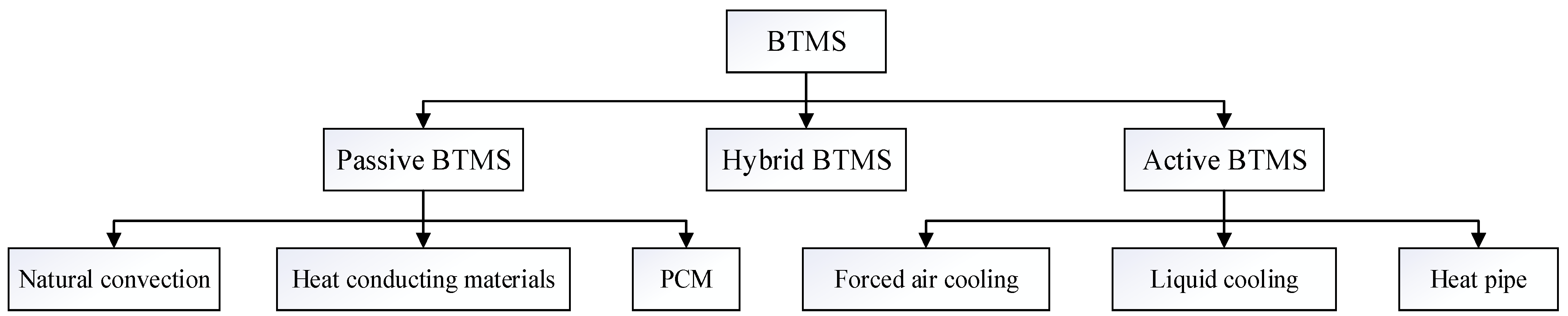

Advances and Challenges in the Battery Thermal Management Systems of Electric Vehicles

Abstract

1. Introduction

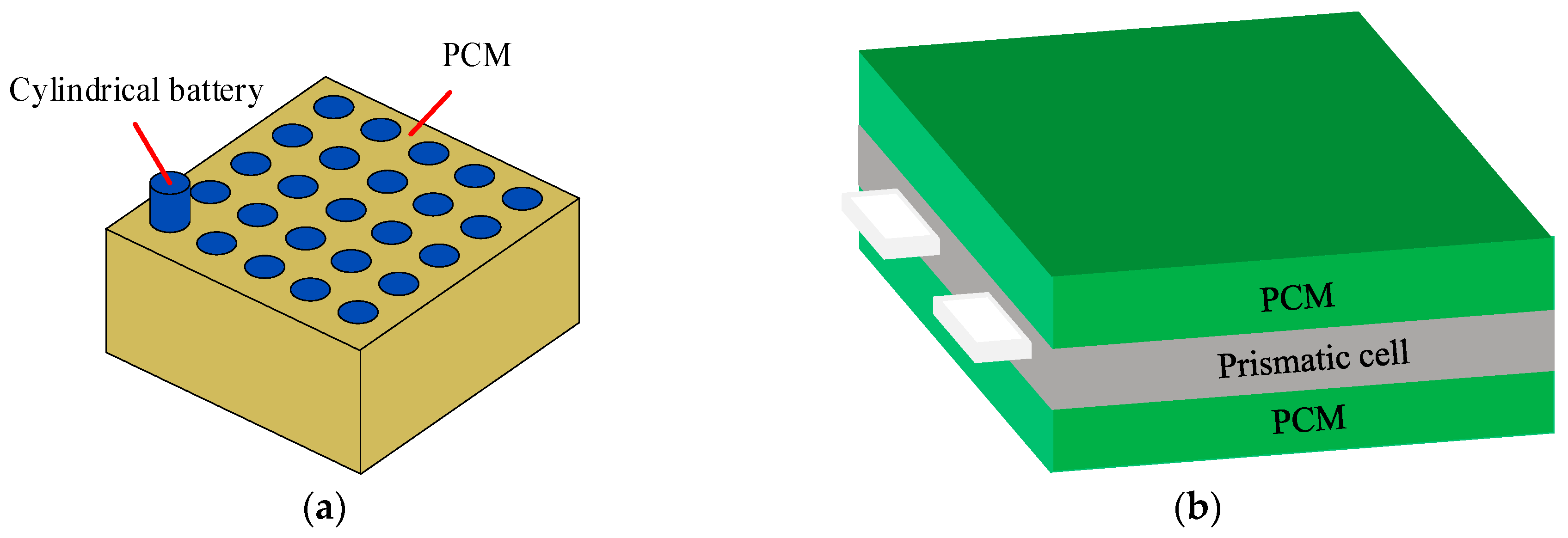

2. Passive BTMS

3. Active BTMS

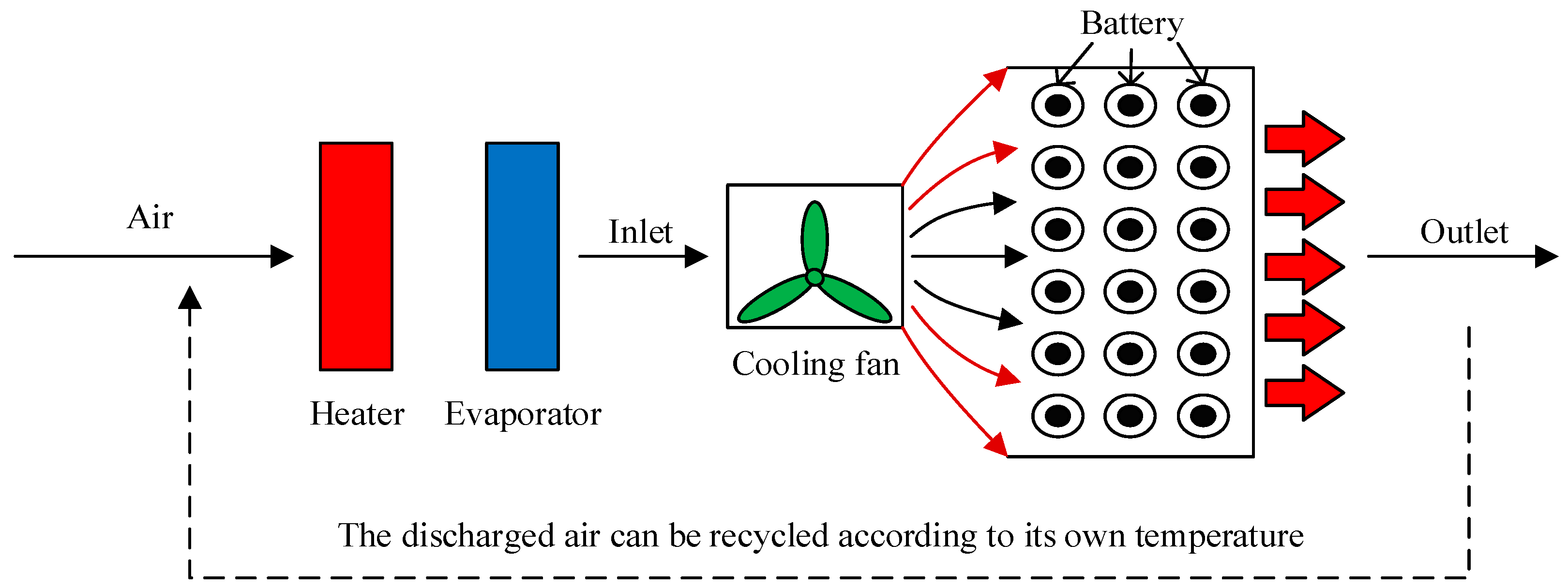

3.1. Forced Air Cooling

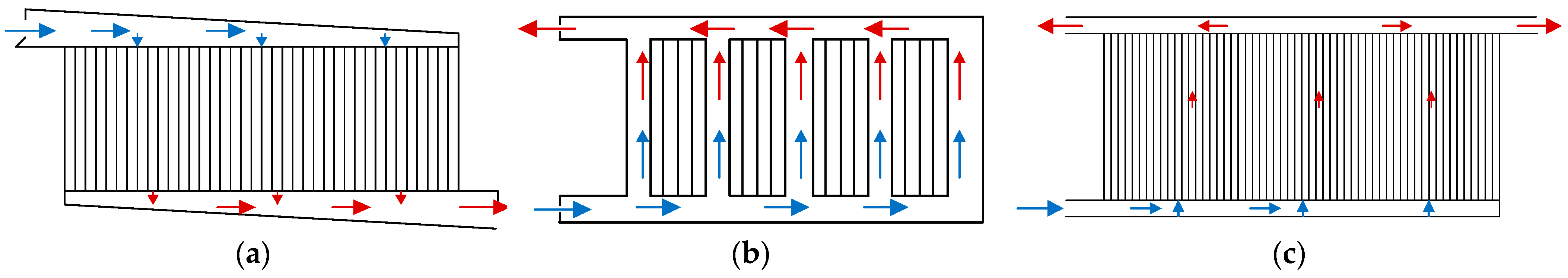

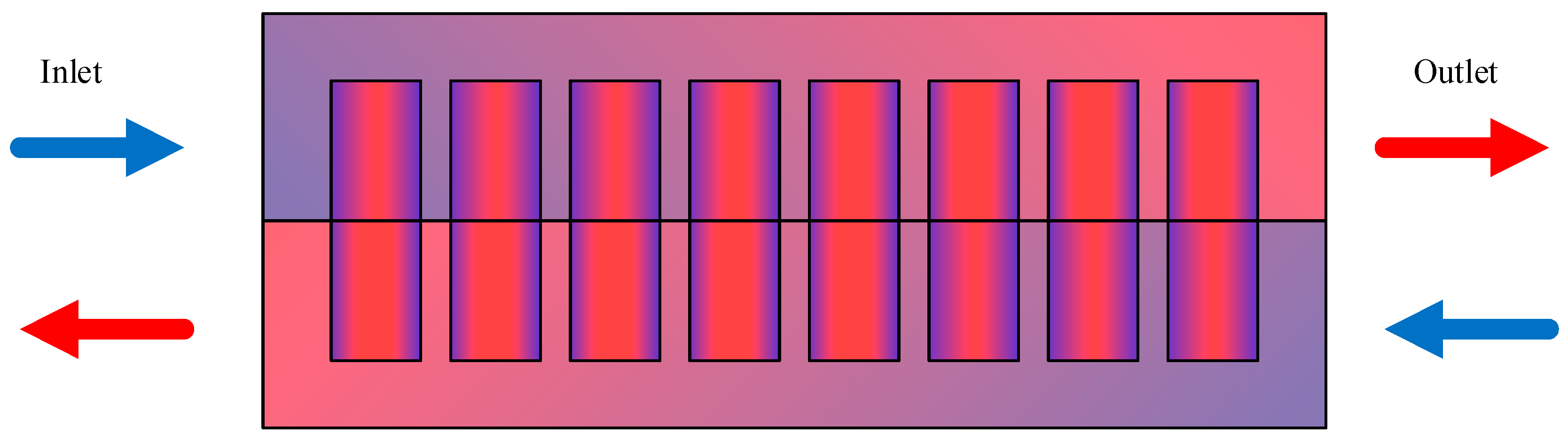

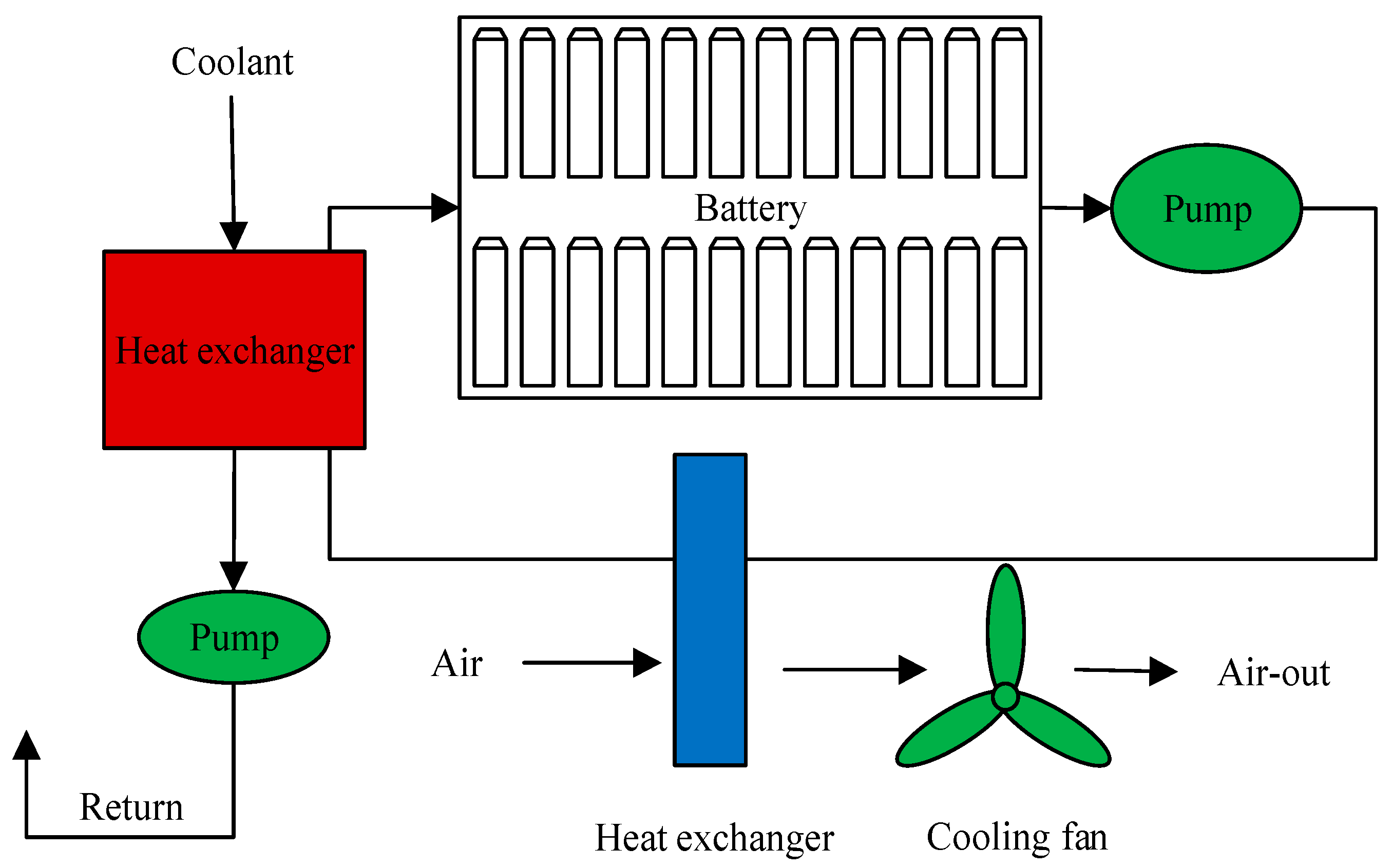

3.2. Liquid Cooling

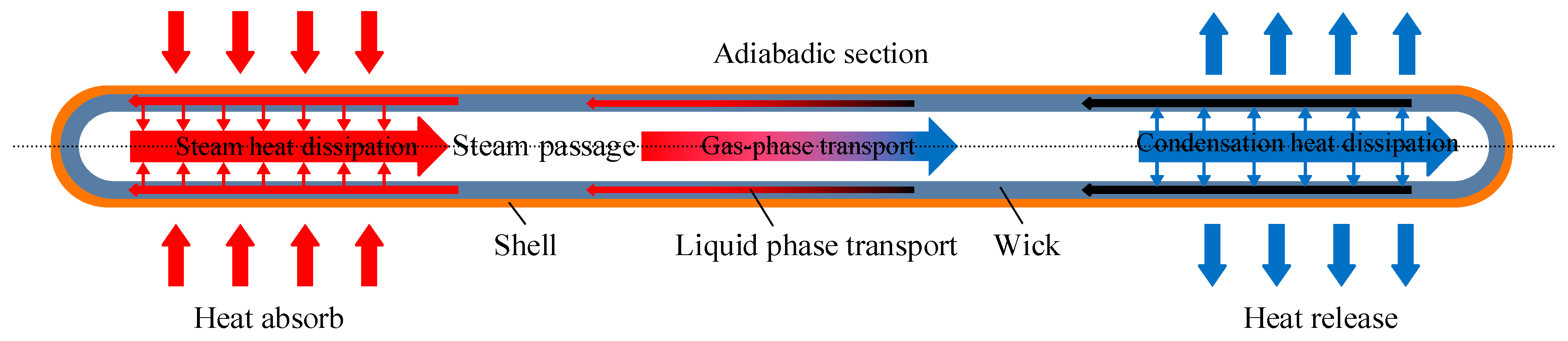

3.3. Heat Pipe

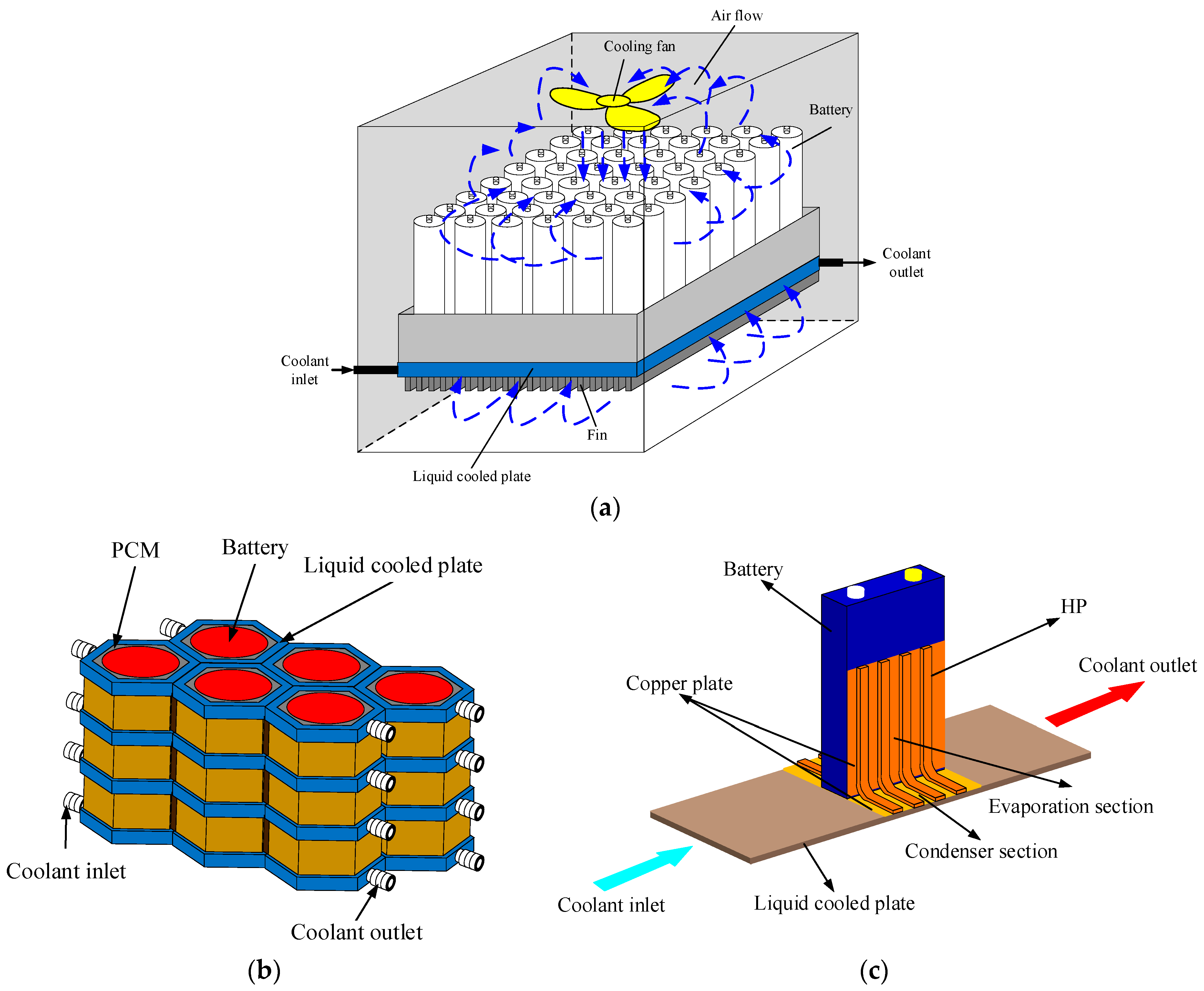

4. Hybrid BTMS

5. Current Challenges

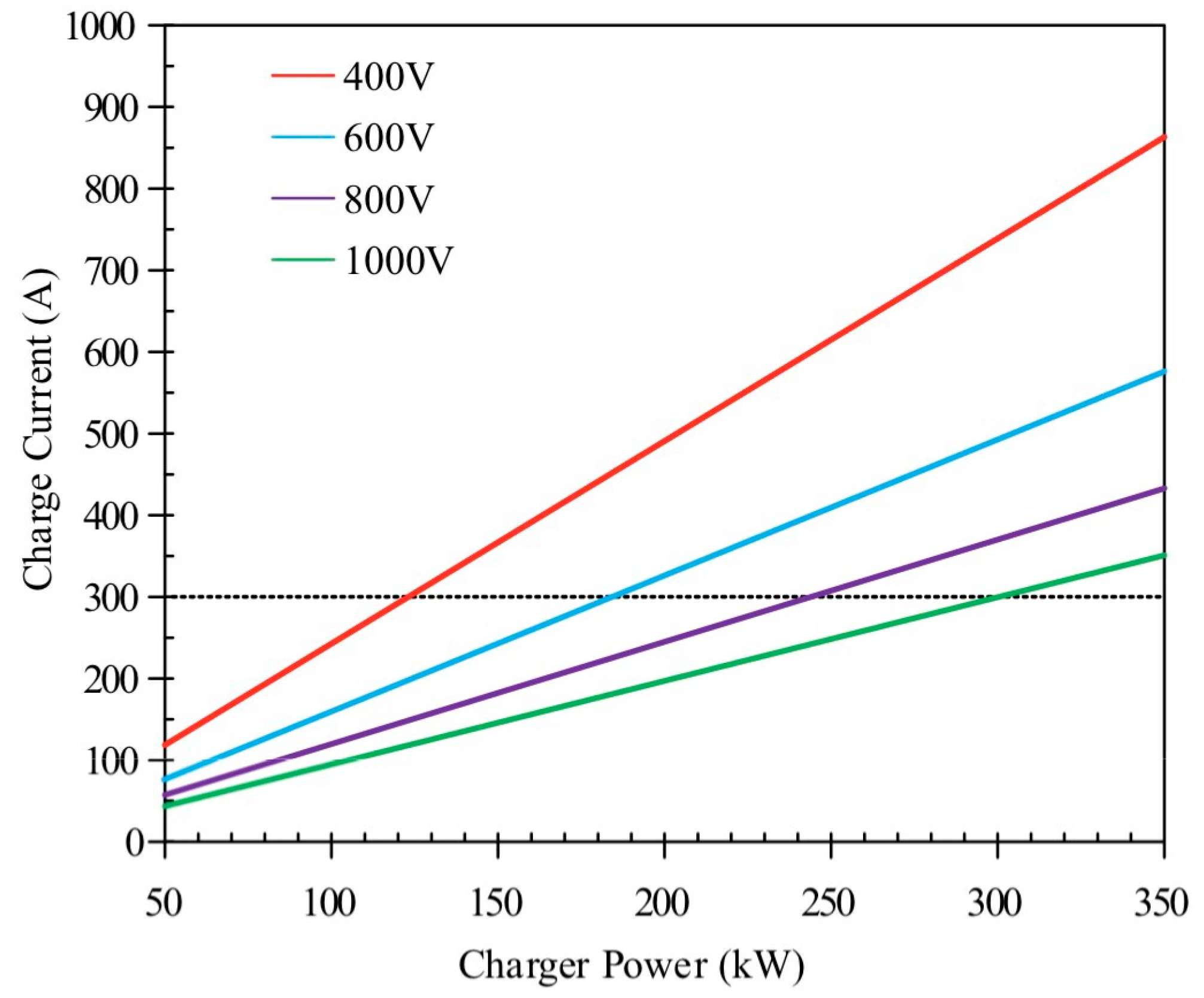

5.1. High-Energy Density Battery and Fast Charging

5.2. New-Type Battery Technology

6. Summary and Outlook

6.1. Technical Summary

6.2. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Gao, Q.; Wang, G.H.; Lu, P.Y.; Zhao, M.D.; Bao, W.D. A review on research status and key technologies of battery thermal management and its enhanced safety. Int. J. Energy Res. 2018, 42, 4008–4033. [Google Scholar] [CrossRef]

- Dan, D.; Zhao, Y.H.; Wei, M.S.; Wang, X.H. Review of thermal management technology for electric vehicles. Energies 2023, 16, 4693. [Google Scholar] [CrossRef]

- Liu, H.Q.; Wei, Z.B.; He, W.D.; Zhao, J.Y. Thermal issues about li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304–330. [Google Scholar] [CrossRef]

- Feng, X.N.; Ouyang, M.G.; Liu, X.; Lu, L.G.; Xia, Y.; He, X.M. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Wu, W.X.; Wang, S.F.; Wu, W.; Chen, K.; Hong, S.H.; Lai, Y.X. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A critical review of thermal issues in lithium-ion batteries. J. Electrochem. Soc. 2011, 158, R1–R25. [Google Scholar] [CrossRef]

- El Kassar, R.; Al Takash, A.; Faraj, J.; Hammoud, M.; Khaled, M.; Ramadan, H. Recent advances in lithium-ion battery integration with thermal management systems for electric vehicles: A summary review. J. Energy Storage 2024, 91, 112061. [Google Scholar] [CrossRef]

- Kumar, P.; Rafat, Y.; Varshney, P.; Chaudhary, D.; Alam, S.; Balasingam, B. Comparative Study and Development of Optimized Energy Efficient Battery Thermal Management System for Electric Vehicles in India. In Proceedings of the 47th Annual Conference of the IEEE-Industrial-Electronics-Society (IECON), Toronto, ON, Canada, 13–16 October 2021. [Google Scholar]

- Gao, S.C.; Ju, F.; Zhuang, W.C.; Wang, Q.; Zong, Y.H.; Wang, L.M. Cooperative energy management and fuel cell thermal management of fuel cell hybrid electric buses via multi-agent reinforcement learning. Energy 2025, 337, 138534. [Google Scholar] [CrossRef]

- Hussain, A.; Shahid, H.; Ali, I.; Ali, H.M. Passive thermal management system of lithium-ion batteries employing metal foam/pcm composite for the development of electric vehicles. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 505–522. [Google Scholar] [CrossRef]

- Garud, K.S.; Tai, L.D.; Hwang, S.G.; Nguyen, N.H.; Lee, M.Y. A review of advanced cooling strategies for battery thermal management systems in electric vehicles. Symmetry 2023, 15, 1322. [Google Scholar] [CrossRef]

- Lian, J.; Wang, X.H.; Zhang, W.X.; Huang, Y.H.; Xia, T.; Lian, Y.F. A ternary polyaniline/active carbon/lithium iron phosphate composite as cathode material for lithium ion battery. J. Nanosci. Nanotechnol. 2016, 16, 6494–6497. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.G.; Liu, T.; Wang, C.Y. Thermally modulated lithium iron phosphate batteries for mass-market electric vehicles. Nat. Energy 2021, 6, 176–185. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Maghrabie, H.M.; Abo-Khalil, A.G.; Adhari, O.H.K.; Sayed, E.T.; Radwan, A.; Rezk, H.; Jouhara, H.; Olabi, A.G. Thermal management systems based on heat pipes for batteries in EVs/HEVs. J. Energy Storage 2022, 51, 104384. [Google Scholar] [CrossRef]

- Ling, Z.Y.; Wang, F.X.; Fang, X.M.; Gao, X.N.; Zhang, Z.G. A hybrid thermal management system for lithium ion batteries combining phase change materials with forced-air cooling. Appl. Energy 2015, 148, 403–409. [Google Scholar] [CrossRef]

- Alami, A.H.; Maghrabie, H.M.; Abdelkareem, M.A.; Sayed, E.T.; Yasser, Z.; Salameh, T.; Rahman, S.M.A.; Rezk, H.; Olabi, A.G. Potential applications of phase change materials for batteries’ thermal management systems in electric vehicles. J. Energy Storage 2022, 54, 105204. [Google Scholar] [CrossRef]

- Dewangan, A.; Shukla, A.K. Enhancing li-ion electric vehicle battery performance: Analysis of advanced thermal management cooling strategies with phase change material. Energy Technol. 2024, 13, 2301665. [Google Scholar] [CrossRef]

- Gulfam, R.; Zhang, P.; Meng, Z.N. Advanced thermal systems driven by paraffin-based phase change materials—A review. Appl. Energy 2019, 238, 582–611. [Google Scholar] [CrossRef]

- Wang, Y.M.; Tang, B.T.; Zhang, S.F. Single-walled carbon nanotube/phase change material composites: Sunlight-driven, reversible, form-stable phase transitions for solar thermal energy storage. Adv. Funct. Mater. 2013, 23, 4354–4360. [Google Scholar] [CrossRef]

- Wu, W.X.; Liu, J.Z.; Liu, M.; Rao, Z.H.; Deng, H.; Wang, Q.; Qi, X.; Wang, S.F. An innovative battery thermal management with thermally induced flexible phase change material. Energy Convers. Manag. 2020, 221, 113145. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.Q.; Wang, Y.S.; Wang, S.; Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): A comprehensive review. Chem. Eng. J. 2022, 430, 132741. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; van Heyst, B. A comprehensive review on a passive (phase change materials) and an active (thermoelectric cooler) battery thermal management system and their limitations. J. Power Sources 2018, 401, 224–237. [Google Scholar] [CrossRef]

- Ling, Z.Y.; Li, S.M.; Cai, C.Y.; Lin, S.; Fang, X.M.; Zhang, Z.G. Battery thermal management based on multiscale encapsulated inorganic phase change material of high stability. Appl. Therm. Eng. 2021, 193, 117002. [Google Scholar] [CrossRef]

- Ping, P.; Peng, R.Q.; Kong, D.P.; Chen, G.M.; Wen, J. Investigation on thermal management performance of pcm-fin structure for li-ion battery module in high-temperature environment. Energy Convers. Manag. 2018, 176, 131–146. [Google Scholar]

- Weng, J.W.; Ouyang, D.X.; Yang, X.Q.; Chen, M.Y.; Zhang, G.Q.; Wang, J. Optimization of the internal fin in a phase-change-material module for battery thermal management. Appl. Therm. Eng. 2020, 167, 114698. [Google Scholar] [CrossRef]

- Jiang, G.W.; Huang, J.H.; Fu, Y.S.; Cao, M.; Liu, M.C. Thermal optimization of composite phase change material/expanded graphite for li-ion battery thermal management. Appl. Therm. Eng. 2016, 108, 1119–1125. [Google Scholar]

- Nasehi, R.; Alamatsaz, A.; Salimpour, M.R. Using multi-shell phase change materials layers for cooling a lithium battery. Therm. Sci. 2016, 20, 391–403. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.F.; Song, M.X.; Chen, L. Structure optimization of parallel air-cooled battery thermal management system. Int. J. Heat Mass Transf. 2017, 111, 943–952. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Zhao, S.P.; Zhou, T.B.; Wang, H.Z.; Li, S.; Yuan, Y.W.; Ma, Z.K.; Wei, J.M.; Zhao, X. Experimental and numerical investigations of a thermal management system using phase-change materials and forced-air cooling for high-power Li-ion battery packs. Batteries 2023, 9, 153. [Google Scholar] [CrossRef]

- Yang, N.X.; Zhang, X.W.; Li, G.J.; Hua, D. Assessment of the forced air-cooling performance for cylindrical lithium-ion battery packs: A comparative analysis between aligned and staggered cell arrangements. Appl. Therm. Eng. 2015, 80, 55–65. [Google Scholar] [CrossRef]

- Du, J.L.; Tao, H.L.; Chen, Y.X.; Yuan, X.D.; Lian, C.; Liu, H.L. Thermal management of air-cooling lithium-ion battery pack. Chin. Phys. Lett. 2021, 38, 118201. [Google Scholar] [CrossRef]

- Peng, X.B.; Cui, X.J.; Liao, X.P.; Garg, A. A thermal investigation and optimization of an air-cooled lithium-ion battery pack. Energies 2020, 13, 2956. [Google Scholar]

- Kang, D.; Lee, P.Y.; Yoo, K.; Kim, J. Internal thermal network model-based inner temperature distribution of high-power lithium-ion battery packs with different shapes for thermal management. J. Energy Storage 2020, 27, 101017. [Google Scholar] [CrossRef]

- Sun, H.G.; Dixon, R.G. Development of cooling strategy for an air cooled lithium-ion battery pack. J. Power Sources 2014, 272, 404–414. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.X.; Wei, W.; Wang, S.F. Structure optimization of parallel air-cooled battery thermal management system with U-type flow for cooling efficiency improvement. Energy 2018, 145, 603–613. [Google Scholar] [CrossRef]

- Lu, Z.; Yu, X.L.; Wei, L.C.; Qiu, Y.L.; Zhang, L.Y.; Meng, X.Z.; Jin, L.W. Parametric study of forced air cooling strategy for lithium-ion battery pack with staggered arrangement. Appl. Therm. Eng. 2018, 136, 28–40. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Zhang, J. Design a J-type air-based battery thermal management system through surrogate-based optimization. Appl. Energy 2019, 252, 113426. [Google Scholar]

- Na, X.Y.; Kang, H.F.; Wang, T.; Wang, Y.C. Reverse layered air flow for li-ion battery thermal management. Appl. Therm. Eng. 2018, 143, 257–262. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating air flow for li-ion battery thermal management to improve temperature uniformity. J. Power Sources 2011, 196, 5685–5696. [Google Scholar] [CrossRef]

- E, J.Q.; Yue, M.; Chen, J.W.; Zhu, H.; Deng, Y.W.; Zhu, Y.; Zhang, F.; Wen, M.; Zhang, B.; Kang, S.Y. Effects of the different air cooling strategies on cooling performance of a lithium-ion battery module with baffle. Appl. Therm. Eng. 2018, 144, 231–241. [Google Scholar] [CrossRef]

- Yu, K.H.; Yang, X.; Cheng, Y.Z.; Li, C.H. Thermal analysis and two-directional air flow thermal management for lithium-ion battery pack. J. Power Sources 2014, 270, 193–200. [Google Scholar]

- Chen, K.; Zhang, Z.L.; Wu, B.H.; Song, M.X.; Wu, X.L. An air-cooled system with a control strategy for efficient battery thermal management. Appl. Therm. Eng. 2024, 236, 121578. [Google Scholar] [CrossRef]

- Liu, J.H.; Chen, H.; Huang, S.L.; Jiao, Y.; Chen, M.Y. Recent progress and prospects in liquid cooling thermal management system for lithium-ion batteries. Batteries 2023, 9, 400. [Google Scholar] [CrossRef]

- Chen, P.R.; Gao, L.; Li, W.; Zhao, J.Y.; Garg, A.; Panda, B. A topology optimization-based-novel design and comprehensive thermal analysis of a cylindrical battery liquid cooling plate. Appl. Therm. Eng. 2024, 252, 123747. [Google Scholar] [CrossRef]

- Sheng, L.; Zhang, H.Y.; Su, L.; Zhang, Z.D.; Zhang, H.; Li, K.; Fang, Y.D.; Ye, W. Effect analysis on thermal profile management of a cylindrical lithium-ion battery utilizing a cellular liquid cooling jacket. Energy 2021, 220, 119725. [Google Scholar] [CrossRef]

- Xie, L.; Huang, Y.X.; Lai, H.X. Coupled prediction model of liquid-cooling based thermal management system for cylindrical lithium-ion module. Appl. Therm. Eng. 2020, 178, 115599. [Google Scholar] [CrossRef]

- Thakur, A.K.; Prabakaran, R.; Elkadeem, M.R.; Sharshir, S.W.; Arici, M.; Wang, C.; Zhao, W.S.; Hwang, J.Y.; Saidur, R. A state of art review and future viewpoint on advance cooling techniques for lithium-ion battery system of electric vehicles. J. Energy Storage 2020, 32, 101771. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, G.Q.; Li, X.X.; Huang, J.; Wang, Z.Y.; Lv, Y.F.; Meng, L.K.; Situ, W.F.; Rao, M.M. Experimental examination of large capacity liFePO4 battery pack at high temperature and rapid discharge using novel liquid cooling strategy. Int. J. Energy Res. 2018, 42, 1172–1182. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal modeling and validation of temperature distributions in a prismatic lithium-ion battery at different discharge rates and varying boundary conditions. Appl. Therm. Eng. 2016, 96, 190–199. [Google Scholar] [CrossRef]

- Monika, K.; Datta, S.P. Comparative assessment among several channel designs with constant volume for cooling of pouch-type battery module. Energy Convers. Manag. 2022, 251, 114936. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, G.D.; Ran, Y.; Liu, P. Thermal performance of lithium ion battery pack by using cold plate. Appl. Therm. Eng. 2019, 160, 114088. [Google Scholar] [CrossRef]

- Karimi, G.; Dehghan, A.R. Thermal analysis of high-power lithium-ion battery packs using flow network approach. Int. J. Energy Res. 2014, 38, 1793–1811. [Google Scholar] [CrossRef]

- Jarrett, A.; Kim, I.Y. Design optimization of electric vehicle battery cooling plates for thermal performance. J. Power Sources 2011, 196, 10359–10368. [Google Scholar] [CrossRef]

- Wiriyasart, S.; Hommalee, C.; Sirikasemsuk, S.; Prurapark, R.; Naphon, P. Thermal management system with nanofluids for electric vehicle battery cooling modules. Case Stud. Therm. Eng. 2020, 18, 100583. [Google Scholar] [CrossRef]

- Al Shdaifat, M.Y.; Zulkifli, R.; Sopian, K.; Salih, A.A. Effect of CuO/water nanofluid as a coolant for liquid cold plate on electric vehicle battery cells. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 2270–2283. [Google Scholar] [CrossRef]

- Liao, G.L.; Wang, W.D.; Zhang, F.; E, J.; Chen, J.W.; Leng, E.R. Thermal performance of lithium-ion battery thermal management system based on nanofluid. Appl. Therm. Eng. 2022, 216, 118997. [Google Scholar] [CrossRef]

- Panchal, S.; Khasow, R.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal design and simulation of mini-channel cold plate for water cooled large sized prismatic lithium-ion battery. Appl. Therm. Eng. 2017, 122, 80–90. [Google Scholar] [CrossRef]

- Malik, M.; Dincer, I.; Rosen, M.A.; Mathew, M.; Fowler, M. Thermal and electrical performance evaluations of series connected li-ion batteries in a pack with liquid cooling. Appl. Therm. Eng. 2018, 129, 472–481. [Google Scholar] [CrossRef]

- Huo, Y.T.; Rao, Z.H.; Liu, X.J.; Zhao, J.T. Investigation of power battery thermal management by using mini-channel cold plate. Energy Convers. Manag. 2015, 89, 387–395. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, G.D.; Ran, Y. Study on thermal management of rectangular Li-ion battery with serpentine-channel cold plate. Int. J. Heat Mass Transf. 2018, 125, 143–152. [Google Scholar] [CrossRef]

- Huang, Y.Q.; Mei, P.; Lu, Y.J.; Huang, R.; Yu, X.L.; Chen, Z.L.; Roskilly, A.P. A novel approach for Lithium-ion battery thermal management with streamline shape mini channel cooling plates. Appl. Therm. Eng. 2019, 157, 113623. [Google Scholar] [CrossRef]

- Darcovich, K.; MacNeil, D.D.; Recoskie, S.; Cadic, Q.; Ilinca, F. Comparison of cooling plate configurations for automotive battery pack thermal management. Appl. Therm. Eng. 2019, 155, 185–195. [Google Scholar] [CrossRef]

- Zhao, C.R.; Cao, W.J.; Dong, T.; Jiang, F.M. Thermal behavior study of discharging/charging cylindrical lithium-ion battery module cooled by channeled liquid flow. Int. J. Heat Mass Transf. 2018, 120, 751–762. [Google Scholar] [CrossRef]

- Qian, Z.; Li, Y.M.; Rao, Z.H. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling. Energy Convers. Manag. 2016, 126, 622–631. [Google Scholar]

- Sun, Y.S.; Bai, R.H.; Ma, J. Design and thermal analysis of a new topological cooling plate for prismatic lithium battery thermal management. Appl. Therm. Eng. 2023, 219, 119547. [Google Scholar]

- Wang, Y.J.; Duong, X.Q.; Zadeh, P.G.; Chung, J.D. Liquid-cooled cold plate for a li-ion battery thermal management system designed by topology optimization. J. Mech. Sci. Technol. 2023, 37, 2079–2086. [Google Scholar]

- Weragoda, D.M.; Tian, G.H.; Burkitbayev, A.; Lo, K.H.; Zhang, T. A comprehensive review on heat pipe based battery thermal management systems. Appl. Therm. Eng. 2023, 224, 120070. [Google Scholar] [CrossRef]

- Gan, Y.H.; He, L.F.; Liang, J.F.; Tan, M.X.; Xiong, T.; Li, Y. A numerical study on the performance of a thermal management system for a battery pack with cylindrical cells based on heat pipes. Appl. Therm. Eng. 2020, 179, 115740. [Google Scholar] [CrossRef]

- Liu, F.F.; Lan, F.C.; Chen, J.Q. Dynamic thermal characteristics of heat pipe via segmented thermal resistance model for electric vehicle battery cooling. J. Power Sources 2016, 321, 57–70. [Google Scholar] [CrossRef]

- Xie, Y.; Li, H.H.; Li, W.; Zhang, Y.J.; Fowler, M.; Tran, M.K.; Zhang, X.; Chen, B.; Deng, S.S. Improving thermal performance of battery at high current rate by using embedded heat pipe system. J. Energy Storage 2022, 46, 103809. [Google Scholar] [CrossRef]

- Ye, X.; Zhao, Y.H.; Quan, Z.H. Experimental study on heat dissipation for lithium-ion battery based on micro heat pipe array (MHPA). Appl. Therm. Eng. 2018, 130, 74–82. [Google Scholar] [CrossRef]

- Wang, S.N.; Li, Y.H.; Li, Y.Z.; Mao, Y.F.; Zhang, Y.A.; Guo, W.; Zhong, M.L. A forced gas cooling circle packaging with liquid cooling plate for the thermal management of li-ion batteries under space environment. Appl. Therm. Eng. 2017, 123, 929–939. [Google Scholar] [CrossRef]

- Li, M.; Liu, F.; Han, B.; Guo, J.L.; Xu, Y.L. Research on temperature control performance of battery thermal management system composited with multi-channel parallel liquid cooling and air cooling. Ionics 2021, 27, 2685–2695. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Li, W.; Wang, G.Y.; Cheng, W.M.; Chen, M.Y. A novel thermal management system for lithium-ion battery modules combining direct liquid-cooling with forced air-cooling. Appl. Therm. Eng. 2023, 232, 120992. [Google Scholar] [CrossRef]

- Zadeh, P.G.; Wang, Y.; Chung, J.D. Thermal management modeling for cylindrical lithium-ion battery packs considering safety and lifespan. J. Mech. Sci. Technol. 2022, 36, 3727–3733. [Google Scholar] [CrossRef]

- Zheng, Y.R.; Shi, Y.; Huang, Y.H. Optimisation with adiabatic interlayers for liquid-dominated cooling system on fast charging battery packs. Appl. Therm. Eng. 2019, 147, 636–646. [Google Scholar] [CrossRef]

- Kong, D.P.; Peng, R.Q.; Ping, P.; Du, J.; Chen, G.M.; Wen, J. A novel battery thermal management system coupling with pcm and optimized controllable liquid cooling for different ambient temperatures. Energy Convers. Manag. 2020, 204, 112280. [Google Scholar] [CrossRef]

- Tran, T.H.; Harmand, S.; Sahut, B. Experimental investigation on heat pipe cooling for hybrid electric vehicle and electric vehicle lithium-ion battery. J. Power Sources 2014, 265, 262–272. [Google Scholar] [CrossRef]

- Mei, N.; Xu, X.M.; Li, R.Z. Heat dissipation analysis on the liquid cooling system coupled with a flat heat pipe of a lithium-ion battery. ACS Omega 2020, 5, 17431–17441. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Tang, A.K.; Shan, C.X.; Liu, Z.Y.; Li, J.M. Experimental investigation on thermal performance of a battery liquid cooling structure coupled with heat pipe. J. Energy Storage 2020, 32, 101984. [Google Scholar] [CrossRef]

- Liang, J.L.; Gan, Y.H.; Li, Y. Investigation on the thermal performance of a battery thermal management system using heat pipe under different ambient temperatures. Energy Convers. Manag. 2018, 155, 1–9. [Google Scholar] [CrossRef]

- Zhang, W.C.; Liang, Z.C.; Wu, W.X.; Ling, G.Z.; Ma, R.X. Design and optimization of a hybrid battery thermal management system for electric vehicle based on surrogate model. Int. J. Heat Mass Transf. 2021, 174, 121318. [Google Scholar] [CrossRef]

- Li, X.X.; Zhong, Z.D.; Luo, J.H.; Wang, Z.Y.; Yuan, W.Z.; Zhang, G.Q.; Yang, C.Z.; Yang, C.X. Experimental Investigation on a Thermoelectric Cooler for Thermal Management of a Lithium-Ion Battery Module. Int. J. Photoenergy 2019, 3725364. [Google Scholar] [CrossRef]

- Li, W.Z.; Zhou, Y.H.; Zhang, H.N.; Tang, X. A review on battery thermal management for new energy vehicles. Energies 2023, 16, 4845. [Google Scholar] [CrossRef]

- Lin, J.Y.; Liu, X.H.; Li, S.; Zhang, C.; Yang, S.C. A review on recent progress, challenges and perspective of battery thermal management system. Int. J. Heat Mass Transf. 2021, 167, 120834. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Shao, D.; Jiang, L.Q.; Zhang, G.Q.; Wu, H.W.; Day, R.; Jiang, W.Z. Advanced thermal management system driven by phase change materials for power lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2022, 159, 112207. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, L.; Chen, Z.H.; He, X.M. Challenges of fast charging for electric vehicles and the role of red phosphorous as anode material: Review. Energies 2019, 12, 3897. [Google Scholar] [CrossRef]

- Kerman, K.; Luntz, A.; Viswanathan, V.; Chiang, Y.M.; Chen, Z.B. Review-practical challenges hindering the development of solid state li ion batteries. J. Electrochem. Soc. 2017, 164, A1731–A1744. [Google Scholar] [CrossRef]

- Janek, J.; Zeier, W.G. A solid future for battery development. Nat. Energy 2016, 1, 16141. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; He, X.F.; Mo, Y.F. Origin of outstanding stability in the lithium solid electrolyte materials: Insights from thermodynamic analyses based on first-principles calculations. ACS Appl. Mater. Interfaces 2015, 7, 23685–23693. [Google Scholar] [CrossRef]

- Manthiram, A.; Yu, X.W.; Wang, S.F. Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2017, 2, 16103. [Google Scholar] [CrossRef]

- Kamaya, N.; Homma, K.; Yamakawa, Y.; Hirayama, M.; Kanno, R.; Yonemura, M.; Kamiyama, T.; Kato, Y.; Hama, S.; Kawamoto, K.; et al. A lithium superionic conductor. Nat. Mater. 2011, 10, 682–686. [Google Scholar] [CrossRef]

- Sakuda, A.; Hayashi, A.; Tatsumisago, M. Sulfide solid electrolyte with favorable mechanical property for all-solid-state lithium battery. Sci. Rep. 2013, 3, 2261. [Google Scholar] [CrossRef]

- Xia, S.X.; Wu, X.S.; Zhang, Z.C.; Cui, Y.; Liu, W. Practical challenges and future perspectives of all-solid-state lithium-metal batteries. Chem 2019, 5, 753–785. [Google Scholar] [CrossRef]

- Kim, T.; Song, W.T.; Son, D.Y.; Ono, L.K.; Qi, Y.B. Lithium-ion batteries: Outlook on present, future, and hybridized technologies. J. Mater. Chem. A 2019, 7, 2942–2964. [Google Scholar] [CrossRef]

- Ju, F.; Gao, S.; Zhuang, W.C.; Wang, Q.; Li, B.B. Multi-objective thermal-health ECMS with equivalent factor regulated by DRL for fuel-cell hybrid heavy trucks. Int. J. Hydrogen Energy 2025, 165, 150899. [Google Scholar] [CrossRef]

- Manthiram, A.; Fu, Y.Z.; Su, Y.S. Challenges and prospects of lithium-sulfur batteries. Acc. Chem. Res. 2013, 46, 1125–1134. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Zhou, G.M.; Liu, K.; Cui, Y. Design of complex nanomaterials for energy storage: Past success and future opportunity. Acc. Chem. Res. 2017, 50, 2895–2905. [Google Scholar] [CrossRef]

- Ding, B.; Wang, J.; Fan, Z.J.; Chen, S.; Lin, Q.Y.; Lu, X.J.; Dou, H.; Nanjundan, A.K.; Yushin, G.; Zhang, X.G.; et al. Solid-state lithium-sulfur batteries: Advances, challenges and perspectives. Mater. Today 2020, 40, 114–131. [Google Scholar] [CrossRef]

- Wang, H.C.; Cao, X.; Liu, W.; Sun, X.M. Research progress of the solid state lithium-sulfur batteries. Front. Energy Res. 2019, 7, 112. [Google Scholar] [CrossRef]

- Pang, Q.; Liang, X.; Kwok, C.Y.; Nazar, L.F. Advances in lithium-sulfur batteries based on multifunctional cathodes and electrolytes. Nat. Energy 2016, 1, 16132. [Google Scholar] [CrossRef]

- Zhou, G.M.; Zhao, Y.B.; Manthiram, A. Dual-confined flexible sulfur cathodes encapsulated in nitrogen-doped double-shelled hollow carbon spheres and wrapped with graphene for Li-S batteries. Adv. Energy Mater. 2015, 5, 1402263. [Google Scholar] [CrossRef]

- Cheng, X.B.; Huang, J.Q.; Zhang, Q. Review-li metal anode in working lithium-sulfur batteries. J. Electrochem. Soc. 2018, 165, A6058–A6072. [Google Scholar] [CrossRef]

- Gopalakrishnan, D. Advanced Electrodes and Electrolytes for Long-Lived and High-Performance Lithium-Sulfur Batteries. Ph.D. Thesis, Wayne State University, Detroit, MI, USA, 2020. [Google Scholar]

| References | Technology Type | Advantages | Disadvantages |

|---|---|---|---|

| Ling et al. [23] Ping et al. [24] Weng et al. [25] Jiang et al. [26] Nasehi et al. [27] | PCM cooling |

|

|

| Yang et al. [30] Du et al. [31] Peng et al. [32] Kang et al. [33] Sun et al. [34] Chen et al. [35] Lu et al. [36] Liu et al. [37] | Air cooling |

|

|

| Karimi et al. [52] Al Shdaifat et al. [55] Liao et al. [56] Panchal et al. [57] Malik et al. [58] Huo et al. [59] Deng et al. [60] | Liquid cooling |

|

|

| Gan et al. [68] Liu et al. [69] Xie et al. [70] Ye et al. [71] | Heat pipe |

|

|

| Wang et al. [72] Li et al. [73] Zhao et al. [74] Zadeh et al. [75] Zheng et al. [76] Kong et al. [77] Mei et al. [79] Yuan et al. [80] Zhang et al. [82] | Hybrid system |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, T.; Zhou, Z.; Zhang, Y.; Xu, X. Advances and Challenges in the Battery Thermal Management Systems of Electric Vehicles. Materials 2025, 18, 4718. https://doi.org/10.3390/ma18204718

Wen T, Zhou Z, Zhang Y, Xu X. Advances and Challenges in the Battery Thermal Management Systems of Electric Vehicles. Materials. 2025; 18(20):4718. https://doi.org/10.3390/ma18204718

Chicago/Turabian StyleWen, Tianze, Zhequan Zhou, Yongyi Zhang, and Xiaomei Xu. 2025. "Advances and Challenges in the Battery Thermal Management Systems of Electric Vehicles" Materials 18, no. 20: 4718. https://doi.org/10.3390/ma18204718

APA StyleWen, T., Zhou, Z., Zhang, Y., & Xu, X. (2025). Advances and Challenges in the Battery Thermal Management Systems of Electric Vehicles. Materials, 18(20), 4718. https://doi.org/10.3390/ma18204718