Performance Degradation Behavior and Service Life Prediction of Hydraulic Asphalt Concrete Under Long-Term Water Immersion

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Asphalt

2.1.2. Aggregate

2.1.3. Mixing Ratio

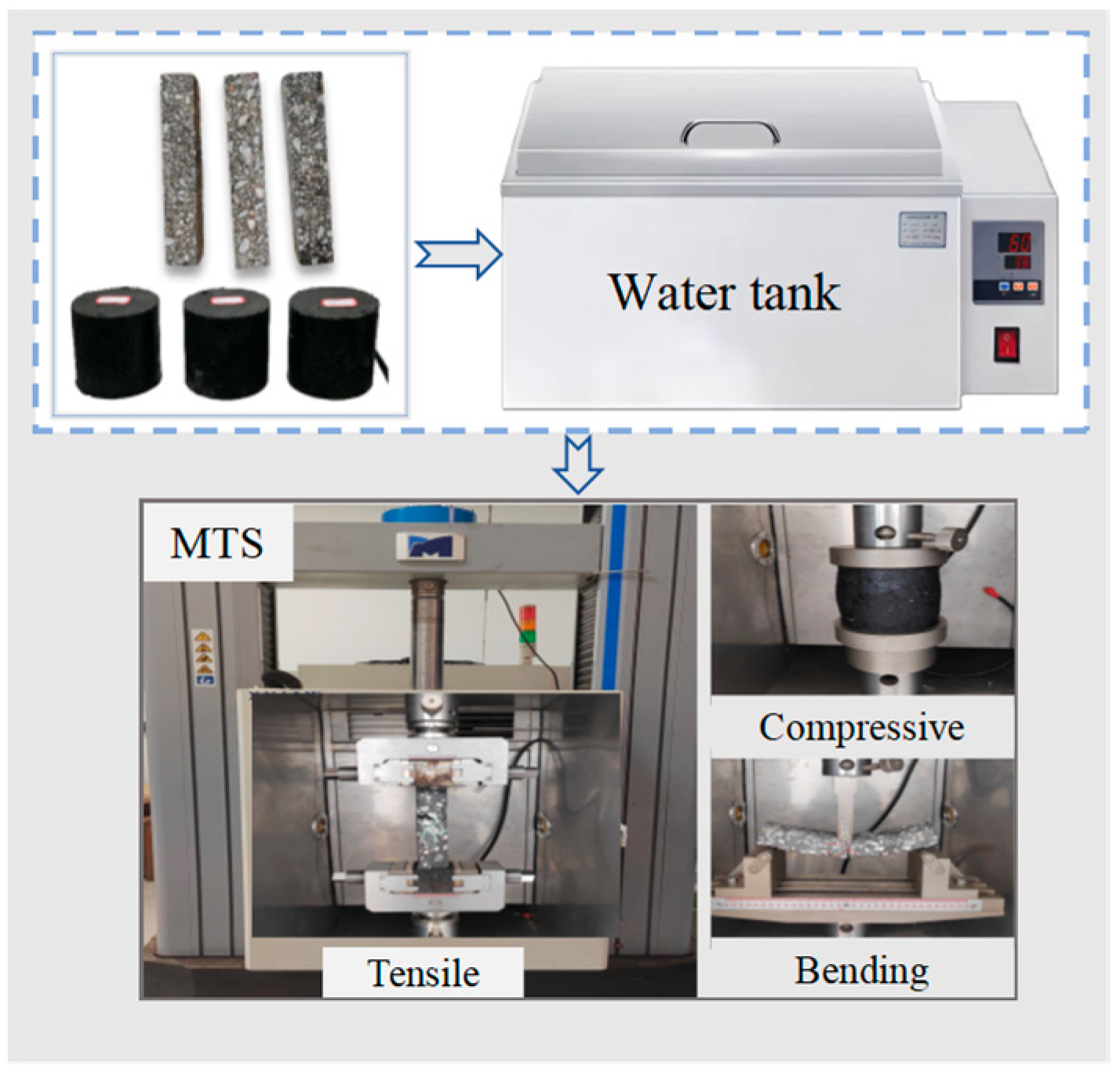

2.2. Experimental Methods

2.2.1. Specimen Preparation

2.2.2. Specimen Immersion Treatment

2.2.3. Measuring Porosity

2.2.4. Measuring Mass Loss Rate

2.2.5. Test Setup

3. Analysis of Experimental Results

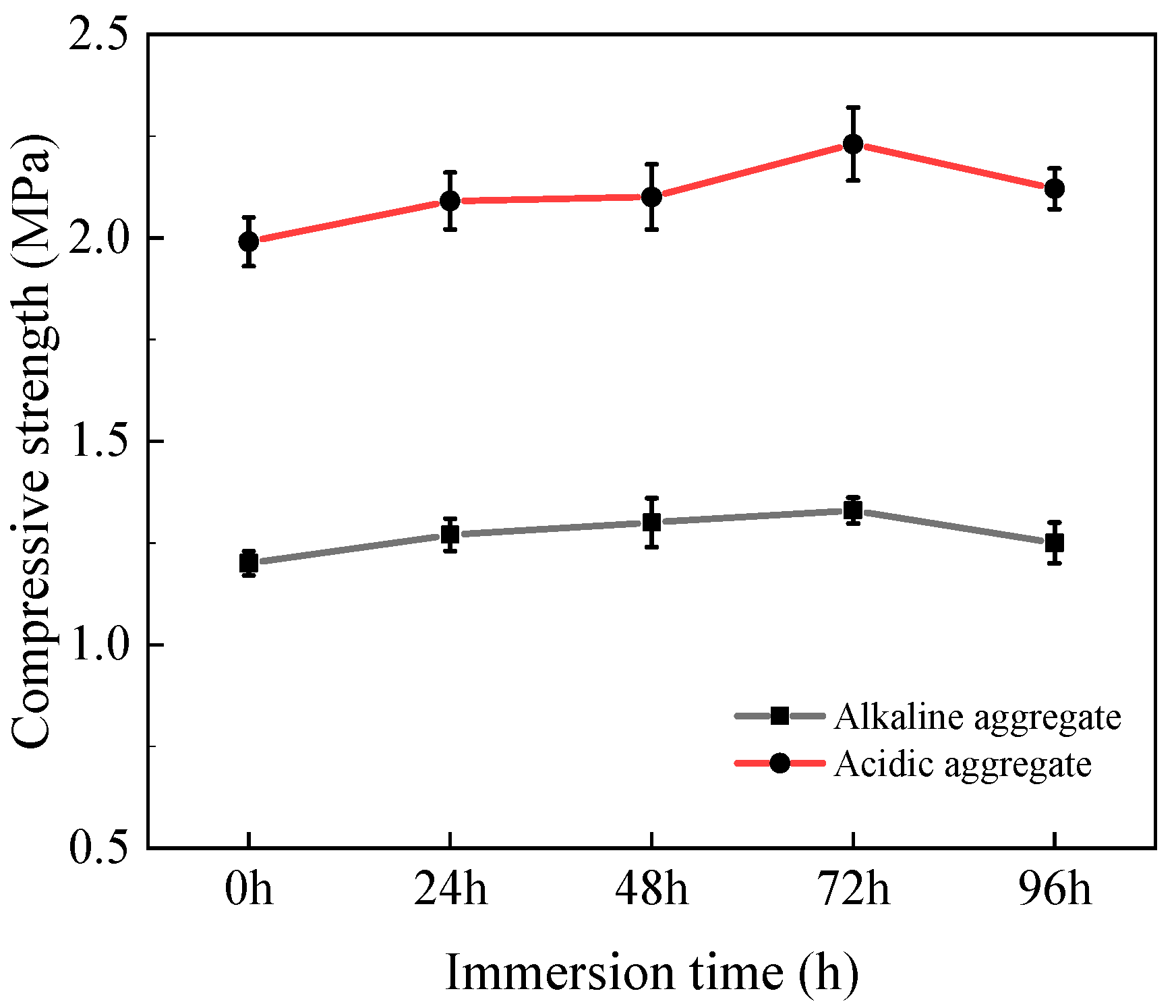

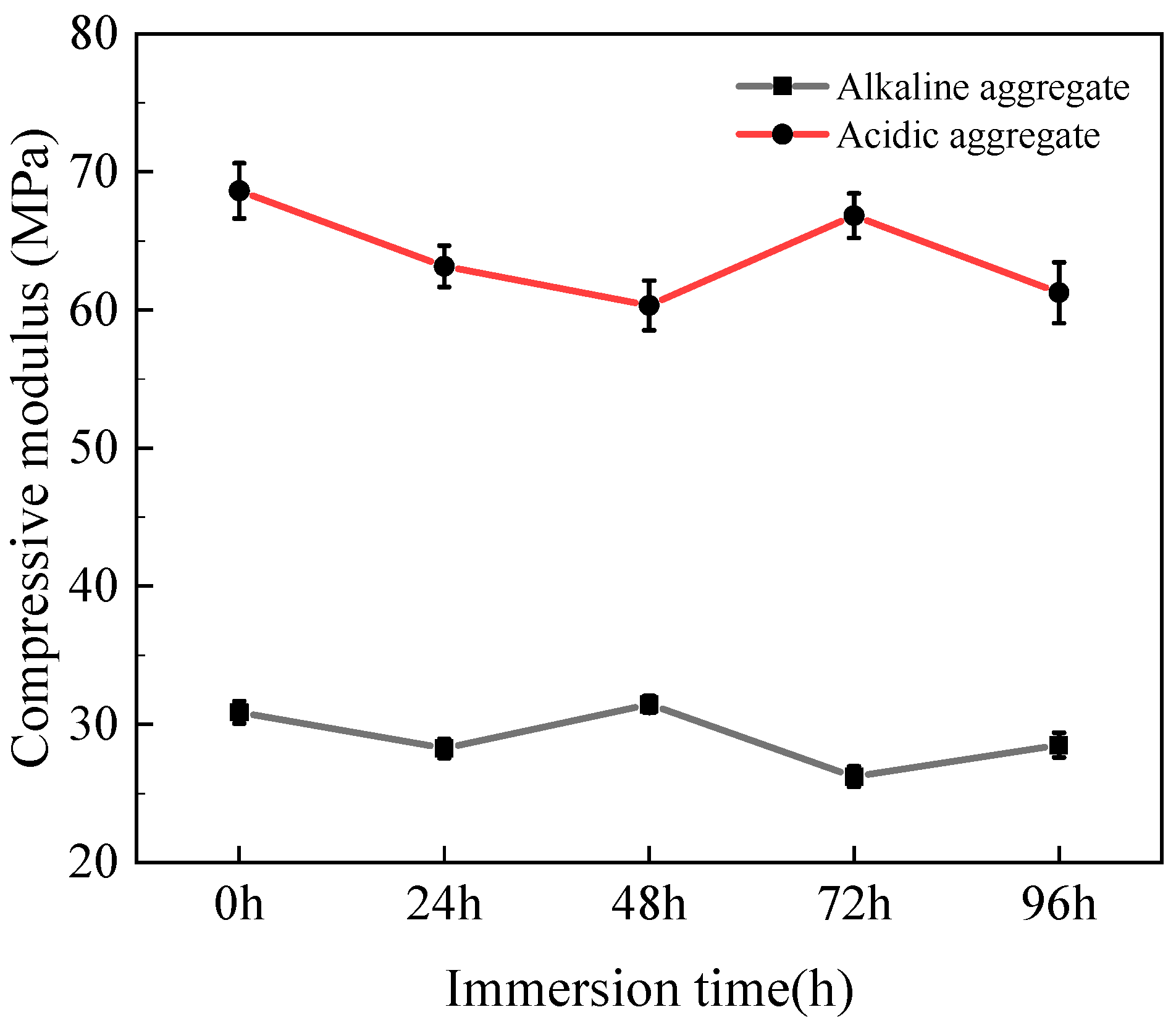

3.1. Compressive Performance

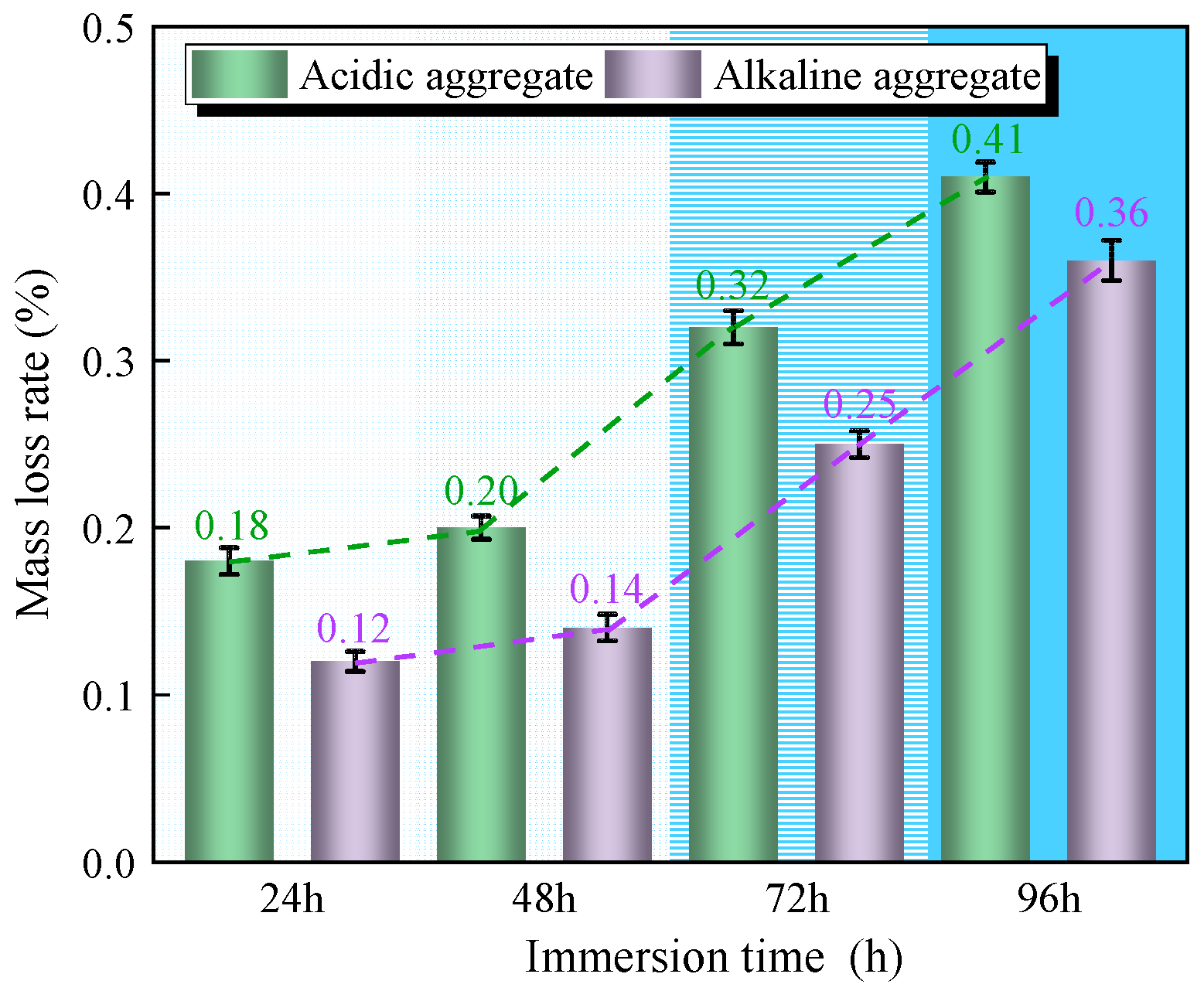

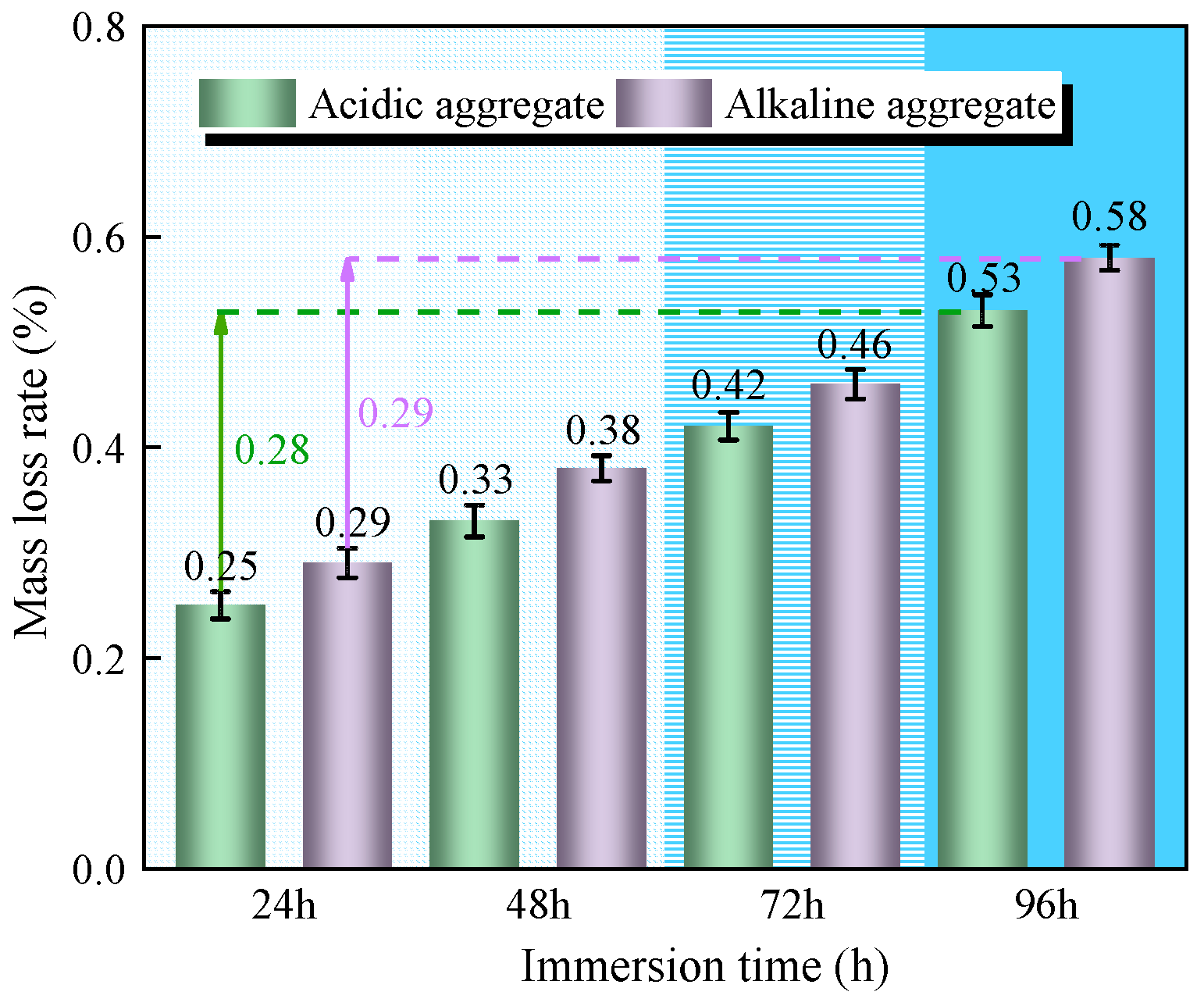

3.1.1. Compressive Mass Loss Rate

3.1.2. Compressive Strength

3.1.3. Compressive Modulus

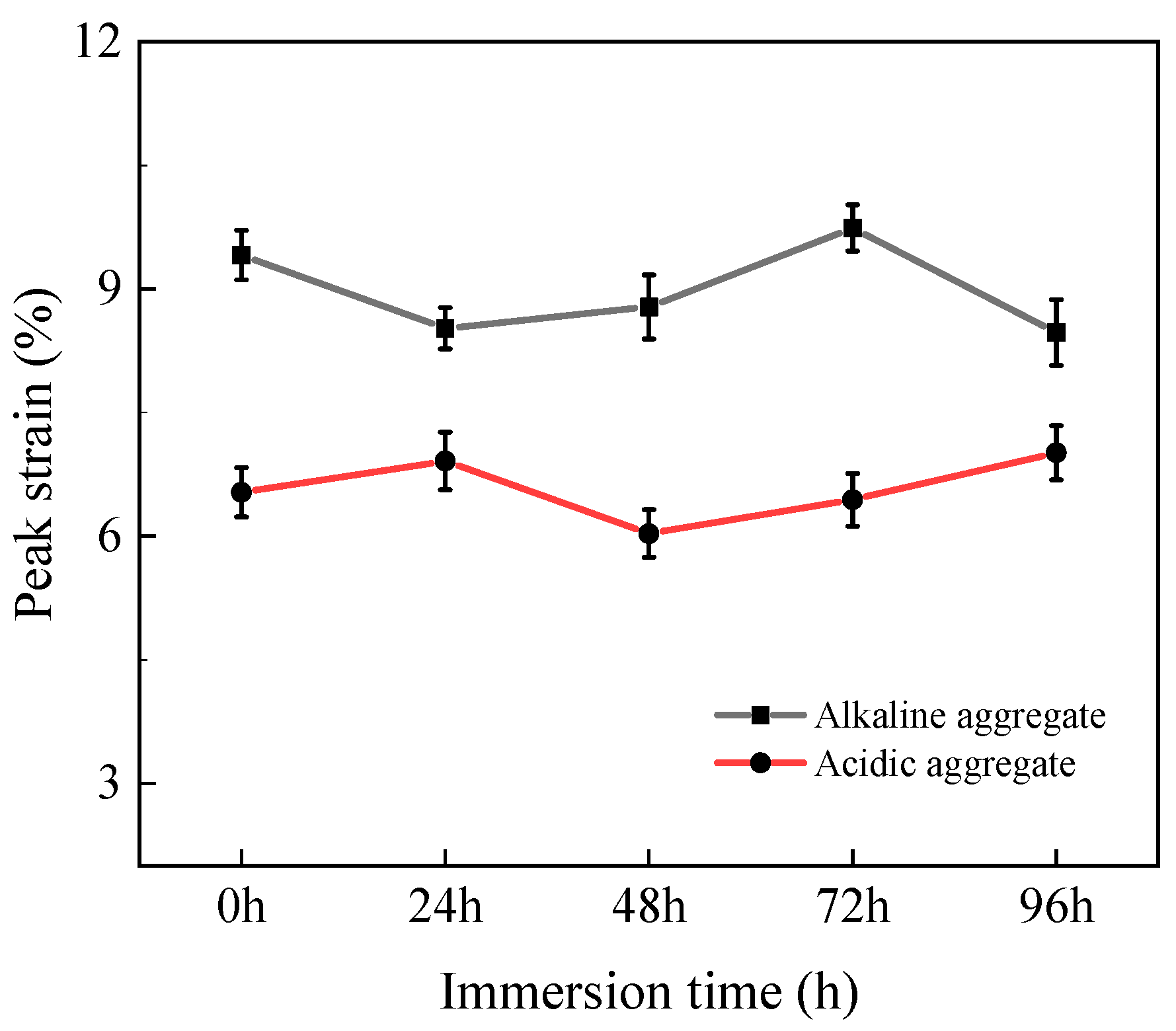

3.1.4. Peak Strain

3.2. Tensile Performance

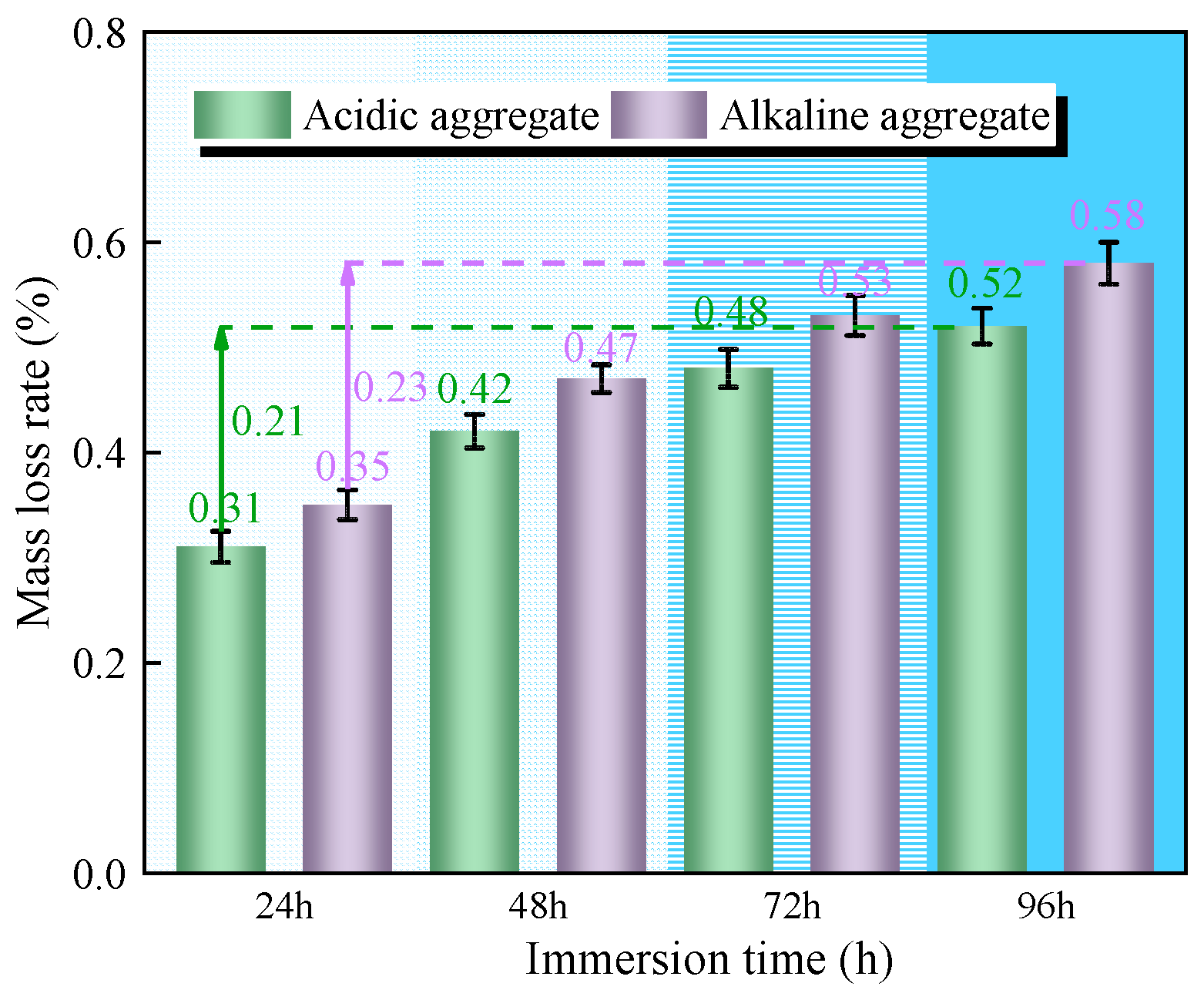

3.2.1. Tensile Mass Loss Rate

3.2.2. Tensile Strength

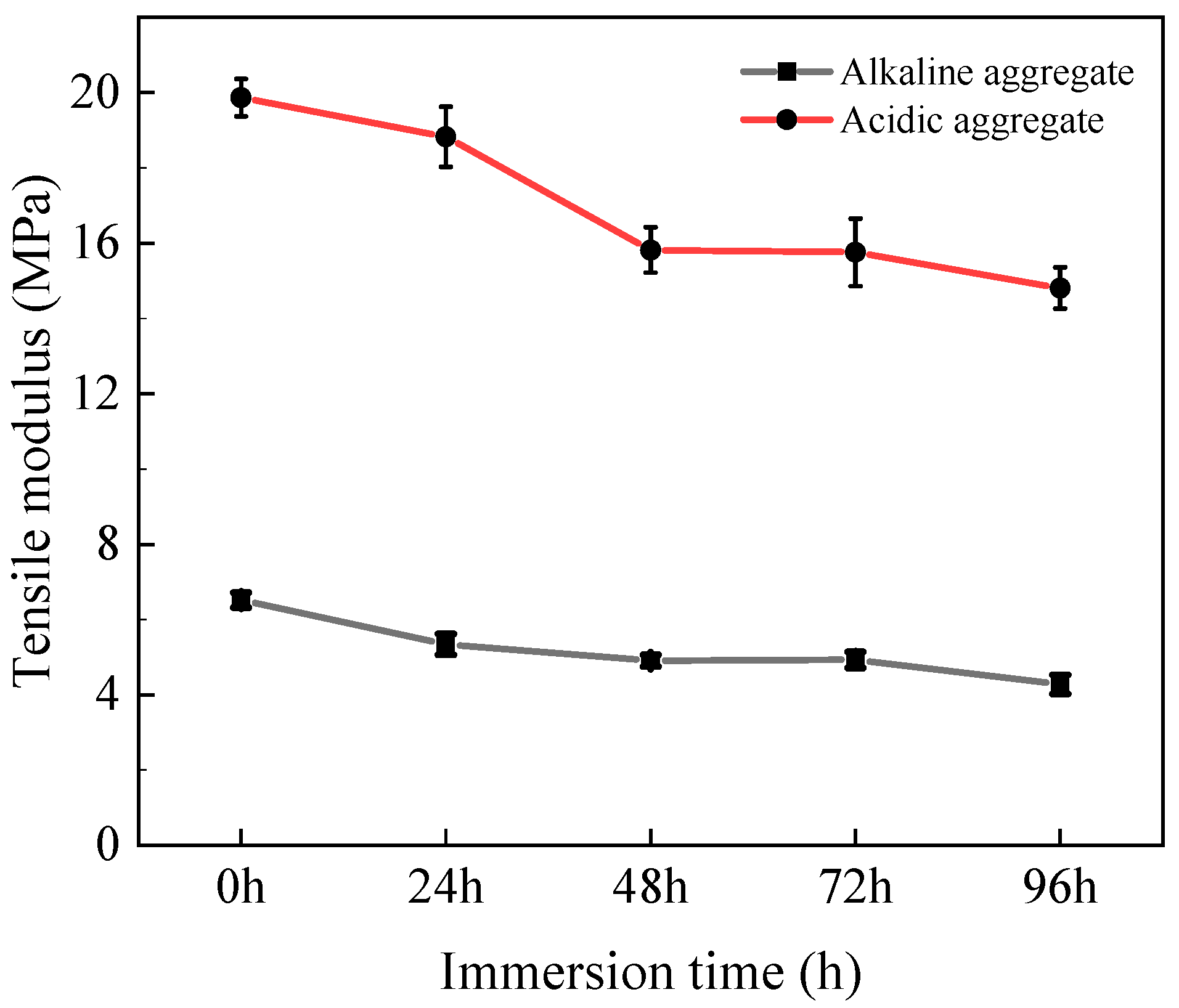

3.2.3. Tensile Modulus

3.2.4. Peak Strain

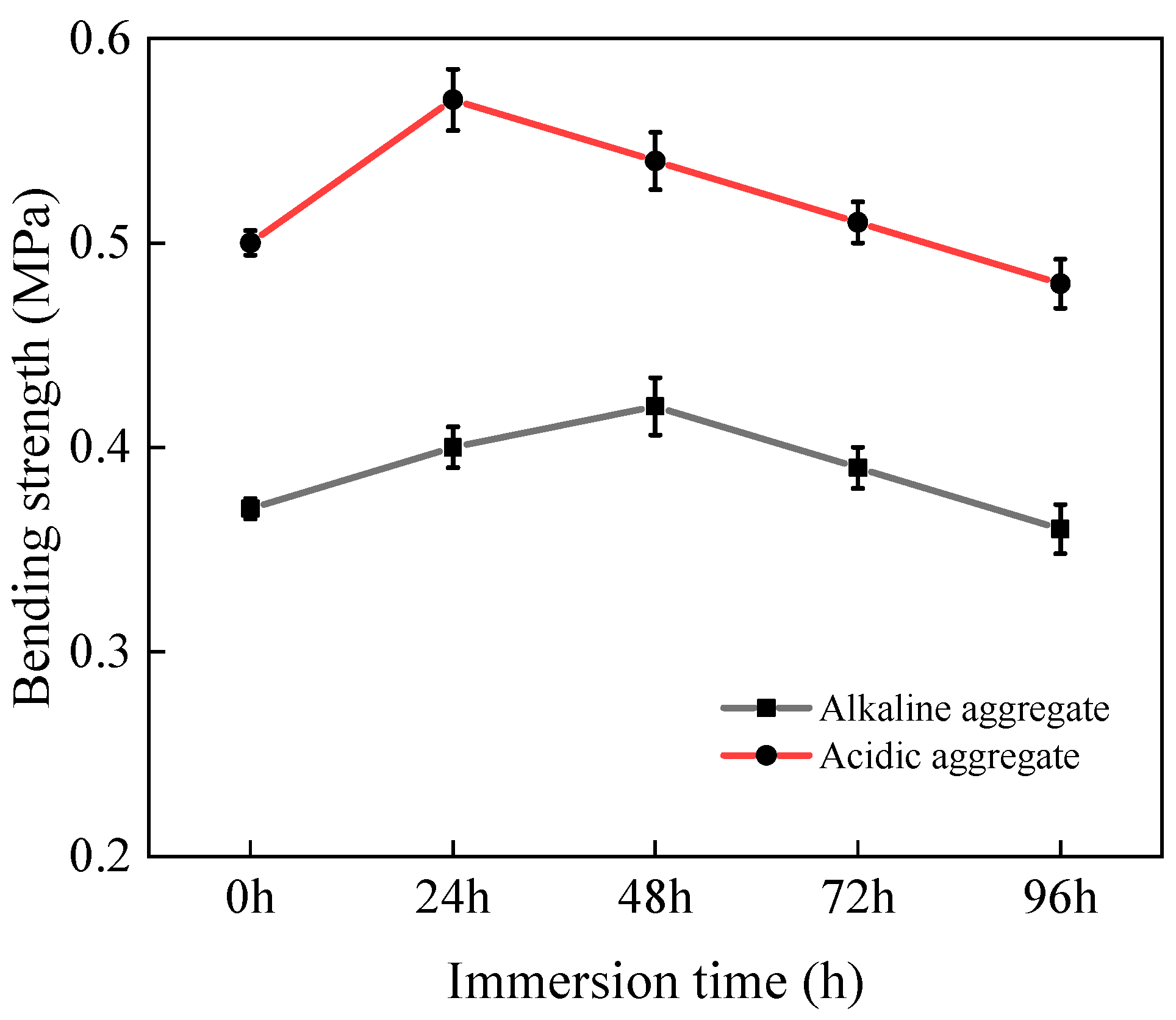

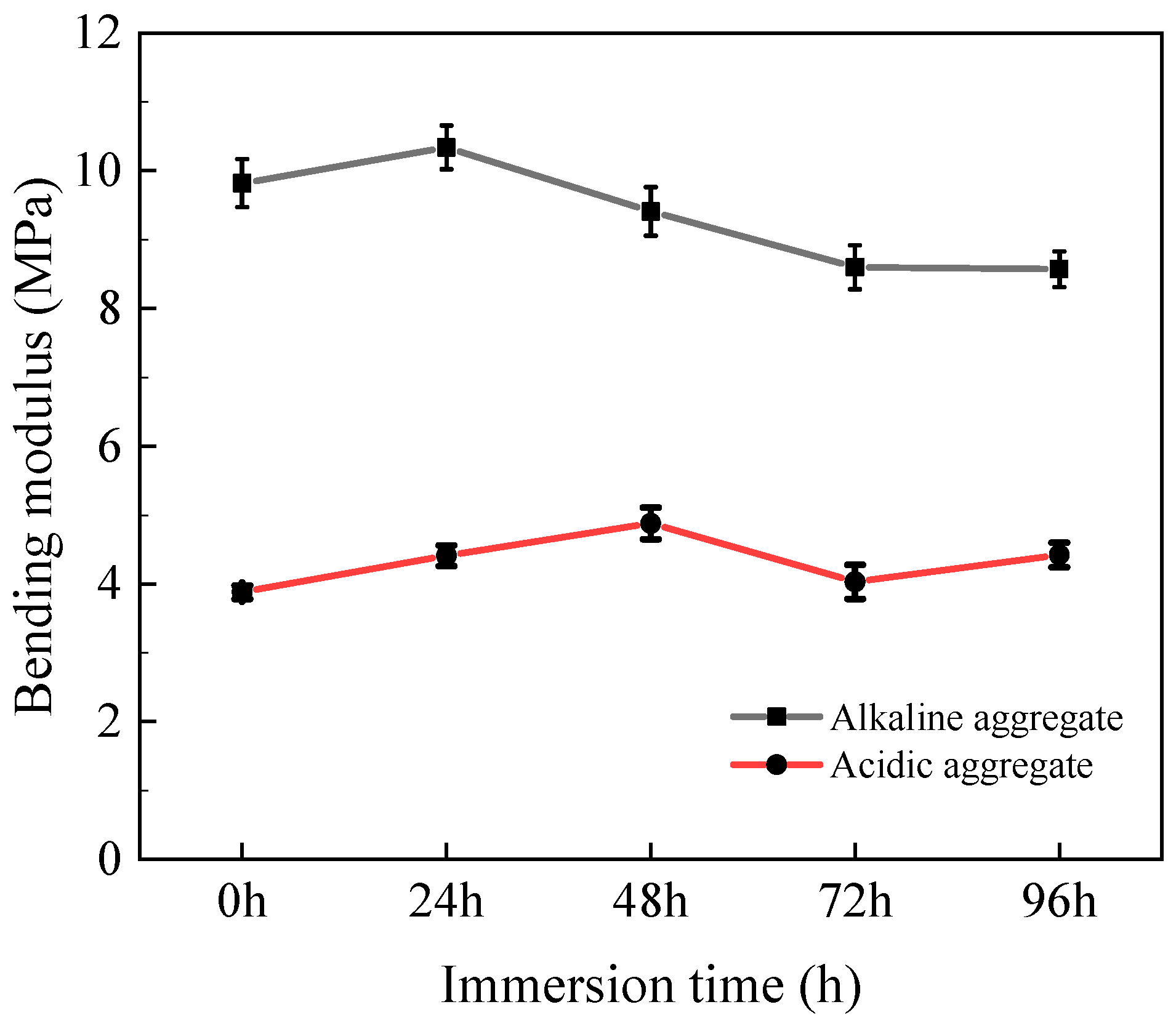

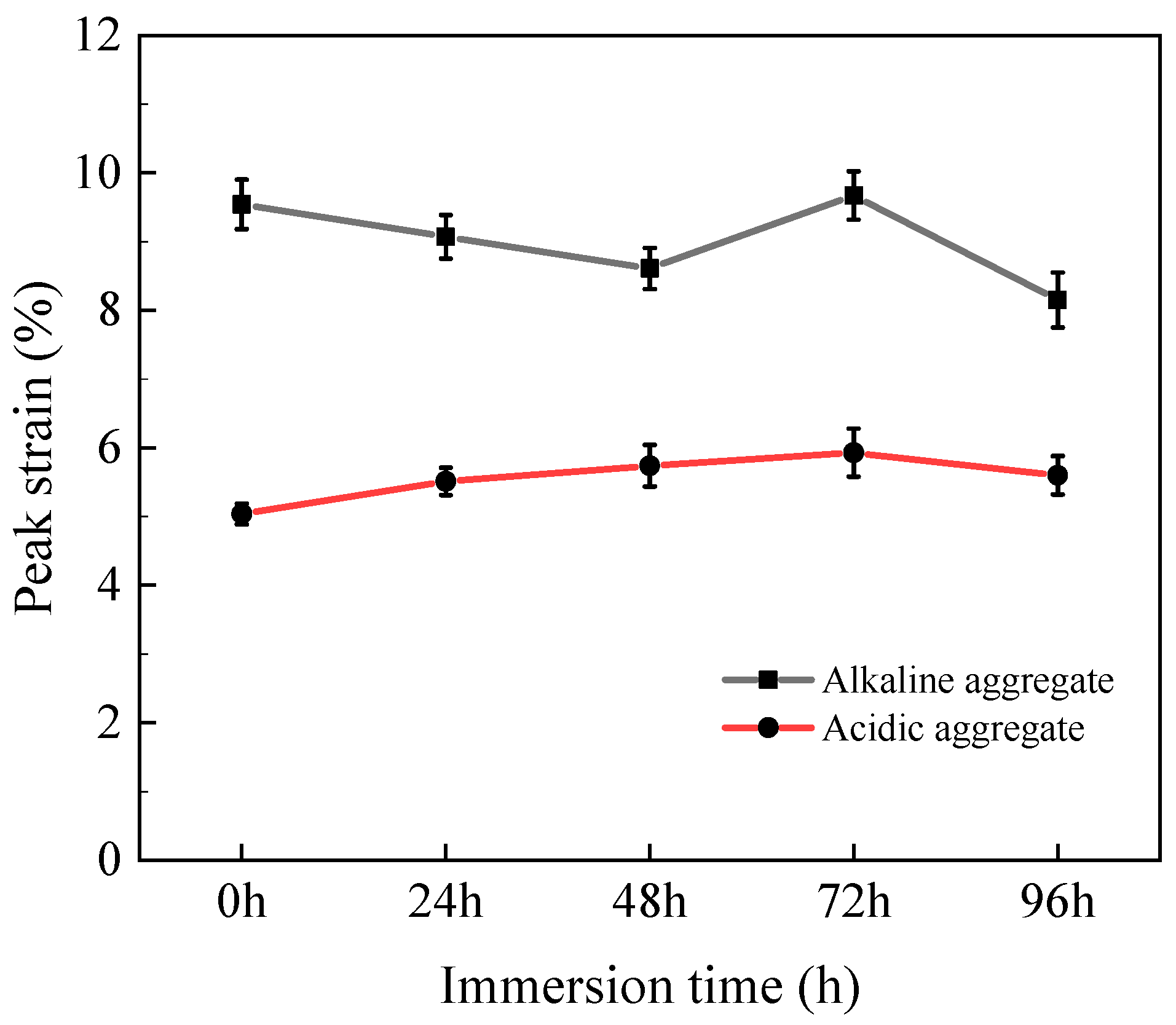

3.3. Bending Performance

3.3.1. Bending Mass Loss Rate

3.3.2. Bending Strength

3.3.3. Bending Modulus

3.3.4. Peak Strain

4. Performance Evaluation and Predictive Model

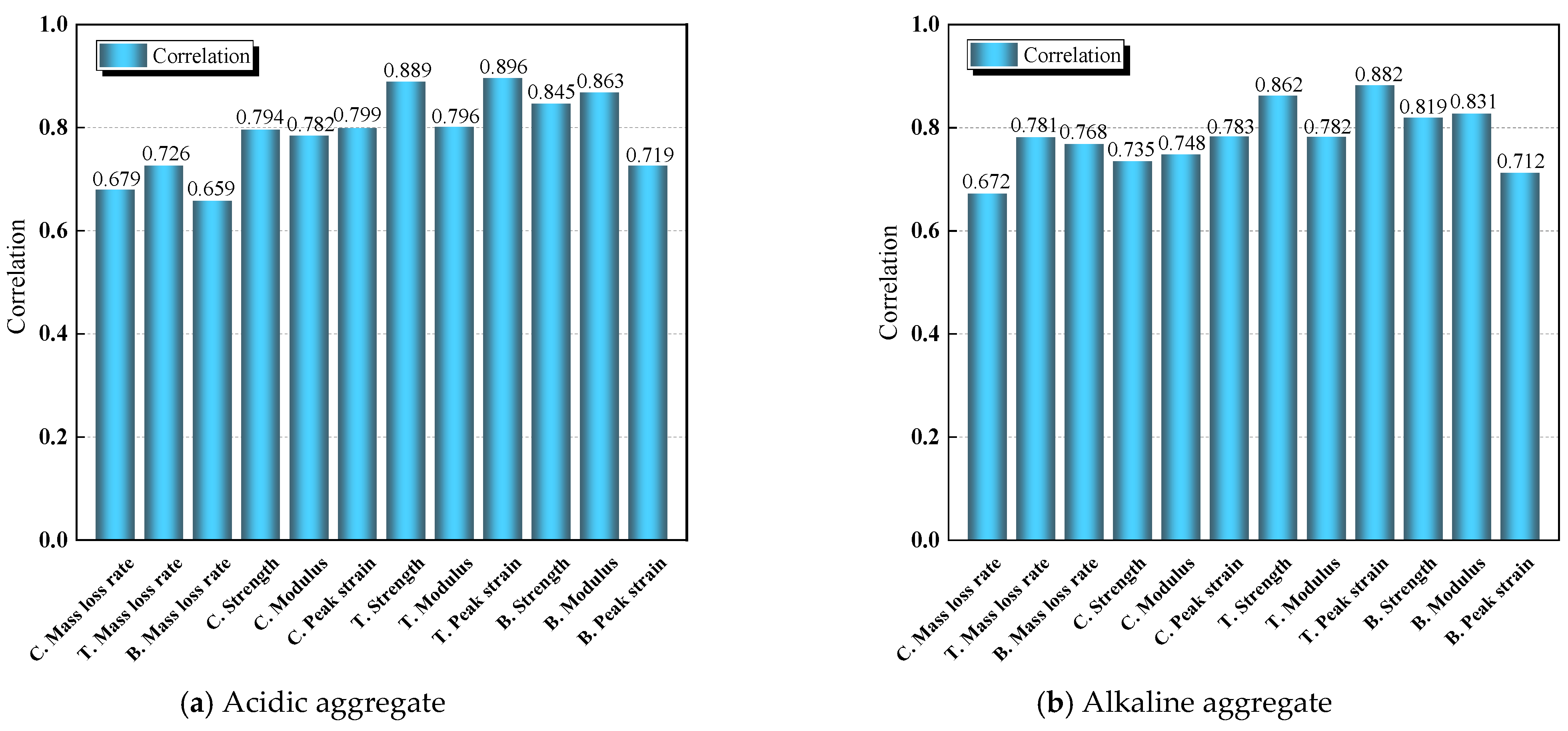

4.1. Gray Relational Analysis

4.2. Performance Assessment

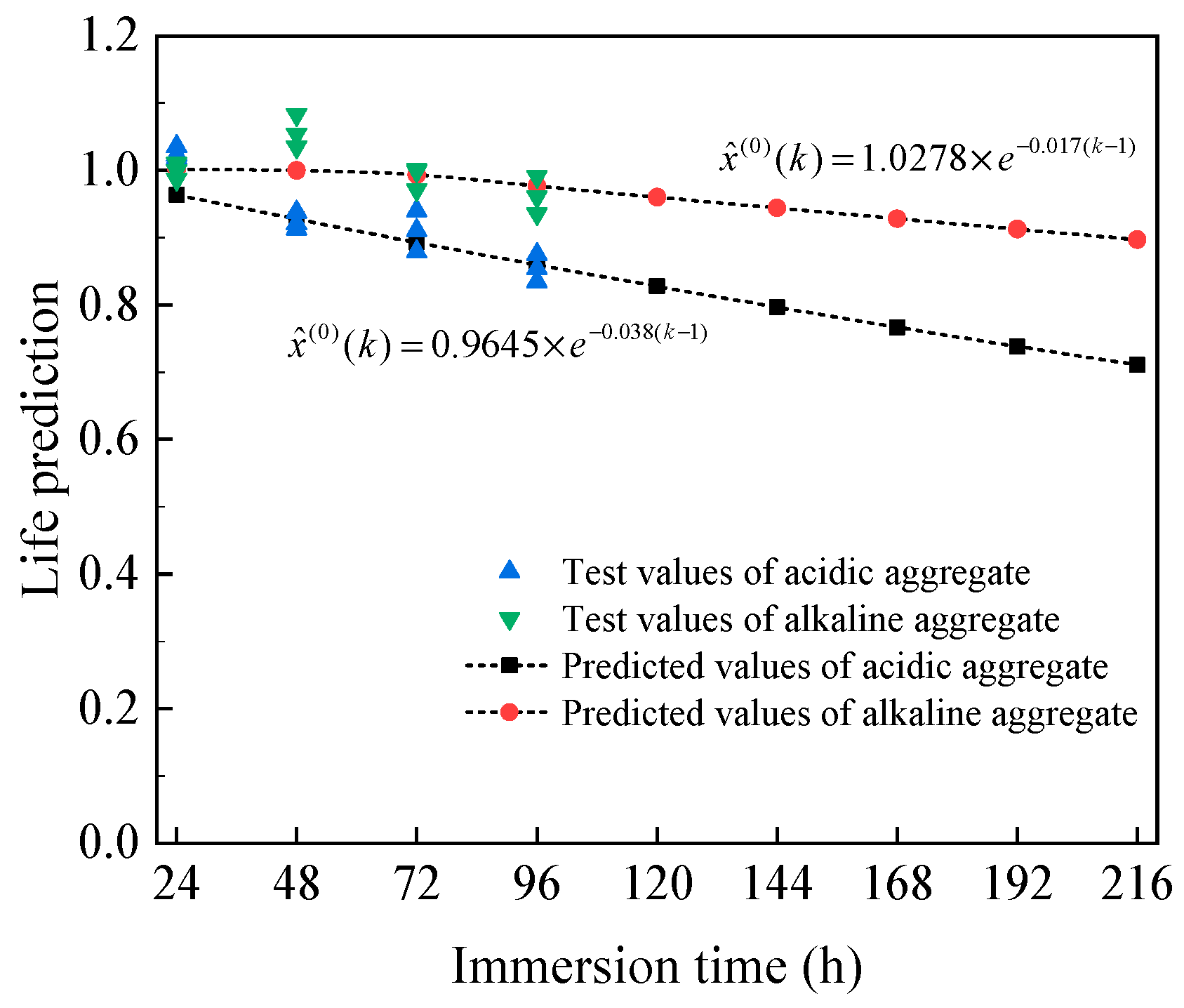

4.3. Life Prediction

4.4. Failure Mechanism

5. Conclusions

- (1)

- Within a short immersion period, the mechanical properties of asphalt concrete do not exhibit obvious patterns. As the immersion time increases, the mass loss rate gradually increases, the peak compressive stress increases, while the peak tensile and bending stresses decrease. The modulus of deformation generally shows a decreasing trend, while the peak strain varies depending on the acidity or alkalinity of the aggregate.

- (2)

- The correlation between the porosity of HAC and the evaluation indicators of water stability is as follows: tensile strength, bending modulus, and bending strength, with a correlation coefficient greater than 0.8 for all. Tensile strength, bending strength, and bending modulus are used as comprehensive indicators for evaluating water stability.

- (3)

- The GM(1,1) model was used to predict the service life of asphalt concrete long-term water immersion. The predicted values were found to be in good agreement with the actual values, thereby validating the model’s effectiveness. After 192 h of water immersion, the D-value of alkaline asphalt concrete degraded to 91.25%, while the D-value of acidic aggregate degraded to 73.85%.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Zhu, Y.; Wang, W. Compressive and tensile stress–strain-strength behavior of asphalt concrete at different temperatures and strain rates. Constr. Build. Mater. 2021, 311, 125362. [Google Scholar] [CrossRef]

- Feng, S.; Wang, W.; Hu, K. Stress-strain-strength behavior of asphalt core in embankment dams during construction. Constr. Build. Mater. 2020, 259, 119706. [Google Scholar] [CrossRef]

- ICOLD. Asphalt Cores for Embankment Dams; Bulletin 179, International Commission on Large Dams: Chatou, France, 2018. [Google Scholar]

- Wang, W. Research on the Suitability of Asphalt Concrete as Water Barrier in Dams and Dikes. Ph.D. Thesis, University of Oslo, Oslo, Norway, 2008. [Google Scholar]

- Ning, Z.; Sun, Z.; Liu, Y. Evaluating the impervious performance of hydraulic asphalt concrete in embankment dams: A study of crack evolution at different temperatures. Constr. Build. Mater. 2024, 440, 137247. [Google Scholar] [CrossRef]

- Li, Q.; Shen, A.; Wang, L. Long-Term Performance of Modified Nature Asphalt-Derived High Modulus Asphalt Mixtures under Heavy Loads and Humid-Hot Climates. J. Mater. Civil. Eng. 2024, 36, 04024227. [Google Scholar] [CrossRef]

- Zhang, M.; Kou, C.; Kang, A. Microscopic characteristics of interface transition zones of hot mix asphalt containing recycled concrete aggregates. J. Clean. Prod. 2023, 389, 136070. [Google Scholar] [CrossRef]

- Sun, Y.; Chu, L.; Chi, F. Water Stability Improvement of Acid Fine Aggregate-Based Asphalt Concrete. Fluid Dyn. Mater. Proc. 2023, 19, 2171–2180. [Google Scholar]

- Ma, X.; Zhou, P.; Wang, L. Internal structure change of porous asphalt concrete under coupled conditions of load, moisture and temperature. Constr. Build. Mater. 2022, 314, 125603. [Google Scholar]

- Jiang, Q.; Liu, W.; Wu, S. Study on the mechanical performance damage in laboratory-simulated periodic salt environment for asphalt concrete. Constr. Build. Mater. 2024, 411, 134306. [Google Scholar]

- Valentin, J.; Trejbal, J. Characterization of quarry dusts and industrial by-products as potential substitutes for traditional fillers and their impact on water susceptibility of asphalt concrete. Constr. Build. Mater. 2021, 301, 124294. [Google Scholar]

- Wang, H.; Chen, G.; Kang, H. Asphalt-aggregates interface interaction: Correlating oxide composition and morphology with adhesio. Constr. Build. Mater. 2024, 457, 139317. [Google Scholar]

- Kumlai, S.; Jitsangiam, P.; Nikraz, H. Assessments of moisture damage resistance of asphalt concrete mixtures and asphalt mastic with various mineral fillers. Transp. Eng. 2022, 7, 100106. [Google Scholar]

- Nobakht, M.; Zhang, D.; Sakhaeifar, M. Characterization of the adhesive and cohesive moisture damage for asphalt concrete. Constr. Build. Mater. 2020, 247, 118616. [Google Scholar]

- Oldham, D.; Mallick, R.; Fini, E. Reducing susceptibility to moisture damage in asphalt pavements using polyethylene terephthalate and sodium montmorillonite clay. Constr. Build. Mater. 2021, 269, 121302. [Google Scholar]

- Ren, D.; Wu, P.; Yang, H. Mesoscopic evaluation of dynamic water scour resistance of basalt fiber-reinforced porous asphalt concrete using CT scanning technology. Constr. Build. Mater. 2025, 465, 140186. [Google Scholar]

- Jiang, Q.; Liu, W.; Wu, S. Analysis on factors affecting moisture stability of steel slag asphalt concrete using grey correlation method. J. Clean. Prod. 2023, 397, 136490. [Google Scholar]

- Li, S. Research on Long-Term Water Stability of Granite Aggregate Hydraulic Asphalt Concrete. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2022. [Google Scholar]

- Gao, B. Study on Moisture Damage to Slope Stability of Hydraulic Asphalt Concrete Impact. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar]

- NDRCPRC (National Development and Reform Commission of the People’s Republic of China). Test Code for Hydraulic Asphalt Concrete SL/T 5362-2018; NDRCPRC: Beijing, China, 2018. [Google Scholar]

- Wang, G. Evaluation and Influencing Factors of Interfacial Bonding Properties Between Asphalt and Aggregate. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2018. [Google Scholar]

- NEAPRC (National Energy Administration of the People’s Republic of China). Code for Design of Asphalt Concrete Facings and Cores for Embankment Dams NB/T 11015-2022; NDRCPRC: Beijing, China, 2022. [Google Scholar]

- Sun, Y.; Huang, W.; Xu, G.; Gan, L.; Shen, Z.; Luo, S.; Zhang, H.; Feng, Y.; Xiong, H.; Shu, Y. Experimental investigation on the performance of hydraulic asphalt concrete with varying epoxy system content. Constr. Build. Mater. 2025, 484, 141755. [Google Scholar]

- Rehaman, K.; Li, Y.; Liu, Y.; Wen, L.; Zhang, Y. Selection method of gradation index in hydraulic asphalt concrete considering skeleton effect. Constr. Build. Mater. 2025, 476, 141270. [Google Scholar]

- Tan, Y.; Wei, D.; Xu, J. Mussel-inspired biomimetic modification to enhance adhesion properties between granite and asphalt: Multi-scales characterizations and molecular mechanisms. Appl. Surf. Sci. 2025, 681, 161561. [Google Scholar]

- Zulkati, A.; Wong, Y.D.; Sun, D.D. Mechanistic Performance of Asphalt-Concrete Mixture Incorporating Coarse Recycled Concrete Aggregate. J. Mater. Civil. Eng. 2013, 25, 1299–1305. [Google Scholar]

- Xiao, M.; Li, C.; Zhu, X. Asphalt complex cracks’ sensitivity to temperature and crack depth and adjustment of the composite stress intensity factor. Theor. Appl. Fract. Mec. 2022, 122, 103628. [Google Scholar]

- Jiu, X.; Wang, Y.; Wu, Z.; Xiao, P.; Kang, A. High-Temperature Performance Evaluation of Asphalt Mixtures by Adding Short-Chopped Basalt Fiber. Buildings 2023, 13, 13020370. [Google Scholar]

- Mirzanamadi, R.; Johansson, P.; Grammatikos, S.A. Thermal properties of asphalt concrete: A numerical and experimental study. Constr. Build. Mater. 2018, 158, 774–785. [Google Scholar]

- Wu, W.; Chen, B.; Li, Z. Effect of aqueous solution exposure on the long-term aging performance of asphalt. Constr. Build. Mater. 2025, 460, 139760. [Google Scholar]

- Ning, Z.; Liu, Y.; Wang, W. Compressive Behavior of Hydraulic Asphalt Concrete under Different Temperatures and Strain Rates. J. Mater. Civil. Eng. 2021, 33, 3594. [Google Scholar]

- Ding, G.; Yu, X.; Dong, F. Using Silane Coupling Agent Coating on Acidic Aggregate Surfaces to Enhance the Adhesion between Asphalt and Aggregate: A Molecular Dynamics Simulation. Materials 2022, 13, 5580. [Google Scholar]

- Xiang, H.; Wang, Z.; Deng, M. Adhesion Characteristics of an Asphalt Binder-Aggregate Interface Based on Molecular Dynamics. Materials 2025, 18, 981. [Google Scholar]

- Guo, M.; Yin, X.; Du, X. Effect of aging, testing temperature and relative humidity on adhesion between asphalt binder and mineral aggregate. Constr. Build. Mater. 2023, 363, 129775. [Google Scholar]

- Ning, Z.; Li, Y.; Liu, Y.; Li, Y.; Dong, J.; Meng, X. Non-uniform tensile deformation and damage evaluation of asphalt concrete core wall-base combination using digital image correlation. Constr. Build. Mater. 2025, 485, 141886. [Google Scholar]

- Bao, L.; He, M.; Wang, S. Study on the Effect of Asphalt Static Conditions on the Tensile Properties of Acidic Aggregate Hydraulic Asphalt Concrete. Materials 2024, 17, 2627. [Google Scholar]

- Wang, W.; Xu, Q.; Zhou, S. A Review on Evaluation Methods of Asphalt-Aggregate Adhesion. Mater. Rev. 2019, 33, 2197–2205. [Google Scholar]

- Liao, W.; Liang, B.; Hu, M. Digital imaging technology-assisted water-sensitivity assessment of asphalt mixtures: A comprehensive review. Measurement 2025, 242, 115871. [Google Scholar]

- Yu, Z.; Hou, Y.; Zhu, J. Frost resistance and service life prediction of recycled aggregate concrete (RAC) under flexural fatigue damage. Constr. Build. Mater. 2025, 458, 139787. [Google Scholar]

- Osman, H.; Hasan, M. Effects of bonding enhancers on shear stress and bonding strength of modified asphalt binders under different aging and moisture conditions. Constr. Build. Mater. 2024, 453, 139020. [Google Scholar]

- Sun, G.; Sun, D.; Guarin, A.; Ma, J.; Chen, F.; Ghafooriroozbahany, E. Low temperature self-healing character of asphalt mixtures under different fatigue damage degrees. Constr. Build. Mater. 2019, 223, 870–882. [Google Scholar]

- Zhang, H.; Liu, Z.; Meng, X. Noise reduction characteristics of asphalt pavement based on indoor simulation tests. Constr. Build. Mater. 2019, 215, 285–297. [Google Scholar]

- Guan, Y.; Zhang, B.; Li, Z.; Zhang, D. Enhanced flow number prediction of asphalt mixtures using stacking ensemble-based machine learning model and grey relational analysis. Constr. Build. Mater. 2025, 463, 140001. [Google Scholar]

- Qin, Y.; Guan, K.; Kou, J.; Ma, Y.; Zhou, H.; Zhang, X. Durability evaluation and life prediction of fiber concrete with fly ash based on entropy weight method and grey theory. Constr. Build. Mater. 2022, 327, 126918. [Google Scholar]

- Deng, J. Introduction of grey system. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Yu, J.; Qiao, H.; Zhu, F.; Wang, X. Research on Damage and Deterioration of Fiber Concrete under Acid Rain Environment Based on GM(1,1)-Markov. Materials 2021, 14, 6326. [Google Scholar]

- Chen, G.; Luo, J. Prediction of Skid Resistance of Steel Slag Asphalt Mixture Based on Grey Residual GM(1,1)-Markov Model. J. Mater. Civil. Eng. 2024, 36, 16280. [Google Scholar]

| Penetration (mm) | Penetration Index | Ductility (cm) | Softening Point (°C) | After Thin Film Oven | |

|---|---|---|---|---|---|

| Mass Change | Penetration Ratio | ||||

| 6.2 | 0.78 | 21.7 | 51.1 | −0.19% | 74.54% |

| Chemical Composition | Granite Aggregates | Limestone Aggregates |

|---|---|---|

| ω(CaO)/10−2 | 0.87 | 94.72 |

| ω(SiO2)/10−2 | 76.10 | 1.27 |

| Mesh Size (mm) | Coarse Aggregate (19~4.75) | Fine Aggregate (2.36~0.15) | Filler | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | <0.075 | |

| Pass rate (%) | 100 | 93.4 | 86.6 | 76.1 | 57.9 | 44.1 | 33.7 | 26.0 | 20.0 | 15.4 | 12 |

| Aggregates Type | Acidic Aggregates | Alkaline Aggregates | ||||||

|---|---|---|---|---|---|---|---|---|

| Immersion time (h) | 24 | 48 | 72 | 96 | 24 | 48 | 72 | 96 |

| Porosity (%) | 0.9 | 0.95 | 0.99 | 1.12 | 0.85 | 0.97 | 1.08 | 1.2 |

| Weight | Tensile Strength | Bending Strength | Bending Modulus |

|---|---|---|---|

| Acidic aggregate | 0.4583 | 0.1667 | 0.3750 |

| Alkaline aggregate | 0.4232 | 0.1538 | 0.4230 |

| Model Accuracy | a | b | C | P | Model Accuracy |

|---|---|---|---|---|---|

| Acidic aggregate | 0.038 | 0.985 | 0.0087 | 1 | First-level |

| Alkaline aggregate | 0.017 | 1.036 | 0.0022 | 1 | First-level |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Li, F.; Li, K.; Ning, Z.; Dong, J. Performance Degradation Behavior and Service Life Prediction of Hydraulic Asphalt Concrete Under Long-Term Water Immersion. Materials 2025, 18, 3706. https://doi.org/10.3390/ma18153706

Cai X, Li F, Li K, Ning Z, Dong J. Performance Degradation Behavior and Service Life Prediction of Hydraulic Asphalt Concrete Under Long-Term Water Immersion. Materials. 2025; 18(15):3706. https://doi.org/10.3390/ma18153706

Chicago/Turabian StyleCai, Xinhe, Feng Li, Kangping Li, Zhiyuan Ning, and Jing Dong. 2025. "Performance Degradation Behavior and Service Life Prediction of Hydraulic Asphalt Concrete Under Long-Term Water Immersion" Materials 18, no. 15: 3706. https://doi.org/10.3390/ma18153706

APA StyleCai, X., Li, F., Li, K., Ning, Z., & Dong, J. (2025). Performance Degradation Behavior and Service Life Prediction of Hydraulic Asphalt Concrete Under Long-Term Water Immersion. Materials, 18(15), 3706. https://doi.org/10.3390/ma18153706