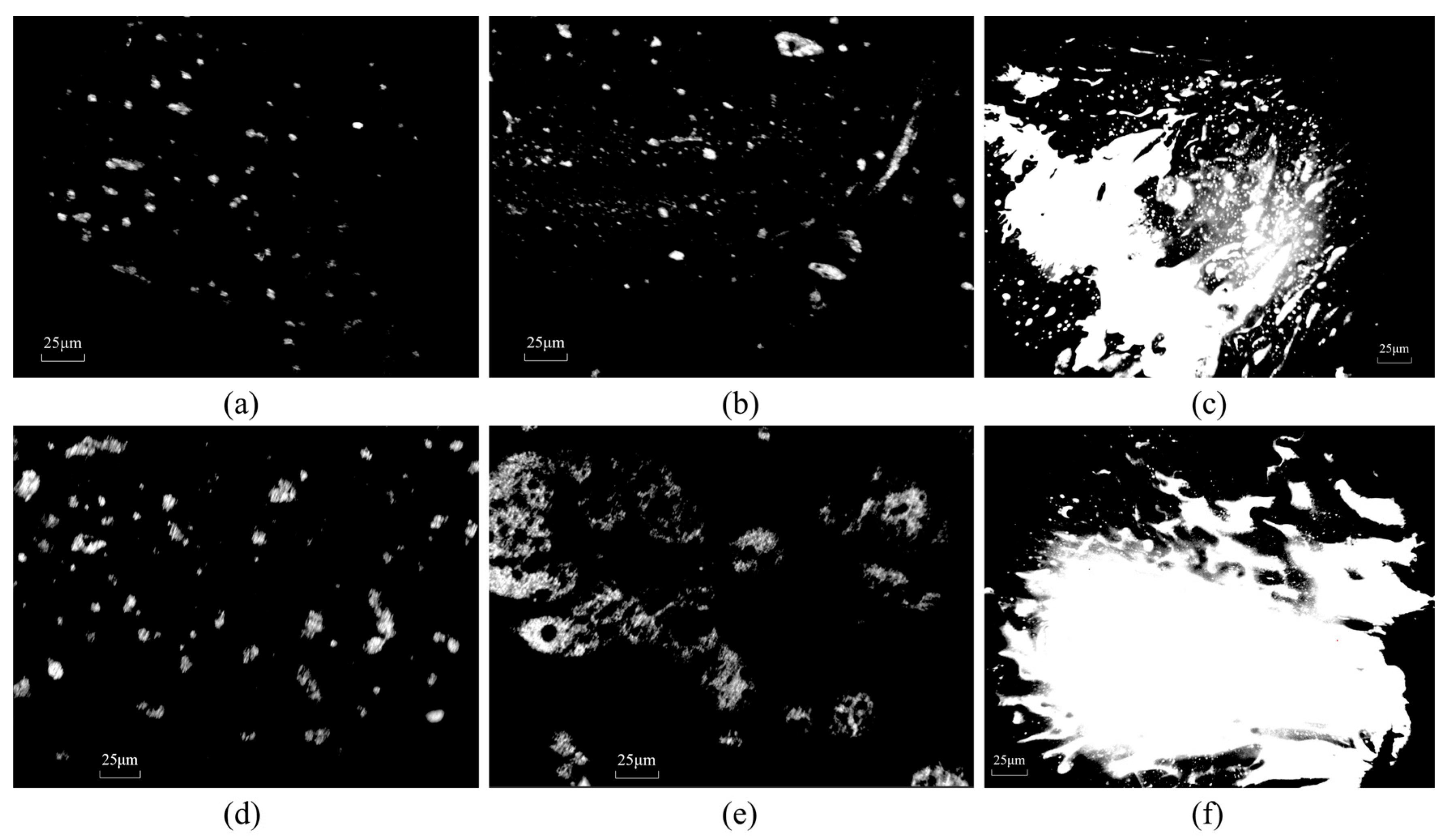

3.1. Fluorescence Microscopy Test

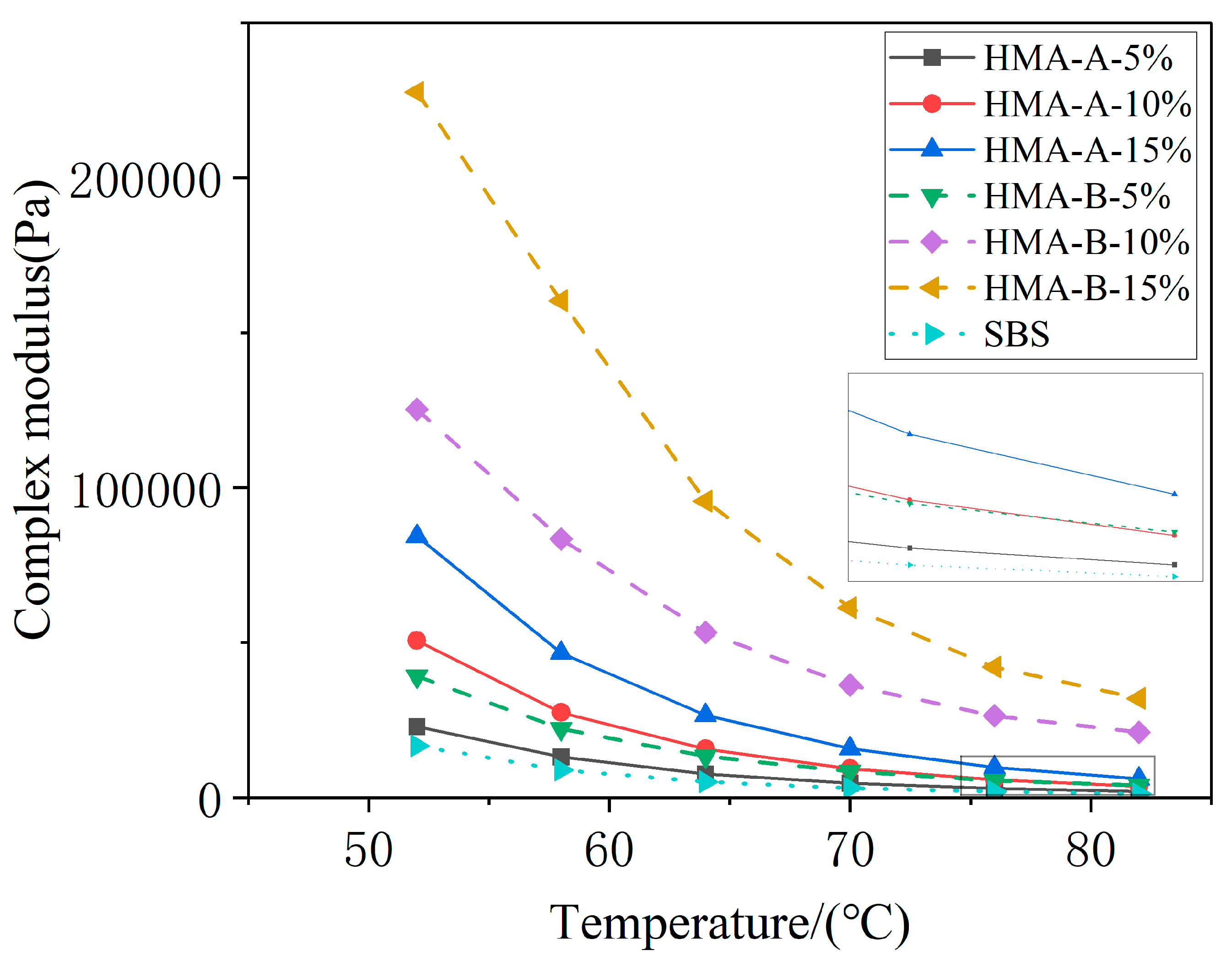

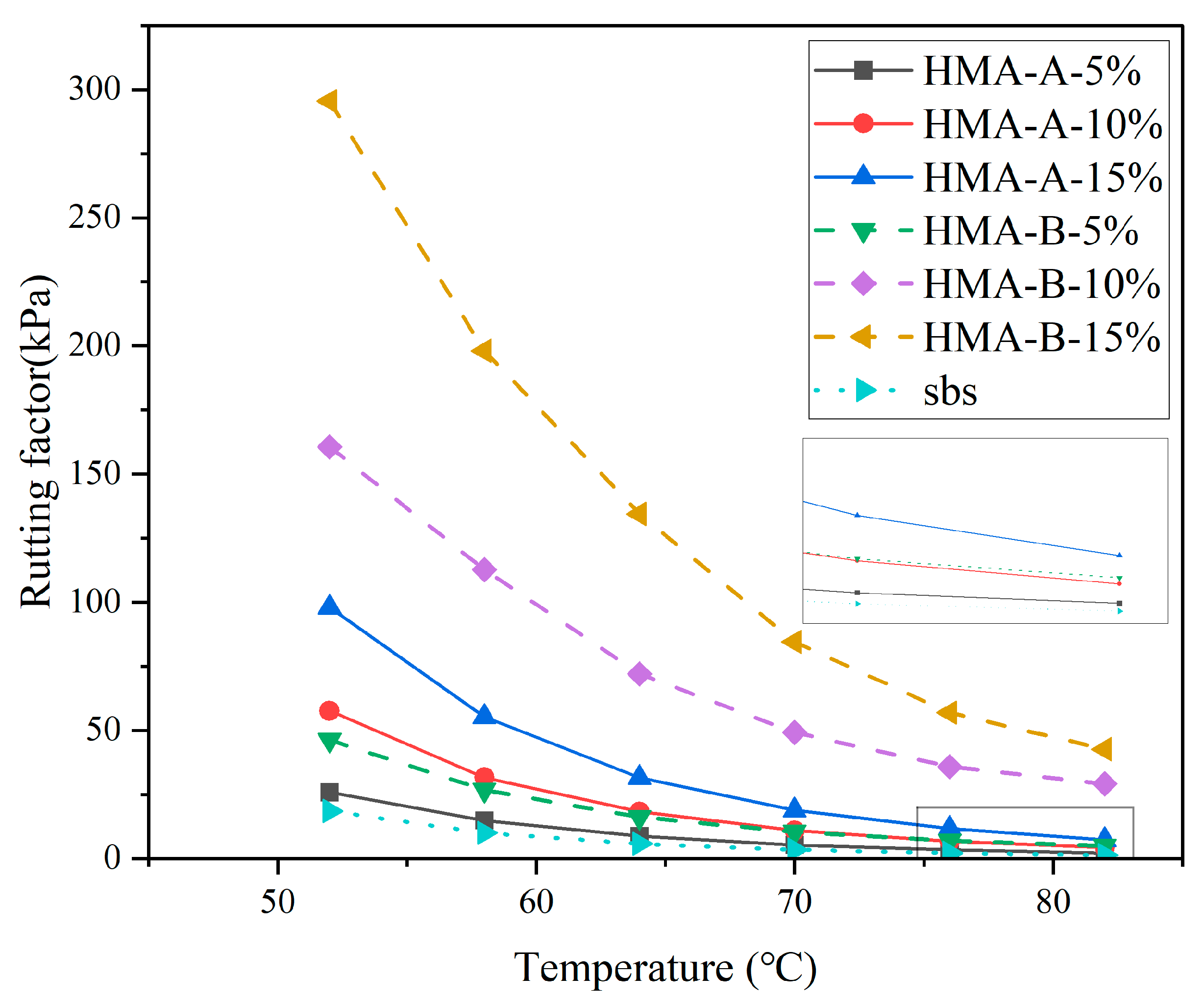

3.2. Temperature Sweep Test

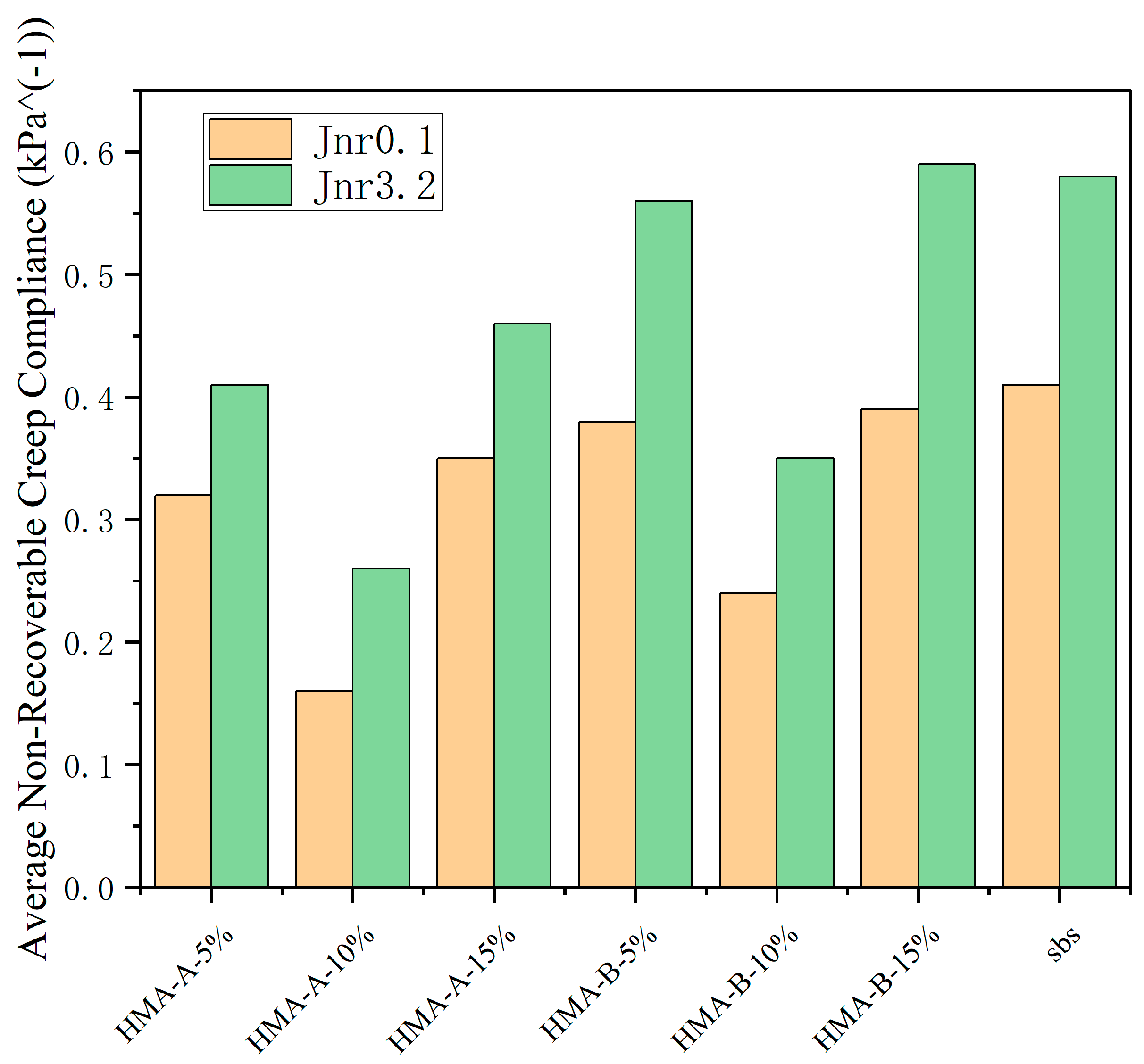

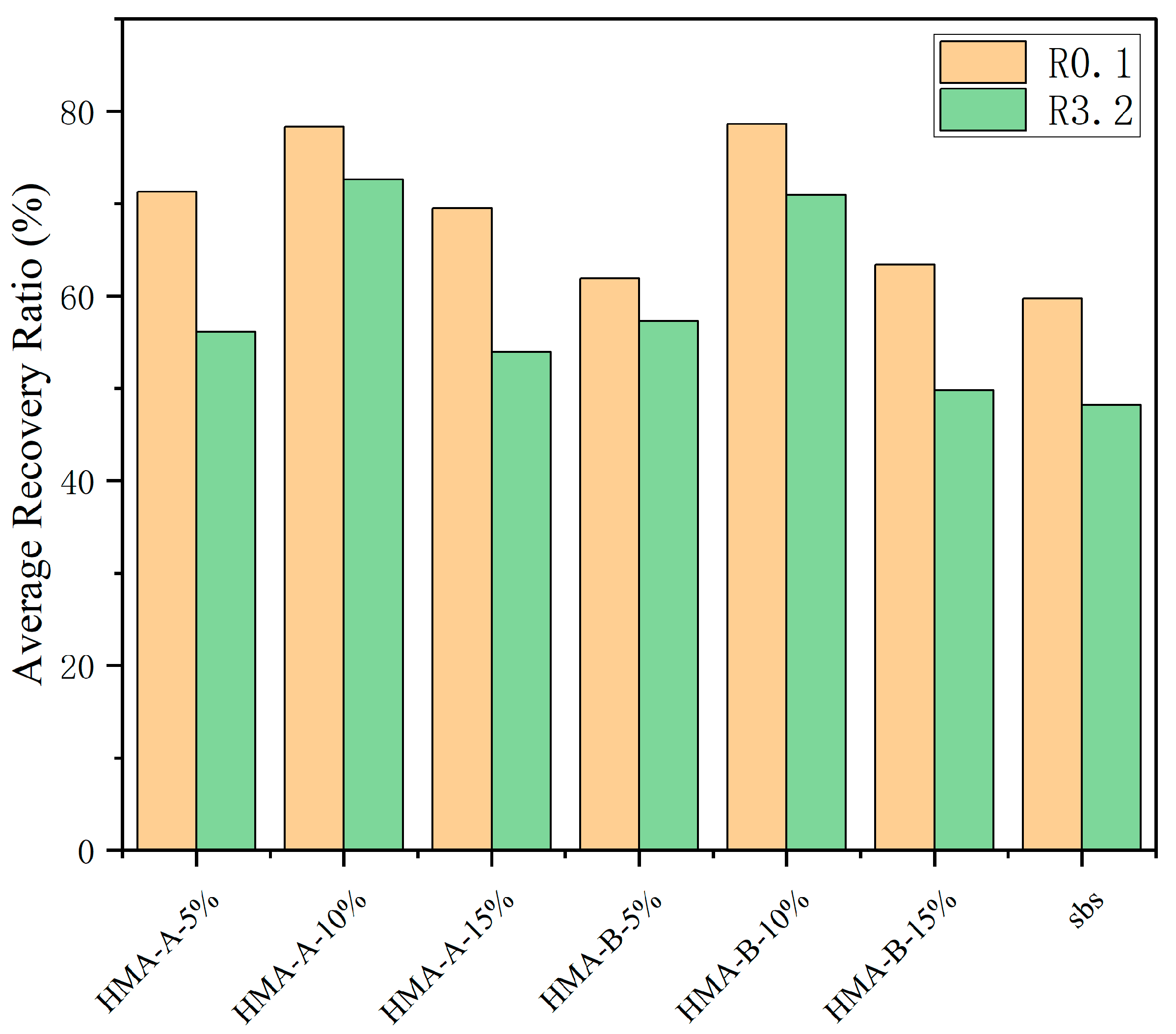

3.3. Multiple Stress Creep Recovery (MSCR) Test

- Increased Average Recovery (R%). The addition of HMAs resulted in a substantial increase in the average percent recovery compared to the control SBS-modified asphalt (Figure 6). This indicates an enhancement in the elastic response and stress recovery capacity of the composite binders.

- Reduced Non-Recoverable Creep Compliance. Concurrently, the average non-recoverable creep decreased markedly upon HMA modification (Figure 5). Lower Jnr values signify a greater resistance to permanent, viscous deformation under load.

- Optimum Dosage at 10%. For both HMA-A and HMA-B, the optimal improvement in MSCR parameters manifested as the highest R%.

- Performance Decline Beyond Optimum Dosage. Notably, when the HMA dosage exceeded 10%, a subsequent decline in performance was observed for both modifiers. The average percent recovery (R%) decreased, and the non-recoverable creep increased compared to their respective values at the 10% dosage level.

- These MSCR results collectively demonstrate that the HMAs effectively enhance the high-temperature elastic recovery and reduce the permanent deformation susceptibility of SBS-modified asphalt. The existence of a clear performance optimum at 10% dosage suggests potential saturation or detrimental microstructural changes occurring at higher additive concentrations.

- A performance reversal was observed when the HMA content exceeded 10%. This phenomenon may be attributed to the limited compatibility between the asphalt matrix and the modifier. Beyond this critical dosage, excessive modifiers could no longer be uniformly dispersed within the asphalt. Instead, the particles tended to agglomerate, forming large-scale domains rather than a continuous network. These macroscopic, rigid aggregates create weak interfacial zones with the surrounding softer asphalt matrix. Under mechanical loading, stress concentrations readily develop at these interfaces, leading to interfacial debonding or microcrack initiation. Once interfacial failure occurs, these aggregates act as internal defects, thereby accelerating material damage and promoting irreversible deformation. The elevated non-recoverable creep observed in SBS-modified asphalt may also be attributed to this mechanism.

3.4. Rotational Viscosity (RV) Test

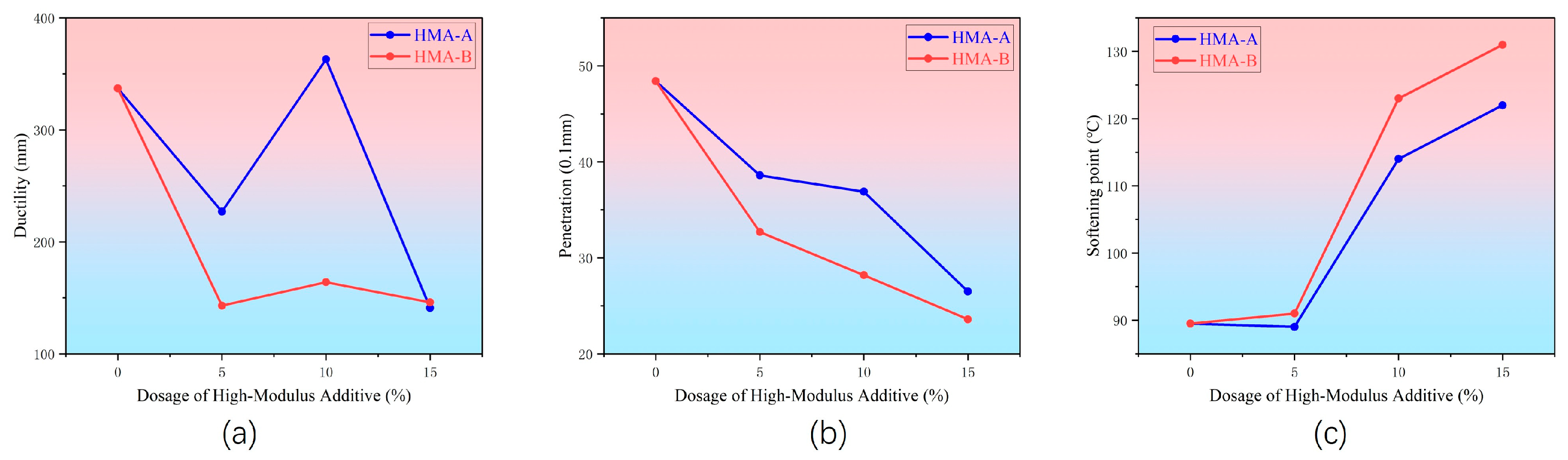

3.5. Conventional Tests

4. Discussion

- Microstructural

- 2.

- Performance Enhancement and Trade-offs

- 3.

- Existence of an Optimal Dosage Threshold

- 4.

- Differential Effects of Additive Type

- 5.

- Engineering Application Recommendations

- 6.

- Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Wei, J.C.; Wu, W.J.; Zhang, X.M.; Xu, X.Z.; Yan, X.P. Technical development and long-term performance observations of long-life asphalt pavement: A case study of Shandong Province. J. Road Eng. 2022, 2, 369–389. [Google Scholar] [CrossRef]

- Li, Q.; Yang, H.; Ni, F.; Ma, X.; Luo, L. Cause analysis on permanent deformation for asphalt pavements using field cores. Constr. Build. Mater. 2015, 100, 40–51. [Google Scholar] [CrossRef]

- Hao, Y.; Ye, Y.; Zhuang, C.; Hou, F. Research on High-Temperature Evaluation Indexes and Performance of Qingchuan Rock-SBS Composite Modified Asphalt. Materials 2022, 15, 7455. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Tian, T.; Jiang, Y.; Yi, Y.; Nie, C. The splitting fatigue properties of ultra-large particle size asphalt mixture under the coupling effect of temperature and load. Eng. Fract. Mech. 2025, 319, 110990. [Google Scholar] [CrossRef]

- Mu, Y.; Fu, Z.; Liu, J.; Li, C.; Dong, W.; Dai, J. Evaluation of High-Temperature Performance of Asphalt Mixtures Based on Climatic Conditions. Coatings 2020, 10, 535. [Google Scholar] [CrossRef]

- Xu, S.; Ruan, P.; Lu, Z.; Liang, L.; Han, B.; Hong, B. Effects of the high temperature and heavy load on the rutting resistance of cold-mix emulsified asphalt mixture. Constr. Build. Mater. 2021, 298, 123831. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Yang, W.; Zhong, X.; Liang, S.; Tang, Z.; Quan, W. Influence of temperature and humidity coupling on rutting deformation of asphalt pavement. Sci. Eng. Compos. Mater. 2023, 30, 20220232. [Google Scholar] [CrossRef]

- Shang, K.; Wan, C.; Guo, M.; Zhou, C.; Jiang, Y.; Ren, J. Temperature-Dependent Model of Rutting Behavior for Connected Layer Mixtures in Flexible Base Asphalt Pavement. Materials 2025, 18, 808. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.-s.; Chen, Y.-l.; Li, X.-l. Rutting in Asphalt Pavement under Heavy Load and High Temperature. In Asphalt Material Characterization, Accelerated Testing, and Highway Management, Proceedings of the GeoHunan International Conference, Changsha, China, 3–6 August 2009; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 39–48. [Google Scholar]

- Li, N.; Zhan, H.; Yu, X.; Tang, W.; Yu, H.; Dong, F. Research on the high temperature performance of asphalt pavement based on field cores with different rutting development levels. Mater. Struct. 2021, 54, 70. [Google Scholar] [CrossRef]

- Fares, A.; Wong, M.-N.; Zayed, T.; Faris, N. Impact of Rutting on Traffic Safety: A Synthesis of Research Findings. Appl. Sci. 2025, 15, 253. [Google Scholar] [CrossRef]

- Fares, A.; Zayed, T.; Abdelkhalek, S.; Faris, N.; Muddassir, M. Rutting measurement in asphalt pavements. Autom. Constr. 2024, 161, 105358. [Google Scholar] [CrossRef]

- Rahman, M.A.; Ghabchi, R.; Zaman, M.; Ali, S.A. Rutting and moisture-induced damage potential of foamed warm mix asphalt (WMA) containing RAP. Innov. Infrastruct. Solut. 2021, 6, 158. [Google Scholar] [CrossRef]

- Luo, L.; Yang, S.-H.; Oeser, M.; Liu, P. Moisture damage mechanism of asphalt mixtures containing reclaimed asphalt pavement binder: A novel molecular dynamics study. J. Clean. Prod. 2024, 475, 143711. [Google Scholar] [CrossRef]

- Neupane, P.; Wu, S. A comprehensive review of moisture damage in asphalt mixtures: Mechanisms, evaluation methods, and mitigation strategies. Constr. Build. Mater. 2025, 471, 140740. [Google Scholar] [CrossRef]

- Figliozzi, M.; Johnson, P.; Monsere, C.; Nordback, K. Methodology to Characterize Ideal Short-Term Counting Conditions and Improve AADT Estimation Accuracy Using a Regression-Based Correcting Function. J. Transp. Eng. 2014, 140, 04014014. [Google Scholar] [CrossRef]

- Lee, J.; Guan, H.; Loo, Y.-C.; Blumenstein, M. Development of a Long-Term Bridge Element Performance Model Using Elman Neural Networks. J. Infrastruct. Syst. 2014, 20, 04014013. [Google Scholar] [CrossRef]

- Lu, Q.; Sha, A.; Jiang, W.; Jiao, W.; Chen, Y.; Feng, Z.; Wang, S.; Li, Z. Cooling water-retentive semi-flexible pavement with light-colored grout and recycled materials. Constr. Build. Mater. 2025, 460, 139854. [Google Scholar] [CrossRef]

- Li, X.; Sha, A.; Jiao, W.; Cao, Y.; Song, R. Strain response and creep behavior of asphalt mixture based on multi-damage fractional visco-elasto-plastic constitutive model. Constr. Build. Mater. 2025, 472, 140834. [Google Scholar] [CrossRef]

- Fu, Z.; Song, R.M.; Qin, W.; Shi, K.; Ma, F.; Li, J.R.; Li, C. Investigation on the low temperature rheological properties of polymer modified asphalt. J. Traffic Transp. Eng.-Engl. Ed. 2025, 12, 319–330. [Google Scholar] [CrossRef]

- Chen, Y.J.; Sha, A.M.; Jiang, W.; Lu, Q.; Du, P.D.; Hu, K.; Li, C. Eco-friendly bismuth vanadate/iron oxide yellow composite heat-reflective coating for sustainable pavement: Urban heat island mitigation. Constr. Build. Mater. 2025, 470, 140645. [Google Scholar] [CrossRef]

- Chen, Y.; Sha, A.; Cao, Y.; Lu, Q.; Li, C.; Hu, K.; Li, Z. Iron-chromium based high infrared reflectance coating for cooling asphalt pavements towards low-carbon cities. Constr. Build. Mater. 2025, 484, 141611. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Sha, A.M.; Jiao, W.X.; Shi, K.; Ren, X.Y.; Du, P.D.; Li, X.Z. Investigation on the self-healing performance of asphalt binder under the coupling effect of multiple factors. Constr. Build. Mater. 2025, 491, 142701. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, J.Q.; Sun, Y.X.; Benny, C.M.; Wang, D.; Falchetto, A.C. Effect analysis of using tall oil pitch (TOP) to partially extend bitumen in asphalt pavements: Comparison of different TOPs. Road Mater. Pavement Des. 2025, 26, 361–380. [Google Scholar] [CrossRef]

- Raeis-Hosseini, N.; Rho, J. Metasurfaces Based on Phase-Change Material as a Reconfigurable Platform for Multifunctional Devices. Materials 2017, 10, 1046. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.X.; Song, Z.Z.; Kanungo, D.P.; Wang, Y.; Bu, F.; Chen, Z.H.; Shi, X. Stabilization of sand using different types of short fibers and organic polymer. Constr. Build. Mater. 2020, 253, 119164. [Google Scholar] [CrossRef]

- Baldovino, J.D.A.; Izzo, R.L.D.; da Silva, E.R.; Rose, J.L. Sustainable Use of Recycled-Glass Powder in Soil Stabilization. J. Mater. Civ. Eng. 2020, 32, 04020080. [Google Scholar] [CrossRef]

- Fu, Y.X.; Soldera, M.; Wang, W.; Voisiat, B.; Lasagni, A.F. Picosecond Laser Interference Patterning of Periodical Micro-Architectures on Metallic Molds for Hot Embossing. Materials 2019, 12, 3409. [Google Scholar] [CrossRef]

- Qi, X.Q.; Zhang, S.L.; Wang, T.T.; Guo, S.Y.; Ren, R. Effect of High-Dispersible Graphene on the Strength and Durability of Cement Mortars. Materials 2021, 14, 915. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Zhang, J.Y.; Wang, R.; Monti, G.; Xiao, Y. Design Embedment Strength of Plybamboo Panels Used for GluBam. J. Mater. Civ. Eng. 2020, 32, 04020082. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, Y.; Li, G.; Liu, C.; SiMa, X.; Liu, C.; Si, B.; He, Y.; Shao, J. Study on the composition and properties of EME-SBS-Nano ZnO high modulus asphalt material. Sci. Rep. 2024, 14, 23826. [Google Scholar] [CrossRef]

- Khan, I.; Bilal, M.; Khaliq, W.; Khan, N.; Khahro, S.H.; Memon, Z.A.; Malik, M.A. Evaluating the dynamic response and phase angle behavior of SBS-modified asphalt mixtures for enhanced pavement performance. Sci. Rep. 2024, 14, 29480. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Xing, C.; Zhu, B.; Zhang, X.; Gao, Y.; Tang, S.; Cheng, H. Comparative analysis of four styrene-butadiene-styrene (SBS) structure repair agents in the rejuvenation of aged SBS-modified bitumen. Constr. Build. Mater. 2025, 476, 141232. [Google Scholar] [CrossRef]

- Xu, X.; Lu, G.; Yang, J.; Liu, X. Mechanism and Rheological Properties of High-Modulus Asphalt. Adv. Mater. Sci. Eng. 2020, 2020, 8795429. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, S.; Pei, Z.; Zhan, S.; Lin, S.; Ma, K.; Lei, J.; Yi, J. Study of the Properties and Modification Mechanism of SBS-Modified Asphalt by Dry Process. Materials 2024, 17, 1454. [Google Scholar] [CrossRef]

- Wang, L.; Liang, F.; Li, Z.; Zhao, Q. Investigation on the Rheological Properties and Microscopic Characteristics of Graphene and SBR Composite Modified Asphalt. Coatings 2023, 13, 1279. [Google Scholar] [CrossRef]

- Han, D.; Hu, G.; Zhang, J. Study on Anti-Aging Performance Enhancement of Polymer Modified Asphalt with High Linear SBS Content. Polymers 2023, 15, 256. [Google Scholar] [CrossRef]

- Yan, C.; Huang, W.; Ma, J.; Xu, J.; Lv, Q.; Lin, P. Characterizing the SBS polymer degradation within high content polymer modified asphalt using ATR-FTIR. Constr. Build. Mater. 2020, 233, 117708. [Google Scholar] [CrossRef]

- Kamran, F.; Ghasemirad, A.; Moghaddam, T.B.; Bayat, A.; Hashemian, L. Performance Evaluation of High Modulus Asphalt Concrete (HMAC) Prepared Using Asphaltenes-Modified Binders. J. Test. Eval. 2022, 50, 2636–2651. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, Z.W.; Wu, W.J.; Tian, Y.; Fan, J.T.; Wang, X.C. Development of a novel cement-based microwave deicing functional overlay using waterborne epoxy resin: Heating properties, influencing factors, and mechanism. Constr. Build. Mater. 2025, 492, 142849. [Google Scholar] [CrossRef]

- Shi, K.; Ma, F.; Falchetto, A.C.; Fu, Z.; Yuan, D.D.; Song, R.M.; Dai, J.S.; Wang, H.P. Comprehensive review on the composition, influence, and inhibition of asphalt fumes. J. Traffic Transp. Eng.-Engl. Ed. 2025, 12, 926–964. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.H.; Park, H.M. Performance evaluation of high modulus asphalt mixtures for long life asphalt pavements. Constr. Build. Mater. 2007, 21, 1079–1087. [Google Scholar] [CrossRef]

- Han, Z.Q.; Tang, J.Q.; Hu, L.Q.; Jiang, W.; Sha, A.M. Automated measurement of asphalt pavement rut depth using smartphone imaging. Autom. Constr. 2025, 174, 106124. [Google Scholar] [CrossRef]

- Wang, D.; Falchetto, A.C.; Riccardi, C.; Poulikakos, L.; Hofko, B.; Porot, L.; Wistuba, M.P.; Baaj, H.; Mikhailenko, P.; Moon, K.H. Investigation on the combined effect of aging temperatures and cooling medium on rheological properties of asphalt binder based on DSR and BBR. Road Mater. Pavement Des. 2019, 20, S409–S433. [Google Scholar] [CrossRef]

- Zaumanis, M.; Arraigada, M.; Poulikakos, L.D. 100% recycled high-modulus asphalt concrete mixture design and validation using vehicle simulator. Constr. Build. Mater. 2020, 260, 119891. [Google Scholar] [CrossRef]

- Ullah, A.; Wen, H.P.; Ullah, Z.; Ali, B.; Khan, D. Evaluation of high modulus asphalts in China, France, and USA for durable road infrastructure, a theoretical approach. Constr. Build. Mater. 2024, 432, 136622. [Google Scholar] [CrossRef]

- Zhang, J.; Walubita, L.F.; Faruk, A.N.M.; Karki, P.; Simate, G.S. Use of the MSCR test to characterize the asphalt binder properties relative to HMA rutting performance—A laboratory study. Constr. Build. Mater. 2015, 94, 218–227. [Google Scholar] [CrossRef]

- Chaturabong, P.; Bahia, H.U. Effect of moisture on the cohesion of asphalt mastics and bonding with surface of aggregates. Road Mater. Pavement Des. 2018, 19, 741–753. [Google Scholar] [CrossRef]

- Li, Z.; Yu, X.; Liang, Y.; Wu, S. Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders. Materials 2021, 14, 2585. [Google Scholar] [CrossRef] [PubMed]

- Xue, Z.; Xu, W. A Study on High and Low Temperature Rheological Properties and Oil Corrosion Resistance of Epoxy Resin/SBS Composite Modified Bitumen. Polymers 2023, 15, 104. [Google Scholar] [CrossRef] [PubMed]

- GB/T 2294-2019; Determination of Softening Point in Solid Products of Coal Carbonization. Chinese National Standard: Beijing, China, 2019.

- GB/T 27761-2011; Standard Test Method of Mass Loss and Residue Measurement Validation of Thermogravimetric Analyzers. Chinese National Standard: Beijing, China, 2011.

- GB/T 3682.1-2018; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. Chinese National Standard: Beijing, China, 2018.

- JTGE 20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- Zou, X.; Sha, A.; Jiang, W.; Huang, X. Modification mechanism of high modulus asphalt binders and mixtures performance evaluation. Constr. Build. Mater. 2015, 90, 53–58. [Google Scholar] [CrossRef]

- Lu, Q.; Sha, A.; Jiao, W.; Shi, K.; Peng, Z.; Song, R. Synergistic effects of sulfur and polyphosphoric acid additives in warm mix bio-rejuvenated asphalt modification. Constr. Build. Mater. 2024, 433, 136676. [Google Scholar] [CrossRef]

- ASTM D7405; Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM: West Conshohocken, PA, USA, 2024.

- Lu, Q.; Sha, A.; Jiao, W.; Shi, K.; Li, Z.; Chen, Y.; Du, P.; Peng, Z.; Song, R. Waste coffee biochar and bi-oil composite modified rejuvenated asphalt: Preparation, characterization, and performance evaluation. Constr. Build. Mater. 2024, 450, 138588. [Google Scholar] [CrossRef]

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM: West Conshohocken, PA, USA, 2002.

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- T/CECS G:K44-02-2020; Technical Specification of SBS and Crumb Rubber Modified Asphalt Mixture for Highway Pavement. CECS: Beijing, China, 2020.

| The Fundamental Physical Characteristics | Result | Methods |

|---|---|---|

| Outlook | Black particles | Estimate visually |

| Softening point/(°C) | ≥160 | GB/T 2294-2019 [52] |

| Density/(kg/) | 952 | Density bottle method |

| Particle diameter/(mm) | ≤5.0 | Sieve mesh |

| Polymer content/(%) | ≥90% | GB/T 27761-2011 [53] |

| Melt index/(g/10 min) | 5–7 | GB/T 3682.1-2018 [54] |

| The Fundamental Physical Characteristics | Result | Methods |

|---|---|---|

| Outlook | Black particles | Estimate visually |

| Softening point/(°C) | ≥160 | GB/T 2294-2019 |

| Density/(kg/) | 1198 | Density bottle method |

| Particle diameter/(mm) | ≤5.0 | Sieve mesh |

| Polymer content/(%) | ≥95% | GB/T 27761-2011 |

| Melt index/(g/10 min) | 7–10 | GB/T 3682.1-2018 |

| Detection Parameters | Technical Requirements | Test Results | Test Methods |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s)/(0.1) mm | 40~60 | 48.4 | JTGE 20-2011 [55] |

| Penetration Index (PI) | ≥0 | 2.08 | JTGE 20-2011 |

| Ductility (5 °C, 5 cm/min)/(cm) | ≥20 | 33.7 | JTGE 20-2011 |

| Softening point (TR&B)/(°C) | ≥60 | 89.5 | JTGE 20-2011 |

| Flash point/(°C) | ≥230 | 321 | JTGE 20-2011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Q.; Li, Z.; Huang, J.; Chen, J.; Zhao, L.; Xing, C.; Cui, T.; Zou, J. Synergistic Effects of High-Modulus Additives on SBS-Modified Asphalt: Microstructural, Rheological Enhancement, and Dosage-Dependent Performance Optimization. Materials 2025, 18, 4724. https://doi.org/10.3390/ma18204724

He Q, Li Z, Huang J, Chen J, Zhao L, Xing C, Cui T, Zou J. Synergistic Effects of High-Modulus Additives on SBS-Modified Asphalt: Microstructural, Rheological Enhancement, and Dosage-Dependent Performance Optimization. Materials. 2025; 18(20):4724. https://doi.org/10.3390/ma18204724

Chicago/Turabian StyleHe, Qinghua, Zhuosen Li, Jianqi Huang, Jie Chen, Liujun Zhao, Chengwei Xing, Tong Cui, and Jiabiao Zou. 2025. "Synergistic Effects of High-Modulus Additives on SBS-Modified Asphalt: Microstructural, Rheological Enhancement, and Dosage-Dependent Performance Optimization" Materials 18, no. 20: 4724. https://doi.org/10.3390/ma18204724

APA StyleHe, Q., Li, Z., Huang, J., Chen, J., Zhao, L., Xing, C., Cui, T., & Zou, J. (2025). Synergistic Effects of High-Modulus Additives on SBS-Modified Asphalt: Microstructural, Rheological Enhancement, and Dosage-Dependent Performance Optimization. Materials, 18(20), 4724. https://doi.org/10.3390/ma18204724